Eaton Ampgard 400 Instruction Manual

Instructional Leaflet IB48041

Effective December 2009

Instructions for AMPGARD 400A

medium voltage starter

DANGER

READ AND UNDERSTAND THIS MANUAL IN ITS

ENTIRETY BEFORE INSTALLING OR OPERATING THE

CONTROLLER. INSTALLATION, ADJUSTMENT, REPAIR,

AND MAINTENANCE OF THESE CONTROLLERS

MUST BE PERFORMED BY QUALIFIED PERSONNEL.

A QUALIFIED PERSON IS ONE WHO IS FAMILIAR

WITH THE CONSTRUCTION AND OPERATION OF

THIS EQUIPMENT AND THE HAZARDS INVOLVED.

Introduction

This instruction book is intended to cover

the handling, installation, operation, and maintenance of AMPGARDT 400A, 7.2 kV starters and

associated equipment. The function of these

controllers is to start, stop, and protect medium

voltage motors, transformers, capacitors, and

other loads. Controllers may be of full voltage,

reduced voltage reactor, reduced voltage

autotransformer, reduced voltage solid-state, or

two-speed type. They may control induction or

synchronous machines, and they may be

non-reversing or reversing.

While this instructional leaflet is dedicated primarily

to full-voltage starting, the other applications listed

are an expansion of the principles identified in this

leaflet. This leaflet does not purport to cover all

possible contingencies, variations, and details that

may arise during operation or maintenance of this

equipment. If further information is desired

regarding this product, contact your local Eaton

sales office.

