Eaton APS3-300 Installation And Operation Manual

Access Power Solutions

Installation and Operation Guide

(APS3-300 Series)

Issue: IPN 997-00012-48D

Issue Date: November 2012

Refer to the separate SC200 or SC100 system controller handbook for full

details of the system controller operation -

dcpower.eaton.com/Manuals.asp

Eaton Corporation

Telecommunications Power Solutions

dcpower.eaton.com

DCinfo@eaton.com

The product discussed in this literature is subject to terms and conditions outlined in Eaton selling policies. The

sole source governing the rights and remedies of any purchaser of this equipment is the relevant Eaton selling

policy.

No warranties, express or implied, including warranties of fitness for a particular purpose or merchantability, or

warranties arising from course of dealing or usage of trade, are made regarding the information,

recommendations and descriptions contained herein.

In no event will Eaton be responsible to the purchaser or user in contract, in tort (including negligence), strict

liability or otherwise for any special, indirect, incidental or consequential damage or loss whatsoever, including but

not limited to damage or loss of use of equipment, plant or power system, cost of capital, loss of power, additional

expenses in the use of existing power facilities, or claims against the purchaser or user by its customers resulting

from the use of the information, recommendations and descriptions contained herein.

The information contained in this literature is subject to change without notice.

Subject to the right to use its equipment, Eaton Corporation does not convey any right, title or interest in its

intellectual property, including, without limitation, its patents, copyrights and know-how.

No part of this literature may be reproduced or transmitted in any form, by any means or for any purpose other

than the Purchaser’s personal use, without the express written permission of Eaton Corporation.

Eaton®, Matrix, Powerware®, IntergyTM, CellSureTM, SiteSureTM, PowerManagerIITM and DCToolsTM are trade

names, trademarks, and/or service marks of Eaton Corporation or its subsidiaries and affiliates. Unless otherwise

noted, brands, product names, trademarks or registered trademarks are the property of their respective holders.

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

About This Guide

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

i

About This Guide

Scope

This guide covers installation, operation and maintenance of Access Power Solutions (APS3-300

Series) dc power systems (APS), controlled by the SC200 or SC100 system controller.

Refer to the separate SC200 or SC100 system controller handbook for full details of the system

controller operation - dcpower.eaton.com/Manuals.asp.

Audience

This guide is intended for use by:

Installers competent in:

installing and commissioning dc power systems

safe working practices for ac and dc powered equipment

the relevant local electrical safety regulations and wiring standards

Operators and maintenance staff competent in:

operation of dc power systems

safe working practices for ac and dc powered equipment

Related Information

SC100 System Controller Operation Handbook* – IPN 997-00012-63

SC200 System Controller Operation Handbook* – IPN 997-00012-50

PowerManagerII Online Help

DCTools Online Help

SiteSure-3G Installation and Operation Guide – IPN 997-00012-51

* Download from: http://dcpower.eaton.com/Manuals.asp.

Reporting Problems with this Guide

Please use this email address to report any problems you find in this guide:

Eaton DC Product Marketing Communications

EMAIL: DCMarketingNZ@eaton.com

For Further Information and Technical Assistance

For further information and technical assistance see Worldwide Support on page 101.

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

ii

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

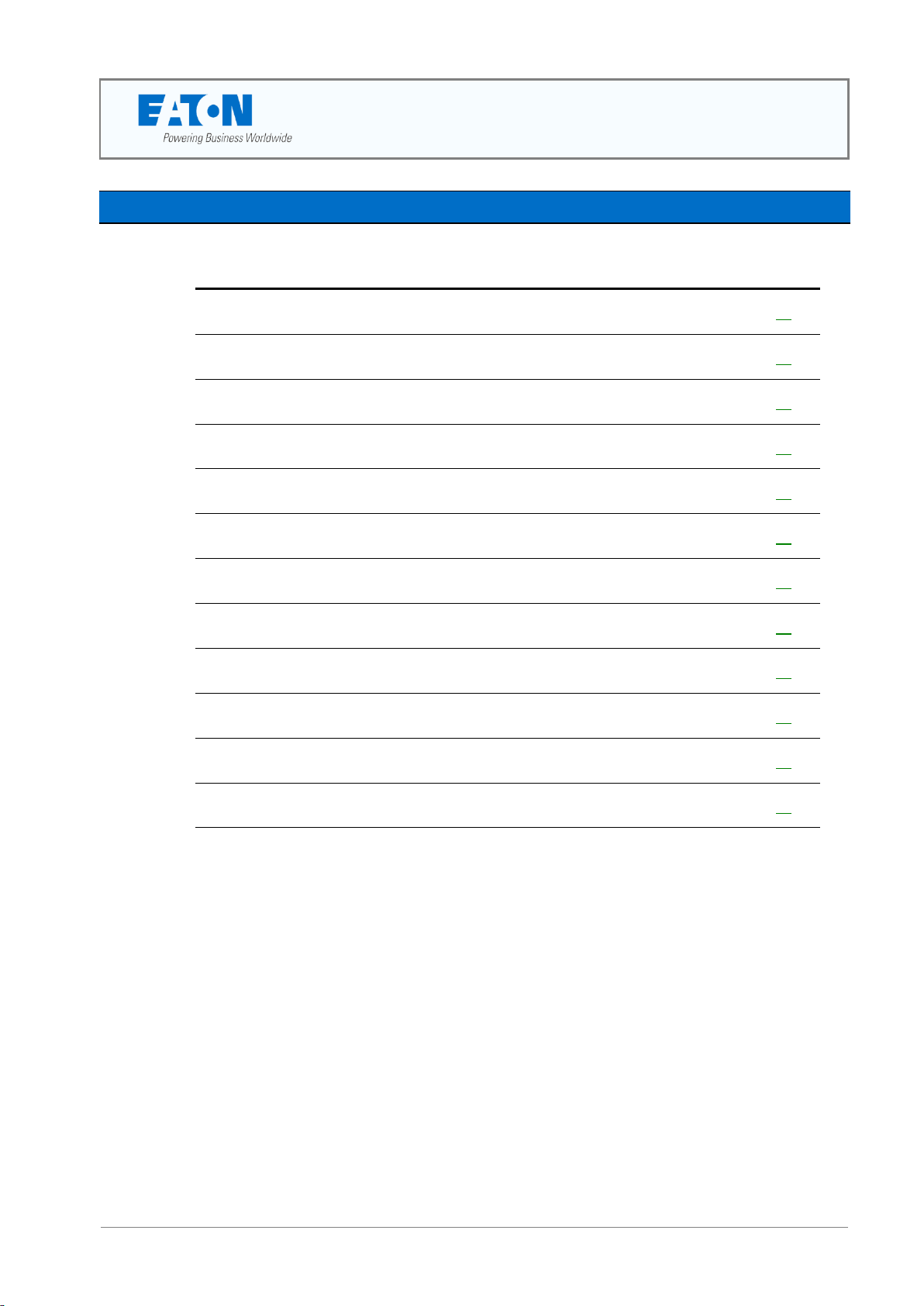

Table of Contents

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

iii

Table of Contents

About This Guide

Scope ........................................................................................................................................... i

Audience ..................................................................................................................................... i

Related Information .................................................................................................................. i

Reporting Problems with this Guide ...................................................................................... i

For Further Information and Technical Assistance .............................................................. i

Chapter 1 General Description

Overview ................................................................................................................................... 1

Access Power Solutions DC Power Systems ........................................................................ 2

Front View ........................................................................................................................................ 2

Rear View ......................................................................................................................................... 3

Rectifiers .................................................................................................................................... 4

System Controller ..................................................................................................................... 5

SC200 System Controller ................................................................................................................ 5

SC100 System Controller ................................................................................................................ 6

Compatible Software ....................................................................................................................... 6

Input/Output Board ................................................................................................................ 7

Connections ...................................................................................................................................... 8

Other Features .......................................................................................................................... 9

External communications ............................................................................................................... 9

Low Voltage Disconnect Option .................................................................................................... 9

Battery Mid-point Monitoring Option (SC200 only) ................................................................... 9

Battery Time Remaining ............................................................................................................... 10

Chapter 2 Preparation

Overview ................................................................................................................................. 11

Warnings ................................................................................................................................. 12

Inspecting the Equipment and Reporting Damage ........................................................... 14

Chapter 3 Installation

Overview ................................................................................................................................. 15

Installation Tasks .................................................................................................................... 16

Task 1 - Check the AC Supply and Earthing ...................................................................... 16

Task 2 - Prepare APS .............................................................................................................. 19

Task 3 - Connect the AC Supply Cable ............................................................................... 22

Task 4 - Mount the APS in the Rack .................................................................................... 25

Task 5 - Connect the DC Load and Battery Cables ............................................................ 26

Task 6 - Install the Batteries .................................................................................................. 27

Task 7 - Mount the Battery Temperature Sensor ............................................................... 29

Task 8 - Connect External Input/Output Cabling (if required) ....................................... 30

Task 9 - Connect Additional Input/Output (if required - SC200 only) .......................... 31

Task 10 - Connect to the AC Supply Point .......................................................................... 32

Installation Completed .......................................................................................................... 32

Chapter 4 Start-Up

Overview ................................................................................................................................. 33

Start-Up Tasks......................................................................................................................... 34

Task 1 - Inserting the Rectifiers ............................................................................................ 34

Task 2 - Pre-Power-Up Checklist ......................................................................................... 35

Task 3 - Applying AC Power ................................................................................................ 35

Task 4 - Configuring the DC Power System ....................................................................... 36

Task 5 - Applying DC Power to Battery and Load ............................................................ 37

Start-Up Completed ............................................................................................................... 38

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

iv

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

Chapter 5 System Controller

Configuration File ................................................................................................................... 40

Backup and Restore ....................................................................................................................... 40

Starting the SC200 or SC100 .................................................................................................. 41

SC200 ............................................................................................................................................... 41

SC100 ............................................................................................................................................... 41

SC200 or SC100 Operation using the Keypad and Screen ................................................. 42

Keypad Access Security ................................................................................................................ 42

Alarm Indicators ............................................................................................................................ 43

SC200 or SC100 Operation Using a PC/Laptop ................................................................. 44

Using DCTools via USB (SC200 only) ......................................................................................... 44

Using DCTools via RS232 ............................................................................................................. 44

SC200 or SC100 Identity Information ................................................................................... 46

Chapter 6 Maintenance

Overview .................................................................................................................................. 47

Troubleshooting ...................................................................................................................... 48

System Problems ............................................................................................................................ 48

System Controller Problems ......................................................................................................... 51

Replacing or Adding a Rectifier ............................................................................................ 56

Replacing or Adding a Load MCB ....................................................................................... 57

Replacing the System Controller........................................................................................... 58

Replacing the Input/Output Board ...................................................................................... 61

Battery Mid-point Monitoring (String Fail) Alarm (SC200 only) ..................................... 63

Battery Disposal and Recycling............................................................................................. 63

Appendix A Equipment and Tools

Safety Equipment ........................................................................................................................... 65

Essential Tools ................................................................................................................................ 65

Recommended Tools ..................................................................................................................... 65

Spare Parts ............................................................................................................................... 66

Standard Torque Settings ....................................................................................................... 67

Appendix B Specifications

Appendix C Cable Ratings

Appendix D Controller Menus

SC200 Menu ............................................................................................................................. 75

SC100 Menu ............................................................................................................................. 76

Appendix E Connector Pin-outs

System Controller Connector Pin-outs ................................................................................. 77

I/O Board (IOBGP-00, -01) Connector Pin-outs ................................................................. 78

Appendix F Transient Protection

Appendix G Earth Bonding

Appendix H Commissioning

Analog Inputs .......................................................................................................................... 88

System Controls ...................................................................................................................... 90

System Alarms ......................................................................................................................... 93

Digital Inputs ........................................................................................................................... 96

Digital Outputs (Relays) ........................................................................................................ 97

Commissioning Completed ................................................................................................... 97

