Eaton Aeroquip AE246 Assembly And Disassembly Instructions For Hand And Machine Assembly

Aeroquip

®

AE246 High Pressure

PTFE Hose

and “super gem”™

Reusable Fittings

Assembly and disassembly instructions

for hand and machine assembly

Table of Contents

Section I Introduction 1

1. Purpose 1

2. Scope — “super gem” Fittings 1

3. Description 1

Section II Identification 2-4

1. Identification and Construction of AE246 PTFE Hose 2

2. Fire Sleeve 2

3. Fittings - “super gem” Fittings 3

4. Hose Assemblies 3

Section III Disassembly 5

Section IV Cleaning 6

Section V Repair and Replacement 7

1. General 7

2. Fire Sleeved Hose Lines 7

Section VI Assembly Procedure — Hand Tool Method 8-11

Section VII Assembly Procedure — Machine Tool Method 12

1. General 12

2. Assembly of Fitting to Hose 12

Section VIII Proof Test Procedures 13

1. Equipment 13

2. Recommended Hydrostatic and Pneumatic Proof Test Pressures 13

3. Hydraulic Proof Test 13

4. Pneumatic Proof Test 13

5. Disposition If Fitting Leakage Is Noted 13

6. After Proof Test Operation 13

Section IX Removal of Hose Assemblies from Installation 14

1. Inspection 14

2. AN-MS Flared and Flareless Connections 14

3. Handling General 14

Section X Installation of Hose Assemblies 15-16

1. Installation, General 15

2. Routing and Clamping 15

3. Torque Values, Installations 16

4. “super gem” Fittings Used on Aeroquip AE246 Hose 16

Section XI Inspection Procedures 17-18

1. External Inspection of Hose Lines Removed from Service 17

2. Internal Inspection of Hose Lines Removed from Service 17

3. Hose End Fittings 17

4. Inspection of Component Parts 18

Section XII Permissible Rework 19

1. Hose Assemblies 19

2. Hose 19

3. Fittings 19

4. Fire Sleeves 19

Section XIII Storage of Hose and Hose Assemblies 20

1. Age Limitations 20

2. Bulk Hose 20

3. Hose Assemblies 20

Section XIV Disposition 20

Section XV Assembly Equipment, Special Tools, Fixtures and Service 21

1. Purpose

This manual provides specific instructions for

maintenance and overhaul of Eaton’s Aeroquip hose

assemblies made of high-pressure tetrafluoroethylene

(PTFE) hose. Eaton’s Jackson, Michigan facility

manufactures Aeroquip products (Federal Code

Number 00624). The manual is divided into three

areas of maintenance to enable each maintenance

group to complete its service within a sequence

of sections. The first area, following “Introduction”

and “Identification” which are common to all levels,

contains the maintenance and overhaul procedures for

hose assemblies removed from service (Sections III

through VIII). The second area provides maintenance

and replacement instructions for hose assemblies which

are in service (Sections IX through X). The last area of

the manual is devoted specifically to inspection, storage

and disposition of hose assemblies (Sections XI through

XIV).

2. Scope

Hose assemblies fabricated in accordance with this

manual will conform to the requirements listed in

Specification MIL-H-38360 and are suitable for use in

high temperature, 3,000 psi hydraulic and pneumatic

systems. Use in other systems is permissible where

pressure and fluid are compatible with the requirements

of the specifications and as further specified in

paragraph 6.1 of MIL-H-38360 or when specifically

approved by Eaton.

One gap - all sizes

1/32 inch (.793 mm)

Section I

Introduction

+ .015

- .008

3. Description

AE246 High Pressure PTFE Hose and reusable “super

gem” fittings are manufactured by Eaton. Where

applicable, supplementary information covering these

hose lines protected with Eaton’s Aeroquip fire sleeve is

included.

EATON Aerospace Group TF100-63B October 2018 1

Section II

Identification

1. Identification and Construction of AE246 High Pressure

PTFE Hose

A. AE246 PTFE hose (Figure 1) conforming to the

requirements of MIL-H-38360 has a corrosion resistant

steel wire braid reinforcement covering an extruded

PTFE inner tube. See Table 1.

B. Identification of AE246 PTFE Hose

1) Bulk hose Identification — Bulk hose has a tape

with black letters specifying Aeroquip hose – size,

operating pressure, lot number and hose manufacturer’s code. Tape is located at each end and in

middle of hose.

2) Hose Assembly Tag Identification — All factory

assembled hose assemblies are identified with

a metal band. Identification may include such

information as customer part number, Federal Stock

Number if required, hose assembly specification

number, operating pressure in psig, manufacturer’s

assembly part number, proof test symbol, date of

assembly, and hose manufacturer’s Federal Code

Number. See Figure 5.

