Eaton ATC-600 Instructions For Installation, Operation And Maintenance

Instructions for Installation, Operation

and Maintenance of the

Eaton ATC-600 Automatic

Transfer Switch Controller

Instructional Booklet

Description Page

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6. Troubleshooting and Maintenance . . . . . . . . . . . . . . . . 22

Appendix A: Status Display Messages . . . . . . . . . . . . . 27

Appendix B: Historical Display Information . . . . . . . . . . 28

Appendix C: Time/Date Display Information . . . . . . . . . 30

Appendix D: ATC-600 Menu Tree . . . . . . . . . . . . . . . 31

Appendix E: Operational Flowcharts . . . . . . . . . . . . . . . 33

IB ATS-1005 For more information visit: www.eaton.com

Instructional Booklet

Page 2 Effective: March 2010

CAUTION

THE ATC-600 IS FACTORY PROGRAMMED FOR A SPECIFIC TRANSFER SWITCH. DO NOT ATTEMPT TO INTERCHANGE ATC-600 CONTROL DEVICES WITHOUT CONSULTING THE FACTORY.

All possible contingencies which may arise during installation,

operation, or maintenance, and all details and variations of this

equipment do not purport to be covered by these instructions. If

further information is desired by purchaser regarding his particular

installation, operation or maintenance of his equipment, the local

Eaton representative should be contacted.

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

Section 1: Introduction

1.1 Preliminary Comments and Safety Precautions

This technical document is intended to cover most aspects associated with the installation, application, operation and maintenance

of the ATC-600. It is provided as a guide for authorized and qualified personnel only in the selection and application of the ATC-

600. Please refer to the specific WARNING and CAUTION in Section 1.1.2 before proceeding. If further information is required by

the purchaser regarding a particular installation, application or

maintenance activity, a Eaton representative should be contacted.

NOTICE

DURING CONVERSATIONS WITH EATON CONCERNING TROUBLESHOOTING OR PRODUCT RETURN, THE CUSTOMER MAY BE ASKED

FOR INFORMATION PERTAINING TO THE SOFTWARE VERSION AND

OPTIONS INCLUDED IN THE SPECIFIC UNIT. REFER TO THE “NOTE”

UNDER THE TOPIC “HELP PUSHBUTTON” IN PARAGRAPH 3.4 FOR

INSTRUCTIONS ON HOW TO OBTAIN THIS INFORMATION.

1.1.1 Warranty and Liability Information

NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OF MERCHANTABILITY, OR WARRANTIES ARISING FROM COURSE OF

DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE

INFORMATION, RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no event will Eaton be responsible to the purchaser or user in contract, in tort (including negligence), strict

liability or otherwise for any special, indirect, incidental or consequential damage or loss whatsoever, including but not limited to

damage or loss of use of equipment, plant or power system, cost

of capital, loss of power, additional expenses in the use of existing

power facilities, or claims against the purchaser or user by its customers resulting from the use of the information and descriptions

contained herein.

1.1.2 Safety Precautions

All safety codes, safety standards and/or regulations must be

strictly observed in the installation, operation and maintenance of

this device.

WARNING

THE WARNINGS AND CAUTIONS INCLUDED AS PART OF THE PROCEDURAL STEPS IN THIS DOCUMENT ARE FOR PERSONNEL SAFETY

AND PROTECTION OF EQUIPMENT FROM DAMAGE. AN EXAMPLE

OF A TYPICAL WARNING LABEL HEADING IS SHOWN IN REVERSE

TYPE TO FAMILIARIZE PERSONNEL WITH THE STYLE OF PRESENTATION. THIS WILL HELP TO INSURE THAT PERSONNEL ARE ALERT TO

WARNINGS, WHICH MAY APPEAR THROUGHOUT THE DOCUMENT.

IN ADDITION, CAUTIONS ARE ALL UPPER CASE AND BOLDFACE AS

SHOWN BELOW.

CAUTION

COMPLETELY READ AND UNDERSTAND THE MATERIAL PRESENTED IN THIS DOCUMENT BEFORE ATTEMPTING INSTALLATION,

OPERATION OR APPLICATION OF THE EQUIPMENT. IN ADDITION,

ONLY QUALIFIED PERSONS SHOULD BE PERMITTED TO PERFORM

ANY WORK ASSOCIATED WITH THE EQUIPMENT. ANY WIRING

INSTRUCTIONS PRESENTED IN THIS DOCUMENT MUST BE FOLLOWED PRECISELY. FAILURE TO DO SO COULD CAUSE PERMANENT EQUIPMENT DAMAGE.

For more information visit: www.eaton.com IB ATS-1005

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

Instructional Booklet

Effective: March 2010 Page 3

1.2 Background

Transfer switches are used to protect critical electrical loads

against loss of power. The load’s normal power source is backed

up by a secondary (emergency) power source. A transfer switch is

connected to both the normal and emergency sources and supplies the load with power from one of these two sources. In the

event that power is lost from the normal source, the transfer

switch transfers the load to the secondary source. Transfer can be

automatic or manual, depending upon the type of transfer switch

equipment being used. Once normal power is restored, the load is

transferred back to the normal power source.

In automatic transfer switch equipment, the switch’s intelligence

system initiates the transfer when normal power fails or falls

below a preset voltage. If the emergency source is a standby generator, the transfer switch initiates generator starting and transfers to the emergency source when sufficient generator voltage is

available. When normal power is restored, the transfer switch

automatically transfers back and initiates engine shutdown.

An automatic transfer switch consists of three basic elements:

1. Main contacts to connect and disconnect the load to and from

the source of power

2. A transfer mechanism to affect the transfer of the main con-

tacts from source to source

3. Intelligence/supervisory circuits to constantly monitor the con-

dition of the power sources and thus provide the intelligence

necessary for the switch and related circuit operation

This manual deals with the third basic element of the automatic

transfer switch, the required intelligence/ supervisory circuits.