Identification

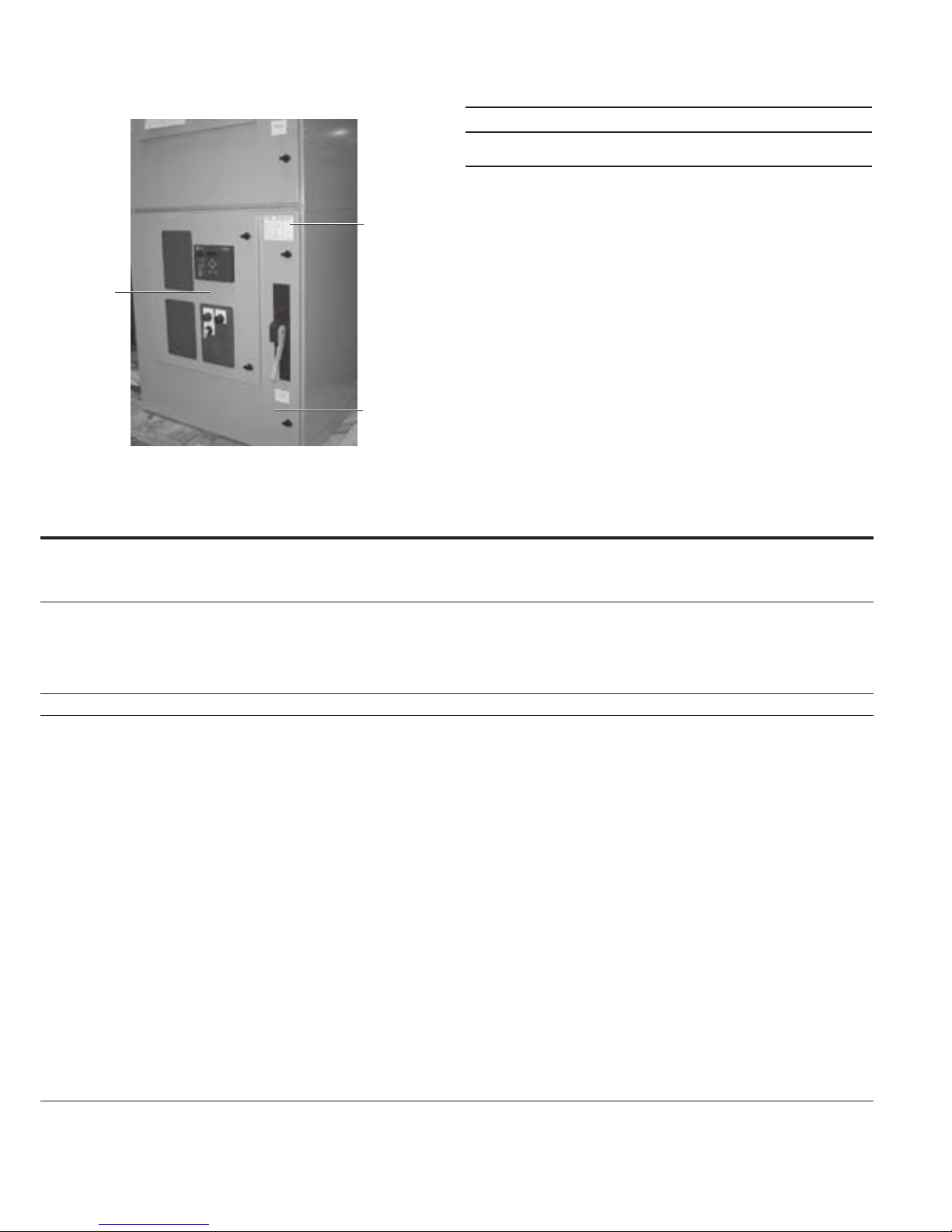

A rating nameplate is located on the door of each

controller. Contained on this nameplate are the

controller type and ratings as required by industry

standards. Also contained on this nameplate is the

factory’s general order number. This number should

be given to the Eaton sales office if a question

should arise concerning the equipment or if renewal parts are required. Refer to Figure 1 for typical

location of rating nameplates.

Instructional Leaflet IB48041

Effective December 2009

Low

Voltage

Door

Figure 1. Starter with Rating Nameplate

Instructions for AMPGARD 400A

medium voltage starter

DANGER

EXCEEDING THE NAMEPLATE RATINGS OF AN AMPGARD CONTROLLER

MAY CAUSE EQUIPMENT DAMAGE, SEVERE INJURY, OR DEATH.

Do not apply an AMPGARD controller beyond its nameplate ratings.

Rating

Nameplate

Medium

Voltage

Door

Table 1. Contractor Ratings

Rated Utilization Voltage 2200–2500V 3000–3600V 3800–4800V 6000–6900V

Interrupting rating

NEMAT unfused (E1)

NEMA fused (E2)

Application table

Induction motor

Synchronous motor (0.8 PF)

Synchronous motor (1.0 PF)

Transformer

Capacitor three-phase

8.5 kA

50 kA

200 MVA at 2400V

1750 hp

1750 hp

2000 hp

1500 kVA

1200 kVAR

8.5 kA

50 kA

295 MVA at 3300V

2250 hp

2250 hp

2500 hp

2000 kVA

1650 kVAR

8.5 kA

50 kA

400 MVA at 4600V

3000 hp

3000 hp

3500 hp

2500 kVA

2100 kVAR

8.5 kA

50 kA

570 MVA at 6600V

4500 hp

4500 hp

5500 hp

4000 kVA

3300 kVAR

Maximum insulation voltage: 7200V

Maximum interrupting current

(3 operations)

Rated current

IEC make-break capability-AC1

Make

Break

Short-time current

30 seconds

1 second

8.6 milliseconds (0.5 cycle)

Standard service altitude

Optional service altitude

Mechanical life

Electrical life

BIL

Dielectric strength (60 Hz)

Closing time

(energization to contact touch)

Operating time

Time-rated cycles on 60 Hz base.

8500A

400A enclosed

4000A

3200A

2400A

6000A

63 kA peak

–1000 to +2000 meters

–3500 to –1001 meters

+2001 to +5000 meters

2.5 million operations

300,000 operations

60 kV (1.2 x 50 microseconds)

20 kV (1 minute)

90 milliseconds

30 to 330 milliseconds

(selectable)

Arcing time

Pickup voltage

Dropout voltage

Control voltages

AC

DC

Control circuit burden

Closing (AC/DC)

Holding (AC/DC)

Auxiliary contact rating

Voltage (maximum)

Continuous current

Making capacity (AC)

Making capacity (DC)

Breaking capacity (AC)

Breaking capacity (DC)

Latch (when specified)

Mechanical life

Trip voltages (DC)

