Eaton DeviceNet User Manual

DeviceNet Option Board for 9000X Drive

User Manual

New Information

March 2004

MN04003005E

For more information visit: www.eatonelectrical.com

March 2004

Important Notice – Please Read

The product discussed in this literature is subject to terms and conditions outlined in Eaton

Electrical Inc. selling policies. The sole source governing the rights and remedies of any

purchaser of this equipment is the relevant Eaton Electrical Inc. selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING FROM COURSE

OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE INFORMATION,

RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no event will Eaton

Electrical Inc. be responsible to the purchaser or user in contract, in tort (including

negligence), strict liability or otherwise for any special, indirect, incidental or consequential

damage or loss whatsoever, including but not limited to damage or loss of use of equipment,

plant or power system, cost of capital, loss of power, additional expenses in the use of

existing power facilities, or claims against the purchaser or user by its customers resulting

from the use of the information, recommendations and descriptions contained herein.

The information contained in this manual is subject to change without notice.

Cover Photo: Cutler-Hammer

®

9000X Drives.

DeviceNet Option Board User Manual

MN04003005E

For more information visit:

www.eatonelectrical.com

i

DeviceNet Option Board User Manual

Table of Contents

March 2004

LIST OF FIGURES

LIST OF TABLES

SAFETY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Definitions and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Hazardous High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Warnings, Cautions and Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

CHAPTER 1 — GENERAL

CHAPTER 2 — DEVICENET OPTION BOARD TECHNICAL DATA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . 2-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

DeviceNet Features and Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

CHAPTER 3 — DEVICENET

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

DeviceNet Physical Layer and Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

CHAPTER 4 — DEVICENET OPTION BOARD LAYOUT AND CONNECTIONS

. . . . . . . . 4-1

DeviceNet Option Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

LED Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Connection of DeviceNet Drop-Line Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

CHAPTER 5 — INSTALLATION OF DEVICENET OPTION BOARD

. . . . . . . . . . . . . . . . . . 5-1

Board Information Sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

CHAPTER 6 — COMMISSIONING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

DeviceNet Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Setting DeviceNet Parameters with the Control Keypad . . . . . . . . . . . . . . . . . . . . . 6-2

CHAPTER 7 — DEVICENET INTERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

I/O Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Input and Output Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

CHAPTER 8 — FAULT TRACKING

APPENDIX A — DEVICENET INTERFACE ERRORS

APPENDIX B — OPTC7 COMMUNICATION INTERFACE OBJECT PROFILES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

. . . . . . . . . B-1

Identity Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Message Router Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

DeviceNet Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Assembly Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

DeviceNet Connection Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Motor Data Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Control Supervisor Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

AC/DC Drive Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-19

Monitoring Data Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20

ii

For more information visit:

www.eatonelectrical.com

MN04003005E

March 2004

List of Figures

Figure 3-1: Trunk Lines or Drop Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 4-1: DeviceNet Option Board OPTC7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4-2: LED Indications on the DeviceNet Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 5-1: Identification Sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 6-1: Changing the DeviceNet Board Parameter Values . . . . . . . . . . . . . . . . . . . . . 6-3

Figure 6-2: DeviceNet Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Figure 7-1: DeviceNet I/O Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Figure 7-2: Control Supervisor State Transition Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

List of Tables

Table 2-1: DeviceNet Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Table 2-2: DeviceNet Features and Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 4-1: OPTC7 Bus Connector Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Table 4-2: Network Status LED (N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-3: Module Status LED (M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-4: Connection and Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Table 5-1: Installation of DeviceNet Option Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 6-1: Monitoring Data Class — Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Table 6-2: DeviceNet Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Table 6-3: DeviceNet Status Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Table 7-1: Output 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-2: Output 21 (Default) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-3: Output 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-4: Output 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-5: Input 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-6: Input 71 (Default) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Table 7-7: Input 73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Table 7-8: Input 75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Table 7-9: Explanation of the Control Supervisor State Transition Diagram . . . . . . . . . . 7-5

Table 7-10: Object Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Table 7-11: Supported Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Table 7-12: Elementary Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Table 7-13: Constructed Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Table 7-14: Inverter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Table 8-1: DeviceNet Option Board Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Table 8-2: Drive Responses to Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Table A-1: Event List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table B-1: Identity Class (1) — Class Attributes (0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Table B-2: Identity Class (1) — Instance Attributes (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Table B-3: Message Router Class (2) — Class Attributes (0). . . . . . . . . . . . . . . . . . . . . . . . B-3

Table B-4: Message Router Class (2) — Instance Attributes (1) . . . . . . . . . . . . . . . . . . . . . B-4

Table B-5: DeviceNet Class (3) — Class Attributes (0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Table B-6: DeviceNet Class (3) — Instance Attributes (1) . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table B-7: Assembly Class (4) — Class Attributes (0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Table B-8: Assembly Class (4) — Basic Control (20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Table B-9: Assembly Class (4) — Speed Control (21) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

DeviceNet Option Board User Manual

MN04003005E

For more information visit:

www.eatonelectrical.com

iii

DeviceNet Option Board User Manual

List of Tables, continued

Table B-10: Assembly Class (4) — Torque Control (23) . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Table B-11: Assembly Class (4) — Extended Process Control (25) . . . . . . . . . . . . . . . . . . B-7

Table B-12: Assembly Class (4) — Basic Status (70) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Table B-13: Assembly Class (4) — Speed Status (71) . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Table B-14: Assembly Class (4) — Torque Status (73) . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Table B-15: Assembly Class (4) — Extended Process Control (75) . . . . . . . . . . . . . . . . . . B-8

Table B-16: DeviceNet Connection Class (5) — Class Attributes (0) . . . . . . . . . . . . . . . . . B-9

Table B-17: DeviceNet Connection Class (5) — Explicit Connection Instance (1) . . . . . . B-10

Table B-18: DeviceNet Connection Class (5) — I/O Connection Instance (1) . . . . . . . . . . B-11

Table B-19: Motor Data Object Class (40) — Class Attributes (0) . . . . . . . . . . . . . . . . . . . B-12

Table B-20: Motor Data Object Class (40) — Instance Attributes (1). . . . . . . . . . . . . . . . . B-13

