Intelligent Technologies

DeviceNet Starter Network Adapter Product

(D77B-DSNAP)

Installation and User Manual

Publication No. MN05004001E

September 2002

Supersedes February 2002

September 2002

Important Notice – Please Read

The product discussed in this literature is subject to terms and conditions outlined in

appropriate Eaton’s Cutler-Hammer selling policies. The sole source governing the

rights and remedies of any purchaser of this equipment is the relevant Eaton’s

Cutler-Hammer selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS

FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING

FROM COURSE OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE

INFORMATION, RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In

no event will Eaton’s Cutler-Hammer be responsible to the purchaser or user in

contract, in tort (including negligence), strict liability or otherwise for any special,

indirect, incidental or consequential damage or loss whatsoever, including but not

limited to damage or loss of use of equipment, plant or power system, cost of

capital, loss of power, additional expenses in the use of existing power facilities, or

claims against the purchaser or user by its customers resulting from the use of the

information, recommendations and descriptions contained herein.

IT.

Cover Photo:

D77B-DSNAP

Intelligent Technologies (

IT.

) D77B-DSNAP

Pub. No. MN05004001E

i

Intelligent Technologies (

IT.

Table of Contents

PRODUCT OVERVIEW

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Environmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Approvals/Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Catalog Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PHYSICAL FEATURES

Physical Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION

Mount the D77B-DSNAP to the Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connect the Starter Terminal Adapter to the Starter . . . . . . . . . . . . . . . . . . . . . . . 9

Connect the D77B-DSNAP to DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Set the DeviceNet MAC ID and Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

OPERATION

“Out of Box” Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safe State Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Input and Output Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Typical Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DeviceNet Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CONFIGURATION

Using CH Studio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Using a Generic DeviceNet Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Autoconfiguring the D77B-DSNAP for the Starter . . . . . . . . . . . . . . . . . . . . . . . . . 27

TROUBLESHOOTING AND MAINTENANCE

Renewal Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

APPENDIX A: SUPPORTED DEVICENET OBJECTS

DeviceNet Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DeviceNet I/O Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

IT.

PUBLICATIONS AND SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

) D77B-DSNAP

September 2002

FVNR Motor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FVR Motor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

S751 Motor Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Input Assemby Data Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Output Assembly Data Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

General Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configuring Enhanced Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Monitor the D77B-DSNAP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Change the I/O Assemblies of the D77B-DSNAP . . . . . . . . . . . . . . . . . . . . . . 26

DeviceNet Input Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DeviceNet Output Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

ii

Pub. No. MN05004001E

September 2002

List of Figures

List of Tables

Intelligent Technologies (

Figure 1: D77B-DSNAP Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2: D77B-DSNAP Dimensions, mm [in] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3: Starter Terminal Adapter Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4: D77B-DSNAP Alignment and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5: D77B-DSNAP Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6: Connecting Starter Terminal Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7: Jumper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

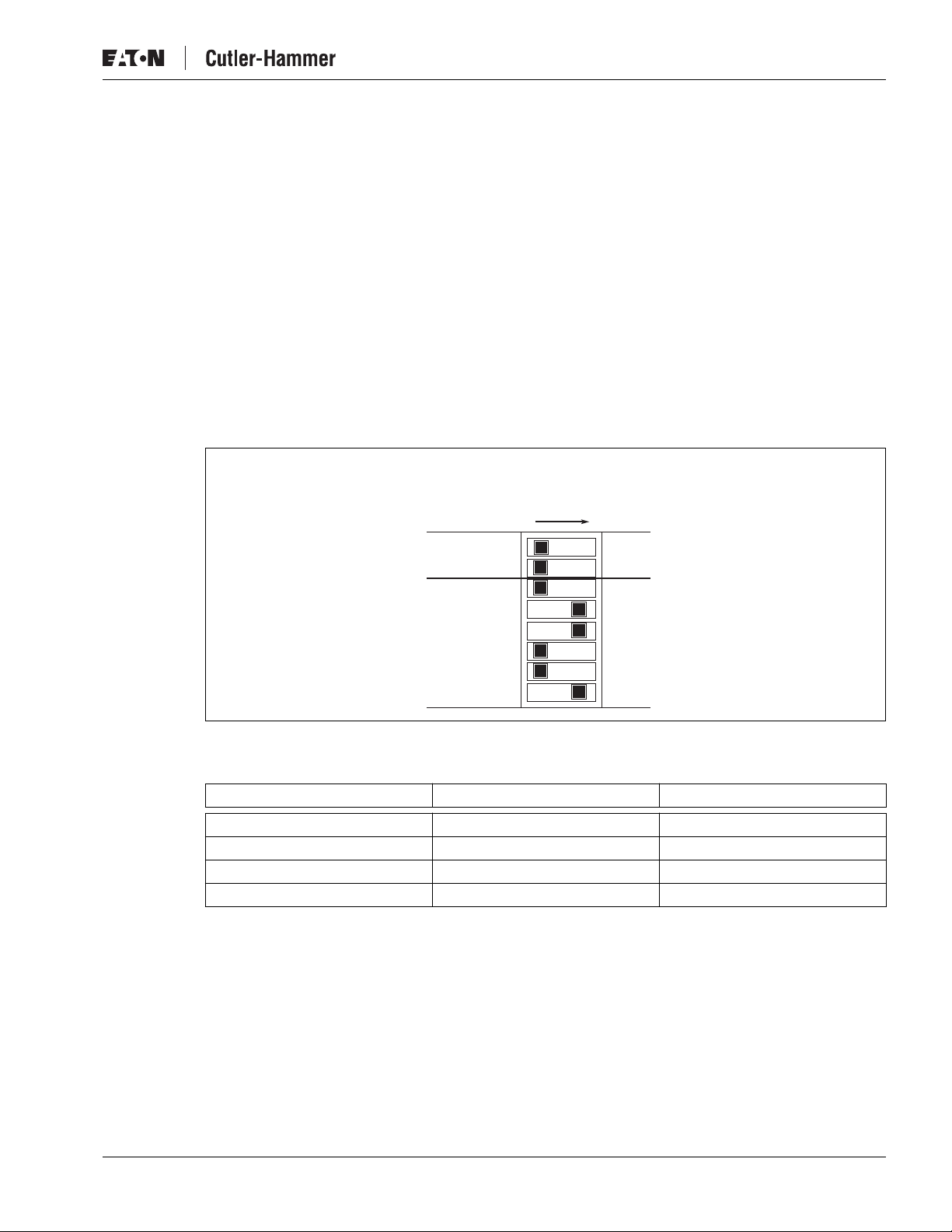

Figure 8: DIP Switch Setting Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9: D77B-DSNAP-X1 on FVNR

Figure 10: D77B-DSNAP-X2 on FVR

Figure 11: D77B-DSNAP-X1 on S751

Figure 12: Typical D77B-DSNAP Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 1: D77B-DSNAP Electromechanical Starter Connectivity Table. . . . . . . . . . 1

Table 2: D77B-DSNAP S751 Connectivity Table . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 3: Environmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 4: Approvals/Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 5: Catalog Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 6: Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 7: Starter Size/Available Auxiliary Locations on Mounted D77B-DSNAP. . 7

Table 8: DeviceNet Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 9: Baud Rate Configuration Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 10: Input Assembly for Non-reversing Starter (E101, N101) . . . . . . . . . . . . 13

Table 11: Output Assembly for Non-reversing Starter (E101, N101)

and S751 Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 12: Input Assembly for Reversing Starter (E501, N501) . . . . . . . . . . . . . . . . 15

Table 13: Output Assembly for Reversing Starter (E501, N501) . . . . . . . . . . . . . . 15

Table 14: Input Assembly for S751 Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 15: Output Assembly for S751 Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 16: Allowable DeviceNet I/O Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 17: Input Assembly Data Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 18: Output Assembly Data Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 19: Standard Protective Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 20: Enhanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 21: Combined MS/NS LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 22: Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 23: D77B-DSNAP Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 24: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 25: Supported Objects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 26: DeviceNet Object Common Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 27: Identity Object 0x01. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 28: DeviceNet Object 0x03 — Instance 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 29: Connection Object 0x05 — Instance 1 (Explicit Connection) . . . . . . . . . 32

Table 30: Connection Object 0x05 — Instance 2 (I/O Message). . . . . . . . . . . . . . . 32

Table 31: Discrete Input Object 0x08 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 32: Motor Data Object 0x28 — Instance 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 33: Control Supervisor Object 0x29 — Instance 1 . . . . . . . . . . . . . . . . . . . . 35

Table 34: Overload Object 0x2C — Instance 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 35: Soft Start Object 0x2D — Instance 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 36: Allowable DeviceNet I/O Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 37: Reading Current Input Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 38: Setting Input Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 39: Reading Current Output Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

IT.

Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

IT.

Starter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

IT.

Soft Starter . . . . . . . . . . . . . . . . . . . . . . . 16

IT.

) D77B-DSNAP

Pub. No. MN05004001E

iii

Intelligent Technologies (

Table 40: Setting Output Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 41: Assembly 52 (0x34) — Basic Motor Starter . . . . . . . . . . . . . . . . . . . . . . . 40

Table 42: Assembly 53 (0x35) — Extended Motor Starter 1 . . . . . . . . . . . . . . . . . . 40

Table 43: Assembly 54 (0x36) — Extended Motor Starter 2 . . . . . . . . . . . . . . . . . . 40

Table 44: Assembly 60 (0x3C) — Basic Soft Start Input . . . . . . . . . . . . . . . . . . . . . 40

Table 45: Assembly 102 (0x66) — D77B-DSNAP Motor Starter . . . . . . . . . . . . . . . 40

Table 46: Assembly 103 (0x67) — D77B-DSNAP Extended Motor Starter. . . . . . . 40

Table 47: Assembly 105 (0x69) — D77B-DSNAP Abbreviated Motor Starter 1. . . 41

Table 48: Assembly 106 (0x6A) — D77B-DSNAP Abbreviated Motor Starter 2 . . 41

Table 49: Assembly 108 (0x6C) — D77B-DSNAP Motor Starter with Fault Code . 41

Table 50: Assembly 109 (0x6D) — D77B-DSNAP Expanded Motor Starter

Table 51: Assembly 114 (0x72) — Complete Status Assembly . . . . . . . . . . . . . . . 41

Table 52: Input Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 53: Assembly 3 (0x03) — Basic Motor Starter . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 54: Assembly 5 (0x05) — Extended Motor Starter . . . . . . . . . . . . . . . . . . . . 42

Table 55: Output Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 56:

IT.

) D77B-DSNAP

with Fault Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

IT.

September 2002

Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

iv

Pub. No. MN05004001E

A

September 2002

Product Overview

Description

Cutler-Hammer Intelligent Technologies (

dapter P roduct) by Eaton Corporation is the result of a substantive engineering and

marketing effort, involving extensive customer input. This product has greatly increased

functionality of the

front-mount device is a single DeviceNet node providing control and monitoring of an

Electromechanical Starter application.

The D77B-DSNAP provides a communication interface to the following

Starters.

Table 1: D77B-DSNAP Electromechanical Starter Connectivity Table

IEC

E101, FVNR

E501, FVR

B 00 45 mm

C 1 54 mm

D 2 76 mm

E 3 105 mm

F 5 140 mm

Intelligent Technologies (

IT.

) D77B-DSNAP ( D eviceNet S tarter N etwork

IT.

Electromechanical Starter with the addition of enhanced features. This

IT.

NEMA

N101, FVNR

N501, FVR

0

4

Frame

Width

IT.

) D77B-DSNAP

Electromechanical

IT.