Trip voltages (DC)

Minimum trip voltage

Trip burden

(24 Vdc)

(125 Vdc)

(110/125 Vac)

Trip Time

Weight

12 milliseconds (3/4 cycle) or less

90% rated coil voltage

60% rated coil voltage

110/120/220/240 (50/60 Hz)

125

—

30 VA

600V

10A

7200 VA

125 VA

720 VA

125 VA

250,000 operations

24/120V

110/120V

90% rated coil voltage

—

—

—

30 milliseconds

60 lbs (27 kg) (rollout)

2

EATON CORPORATION www.eaton.com

Instructions for AMPGARD 400A

medium voltage starter

Description

Controller

The AMPGARD 400A, 7.2 kV controller consists of a non-loadbreak

isolation switch, medium voltage current-limiting fuses, one or

more Type SL vacuum-break contactors, a set of current transformers, plus control and protection devices. The isolating switch has a

limited make and break rating, suitable only for closing and opening

limited transformer magnetizing currents. The controller is designed

to start, stop, and protect a three-phase medium voltage motor

within the ratings shown in Table 1. The controller may also be used

to switch transformer windings or capacitor loads as shown. For

applications other than those indicated, consult the factory. Each

AMPGARD controller occupies all or a portion of a steel structure

that may also enclose a horizontal bus system to distribute power to

two or more sections and a vertical bus system to connect individual

starters to the horizontal bus. The controllers are configured for fullvoltage or reduced-voltage starting, reversing or non-reversing, in

single-speed or two-speed applications.

Starters are available with bolt-in or clip-in main fuses. Contactors

may have bolted connections or stab-in connections to the

starter cell.

The flow of current through a starter with bolted fuses and a

stab-in contactor can be described as follows: The line finger

assembly mounted at the back of the enclosure serves to connect

the isolation switch moving stabs to the controller line terminals

when the switch is closed. Power flows from the switch moving

stabs through a flexible shunt to the upper fuse mountings. The

fuses are connected to the lower fuse mountings that contain the

line-side stab connections to the line finger assemblies for the main

contactor. With the main contactor energized, power flows through

the contactor’s vacuum interrupters to the contactor load fingers,

which are engaged on to the contactor load-side stabs. Medium

voltage cables connect the load-side stabs to the motor load

connections. The contactor is held in place by a set of rails

mounted in the lower part of the cell. Current transformers are

typically mounted immediately behind the main contactor, under the

load-side stabs. The motor load connections are mounted to the left

of the main fuses in the rear of the compartment, facing forward.

Instructional Leaflet IB48041

Effective December 2009

Isolation Switch

Position View

Window

Figure 3. Low Voltage Compartment

Isolation switch

The controller isolation switch is a non-loadbreak device.

Mechanical and electrical interlocks are provided to ensure that

the main contactor is de-energized before the switch can be

operated. In the open position, the switch isolates medium voltage

from the main controller compartment, allowing access to the

controller for inspection and maintenance. For standard applications,

the isolation switch includes ground fingers that ground the line side

of the power fuses when the switch is in the open position. The

isolation switch has a mechanical endurance rating of 10,000

operations. Isolation switches in starters with double-barrel fuses

are supplied with additional phase barriers that must be installed to

maintain the proper dielectric rating of the starter.

DANGER

AMPGARD CONTROLLERS ARE SOMETIMES ENERGIZED BY A BACK-FED

CONDITION THAT ALLOWS THE MEDIUM VOLTAGE COMPARTMENT TO BE

ENERGIZED WITH THE ISOLATION SWITCH IN THE OPEN POSITION. STUDY

THE PLANT SINGLE LINE DIAGRAMS TO MAKE CERTAIN THAT NO BACKFEED SITUATION EXISTS BEFORE ENTERING THE MEDIUM VOLTAGE

COMPARTMENT.

Figure 2. Medium Voltage Compartment

Low voltage components

The low voltage components consisting of a protective relay,

interposing relay, test power circuit, terminal blocks, and optional

equipment are mounted in the low voltage control compartment

located on the front of the controller medium voltage door. The low

voltage compartment is fabricated from steel sheets to provide isolation from the medium voltage components mounted behind the

low voltage compartment. A window is provided in the low voltage

compartment to allow the user to view the position of the isolation

switch before entering the medium voltage compartment. See the

“Isolation Switch” section for further details.

