Eaton ATC-900 Instruction Booklet

O & M Manual for 40-1200A (480/600 Vac)

ATC-900 3-Position, Open/Closed

Transition Contactor Based Transfer Switch

Instruction Booklet

Description Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving, Handling, and Storage . . . . . . . . . . . .

Equipment Description . . . . . . . . . . . . . . . . . . . .

Installation and Wiring . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing and Problem Solving . . . . . . . . . . . . . . . .

Adjustments . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .

Renewal Parts Guide . . . .

ATC-900 Controlled ATS Quick Start Instructions . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .23

. . . . . . . . . . . . . . . . . . . . . . . .25

. . . . . . . 2

. . . . . . . 6

. . . . . . . 7

. . . . . . .14

. . . . . . .20

. . . . . . .21

. . . . . . .24

26

IB140036EN For more information visit: www.eaton.com

Instruction Booklet

Cat No: ATC9C3X31200XRU

Style No:

ASSEMBLED IN MEXICO

WITH U.S. COMPONENTS 30 - 43465

ITEM: 001

PIECE: 001

CS#: 123456

J050412234

Volts: 480

Poles: 3

Amps: 1200

Phase: 3

Hertz: 60

Wire: 3/4

GO No: ABC0123

OF: 001

Page 2 Effective: October 2014

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

Open/Closed Transition Contactor Based Transfer Switch

Section 1: Introduction

WARNING

READ AND UNDERSTAND THE INSTRUCTIONS CONTAINED HEREINAFTER BEFORE ATTEMPTING TO UNPACK, ASSEMBLE, OPERATE,

OR MAINTAIN THIS EQUIPMENT.

HAZARDOUS VOLTAGES ARE PRESENT INSIDE TRANSFER SWITCH

ENCLOS

INJURY. FOLLOW PROPER INSTALLATION, OPERATION, AND MAINTENANCE PROCEDURES TO AVOID THESE VOLTAGES.

TR

BOOK IS DE

PLATE RATINGS. OPERATION OUTSIDE OF THESE RATINGS MAY

CAUSE

BODILY INJURY, AND/OR PROPERTY DAMAGE. ALL RESPONSIBLE

PERSONNEL SHOULD LOCATE THE DOOR MOUNTED EQUIPMENT

NAMEPLATE AND BE FAMILIAR WITH THE INFORMATION PROVIDED

ON THE NAMEPLATE. A TYPICAL EQUIPMENT NAMEPLATE IS

SHOWN IN FIGURE 1.

URES THAT CAN CAUSE DEATH OR SEVERE PERSONAL

ANSFER SWITCH EQUIPMENT COVERED BY THIS INSTRUCTION

SIGNED AND TESTED TO OPERATE WITHIN ITS NAME-

THE EQUIPMENT TO FAIL RESULTING IN DEATH, SERIOUS

1.1 Preliminary Comments and Safety Precautions

This technical document is intended to cover most aspects associated with the installation, application, operation, and maintenance of the Automatic Transfer Controller (ATC-900) controlled

contactor base

(A). It is provided as a guide for authorized and qualified personnel only. Please refer to the specific WARNING and CAUTION in

Section 1.1.2 before proc

by the purchaser regarding a particular installation, application, or

maintenance activity, please contact an authorized Eaton sales

representative or the installing contractor.

1.1.1 Warranty and Liability Information

No warranties, expressed or implied, including warranties of fitness for a particular purpose of merchantabilit

arising from course of dealing or usage of trade, are made regarding the information, recommendations and de

her

ein. In no event will Eaton be responsible to the purchaser or

user in contract, in tort (including negligence), strict liability or

otherwise for any special, indirect, incidental or consequential

damage or loss whatsoever, including but not limited to damage

or loss of use of equipment, plant or power system, cost of capital, loss of power, additional expenses in the use

power facilities, or claims against the purchaser or user by its

customers resulting from the use of the information and descriptions contained herein.

1.1.2 Safety Precautions

All safety codes, safety standards, and/or regulations must be

strictly observed in the installation, operation, and maintenance

of this device.

d

ATS with ratings from 40 through 1200 amperes

eeding. If further

information is required

y, or warranties

scriptions contained

xisting

of e

Figure 1. Typical Automatic Transfer Switch (ATS) Equipment

Nameplate.

All possible contingencies that may arise du

ring installation, oper-

ation, or maintenance, and all details and variations of this equip-

do no purport to be covered by these instructions. If further

ment

information is desired by the purchaser re

garding a particular

installation, operation, or maintenance of particular equipment,

please contact an authorized Eaton Sales Representative or the

installing contractor.

For more information visit: www.eaton.com IB140036EN

WARNING

THE WARNINGS AND CAUTIONS INCLUDED AS PART OF THE PROCEDURAL STEPS IN THIS DOCUMENT ARE FOR PERSONAL SAFETY

AND PROTECTI

OF A TYPICAL WARNING LABEL HEADING IS SHOWN ABOVE TO

FAMILIARIZE PERSONNEL WITH THE STYLE OF PRESENTATION.

THIS WILL HELP TO INSURE THAT PERSONNEL ARE ALERT TO

WARNINGS, WHICH APPEAR THROUGHOUT THE DOCUMENT. IN

ADDITION, WARNINGS AND CAUTIONS ARE ALL UPPER CASE AND

BOLDFACE.

ON OF EQUIPMENT FROM DAMAGE. AN EXAMPLE

CAUTION

COMPLETELY READ AND UNDERSTAND THE MATERIAL PRESENTED

IN THIS DOCUMENT BEFORE ATTEMPTING INSTALLATION, OPERATION, OR APPLICATION OF THE EQUIPMENT. IN ADDITION, ONLY

QUALIFIED PERSO

WORK ASSOCIATED WITH THIS EQUIPMENT. ANY WIRING

INSTRUCTIONS PRESENTED IN THIS DOCUMENT MUST BE FOLLOWED PRECISELY. FAILURE TO DO SO COULD CAUSE PERMANENT

EQUIPMENT DAMAGE.