Figure 1 - AE246 Bulk Hose

Table I

General Specifications — Aeroquip AE246 PTFE Hose

Hose Size Tube Size

O. D.

inches (mm)

- 4 1/4 (6.35) 3000 (206.84) 16000 (1103.16) 1.50 (38.09)

- 6 3/8 (9.52) 3000 (206.84) 14000 (965.26) 2.50 (63.50)

- 8 1/2 (12.70) 3000 (206.84) 14000 (965.26) 2.88 (73.15)

- 10 5/8 (15.87) 3000 (206.84) 12000 (827.37) 3.25 (82.55)

- 12 3/4 (19.05) 3000 (206.84) 12000 (827.37) 3.88 (98.55)

Operating

Pressure

psig (bar)

Min. Burst

Pressure

psig (bar)

Min. Bend

Radius

inches (mm)

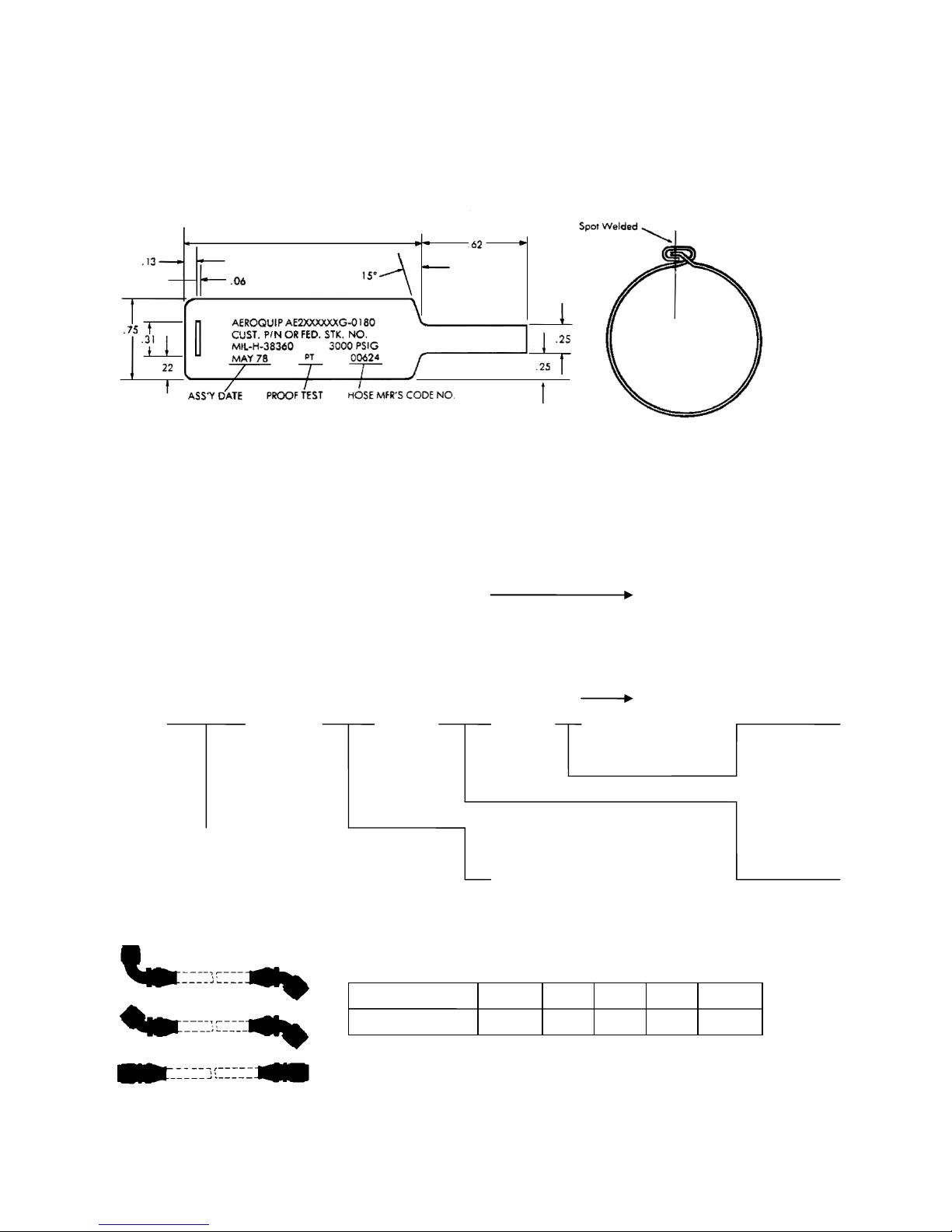

2. Fire Sleeve

AE102/624 firesleeve is identified by a red silicone

impregnated, braided asbestos sleeve having a black lay

line with “Aeroquip AE102/624”– size repeated at 10 inch

intervals.

