Eaton Aeroquip Rynglok Fitting System Installation Manual

Aeroquip

Rynglok

®

®

Fittings

Rynglok

Fitting System

Installation Guide

Rynglok Fitting System Installation Guide

1.0 Initial Preparation .................................................................................... 3

1.1 Cutting Tubes

1.2 Tube End Preparation

1.2.1 Painted Tube End Preparation

1.3 Pre-applied Tube End Marking

1.4 Marking Gauge Positioning

2.0 Fitting Installation ................................................................................... 4

2.1 Positioning Mark

2.1.1 End Fittings

3.0 Fitting Assembly ..................................................................................... 5

3.1 Assembly Tool Selection

3.1.1 Assembly Tool/Fitting Compatibility

3.2 Assembly Tool Pressure Connection

3.3 Tool Installation

3.4 Tool Pressure

3.4.1 Pressure Level

4.0 Assembled Fitting Inspection ................................................................. 6

4.1 Ring Advancement Inspection

4.1.1 Insertion Inspection Mark Position

4.2 Shared Insertion - Unions

4.2.1 Over Insertion Condition - Fittings Other Than Unions

5.0 Tubing Repair With Rynglok Unions ........................................................ 7

5.1 Single Union Repair

5.1.1 Cutting Through Center Of Defect

5.1.2 Cutting Out Defect

5.2 Two Union Repair

6.0 Special Considerations ........................................................................... 8

6.1 Using The “Reversed Tool”

6.2 Special Considerations When Using The “Reversed Tool”

6.3 Special Considerations When Using The -20 and -24 Tools

7.0 Tube Cut Dimensions ............................................................................. 9

7.1 Female Arcseal™ Fitting

7.2 Female Flareless Fitting

7.3 Female Flared Fitting

8.0 Fitting Selection Chart ........................................................................10 – 11

2 EATON Aerospace Group TF100-67A March 2013

Rynglok Fitting System Installation Guide

1.0 Initial Preparation

1.1 Cutting Tubes

Tubes may be cut using any appropriate cutting tool whether by

hand or by a production method. Tube ends should be reasonably

square, recognizing that any out-of-squareness condition will detract

from the amount of positioning tolerance allowed. (See paragraph

1.4)

1.2 Tube End Preparation

The tube ends should be deburred with appropriate deburring tools

on the O.D. and I.D. to prevent damage of the fitting I.D. during tube

insertion and to prevent FOD (Foreign Object Damage) from entering

and contaminating the fluid system.

1.2.1 Painted Tube End Preparation

Painted tube ends shall be deburred in accordance with paragraph

1.2. Painted tube ends do not require the paint to be removed when

the tubing O.D. is in accordance with Table 1. The max. tubing O.D.

(dim. A) must be held a min. distance (dim. B) per Table 1 for proper

fitting installation. If paint removal is necessary, the tube shall be

sanded in a radial direction using a mild grit paper. Care should be

taken to prevent longitudinal marks. It will be necessary to reclean

and remark tube ends. It is recommended to repaint the exposed

tubing after installation. Please contact Eaton’s Jackson, MI facility at

(517) 787-8121 if there are any questions regarding this procedure.