NS SHOULD BE PERMITTED TO PERFORM ANY

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

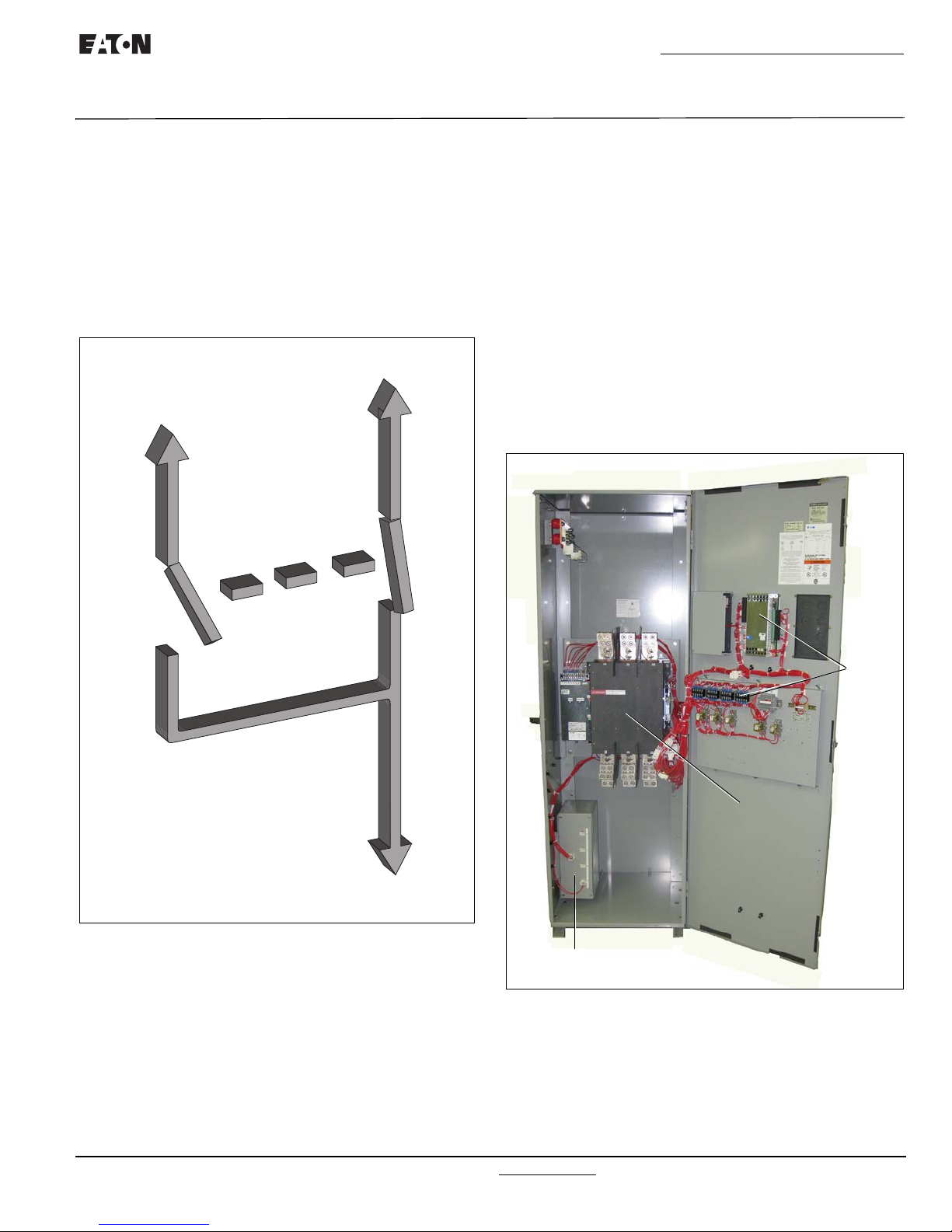

Source 1

Source 2

Load

LOGIC

PANEL

POWER

PANEL

VOLTAGE SELECTION

& TRANSFORMER PANEL

Open/Closed Transition Contactor Based Transfer Switch

Instruction Booklet

Effective: October 2014 Page 3

1.2 General Information

Transfer switches are used to protect critical electrical loads

against loss of power. The load’s Source 1 power source is

backed up by a Source 2 power source. A transfer switch is

connected to both the Source 1 and Source 2 power sources and

supplies the load with power from one of the two sources. In the

event that power is lost from Source 1, the transfer switch transfers the load to the Source 2 power source. This transfer is automatic. Once Source 1 power is restored, the load is

automatically trans

(Figure 2).

f

erred back to the Source 1 power source

and the Source 2 power source fails while the Source 1 power

source is still unavailable, the ATS remains connected to the

Source 2 power source.

ATSs automatically perform the transfer function and include

thre

1. A power contactor to connect and disconnect the load to

2. Solenoids to make the transfer of the main contacts from

3. Intelligence/supervisory circuits

elements:

e basic

nd fr

om either power source.

a

source to source.

condition of the power sources and thus provide the intelli-

to const

gence necessary for the switch and related circuit operation.

antly monitor the

1.2.1 Design Configuration

The Eaton contactor based ATS is a compact design that uses a

power contactor to transfer essential loads from one power

source to another (Figure 3 [1200A]).

Figure 2. Typical Load Transfer Switch Schematic (Contactor

Type).

In ATS equipment, the switch’s intelligence system initiates the

er when the Source 1 power fails, falls below, or rises

transf

above a preset voltage. If the Source 2 power source is a

standby generator, the ATS initiates generator startup and transfers to the Source 2 power source when sufficient generator

age is available. W

volt

automatically transfers back and initiates generator shutdown.