Equipment Incident Report

Worldwide Support

Index

Chapter 1

General Description

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

1

Topic Page

Access Power Solutions DC Power Systems 2

Rectifiers 4

System Controller 5

Input/Output Board 7

Other Features 9

C h a p t e r 1

General Description

Overview

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

2

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

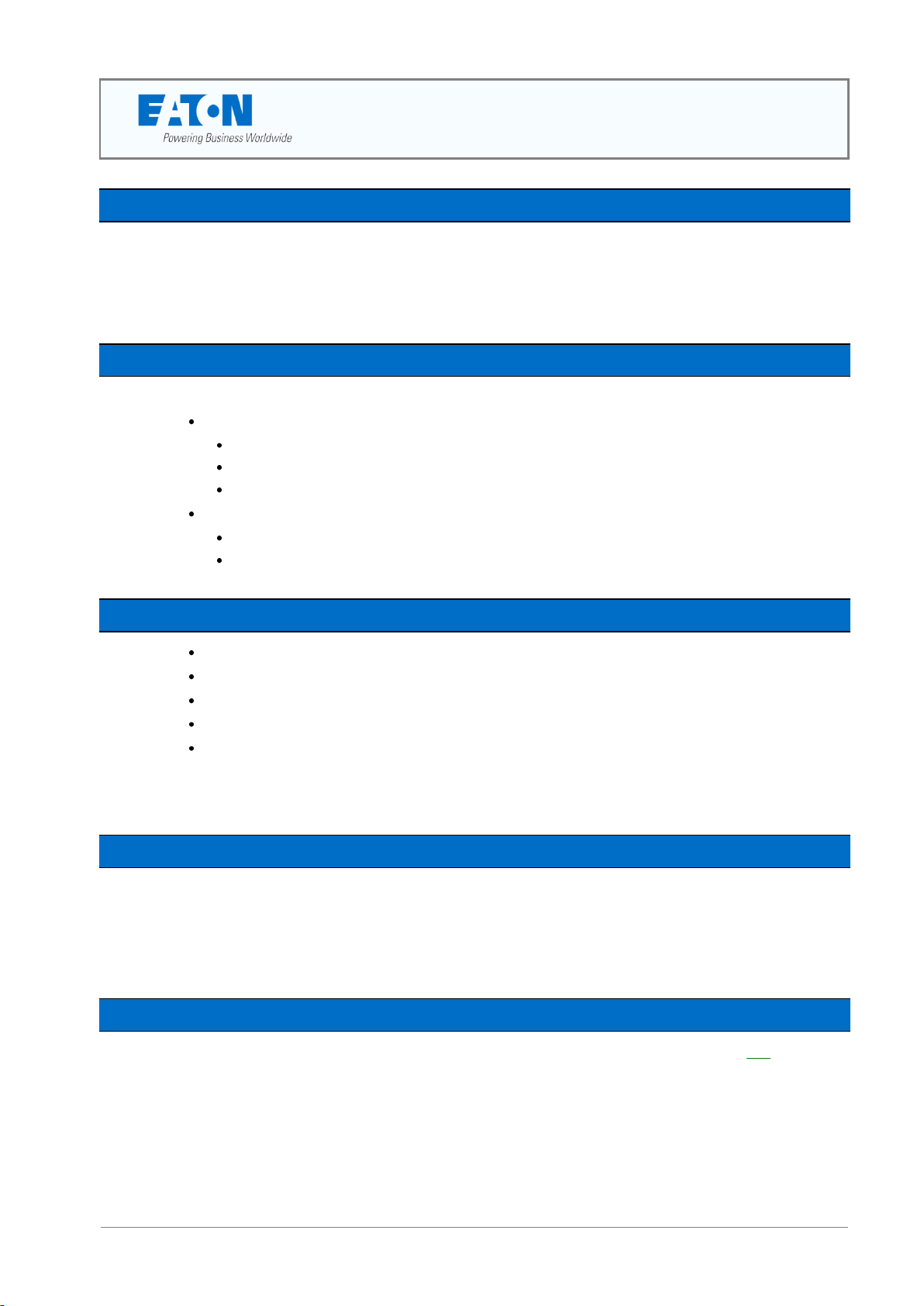

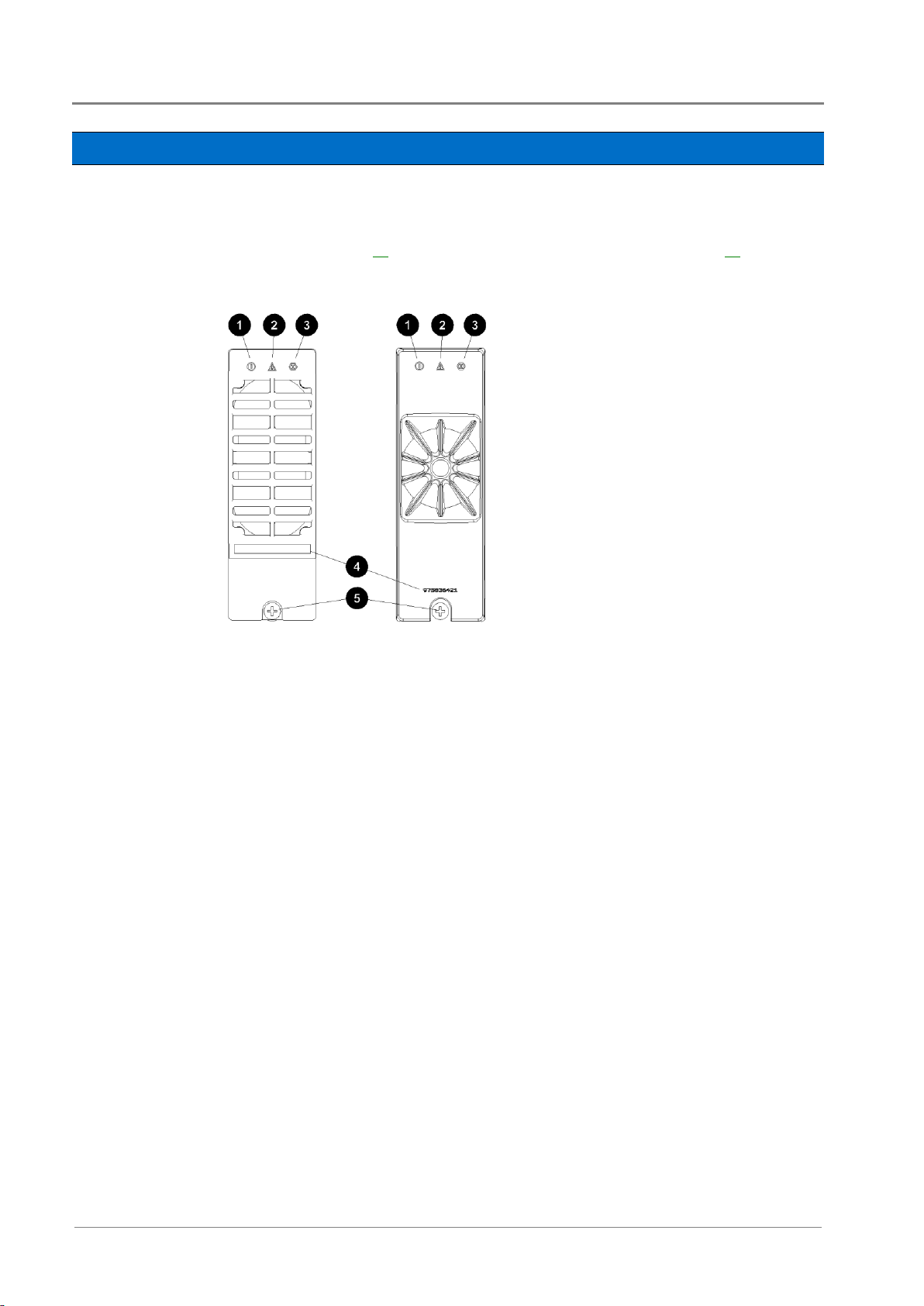

System labels

Rectifier modules (see details on page 4)

SC200 or SC100 system controller (see details

on page 5)

Integrated dc distribution with up to 10 Load and

2 Battery Miniature Circuit Breakers (MCBs)

DC distribution cover

DC common bus battery terminals

DC common bus load terminals

Voltage Feed Module with connector for optional

SiteSure-3G I/O module

Access Power Solutions DC Power Systems

Front View

Optional top cover not shown (IPN: 621-08919-30).

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

3

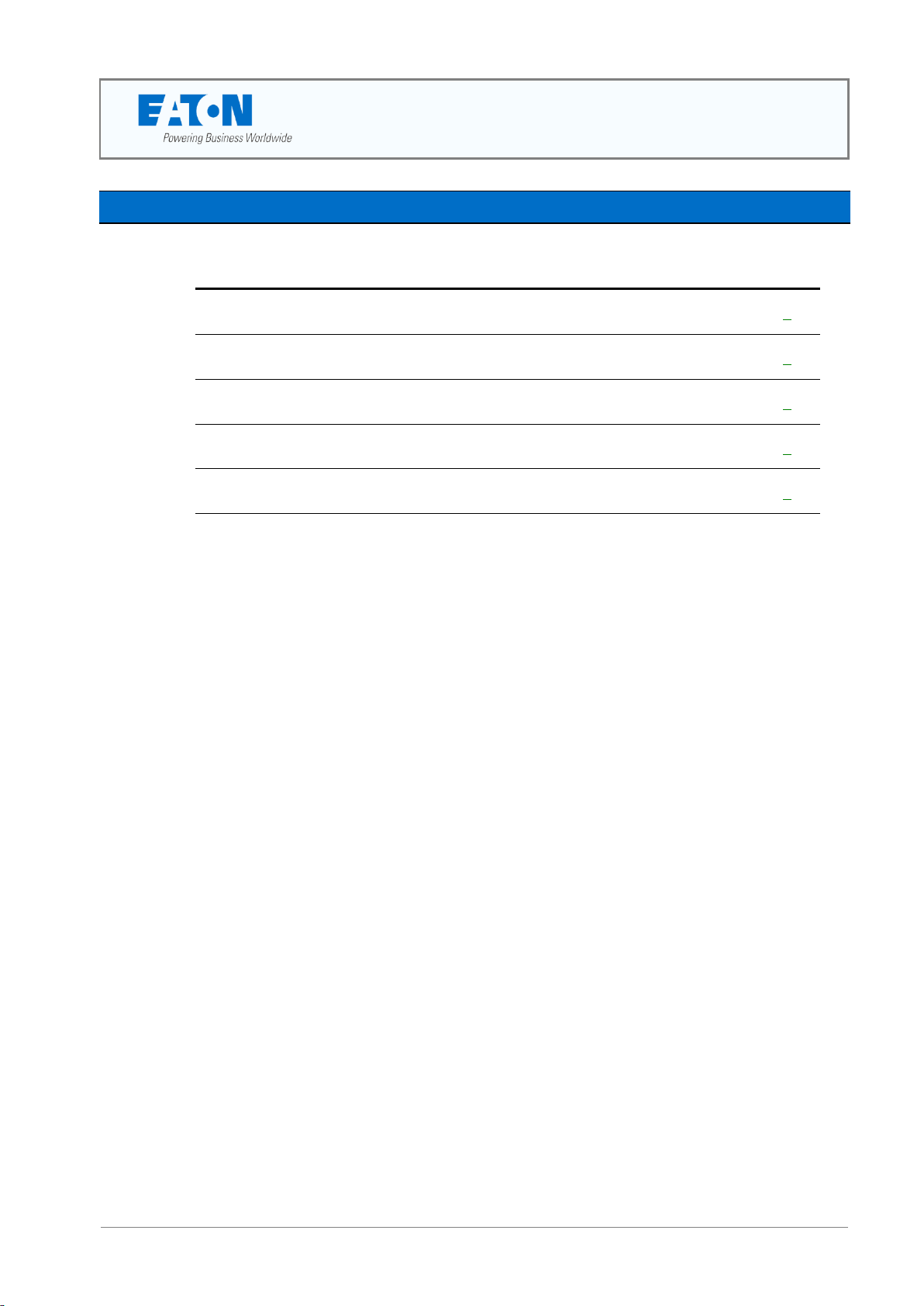

AC terminal cover

AC phase/neutral terminals (see connection

details on page 22)

AC earth conductor connection point (see

connection details on page 22)

AC cable entry gland

Cable tie points

Optional Low Voltage Disconnect (LVD) (see

details on page 9)

Load and battery cable tie rod

I/O Board (see details on page 7)

Rear View

General Description

AC supply cord(s) may be pre-fitted.