Table 2: D77B-DSNAP S751 Connectivity Table

S751 Soft Start

All

This manual specifically addresses the DeviceNet Starter Network Adapter Product

(D77B-DSNAP). The D77B-DSNAP provides connectivity to DeviceNet supporting Group 2

slave, I/O poll and explicit messaging.

For further information on the

.cutler-hammer.eaton.com/it

www

IT.

family of devices, visit our Web site at:

Notice

The D77B-DSNAP can only be applied with the

IT.

family of starters.

Pub. No. MN05004001E

1

Intelligent Technologies (

IT.

) D77B-DSNAP

Features and Benefits

The

IT.

D77B-DSNAP includes the following significant features:

●

Communication to DeviceNet consuming one DeviceNet MAC ID

●

Control of non-reversing and reversing

●

Monitoring of non-reversing and reversing

●

Easy direct mounting to the front of

●

Optional ground fault detector

●

No special software application required for normal setup. MAC ID and baud rate are

set with DIP switches

●

Warning levels that are user-settable

IT.

Starters and S751 Soft Start

IT.

Starters and S751 Soft Start

IT.

Starters and S751 Soft Start

September 2002

2

Pub. No. MN05004001E

September 2002

Safety

Intelligent Technologies (

IT.

) D77B-DSNAP

The following safety statements relate to the installation, setup and operation of the Eaton’s

Cutler-Hammer

IT.

D77B-DSNAP and Starter.

Notice

Make sure you read and understand the installation procedures in

this manual before you attempt to set up or operate the equipment.

WARNING

This instruction manual should be used for proper installation,

setup and operation of the

IT.

D77B-DSNAP. Improperly installing

and maintaining this product can result in serious personal injury

or property damage. Before attempting installation, setup or

operation, read and understand this entire manual.

WARNING

Hazardous voltage can cause electric shock and burns. Always

disconnect power before proceeding with any work on this product.

Only apply 24V DC to the Terminal Adapter power terminals. Use

of any other voltage may result in personal injury, property damage

and damage to the

To provide continued protection against fire or shock hazard, the

complete

inoperative.

Environmental Ratings

The following environmental ratings apply to the D77B-DSNAP.

Table 3: Environmental Ratings

Category Description Specification

Transportation/

Storage

Operating Temperature 0°C to 60°C [32°F to 140°F]

WARNING

IT.

D77B-DSNAP.

WARNING

IT.

D77B-DSNAP must be replaced if it becomes

Temperature -50°C to 80°C [-58°F to 176°F]

Humidity 5 – 95% non-condensing

Humidity 5 – 95% non-condensing

Altitude Above 2000 meters [6600 feet] consult factory

Shock (IEC 68-2-27) 15G in any direction for 11 milliseconds

Vibration (IEC 68-2-6) 5 – 150 Hz, 5G, 0.7 mm maximum peak-to-peak

Pub. No. MN05004001E

3

6

6

6

6

6

Intelligent Technologies (

IT.

) D77B-DSNAP

Approvals/Certifications

The following approvals and certifications apply to the D77B-DSNAP.

Table 4: Approvals/Certifications

Standard Approval/Certification

Agency Certifications UL 508

Radiated and Conducted Emissions EN 5011 Class A

Electrical/EMC

ESD Immunity (IEC 61000-4-2)

Radiated Immunity (IEC 61000-4-3) 10 V/m 80 – 1000 MHz, 80% amplitude modulation @ 1 kHz

Fast Transient (IEC 61000-4-4)

Surge (IEC 61000-4-5)

RF Conducted (IEC 61000-4-6) 10V, 0.15 – 80 MHz

Magnetic Field (IEC 61000-4-8) 30 A/m, 50 Hz

Voltage Dips (IEC 61000-4-11) 30% dip @ 10 ms

September 2002

CE (Low Voltage Directive)

CSA C22.2 No. 14

ODVA Group 2 slave no UCMM

8 kV air, 6 4 kV contact

2 kV supply and control

1 kV communications

1 kV line-to-line

2 kV line-to-ground

60% dip @ 100 ms

>95% interrupt @ 5 ms

Protection Degree (IEC 60947-1) IP20

Catalog Numbering System

The D77B-DSNAP can be ordered as an assembly or as individual components. The

assembly includes all components for normal operation.

Table 5: Catalog Numbers

Description Catalog Number

SNAP Jumper to terminal adapter D77B-RJJ1

D77B-DSNAP Assembly of terminal adapter, jumper and D77B-DSNAP D77B-DSNAP-X1

D77B-DSNAP Assembly of terminal adapter, jumper, D77B-DSNAP and second

contactor sensor

DeviceNet Start Network Adapter Product D77B-DSNAP

SNAP Terminal Adapter for FVR and FVNR starters and S751 Soft Start D77B-TC8

Second contactor sensor for FVR starters and contactors D77B-A2

Ground Fault Detector for 45 mm and 54 mm frame starters D77B-GF1

Ground Fault Detector for 76 mm and 105 mm starters D77B-GF2

Ground Fault Detector for 140 mm starters D77B-GF3

D77B-DSNAP-X2

4

Pub. No. MN05004001E

September 2002

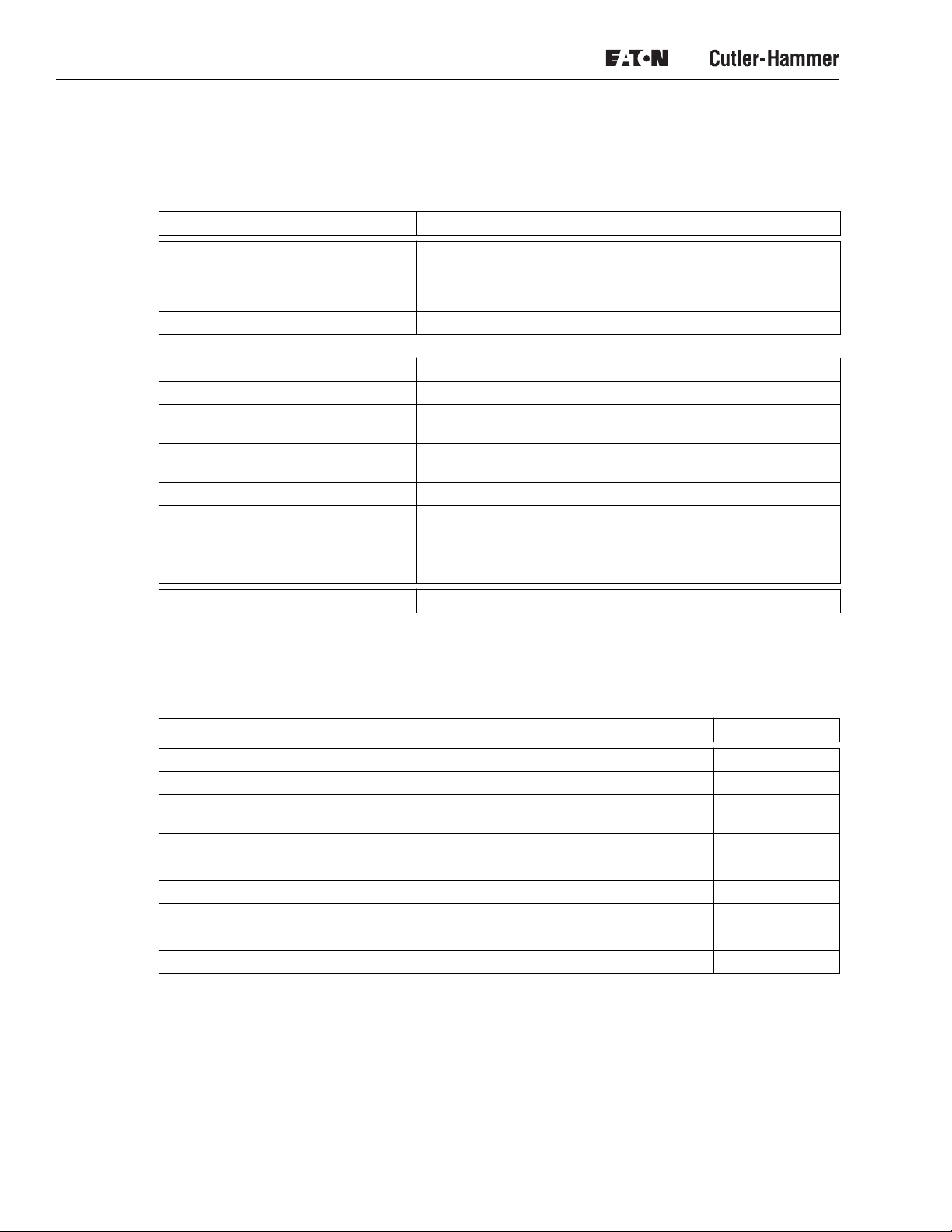

Physical Features

Physical Description

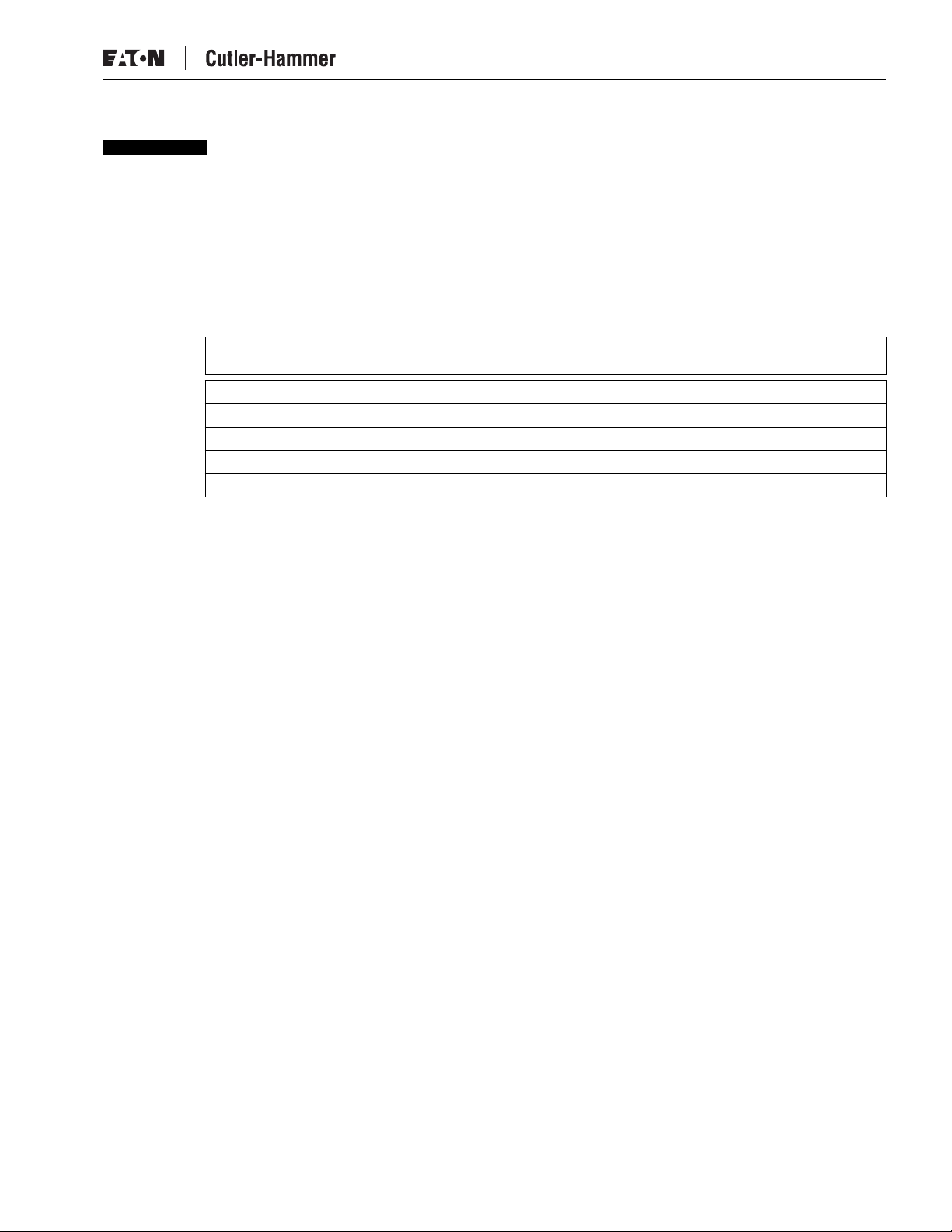

Figure 1 illustrates the front and back of the

Starter

Connector

Push Tab

DeviceNet

Status

LED

Connector

Breakout

Baud and

MAC ID

Switches

Intelligent Technologies (

IT.

