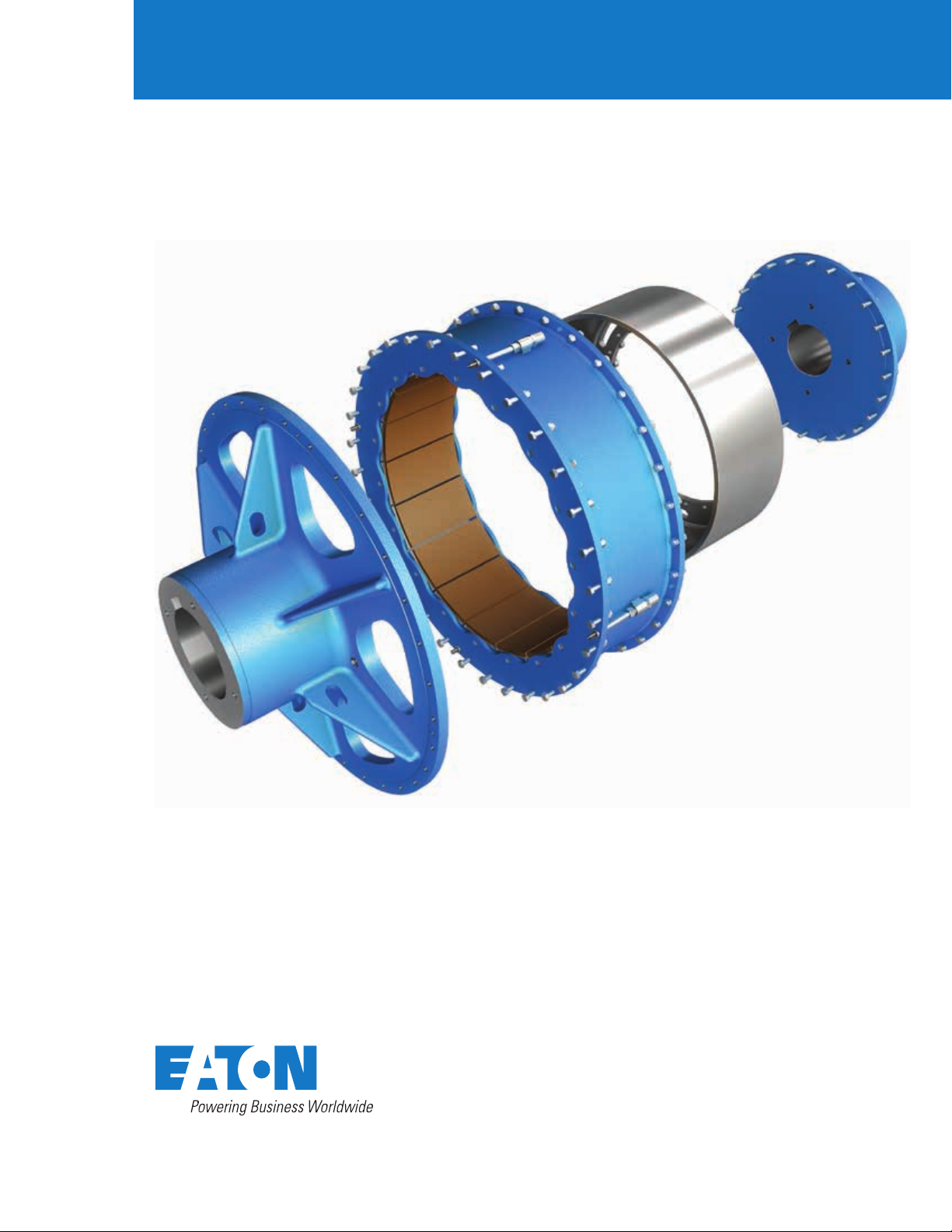

Eaton AirFlex TLC 5004 Installation, Operation And Maintenance Manual

TLC 5004 - Installation, Operation and Maintenance Manual

®

Airex

Torque Limiting Coupling

Torque Limiting Coupling

General information

Warning

Forward this manual to the person responsible for Installation,

Operation and Maintenance of the product described herein.

Without access to this information, faulty Installation,

Operation or Maintenance may result in personal injury or

equipment damage.

Caution

Use Only Genuine Airex Replacement Parts.

The Airex Division of Eaton Corporation recommends

the use of genuine Airex replacement parts. The use of

non-genuine Airex replacement parts could result in

substandard product performance, and may void your

Eaton warranty.