1.3 Pre-applied Tube End Marking

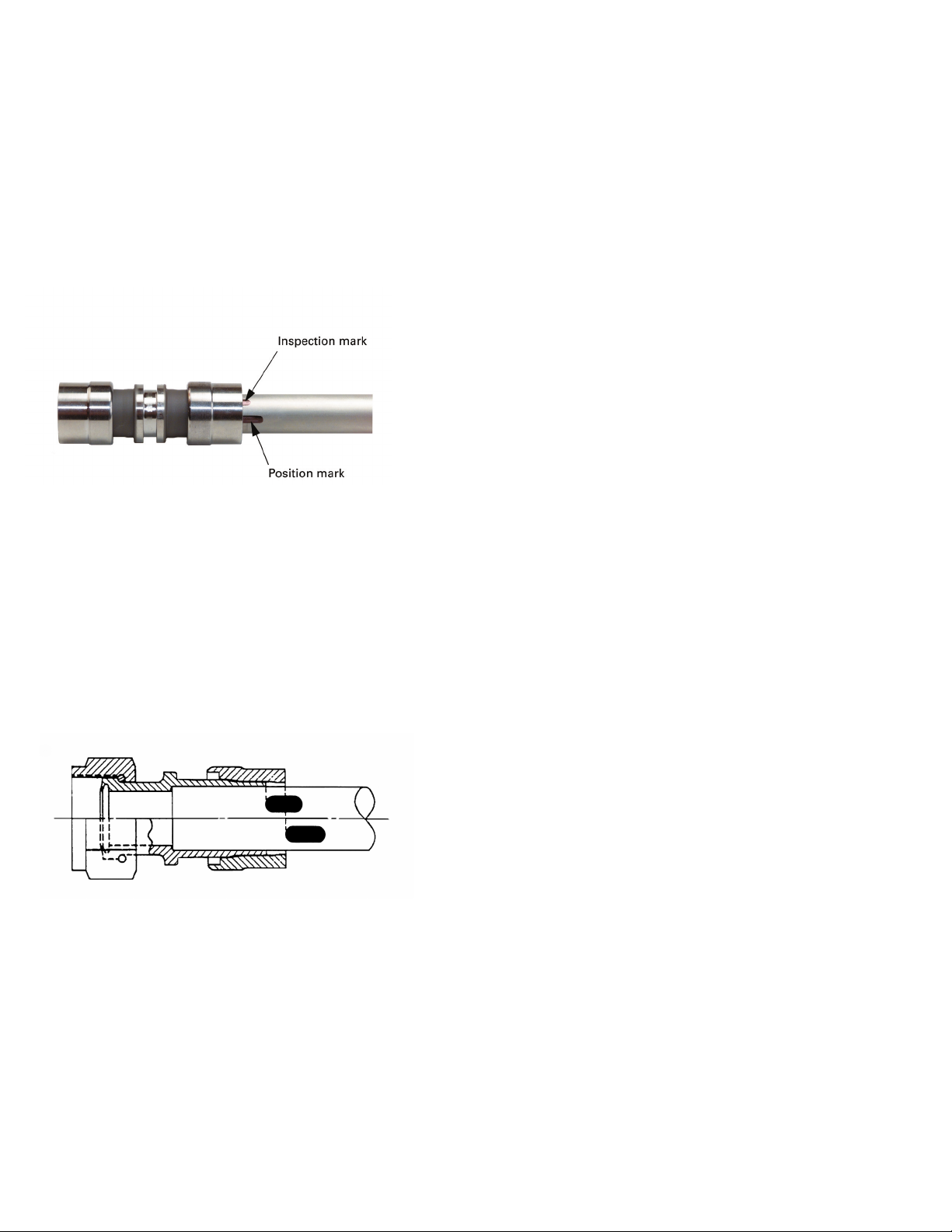

A pair or pairs of marks, (positioning marks and inspection marks) as

shown in Figure 1, should be pre-applied with the given dimensions

from Table 1 to each prepared tube end prior to fitting installation.

A suitable method such as ink stamp, electro-etch, laser, etc. may

be used. Should the tube ends be unmarked, the appropriate marks

should be applied using Eaton’s Aeroquip brand tube marking gauge

P/N RTSG0-01-SIZE as shown in Figure 2, and using a suitable permanent ink felt tipped pen.

Notice: Due to the possibility of contaminating titanium tubing, inks

which contain lead or free halogens should not be used for marking.

Table 1

Dimensions for electro-etch, ink stamp, or laser marking.

Dash

Size

-03 .190 .453 .300 .453 .644

-04 .254 .525 .300 .525 .717

-05 .316 .588 .300 .588 .780

-06 .379 .656 .300 .656 .843

-07 .441 .730 .300 .730 .918

-08 .505 .773 .350 .773 .963

-09 .567 .836 .350 .836 1.026

-10 .630 .899 .350 .899 1.088

-11 .692 .983 .350 .983 1.175

-12 .755 1.042 .350 1.042 1.232

-13 .817 1.110 .350 1.110 1.303

-14 .880 1.178 .350 1.178 1.369

-15 .942 1.249 .400 1.249 1.448

-16 1.006 1.299 .400 1.299 1.498

-20 1.256 1.572 .400 1.572 1.781

-24 1.507 1.882 .400 1.862 2.086

A

Max.

B

Min.

C

± .005D ± .005E ± .005

Figure 1

Tube marking using electro-etch, ink stamp, or laser marking.

1.4 Marking Gauge Positioning

The RTSG0-01-SIZE series of marking gauges is common for all

pressure classes of Rynglok fittings. The marking gauge should be

bottomed on the end of the cut tube. If an out-of-square condition

exists, the marking gauge should be positioned toward the end that

is most square. This is only for fittings which require shared insertion, such as in the case of a union fitting. This allows minimum tube

insertion on the opposite end of a union configuration should the

skew end be inserted to the maximum tube insertion condition. (See

paragraph 4.1.1 and Figure 7).

(All tubes should be marked prior to assembly in insure proper tube

insertions.)

Figure 2

Application of tube insertion marks using RSTG0-01-SIZE marking gauge and

pen.

EATON Aerospace Group TF100-67A March 2013 3

Rynglok Fitting System Installation Guide

2.0 Fitting Installation

2.1 Positioning Mark

The installer must use this positioning mark to position the edge of

the unswaged fitting “ring” over the marks as shown in Figure 3.

The length of the positioning mark is the amount of positioning tolerance allowed. The edge of the fitting “ring” may be anywhere along

the length of the positioning mark.

Figure 3

Fitting position for tube insertion

2.1.1 End Fittings

In general, end fittings are designed to have the tube end bottomed

into the fitting, and do not have as much positioning allowance. See

Figure 5. Even with this condition, the tube end should be marked

for inspection purposes to verify that the tube was inserted to at

least the minimum insertion depth. Refer to section 7.0 when installing fittings of this type.

Figure 4

End fitting tube positioning. Note: Tube is bottomed into fitting.

4 EATON Aerospace Group TF100-67A March 2013

Loading...

Loading...