In the event the Source 1 power source fails and the Source 2

power source does not appear, the ATS remains connected to

the Source 1 power source until the Source 2 power source does

appear. Conversely, if connected to the Source 2 power source

hen Source 1 power is restored, the ATS

Figure 3. Typical 1200A Open Transition ATS.

The Eaton contactor based ATS is designed with easy installation

and

simplified maintenance in mind. Three main panels comprise

the contactor based ATS design:

1. Power panel;

2. Voltage selection and transformer panel; and

3. Microprocessor-based logic panel.

IB140036EN For more information visit: www.eaton.com

LOGIC

PANEL

POWER

PANEL

VOLTAGE SELECTION

& TRANSFORMER PANEL

Instruction Booklet

LOGIC

PANEL

POWER

PANEL

VOLTAGE SELECTION

& TRANSFORMER PANEL

AT C 9 C3 X 3 1200 X R U

1to2 3 45 6 7 8 9to

12 13 14 15

to

Page 4 Effective: October 2014

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

Open/Closed Transition Contactor Based Transfer Switch

Figure 4A. Open Transition Contactor Based ATS (1200A).

Each panel is independently mounted with interconnecting wiring

terminated at the connector receptacles on the ATC-900 Controller.

For open transition contactor based transfer switch, enclosure

ied

mounting is simplif

gated (teardrop) mounting holes on top a

by utilizing mounting flanges with elon-

n

d floor mount (wall

supported) flanges with two standard mounting holes on the bottom.

For close transition contactor based transfer switch, enclosure is

standing and

free

cific mounting and modification details.

is seismic approved. Refer to Section 4 for spe-

Table 1. Withstand Ratings.

UL 1008 WITHSTAND AND CLOSE-ON RATINGS (kA)

480 Vac 600 Vac

Switch

Rating

(Amps)

100A 50,000 65,000 50,000 65,000

200A 50,000 65,000 50,000 65,000

260A 50,000 65,000 50,000 65,000

320A 50,000 65,000 50,000 65,000

400A 50,000 65,000 50,000 65,000

600A 50,000 65,000 50,000 65,000

800A 50,000 65,000 50,000 65,000

1000A 50,000 65,000 50,000 65,000

1200A 50,000 65,000 50,000 65,000

Any

Breaker

(Amps)

Specific

Breaker

Amps)

Breaker

Any

Amps)

Specific

Breaker

Amps)

Figure 4B. Closed Transition Contactor Based ATS (1200A)

1.3 ATS Catalog Number Identification

Transfer switch equipment catalog numbers provide a significant

amount of relevant information that pertains to a particular piece

of equipment. The Catalog Number Identification Table (Table 2)

provides the required interpretation information. An example is

offered here to initially simplify the process.

a

Example: C

The catalog number ATC9C3X31200XRU describes an ATS with

a 3 pole, 3 position Power Contactor mounted on a baseplate

within the enclosure. The intelligence represented by the logic

panel is ATC-900 controller. The continuous current rating of

this equipment is 1200A and applicable at 480 Vac, 60 Hz. The

transfer switch equipment is enclosed in a NEMA 3R enclosure

and is listed for UL applications.

talog Number (circled numbers correspond to position

headings in Table 2).

For more information visit: www.eaton.com IB140036EN

Instruction Booklet

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

Open/Closed Transition Contactor Based Transfer Switch

Table 2. Transfer Switch Catalog Number Explanation

POSITIONS 1 TO 2 POSITION 3 POSITION 4 POSITIONS 5 TO 6

BASIC DEVICE SWITCHING DEVICE CONTROL PANEL SWITCHING DEVICE

Automatic Transfer Switch (Open Transition) AT

Automatic Transfer Switch (Closed Transition) CT

POSITION 7 POSITION 8 POSITIONS 9 TO 12 POSITION 13 POSITION 14 POSITION 15

SWITCHING DEVICE

ARRANGEMENT

Fixed Mount X Two (2)40A – 0040 120 Vac/60 Hz A Type 1 S UL/CSA Listing U

150A – 0150 240 Vac/60 Hz W

NUMBER

OF POLES

Three (3)80A – 0080 208 Vac/60 Hz B Type 12 J No Listing X

Contactor C ATC-900 Controller 9 3 Position Power Contactor

AMPERE

RATING

Four (4)100A – 0100 220 Vac/50 Hz G Type 3R R

200A – 0200 380 Vac/50 Hz H

225A – 0225 415 Vac/50 Hz O

260A – 0260 480 Vac/60 Hz X

400A – 0400 600 Vac/60 Hz E

600A – 0600

800A – 0800

1000A – 1000

1200A – 1200

VOLTAGE/

FREQUENCY ENCLOSURE LISTING

Effective: October 2014 Page 5

3 Position w In-Phase to TDN

C3

C5

1.4 Environmental Conditions

1.4.1 Operational Conditions

Normally, an ATS is applied indoors in an electrical equipment

room. In the appropriate enclosure, it can be used for outdoor

applications where the equipment is subject to falling rain, freezing temperatures, and no greater than 90% humidity (non-condensing). The ambient temperature range for operation is

between -20

and 70°C (-4 to 158°F).

1.5 Glossary

With respect to their use within this document and as they relate

to transfer switch and controller operation, the following terminology is defined.

Available

A source is defined as “available” when it is within its unde

age/overvoltage/ underfrequency/overfrequency (if applicable)

setpoint ranges fo

r the nominal voltage and frequency setting.

Connected

Connected is defined as when the input

is shorted by an external

contact or connection.

Failed or Fails

A source is defined as “failed” whe

n it is outside of the applicable voltage and frequency setpoint ranges for the nominal voltage and frequency setting for a time exceeding 0.5 seconds

r the time delay emergency fail (TDEF) time delays expires.

afte

Failsafe

Failsafe is a feature that prevents disconnection from the only

available powe

r source and also forces a transfer or re-transfer

operation to the only available power source.