All power sources must be isolated and locked out before

servicing the equipment.

For applications where the controller is back fed, the grounding

fingers should be removed from the isolation switch.

The switch consists of a fixed rear portion and a removable front

portion. Refer to Figures 5 and 6. The fixed portion includes the

controller line fingers and a moveable shutter that isolates the line

fingers when the switch is in the open position. The removable

portion is operated by a handle mechanism that extends through the

controller medium voltage door. With the handle in the up position,

the switch is closed and medium voltage is available for connection

to the controller load. With the handle in the down position, the

switch is open and medium voltage is isolated from the controller

and the controller load.

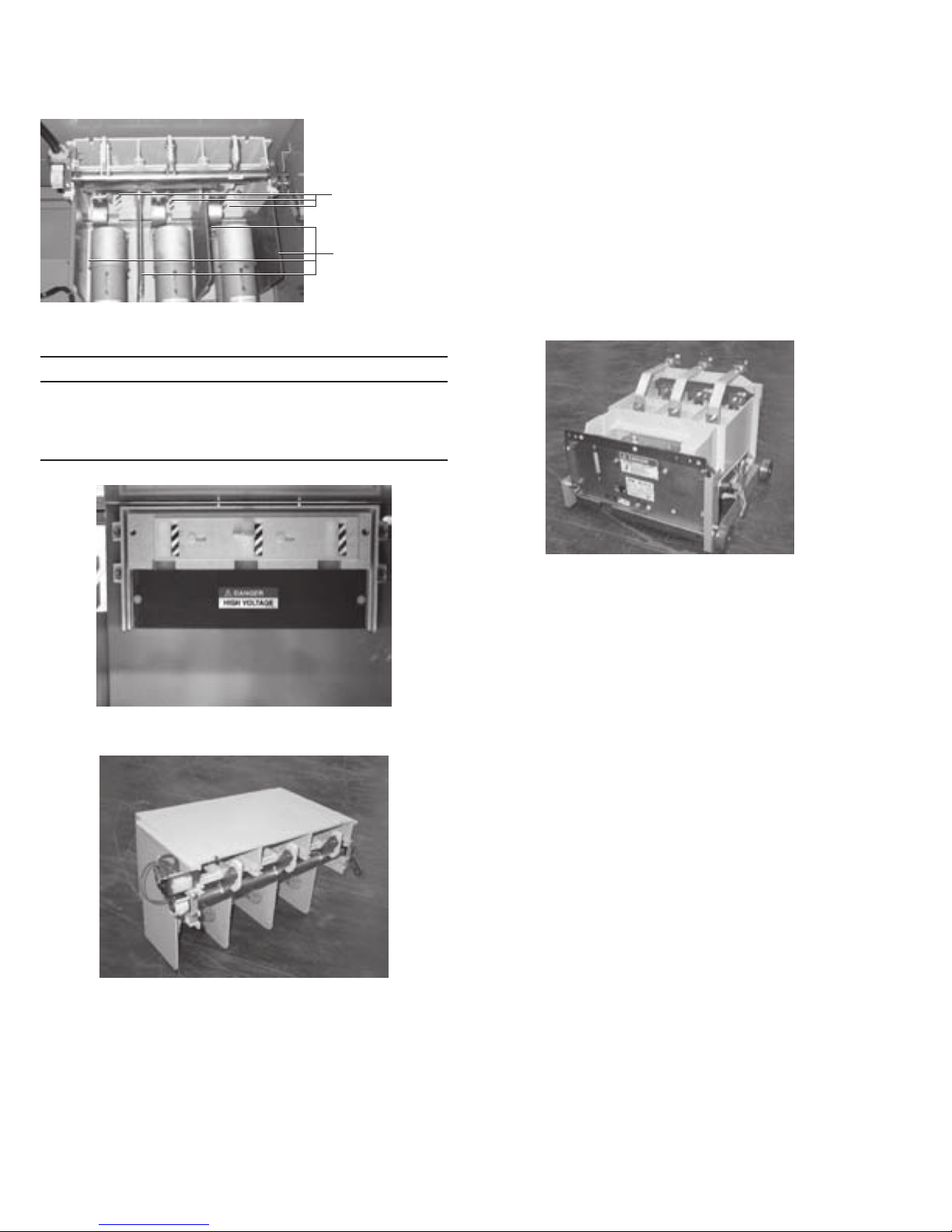

An isolation switch viewing window is provided in the upper rear

corner of the low voltage control compartment. After opening the

isolation switch and before opening the medium voltage door, the

switch should be visually examined through the viewing window to

verify that it is in the open position. Three green and white “barber

poles” will be visible when the switch is in the open position and

the shutter assembly is in the isolating position. See Figure 4 for

location of barber poles. The use of a flashlight will help in verifying

the position of the barber poles.

EATON CORPORATION www.eaton.com

3

Instructional Leaflet IB48041

Effective December 2009

Barber Poles

Indicating

Shutter

Closed

Phase

Barriers (4)

for DoubleBarrel Fuses

Figure 4. Shutter Closed

DANGER

DO NOT ENTER THE MEDIUM VOLTAGE STARTER COMPARTMENT WITHOUT VISUALLY VERIFYING THAT THE ISOLATION SWITCH IS OPEN AND

THE ISOLATING SHUTTER IS IN PLACE. ENTERING A COMPARTMENT

WITHOUT THE ISOLATING SHUTTER IN PLACE MAY RESULT IN SEVERE

INJURY OR DEATH.

Instructions for AMPGARD 400A

medium voltage starter

Vacuum contactor

400A AMPGARD medium voltage controllers are supplied with 400A

vacuum contactors. The contactors are supplied with one of two

interrupting ratings: The standard contactor has an interrupting rating

of 4500A, while the high-interrupting contactor has an interrupting

rating of 8500A. The standard contactors are typically supplied on

controllers with single-barrel main fuses (<188 FLA). They are also

supplied when auxiliary contactors are required, such as start and

run contactors on autotransformer starters and run contactors on

