Eaton DeviceNet E50DNA, DeviceNet E50DNAC Installation Instructions Manual

Installation Instructions for

DeviceNet™ E50 Limit Switches

MODELS COVERED BY THIS MANUAL

Catalog Number Description

E50DNA Solid State Switch Body

with 2-meter cable

E50DNAC Solid State Switch Body

with 5-pin DeviceNet

micro-connector

111032 Rev --Cutler-Hammer

DESCRIPTION

General Information

• Network Media - DeviceNet

• Protocol - DeviceNet Rel 2.0

• Type - Group 2 Only Slave Device using Predefined

Master Slave Connection Set

• Bandwidth - 125, 250, 500 Kbaud

All E50 Limit Switches consist of two modular, interchangeable plug-in components: operating head and a solid state

switch body. Operating heads (side rotary, top and side

push, and wobble stick) are mounted on top of the switch

body in any of four positions. All assembled limit switches are

rated NEMA 3, 3S, 4, 4X, 6, 6P and 13. Obtain renewal parts by

ordering the catalog number labeled on each of the two limit

switch components.

NEMA ICS 2-225 describes preferred installation recommendations which ensure greatest reliability and longest life expectancy for Industrial Limit Switches.

INSTALLATION

WARNING

DO NOT INSTALL OR PERFORM MAINTENANCE ON THIS

DEVICE WHILE THE CONTROLLER IS ENERGIZED. DEATH OR

SEVERE PERSONAL INJURY CAN RESULT FROM CONTACT

WITH ENERGIZED EQUIPMENT. VERIFY THAT NO VOLTAGE IS

PRESENT BEFORE PROCEEDING WITH INSTALLATION OR

MAINTENANCE. Only qualified persons, as defined in the

National Electric Code, who are familiar with the installation,

maintenance and operation of this device and the equipment

onto which is to be installed, as well as applicable local, state

and national regulations and industry standards and

accepted practices regarding safety of personnel and the

equipment safety should be permitted to install, maintain or

operate this device. These instructions are provided only as

a general guide to such qualified persons and are not allinclusive. They do not cover every application or circumstances which may arise in the installation, maintenance or

operation of this equipment. Users are advised to comply

with all local, state and national regulations and industry

standards and accepted practices regarding safety of

personnel and the equipment safety.

111032 Rev --Page 2

TORQUE REQUIREMENTS FOR LIMIT SWITCH ASSEMBLY

Tighten the operating head screws to a torque value within the

following ranges to ensure and maintain the Enclosure Type

Ratings for the assembled limit switch.

Operating Head Screws — Tighten to ensure contact of head

to switch body: 14 - 18 lb. in.

OPERATING HEAD POSITIONING

Heads can be mounted on the switch body in any of four

directions, 90° apart. Torque screws according to requirements on page 1.

