Eaton 93PM Series, 93PM-100-3, 93PM-100-1, 93PM-100-2, 93PM-50-2 Installation And Operation Manual

...

Eaton® 93PM UPS

480V Three-Wire – 100 kW Frame

Installation and Operation Manual

p/n: 164000227

Revision 07

IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

!

This manual contains important instructions that you should follow during installation and maintenance

of the UPS and batteries. Please read all instructions before operating the equipment and save this

manual for future reference.

CONSIGNES DE SÉCURITÉ IMPORTANTES — CONSERVER CES INSTRUCTIONS

Ce manuel comporte des instructions importantes que vous êtes invité à suivre lors de toute

procédure d'installation et de maintenance des batteries et de l'onduleur. Veuillez consulter

entièrement ces instructions avant de faire fonctionner l'équipement et conserver ce manuel afin de

pouvoir vous y reporter ultérieurement.

IMPORTANT

To ensure you have the most up-to-date content and information for this product, please review the

latest manual revision on our website, www.eaton.com/93PM.

Eaton reserves the right to change specifications without prior notice. Modbus is a registered trademark of Schneider Automation, Inc.

MOXA is a registered trademark and MGate is a trademark of MOXA, Inc. Spiralock is a registered trademark of Spiralock Corporation.

KIRK is a registered trademark of Kirk Key Interlock company, LLC, a subsidiary of Halma plc. National Electrical Code and NEC are

registered trademarks of National Fire Protection Association, Inc. ERIFLEX and FLEXIBAR are registered trademark of Erico International

Corporation. All other trademarks are property of their respective companies.

©Copyright 2013-2019 Eaton, Raleigh, NC, USA. All rights reserved. No part of this document may be reproduced in any way without the

express written approval of Eaton.

EATON

END-USER LICENSE AGREEMENT

IMPORTANT, READ CAREFULLY. THIS END USER LICENSE AGREEMENT (THE

“AGREEMENT”) IS A BINDING CONTRACT BETWEEN YOU, THE END-USER (THE

“LICENSEE”) AND EATON INTELLIGENT POWER LIMITED, IRELAND, OR ONE OF ITS

AFFILIATES (“EATON” OR “LICENSOR”). BY OPERATING THIS UNINTERRUPTIBLE

POWER SUPPLY (UPS) PRODUCT INCLUDING SOFTWARE EMBEDDED IN IT

(FIRMWARE), YOU, THE LICENSEE, ARE AGREEING TO BE BOUND BY THE TERMS,

CONDITIONS, AND LIMITATIONS OF THIS AGREEMENT. READ THE TERMS AND

CONDITIONS OF THIS AGREEMENT CAREFULLY BEFORE, INSTALLING OR OPERATING

THE PRODUCT. IF YOU DO NOT AGREE TO THE TERMS OF THIS AGREEMENT,

PROMPTLY RETURN THE UNUSED PRODUCT TO EATON.

1.0 DEFINITIONS

1.1 Documentation. “Documentation” means the user guides and manuals for the installation

and use of the UPS, whether made available over the internet, provided in CD-ROM, DVD,

hard copy or other form.

1.2 Firmware. “Firmware” means software programs that are embedded in the product for

which Licensee is granted a license hereunder, the Documentation therefore and, to the extent

available, Updates thereto. The Firmware is licensed hereunder in object code (machinereadable) form only except that certain software programs may include limited portions in

source code (human-readable) form.

1.3 Update. “Update” means a subsequent release of the Firmware, if and when developed by

Eaton. An Update does not include any release, new version, option, or future product, which

Eaton licenses separately.

2.0 FIRMWARE LICENSE

2.1 Ownership. Eaton or its third party licensors retains all title, copyright and other proprietary

rights in, and ownership of the Firmware regardless of the media upon which the original or any

copy may be recorded or xed.

2.2 License Grant. Eaton grants to Licensee a limited, revocable, non-exclusive, non-assignable

license to use the Firmware in conjunction with the operation of the product to which the Firmware

pertains or other products as described by Eaton in the Documentation. Licensee does not

acquire any rights, express or implied, other than those expressly granted in this Agreement.

2.3 Restrictions and Requirements. Licensee will not, nor will it permit others to, modify,

adapt, translate, reverse engineer, decompile, or disassemble the Firmware or any component

thereof (including the Documentation), or create derivative works based on the Firmware

(including the Documentation), except to the extent such foregoing restriction is prohibited by

applicable law or applicable open source license to, and only to, any open source software

component that is incorporated into the Firmware (if any). Copyright laws and international

treaties protect the Firmware, including the Documentation. Unauthorized copying of the

Firmware, the Documentation or any part thereof, is expressly prohibited. For avoidance of

doubt, Eaton does not grant Licensee a license to any of Eaton’s brands, logos, designs, trade

dress, service marks, trademarks, domain names or trade names, in whole or in part.