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

4

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

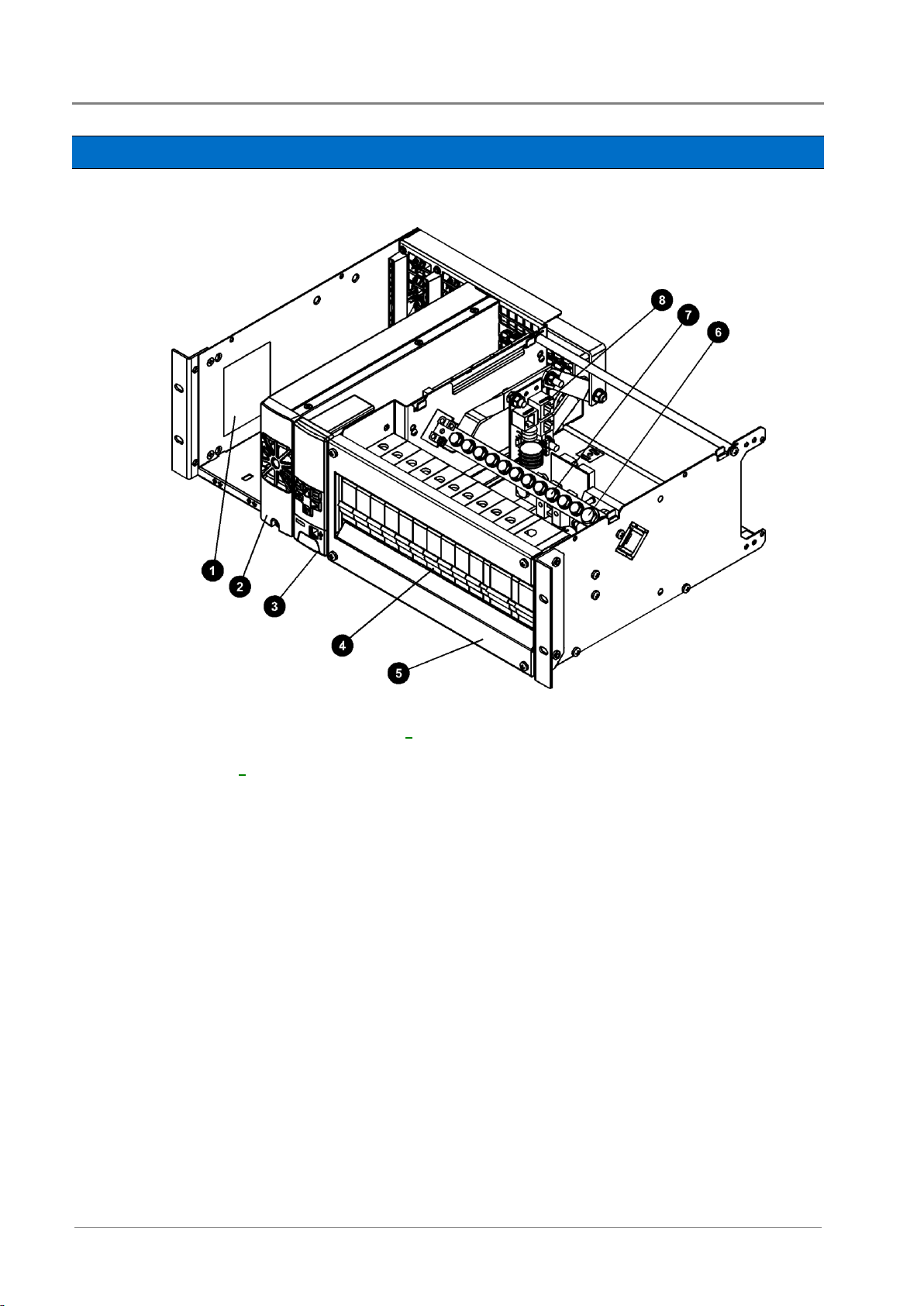

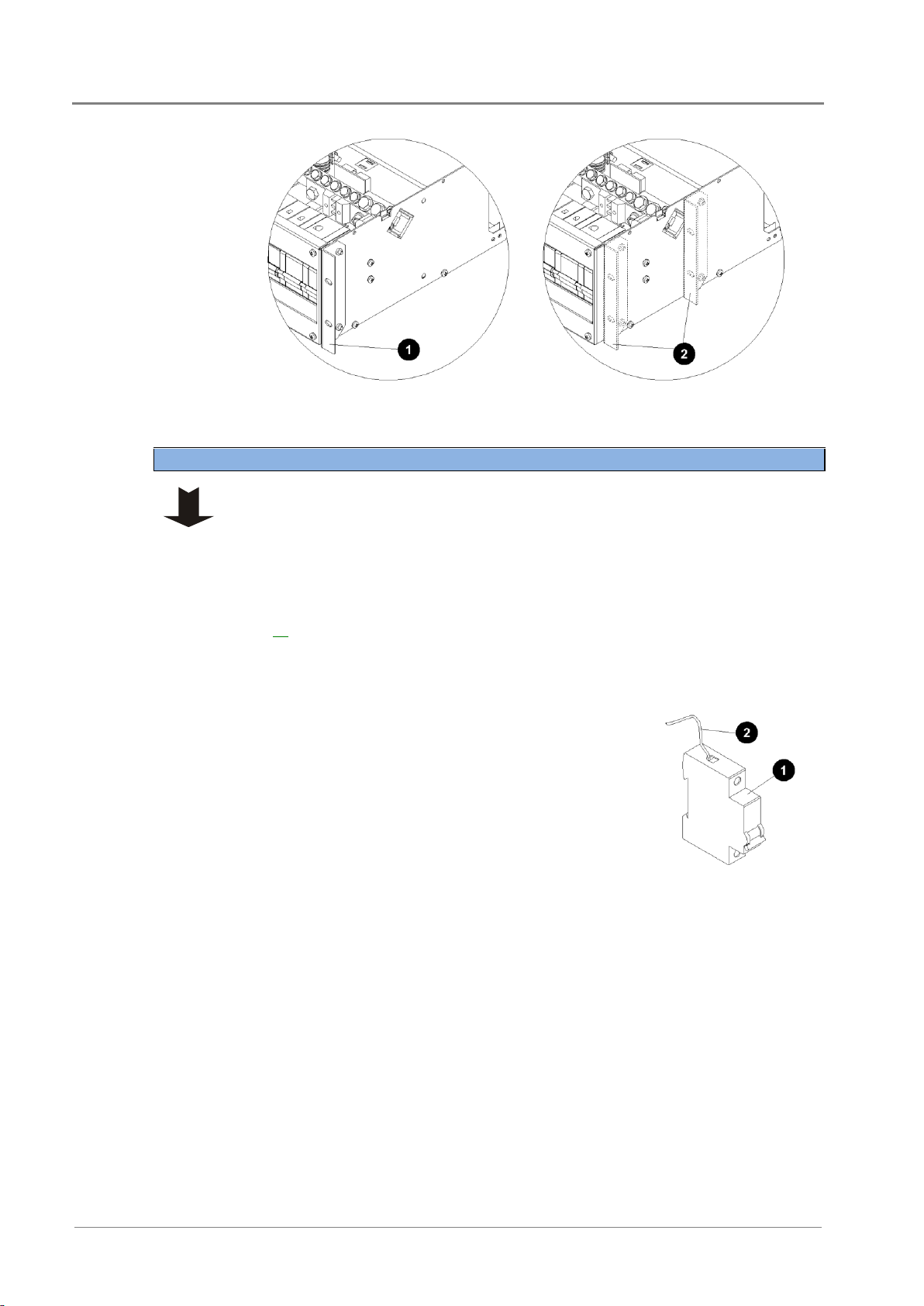

Left: APR24-3G and APR48-3G

Right: APR48-ES

Power On LED (Green)

Minor Alarm LED (Yellow)

Major Alarm LED (Red)

Serial Number

Retaining Screw. Tighten to 1.5Nm

(13.3 inch-pounds).

Rectifiers

Access Power Solutions are fitted with either 48V, 2000W (APR48-ES); 48V, 1800W (APR48-3G);

48V, 900W (EPR48-3G) or 24V, 1440W (APR24-3G) rectifiers. The rectifiers are fan-cooled and

hot-pluggable.

See Specifications on page 69 for further information. See Troubleshooting on page 48 for details of

rectifier alarms.

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

5

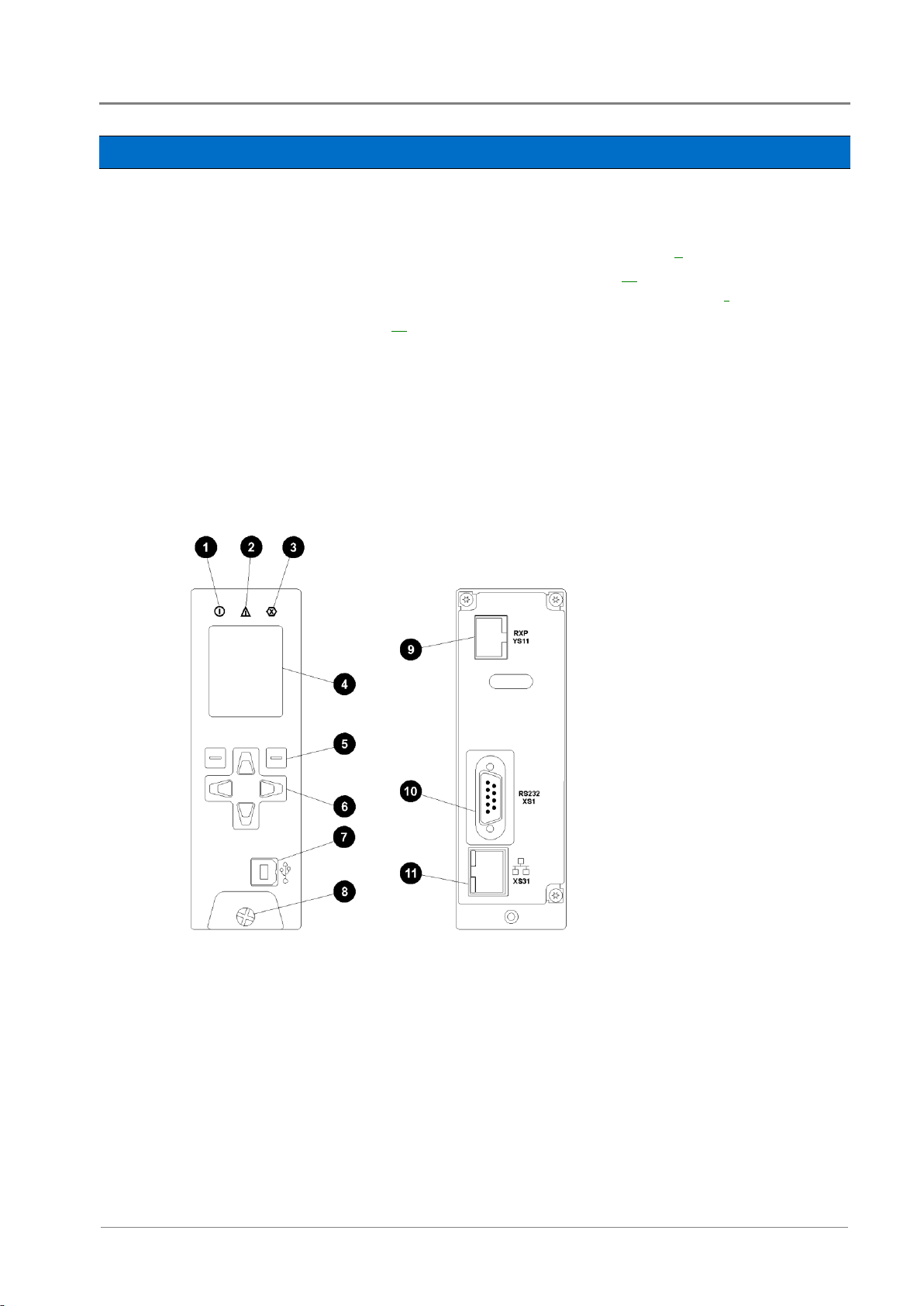

Power on LED (green)

Minor alarm LED (yellow)

Critical/Major alarm LED (red)

Color LCD

Soft keys (2)

Navigation keys (4)

USB 1.1 connector (12Mb/s)

Retaining screw

Power and system

communications connector

RS232 connector

Ethernet connector and

status LEDs

System Controller

The SC200 or SC100 system controller provides control, communications and alarm functions.

The system controller is supplied pre-configured. Configuration changes can be made with the

keypad, or via a PC connected to the USB connector (SC200) or RS232 (SC100) connector. Or

changes can be made remotely (see External Communications on page 9).

For basic operating information see System Controller on page 39. For further details refer to

SC200 System Controller

the System Controller Operation Handbook (see Related Information on page i).

See Troubleshooting on page 48 for details of system controller alarms.

The SC200 system controller is an advanced control and monitoring solution which provides a

full suite of communications options, including built-in Ethernet interface, Web server, and

SNMP agent.

Alarm notifications may be by Email, SNMP traps, SMS text messaging, dial-out to

PowerManagerII remote monitoring software, or relay contact closures.