For optimum performance, contact Airex:

In the U.S.A. and Canada: (800) 233-5890

Outside the U.S.A. and Canada: (216) 281-2211

EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 20152

Table of contents

Section Description Page no

1.0 Introduction 6

1.1 Description 6

1.2 How it works 6

1.3 TLC adjustment 7

2.0 Installation 7

2.1 Mounting arrangements 7

2.2 Mounting considerations 7

2.3 Mounting spider and drum hub 8

2.4 Shaft alignment 9

2.5 Axial locking device adjustment 10

2.6 Installation of single wide element and drum 11

2.7 Air control system 11

2.8 Electrical controls 11

3.0 Operation 12

3.1 Torque, RPM and Pressure Limits 12

3.2 Control component adjustment 12

4.0 Maintenance 12

4.1 Periodic inspection 12

4.2 Removal of element assembly and drum 14

4.3 Removal of spider and drum hub 14

4.4 Disassembly of the element 14

4.5 Friction shoe assembly replacement 14

4.6 Assembly of the element 15

5.0 Spare parts storage 15

5.1 Element assemblies 15

5.2 Drums 15

5.3 Air actuating tubes 15

6.0 Ordering information/technical assistance 15

6.1 Equipment reference 15

7.1 Parts breakdown of TLC element assemblies gures 1 and 10 16