Source 1

Source 1 is the primary source (normal source, normal power

e, or normal).

sourc

rvolt-

Source 2

Source 2 is the secondary source (emergency source, emergency power source, emergency, standby, or backup source).

Source 1: Failed or Fails

Source 1 is defined as “failed” when it is outside of its undervoltage/overvoltage/ underfrequency/overfrequency (if applicable) setpoint ranges for the nominal voltage and frequency

setting.

Source 2: Failed or Fails

Source 2 is defined as “failed” when it is outside of its undervoltage/overvoltage/ underfrequency/overfrequency (if applicable) setpoint ranges for the nominal voltage and frequency

setting for a time

exceeding 0.5 seconds after the Time Delay

Emergency Fail (TDEF) time delay expires.

Transfer

Transfer is defined as a change of the load connection from the

Source 1

to the Source 2 power source.

Re-Transfer

Re-transfer is defined as a change

of the load connection from

the Source 2 to the Source 1.

Unconnected

Unconnected is defined as when the input is not shorted by an

external c

ontact or connection.

Features

ATC-900 has many features that are available to the user.

The

These features are standard and are available depending on the

type of transfer switch used (i.e. Contactor, Power Case Switch/

Breaker, or Molded Case Switch/Breaker, 2 or 3 position).

Appendix A of the ATC-900 manual has a list of all of the features including any acronyms used along with a brief description. There are many new features in the ATC-900 that are

shown in the ATC-900 manual.

The ATC-900 connections are shown in Figure 16. Some connections, like engine start are wire to a separate terminal block.

IB140036EN For more information visit: www.eaton.com

Instruction Booklet

Page 6 Effective: October 2014

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

Open/Closed Transition Contactor Based Transfer Switch

There are three optional accessory items that also interface to

the ATC-900, the DCT module, the I/O Module, and the Ethernet

Module. See the ATC-900 manual for specific instructions on

these modules. A small description of each follows:

The DCT (Direct Current-Current Transformer) Module is a current transformer interface to the ATC-900 allowing current to be

tered along with voltage and frequency that is already inte-

me

grated into the controller. The DCT Module simply secures to the

00 back using four #8 x less than 1/2 inch screws. The

ATC-9

ribbon cable then plugs into J14. When equipped with a DCT

module, the ATC-900 serves as a multifunction power meter and

provides multifunction measurement of most electrical parameters including voltage, current, power

The meter capabilities is specified as a 1% class energy meter.

The information is displayed on the color display on the front of

the ATC-900. Readings can also be monitored through the RS485 modbus on the controller. The DCT is used to measure load

current when selective load shed is enabled. The DCT Module

also has a 24 Vdc input for powering the ATC-900 controller. If

120 VAC and 24 Vdc is supplied to the controller simultaneously, then the 120 Vac will be the powering supply.

The I/O Module (Figure 16B) is an extension of the ATC-900 controller's programmable inputs and outputs. Each I/O Module has

four inputs and four outputs. The inputs a

at 10 ma) connections for various functional inputs. Up to four

modules can be used with the ATC-900 giving the user up to 20

inputs or 20 outputs (including the controller's standard I/Os).

Depending on the options selected with the transfer switch,

some of the I/Os may be required to be fixed from the factory so

that the user cannot change that particular input or output.

The Ethernet Communications Module is

ates as a communicating device in conjunction with a the ATC-

via an Ethernet network. The Ethernet Module provides

900

Ethernet TCP/IP.

, frequency, energy, etc.

re DC wetted (50 Volts

an accessory that oper-

Section 2: Receiving, Handling, and

Storage

2.1 Receiving

Every effort is made to ensure that the ATS equipment arrives at

its destination undamaged and ready for installation. Packing is

designed to protect internal components as well as the enclosure. Care should be exercised, however, to protect the equipment from impact at all times. D

packaging until the equipment is ready for installation.

When the ATS equipment reaches its destination, the customer

should inspect the ship

rough handling and/or external damage that occurred during

transportation. Record any external and internal damage for

reporting to the transportation carrier and Eaton, once a thorough

inspection is complete. All claims should be as specific as possible and include the catalog and General Order numbers.

A shipping label affixed to the shipping container includes a variety of equipment and customer information, such a

Order Number and catalog numbers. Make certain that this information matches other shipping paper information.

Each transfer switch is packed securely with appropriate shipping materials to prevent damage during shipment. Do not

emove or discard the packing material until the equipment is

r

ready for installation.

Once the top packaging is removed from the shipment, the

enclosure door can be opened. A plast

be found in the enclosure, usually attached to the inside of the

enclosure. Important documents, such as test reports, wiring

diagrams, and appropriate instruction leaflets, are enclosed

within the bag and should be filed in a safe place.

ping container for any obvious signs of

2.2 Handling

o not remove the protective

s General

ic bag of documents will

As previously mentioned, ATS equipment is packaged for forklift

movement. Protect the equipment from impact at all times and

DO NOT double stack.

Once the equipment is at the installation location and ready to be

talled, packaging material can be removed and discarded.

ins

Once the enclosure is unbolted from the wooden pallet, it can be

hand moved to its installation position. Be careful not to damage

the top or bottom enclosure mounting flanges. Refer to Section

4 of this manual for specific installation instructions.

2.3 Storage

Although well packaged, this equipment is not suitable for outdoor storage. The equipment warranty

there is evidence of outdoor storage. If the equipment is to be

stored indoors for any period of time, it should be stored with its

protective packaging material in place. Protect the equipment at

all times from excessive moisture, construction dirt, corrosive

conditions, and other contaminants.