General Description

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

6

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

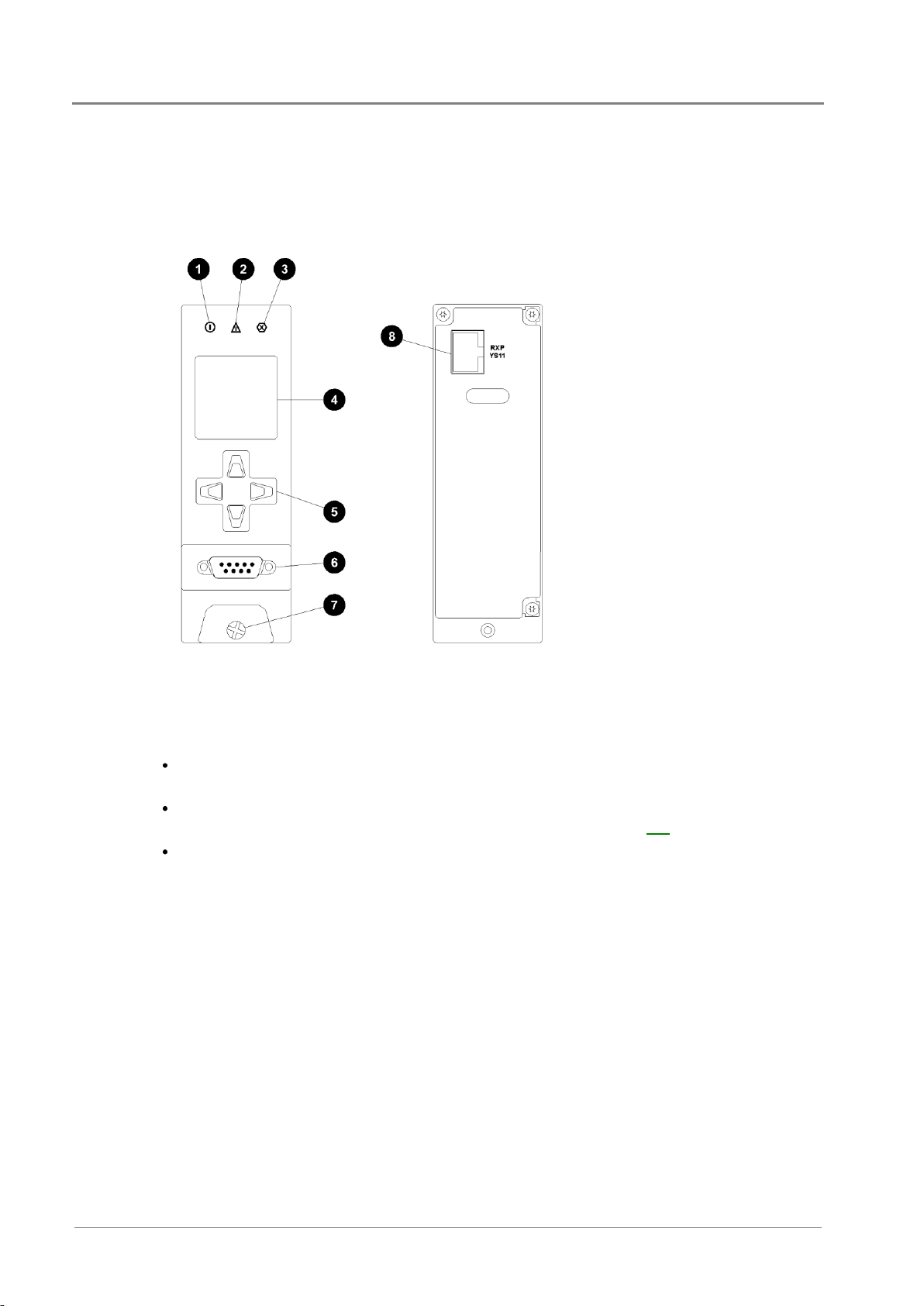

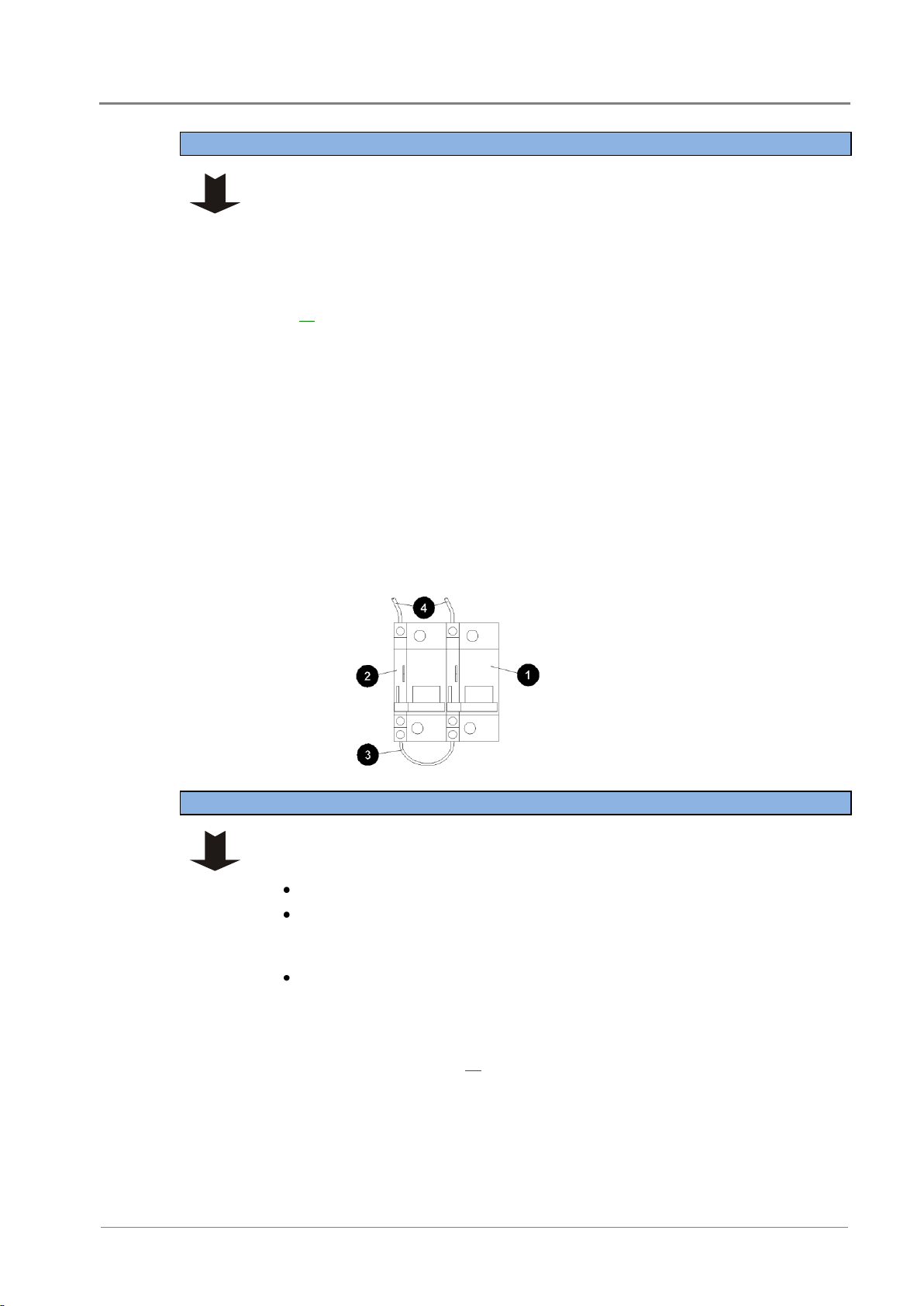

Power on LED (green)

Minor alarm LED (yellow)

Critical/Major alarm LED (red)

LCD

Navigation keys (4)

RS232 D9M connector

Retaining screw

Power and system

communications connector

SC100 System Controller

The SC100 system controller is a full-featured control and monitoring solution which provides

alarm notifications via dial-out modem to PowerManagerII remote monitoring software, SMS

text messaging, or by relay contact closures.

Compatible Software

The following software is compatible with the SC200 or SC100 system controller:

DCTools Configuration Software. Latest version is available free from

dcpower.eaton.com/downloads.

PowerManagerII Remote Control and Monitoring Software. Contact your Eaton dc product

supplier for further information (see Worldwide Support on page 101).

Recommended web browsers (SC200 only): Microsoft Internet Explorer 8 or later (IE6 is

compatible but with reduced performance), Mozilla Firefox 3.0 or later.