Table B-21: Control Supervisor Object Class (41) — Class Attributes (0). . . . . . . . . . . . . B-14

Table B-22: Control Supervisor Object Class (41) — Instance Attributes (1) . . . . . . . . . . B-15

Table B-23: AC/DC Drive Object Class (42) — Class Attributes (0) . . . . . . . . . . . . . . . . . . B-17

Table B-24: AC/DC Drive Object Class (42) — Instance Attributes (1). . . . . . . . . . . . . . . . B-18

Table B-25: Parameter Class (160) — Class Attributes (0) . . . . . . . . . . . . . . . . . . . . . . . . . B-19

Table B-26: Parameter Class (160) — Class Attributes (1) . . . . . . . . . . . . . . . . . . . . . . . . . B-20

Table B-27: Monitoring Data Class (170) — Class Attributes (0) . . . . . . . . . . . . . . . . . . . . B-20

Table B-28: Monitoring Data Class (170) — Instance Attributes (1) . . . . . . . . . . . . . . . . . B-21

March 2004

iv

For more information visit:

www.eatonelectrical.com

MN04003005E

March 2004

Safety

Definitions and Symbols

This symbol indicates high voltage. It calls your attention to items

or operations that could be dangerous to you and other persons

operating this equipment. Read the message and follow the

instructions carefully.

This symbol is the “Safety Alert Symbol.” It occurs with either of

two signal words: CAUTION or WARNING, as described below.

Indicates a potentially hazardous situation which, if not avoided,

can result in serious injury or death.

DeviceNet Option Board User Manual

WARNING

WARNING

Indicates a potentially hazardous situation which, if not avoided,

can result in minor to moderate injury, or serious damage to the

product. The situation described in the CAUTION may, if not

avoided, lead to serious results. Important safety measures are

described in CAUTION (as well as WARNING).

Hazardous High Voltage

Motor control equipment and electronic controllers are connected

to hazardous line voltages. When servicing drives and electronic

controllers, there may be exposed components with housings or

protrusions at or above line potential. Extreme care should be taken

to protect against shock.

Stand on an insulating pad and make it a habit to use only one

hand when checking components. Always work with another

person in case an emergency occurs. Disconnect power before

checking controllers or performing maintenance. Be sure

equipment is properly grounded. Wear safety glasses whenever

working on electronic controllers or rotating machinery.

CAUTION

WARNING

MN04003005E

For more information visit:

www.eatonelectrical.com

v

DeviceNet Option Board User Manual

Warnings, Cautions and Notices

Internal components and circuit boards are at high potential when

the drive is connected to the power source. This voltage is

extremely dangerous and may cause death or severe injury if you

come into contact with it.

Make sure that the drive

fieldbus board is changed or added.

Before taking any commissioning actions, carefully read the safety

instructions in the

WARNING

CAUTION

IS SWITCHED OFF

IMPORTANT

!

9000X User’s Manual

March 2004

before an option or

.

vi

For more information visit:

www.eatonelectrical.com

MN04003005E

March 2004

Chapter 1 — General

Instead of sending and receiving information to and from adjustable frequency drives

through I/O, you can connect them to a fieldbus.

Cutler-Hammer® 9000X drives from Eaton Electrical® can be connected to the DeviceNet

using a fieldbus board. The drive can then be controlled, monitored and programmed from

the Host system.

If you purchase your DeviceNet Option Board separately, please note that the it shall be

installed in

Slot E

Internal components and circuit boards are at high potential when

the drive is connected to the power source. This voltage is

extremely dangerous and may cause death or severe injury if you

come into contact with it.

DeviceNet Option Board User Manual

on the control board of the drive.

WARNING

MN04003005E

For more information visit:

www.eatonelectrical.com

1-1

DeviceNet Option Board User Manual

March 2004

1-2

For more information visit:

www.eatonelectrical.com

MN04003005E

March 2004

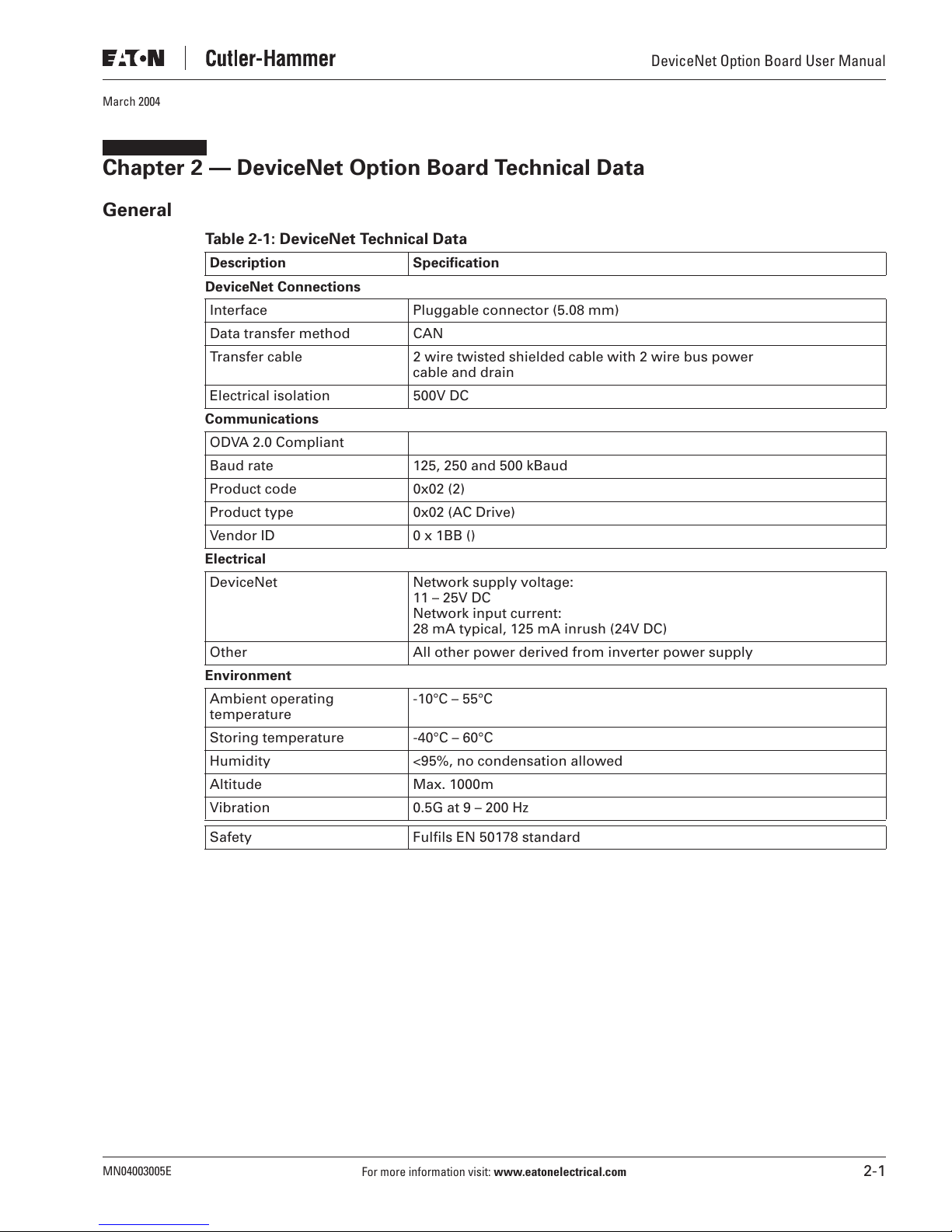

Chapter 2 — DeviceNet Option Board Technical Data

General

Table 2-1: DeviceNet Technical Data

Description Specification

DeviceNet Connections

Interface Pluggable connector (5.08 mm)

Data transfer method CAN

Transfer cable 2 wire twisted shielded cable with 2 wire bus power

Electrical isolation 500V DC

Communications

ODVA 2.0 Compliant

Baud rate 125, 250 and 500 kBaud

Product code 0x02 (2)

Product type 0x02 (AC Drive)

Vendor ID 0 x 1BB ()

Electrical

DeviceNet Network supply voltage:

Other All other power derived from inverter power supply

Environment

Ambient operating

temperature

Storing temperature -40°C – 60°C

Humidity <95%, no condensation allowed

Altitude Max. 1000m

Vibration 0.5G at 9 – 200 Hz

cable and drain

11 – 25V DC

Network input current:

28 mA typical, 125 mA inrush (24V DC)

-10°C – 55°C

DeviceNet Option Board User Manual

Safety Fulfils EN 50178 standard

MN04003005E

For more information visit:

www.eatonelectrical.com

2-1

DeviceNet Option Board User Manual

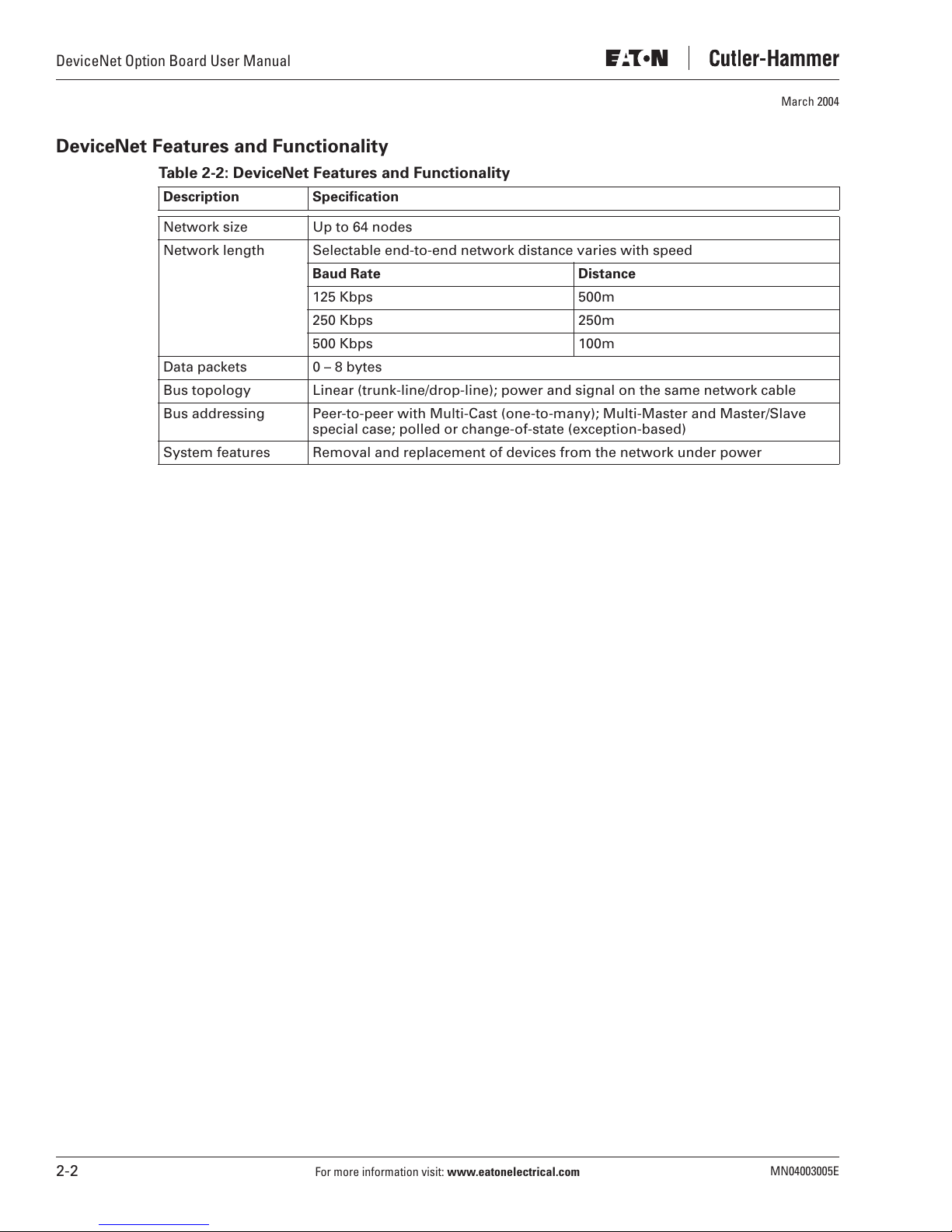

DeviceNet Features and Functionality

Table 2-2: DeviceNet Features and Functionality

Description Specification

Network size Up to 64 nodes

Network length Selectable end-to-end network distance varies with speed

Baud Rate Distance

125 Kbps 500m

250 Kbps 250m

500 Kbps 100m

Data packets 0 – 8 bytes

Bus topology Linear (trunk-line/drop-line); power and signal on the same network cable