Prior to the introduction of ATC-600, this function was performed

by a door mounted logic panel. The logic panel could be the relay

logic type or the solid state logic type. In either case, the panel

consisted of a number of individually mounted and wired devices

offering a limited amount of system flexibility, especially in the

case of the relay logic design. ATC-600 brings intelligence, supervisory and programming capabilities, never before available, to

automatic transfer switch equipment.

1.3 Product Overview

The ATC-600 is a comprehensive, multi-function, microprocessor

based automatic transfer switch controller. It is a compact, selfcontained, panel mounted device designed to replace traditional

relay and solid state logic panels (Figures 1 and 2).

Designed to meet the needs of markets worldwide, ATC-600:

• Is a UL Recognized Component

• Meets Seismic Requirements of Uniform and California Building

Codes (exceeding requirements of worst case Zone 4 levels)

• Complies with UL 991 environmental tests

• Complies with IEC 61000-4-2, 61000-4-3, 61000-4-4, and

61000-4-5

• Complies with CISPR 11, Class A

• Complies with FCC Part 15, Subpart B, Class A

ATC-600 provides an unmatched degree of programmed flexibility

to address the needs of any system. It operates from most system

voltages available worldwide at 50 or 60 Hertz. In addition, a

period of no control power operation is provided. ATC-600 monitors the condition of the 3-phase line-to-line voltage and frequency

of both the Normal and Emergency sources. It can also be programmed for single phase operation. ATC-600 provides the necessary intelligence to insure that the switch operates properly

through a series of programmed sensing and timing functions.

A standard ATC-600 will:

• Monitor Normal and Emergency source voltages and frequen-

cies

• Provide undervoltage monitoring of Normal and Emergency

sources

• Permit customer programming

• Display real time and historical information

• Permit system testing

• Offer Help Screen assistance

• Store customer/factory established parameters in nonvolatile

memory

• Communicate using a PONI

• Provide faceplate source/load status indications

A wide array of additional features are available to address the

most sophisticated system requirements, such as:

• Previously unavailable Load Monitoring and Delayed Transition

• In-phase Transition

1.4 Functions/Features/Options

The primary function of ATC-600 is to accurately monitor power

sources and provide the necessary intelligence to operate a transfer switch in an appropriate and timely manner. In addition,

ATC-600 provides useful present and historical data, reliable twoway communications, and programming through the device’s faceplate or communications option. ATC-600 features proprietary

microprocessor technology to provide and maintain superior precision and versatility during both programming and data access.

1.4.1 Operational Simplicity

From installation to programming to usage, ATC-600 was

designed with operational simplicity in mind. Only one style needs

to be considered, regardless of input/output requirements or system voltages and frequencies. ATC-600 provides the functionality

of numerous other devices combined in one package that mounts

in less than 7 by 11 inches of panel space.

The user friendly front panel interface simplifies routine operation,

programming, data presentation and setting adjustments. An LED

based display provides the flexibility of large character displays for

enhanced visibility. The operation of front panel membrane pushbuttons moves the ATC-600 display from function to function or

step to step within a function. Three LEDs at the top of the faceplate provide an immediate indication as to the device’s operational

mode. An integral Help Mode provides immediate user assistance in

the form of English language message displays through the use of a

front panel Help pushbutton.

With a Product Operated Network Interface (PONI), the ATC-600

is communications ready and compatible with other devices in the

IQ Family of products. The Communication Module (PONI) is available in three versions, the INCOM PONI, RS-232 PONI and PONI

Modem. Reliable two-way communications can be provided over a

twisted pair communications network. With the INCOM PONI,

ATC-600 is compatible with the Eaton IMPACC system.

1.4.2 Standard and Optional Features

A variety of programmable features are available to meet a wide

variety of application requirements. Individual features or feature

combinations provide the intelligence required to tailor switches to

individual needs.

IB ATS-1005 For more information visit: www.eaton.com

Instructional Booklet

Page 4 Effective: March 2010

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

The features are factory activated, depending upon customer

requirements. The specific variable setpoints associated with standard and factory activated features are stored in a nonvolatile

memory. Activated feature setpoints are available for customer

adjustment. Any feature not selected and factory activated cannot

be viewed or adjusted.

NOTICE

WITH RESPECT TO THEIR USE IN THIS DOCUMENT AND AS THEY

RELATE TO AUTOMATIC TRANSFER SWITCH OPERATION, THE FOLLOWING WORDS OR PHRASES ARE DEFINED:

Available

A source is defined as available when it is within its undervoltage/

overvoltage/underfrequency/overfrequency (if applicable) setpoint

ranges for the nominal voltage and frequency setting.

Fails

A source is defined as failed when it is outside of its undervoltage/

overvoltage/underfrequency/overfrequency (if applicable) setpoint

ranges for the nominal voltage and frequency setting.

Normal Source

The Normal Source is defined as the source that is preferred. The

Preferred Source setting allows the operator to select Source 1,

Source 2 or NONE as the Preferred Source. If NONE is chosen, the

Preferred Source or the Normal Source will be the source that is

presently attached to the load. If the Preferred Source feature is

not available from the factory, the default is set as being Source 1

as the Preferred and Normal Source.

Emergency Source

The Emergency Source is defined as the source that is not preferred. If NONE is chosen for the Preferred Source setting, the

Emergency Source will be the source that is presently not

attached to the load. Therefore, in this condition after a transfer,

what was the Normal and Emergency Sources will switch

between Source 1 and 2. If the Preferred Source feature is not

available from the factory, the default is set with Source 2 as the

Emergency Source.