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

7

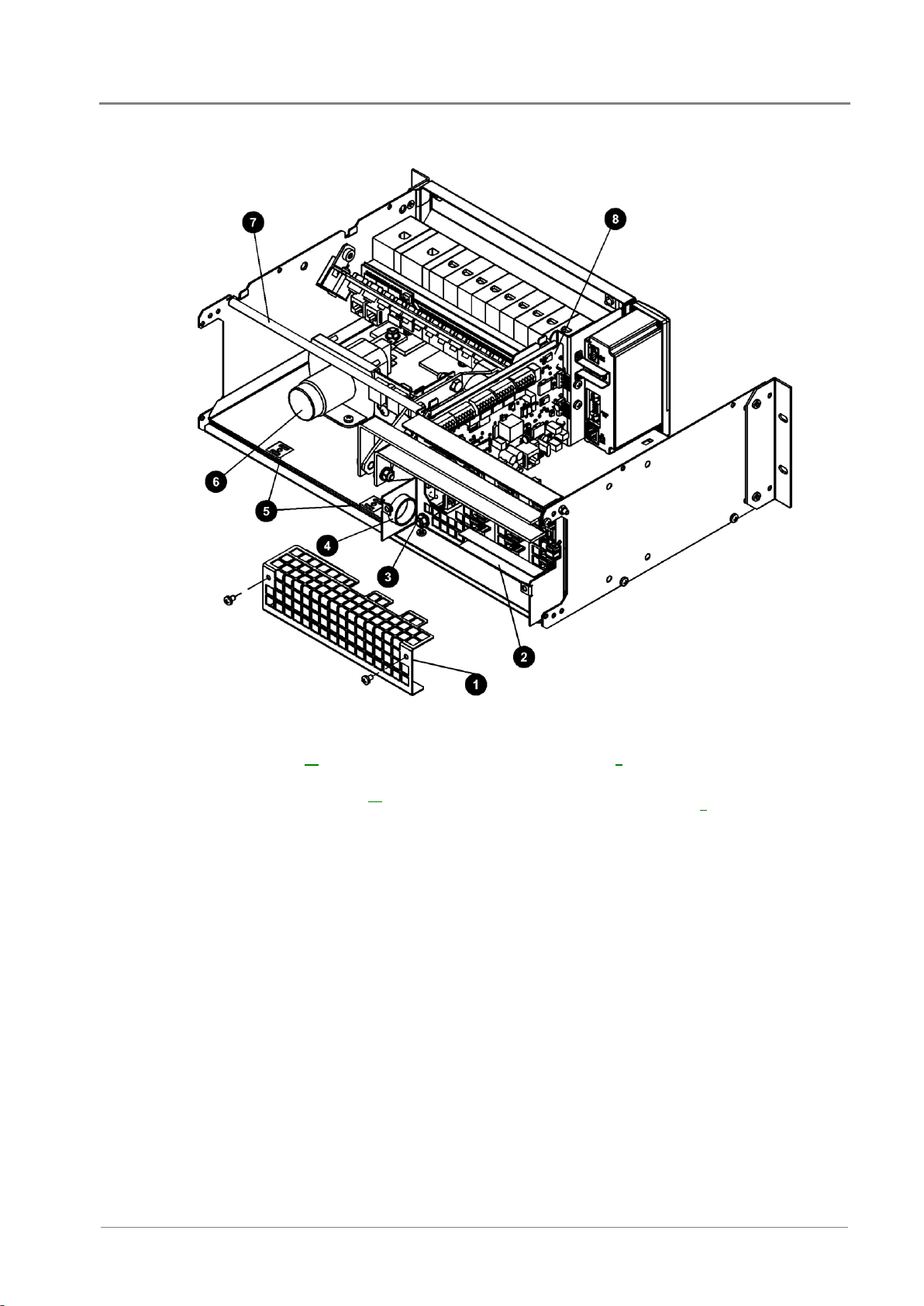

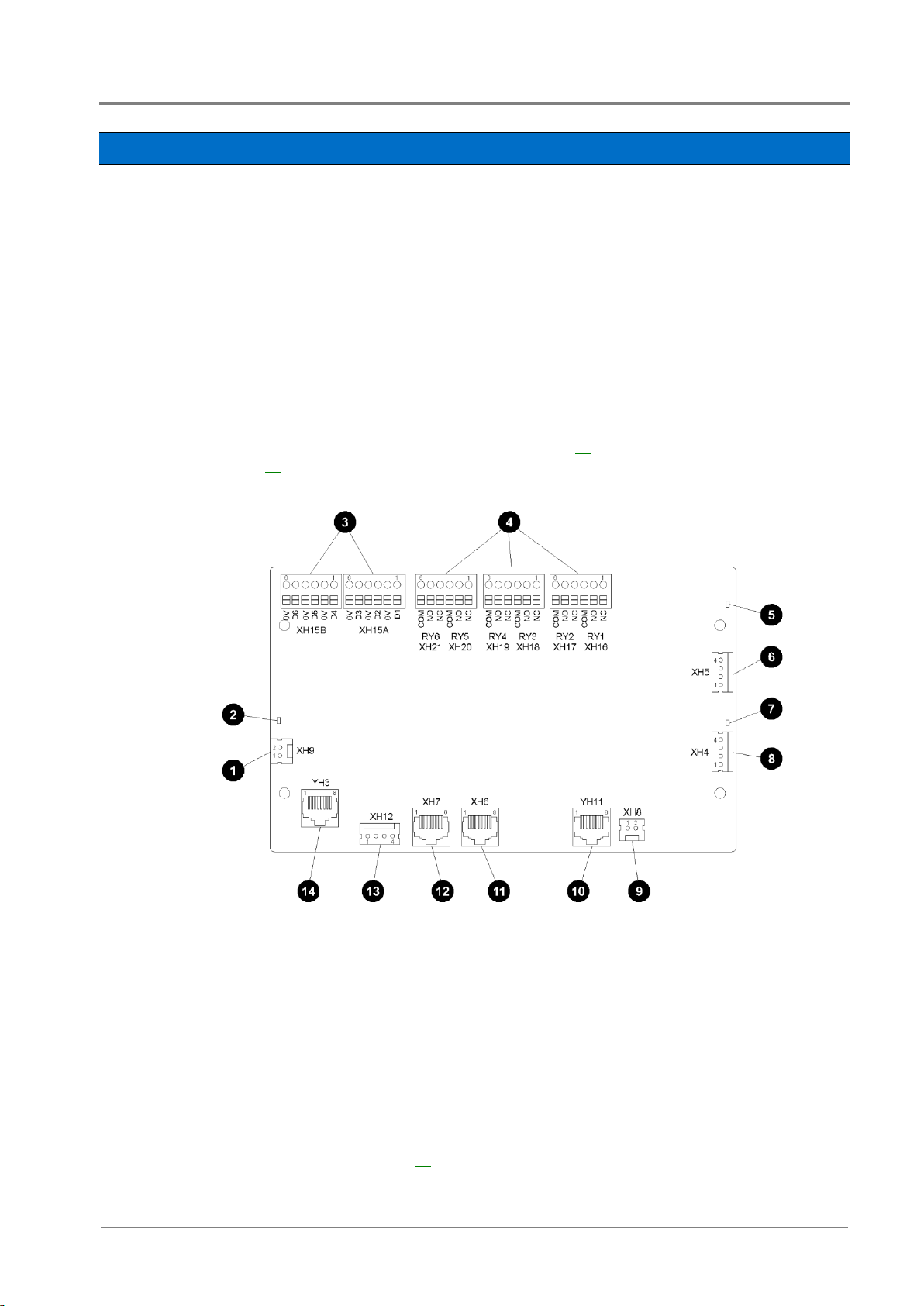

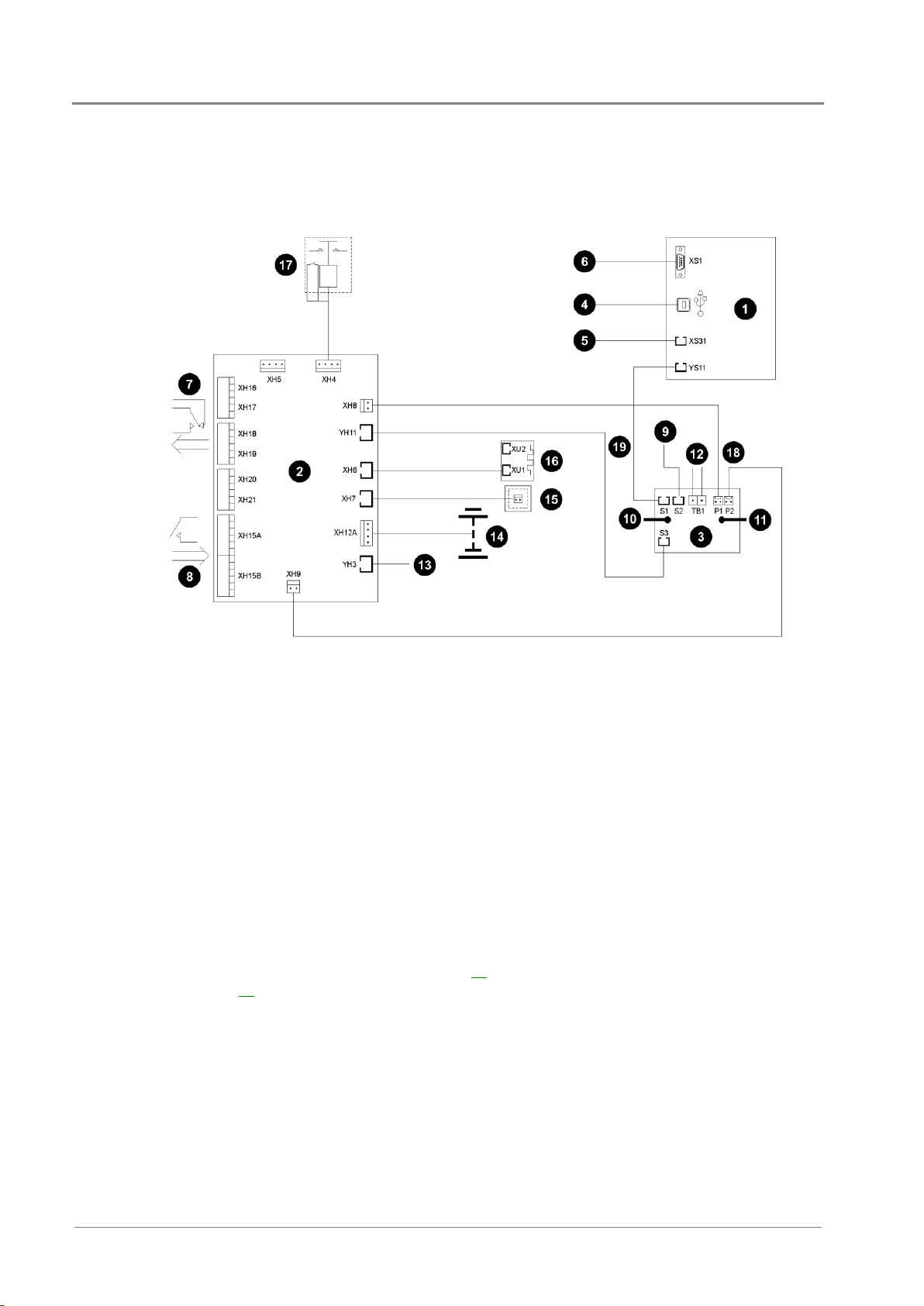

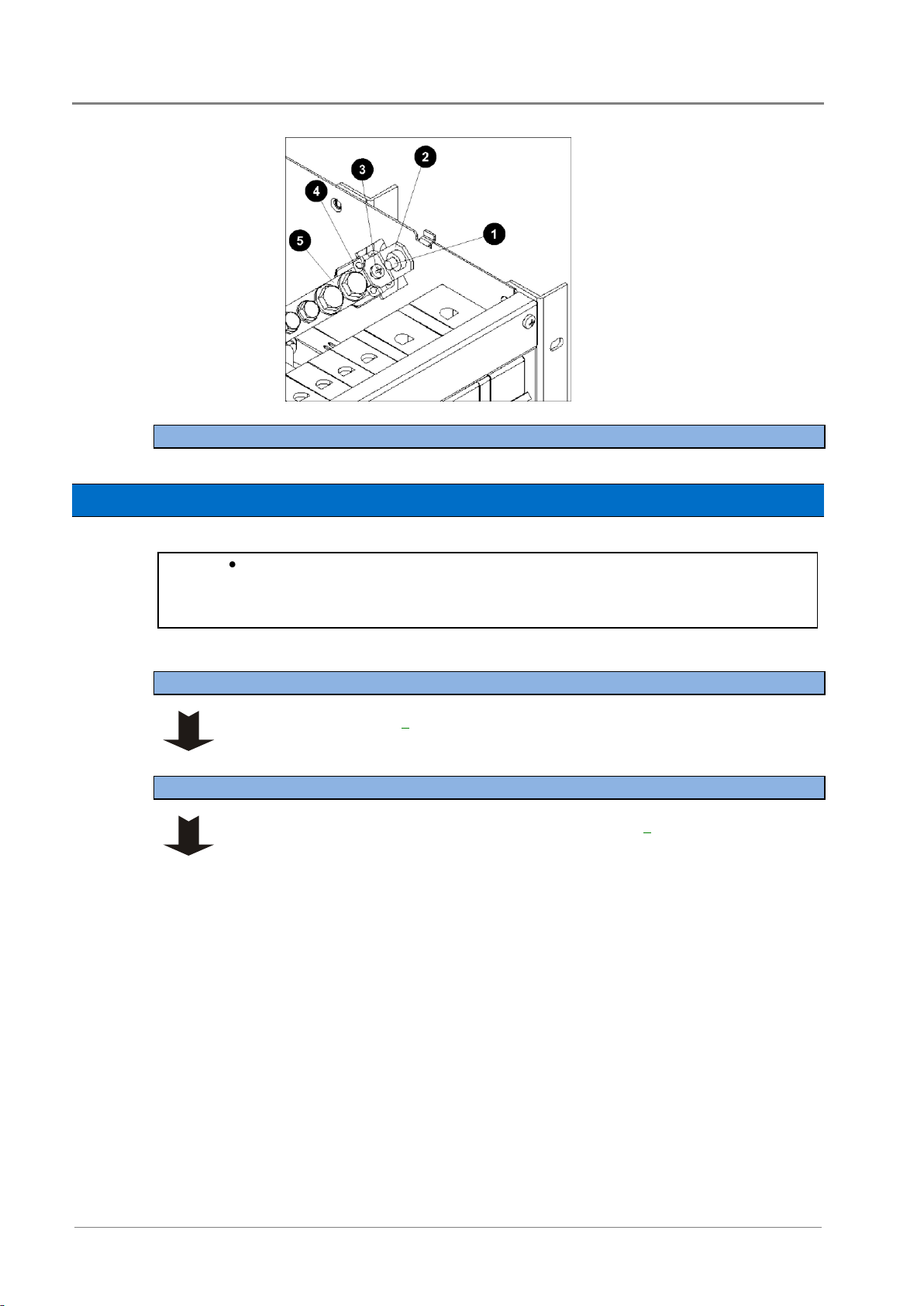

Sensors:

Current - 3, Bus voltage - 1, Temperature - 2, Battery Mid-point - 4

(SC200 only)

Input/Output:

Digital inputs: 4 pre-defined system functions, 6 user-defined

Relay outputs: 6 (one also used as Monitor OK alarm)

LVD contactor outputs: 2

Bus voltage sense input - XH9

Power/Comms OK LED (green)

Digital inputs D1-D6 (6 user defined) - XH15A,

XH15B

Digital (relay) outputs RY1-RY6 (6) - XH16-XH21

LVD contactor 2 status LED (green)

LVD contactor 2 connector - XH5

LVD contactor 1 status LED (green)

LVD contactor 1 connector - XH4

LVD power input connector - XH8

Power and RXP comms input - YH11

Current sense inputs (3) - XH6

Temperature sense inputs (2) - XH7

Battery Mid-point Monitoring sense inputs (SC200

only) - XH12

DC power system digital inputs (4 pre-defined:

Load Fuse Fail, Battery Fuse Fail, AC Distribution

Fan Fail, AC Distribution MOV Fail) - YH3

Input/Output Board

The input/output (I/O) board provides the I/O interfaces and connections for the SC200 or

SC100 system controller.

The I/O board includes a range of sense inputs for dc power system control and monitoring. It

also allows real time data collection from building services and other external devices, and relay

outputs for alarm signals or control of external devices.

The I/O functions are:

For input and output specifications see details on page 70. For connector pin-outs see details on

page 78.