Bus addressing Peer-to-peer with Multi-Cast (one-to-many); Multi-Master and Master/Slave

special case; polled or change-of-state (exception-based)

System features Removal and replacement of devices from the network under power

March 2004

2-2

For more information visit:

www.eatonelectrical.com

MN04003005E

March 2004

Chapter 3 — DeviceNet

Introduction

DeviceNet is an open network based on CAN that is designed to connect low cost industrial

control devices (such as limit switches, photoelectric sensors, motor starters, process

sensors, adjustable frequency drives, panel displays and operator interfaces) to a network

and eliminate expensive hardwiring.

The direct connectivity provides improved communication between devices as well as

important device-level diagnostics not easily accessible or available through hardwired

I/O interfaces.

The DeviceNet Model is application independent; it provides the communication services

needed by various types of applications.

Many of today’s lower level industrial control devices must retain their low cost/low resource

characteristics even when directly connected to a network. DeviceNet takes this into

consideration by defining a specific instance of the Model for communications typically

seen in a Master/Slave application. This is referred to as the Predefined Master/Slave

Connection Set.

DeviceNet Option Board User Manual

DeviceNet allows the interchangeability of simple devices while making interconnectivity for

more complex devices possible. In addition to reading the state of discrete devices,

DeviceNet provides the capability to report temperatures, to read the load current in a motor

starter, to change the deceleration rate of drives, or to count the number of packages that

have passed on a conveyor in the previous hour.

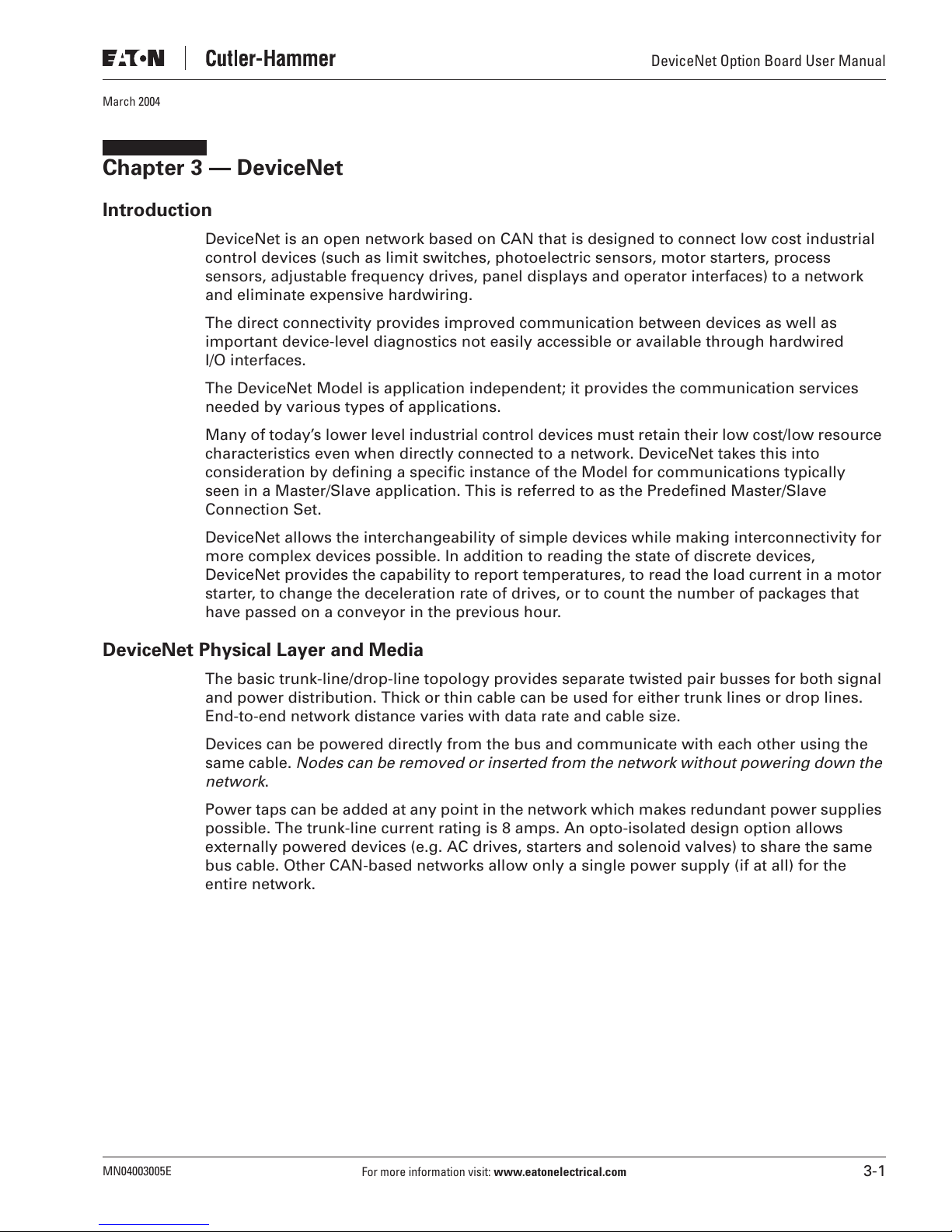

DeviceNet Physical Layer and Media

The basic trunk-line/drop-line topology provides separate twisted pair busses for both signal

and power distribution. Thick or thin cable can be used for either trunk lines or drop lines.

End-to-end network distance varies with data rate and cable size.

Devices can be powered directly from the bus and communicate with each other using the

same cable.

network

Power taps can be added at any point in the network which makes redundant power supplies

possible. The trunk-line current rating is 8 amps. An opto-isolated design option allows

externally powered devices (e.g. AC drives, starters and solenoid valves) to share the same

bus cable. Other CAN-based networks allow only a single power supply (if at all) for the

entire network.