Option #

For personnel who are familiar with previous transfer switch controller option specifications, an attempt at equivalence to some of

the features is made.

ATC-600 features with a brief description follow. The actual programmable setpoints for each feature are covered in Section 5.

Standard Feature: Time Delay Engine Start (TDES)

TDES is used where the source is an engine generator. It delays

initiation of the engine start circuit in order to override momentary

power outages and/or fluctuations. This timer and the associated

engine start circuit will operate with or without control power.

There are two separate start circuits, one for each source when

applications of two generators are selected, although the same

TDES timer value is used for both. When one generator is

selected, this timer’s engine start circuit will operate on generator

2 for source 2. If the source that is being transferred to has a generator and that source is already available, the TDES timer is

bypassed.

Standard Feature: Time Delay Normal to Emergency (TDNE)

TDNE delays the transfer to the Emergency Source to permit stabilization of the Emergency power source before the transfer is

made. This timer will begin the countdown from its setting value

when the Emergency Source becomes available. If the Normal

Source should become available during the countdown of this

timer, the timer will be aborted.

Standard Feature: Time Delay Emergency to Normal (TDEN)

TDEN delays the transfer to the Normal Source to permit stabilization of the Normal power source before the transfer is made. This

timer will begin the countdown from its setting value when the

Normal Source becomes available. During the countdown of this

timer, if the Normal Source should become unavailable, the timer

will be aborted. If the Preferred Source is available and the Emergency Source fails while the TDEN timer is counting down, the

TDEN timer will be bypassed.

Standard Feature: Time Delay for Engine Cool-Off (TDEC)

TDEC permits the generator to run under a no-load condition after

a transfer from the generator source has been made. Countdown

timing begins when the transfer is completed. In applications

where two generators are selected, the same cool-off timer setting value is used for both.

Standard Feature: Time Delay Emergency Failure (TDEF)

TDEF is used where at least one source is an engine generator.

TDEF will delay an available source from being declared unavailable in order to override momentary generator fluctuations. This

time delay is only implemented when the load is connected to a

generator source. TDEF is not displayed when the number of generators is zero.

CAUTION

CHANGING THE SYSTEM NOMINAL VOLTAGE OR FREQUENCY SETPOINTS WILL CAUSE PICKUP AND DROPOUT SETPOINTS TO

CHANGE AUTOMATICALLY TO NEW DEFAULT VALUES.

Standard Feature : System Nominal Frequency (NOMF)

There are only two choices for system nominal frequency of the

distribution system, 50 or 60 Hertz. The dropout/pickup, underfrequency and overfrequency upper and lower setting limits are

based on the nominal frequency value.

Standard Feature: System Nominal Voltage (NOMV)

This refers to the standard system nominal RMS line to line voltage. A wide range (120 to 600) of sensing voltage is available to

be programmed. The dropout/pickup, undervoltage and overvoltage upper and lower setting limits are based upon the nominal

voltage value.

Standard Feature: Undervoltage Monitoring for Source 1 (1UVD,

1UVP)

This feature constantly monitors Source 1 for an undervoltage

condition. When the Source 1 voltage drops to a value equal to or

below the undervoltage dropout setting, the source will become

unavailable. The source’s voltage will then have to rise to a value

that is equal to or above the pickup setting to become available

again.

Standard Feature: Undervoltage Monitoring for Source 2 (2UVD,

2UVP)

This feature functions the same as Standard Feature (1UVD,

1UVP), except for Source 2 instead of Source 1.

Standard Feature: Underfrequency Monitoring for Source 2

(2UFD, 2UFP)

This feature functions the same as Optional Feature 26E, except

for Source 2 instead of Source 1.

For more information visit: www.eaton.com IB ATS-1005

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

Instructional Booklet

Effective: March 2010 Page 5

Standard Feature: Commit to Transfer During TDNE Timing

(CTDNE)

This feature provides for selection as to whether or not commitment to transfer is desired when Time Delay Normal to Emergency

countdown has begun. If no commitment is chosen and the Normal Source returns to availability when the TDNE timer is counting

down, the transfer is aborted and the engine generator (if applicable) is cooled down.

Standard Feature: Engine Test Mode (TMODE)

This feature provides selection of the type of test that can be initiated by the front panel Engine Test pushbutton. An engine test

without transferring the load to it, or an engine test with a full

transfer of the load to the engine can be chosen. Load testing is

fail-safe. If the generator fails during testing for any reason, the

ATC-600 will signal the transfer switch to return to normal. If disable test mode is chosen, the front panel pushbutton cannot be

used to initiate a test.

Standard Feature: Test Engine Run (TER)

This feature provides selection of the length of time in hours and

minutes that the ATC-600 will enable the generator contacts during an Engine Test that was initiated from the front panel pushbutton or for the plant exerciser feature, if applicable.

Standard Feature 5C: Overfrequency Monitoring for Source 2

(2OFD, 2OFP)

This feature constantly monitors Source 2 for an overfrequency

condition. When the Source 2 frequency rises to a value equal to

or above the overfrequency dropout setting, the source will

become unavailable. The source’s frequency will then have to

drop to a value that is equal to or below the pickup setting to

become available again.

Standard Feature 5E: Overvoltage Monitoring for Source 2

(2OVD, 2OVP)

This feature constantly monitors Source 2 for an overvoltage condition. When the Source 2 voltage rises to a value equal to or

above the overvoltage dropout setting, the source will become

unavailable. The source’s voltage will then have to drop to a value

that is equal to or below the pickup setting to become available

again.