General Description

See Troubleshooting on page 48 for details of I/O board LED signals.

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

8

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

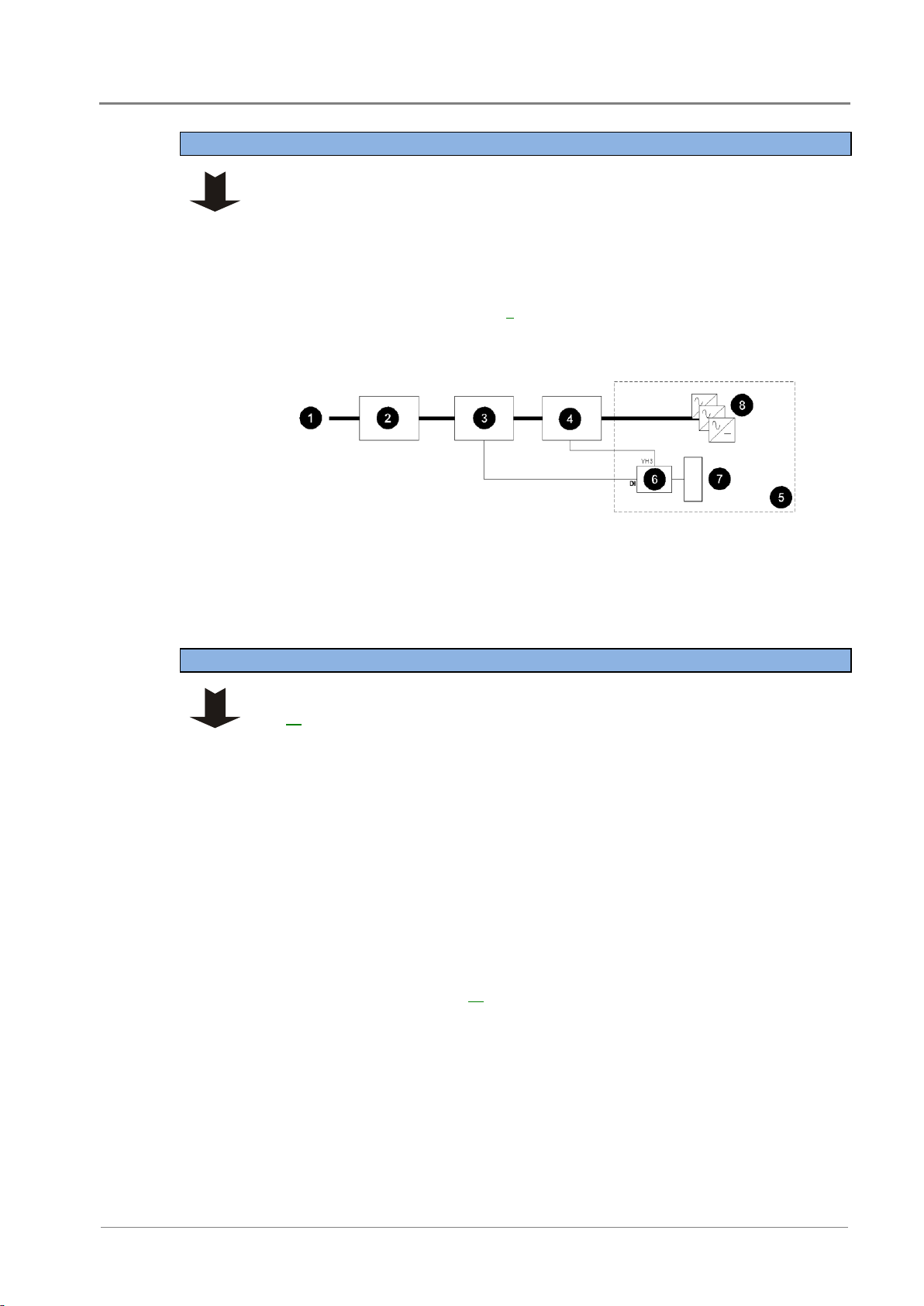

SC200 or SC100 system controller

I/O board

Voltage feed module

USB communications (SC200 only)

Ethernet communications (SC200 only)

RS232 communications

Digital relay outputs (6) to external devices

and/or alarm indication system

Digital inputs (6) from external voltage-free

switches or relay contacts

Connection to additional I/O board(s) and/or

SiteSure-3G I/O module(s) (SC200 only)

Connection to dc common bus

Connection to dc live bus

Communications to rectifiers

DC power system digital inputs (Load Fuse Fail,

Battery Fuse Fail, AC Distribution Fan Fail, AC

Distribution MOV Fail)

Connections to battery mid-points (4)

(SC200 only)

Connection to temperature sensors (2)

Connection to current sensors (3)

Optional LVD contactor and auxiliary switch

Bus voltage sense and LVD power connections

I/O and system controller power and RXP comms

connection

Connections

The following diagram shows the connections between the SC200 or SC100, the I/O board, the

other dc power system components and external devices.

For connector pin-outs see details on page 78. For input and output specifications see details on

page 69.

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

9

Communications options

SC200

SC100

Communication with DCTools via USB

-

Communication with DCTools or PowerManagerII via RS232

Communication with DCTools or PowerManagerII via

an external PSTN or GSM modem (dial-in and dial-out on alarm)

Communication with DCTools or PowerManagerII via Ethernet

-

Communication with web browser software via an IP network

-

Communication with a Network Management System (NMS) using

SNMP

-

Communication with a Building Management System (BMS) using

Modbus

-

Alarm and status messages to GSM Short Messaging Service (SMS)

text capable cell phones

Communication with an alarm management system using

voltage-free relay contacts (on an IOBGP I/O board)

Other Features

External communications

Refer to the system controller handbook for information on these communications options.

General Description

Low Voltage Disconnect Option

An optional Low Voltage Disconnect (LVD) is available for the Access Power Solutions

(APS3-300 Series). See the diagram on page 3 for location. This is connected as a battery

disconnect.

For information on operation see Low Voltage Disconnect (LVD) in the System Controller

Operation Handbook.

Battery Mid-point Monitoring Option (SC200 only)

Battery Mid-point Monitoring provides a cost-effective method for the early detection of

internal battery faults. The voltages of the two halves of a battery string are measured and the

system controller generates an alarm signal if a voltage imbalance is detected.

A voltage imbalance is an indication that one or more cells has an internal fault. Further

investigation can then isolate the faulty cell(s) and action can be taken to correct the problem

and prevent a total battery failure.

To connect Battery Mid-point Monitoring see details on page 28. If a String Fail alarm is

generated see Troubleshooting on page 48.

To ensure reliable operation Mid-point Monitoring operates only when the battery is in float

charge and after a configurable lockout period since the last battery discharge, Fast Charge,

Equalize or Battery Test.

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

10

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

Battery Time Remaining

The SC200 or SC100 obtains characterization data from either periodic battery discharges

(SC100) or every full battery discharge (SC200), to a specified end voltage.

During a battery discharge, the SC200 or SC100 uses this characterization data to calculate an

estimated time until the battery will reach the specified end voltage.

If a battery disconnect LVD is fitted then the end voltage will usually be the voltage at which the

LVD disconnects the battery.

Battery Time Remaining is designed for a constant power load. The accuracy of the time

remaining calculation will be reduced if the dc power system is connected to a predominantly

resistive (constant current) load.

The time remaining calculation will not be correct if a non-essential load is disconnected during

the battery discharge.

For details refer to Battery Time Remaining in the SC200 or SC100 System Controller Operation

Handbook (see Related Information on page i).

Chapter 2

Preparation

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

11

Topic Page

Warnings 12

Inspecting the Equipment and Reporting Damage 14

C h a p t e r 2

Preparation

Overview

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

12

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

Electrical Safety

Access Power Solutions (APS3-300 Series) dc power systems must be mounted in an enclosed cabinet that

meets safety and fire enclosure requirements as specified in AS/NZS 60950.1 and EN 60950-1.

The dc power system may be powered from multiple ac sources. All ac sources must be isolated before

internally servicing the equipment.

The dc power system MCBs are not a disconnect device. The APS dc power system must be connected to

a suitable upstream ac supply disconnect device such as Miniature Circuit Breaker(s) (MCB) or fuses.

This device must isolate both the phase and neutral conductors in single-phase and three-phase

connections, unless the neutral conductor is clearly identified.

If the dc power system is to be installed in a location where the ambient temperature may rise above 50ºC

(122ºF), then 90°C rated cable rated cable must be used for all connections.

The dc power system is not compatible with IT (Impedance Terra) ac power distribution topologies. For

advice see Worldwide Support on page 101.

A registered electrician (or suitably qualified person) must check the integrity of the installed cabling,

BEFORE the dc power system is powered up.

Tasks must be performed in the sequence documented in this guide.

Location and Environment

An APS dc power system must be installed in a restricted access location.

For ease of access and to maintain optimum system cooling observe the clearances stated on page 25.

Dust build-up within the dc power system may cause premature failure. In dusty environments filter the

ventilation air entering the equipment room. Ensure regular cleaning of the air filters.

Do not allow water or any foreign object to enter the dc power system. Do not place objects containing

liquid on top of or near the unit.

Flooded cell and VRLA lead acid batteries can emit explosive gases and must be installed with adequate

ventilation. Refer to the battery manufacturer or supplier for advice on minimum ventilation levels.

Reverse Polarity

Always check that the battery cables have been terminated to the correct system polarity BEFORE

connecting the batteries or closing the battery disconnect device. Connecting batteries to the dc power

system with incorrect system polarity will damage the rectifiers and void all warranty claims.

Hazardous Energy Levels

Rectifiers and batteries contain hazardous energy levels. Only personnel trained and experienced in dc

power systems are to service/maintain this equipment.

Always use insulated tools.

Do not short-circuit the live and common bus bars or cables.

Warnings

This section contains important warnings. Read these warnings before installing or operating an

Eaton Access Power Solutions dc power system.

Preparation

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

13

Batteries

The plastic cases of batteries installed in Eaton dc power system racks must have a flammability rating of

UL 94-V2 or better.

Flooded cell and VRLA lead acid batteries can emit explosive gases and must be installed with adequate

ventilation. Refer to the battery manufacturer or supplier for advice on minimum ventilation levels.

Do not wear a synthetic dust-coat or overalls. Synthetic fabrics can hold static electric charges that create

sparks during discharge.

Remove rings, wristwatch and other metal jewelry that might be exposed to battery terminals, before

installing batteries.

Batteries are powerful sources of energy and present a potential electrical shock and energy hazard. The

energy hazard is always present, even if the batteries are not connected. Avoid short circuiting terminals

of opposite polarity.

Always use insulated tools.

Do not place tools, loose cables or metal objects (such as interconnecting bars) on top of batteries.

Do not drop tools, loose cables or metal objects onto intercell connections or terminals of opposite

polarity.

Only terminate cables and interconnecting bars after confirming that the termination will not create a

short circuit.

Always tighten battery terminal bolts according to the battery manufacturer’s specification. Failing to do

so can cause erratic battery performance, possible damage to the battery, and/or personal injury.

There is a risk of electric shock or explosion if a battery is replaced by an incorrect type.

Dispose of batteries according to the instructions on page 63.

Rectifiers

Only operate the rectifiers when the surrounding area is clean and dust free.

To reduce the risk of electric shock and maintain optimum system cooling, always cover empty rectifier

slots with blanking panels.

To avoid electrical shock, do not place hands inside the rectifier magazine.

Rectifier cases may exceed 100ºC (212ºF), especially after prolonged operation. Use suitable gloves when

removing a rectifier from the magazine.

Do not attempt to disassemble faulty rectifiers. Return them (in their original packaging) with a

completed Equipment Incident Report on page 99.

Ensure that any upstream Residual Current Devices (RCDs) are appropriately rated for the rectifiers'

maximum earth leakage current (see Specifications on page 69 for value).

DC Distribution(s)

The dc common bus of the dc power system can be connected to earth (ground). If this connection is

made all of the following conditions must be met:

Your equipment and the dc power system must be located within the same premises.

No switching or disconnecting devices are allowed in the conductor between the dc common line

and the point of connection to the earth electrode conductor.

See Connecting the Output to Earth on page 19 for further information.

For installations in the United States, Listed compression connectors must be used to terminate Listed

field-wired conductors where required. For all installations, use the appropriate connector for the

conductor size as specified by the connector manufacturer. And use only the connector manufacturer's

recommended tooling or tooling approved for that connector.

Follow all applicable local and national rules and regulations when making field connections.

Tighten all electrical connections to the torques stated in this guide or on the manufacturer's label.