D77B-DSNAP and its various features.

Contactor

Position

Detector

Lock Tab

IT.

) D77B-DSNAP

Feet

Dimensions

Figure 1: D77B-DSNAP Features

Figure 2 illustrates the dimensions of the

Front

62

[2.4]

26

[1.0]

Figure 2: D77B-DSNAP Dimensions, mm [in]

IT.

D77B-DSNAP.

Side

49

[1.9]

Pub. No. MN05004001E

5

Intelligent Technologies (

Power Source

The

IT.

from two sources, the DeviceNet subnet and the Eaton’s Cutler-Hammer

allows the D77B-DSNAP to indicate to the user that the

power, signaling a fault or an E-Stop.

Power for DeviceNet communication CPU comes from DeviceNet, as illustrated in Table 6.

Some power is required from the starter for communication to be present between the

Starters and the D77B-DSNAP.

The power for the

Table 6: Power Requirements

Current Source Load

DeviceNet 90 mA

IT.

Starter Less than 1 mA

When a power supply is chosen for the starter(s), size it for the load of the starter(s) and the

D77B-DSNAP using the appropriate

The power for Eaton’s Cutler-Hammer

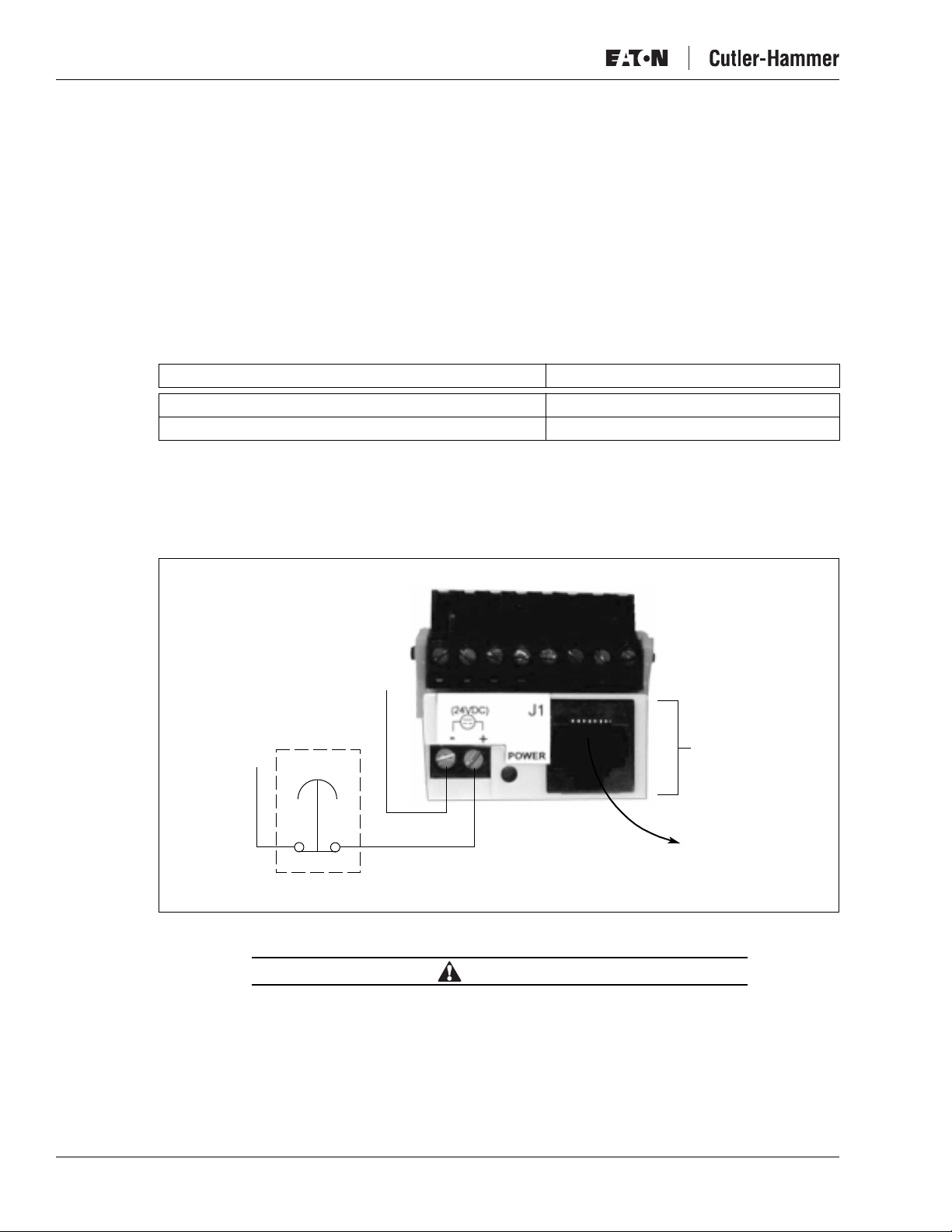

terminal, as illustrated in Figure 3.

IT.

) D77B-DSNAP

September 2002

D77B-DSNAP is designed for use with 24V DC power. The D77B-DSNAP uses power

IT.

Starter. This

IT.

Starter does not have 24V DC

IT.

IT.

Starter must be connected to the Starter Terminal Adapter.

IT.

contactor and starter user manual.

IT.

Starter must be connected to the

IT.

Starter

To Starter

–

SNAP

Te rminal

Adapter

To DS NAP

+

(Push to Open)

24V DC

Optional

J1

E-Stop

Figure 3: Starter Terminal Adapter Connection

CAUTION

Only apply 24V DC to the D77B-DSNAP. Use of any other voltage

may result in personal injury, property damage and damage to the

D77B-DSNAP.

6

Pub. No. MN05004001E

September 2002

Installation

Mount the D77B-DSNAP to the Starter

The

IT.

D77B-DSNAP is designed to be installed in the auxiliary contact locations of the

family of starters. On all starters, one or more auxiliaries can be used along with the D77BDSNAP. The following table lists starters and indicates the number of available auxiliary

locations for each.

Table 7: Starter Size/Available Auxiliary Locations on Mounted D77B-DSNAP

Starter Frame Size (mm)

45 1 single Auxiliary

54 1 single or 1 dual Auxiliary

76 2 single or 2 dual Auxiliary

105 2 single or 2 dual Auxiliary

140 2 single or 2 dual Auxiliary

Intelligent Technologies (

Number of Available Auxiliary Locations with

Center Mounted D77B-DSNAP

IT.

) D77B-DSNAP

IT.

Pub. No. MN05004001E

7

Intelligent Technologies (

Use the following steps and illustration in Figure 4 to mount the D77B-DSNAP:

1. Align and insert both the D77B-DSNAP feet into the auxiliary starter contact mounting

slots on the starter, as illustrated in Figure 4.

Recommendation: Use the middle auxiliary contact mounting slot on the starter contact

2. Slide the D77B-DSNAP down until a “click” is heard. This ensures that the D77B-DSNAP

is mounted securely to the starter.

IT.

) D77B-DSNAP

block when mounting the D77B-DSNAP.

2. Slide

1. Align

and

Insert

Feet

September 2002

Figure 4: D77B-DSNAP Alignment and Mounting

Use the following steps and illustration in Figure 5 to remove the D77B-DSNAP:

1. Press the push tab protruding from the D77B-DSNAP front, Figure 1 on Page 5.

2. Slide the D77B-DSNAP up.

3. Pull the D77B-DSNAP away from the starter contact block.

3. Pull

Away

2. Slide

1. Push Tab

Figure 5: D77B-DSNAP Removal

8

Pub. No. MN05004001E

September 2002

Connect the Starter Terminal Adapter to the Starter

Loosen the screws on the removable terminal block of the starter and insert the Starter

Terminal Adapter into the removable terminal block. Tighten the screws on the terminal block

(4.5 in-lb or 0.5 Nm) securing the Starter Terminal Adapter into the removable terminal block.

Install the removable terminal block into the starter.

To Starter

Terminal

Block

Intelligent Technologies (

Starter

Terminal

Adapter

IT.

) D77B-DSNAP

Figure 6: Connecting Starter Terminal Adapter

Insert one end of the Starter Adapter Jumper (Catalog Number D77B-RJJ1) into J1 on the

Starter Terminal Adapter and the other end into or on the D77B-DSNAP.

D77B-DSNAP

D77B-RJJ1

(Jumper)

D77B-TC8

Figure 7: Jumper Installation

Pub. No. MN05004001E

9

Intelligent Technologies (

IT.

) D77B-DSNAP

Connect the D77B-DSNAP to DeviceNet

Connect the DeviceNet cable to the 5-position DeviceNet Connector located at the top of the

D77B-DSNAP.

● The 5-position DeviceNet Connector has screws for positive retention that need to be

loosened to remove the terminal block.

● The D77B-DSNAP will work with thick and thin media.

● The DeviceNet cable is color-coded and matches the colors on the DeviceNet

connector.

● Use only one wire per terminal.

● Tighten the screws to 0.5 Nm (4.5 lb-in).

For further information on DeviceNet wiring practices and power considerations, refer to the

DeviceNet Installation Planning Guide

Table 8: DeviceNet Connection

Connector Legend DeviceNet Wire Signal

V+ Red +24V DC

CH White CAN High

D Shield Shield

CL Blue CAN Low

V- Black Signal Common

September 2002

, Publication Number SA-370.

10

Pub. No. MN05004001E

September 2002

Set the DeviceNet MAC ID and Baud Rate

The MAC ID and baud can only be set using the DIP switches on the front of the D77B-DSNAP.

A software tool (such as CH Studio) can view the settings for the D77B-DSNAP MAC ID and

baud rate, but cannot be used to modify them.

Refer to the following instructions, figure and table when setting the MAC ID and baud rate.

● Moving a DIP switch to the right is ON and moving the switch to the left is OFF. The

MAC ID is in binary with the major units numbered to the right of the switch on the side

label. Adding up the major units set to ON determines the MAC ID of the D77B-DSNAP.

Example: To set the MAC ID to 25, start from the top (or 32) and set the switches to OFF, ON,

ON, OFF, OFF, ON (16+8+1=25).

● The baud rate is set using the configuration switches B0 and B1.

Most significant bit to be at top or left end of switch block.

To set the DeviceNet MAC ID and baud rate, set the DIP switches

to the desired settings.

The following example is set to MAC ID=25 and Baud 125K.

Intelligent Technologies (

IT.