Standard Feature 8C/8D: Transfer Time Delay Bypass

This feature allows an external pushbutton input to be used to

bypass the timer for Standard Feature (TDNE) or Standard Feature

(TDEN) individually, or both simultaneously. This feature is usually

used in testing when it is not desirable to wait for completion of

the timing sequence.

Standard Feature 23: Plant Exerciser (EXER)

This feature provides for the automatic test operation of the generator for a pre-selected weekly interval. When the test is running,

pressing and releasing the Engine Test pushbutton will cancel the

test. The day of the week, hour, and minute that exercising is

desired can be programmed into the ATC-600. The type of test,

whether a load transfer or just an engine test, can also be

selected. Load testing is fail-safe. If the generator fails during testing for any reason, the ATC-600 will signal the transfer switch to

return to normal.

Standard Feature 26C: Overvoltage Monitoring for Source 1

(1OVD, 1OVP)

This feature constantly monitors Source 1 for an overvoltage condition. When the Source 1 voltage rises to a value equal to or

above the overvoltage dropout setting, the source will become

unavailable. The source’s voltage will then have to drop to a value

that is equal to or below the pickup setting to become available

again.

Standard Feature 26D: Go To Emergency

This feature enables an external contact closure to initiate a transfer from the Normal Source to the Emergency Source. If the

external contact is closed and the Emergency Source fails, the

ATC-600 will transfer the load back to the Normal Source.

Standard Feature 26E: Underfrequency Monitoring for Source 1

(1UFD, 1UFP)

This feature constantly monitors Source 1 for an underfrequency

condition. When the Source 1 frequency drops to a value equal to

or below the underfrequency dropout setting, the source will

become unavailable. The source’s frequency will then have to rise

to a value that is equal to or above the pickup setting to become

available again.

Standard Feature 26F: Overfrequency Monitoring for Source 1

(1OFD, 1OFP)

This feature constantly monitors Source 1 for an overfrequency

condition. When the Source 1 frequency rises to a value equal to

or above the overfrequency dropout setting, the source will

become unavailable. The source’s frequency will then have to

drop to a value that is equal to or below the pickup setting to

become available again.

Optional Feature 9B: Maintenance Selector Switch (MSS)

Marked “OFF”, “ON”. This feature provides selector switch disconnection of control to the transfer motor thus allowing testing

of the transfer switch control logic circuitry without initiating load

transfer. Manual disconnection is standard on all Eaton transfer

switches. Positioning the MSS in the “OFF” position isolates the

control circuit from the transfer motor, permitting manual operation of the transfer switch or testing of logic circuitry without load

transfer.

Optional Feature 10: Preferred Source Selection (PRF SRC)

This feature permits the selection of either source (1 or 2) as the

Preferred or Normal Source. The Normal Source is the source that

the switch always looks to for availability so that it can transfer to

it. When two generators are selected and the switch has transferred to the Emergency Source, the ATC-600 will constantly be

waiting and attempting to start the generator on the Preferred

Source so that it may return to it. IF NONE is chosen, the Preferred Source or the Normal Source will be the source that is presently attached to the load.

Optional Feature 16: Overcurrent Protection

When integral overcurrent protection is provided for either one or

both sources, the need for separate upstream overcurrent protection, in most instances, is eliminated. With this factory installed

feature in the ATC-600, further automatic transfer operation is

locked-out until the appropriate source breaker is reset.

Optional Feature 29G: Type of Operation (Selectable Automatic or

Manual)

This feature provides a two position selector switch marked Auto/

Manual which permits the selection of automatic or manual operation. It includes devices for manual operation when the selector

switch is in the manual position.

Optional Feature 29J: Type of Operation (MANTR)

This feature provides for a selection between an automatic transfer and re-transfer mode or a manual pushbutton re-transfer to

Normal from the Emergency Source mode. If this option is not

selected the factory default selection is automatic.

IB ATS-1005 For more information visit: www.eaton.com

Instructional Booklet

Page 6 Effective: March 2010

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

Optional Feature 32A: Time Delay Neutral (TDN)

This feature provides a time delay in the transfer switch Neutral

position when both breakers are open. This delay takes place

when the load is transferred in either direction to prevent excessive in-rush currents due to out-of-phase switching of large motor

loads. This feature is not available with the Neutral Load Sense

Delay (TDNLD) feature.

Optional Feature 32B: Load Voltage Decay (LDCY)

This feature utilizes the load voltage measurements to sense back

EMF that is generated when the transfer switch is in the Neutral

position. It provides a delay in transfer in either direction if an

unacceptable level is sensed as established by a customer programmed level. The transfer will not take place until the back EMF

decays below the acceptable programmed level. This feature has a

separate setting of enabling or disabling the operation. If disabled,

the transfer switch will not delay in the Neutral position and will

transfer between the sources as fast as possible. This feature is

not available with the Time Delay Neutral (TDN) Feature 32A.

Optional Feature 32C: In-Phase/Load Voltage Decay

In-phase transition is a feature that will allow a transfer between

two live sources only when the phase difference between the two

sources is near zero. This is an open transition transfer that prevents in-rush currents from exceeding normal starting currents in

the case where motor loads are being transferred.

Load Voltage Decay utilizes the load voltage measurements to

sense back EMF that is generated when the transfer switch is in

the Neutral position. It provides a delay in transfer in either direction if an unacceptable level is sensed as established by a customer programmed level. The transfer will not take place until the

back EMF decays below the acceptable programmed level. This

feature has a separate setting of enabling or disabling the operation. If disabled, the transfer switch will not delay in the Neutral

position and will transfer between the sources as fast as possible.

This feature is not available with the Time Delay Neutral (TDN)

Feature 32A.

Optional Feature 32D: In-Phase/Time Delay Neutral

In-phase transition is a feature that will allow a transfer between

two live sources only when the phase difference between the two

sources is near zero. This is an open transition transfer that prevents in-rush currents from exceeding normal starting currents in

the case where motor loads are being transferred.