reactor starters. High-interrupting contactors are supplied on

controllers with double-barrel fuses. A code plate is provided in

cells originally equipped with high-interrupting contactors to prevent

the inadvertent installation of standard interrupting contactors into

those cells.

Figure 5. Fixed Portion—ISO Switch

Figure 6. Removable Portion—ISO Switch

Power fuses

AMPGARD controllers are supplied with Eaton Type CLS, CLE,

or HLE current-limiting power fuses. Fuses may be either bolt-in

type or clip-in type. All fuses include an indicator that pops up when

the fuse has blown. An optional blown fuse trip bar may be supplied

with bolt-in fuses. The mechanism is mounted on the controller

isolation switch and may be wired to trip the controller off-line in

the event of a blown fuse.

Figure 7. SL Vacuum Contactor

Contactors are typically three-pole devices except in the case of the

start contactor on autotransformer starters, which are normally twopole devices.

Refer to Instruction Book IB48018N for further details on the

operation and maintenance of the vacuum contactors.

Controllers supplied as transformer feeders, or for other specialized

applications, are sometimes supplied with contactors that include

a mechanical latch device. Refer to Instruction Book IB48020

for further details on the operation and maintenance of the

latch mechanism.

Safety interlocks

AMPGARD controllers are manufactured with several built-in interlock provisions and safety features to reduce hazards and provide

proper operating sequences:

•

A mechanical interlock prevents opening the medium voltage door

with the switch in the closed position. Ensure that the medium

voltage door is fully closed and latched using the two latches on

the right side of the door to prevent damage to the interlock

bracket on the back of the door

•

An additional interlock prevents closing of the switch unless the

medium voltage door is closed (see MV door interlock plunger in

Figure 8). On controllers that require two structures (reduced

voltage starters, for example), the door to the second structure

will also be interlocked with the switch-operating mechanism. The

second door must be closed before the main door is closed. Both

doors must be closed before the switch operator can be moved

to the closed position

ote:N Attempting to close the switch with the door open can cause damage

to the operating mechanism.

4

EATON CORPORATION www.eaton.com

Loading...

Loading...