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

14

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

Servicing and Maintenance

The APS contains hazardous voltages and hazardous energy levels. Before undertaking any maintenance

task refer to the Warnings on page 12.

If a maintenance task must be performed on a "live" system then take all necessary precautions to avoid

short-circuits or disconnection of the load equipment, and follow any "live-working" instructions

applicable to the site.

Only perform the maintenance tasks described in the Maintenance chapter. All other tasks are classified

as Servicing. Servicing must only be performed according to specific instructions and only by personnel

authorized by Eaton. This includes disassembly and/or servicing of any modules.

For further information on Servicing contact your local Eaton dc product supplier, or refer to the contact

details on page 101.

EMC Compliance

This dc power system may be used in close proximity to other electronic equipment, provided

installation is carried out according to instructions in this guide. However, proper installation and

compliance with EMC standards does not guarantee that the dc power system will not respond to

electromagnetic disturbances, or will not cause interference to other equipment in a particular

installation.

In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that the interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio/TV technician for help.

Inspecting the Equipment and Reporting Damage

Unpack the equipment and inspect it carefully for possible damage that may have occurred

while in transit. Do not use any damaged equipment.

Report any damage immediately, using a completed Equipment Incident Report on page 99.

Keep the original packaging to use if any item needs to be returned for replacement or repair.

Chapter 3

Installation

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

15

Topic Page

Installation Tasks 16

Task 1 - Check the AC Supply and Earthing 16

Task 2 - Prepare APS 19

Task 3 - Connect the AC Supply Cable 22

Task 4 - Mount the APS in the Rack 25

Task 5 - Connect the DC Load and Battery Cables 26

Task 6 - Install the Batteries 27

Task 7 - Mount the Battery Temperature Sensor 29

Task 8 - Connect External Input/Output Cabling (if required) 30

Task 9 - Connect Additional Input/Output (if required - SC200 only) 31

Task 10 - Connect to the AC Supply Point 32

Installation Completed 32

C h a p t e r 3

Installation

Overview

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

16

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

Task

Description

Reference

1

Check the AC Supply and Earthing

See details on page 16

2

Prepare the APS

See details on page 19

3

Connect the AC Supply Cable

See details on page 22

4

Mount the APS in the Rack

See details on page 25

5

Connect the dc Load and Battery Cables

See details on page 26

6

Install the Batteries

See details on page 27

7

Mount the Battery Temperature Sensor

See details on page 29

8

Connect External Input/Output Cabling (if required)

See details on page 30

9

Connect Additional Input/Output (if required - SC200

only)

See details on page 31

10

Connect to the AC Supply Point

See details on page 32

1 Confirm that there is a transient protection plan (compliant with IEC 61643-12)

for the site.

For more information see Transient Protection on page 81.

2 If necessary, install suitable transient protection.

Installation Tasks

Before starting the installation, review the following information:

Required Equipment and Tools on page 65

Warnings and Cautions on page 12

Inspecting the Equipment and Reporting Damage on page 14

Complete the Installation tasks in the following order:

For installation of external communications see Communications Options in the System

Controller Operation Handbook.

Task 1 - Check the AC Supply and Earthing

It is important that the ac supply for the Access Power Solutions dc power system includes the

correct levels of protection.

Step 1 - Check transient voltage protection at the site

Installation

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

17

1 Check if the ac voltage is expected to exceed 275V (L-N).

2 If so, then it is strongly recommended that an external high voltage protection

unit (HVPU) be installed. This will automatically disconnect the ac at high

voltage and reconnect it at normal voltage.

3 Install the HVPU as in the following diagram.

4 Connect the High VAC alarm output to one of the Digital Inputs on the I/O

board (see the diagram on page 7 for location).

The High VAC alarm signal lines must be isolated from the ac supply by a

voltage-free relay contact.

AC supply

Primary transient protection devices

High voltage protection unit with alarm output

Secondary transient protection devices

(MOVs)

dc power system

I/O board

SC200 or SC100 system controller

Rectifiers

1 Check the type of ac supply. Only the types of ac supply listed in Task 3 on page

22 are suitable for the APS.

Only use a two-phase or three-phase (L-L) ac supply if referenced to earth, or a

protection system is in place so that the phase-earth voltage cannot exceed the

rating of the rectifier.

2 Check that the APS will be connected to a suitable upstream ac disconnect

device such as Miniature Circuit Breaker(s) (MCB) or fuses.

3 Check the disconnect device will isolate both the phase and neutral conductors

in single-phase and three-phase connections, unless the neutral conductor is

clearly identified.

4 Check that any Residual Current Devices (RCD) upstream of the APS are rated

for the maximum earth leakage current of the rectifiers. If necessary, install

higher rated RCD(s).

The maximum earth leakage current of Access Power Rectifiers is given in the

Specifications on page 69.

Step 2 - Check high ac voltage protection at the site

Step 3 - Check the type of ac supply, disconnect device and RCDs

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

18

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

Each rectifier has two internal fast-acting fuses. Under certain internal fault

conditions these fuses will blow.

If there is insufficient discrimination between these fuses and any upstream ac

supply-disconnect device then the upstream ac supply-disconnect device will

operate before a rectifier fuse blows. This will disconnect the ac supply to all

rectifiers.

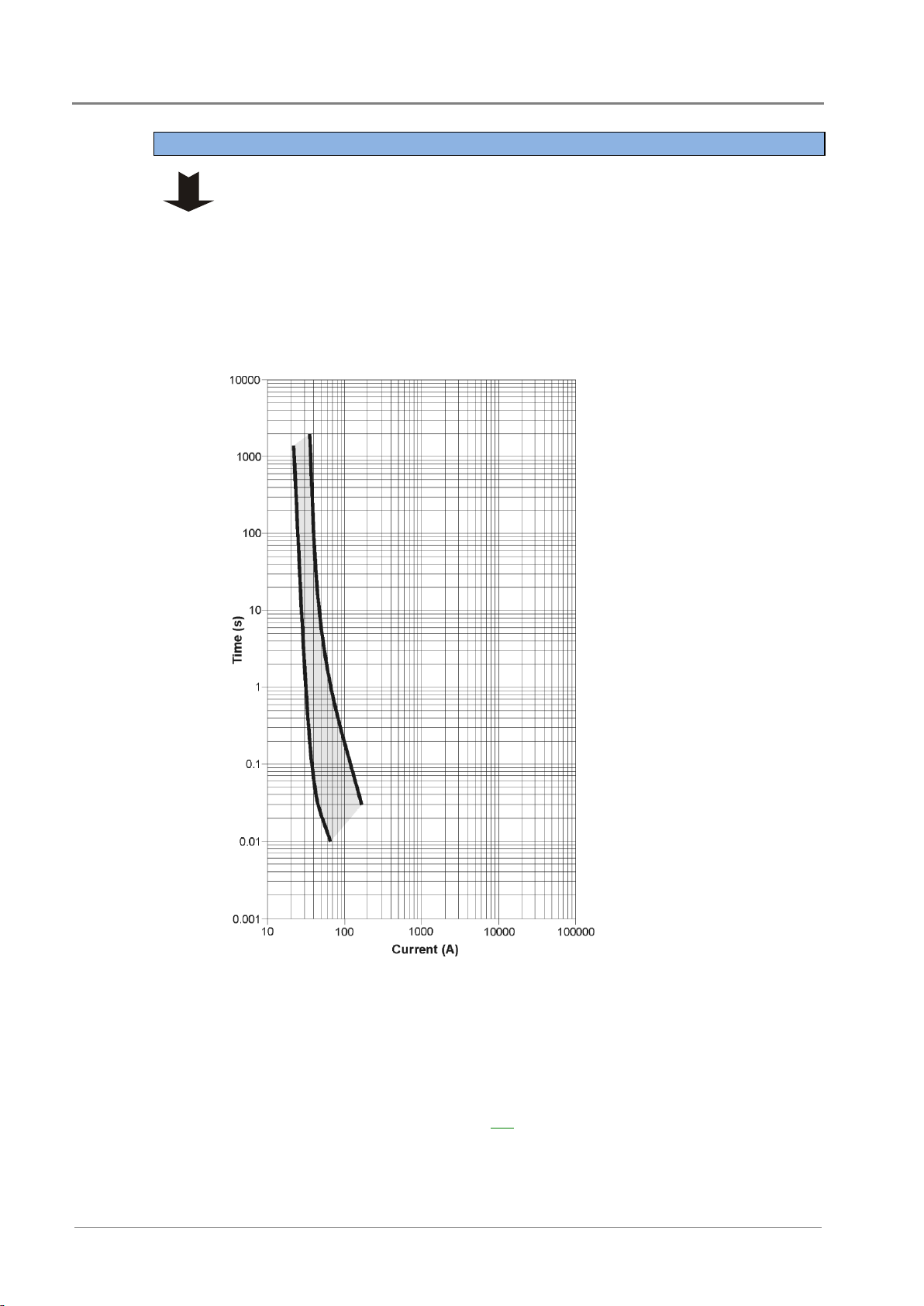

1 Check the time-current (tripping) curve(s) of all ac supply-disconnect device(s)

upstream of the APS with the following curve for the rectifier fuses.

Refer to the manufacturer's data for tripping curves.

Time-Current Curve

(minimum and

maximum) for rectifier

internal fuses (IEC

60127-2).

Source: Schurter SP 5x20

Pigtail data sheet.

2 No action is required if the time-current curves of the upstream ac

supply-disconnect devices are entirely to the right of the curves for the rectifier

fuses.

3 If the curve of an upstream ac supply-disconnect device crosses the curve for the

rectifier fuse there may not be adequate discrimination.

If necessary, replace the upstream ac supply-disconnect device to achieve

adequate discrimination. Or, contact your Eaton dc product supplier for advice

(see Worldwide Support on page 101).

Step 4 - Check ac discrimination

Installation

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

19

Confirm that all earths are brought together at one "star" point so that surge currents

cannot flow in "earth loops" and create large voltages.

For more information see Transient Protection on page 81.

Ignore this Step if the system controller is already fitted.

1 Connect the power/communications cable from the APS to the RJ45 socket YS11

(RXP) socket on the back of the system controller.

2 Fit the system controller into the APS and tighten the retaining screw.

See the diagram on page 2 for position of system controller.

The APS can be configured for either positive earth or negative earth operation.

1 Remove top cover if fitted.

2 Check the polarity label on the dc common bus bar(s).

(+) on the common bar(s) indicates positive earth. (-) indicates negative earth.

3 If the polarity of the APS matches the equipment at the site then no further action

is required.

4 If the polarity of the APS is not correct for the equipment to be powered then

contact your Eaton dc product supplier for advice (see Worldwide Support on

page 101).

APSs are pre-assembled with 19-inch rack-mounting brackets as shown in the

following diagram. If required, the brackets can be moved to alternative positions to

reduce the effective depth of the unit.

Rack-mounting brackets are also available for use in 23-inch wide racks.