Time Delay Neutral provides a time delay in the transfer switch

Neutral position when both breakers are open. This delay takes

place when the load is transferred in either direction to prevent

excessive in-rush currents due to out-of-phase switching of large

motor loads. This feature is not available with the Neutral Load

Sense Delay (TDNLD) feature.

Optional Feature 35: Pre-Transfer Signal (TPRE)

Typically associated with elevator controls, this feature provides

for the control of an addressable relay to remotely signal an elevator that a re-transfer is about to take place. A permissive reportback signal from the elevator, telling the ATC-600 that the elevator has reached the floor and opened its doors, is also recognized

to facilitate faster transfer operation. Should the permissive signal

not be used or does not occur, the ATC-600 has a programmed

overriding pre-transfer delay timer that can be set from 0 to 5 minutes.

Optional Feature 36: Emergency Inhibit

This feature enables the Emergency Inhibit control input to inhibit

transfers to the Emergency Source. See Control Inputs section for

more information.

Optional Feature 37: Service Equipment

This factory programmed feature makes the transfer switch suitable for a service equipment rating by responding to a Go-To-Neutral input.

Optional Feature 45: Load Sequencing Capability (TSEQ)

This feature provides the sequential closure of up to 10 remote

relays after a transfer. A customer programmed time delay is

available to delay closure between each of the relays.

Optional Feature 46: Potential Transformer (PT) Ratio

This feature allows external voltage transformers to be used on

the ATC-600’s source and load sense inputs. Once this option is

enabled, the PT Ratio setpoint can be adjusted in steps of 1,

between 2:1 and 500:1. Also when this option is enabled the

Nominal System Voltage setting will be fixed at 120 or 110 volts,

depending upon the Nominal System Frequency setting. If the

Nominal System Frequency setting is 60Hz then the Nominal System Voltage will be fixed at 120 volts and all voltage pick-up and

drop-out setpoints will be based upon the 120 volt level. The

same is true of a Nominal System Frequency of 50Hz whose Nominal System Voltage will be fixed at 110 volts. The metering display will use the PT ratio value to calculate and display the load

and source voltages with up to three significant digits. There will

be four possible types of displays, as an example they could display 999K, 99.9K, 9.99K, or 999 volts.

48: Communication Modules

Provides communications modules for the ATC-600 and ATC-800

transfer switch controllers. These controllers are PowerNet and

Modbus compatible devices. A separately mounted communications module will enable the automatic transfer controller to be

remotely monitored controlled and programmed via the network.

48F: RS-232 and RS-485 with Modbus

Provides communications for the ATC-600 via RS-232 or Modbus

through an RS-485 port. Registers are available to read back status, voltages, frequencies, and historical data. Registers are also

available for transfer switch control. Setpoints may be read back

and/or programmed via a pass-through command.

For more information visit: www.eaton.com IB ATS-1005

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

Instructional Booklet

Effective: March 2010 Page 7

Section 2: Hardware Description

2.1 General

The purpose of this section is to familiarize the reader with ATC600 hardware, its nomenclature, and to list the unit’s specifications. The information presented is divided into the following four

parts:

• Operator Panel

• Rear Access Area

• External Hardware

• Specification Summary

2.2 Operator Panel

The operator panel, which is normally accessible from the outside

of a panel or door, provides a means for:

• Being alerted to specific conditions

• Receiving functional help

• Programming

• Parameter Monitoring/Selection/Metering

LEDs, a display window, pushbuttons, and a mimic bus make up

the front accessible operator panel (Figure 1).

Seventeen individual LEDs are lit when performing or indicating a

specific function. For detailed information on individual LEDs refer

to Paragraph 3.2.

The LED type display window is used to display all ATC-600 monitored parameters, setpoints and messages in easy to read formats. The alpha numeric display is approximately 0.75 by 4.25

inches and is able to display up to eight characters at a time. For

details concerning the kind of information that can be viewed in

the display window refer to Paragraph 3.3.

The front operator panel supports six long-life membrane pushbuttons. Pushbuttons accomplish their function when pressed and

released. Refer to Paragraph 3.4 for information concerning the

function of specific pushbuttons.