Figure 2 - Fire Sleeve

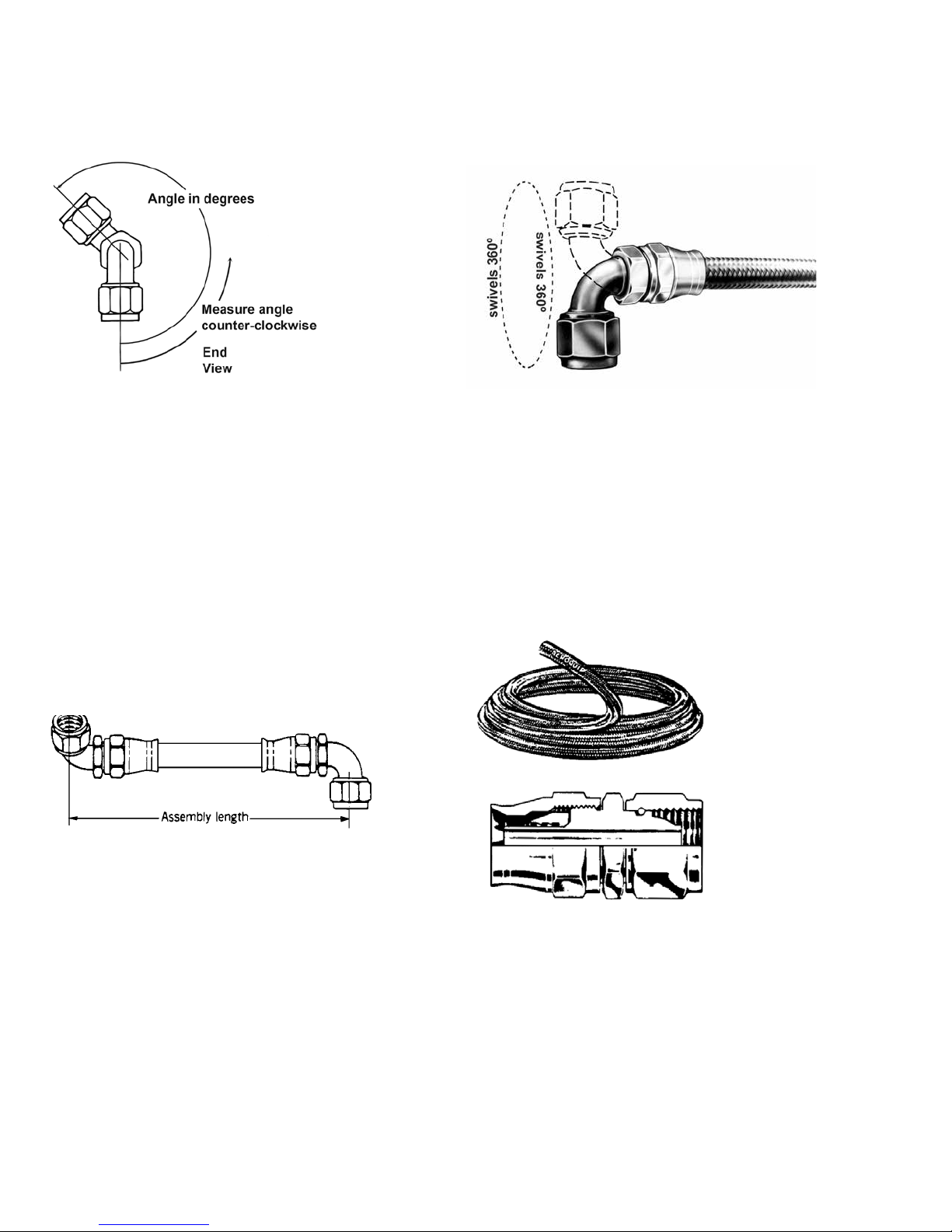

3. Fittings

All component parts of fittings are impression-stamped

with the part number.

Sleeve Nipple Assembly Socket

Figure 3. “super gem” fitting consists of 3 pieces: socket, sleeve and nipple assembly.

90º Adjustable Elbow 45º Adjustable Elbow

Figure 4. “super gem” elbow fittings

2 EATON Aerospace Group TF100-63B October 2018

4. Hose Assemblies

AE2460500 E 0184

Complete assembly number

(hose assembly with straight fittings

or elbow on one end only)

Complete assembly number

AE4108 E 0184 225

(hose assembly with elbow or

BASIC STYLE NUMBER

HOSE SIZE (letter code)

Hose size is expressed as a letter code which designates

following the basic style.