) D77B-DSNAP

OFF ON

Baud

MAC ID

B1

B0

32

16

8

4

2

1

Figure 8: DIP Switch Setting Example

Table 9: Baud Rate Configuration Switches

B1 B0 Baud

OFF OFF 125K

OFF ON 250K

ON OFF 500K

ON ON Not Allowed

Pub. No. MN05004001E

11

Intelligent Technologies (

IT.

) D77B-DSNAP

Operation

This section provides details about the following features and functions of D77B-DSNAP

operation:

● “Out of box” operation

● Quick Start

● Typical application

● Enhanced features

● DeviceNet input/output assemblies

● DeviceNet Status LED

● Functional Description

“Out of Box” Operation

Note: Before applying power to the D77B-DSNAP for the first time, make sure it is properly

mounted on the starter and that all connections are made (DeviceNet, terminal adapter

and auxiliary connector).

September 2002

When the D77B-DSNAP is properly installed, and has a properly set baud and MAC ID, per the

“Installation” section on Page 11, the following tables in the Quick Start section indicate the

information to expect for I/O assemblies on DeviceNet.

Quick Start

This part of the section provides the information necessary to install and operate the D77BDSNAP on a Full Voltage Non-reversing (FVNR)

Starter and an S751 Soft Start motor controller. Detailed information is available in Appendix A

for setup of enhanced parameters and extended Input and Output data (assemblies).

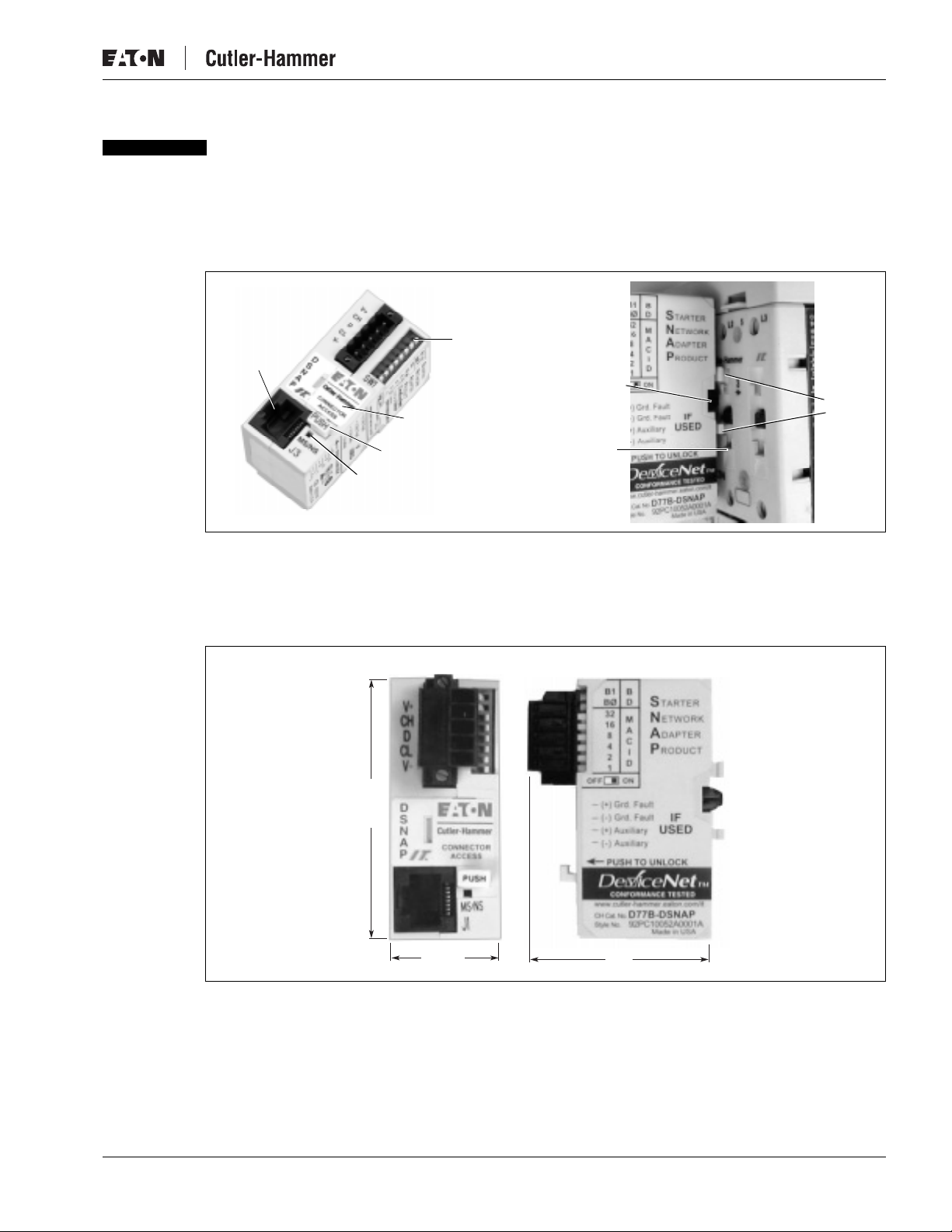

FVNR Motor Controller

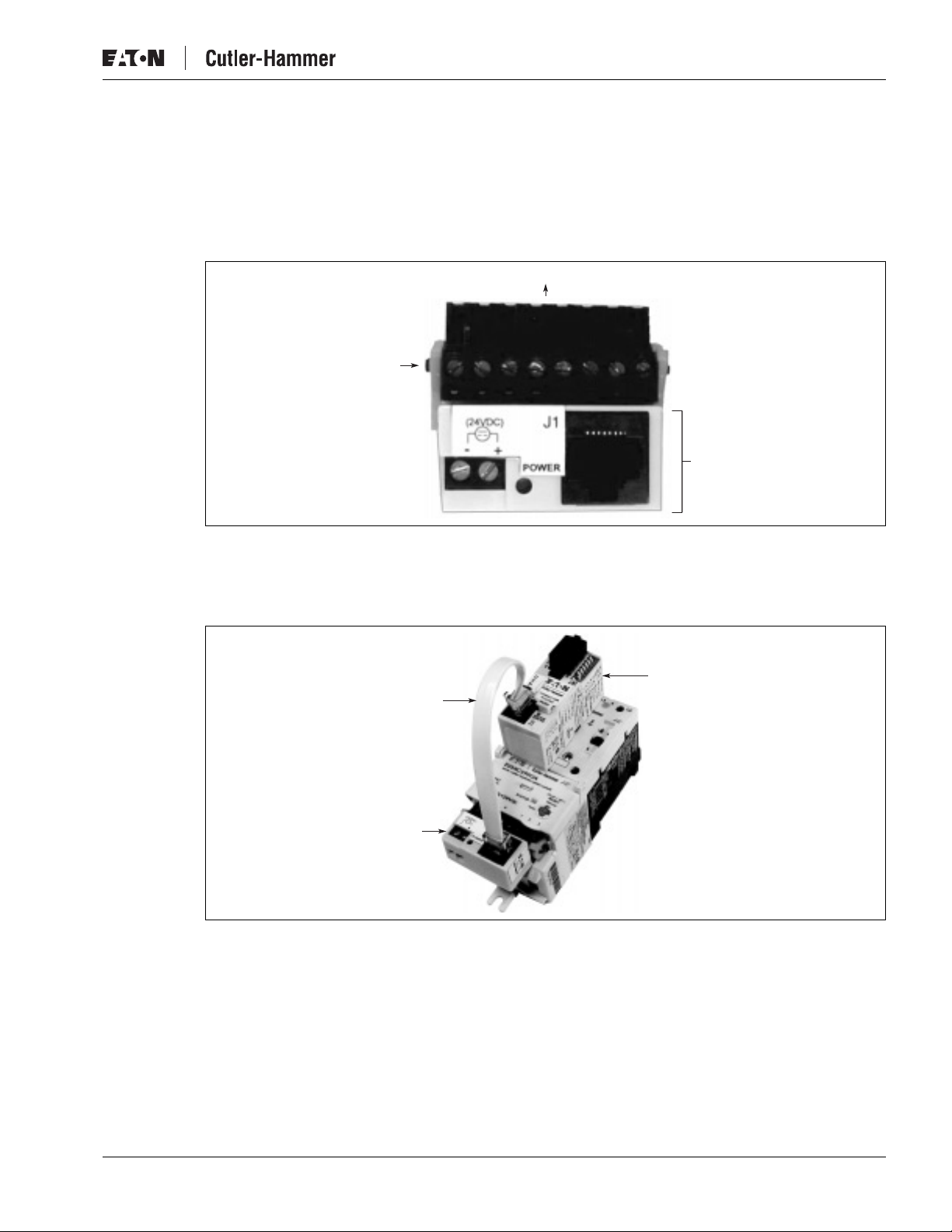

First, follow the instructions on how to mount the D77B-DSNAP as outlined in Mount the

D77B-DNSAP to the Starter on Page 7.

Second, follow the instruction on how to connect the Starter Terminal Adapter to the starter as

outlined in Connect the Starter Terminal Adapter to the Starter on Page 9.

IT.

Starter, Full Voltage Reversing (FVR)

IT.

12

Pub. No. MN05004001E

September 2002

Jumper

Intelligent Technologies (

Terminal

Adapter

IT.

) D77B-DSNAP

Figure 9: D77B-DSNAP-X1 on FVNR

IT.

Starter

Third, follow the instructions on how to set the MAC ID and Baud Rate as outlined in Set the

DeviceNet MAC ID and Baud Rate on Page 11.

Fourth, follow the instructions on how to wire the D77B-DSNAP to DeviceNet as outlined in

Connect the D77B-DSNAP to DeviceNet on Page 10.

The D77B-DSNAP will auto configure to the FVNR

IT.

Starter when the D77B-DSNAP and the

IT.

Starter are first powered (together). After the auto configuration is complete, the D77B-DSNAP

is “married” to that specific size, type and overload range of

an already “married” D77B-DSNAP onto another

IT.

Starter without first performing a reset

IT.

Starter. Any attempt to install

(Appendix A, Page 30) will result in the D77B-DSNAP entering a recoverable fault state

(flashing red MS/NS LED); the D77B-DSNAP will not operate the

IT.

Starter.

Default Input Assembly

The out of box input assembly (data mapped to the input registers within the system

controller) is the following:

Table 10: Input Assembly for Non-reversing Starter (E101, N101)

Assembly 105 (0x69) – Input (Producing) – D77B-DSNAP Abbreviated Motor Starter 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At

Reference

1 % Thermal Capacity

2 % FLA

3 Fault Code (Low byte only)

Reserved CtrlFrom

Net

Ready Reserved Running1 Warning Fault

Pub. No. MN05004001E

13

Intelligent Technologies (

Default Output Assembly

The out of box output assembly (data mapped to the output registers within the system

controller) is the following:

Table 11: Output Assembly for Non-reversing Starter (E101, N101) and S751 Soft Start

Instance 3: Basic Motor Starter

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Reserved Reserved Reserved Reserved FaultReset Reserved Run1

FVR Motor Controller

First, follow the instructions on how to mount the D77B-DSNAP as outlined in Mount the

D77B-DNSAP to the Starter on Page 7.

IT.

) D77B-DSNAP

September 2002

Note: The 45 mm and 54 mm frame

IT.

Starters will require the user to depress the cross over

cover locking tab while installing the D77B-DNSAP. Simply depress the tab while

inserting the D77B-DSNAP feet into the slot on the

IT.

Starter to ease installation.