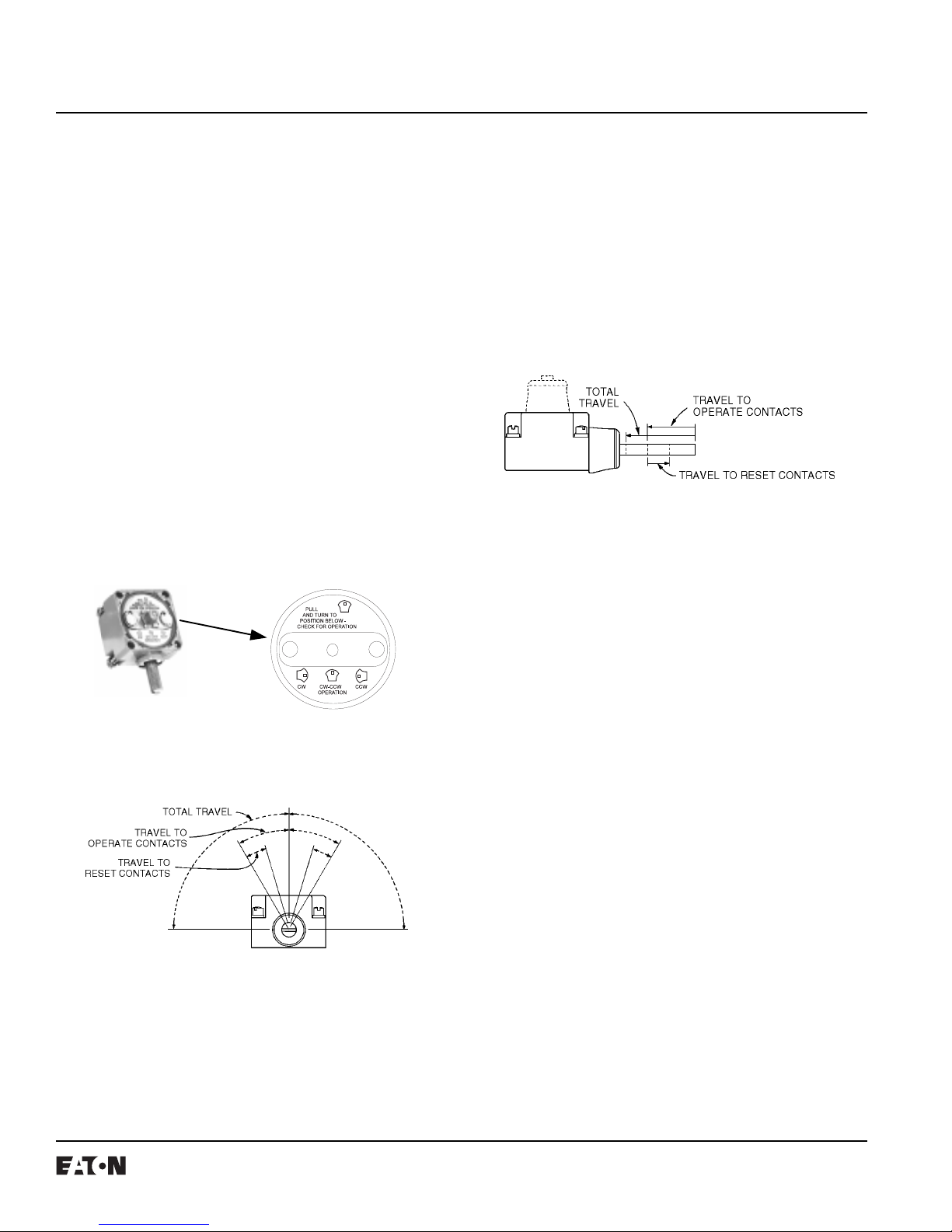

OPERATING HEADS — SIDE ROTARY

The operating mode (CW, CCW or CW and CCW) of these

spring return operating heads is easily changed without

tools as shown in the illustration. Remove the head from

switch body. Pull out the plunger and turn until its position

matches that shown on the diagram for the desired operation mode. Levers are adjustable to any angle (360°). The

operating shaft screwdriver slot can be used to maintain

shaft position during lever installation.

OPERATING HEADS — PUSH OPERATED

These spring return top push or side push operating heads

are available in pushbutton and roller styles.

The push roller style can be converted from vertical to

horizontal operation or vice versa. Pull roller out of the head

until it can be rotated 90° to the desired orientation. When

released, it will snap into the set position.

The Maintained Contact head has the reset pushbutton

located opposite of the actuator pushbutton.

Push Operational Head

OPERATING HEADS — WOBBLE STICK

These spring return, top operated heads use different rodtype operators to detect motion in any direction perpendicular to the operator. The operator screws onto the threaded

head stub.

Set Operating Head Mode

Before Assembly

Side Rotary Operational Head

Bottom View of Side Operated

Rotary Head (Note Mode Change

Instructions in Head)

Effective 9/97

111032 Rev -- Page 3

REPEAT ACCURACY

The type of operating head used on an assembled limit

switch determines repeat accuracy for the switch assembly.

Assembled limit switches, without rollers used on operating

heads or levers, have a repeat accuracy as listed in Table 1

only.

Assembled limit switches with rollers used on operating

heads or levers have a repeat accuracy determined as

follows: add the repeat accuracy tolerance of Table 1 for the

type of operating head used to the concentricity tolerance of

Table 2 for the type of roller used on the lever or operator.

The combination of these two tolerances is the limit switch

repeat accuracy.