Nodes can be removed or inserted from the network without powering down the

.

MN04003005E

For more information visit:

www.eatonelectrical.com

3-1

DeviceNet Option Board User Manual

March 2004

Terminator Tap Terminator

Trunk Line

Node Node

Node

Node

Node

Drop

Line

Node

Node

Node

Node

Short DropsZero Drop

Node

Node Node

Node

Figure 3-1: Trunk Lines or Drop Lines

Thick or Thin Cable can be used for either trunk lines or drop lines.

3-2

For more information visit:

www.eatonelectrical.com

MN04003005E

DeviceNet Option Board User Manual

March 2004

Chapter 4 — DeviceNet Option Board Layout and Connections

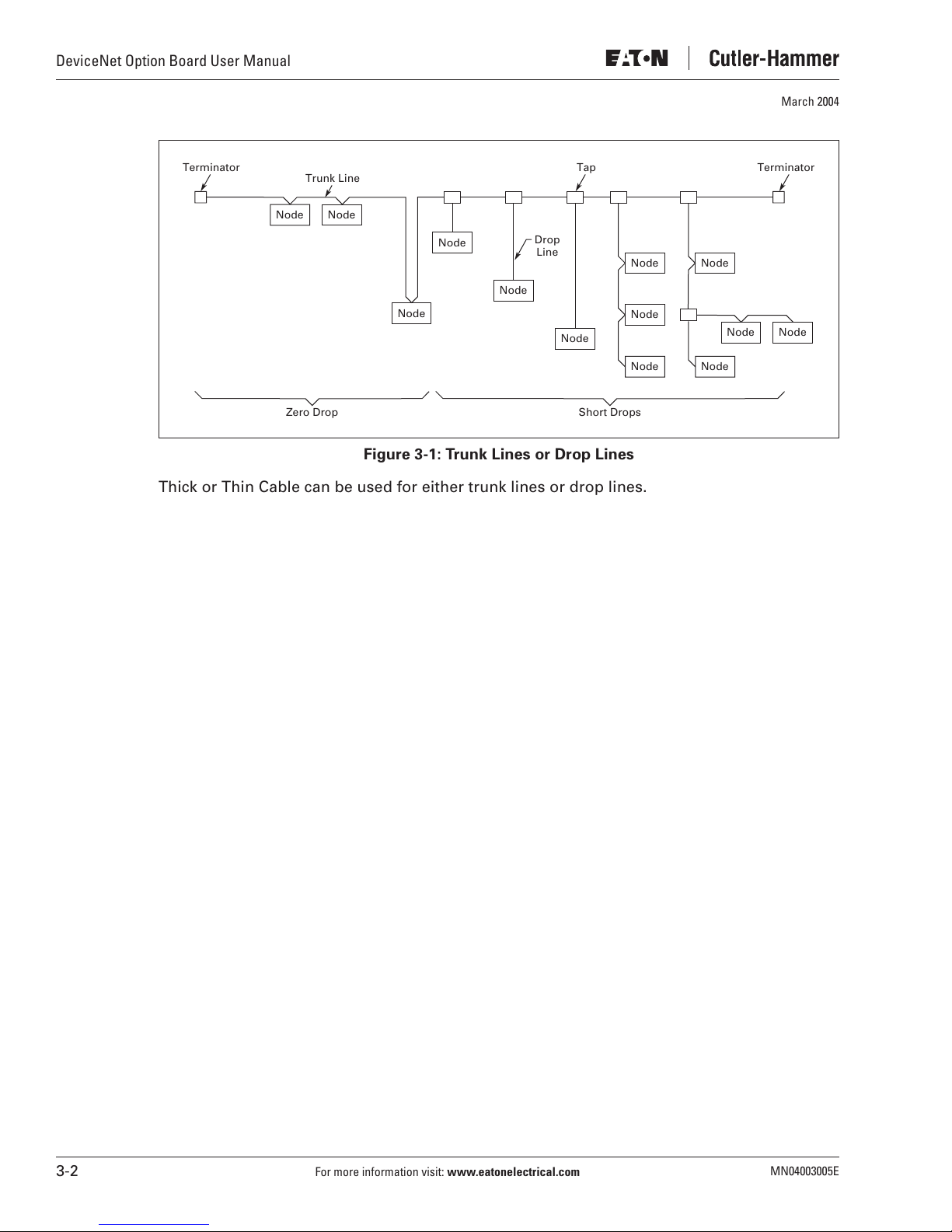

The Cutler-Hammer DeviceNet Option Board from Eaton Electrical is connected to the

fieldbus through a 5-pin pluggable bus connector (board OPTC7).

The communication with the control board of the drive takes place through the standard

Interface Board Connector.

DeviceNet Option Board

N

A

M

1

2

3

4

5

X1

Bus

Connector

Grounding

Plate

Jumper

Figure 4-1: DeviceNet Option Board OPTC7

Table 4-1: OPTC7 Bus Connector Signals

Signal Connector Description

V- 1 Communication power supply, Ground

CAN_L 2 Communication signal, Low

Drain 3 Cable shield (bare)

CAN_H 4 Communication signal, High

V+ 5 Communication power supply, +24V

Interface

Board Connector

MN04003005E

For more information visit:

www.eatonelectrical.com

4-1

DeviceNet Option Board User Manual

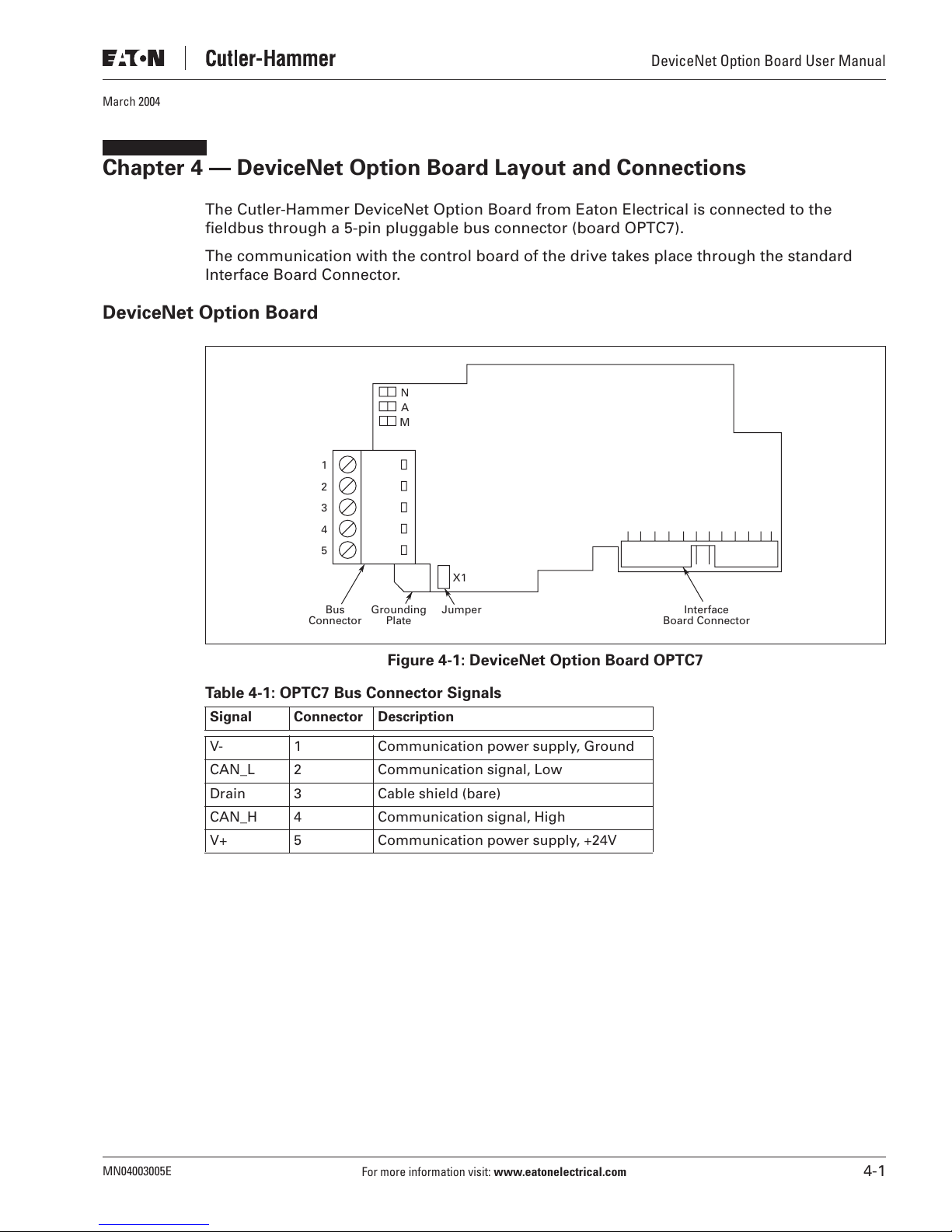

LED Indications

The DeviceNet Option Board includes three LED status indicators next to the connector:

Network status (N), Node address (A) and Module status (M). Network status provides

information on the network connection status, Node address blinks the MAC ID of the unit

while it is powered and Module status provides information on the DeviceNet module.

1

2

3

4

5

NGreen/Red

Green/Red

A

Green/Red

M

March 2004

X1

Figure 4-2: LED Indications on the DeviceNet Board

Table 4-2: Network Status LED (N)

LED is: Meaning:

OFF The OPTC7 is not on-line —

• The device has not completed the Dup_MAC_ID test yet

• If the Module status LED is off, the device is not powered

Green The OPTC7 is on-line and allocated to a Master

Blinking Green The OPTC7 has passed the Dup_MAC_ID test, is on-line, but is not allocated to a

master

Blinking Red One or more I/O connections are in the Timed-Out state

Red The OPTC7 cannot communicate on the network (Duplicate MAC ID or Bus-off)

Table 4-3: Module Status LED (M)

LED is: Meaning:

OFF There is no power applied to the OPTC7

Green The OPTC7 is operating normally

Blinking Green The OPTC7 board is in Standby state or the device needs commissioning due to a

missing, incomplete or incorrect configuration

Blinking Red The option board has detected a Recoverable Fault

Red The option board has detected an Unrecoverable Fault

4-2

For more information visit:

www.eatonelectrical.com

MN04003005E

March 2004

Node Address LED (A)

This LED blinks the MAC ID of the unit while it is powered. The tens are displayed with red

blinks and the ones with green blinks. The unit plays the tens, then the ones and finally

delays about 2 seconds before repeating the sequence.

LED Test

An LED test is performed at power-up. The following sequence is performed:

1. All LEDs OFF

2. All LEDs Green (0.25 s)

3. All LEDs Red (0.25 s)

4. All LEDs OFF

5. Start of Normal Operation

Connection of DeviceNet Drop-Line Cable

The following instructions lead you through the connection of the OPTC7 to the DeviceNet

system and show you the power-up and grounding of the board.

DeviceNet Option Board User Manual

Table 4-4: Connection and Power-Up

Step Procedure

A

Lead the DeviceNet drop-line cable through

the right gridded hole on the bottom of the

drive. Make a sufficiently wide opening for

the cable by cutting the grid as wide as

necessary (see Step E on

Page 5-2

)