8.1 Parts breakdown of TLC hub, spider, drum, axial locking assy. and rotorseal gure 2 16

9.1 (Standard) Torque bar kit 17

9.2 (Standard) Friction shoe assembly, torque bar and release spring kit 17

10.1 Description axial locking assembly 17

EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015 3

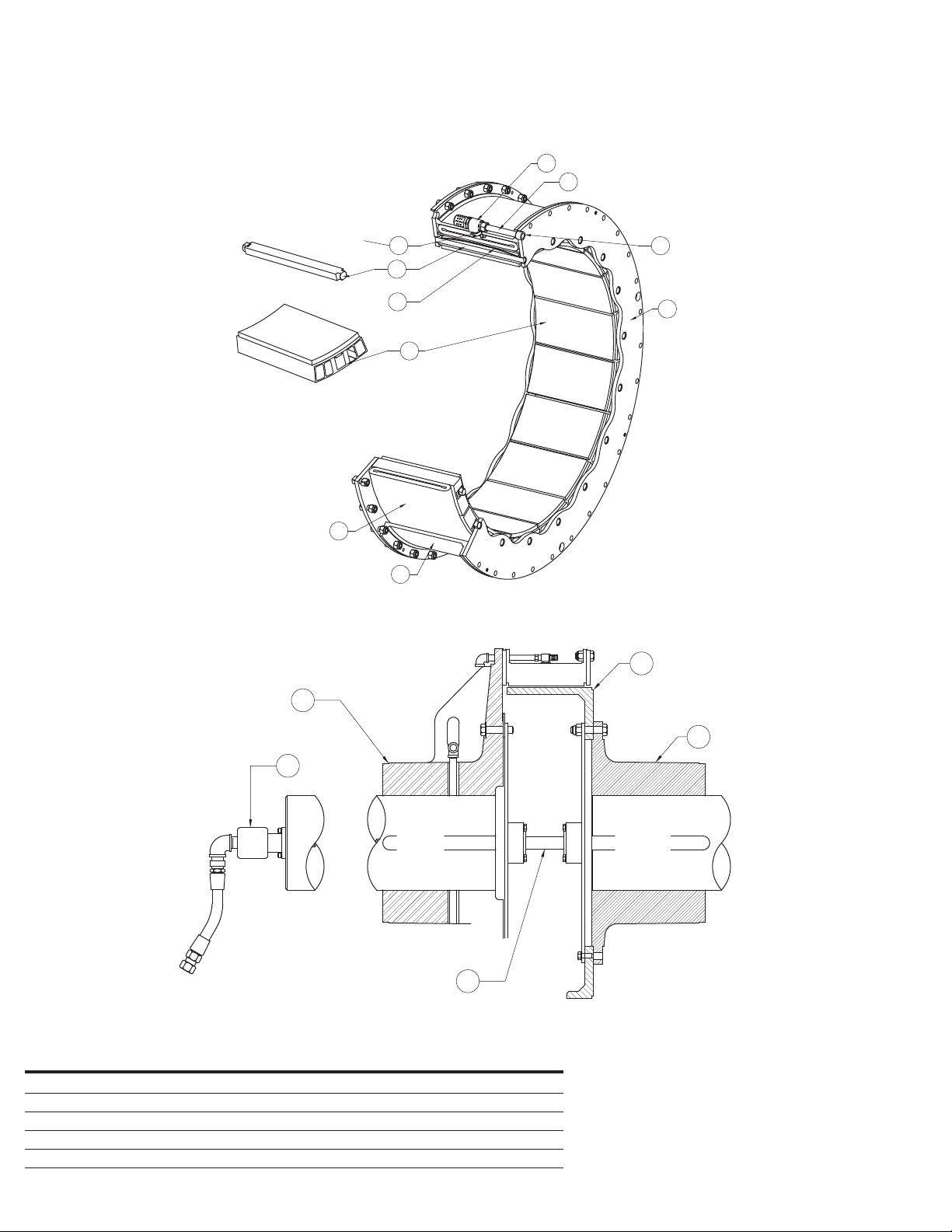

Torque Limiting Coupling

4

5

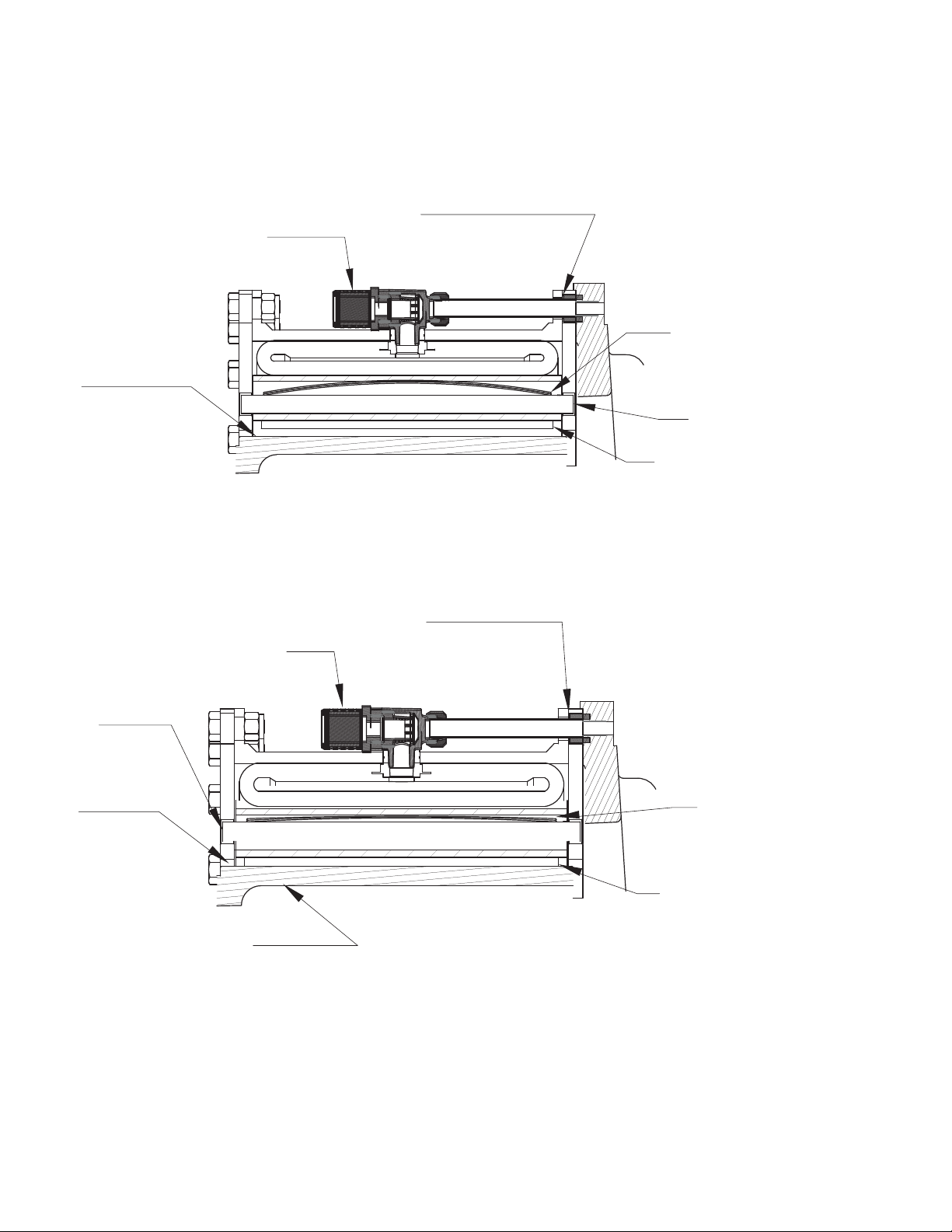

See Figure 10

3

9

10

7

2

1

Figure 1

6

8

13

Item Description

1 Rim

2 Tube

3 Snap rings

4 QRV

5 Air tube

12

15

Item Description

6 Rubber washer

7 Friction shoe assembly

8 Side plate (2 required)

9 Torque bar

10 Release spring

11

14

Figure 2

Item Description

11 Hub

12 Spider

13 Drum

14 Axial locking assembly

15 Rotorseal

EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 20154

Torque Limiting Coupling

Friction Material in contact with the drum

Drum surface

Friction shoe assembly retracted

QRV

Drum surface

Rubber backed washer

Release spring

Torque bar

Friction shoe assembly

Figure 3

QRV

Torque bar

Drum surface

Rubber backed washer

Release spring

(Compressed)