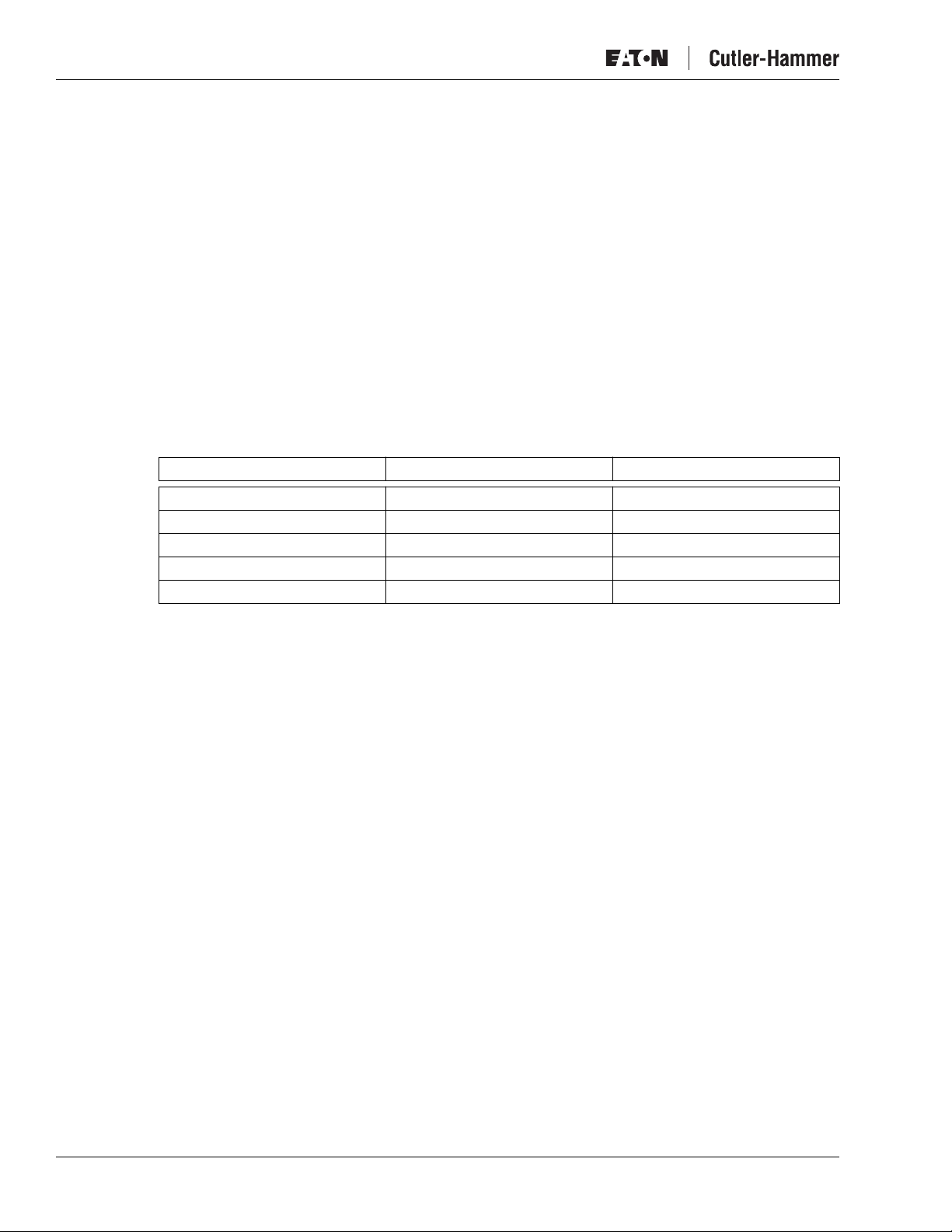

Second, follow the instruction on how to connect the Starter Terminal Adapter to the starter as

outlined in Connect the Starter Terminal Adapter to the Starter on Page 9.

Third, the secondary contactor sensor (D77B-A2) needs to be installed. Install the secondary

contactor sensor on the second contactor just as you would install an auxiliary (align the feet

and slide towards the bottom). Using a screwdriver, pry up the connector access breakout

(Figure 1, Page 5) and remove the breakout. Insert the green connector that is connected via a

wire to the second contactor sensor into the breakout making sure to take notice of the

alignment tabs for proper orientation.

Cover Locking Tab

D77B-A2 Second

Contactor Sensor

Connector Breakout

Alignment Tab

14

Figure 10: D77B-DSNAP-X2 on FVR

Jumper

IT.

Starter

Terminal Adapter

Pub. No. MN05004001E

September 2002

Intelligent Technologies (

IT.

) D77B-DSNAP

Fourth, follow the instructions on how to set the MAC ID and Baud Rate as outlined in Set the

DeviceNet MAC ID and Baud Rate on Page 11.

Fifth, follow the instructions on how to wire the D77B-DSNAP to DeviceNet as outlined in

Connect the D77B-DSNAP to DeviceNet on Page 10.

The D77B-DSNAP will auto configure to the FVR

IT.

Starter when the D77B-DSNAP and the

IT.

Starter are first powered (together). It is important that the second contactor sensor is installed

on the second contactor and that the green connector is installed into the breakout. If this is not

performed, the auto configuration will set the D77B-DSNAP up for an FRNR

IT.

Starter. After the

auto configuration is complete, the D77B-DSNAP is “married” to that specific size, type and

overload range of

another

IT.

Starter without first performing a reset (Appendix A, Page 30) will result in the

IT.

Starter. Any attempt to install an already “married” D77B-DSNAP onto

D77B-DSNAP entering a recoverable fault state (flashing red MS/NS LED); the D77B-DSNAP

IT.

will not operate the

Starter.

Default Input Assembly

The out of box input assembly (data mapped to the input registers within the system

controller) is the following:

Table 12: Input Assembly for Reversing Starter (E501, N501)

Assembly 106 (0x6A) – Input (Producing) – D77B-DSNAP Abbreviated Motor Starter 2

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At

Reference

1 % Thermal Capacity

2 % FLA

3 Fault Code (Low byte only)

Reserved CtrlFrom

Net

Ready Running2 Running1 Warning Fault

Default Output Assembly

The out of box output assembly (data mapped to the output registers within the system

controller) is the following:

Table 13: Output Assembly for Reversing Starter (E501, N501)

Instance 5: Extended Motor Starter

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Reserved Reserved Reserved Reserved FaultReset Run2 Run1

S751 Motor Controller

First, follow the instructions on how to mount the D77B-DSNAP as outlined in Mount the

D77B-DNSAP to the Starter on Page 7 (mounts in the same position as an FVNR starter).

Second, follow the instruction on how to connect the Starter Terminal Adapter to the starter as

outlined in Connect the Starter Terminal Adapter to the Starter on Page 9.

Pub. No. MN05004001E

15

Intelligent Technologies (

IT.

) D77B-DSNAP

Jumper

Terminal

Adapter

September 2002

Figure 11: D77B-DSNAP-X1 on S751

IT.

Soft Starter

Third, follow the instructions on how to set the MAC ID and Baud Rate as outlined in Set the

DeviceNet MAC ID and Baud Rate on Page 11.

Fourth, follow the instructions on how to wire the D77B-DSNAP to DeviceNet as outlined in

Connect the D77B-DSNAP to DeviceNet on Page 10.

The D77B-DSNAP will auto configure to the S751 Starter when the D77B-DSNAP and the

IT.

Starter are first powered (together). After the auto configuration is complete, the D77B-DSNAP

is “married” to that specific size, and overload range of S751. Any attempt to install an already

“married” D77B-DSNAP onto another S751 without first performing a reset (Appendix, Page

30) will result in the D77B-DSNAP entering a recoverable fault state (flashing red MS/NS LED);

the D77B-DSNAP will not operate the

IT.

Starter.

Default Input Assembly

The out of box input assembly (data mapped to the input registers within the system

controller) is the following:

Table 14: Input Assembly for S751 Soft Start

Assembly 105 (0x69) – Input (Producing) – D77B-DSNAP Abbreviated Motor Starter 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At

Reference

1 % Thermal Capacity

2 % FLA

3 Fault Code (Low byte only)

Reserved CtrlFrom

Net

Ready Reserved Running1 Warning Fault

16

Pub. No. MN05004001E

September 2002

Default Output Assembly

The out of box output assembly (data mapped to the output registers within the system

controller) is the following:

Table 15: Output Assembly for S751 Soft Start

Instance 5: Extended Motor Starter

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Reserved Reserved Reserved Reserved FaultReset Run2 Run1

Safe State Behavior

The safe state behavior of the D77B-DSNAP is factory set to Fault and Stop. Refer to Page 35,

Table 33 Control Supervisor Object (0x29) Instance 0x01 (16 Dec.) for more information. Safe

State is defined as the state in which the D77B-DSNAP will place the motor controller when a

communication loss is detected. The D77B-DSNAP will be in a safe state when the unit is

powered but does not have a valid I/O connection established.

WARNING

Intelligent Technologies (

IT.

) D77B-DSNAP

If the Safe State value is set to Run1 or Run2, any time the D77BDSNAP is powered and does not have a valid I/O connection, the

motor controller will be commanded to the Safe State value. This

includes first powering up the DeviceNet system (D77B-DSNAP)

and not having the controller on-line.

Input and Output Assemblies

An I/O assembly is an ordered collection of data that the system controller exchanges with

the D77B-DSNAP for monitoring and control. The input assembly is the data that is sent from

the D77B-DSNAP to the system controller for monitoring of the D77B-DSNAP. The output

assembly is the data that is sent from the system controller to the D77B-DSNAP for control of

the D77B-DSNAP.

The D77B-DSNAP offers a variety of input and output assemblies, as indicated in the following

table. The tables in this part of the section provide data definitions and details on these

assemblies.

Table 16: Allowable DeviceNet I/O Assemblies

Motor Controller

Non-reversing (E101, N101) 52, 53, 102, 105*, 108, 114 3*

Reversing (E501, N501) 52, 53, 54, 102, 103, 105, 106*, 108, 109, 114 5*

Soft Start (S751) 52, 53, 60, 102, 105*, 108, 114 3*

* Indicates the default

Allowable Input

Assemblies

Allowable Output

Assemblies

Pub. No. MN05004001E

Use a DeviceNet configuration tool to select the assemblies of the D77B-DSNAP. The CH

Studio configuration tool provides the means to configure the assemblies quickly and easily,

as described in the “Configuration” section of this manual. When using a generic DeviceNet

tool, use the tables within this section to set up the assemblies. An EDS is available on Eaton’s

Cutler-Hammer Web site (www.cutler-hammer.eaton.com/it).

Refer to Appendix A on Page 39 for all input and output assembly information.

17

Intelligent Technologies (

IT.

) D77B-DSNAP

Input Assembly Data Definition

Use the following tables when setting up the D77B-DSNAP input assemblies.

Table 17: Input Assembly Data Definitions

Data Description

September 2002

Fault/Trip The motor controller is faulted or tripped

Warning The motor controller has a warning of an impending trip

Running 1 Primary contactor is being commanded to run

Running 2 Secondary contactor is being commanded to run

Ready The motor controller is configured and communicating with starter

CtrlFrom Net The motor controller is controlled from DeviceNet

At Reference This states that the motor controller is in the state that it is commanded to be

% Thermal Capacity % thermal capacity of the motor from 0 to 100%

Average Current Average RMS current of the motor

% FLA The ratio of the running current divided by the FLA setting on the overload

Fault Codes and

Warning Codes

Note: A “Faulted” M.C. may still respond to a Run1 or Run2 command

in, or that the S751 is in bypass. For FVR applications, a D77B-AC2 is required

for this bit to be active while in reverse.