It is strongly suggested that the package-protected equipment be

stored in a climat

from -30 to 85°C (-22 to 185°F) and with a relative humidity of

80% or less. DO NOT, under any circumstance, stack other

equipment on top of a transfer switch equipment enclosure,

whether packaged or not.

e-controlled environment with temperatures

will not be applicable if

For more information visit: www.eaton.com IB140036EN

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

LOGIC

PANEL

POWER

PANEL

VOLTAGE SELECTION

& TRANSFORMER PANEL

LOGIC

PANEL

POWER

PANEL

VOLTAGE SELECTION

& TRANSFORMER PANEL

Open/Closed Transition Contactor Based Transfer Switch

Section 3: Equipment Description

3.1 General

The ATS consists of three basic panels:

1. The power panel;

2. The voltage selection and transformer panel; and

3. The microprocessor-based logic panel.

These panels are interconnected via connector plugs and

mounted in an enclosure (Figure 5

.

A

& 5B)

Instruction Booklet

Effective: October 2014 Page 7

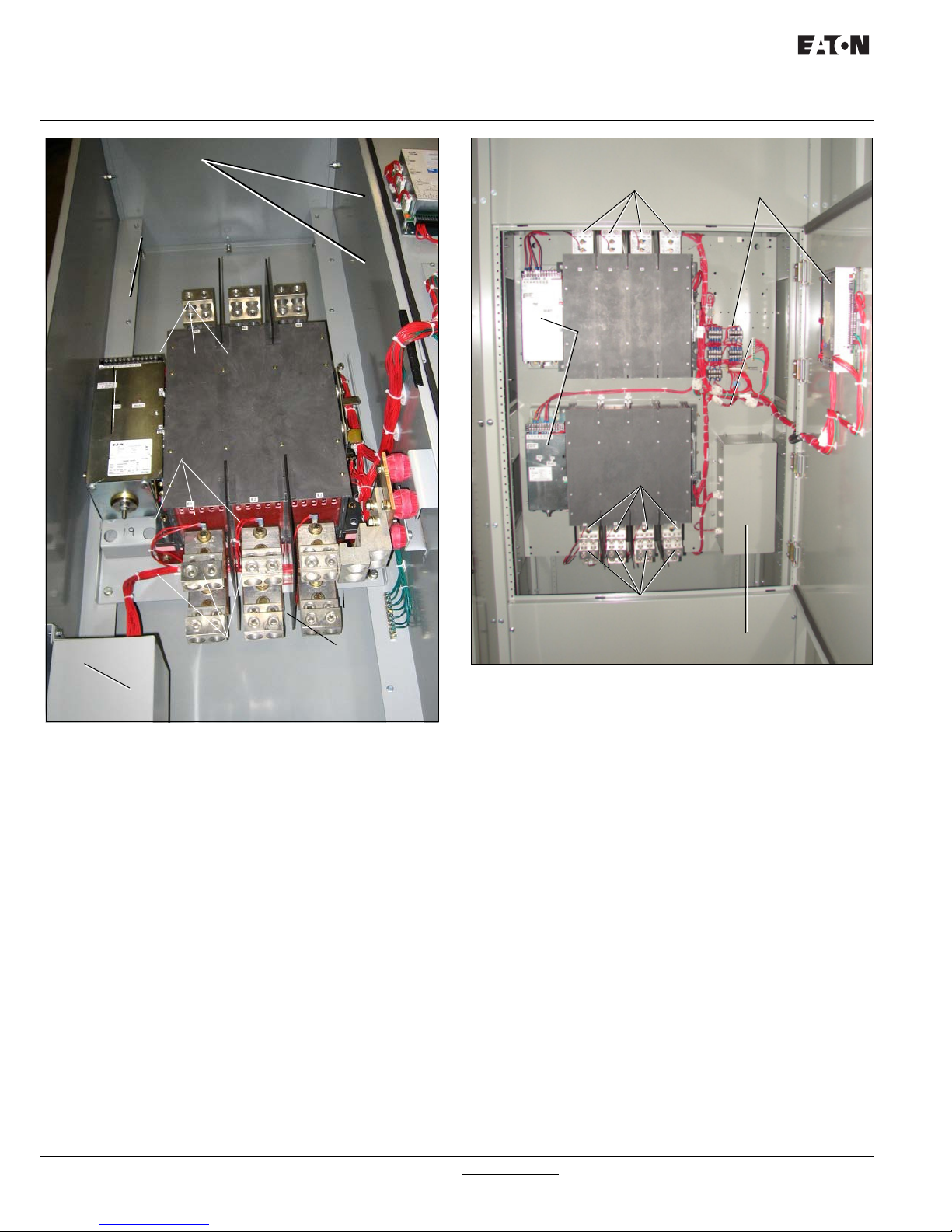

Figure 5A. Three Basic Panels of an Open Transition ATS

(1200A).

Figure 5B. Three Basic Panels of a Close Transition ATS

(1200A).

3.2 Power Panel

The power panel is used for making load, power, and neutral connections. The power contactor is mounted on a steel baseplate

(Figure 6)

3.2.1 Main Contacts

This ATS incorporates a power contactor. The main contacts

connect and disconnect the load to and from the different power

sources. The power contactor is mechanically and electrically

interlocked to prevent the two sets of main contacts from being

closed simultaneously (applicable for open transition ATS only).

.

IB140036EN For more information visit: www.eaton.com

LOGIC

PANEL

SOURCE 1

LUGS

TRANSFER

MECHANISM

SOURCE 2

LUGS

LOAD

LUGS

GROUND

CONNECTION

VOLTAGE

PANEL

NEUTRAL

CONNECTION

SELECTION

Instruction Booklet

LOGIC

PANEL

SOURCE-1 LUGS

VOLTAGE SELECTION

& TRANSFORMER PANEL

TRANSFER

MECHANISM

SOURCE-2 LUGS

LOAD LUGS

GROUND

CONNECTION

Page 8 Effective: October 2014

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

Open/Closed Transition Contactor Based Transfer Switch

Figure 6A. Typical for 1200A Open Transition ATS.

Figure 6B. Typical for 1200A Close Transition ATS.