Hose dash size -4 -6 -8 -10 -12

Letter code E G H J K

All factory assembled hose lines are identified with a metal

band (Figure 5) containing part numbers, date of assembly,

etc. A detailed explanation of the different elements of a

hose assembly part number is shown in Figure 6.

Figure 5. Identifying Metal Band

How To Complete Assembly Part Number

Basic types of hose assembly numbers are shown below.

A detailed explanation of the different elements of the part

numbers are given on these pages.

Section II

Identification

Select hose required and choose correct assembly part

number – basic style number – covering desired

configuration. Use Aeroquip Aerospace Engineering Bulletin

AEB 212 as a reference guide.

Figure 6 - Assembly Part Number Explanation

special fitting on each end)

the tube O.D. in 1/16’s of an inch, for example, ½ - inch = 8 or letter code H. This code is added immediately

EATON Aerospace Group TF100-63B October 2018 3

Section II

Identification

Position Angle (Angle of Rotation)

For assemblies with an elbow fitting on each end, measure the

position angle as shown and suffix the angle to the basic style

number. The angle is expressed in three digits. For example: 35°

would be written as 035. If the angle desired is 0°, specify as

000. The angle shown in the example is 225°.

Assembly Length

Assembly length is measured from sealing surface to sealing

surface. On elbow fittings the measuring point is the intersection of the centerline of the elbow with the face of the sealing

surface. Assembly length will always be expressed in four digits.

Last digit shall always indicate fractional length in 1/8’s of an

inch. Thus, an assembly 18-1/2 long will be indicated as 0184.

Assembly Length Tolerances (PTFE Hose)

18 inches or less ± 1/8 inch

18 inches to 36 inches ± 1/4 inch

36 inches or longer ± 1% length

Adjustable elbow fittings are easily positioned through 360°

to the desired relative angle between opposite elbow fittings.

Mock-up and prototype installation changes are simplified as the

position angle can be determined on the actual installation.

Bulk Hose

300 ft., AE246-8 Hose (random lengths)

300 pcs., AE246-8-0120 (specific lengths)

PTFE hose will be shipped in random lengths. If specific lengths

are required, order as shown in the example above. An additional

charge is made on orders for specific lengths.

Typical Straight Flareless Fitting Assembly

For complete configuration and style information, use Eaton Bulletin AEB 212

as a reference guide.