Code for the fault of the motor controller.

Valid fault and warning codes are:

0 = No Fault

10 = Test

20 = Current Trip

21 = Thermal Overload

22 = Phase Loss

26 = Phase Imbalance

27 = Ground Fault

41 = Control Undervoltage

62 = Memory Fault

63 = Hardware Link Fault (Not Communicating with Starter)

64 = No Device Power

71 = Fail to Close Primary Contactor

72 = Fail to Open Primary Contactor

101 = Invalid Attached Device Version

102 = SCR Over Temperature

103 = Watchdog

104 = SNAP Protocol Failure to Connect

105 = SNAP Protocol Fault

106 = Temperature Sensor Fault

171 = Fail to Close Second Contactor

172 = Fail to Open Second Contactor

173 = Invalid Action Attempted

Output Assembly Data Definition

Use the following table when setting up the D77B-DSNAP output assemblies.

Table 18: Output Assembly Data Definitions

Data Description

Run 1 Energize the primary contactor/Soft Starter

Run 2 Energize the secondary contactor

Fault Reset Reset the fault

18

Pub. No. MN05004001E

September 2002

Typical Application

The following figure illustrates a typical D77B-DSNAP application, where a single D77BDSNAP is connected to a single motor controller and where the motor controllers are

distributed throughout the DeviceNet subnet. The subnet is then being controlled by a PC or

PLC, which scans the D77B-DSNAP for control and monitoring information.

DeviceNet

System

Controller

Intelligent Technologies (

IT.

) D77B-DSNAP

Features

Figure 12: Typical D77B-DSNAP Application

Note: Such an application typically has more devices on DeviceNet than are shown in this

illustration, such as drives, I/O and user interface units.

Table 19: Standard Protective Features

Trip Definition

Phase Current

Unbalance/Phase

Loss

Thermal

Overload

A phase current unbalance trip will occur if one or two of the line currents are 40 –

60% or less of the remaining line(s) for longer than 10 seconds.

A phase loss trip will occur with a load current of at least 75% of the minimum FLA

if one of the two input line voltages is lost, with the line current going to zero for

longer than 10 seconds.

While the motor is running and depending on the FLA and trip class settings, when

the FLA is exceeded for a period of time (depending on the trip class setting), a

thermal overload trip will occur. For more information on this feature, see the

Contactor and Starter User Manual

(Publication No. 49400).

Note: The threshold values for Thermal Overload and Phase Current Unbalance can not be

modified.

Pub. No. MN05004001E

19

Intelligent Technologies (

Table 20: Enhanced Features

Fault Definition

IT.

) D77B-DSNAP

September 2002

Ground Fault With the addition of a Ground Fault module, the D77B-DSNAP will trip when the

Underload

Warning

Current

Threshold Warning

SCR Over

Temperature

Contactor

Dropout

DeviceNet Status LED

The combined module status/network status (MS/NS) LED is located on the lower right of the

D77B-DSNAP as pictured in Figure 1: D77B-DSNAP Features.

The following table describes the state of the MS/NS LED.

Table 21: Combined MS/NS LED

State LED

Non-existent OFF

Standby Flashing Green

Operational Not connected: Flashing Green

Operational Connected: Green

Recoverable Fault Flashing Red

Unrecoverable Fault Red

Initializing Red/Green Flash

module detects a ground fault. The level of the trip is adjusted on the Ground Fault

Module. The Ground Fault Module is connected to the D77B-DSNAP through the

Auxiliary opening on the front of the D77B-DSNAP.

While the motor is running, a warning will be activated when the current falls below

a user-settable % of overload’s FLA pot setting.

While the motor is running, a warning will be activated when the current rises

above a user-settable % of overload’s FLA pot setting.

To protect the SCRs from premature damage, a temperature sensor monitors the

SCR temperature. If the monitored temperature is too high, the S751 will trip on

SCR overtemperature.

The contactor dropped out when it was commanded to be energized.

20

Pub. No. MN05004001E

September 2002

Functional Description

Table 22: Truth Table

Old State

FAULTED – – 1 RESET OFF FAULT = 0

OFF 0 0 – NONE OFF NONE

OFF 1 0 – RUN 1 RUNNING 1 RUNNING 1 = 1

OFF 0 1 – RUN 2 RUNNING 2 RUNNING 2 = 1

OFF 1 1 – RUN 1/RUN 2 OFF NONE

RUNNING 1 1 1 – RUN 2 RUNNING 1 NONE

RUNNING 2 1 1 – RUN 1 RUNNING 2 NONE

RUNNING 1 1 0 – FAULT FAULTED RUNNING 1 = 0

RUNNING 2 0 1 – FAULT FAULTED RUNNING 2 = 0

RUNNING 1 1 0 – WARNING RUNNING 1 WARNING = 1

RUNNING 2 0 1 – WARNING RUNNING 2 WARNING = 1

– = state not important RUNNING 1 = Run/FWD/SLOW

1 = state true (energized) RUNNING 2 = REV/FAST

0 = state false (de-energized) FAULT = any fault in Table 17

WARNING = any warning in Table 17

Fieldbus Inputs

Intelligent Technologies (

Event New State ActionRun 1 Run 2 Reset

FAULT = 1

FAULT = 1

IT.

) D77B-DSNAP

Pub. No. MN05004001E

21

Intelligent Technologies (

Configuration

The only configuration that is necessary for normal operation of the D77B-DSNAP is setting

the MAC ID and baud rate, as described in the “Installation” section, Page 11. However, the

D77B-DSNAP offers a variety of enhanced features. When these features are required, use

the CH Studio software suite or a generic DeviceNet tool to perform the configuration.

This section includes the following configuration procedures, and related instructions and

information:

● Using CH Studio

● Using a generic DeviceNet tool

IT.

) D77B-DSNAP

– View D77B-DSNAP General Properties

– Configure Enhanced Features

– Monitor the D77B-DSNAP Status

– Change the I/O Assemblies

September 2002

Using CH Studio

The CH Studio software application is designed for programming and configuring industrial

automation systems. The application simplifies the monitoring and configuration of entire

networks as well as the enhanced features of individual

those networks.

CH Studio takes advantage of the Windows graphical interface to present a suite of tools that

is easy to learn and efficient to use, while meeting the requirements for developing complex

network configurations.

CH Studio performs the following configuration functions for DeviceNet networks:

● Discover network devices

● Display device properties

● Monitor and configure network devices

● Save existing network configurations

● Configure networks off-line

● Configure devices off-line

IT.

communicating devices within

22

Pub. No. MN05004001E

September 2002

General Properties

Intelligent Technologies (

IT.

) D77B-DSNAP

The general properties of the D77B-DSNAP are located in the General Tab of the Property

Pages for the device. The general properties include the firmware version, serial number,

status and much more.

Pub. No. MN05004001E

23

Intelligent Technologies (

IT.

) D77B-DSNAP

Configuring Enhanced Features

The enhanced features of the D77B-DSNAP are configured using the Property Window and

the Property Pages. A complete list of all the features and settable attributes are available in

the Property Window.

September 2002

24

Pub. No. MN05004001E

September 2002

Monitor the D77B-DSNAP

The running values of the D77B-DSNAP (current, thermal capacity and 24V DC control

voltage) can be monitored from the Monitor Tab of the Property Pages. Switching to the

Status Tab, all operational status can be monitored.

Intelligent Technologies (

IT.

) D77B-DSNAP

Pub. No. MN05004001E

25

Intelligent Technologies (

IT.

) D77B-DSNAP

Change the I/O Assemblies of the D77B-DSNAP

All of the I/O assemblies are viewable and settable from the I/O Info Tab of the Property

Pages. The assembly can be changed by simply selecting on the new assembly and pressing

Apply in the lower right of the page. After the new assembly is chosen, a representation of

the data format and structure for the new I/O assembly is created.

September 2002

26

Pub. No. MN05004001E

September 2002

Using a Generic DeviceNet Tool

When configuring the D77B-DSNAP with a DeviceNet management tool other than CH

Studio, refer to the tables in Appendix A: Supported DeviceNet Objects for the definitions of

individual attributes. In addition, an Electronic Data Sheet (EDS) file is available at the Web

site www.cutler-hammer.eaton.com/it for use with tools that can use an EDS file.

Follow these steps to configure a D77B-DSNAP through a generic DeviceNet tool:

1. Search for EDS and download the D77B-DSNAP EDS file from the Cutler-Hammer Web

site:

www.cutler-hammer.eaton.com/it

Note: There are multiple EDS files for the D77B-DSNAP, depending on whether it is used with

an FVR, FVNR or S751 configuration.

2. Open/start the tool.

3. Load the EDS file into the tool.

4. Go on-line and connect to the D77B-DSNAP you wish to configure.

5. Open the EDS for the D77B-DSNAP and edit the attributes. For a full list of attributes and

definitions, see Appendix A: Supported DeviceNet Objects.

Intelligent Technologies (

IT.

) D77B-DSNAP

6. Send the changed attributes to the D77B-DSNAP.

7. Close the tool.

Autoconfiguring the D77B-DSNAP for the Starter

1. Verify the D77B-RJJ1 is installed between J1 on the D77B-DSNAP and J1 on the Starter

Terminal Adapter.

2. Connect the “out-of-box” D77B-DSNAP to a powered DeviceNet network.

3. Apply power to the starter terminal adapter, the MS/NS LED should change from

blinking red to blinking green.

4. If possible verify that the configuration has occurred by reading the device type from the

Identity Object (instance 1 attribute 2)

0x000C — Configuration has not occurred

0x0016 — Starter

0x0017 — S751 Soft Start

Note: It can take as long as 15 seconds for the autoconfiguration to be performed on an S751

and 7 seconds for an

Note: The autoconfiguration is a one-time event. To autoconfigure the D77B-DSNAP for

another motor controller, an out-of-box reset must be performed. Using a DeviceNet

configuration tool, perform a reset to the Identity Object, instance 1 data = 1.

IT.

Starter.

Pub. No. MN05004001E

27

Intelligent Technologies (

IT.

) D77B-DSNAP

Troubleshooting and Maintenance

Renewal Parts

September 2002

The following table lists the renewal parts for the

IT.

D77B-DSNAP.

Table 23: D77B-DSNAP Renewal Parts

Description Catalog Number

SNAP Jumper to terminal adapter D77B-RJJ1

D77B-DSNAP Assembly of terminal adapter, jumper and D77B-DSNAP D77B-DSNAP-X1

D77B-DSNAP Assembly of terminal adapter, jumper, D77B-DSNAP and second

contactor sensor

DeviceNet Start Network Adapter Product D77B-DSNAP

SNAP Terminal Adapter for FVR and FVNR starters and S751 Soft Start D77B-TC8

Second contactor sensor for FVR starters and contactors D77B-A2

Ground Fault Detector for 45 mm and 54 mm frame starters D77B-GF1

Ground Fault Detector for 76 mm and 105 mm starters D77B-GF2

Ground Fault Detector for 140 mm starters D77B-GF3

D77B-DSNAP-X2

28

Pub. No. MN05004001E

September 2002

Troubleshooting

Table 24: Troubleshooting

Observation Possible Cause Corrective Action

Intelligent Technologies (

IT.

) D77B-DSNAP

MS/NS LED flashing red after

power-up

The MS/NS LED starts flashing

green and then turns to a

flashing red after power-up

IT.