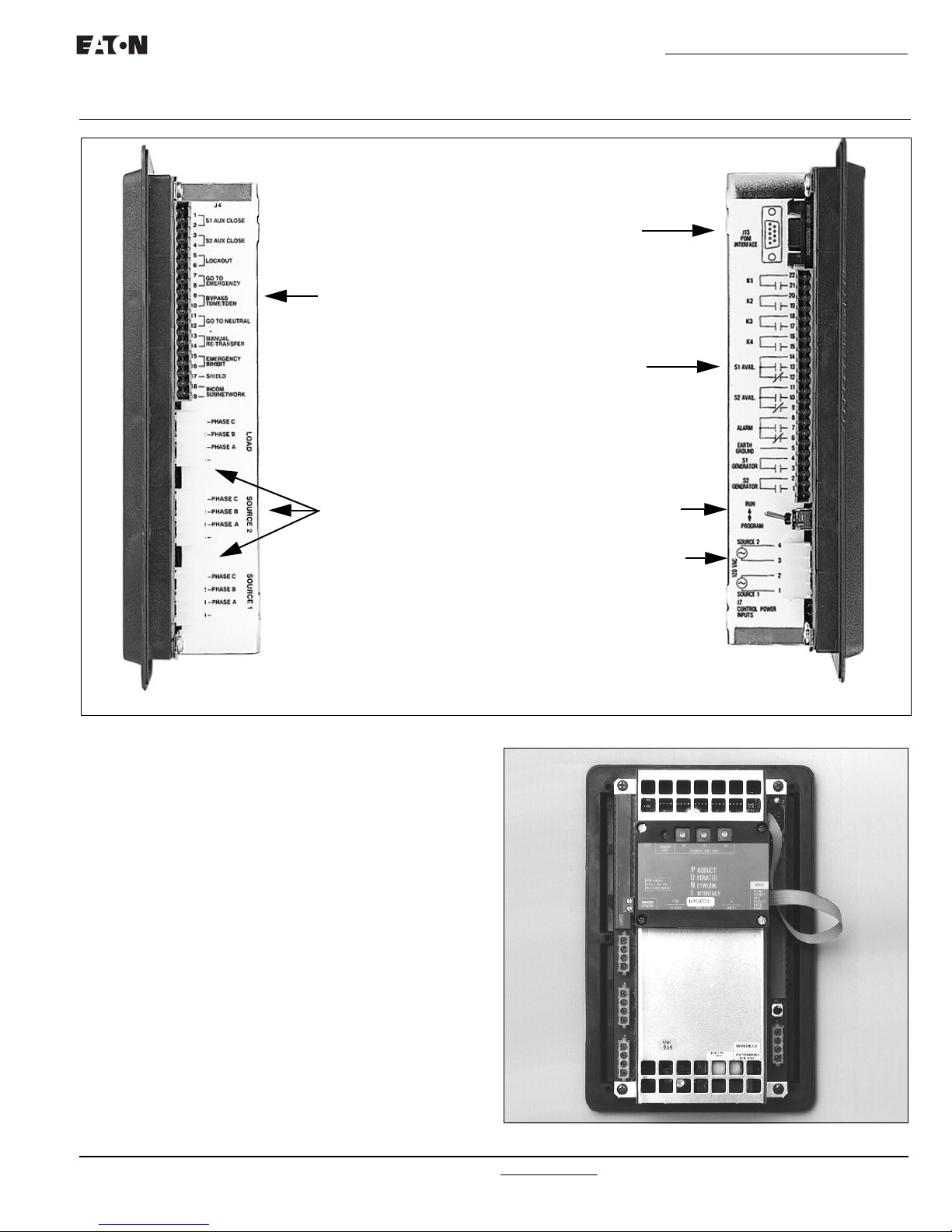

2.3.2 Right Rear of Chassis

The right rear of the chassis provides a port that will accept the

D-sub male connector of the optional Communication Module

(PONI). A self locking female connector J7 is provided for Sources

1 and 2 control power input.

Customer programming is provided through the Program/Run Toggle Switch. While the switch is in the Program position, the

ATC-600 continues to operate in keeping with previously programmed setpoints.

Terminal block J5 provides dry relay contacts for primary control

outputs. Physically these relays are comprised of two latching

Form A relays for generator start contacts, and seven conventional coil Form C relays necessary to complete the electrical control function.

2.3 Rear Access Area

The rear access area of the ATC-600 is normally accessible from

the rear of an open panel door (Figure 2).

All wiring connections to the ATC-600 are made at the rear of the

chassis. For the sake of uniform identification, the frame of reference when discussing the rear access area is facing the back of the

ATC-600 with the panel door open. The communication module

port, for example, is located on the upper right rear of the unit. The

Run/Program Switch, used to determine the ATC-600 Mode, is

located in the lower right near the control power inputs. Detailed

information relative to any connection made to the rear access area

is presented in Section 4 entitled “Operation.”

2.3.1 Left Rear of Chassis

The left rear of the chassis provides self locking female connectors J1, J2 and J3 for voltage monitoring of Source 1 (S1),

Source 2 (S2) and the Load respectively. Terminal block J4 provides DC wetted connections for various functional inputs. See

Paragraph 4.3 for more information on input functionality.

IB ATS-1005 For more information visit: www.eaton.com

Instructional Booklet

1. ATC-600 Faceplate (UV Resistant)

2. Operational Mode LEDs (highlighting ATC-600’s

present operational condition)

3. System Status Mimic Bus (easy to read and understand LED type)

4. Display Window (easy to read monitored parameters,

setpoints and messages)

5. Display LEDs (seven LEDs to identify the Display Window Information)

6. Help Pushbutton (provides English language help

information in any operational mode)

7. Increase/Decrease Pushbuttons (used individually,

pushbuttons move displayed information/setting up or

down through all possibilities – used simultaneously

while viewing historical logged values, values reset to

zero)

8. Step Pushbutton (used to step through different available information within the category being displayed)

9. Display Select Pushbutton (used to move the display

through the categories represented by the 7 LEDs

under the display)

10. Engine Test Pushbutton (pushed and released twice

to initiate a self test in Run or Program Modes

Page 8 Effective: March 2010

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

Figure 1. ATC-600 Operator Panel.

For more information visit: www.eaton.com IB ATS-1005

Instructions for Installation, Operation and Maintenance of the

LEFT SIDE VIEW

Communication Module

Connector

J4 (Inputs) Terminal Block

(DC Wetted Contact)

J5 (Outputs) Terminal

Block (Dry Relay Contacts)

J1, J2, J3 Source/Load

Connectors

Program/Run

Toggle Switch

J7 Sources 1 and 2

Control Power

Connector

RIGHT SIDE VIEW

ATC-600 Controller - Breaker Type (CAT#8160A00G41)

Eaton ATC-600 Automatic Transfer Switch Controller

Instructional Booklet

Effective: March 2010 Page 9

Figure 2. ATC-600 (Left and Right Side Views).