3.3 Voltage Selection

3.3.1 North American Voltage Selection (120, 208, 240,

480, 600, 60 Hz)

The North American market voltage selection panel consists of

multi-tap transformers, contained in a steel case mounted in the

transfer switch enclosure (Figure 7). The cover has two connectors on it, with the one on the right being selectable depending on

the volta

removed by removing the two front screws and disconnecting the

two plugs. The rear of the transformer enclosure has two flanges

that are inserted into two slots. The voltage is selected by simply

removing the plug from the default selected voltage on the cover

plate and installing the plug to the desired available voltage. Plugs

are provided for 120 to 600 Vac to satisfy any required North

American market application voltage. The factory default position is 480 Vac or 600 Vac. There is a similar selection panel for

internat

ge applied to S1 a

ional voltages.

nd S2. The transformer unit is easily

For more information visit: www.eaton.com IB140036EN

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

Open/Closed Transition Contactor Based Transfer Switch

DANGER

WHEN CHANGING THE VOLTAGE SELECTION, THE POWER MUST BE

REMOVED FROM THE TRANSFER SWITCH. ALWAYS VERIFY THAT

NO VOLTAGE IS PRESENT ON EQUIPMENT PRIOR TO SERVICING.

FAILURE TO FOLLOW THIS WARNING COULD LEAD TO DEATH OR

SEVERE INJURY. WHILE ENERGIZED, AN ARC FLASH AND SHOCK

HAZARD EXISTS. CONSULT NFPA 70E AND OSHA GUIDELINES FOR

OPERATOR SAFETY PRIOR TO SERVICING, INSPECTING OR OPERATING EQUIPMENT.

Instruction Booklet

Effective: October 2014 Page 9

Figure 7.North American Market Voltage Selection Terminals

(Shown Connected to the 208 Vac Plug).

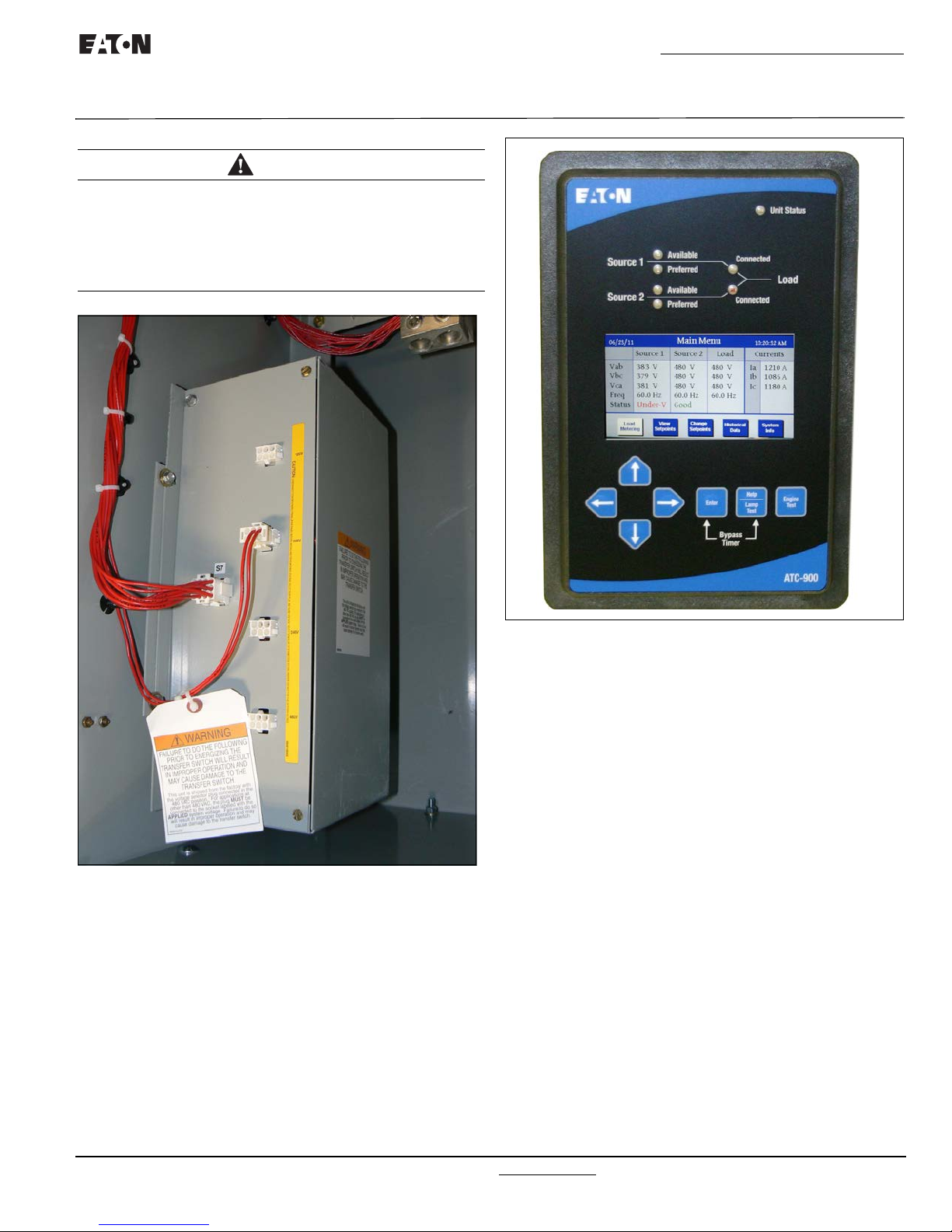

3.4 ATC-900 Logic Panel

The ATC-900 is a microprocessor-based transfer switch logic

control package. The hardware and software of the controller

contain the intelligence/supervisory circuits that constantly monitor the condition of the power sources. It provides the intelligence necessary for the operation of the ATS (Figure 8). It has

r

friendly menus and a color TFT display for easy verification

use

and feature user settings.

Figure 8.

The ATC-900 controller has an operating temperature of

-20 to 70°C (-4 to 158°F).