Starter will not energize

Second Contactor will not

energize

A “failed to close” fault is

generated when the second

contactor is energized

D77B-DSNAP is not

communicating to the

The D77B-DSNAP was

configured or “married” to

another

The D77B-DSNAP is powered but

the

D77B-DSNAP is not

communicating to the

IT.

IT.

Improper bit set in output

assembly

During the “marriage” the wrong

configuration was detected

Improper bit set in output

assembly

Mechanical interlock is jammed

The primary contactor is already

energized

The wiring between the D77B-A2

and the D77B-DSNAP is faulty.

IT.

Starter

IT.

Starter is not

Starter is not powered Verify that the IT. Starter has 24V

Starter may be tripped Reset the trip.

IT.

Starter

IT.

Starter

Check the D77B-RJJ1 jumper

between the D77B-DSNAP and

the D77B-TC8 terminal adapter.

Also check that the terminal

adapter is properly secured and

plugged into the

Perform a reset (Appendix A

Page 30) to re-marry the

D77B-DSNAP to the

Power the

Check the D77B-RJJ1 jumper

between the D77B-DSNAP and

the D77B-TC8 terminal adapter.

Also check that the terminal

adapter is properly secured and

plugged into the

DC on the + and - of the terminal

block, the Power LED should be

green on the D77B-TC8 terminal

adapter.

Check the output assembly data

position and verify with the

control logic.

Verify that the product code

(Table 27 instance 3) is 0x1102

(4354 dec.). If the product code is

not correct, verify that the second

contact sensor is installed and

wired, that the

powered and perform a Reset

to Out of Box (Appendix A,

Page 30).

Check the output assembly data

position and verify with the

control logic. Verify the correct

output assembly is being used.

Only one contactor can be

energized at a time.

Verify all connections on the

D77B-A2 and the D77B-DSNAP.

Verify that the D77B-A2 is

properly connected to the second

contactor.

IT.

Starter.

IT.

Starter.

IT.

IT

. Starter.

IT.

Starter is

Starter.

Pub. No. MN05004001E

29

Intelligent Technologies (

IT.

) D77B-DSNAP

Appendix A: Supported DeviceNet Objects

DeviceNet Objects

Table 25: Supported Objects

Object Object ID Page

Identity 0x01 Page 31

DeviceNet 0x03 Page 31

DeviceNet Connection 0x05 Page 32

Discrete Input Point 0x08 Page 33

Motor Data 0x28 Page 34

Motor Control Supervisor 0x29 Page 35

Overload 0x2C Page 37

Soft Start 0x2D Page 38

Supported DeviceNet I/O Assemblies Page 39

September 2002

Table 26: DeviceNet Object Common Services

Service Code Service Name

0x0E Get_Attribute_Single

0x10 Set_Attribute_Single

0x17 Nop

0x18 Get_Member

0x4B Allocate_Master/Slave_Connection_Set

0x4C Release_Master/Slave_Connection_Set

0x05 Reset

Reset to Out of Box

Service = Reset (0x05)

Class = Identity (0x01)

Instance = 0x01

Data = 01

30

Pub. No. MN05004001E

September 2002

Intelligent Technologies (

IT.

) D77B-DSNAP

Table 27: Identity Object 0x01

Attribute Access Data Type Name Value

Instance 1

01 Get UINT Vendor Id 68 [0x44] = Cutler-Hammer

02 Get UINT Device Type 12 [0x0C] = Communication Adapter

03 Get UINT Product Code 4353 [0x1101] DSNAP, FVNR or S751

04 Get ARRAY Revision Byte 0 = Major Revision

06 Get UDINT Serial Number Serial Number of D77B-DSNAP

09 Get UINT Configuration

176 Set SHORT

STRING

177 Get USINT Fault Value Same as Atrribute 13 of the Control Supervisor

Instance 2 (Overload)/Instance 3 (S751)

03 Get UINT Product Code XY 11

04 Get ARRAY Revision Byte 0 = Major Revision

06 Get UDINT Serial Number Serial Number of connected device

Consistency Value

User Label or

Tag Name

22 [0x16] = Motor Starter

23 [0x17] = Soft Starter

4354 [0x1102] DSNAP, FVR or two speed

Byte 1 = Minor Revision

CRC on configuration values

A user established ASCII string of 16 characters or

less

(0x29) Object — Instance 1

X (Motor Controller) Y (Frame Size)

3 =

IT.

Starter

6 = S751

Byte 1 = Minor Revision

1 = 27 mm

2 = 45 mm

3 = 54 mm

4 = 76 mm

5 = 105 mm

6 = 140 mm

Pub. No. MN05004001E

Table 28: DeviceNet Object 0x03 — Instance 1

Attribute Access Data Type Name Value

1 Get USINT MAC ID 0 – 63

2 Get USINT Baud Rate 0 = 125K

1 = 250K

2 = 500K

3 Get BOOL BOI

4 Get USINT Bus Off Counter 0 – 255

8 Get USINT MAC ID Switch

9 Get USINT Baud Rate Switch

31

Intelligent Technologies (

Table 29: Connection Object 0x05 — Instance 1 (Explicit Connection)

Attribute Access Data Type Name Value

IT.

) D77B-DSNAP

September 2002

1 Get USINT State 0 = nonexistent

2 Get USINT Instance Type 0 = Explicit

3 Get BYTE Transport Class Trigger 131 [0x83]

4 Get UINT Produced Connection Id 10[MAC ID]011

5 Get UINT Consumed Connection Id 10[MAC ID]100

6 Get BYTE Initial Comm Characteristics 33 [0x21]

7 Get UINT Produced Connection Size 37

8 Get UINT Consumed Connection Size 37

9 Get/Set UINT Expected Packet Rate Timer Resolution of 10 mSec.

12 Get USINT Watchdog Timeout Action 1 = Auto Delete

1 = configured

3 = established

4 = timed out

Table 30: Connection Object 0x05 — Instance 2 (I/O Message)

Attribute Access Data Type Name Value

1 Get USINT State 0 = nonexistent

2 Get USINT Instance Type 1 = I/O Message

3 Get BYTE Transport Class Trigger 131 [0x83]

4 Get UINT Produced Connection Id 01111[MAC ID]

5 Get UINT Consumed Connection Id 10[MAC ID]101

6 Get BYTE Initial Comm Characteristics 1 [0x01]

7 Get UINT Produced Connection Size 1 – 7

8 Get UINT Consumed Connection Size 1

9 Get UINT Expected Packet Rate Timer Resolution of 10 mSec.

12 Get USINT Watchdog Timeout Action 1 = Auto Delete

14 Get/Set EPATH Produced Connection Path 20 04 24 XX 30 03

16 Get/Set EPATH Consumed Connection Path 20 04 24 XX 30 03

100 Get/Set USINT Production ID (Input Assembly) See DeviceNet I/O Assemblies,

101 Get/Set USINT Consumption ID (Output Assembly) See DeviceNet I/O Assemblies,

1 = configured

3 = established

4 = timed out

XX = Instance

XX = Instance

Page 39

Page 39

32

Pub. No. MN05004001E

September 2002

Intelligent Technologies (

IT.

) D77B-DSNAP

Table 31: Discrete Input Object 0x08

Attribute Access Data Type Name Value

Instance 1 (Primary Contact Block Detect)

3 Get BOOL Data 0 = Off

Instance 2 (Secondary Contact Block Detect)

3 Get BOOL Data 0 = Off

Instance 3 (Ground Fault Detect)

3 Get BOOL Data 0 = Off

1 = On

1 = On

1 = On

Pub. No. MN05004001E

33

Intelligent Technologies (

Table 32: Motor Data Object 0x28 — Instance 1

Attr ID

IT.

) D77B-DSNAP

Access

Rule

September 2002

DeviceNet

Data Type Name Value

03 Set USINT MotorType 0 = Non-standard motor

04 Set SHORT

STRING

05 Set SHORT

STRING

06 Set UINT RatedCurrent Rated Stator Current

07 Set UINT RatedVoltage Rated Base Voltage

08 Set UDINT RatedPower Rated Power at Rated Freq

09 Set UINT RatedFreq Rated Electrical Frequency

10 Set UINT RatedTemp Rated Winding Temperature

11 Set UINT MaxSpeed Maximum allowed motor speed

12 Set UINT PoleCount Number of poles in the motor

13 Set UDINT TorqConstant Motor torque constant

14 Set UDINT Inertia Rotor Inertia

15 Set UINT BaseSpeed Nominal speed at rated frequency

19 Set USINT ServiceFactor Units: [%]

CatNumber Manufacturer's Motor Catalog Number

Manufacturer Manufacturer's Name 32 characters max

3 = PM Synchronous Motor

6 = Wound Rotor Induction Motor

7 = Squirrel Cage Induction Motor

(Nameplate number) 32 characters max

Units: [100mA]

Units: [V]

Units: [W]

Units: [Hz]

Units: [degrees C]

Units: [RPM]

Units: [0.001 x Nm/A]

Units: [10

from nameplate

Units: [RPM]

Range: 0 .. 255

-6

x kg.m2]

34

Note: Attribute ID’s 06 – 19 only available when attribute ID 03 is 3, 6 or 7.

Pub. No. MN05004001E

September 2002

Intelligent Technologies (

Table 33: Control Supervisor Object 0x29 — Instance 1

Attribute Access Data Type Name Value

3 Set BOOL Run 1 0 = False

4 Set BOOL Run 2 0 = False

5 Set BOOL Net Control 0 = Local Control

1 = Network Control

7 Get BOOL Running 1 0 = Other State

1 = Enabled and Run 1

8 Get BOOL Running 2 0 = Other State

1 = Enabled and Run 2

9 Get BOOL Ready 0 = Other State

1 = Ready or Enabled or Stopping

10 Get BOOL Faulted 0 = No Faults

1 = Fault Occurred

11 Get BOOL Warning 0 = No Warning

1 = Warning

12 Set BOOL Fault Reset 0 > 1 = Fault Reset

0 = No Action

13 Get UINT Fault Code 0 = No Fault

10 = Test

20 = Current Trip

21 = Thermal Overload

22 = Phase Loss

26 = Phase Imbalance

27 = Ground Fault

41 = Control Undervoltage

62 = Memory Fault

63 = Hardware Link Fault

64 = No Device Power

71 = Fail to Close Primary Contactor

72 = Fail to Open Primary Contactor

101 = Invalid Attached Device Version

102 = SCR Overt Temperature

103 = Watchdog

104 = SNAP Protocol Failure to Connect

105 = SNAP Protocol fault

106 = Temperature Sensor Fault

171 = Fail to Close Second Contactor

172 = Fail to Open Second Contactor

173 = Invalid Action Attempted

14 Get UINT Warning Code 0 = No Warning

29 = Underload

41 = Control Undervoltage

71 = Fail to Close Primary Contactor

72 = Fail to Open Primary Contactor

104 = SNAP Protocol Failure to Connect

171 = Fail to Close Second Contactor

172 = Fail to Open Second Contactor

IT.

) D77B-DSNAP

Pub. No. MN05004001E

35

Intelligent Technologies (

Table 32: Control Supervisor Object 0x29 — Instance 1 (Continued)

Attribute Access Data Type Name Value

IT.