Contact with drum

Figure 4

EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015 5

Torque Limiting Coupling

1.0 Introduction

Throughout this manual there are a number of

HAZARD Warnings that must be read and adhered

to in order to prevent possible personal injury and/

or damage to equipment. Three signal words

Danger, Warning and Caution are used

to indicate the severity of a hazard, and are preceded

by the safety alert symbol

Danger

Denotes the most serious hazard, and is used

when serious injury or death WILL result from

misuse or failure to follow specic instructions.

Warning

Used when serious injury or death MAY

result from misuse or failure to follow

specic instructions.

Caution

Used when injury or product/ equipment

damage may result from misuse or failure to

follow specic instructions.

It is the responsibility and duty of all personnel

involved in the installation, operation, and

maintenance of the equipment on which this device

is used to fully understand the Danger, the

Warning and the Caution procedures by which

hazards are to be avoided.

1.1 Description

1.1.1 The Airex Torque Limiting Coupling (TLC) is air

actuated and specically designed and manufactured

for service in grinding mill and other torque limiting

applications. Torque limiting is required by variable

speed grinding mills directly coupled by the TLC

to the mill drive train to prevent damage to the entire

drive system from unintended torque spikes or

overloading conditions. The TLC provides a means to

immediately disengage the mill from the motor(s)

when the torque required to drive the mill is

excessive and detected by the TLC system. The

constricting design and construction make the TLC

high torque capacity possible.

In these applications, the TLC will be engaged by

applying the specied air pressure when the

drive system is at rest. The mill is started from this

static condition by the drive(s) and over time

brought up to the nominal operational speed. For

overload conditions above the rated set point of

the TLC it begins to slip resulting in a differential

of speeds between the driving and driven shafts.

At a predetermined level of slippage based on

rpm, the TLC controls disengage the TLC element(s)

instantaneously by releasing the applied air pressure.

1.1.2 All Airex TLC elements are supplied with long

wearing, NON-ASBESTOS high coefcient friction

material. The material is capable of withstanding

the energy input that is developed during the short

overload condition when slippage occurs

between the driving and driven shaft before the

automatic disengagement of the element(s) by the

control system.

1.1.3 Airex TLC element assemblies are now available in

sizes from a 51TLC1600 through a 76TLC2000.

The element size designation indicates the nominal

drum diameter in inches, the TLC model and the

width of the high coefcient friction material. For

example, size “51TLC1600” indicates the element

operates on a drum having a nominal diameter of

51 inches and has friction material which is 16 inches

in width.

1.2 How it works

1.2.1 Referring to Figures 1, 2, 3 and 4, the neoprene and

cord actuating tube is contained within a steel rim

which is drilled for mounting to the driving

component. As air pressure is applied to the air

actuating tube, the tube inates, forcing the

friction shoe assemblies uniformly against the

drum, which is attached to the driven component.

The friction shoe assemblies, which consist of the

special high coefcient friction pads bonded to

aluminum backing plates, are guided by torque bars

which are inserted into the element side plates.

The torque path is from the driving shaft, through

the element mounting component (typically an iron

spider), through the element rim and side plates and

the torque bars, backing plates and friction material.

The torque is then transmitted through the friction

couple to the driven shaft. When the specied

applied air pressure is exhausted, release springs

and centrifugal force assure immediate and

positive disengagement.

1.2.1.1 In some cases, the spider and element assembly

may be mounted to the driven shaft rather than

the driving shaft. This “reverse-mounted”

arrangement is typically used when retrotting a mill

drive and it is more practical to drill the pinion shaft

for the air supply rather than the motor shaft. In

these cases, the operation and torque ow

description is opposite to what is stated above.

1.2.1.2 For TLC applications that are mounted to the

drive motor(s) an axial locking device is used to hold

the motor on magnetic center during operation.

Refer to the INSTALLATION section for axial locking

device adjustment.

EATON Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 20156

Loading...

Loading...