2.4 External Hardware (Communication Module)

External hardware is viewed as any optional device mounted

directly to or remotely from the ATC-600, such as a communication module. Communications is made possible by mounting a

small, addressable communication module (PONI) to the back of

the ATC-600 (Figure 3) or in a remote location. Since the ATC600 is always supplied with a communications port, a PONI can

be easily retrofitted to the ATC-600 at any time. It is recom-

mended that the control power to the ATC-600 be removed prior

to connecting or disconnecting a PONI. When using the INCOM

PONI on the ATC-600, the PONI function switches should be set

to either of the Standard PONI modes (PONI 9600 Baud or PONI

1200 Baud). Refer to the instruction details supplied with the

PONI for details.

IB ATS-1005 For more information visit: www.eaton.com

Figure 3. Communication Module - PONI (mounted).

Instructional Booklet

Page 10 Effective: March 2010

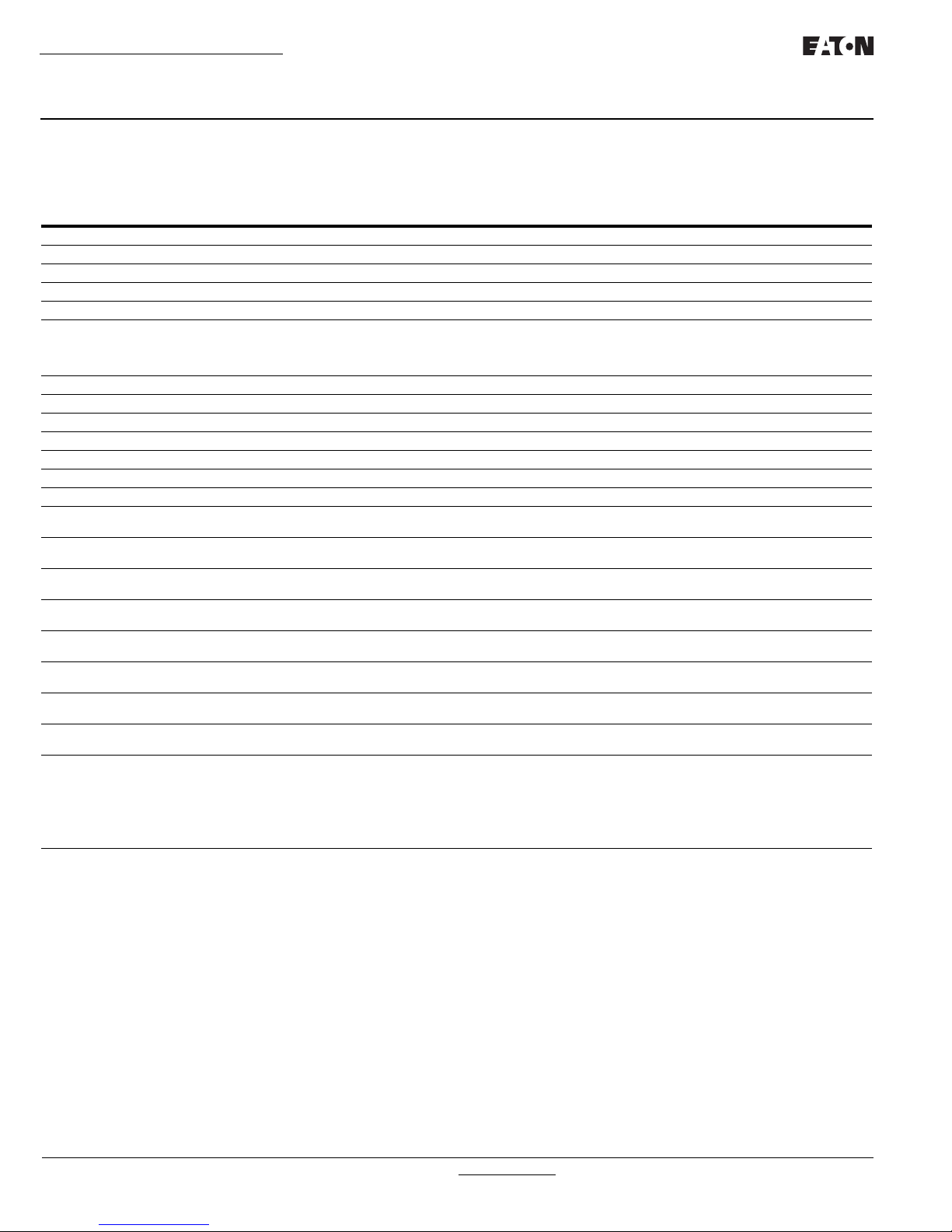

2.5 Specification Summary

Refer to Table 1.

Table 1. ATC-600 Specifications

PARAMETER SPECIFICATION

Control Power: • 120Vac (50/60 Hz) (operating range 65 to 160 Vac)

Power Consumption: • 18VA

Environmental Conditions:

Operating Temperature • -20° to 70°C

Operating Humidity • up to 90% Relative Humidity (non-condensing)

Enclosure Compatibility: • NEMA 12 (standard mounting)

System Voltage Application: • 120 to 600 Vac (50/60 Hz) (single or three phase)

Voltage Measurements: • Source 1, Source 2 and Load (VAB, VBC, VCA for Three Phase System)

Voltage Measurement Range: • 0 to 700 Vac

Voltage Measurement Accuracy: • ±1% of Full Scale

Frequency Measurements: • Source 1 and Source 2

Frequency Measurement Range: • 40 to 80 Hz

Frequency Measurement Accuracy: • ±0.1 Hz

Undervoltage Dropout Range (Volts)

Breaker Switch Style ATS 50 to 97% of Nominal System Voltage

Undervoltage Pickup Range (Volts)

Breaker Switch Style ATS (Dropout +2%) to 99% of Nominal System Voltage

Overvoltage Dropout Range (Volts)