MN04003005E

For more information visit:

www.eatonelectrical.com

4-3

DeviceNet Option Board User Manual

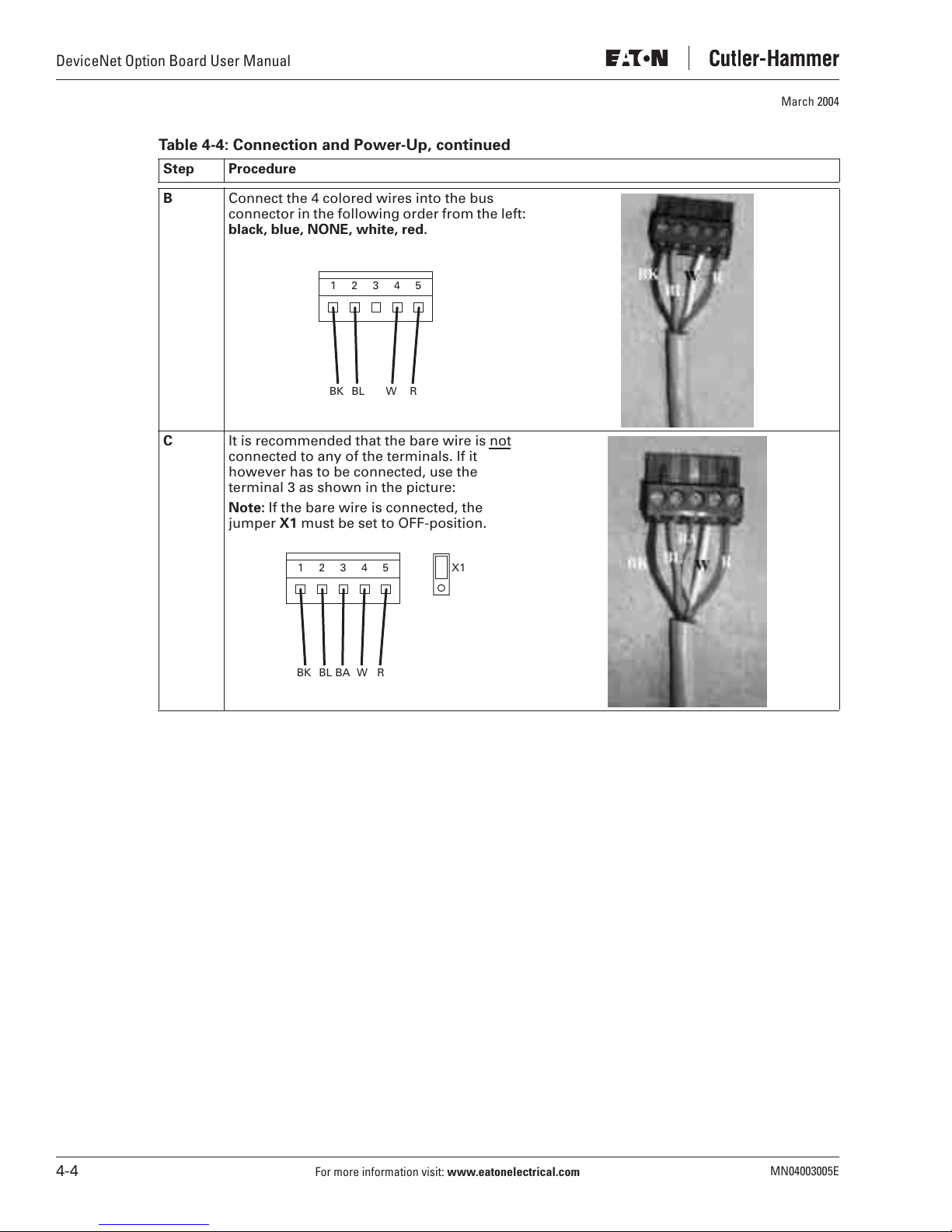

Table 4-4: Connection and Power-Up, continued

Step Procedure

March 2004

B

Connect the 4 colored wires into the bus

connector in the following order from the left:

black, blue, NONE, white, red.