The controller circuit board is prote

mal coating.

The specifications, under normal operating conditions, are as follows:

■ Tolerance for voltage sensing function: ±1% of full scale.

■ Tolerance for frequency sensing function: ±0.3 Hz of setting.

Please see the ATC-900 controller's Instruction Booklet for new

feat

ATC-900 Logic Control Panel.

ures and instructions.

c

ted by an insulating confor-

3.5 Features and Glossary of Terms

A variety of standard and optional features are available for Eaton

ATSs. All features or combinations of features may not be avail-

able on specific ATSs. All fe

writers Laboratories (UL) listed unless noted.

3.5.1 Operational Simplicity

From installation, to programming, to usage, the ATC-900 was

designed with operational simplicity in mind. Only one style

needs to be considered, regardless of input/output requirements

or system voltages and frequencies. ATC-900 provides the functionality of numerous other devices combined in one package

that mounts in less than 7 by 11 inches of panel space.

The user friendly front panel interface simplifies routine operation, programming, data presentation and setting adjustments. A

large color display provides flexibility and ease of use. The operation of front panel membrane pushbuttons moves the ATC-900

display from function to function or step to step within menus. A

atures a

nd/or accessories are Under-

IB140036EN For more information visit: www.eaton.com

Instruction Booklet

Page 10 Effective: October 2014

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

Open/Closed Transition Contactor Based Transfer Switch

single LED at the top of the faceplate provides an immediate indication as to the device’s operational mode. An integrated Help

Mode provides immediate user assistance in the form of English

language message displays through the use of a front panel Help

pushbutton.

The ATC-900 is communications ready, including Modbus 485,

Ethernet (External), and USB for thumb drives (memory sticks).

3.5.2 Features and Glossary of Terms

A variety of programmable features are available to meet a wide

array of application requirements. Individual features or feature

combinations provide the information required to tailor switches

to individual needs.

Unlike earlier controllers, the ATC-900 comes with standard features that are ready to use, with the exception of Closed Transition, In-Phase, Current metering, and Ethernet. Another

advancement is that there are four (4) standard inputs and four

(4) standard outputs that the operator can easily program by

choosing from a wide array of predefined functions. Additional

inputs and outputs can be added in groups of four (4) up to sixteen (16) for a maximum of twenty (20) in total. The inputs are

DC wetted (50 Volts at 10 ma) connections for various functional inputs.

NOTICE

WITH RESPECT TO THEIR USE IN THIS DOCUMENT AND AS THEY

RELATE TO AUTOMATIC TRANSFER SWITCH OPERATION, THE FOLLOWING WORDS OR PHRASES ARE DEFINED:

Options

The only item that is optional for the transfer switch is the closed

ansition optional feature. The switch type

tr

can be programmed. For example, a two position contactor

switch cannot have feature TDN (Time Delay Neutral), as it has

no neutral position available. A motor MCS/MCCB type transfer

switch with motor operator cannot have closed transition as the

switching mechanism is not fast enough and will not meet the

time line.

Standard Feature: In-Phase Type Operation

As shown in the feature list of Appendix A for In-Phase, ther

ee scenarios for In-Phase:

thr

32C= In-Phase default to Load Voltage Decay

32D= In-Phase default to Time Delay Neutral

32F= In-Phase

ges to the In-Phase operation:

There is a setpoint that allows cha

In-Phase = 0 Disables In-Phase (open transition)

In-Phase = 1 Enables In-Phase Defaults to Alarm

(no Transfer)

In-Phase = 2 Enables In-Phase Defaults to Open

(Time Delay Neutral for 3 position switche

With the setpoint at "2", a two position contactor, the switch

will transfer, if

The three position will allow the use of TDN.

no synchronisation occurs, to the other source.

n

also dictates what

e are

Closed Transition Types Operation

Optional Feature 47C: Closed/In-phas

Decay

Closed Transition is a feature that will t

live sources in a make-before-break scheme when performing a

transfer. This achieves a transfer between sources with no

power interruption. Both sources must be synchronized in frequency, phase, and voltage before the transfer is initiated.

In-phase transition is a feature that

two live sources only when the phase difference between the

two sources is near zero. This is an open transition transfer that

prevents in-rush currents from exceeding normal starting currents

in the case where motor loads are being transferred.

Time Delay Load Voltage Decay utilizes the load voltage measurements to sense back EMF that is generated when the transfer switch is in the neutral position. It pr

in either direction if an unacceptable level is sensed as established by a customer programmed level. T

place until the back EMF decays below the acceptable programmed level. This feature has a se

disabling the operation. If disabled, the transfer switch will not

delay in the neutral position and will transfer between the

sources as fast as possible.

Optional Feature 47D: Closed Transition Only

Closed Transition is a feature that will t

live sources in a make-before-break scheme when performing a

transfer.

This achieves a transfer between sources with no power interruption. Both sources must be synchronized in frequency, phase,

and voltage before the trans

If the logic is forced into a fail safe mode (i.e. loss of connected

ce), the logic will per

sour

fer.

Optional Feature 47E: Closed/In-Phase

Neutral

Closed Transition is a feature that will t

live sources in a make-before-break scheme when performing a

transfer. This achieves a transfer between sources with no

power interruption. Both sources must be synchronized in frequency phase, and voltage before the transf

In-phase

two live sources only when the phase difference between the

two sources is near zero. This is an open transition transfer that

prevents in-rush currents from exceeding normal starting currents

in the case where motor loads are being transferred.

Time delay neutral provides a time delay in the transfer switch

neutral pos

place when the load is transferred in either direction to prevent

excessive in-rush currents due to out of phase switching of large

motor loads.

Optional Feature 47F: Closed/Load Voltage Decay

s)

Closed Transition is a feature that will t

live sources in a make-before-break scheme when performing a

transfer. This achieves a transfer between sources with no

power interruption. Both sources must be synchronized in frequency, phase, and voltage before the transfer is initiated.