) D77B-DSNAP

September 2002

16 Set USINT DeviceNet Fault

Mode

(See Warning)

22 Get/Set UDINT Cycle Count Number of times the motor has been started

101 Get DWORD Local Signals Byte0 (Consuming Assemble Data)

110 Get/Set USINT Number of

Contactors

111 Get/Set BOOL Communication

Valid

114 Get/Set BOOL Net Select 0 = Control is Local

115 Get/Set BOOL CB Sensor 0 = Disable Crossbar Sensor detect

0 = Fault + Stop

1 = Hold Last State

3 = Run 1

4 = Run 2

Bit 0 = Run1

Bit 1 = Run2

Bit 3 = Fault Reset

Bit 5 = Control From Net

Byte1 (N/A)

Byte2 (Motor Control Status)

Bit 0 = Run1

Bit 1 = Run2

Bit 2 = Reset

Bit 3 = Permissive

Bit 4 = Ready

Bit 5 = Net Control

Bit 6 = Disconnect Handle

Bit 7 = At Reference

Byte3 (N/A)

1 = 1 Contactor (FVNR)

2 = 2 Contactor (FVR)

0 = Starter Communication Fault

1 = Valid Starter Communication

1 = Control is From Network

1 = Enable Crossbar Sensor detect

36

WARNING

If the DeviceNet Fault Mode value is set to Run1 or Run2, any time

the D77B-DSNAP is powered and does not have a valid I/O

connection, the motor controller will be commanded to the

DeviceNet Fault Mode value. This includes first powering up the

DeviceNet system (D77B-DSNAP) and not having the controller

on-line.

Pub. No. MN05004001E

September 2002

Intelligent Technologies (

Table 34: Overload Object 0x2C — Instance 1

Attribute Access Data Type Name Value

IT.

) D77B-DSNAP

3 Get INT Trip Class Setting Setting of the overloads FLA attribute

4 Get USINT Trip Class 0 – 200

5 Get INT Average of 3 Phase Current Average Current of 3 Phase (RMS)

7 Get USINT %Thermal Capacity 0 – 100%

12 Get SINT Current Scale (CS) Current Scaling Factor

103 Get/Set BOOL Ground Fault Enable 0 = Disabled (default)

105 Get/Set USINT Ground Fault Time Length of time the ground fault must be

106 Get/Set USINT Ground Fault Delay Length of time to delay tripping on a

107 Get BOOL Ground Fault 0 = No ground fault

108 Get BOOL Current Threshold Enable 0 = Disabled (default)

109 Get/Set USINT Current Threshold Percent % of FLA setting to set current threshold

110 Get BOOL Current Threshold Warning 0 = No Warning (default)

111 Get/Set BOOL Underload Enable 0 = Disabled (default)

112 Get/Set USINT Underload Percent % of FLA setting to set underload

113 Get BOOL Underload Warning 0 = No Warning (default)

114 Get UINT Starter 24V DC Value Value of 24V DC connected to the starter

115 Get BYTE Overload Status Bits 0 = Current Trip

116 Get BOOL Impending Trip Warning 0 = current < 115% FLA

117 Get USINT %FLA % Running Current divided by the FLA

121 Get UDINT Max FLA Amps 256

= (INT)*(0.1 Amps)/2^CS

= (INT)*(0.1 Amps)/2^CS

Scaled Current = (INT)*(0.1 Amps)/2^CS

1 = Enabled

true for a trip

0 – 255 seconds

default = 1 second

ground fault from motor controller start

0 – 255 seconds

default = seconds

1 = Ground fault

1 = Enabled

0 – 255%

1 = Warning

1 = Enabled

0 – 255%

1 = Warning

235 = 23.5V DC

1 = Phase Loss

2 = Phase Imbalance

3 = Receiving Run1

4 = Receiving Run2

5 = Ground Fault

6 = Test

7 = Thermal Overload

1 = current > 115% FLA

setting on the overload (0 – 255%)

Pub. No. MN05004001E

37

Intelligent Technologies (

Table 35: Soft Start Object 0x2D — Instance 1

Attribute Access Data Type Name Value

IT.

) D77B-DSNAP

September 2002

3 Get BOOL AtReference Starting/stopping output voltage

4 Get USINT StartMode 1 = Voltage Ramp

5 Get USINT StopMode 1 = Ramp Down

7 Get UINT RampTime1 Tenths of Seconds

16 Get UINT DecelTime Tenths of Seconds

100 Get USINT Start Torque Starting Torque Pot reading

101 Get WORD Status Bits Status bits

reference status

0 = Not At Reference

1 = Output At Voltage Reference

No Current Limit

The DSNAP will always return the value 1

when accessing this attribute.

The DSNAP will always return the value 1

when accessing this attruibute.

38

Pub. No. MN05004001E

September 2002

DeviceNet I/O Assemblies

The changing of the I/O assemblies from the default to other assemblies using CHStudio is

performed in a graphical user environment. When using a generic DeviceNet Management

tool that accepts EDS files, the EDS file will aid in simply choosing the I/O assemblies that are

allowed and available.

Table 36: Allowable DeviceNet I/O Assemblies

Motor Controller

Non-reversing (E101, N010) 52, 53, 102, 105*, 108, 114 3*

Reversing (E501, N501) 52, 53, 54, 102, 103, 105, 106*, 108, 109, 114 5*

S751 Soft Start 52, 53, 60, 102, 105*, 108, 114 3*

*Indicates the default

For users that have a generic DeviceNet Management tool that does not accept EDS files,

follow the simple example below to aid in changing I/O assemblies using explicit messaging.

To read what the current Input assembly is, perform an explicit message of the following:

Table 37: Reading Current Input Assembly

Service Class (HEX) Instance (HEX) Attribute (HEX) Data (HEX)

Allowable Input

Assemblies (Dec.)

Intelligent Technologies (

Allowable Output

Assemblies (Dec.)

IT.

) D77B-DSNAP

Get Single 0x05

(Connection)

0x02

(Polled I/O)

0x64 (Production ID)

(100 Dec.)

0x34

(34 = Basic Motor Starter)

To set the Input assembly, perform an explicit message of the following:

Table 38: Setting Input Assembly

Service Class (HEX) Instance (HEX) Attribute (HEX) Data (HEX)

Set Single 0x05

(Connection)

0x02

(Polled I/O)

0x64 (Production ID) (100

Dec.)

0xXX

(XX = the input assembly

in HEX.

Example: 0x69 is D77BDSNAP Abbreviated Motor

Starter 1)

To read what the current Output assembly is, perform an explicit message of the following:

Table 39: Reading Current Output Assembly

Service Class (HEX) Instance (HEX) Attribute (HEX) Data (HEX)

Get Single 0x05

(Connection)

0x02

(Polled I/O)

0x65

(Consumption ID) (101 Dec.)

0x03

(3 = Basic Motor Starter)

To set the Output assembly, perform an explicit message of the following:

Table 40: Setting Output Assembly

Service Class (HEX) Instance (HEX) Attribute (HEX) Data (HEX)

Pub. No. MN05004001E

Set Single 0x05

(Connection)

0x02

(Polled I/O)

0x65

(Consumption ID) (101 Dec.)

0xXX

(XX = the output assembly

in HEX.

Example: 0x05 (5 Dec.) is

Extended Motor Starter )

39

Intelligent Technologies (

IT.

DeviceNet Input Assemblies

Table 41: Assembly 52 (0x34) — Basic Motor Starter

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved Reserved Reserved Reserved Running1 Reserved Fault

Table 42: Assembly 53 (0x35) — Extended Motor Starter 1

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

) D77B-DSNAP

September 2002

Reserved Reserved CtrlFrom

Net

Ready Reserved Running1 Warning Fault

Table 43: Assembly 54 (0x36) — Extended Motor Starter 2

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved CtrlFrom

Net

Ready Running2 Running1 Warning Fault

Table 44: Assembly 60 (0x3C) — Basic Soft Start Input

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

At

Reference

Reserved Reserved Reserved Reserved Running1 Reserved Fault

Table 45: Assembly 102 (0x66) — D77B-DSNAP Motor Starter

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At Reference Reserved CtrlFrom Net Ready Running2 Running1 Warn Fault

1 % Thermal Capacity

2 Average Current (Low byte)

3 Average Current (High byte)

4 % FLA

40

Table 46: Assembly 103 (0x67) — D77B-DSNAP Extended Motor Starter

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At Reference Reserved CtrlFrom Net Ready Running2 Running1 Warn Fault

1 % Thermal Capacity

2 Average Current (Low byte)

3 Average Current (High byte)

4 % FLA

Pub. No. MN05004001E

September 2002

Intelligent Technologies (

IT.

) D77B-DSNAP

Table 47: Assembly 105 (0x69) — D77B-DSNAP Abbreviated Motor Starter 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At Reference Reserved CtrlFrom Net Ready Reserved Running1 Warn Fault

1 % Thermal Capacity

2 % FLA

3 Fault Code (Low byte only)

Table 48: Assembly 106 (0x6A) — D77B-DSNAP Abbreviated Motor Starter 2

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At Reference Reserved CtrlFrom

Net

1 % Thermal Capacity

2 % FLA

3 Last Fault Code (Low byte only)

Ready Running2 Running1 Warn Fault

Table 49: Assembly 108 (0x6C) — D77B-DSNAP Motor Starter with Fault Code

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At Reference Reserved CtrlFrom

Net

1 % Thermal Capacity

2 Average Current (Low byte)

3 Average Current (High byte)

4 Last Fault Code (Low byte)

5 Last Fault Code (High byte)

Ready Reserved Running1 Warn Fault

Table 50: Assembly 109 (0x6D) — D77B-DSNAP Expanded Motor Starter with Fault Code

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At Reference Reserved CtrlFrom

Net

1 % Thermal Capacity

2 Average Current (Low byte)

3 Average Current (High byte)

4 Last Fault Code (Low byte)

5 Last Fault Code (High byte)

Ready Running2 Running1 Warn Fault

Pub. No. MN05004001E

Table 51: Assembly 114 (0x72) — D77B-DSNAP Complete Status Assembly

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 At Reference Reserved Ctrl From

Net

Ready Running2 Running1 Warning Fault

41

Intelligent Technologies (

Table 52: Input Definitions

Data Description

IT.

) D77B-DSNAP

September 2002

Fault/Trip The motor controller is faulted or tripped

Warning The motor controller has a warning of an impending trip

Running 1 Primary contactor is being commanded to run

Running 2 Secondary contactor is being commanded to run

Ready The motor controller is configured and communicating with starter

CtrlFrom Net The motor controller is controlled from DeviceNet

At Reference This states that the motor controller is in the state that it is commanded to be in,

% Thermal Capacity % thermal capacity of the motor from 0 to 100%

Average Current Average RMS current of the motor

% FLA The ratio of the running current divided by the FLA setting on the overload

Fault Codes and

Warning Codes

Note: A “Faulted” M.C. may still respond to a Run1 or Run2 command

or that the S751 is in bypass. For FVR applications, a D77B-AC2 is required for this

bit to be active while in reverse.

Code for the fault of the motor controller. Valid fault and warning codes are:

0 = No Fault

10 = Test

20 = Current Trip

21 = Thermal Overload

22 = Phase Loss

26 = Phase Imbalance

27 = Ground Fault

41 = Control Undervoltage

62 = Memory Fault

63 = Hardware Link Fault

(Not Communicating

with Starter)

64 = No Device Power

71 = Fail to Close Primary Contactor

72 = Fail to Open Primary Contactor

101 = Invalid Attached Device Version

102 = SCR Over Temperature

103 = Watchdog

104 = SNAP Protocol Failure to Connect

105 = SNAP Protocol Fault

106 = Temperature Sensor Fault

171 = Fail to Close Second Contactor

172 = Fail to Open Second Contactor

173 = Invalid Action Attempted

DeviceNet Output Assemblies

Table 53: Assembly 3 (0x03) — Basic Motor Starter