1 Remove top cover if fitted.

2 Undo the two screws holding each bracket.

3 Refit the brackets at the required location. Tighten the screws.

Step 5 - Check the earthing arrangements at the site

Procedure complete

Task 2 - Prepare APS

Step 1 - Fit the system controller (if required)

Step 2 - Check polarity

Step 3 - Check position of mounting brackets

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

20

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

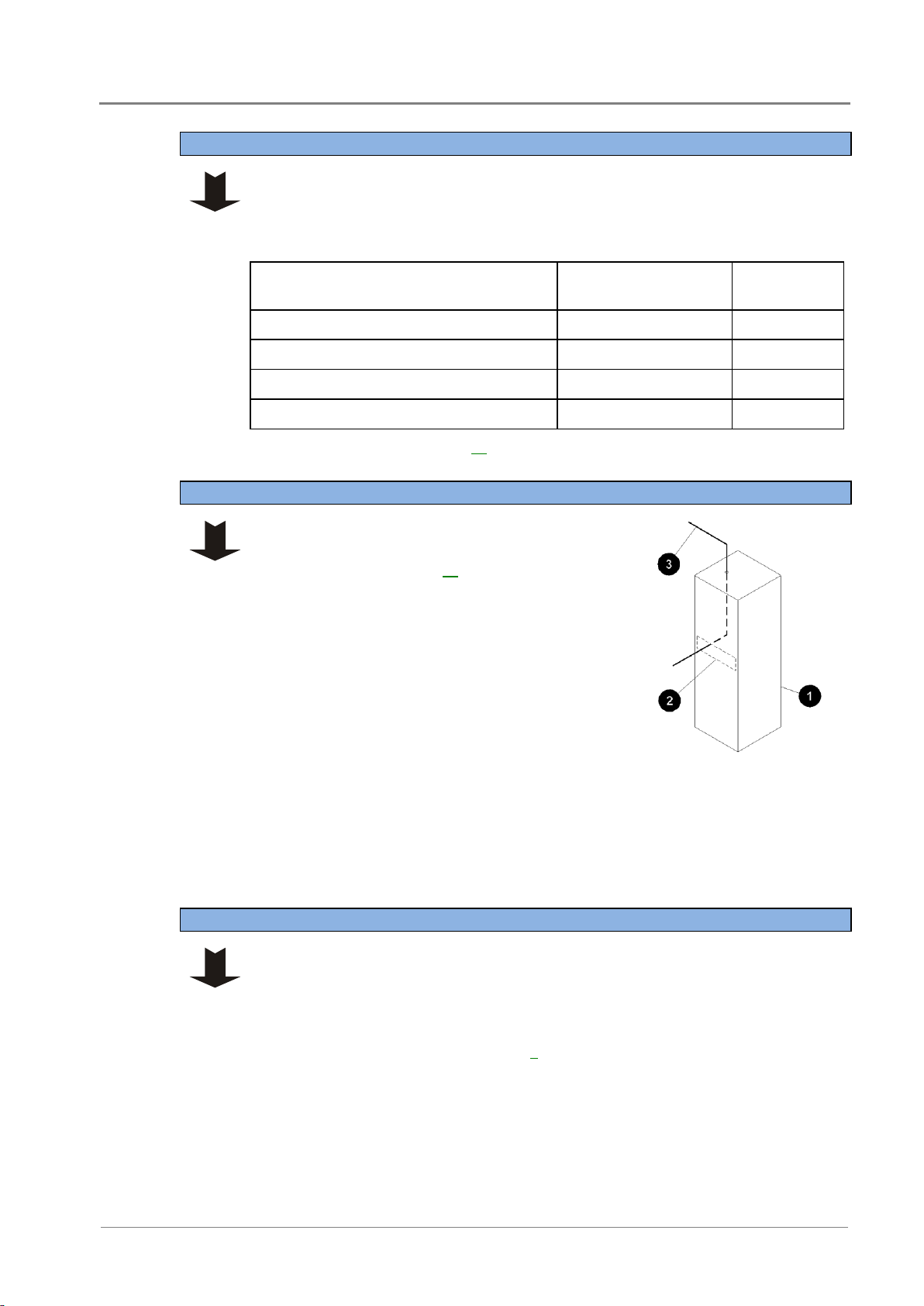

Rack-mounting bracket (available for 19-inch

and 23-inch wide racks)

Alternative bracket mounting positions

Ignore this Step if the load MCBs are already fitted.

The current rating of the MCBs must be derated to 75%.

The APS can use either Chint or Schneider circuit breakers. However, Chint and

Schneider circuit breakers are not interchangeable. When replacing existing circuit

breakers or fitting new ones, use the type that is already in use (see Spare Parts on page

66 for ordering details).

1 Remove the dc distribution front cover and top cover (if fitted).

2 Fit the load MCBs onto the load tooth-comb bus (start at the right-hand end) and

clip onto the DIN rail. Tighten the bottom MCB terminals.

3 Cut the load fuse fail detect wires (from the fuse

fail alarm board on the APS) to the correct length to

reach the MCBs.

There is one load fuse fail detect wire for each load

MCB. These wires are thinner than the battery

fuse fail detect wires.

4 Connect the wires to the top terminals of the MCBs

and tighten terminal to hold the wire in place.

5 Fit MCB blanks to cover any unused positions.

6 Switch OFF all MCBs.

Load MCB

Load fuse fail detect wire

from fuse fail alarm board.

Step 4 - Install Load circuit breakers (if required)

Installation

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

21

Ignore this Step if the Battery MCBs are already fitted.

The current rating of the MCBs must be derated to 75%.

The APS can use either Chint or Schneider circuit breakers. However, Chint and

Schneider circuit breakers are not interchangeable. When replacing existing circuit

breakers or fitting new ones, use the type that is already in use (see Spare Parts on page

66 for ordering details).

1 Place the battery MCBs side-by-side (see following diagram).

2 Use the battery fuse fail detect loop wire to connect the auxiliary switches in

series.

Use the auxiliary switch terminals that will be closed when the MCB is ON.

3 Fit the MCBs onto the battery tooth-comb bus (at the right hand end) and clip

onto the DIN rail.

4 Tighten the bottom MCB terminals.

5 Connect the battery fuse fail detect wires to the MCB auxiliary switches (see

following diagram). Tighten the terminals.

6 Fit MCB blanks to cover any unused positions.

7 Switch OFF all MCBs.

Battery MCBs (front view)

Auxiliary switches

Fuse fail detect loop wire

Battery fuse fail detect wires

There are two options: ac and dc earths bonded or separated.

1 Check if the APS ac and dc earths are bonded:

Remove top cover (if fitted).

If the ac-dc earth link busbar (at one end of the dc common bar) is fitted (see

following diagram) then the ac and dc earths are bonded. This is the

recommended, factory standard arrangement.

If the busbar is not fitted then the ac and dc earths are separated.

2 If the arrangement of the ac and dc earths is as required, no further action is

required.

3 If the arrangement of the ac and dc earths is not as required, follow the procedure

in Earth Bonding on page 85.

Step 5 - Install Battery MCBs (if required)

Step 6 - Check if the APS ac and dc earths are bonded

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

22

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

Busbar chassis screw

Busbar

Busbar stand-off screw

Stand-off

DC common bar

If the APS dc power system is to be installed in a location where the ambient temperature

may rise above 50º (122ºF), then 90°C rated cable rated cable must be used for the ac

connections.

See the diagram on page 2 for location of ac rating label.

1 Remove the ac terminal cover (see the diagram on page 3).

2 If ac MCB(s) fitted, remove the distribution front cover and remove the top

cover (if fitted).

Procedure complete

Task 3 - Connect the AC Supply Cable

If the APS has pre-fitted ac cord(s) then ignore this task.

Step 1 - Check ac rating of the APS

Step 2 - Remove covers

Installation

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

23

Check the ac terminals on the APS are connected to suit the type of ac supply. Refer

to the ac connection diagrams in Step 6.

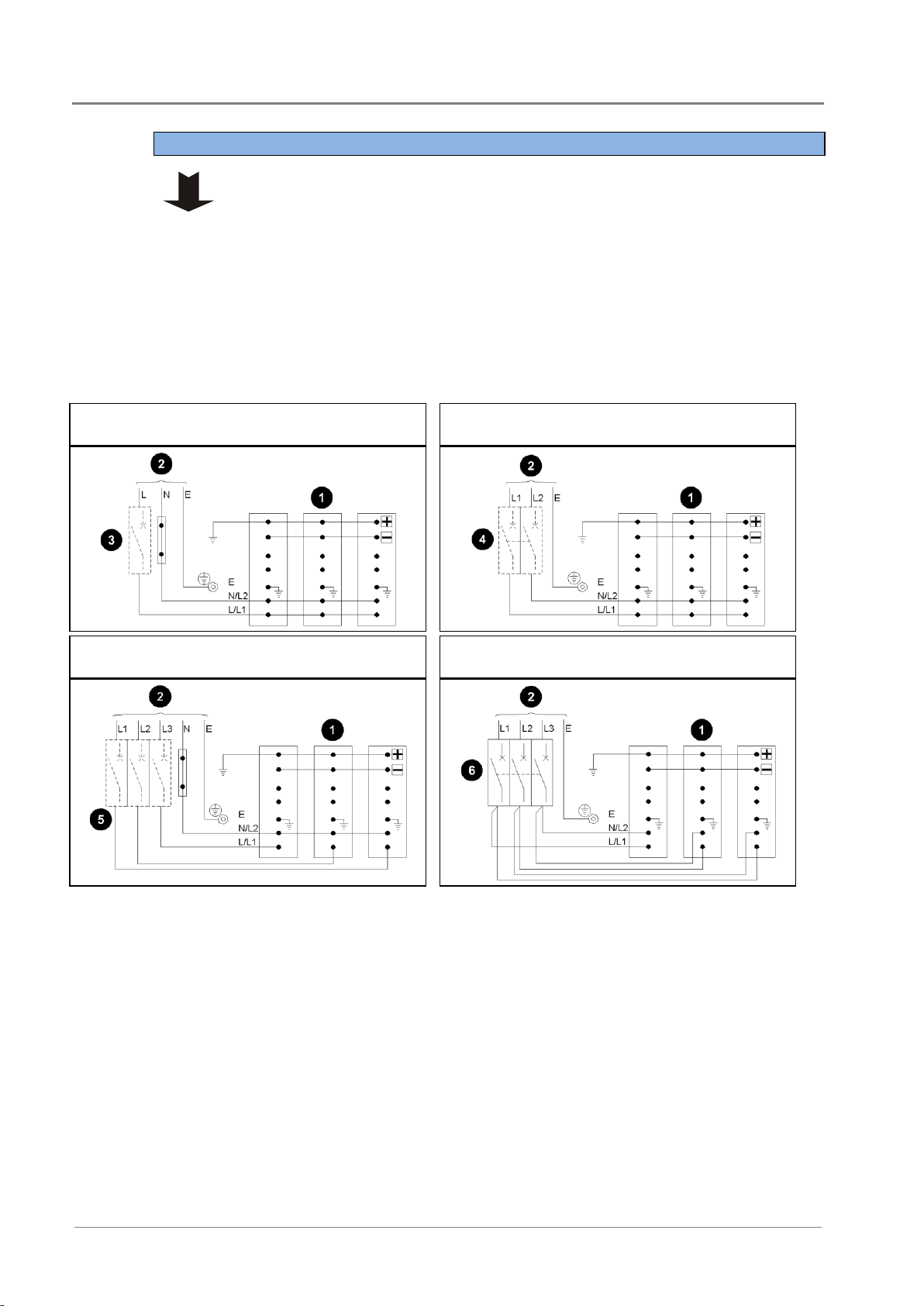

Access Power Solutions dc power systems can only be connected to one of the

following:

AC source

Voltage (nominal)*

AC MCB

(if fitted)

1-phase, neutral and Protective Earth (PE)

220-240V phase-neutral

1-pole

2-phase and PE

208V phase-phase

2-pole (linked)

3-phase, neutral and PE

220-240V phase-neutral

3-pole

3-phase and PE

208V phase-phase

3-pole (linked)

*See Specifications on page 69 for the ac voltage range.

1 Select ac supply cable to suit the ac supply

source, the maximum ac current (see

Specifications on page 69) and in accordance

with the local wiring regulations.

2 Route the ac supply cable from the ac supply

point into the rack. Then bring the cable through

the front of the rack to the APS.

Do not terminate at the ac supply point at this

stage.

3 At the APS end, cut the conductors to suit the

positions of the terminals (and ac MCB(s) if

fitted).

Ensure the earth conductor is 30-50mm (1¼ - 2

inches) longer than the longest phase or neutral

conductor.

Rack cabinet

Proposed position of APS

AC cable from supply point

(top or bottom entry into

rack as required).

1 Position the APS in front of the rack.

2 Terminate the earth conductor with an M6 crimp lug.

Ensure the ferrule of the crimp lug covers all strands of wire.

3 Connect the earth conductor to the earth termination point next to the ac

terminals (see the diagram on page 3).

Step 3 - Check the connection of the ac terminals

Step 4 - Prepare the ac supply cable

Step 5 - Terminate the earth conductor at APS

Access Power Solutions Installation and Operation Guide (APS3-300 Series)

24

Copyright © 2007-2012 Eaton Corporation. All Rights Reserved.

IPN 997-00012-48D November 2012

1 If ac MCB(s) fitted then connect the phase conductor(s) to the MCB(s).

Ensure the insulating card covers the MCB terminal(s).

2 If no ac MCB(s) fitted then terminate the phase conductor(s) with M4 crimp

lug(s) and connect to the ac terminal(s) according to the following diagram that

corresponds to the ac supply source.

Ensure the ferrules of the crimp lugs cover all strands of wire.

3 If fitted, terminate the neutral conductor with an M4 crimp lug and connect to

the ac terminal according to the following diagram that corresponds to the ac

supply source.

Ensure the ferrules of the crimp lug covers all strands of wire.

1-phase, neutral and Protective Earth (PE)

2-phase and PE

3-phase, neutral and PE

3-phase and PE

Rectifier modules

AC supply

Optional 1-pole ac MCB

Optional 2-pole (linked) ac MCB

Optional 3-pole ac MCB

3-pole (linked) ac MCB

Positive earth system shown.

Step 6 - Terminate the phase and neutral (if used) conductor(s) at APS

Loading...

Loading...