Time Delay Load Voltage Decay utilizes the load voltage measurements to sense back EMF that is generated when the transfer switch is in the neutral position. It pr

in either direction if an unacceptable level is sensed as estab-

transition is a feature that will allow a

itio

n when both breakers are open. This delay takes

er is initiated.

f

form a load voltage decay open trans-

e Transition/Load Voltage

e

mporarily parallel two

will allow a

ovides

parate setting

e

Transition/T

e

e

ovides

transfer between

a delay in transfer

h

e transfer will not take

mporarily parallel two

mporarily parallel two

er is initiated.

transfer between

mporarily parallel two

a delay in transfer

of enabling or

ime Delay

For more information visit: www.eaton.com IB140036EN

O&M Manual for 40-1200A (480/600 Vac) ATC-900 3-Position,

Open/Closed Transition Contactor Based Transfer Switch

Instruction Booklet

Effective: October 2014 Page 11

lished by a customer programmed level. The transfer will not

take place until the back EMF decays below the acceptable pro

grammed level. This feature has a separate setting of enabling or

disabling the operati

delay in the neutral position and will transfer between the

sources as fast as possible.

Optional Feature 47G: Closed/Time Delay Neutral

Closed Transition is a feature that will temporarily parallel t

live sources in a make-before-break scheme when performing a

transfer This achieves a transfer between sources with no power

interruption. Both sources must be synchronized in frequency,

phase, and voltage before the transfer is initiated.

Time delay neutral provides a time delay

neutral position when both breakers are open. This delay takes

place when the load is transferred in either direction to prevent

excessive in-rush currents due to out of phase switching of large

motor loads.

Two Options for Closed Transition

If closed transition is available on

receive 47 D or all of the other options 47 C, E, F, G which can

be changed by the setpoints to disable or enable the function.

Screen 3 of 3 in the System Setup menu (See section 3.4.1) is

where the user will set the transition types of the switch. If the

switch can perform closed transition the user will set up the setpoints depending on the scenario required as shown below.

Closed Transition only (47D) or

Closed Transition > In-Phase > TDN

Closed Transition > In-Phase > LVD

Closed Transition > TDN

Closed Transition > LVD

The user can disable closed transition and just use the following:

In-Phase > TDN

In-Phase > LVD

Also with Closed Transition and In-Phase disabled:

TDN or LVD

Standard Feature 3: Time Delay Emergency to Normal (TDEN)

TDEN delays the transfer to t

zation of the Normal power source before the transfer is made.

This timer will begin the countdown from its setting value when

the Normal Source becomes available. During the countdown of

this timer, if the Normal Source should become unavailable, the

timer will be aborted. If the Preferred Source is available and the

Emergency Source fails while the TDEN timer is counting down,

the TDEN timer will be bypassed.

Standard Feature 4: Time Delay for Engine Cool-Off (TDEC)

TDEC permits the generator to run under a no-load condition

after a transfer from the generator source has been made. Countdown timing begins when the transfer is completed. In applications where two generators are selected, the same cool-off timer

setting value is used for both.

Display

There are two displays used on the ATC-900. There is the familiar MIMIC display using LEDs (see below) and the color display

using the push buttons for menu operation.

on. If disabled, the transfer switch will not

w

o

in the transf

the switch, t

e Normal Source to permit stabili-

h

er switch

he user will either

Source 1 Connected - Status LED

-

This LED is lit green if Source 1 is connected. This is accomplished by sensing the Source 1 breaker via the S1 closed auxiliary contact.

Source 2 Connected - Status LED

This LED is lit red if Source 2 is connected. This is accomplished

by sensing the Source 2 breaker via the S2 closed auxiliary contact.

Source 1 Available - Status LED

This LED is lit amber if Source 1 meets the criteria for programmed Source 1 setpoints.

Source 2 Available - Status LED

This LED is lit amber if Source 2 meets the criteria for programmed Source 2 setpoints.

Source 1 Preferred - Status LED

This LED is lit red if Source 1 is the preferred source choice.

Source 2 Preferred - Status LED

This LED is lit red if Source 2 is the preferred source choice.

Load Energized - Status LED

This LED is lit red if the load is connected to a source that is

available.

CAUTION

LOAD ENERGIZE LED IS NOT A POSITIVE INDICATION THAT VOLTAGE IS NOT PRESENT ON THE LOAD TERMINALS.

CAUTION

CHANGING THE SYSTEM NOMINAL VOLTAGE OR FREQUENCY SETPOINTS WILL CAUSE PICKUP AND DROPOUT SETPOINTS TO

CHANGE AUTOMATICALLY TO NEW DEFAULT VALUES.

Optional Feature 9B: Maintenance Selector Switch (MSS)

Marked “OFF”, “ON”. This feature provides selector switch disconnection of control to transfer thus allowing testing of the

transfer switch control logic circuitry without initiating load

transfer. Positioning the MSS in the “OFF” position isolates the

control circuit, permitting manual operation of the transfer

switch or testing of logic circuitry without load transfer.

Optional Feature 29G: Auto/Manual Operation

(Available for 3-Position ATS only)

This feature provides 2-position auto/manual selector switch

marked “Auto/Manual” which permits the selection of automatic

or manual operation. Once the selector switch is transferred to

manual mode, manual transfer between Normal (S1), Neutral and

Emergency (S2) can be achieved by operating 3-position selector

switch marked “Normal-OFF-Emergency”.

Optional Feature 29G: Auto/Manual Operation

(Available for 2-Position ATS only)

This feature provides 2-position auto/manual selector switch

marked “Auto/Manual” which permits the selection of automatic

or manual operation. Once the selector switch is transferred to

manual mode, manual transfer between Normal (S1) and Emergency (S2) can be achieved by operating another 2-position

selector switch marked “Normal-Emergency”.

IB140036EN For more information visit: www.eaton.com

Loading...

Loading...