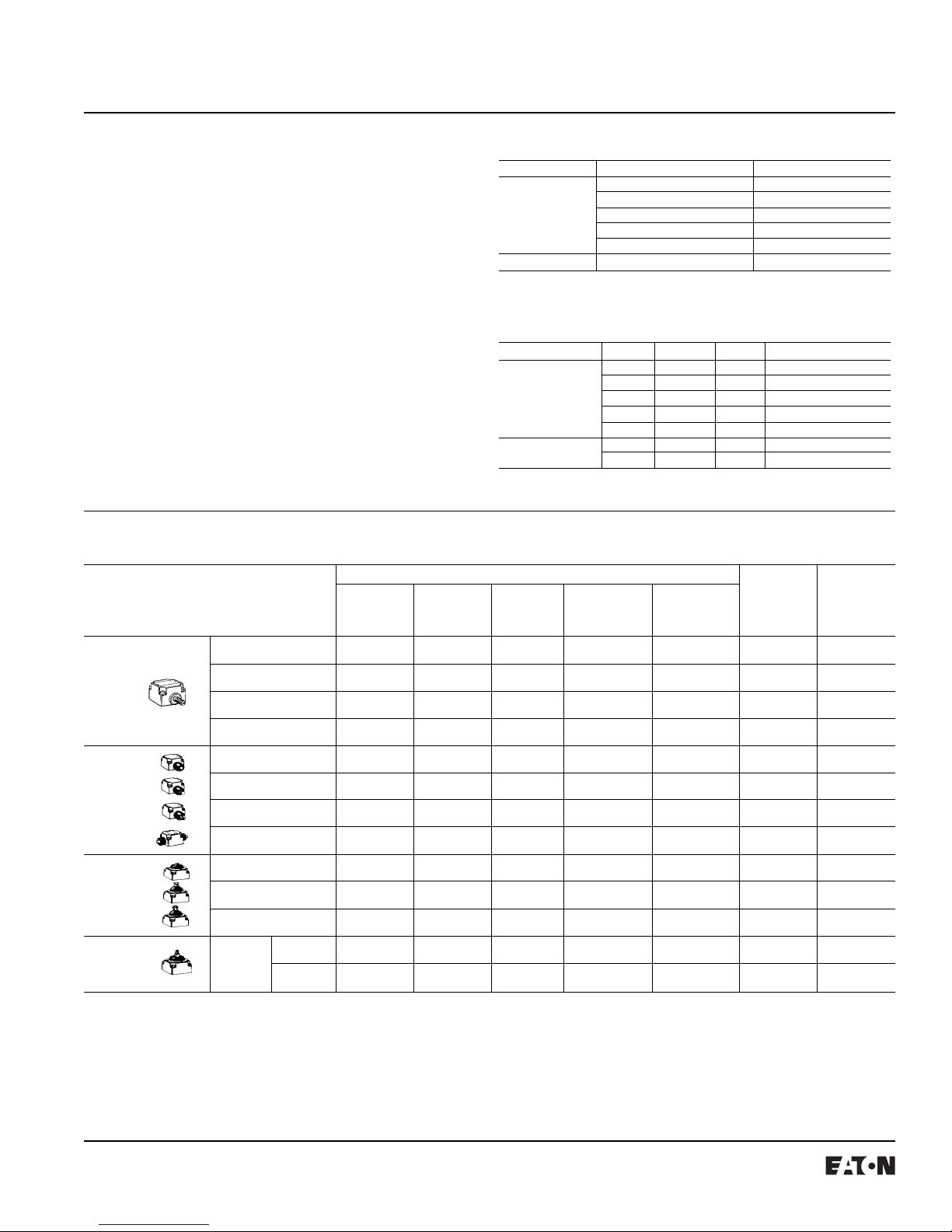

OPERATING HEAD DATA

Operating Data —Nominal Operating

Travel To Travel To Force To Minimum Temp.

Operate Reset

Contacts Contacts

5° 2 ° 90 ° 3 in.-lbs. 4.5 in.-oz. A E50DR1

5° 2 ° 90 ° 3 in.-lbs. 4.5 in.-oz. D E50DR19

15 ° 6° 90 ° 1.5 in.-lbs. 2.5 in.-oz. A E50DL1

50 ° 50 ° 90 ° 3 in.-lbs. — B E50DM1

0.065 in. 0.030 in. 0.290 in. 4 lbs. 8 oz. B E50DS1

0.065 in. 0.030 in. 0.290 in. 4 lbs. 8 oz. B E50DS2

0.065 in. 0.030 in. 0.290 in. 4 lbs. 8 oz. B E50DS3

0.200 in. 0.130 in. 0.320 in. 5 lbs. 5 lbs. B E50DH1

0.040 in. 0.020 in. 0.280 in. 4 lbs. 8 oz. C E50DT1

0.040 in. 0.020 in. 0.280 in. 4 lbs. 8 oz. C E50DT2

0.040 in. 0.020 in. 0.280 in. 4 lbs. 8 oz. C E50DT3

10 ° 6° 15 ° 2 in.-lbs. 2.4 in.-oz. C E50DW1

10 ° 6° 15 ° 2 in.-lbs. 2.4 in.-oz. C E50DW2

Side Rotary

Side Push

Top Push

Wobble Head

Description

Operating Heads

Standard

Spring Return

Low Temperature

Spring Return

Low Force

Spring Return

Maintained

Two position

Pushbutton

Spring Return

Pushbutton Adjustable

Spring Return

Push Roller

Spring Return

Pushbutton

Maintained

Pushbutton

Spring Return

Pushbutton Adjustable

Spring Return

Push Roller

Spring Return

Standard

Spring Duty

Return Heavy

Duty

TABLE 1

Side Operated Standard Construction within 0.0012”

Top Operated Top Push within 0.002”

1

Measured along arc for 1-1/2” lever or measured along push operator axis.

TABLE 2

Lever Roller Type Nylon 3/4” 5/16” +/-0.002”

Push Roller Type Metal 7/16” 5/32” +/-0.002”

Total

Travel

Contacts Force (See Table)

Operating Head Repeat Accuracy

Low Operating Force within 0.0024”

Two-Step within 0.006”

Neutral Position within 0.006”

Side Push within 0.003”

Type Diameter Width Concentricity Tolerance

Metal 3/4” 5/16” +/-0.001”

Nylon 3/4” 1” +/-0.005”

Ball Brg. 11/16” 1/4” +/-0.002”

Nylon 1-1/2” 9/32 +/-0.005”

Metal 3/4” 5/32” +/-0.005”

Operate Return Range

Catalog

No.

1

Effective 9/97

Loading...

Loading...