4 EATON Aerospace Group TF100-63B October 2018

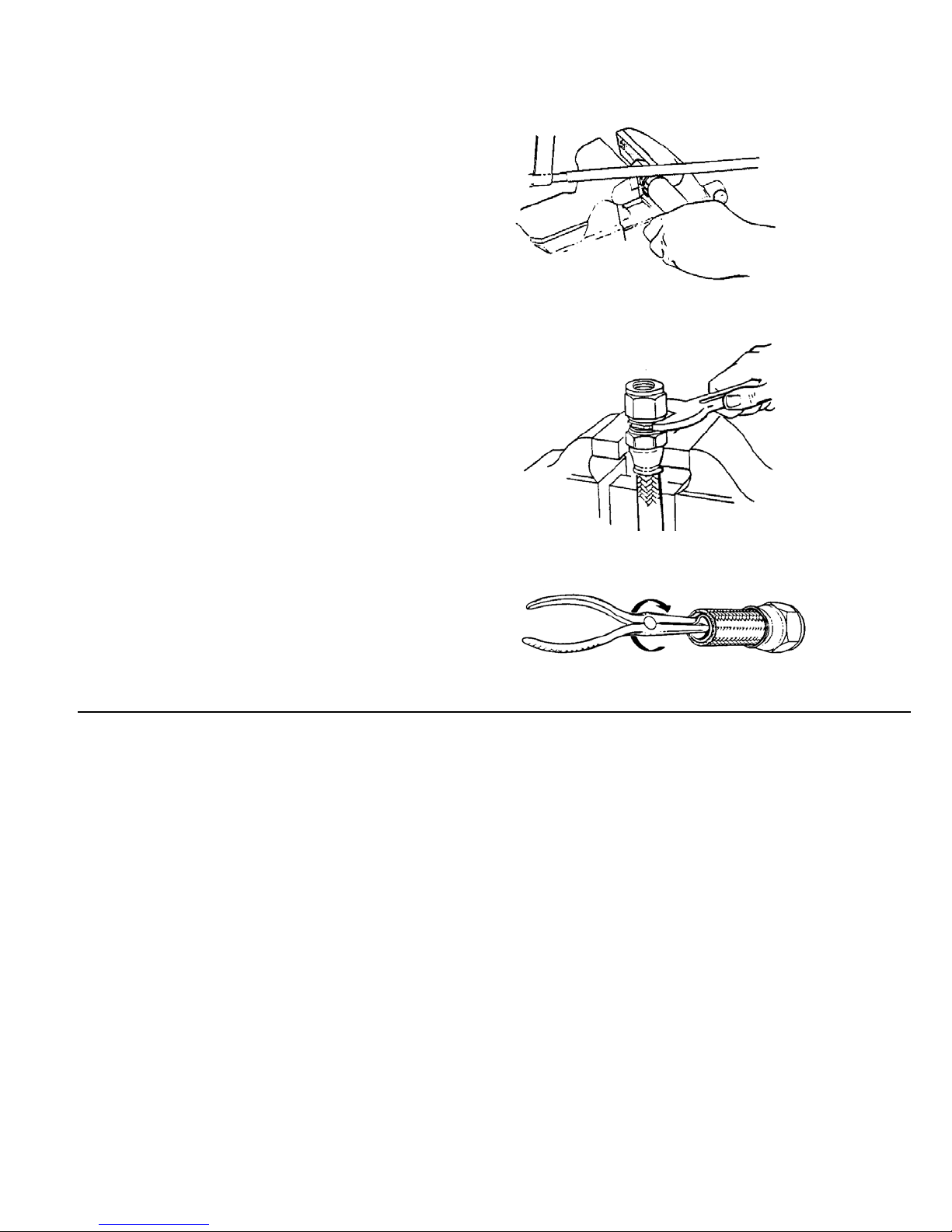

1. Complete Assembly Tear-Down

Procedure for salvage of hose assembly components:

Section III

Disassembly

Step 1. (Fire-sleeved hose lines only). Remove band

clamps by cutting clamp “buckles” with hack

saw. Remove fire sleeve from hose assembly.

(See Figure 7.)

Step 2. Place socket in vise and remove nipple

assembly by applying wrench to nipple hex.

(See Figure 8.)

Step 3. Cut hose approximately 1-inch from socket

skirt.

Step 4. Hold socket firmly in vise. Do not damage

socket. Using needle nose pliers, remove the

tube from the sleeve and hose reinforcement.

(See Figure 8A). The tube may be removed by

folding longitudinally and pulling it out of the

socket.

Step 5. With the socket still in the vise, separate the

sleeve from the socket and hose reinforcement.

The reinforcement can then be pulled out of

the socket.

Step 6. Remove hose fitting from opposite end of

assembly, using the same procedures, step 2

through step 5.

Step 7. Disposition of Component Parts — All hose

shall be scrapped and component parts of

fittings shall be inspected in accordance with

inspection procedures. See Section XI.

Figure 7. Removing Fire Sleeve From Hose Assembly

Figure 8. Removing Nipple From Socket

Figure 8A. Removing Tube From Sleeve

EATON Aerospace Group TF100-63B October 2018 5

Section IV

Cleaning

1. General

It is recommended that all hose assemblies and

component parts be thoroughly cleaned and

degreased before inspection.

A.

Cleaning Hose Assemblies with AE102/624 Fire

Sleeve

— It is suggested that the fire sleeve

be completely removed before cleaning. When

cleaning after proof test, installation of the fire

sleeve should be the last operation performed.

B. Cleaning Hose Assemblies without Fire Sleeve

— Flush hose assembly in cleaning fluid and

brush, if necessary, to dislodge deposits. (For

information covering F-2244 Hose Wash Stand,

contact Eaton’s facility, Jackson, MI.

C. Cleaning Fitting Component Parts — Dip

components parts and blow dry with clean air.

Caution: Do not wire brush parts.

D. Cleaning Fluids — The following fluids may be

used for cleaning PTFE hose assemblies.

Table II

Fluids for Cleaning PTFE Hose Assemblies

Fluid Specification

Hose Assemblies:

Oleum Spirits Commercial

Kerosene P-S-661

Trichloroethylene MIL-T-7003 or OT634-A. Type II

*Synthetic Detergents MIL-D-16791

Fitting Components:

Trichloroethylene MIL-T-7003 or OT634-A. Type II

Caution: All dry filmed parts should be thoroughly

dried after cleaning and before reuse.

E. Hose Assemblies After Proof Test — Flush

hose assembly in cleaning fluid and blow dry

with filtered air or dry nitrogen.

6 EATON Aerospace Group TF100-63B October 2018