12345

BK BL W

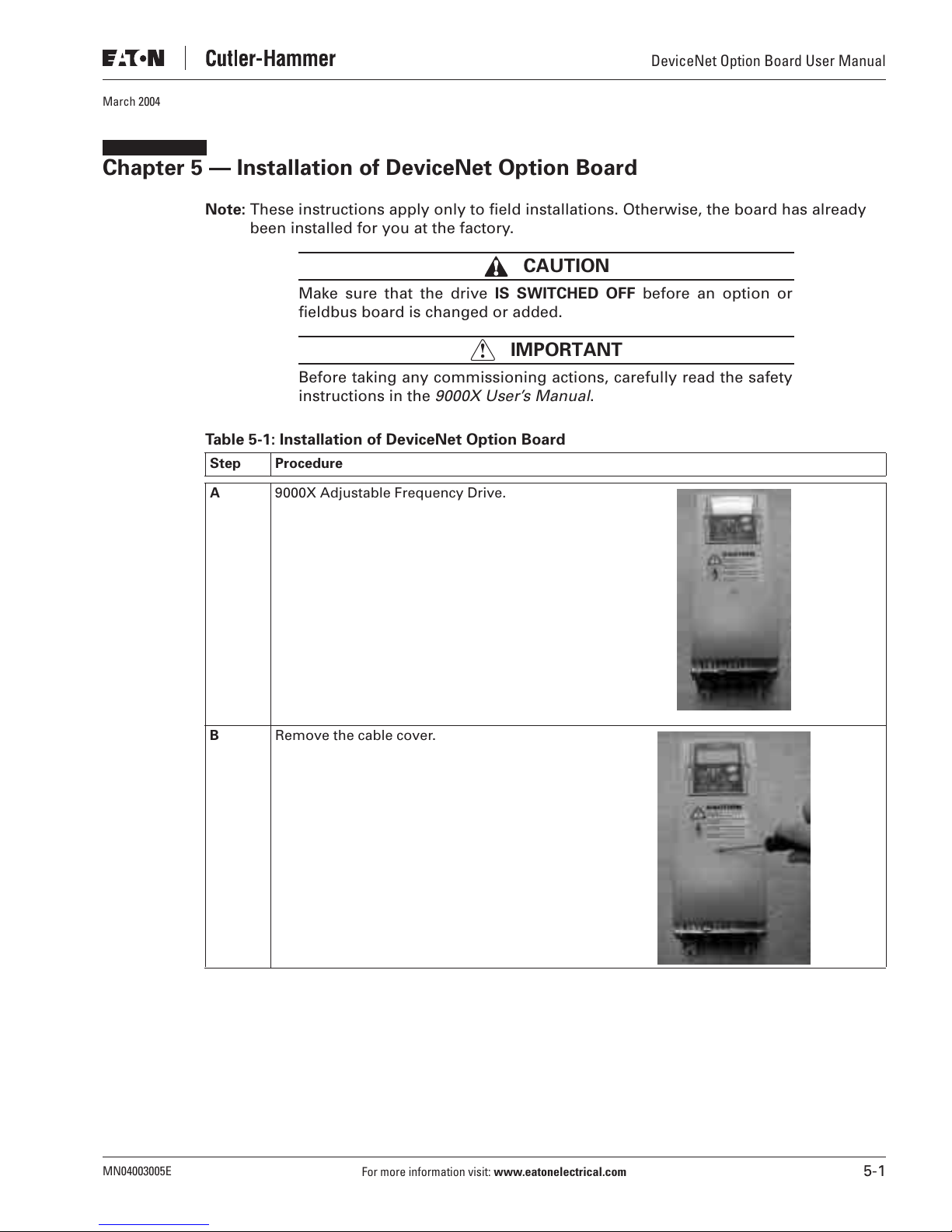

C

It is recommended that the bare wire is not

R

connected to any of the terminals. If it

however has to be connected, use the

terminal 3 as shown in the picture:

Note:

If the bare wire is connected, the

jumper X1 must be set to OFF-position.

12345

X1

BK BL WBA

R

4-4

For more information visit:

www.eatonelectrical.com

MN04003005E

March 2004

Chapter 5 — Installation of DeviceNet Option Board

Note:

These instructions apply only to field installations. Otherwise, the board has already

been installed for you at the factory.

CAUTION

Make sure that the drive

fieldbus board is changed or added.

Before taking any commissioning actions, carefully read the safety

instructions in the

9000X User’s Manual

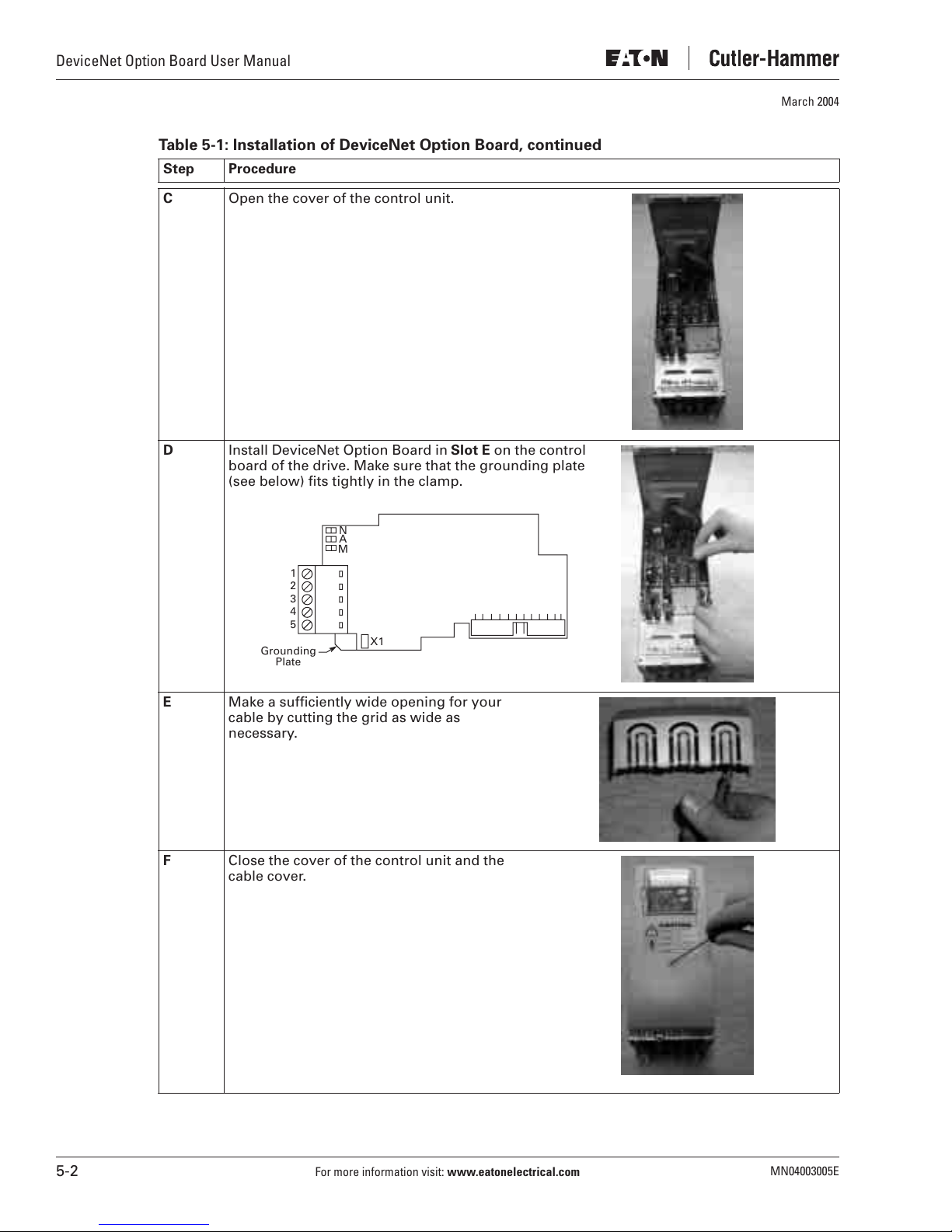

Table 5-1: Installation of DeviceNet Option Board

Step Procedure

IS SWITCHED OFF

IMPORTANT

!

.

DeviceNet Option Board User Manual

before an option or

A

B

9000X Adjustable Frequency Drive.

Remove the cable cover.

MN04003005E

For more information visit:

www.eatonelectrical.com

5-1

DeviceNet Option Board User Manual

Table 5-1: Installation of DeviceNet Option Board, continued

Step Procedure

C Open the cover of the control unit.

D Install DeviceNet Option Board in Slot E on the control

board of the drive. Make sure that the grounding plate

(see below) fits tightly in the clamp.

March 2004

N

A

M

1

2

3

4

5

Grounding

Plate

X1

E Make a sufficiently wide opening for your

cable by cutting the grid as wide as

necessary.

F Close the cover of the control unit and the

cable cover.

5-2

For more information visit:

www.eatonelectrical.com

MN04003005E

Loading...

Loading...