Breaker Switch Style ATS 105 to 120% Nominal System Voltage

Overvoltage Pickup (Volts)

Breaker Switch Style ATS 103% to (Dropout-2%) of Nominal System Voltage

Underfrequency Dropout (Hertz)

Breaker Switch Style ATS 90 to 97% of Nominal System Frequency

Underfrequency Pickup (Hertz)

Breaker Switch Style ATS (Dropout +1 Hz) to 99% of Nominal System Frequency

Overfrequency Dropout (Hertz)

Breaker Switch Style ATS 103 to 110% of Nominal System Frequency

Overfrequency Pickup (Hertz)

Breaker Switch Style ATS 101% to (Dropout -1 Hz) of Nominal System Frequency

Applicable Testing: • UL Recognized Component

• NEMA 4/4X (mounted with gasket between panel and device faceplate)

• NEMA 3R (outdoor)

• UV Resistant ATC-600 Faceplate

• Meets Seismic Requirements of Uniform and California Building Codes

(exceeding requirements of worst case Zone 4 levels)

• Complies with UL 991 environmental tests

• Complies with IEC 61000-4-2, 61000-4-3, 61000-4-4, and 61000-4-5

• Complies with CISPR 11, Class A

• Complies with FCC Part 15, Subpart B, Class A

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

For more information visit: www.eaton.com IB ATS-1005

Instructions for Installation, Operation and Maintenance of the

Eaton ATC-600 Automatic Transfer Switch Controller

Instructional Booklet

Effective: March 2010 Page 11

Section 3: Operator Panel

3.1 General

The operator panel, which is normally accessible from the outside

of a panel or door, provides a means for being alerted to specific

conditions, receiving functional help, programming, and parameter

monitoring/selection (Figure 1). For the purpose of familiarization,

the panel is divided into three sub-sections and discussed individually:

• LEDs

• Pushbuttons

• Display Window

NOTICE

WITH RESPECT TO THEIR USE IN THIS DOCUMENT AND AS THEY

RELATE TO AUTOMATIC TRANSFER SWITCH OPERATION, THE

WORDS “CYCLE” AND “EVENT” ARE DEFINED AS FOLLOWS:

CYCLE –A COMPLETE OPERATION FROM NORMAL TO EMERGENCY

TO NORMAL.

EVENT –A FAILURE RESULTING IN SOM E T YP E OF SWITC H AND/OR

SWITCH INTELLIGENCE ACTION.

NOTICE

REFER TO APPENDIX D FOR AN OVERALL VIEW OF ATC-600 OPERATIONS IN THE FORM OF A MENU TREE.

3.2 LEDS

LEDs are used to indicate the device’s mode of operation, the status

of the system, and the operations and/or conditions of displayed

functions. Three LEDs at the top of the ATC-600 provide a quick

snapshot of the unit’s status (Mode). Seven LEDs, just above the

display window, indicate which portions of the mimic bus are

active, and the actual status of both sources and load. The remaining seven LEDs, just below the display window, are lit to indicate

the identity of information being displayed.

Automatic Mode LED

This LED blinks green indicating that the ATC-600 is operating

and providing the transfer switch control function in keeping with

programmed setpoints. If the LED is not lit or is on continuously, a

problem may be indicated.

Test Mode LED

This LED is lit red upon entering the Test Mode. The Test Mode

can only be entered with the LEDs below the display window not

lit. When a test is initiated, the Status LED lights. Both LEDs will

turn off upon the successful completion of a test cycle.

Program Mode LED

This LED is lit red when the Run/Program switch on the rear of the

chassis is in the Program position. This condition permits programming of control setpoints. When the setpoints LED is lit indicating that existing setpoints can be changed, the Program Mode

LED blinks.

Source 1 Available - Status LED

This LED is lit amber if Source 1 meets the criteria for programmed Source 1 setpoints.

Source 1 Preferred - Status LED

This LED is lit red if Source 1 is the preferred source choice.

Source 1 Connected - Status LED

This LED is lit green if Source 1 is connected. This is accomplished by sensing the Source 1 breaker via the S1 closed auxiliary contact.

Source 2 Available - Status LED

This LED is lit amber if Source 2 meets the criteria for programmed Source 2 setpoints.

Source 2 Preferred - Status LED

This LED is lit red if Source 2 is the preferred source choice.

Source 2 Connected - Status LED

This LED is lit red if Source 2 is connected. This is accomplished

by sensing the Source 2 breaker via the S2 closed auxiliary contact.

Load Energized - Status LED

This LED is lit red if the load is connected to a source that is available.

CAUTION

LOAD ENERGIZE LED IS NOT A POSITIVE INDICATION THAT VOLTAGE IS NOT PRESENT ON THE LOAD TERMINALS.

Status - Display LED

This LED is lit red when action is occurring, such as a timer timing

down, and one of the other display categories has not been

selected. When the action is completed, the display goes blank

and the LED turns off. The Status position is the default position

of the display.

Source 1 - Display LED

This LED is lit green when displaying Source 1 voltage, frequency,

and status information. The LED also lights when displaying specific Source 1 setpoint information.

Source 2 - Display LED

This LED is lit red when displaying Source 2 voltage, frequency,

and status information. The LED also lights when displaying specific Source 2 setpoint information.

Load - Display LED

This LED is lit red when load voltage is being displayed.

History - Display LED

This LED is lit red when displaying historical information.

Time/Date - Display LED

This LED is lit red when displaying the time or date.

Setpoints - Display LED

This LED is lit red when displaying the programmed setpoints of

the ATC-600. When a specific displayed setpoint is associated

with one of the sources, the specific source LED will also be lit.

IB ATS-1005 For more information visit: www.eaton.com

Loading...

Loading...