Licensee agrees to install or allow installation of all corrections of substantial defects, security

patches, minor bug xes and updates, including any enhancements, for the Firmware in

accordance with the instructions and as directed by Eaton.

2.4 Transfer and Assignment Restrictions. Licensee will not sell, resell, assign, lease,

sublicense, encumber, or otherwise transfer its interest in this Agreement or in the Firmware,

or the Documentation in whole or in part, or allow any other person or entity, including any

parent or subsidiary of Licensee or other subsidiary of Licensee’s parent, to copy, distribute,

or otherwise transfer the Firmware without the prior written consent of Eaton. Licensee may

transfer the Firmware directly to a third party only in connection with the sale of the Eaton

product in which it is installed.

3.0 TERMINATION

3.1 Termination. This Agreement and the license granted hereunder automatically terminates

if Licensee breaches any provision of this Agreement. Eaton may terminate this license at any

time with or without cause.

3.2 Effect of Termination. Immediately upon termination of this Agreement or the license

granted hereunder, Licensee will cease using the product. The parties’ rights and obligations

under the following sections of this Agreement will survive termination of this Agreement: Article

1.0, Section 2.1, Section 2.3, Section 2.4, Article 3.0, Article 4.0 and Article 5.0.

4.0 INFRINGEMENT AND WARRANTIES

4.1 Infringement. If Licensee learns of a threat, demand, allegation, or indication that the

UPS with its rmware infringes or misappropriates any third party intellectual property rights

(including but not limited to any patent, copyright, trademark, trade dress, or trade secret)

(“Intellectual Property Claim”), Licensee will notify Eaton promptly of such claim. Eaton may, in

its sole discretion, elect to assume sole control of the defense and settlement of said Intellectual

Property Claim and Licensee will provide reasonable information and assistance to Eaton for

the defense of such claim.

4.2 Disclaimer of Warranties. THE FIRMWARE IS PROVIDED “AS IS” WITHOUT

WARRANTY OF ANY KIND, . EATON DOES NOT WARRANT THAT THE FIRMWARE

WILL BE ERROR-FREE OR SECURE FROM UNAUTHORIZED ACCESS. THE LICENSEE

EXPRESSLY ACKNOWLEDGES THAT TO THE EXTENT PERMITTED BY APPLICABLE

LAW, THE USE OF THE PRODUCT IS AT LICENSEE’S SOLE RISK.

5.0 GENERAL PROVISIONS

5.1 Update Policy. Eaton may from time to time, but has no obligation to, create Updates of

the Firmware or components thereof.

5.2 Limitation on Liability. NOTWITHSTANDING ANY PROVISION OF THIS AGREEMENT

TO THE CONTRARY, LICENSEE EXPRESSLY UNDERSTANDS AND AGREES THAT

EATON, ITS AFFILIATES, AND ITS LICENSORS, WILL NOT BE LIABLE FOR: (A) ANY

DIRECT, INDIRECT, INCIDENTAL, SPECIAL, CONSEQUENTIAL OR EXEMPLARY

DAMAGES WHICH MAY BE INCURRED BY LICENSEE OR ANY THIRD PARTY,

HOWEVER CAUSED AND UNDER ANY THEORY OF LIABILITY. THIS WILL INCLUDE,

BUT NOT BE LIMITED TO, ANY LOSS OF PROFIT (WHETHER INCURRED DIRECTLY OR

INDIRECTLY), ANY LOSS OF GOODWILL OR BUSINESS REPUTATION, ANY LOSS OF

DATA SUFFERED, COST OF PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES,

OR OTHER INTANGIBLE LOSS; (B) ANY LOSS OR DAMAGE WHICH MAY BE INCURRED

BY LICENSEE OR ANY THIRD PARTY. THESE LIMITATIONS ON EATON’S LIABILITY WILL

APPLY WHETHER OR NOT EATON HAS BEEN ADVISED OF OR SHOULD HAVE BEEN

AWARE OF THE POSSIBILITY OF ANY SUCH LOSSES ARISING.

TO THE EXTENT PERMITTED BY LAW, THE TOTAL LIABILITY OF EATON, ITS AFFILIATES,

AND ITS LICENSORS, FOR ANY CLAIMS UNDER THESE TERMS, INCLUDING FOR ANY

IMPLIED WARRANTIES, IS LIMITED TO THE AMOUNT PAID FOR THE UPS.

THIS SECTION 5.2 STATES EATON’S ENTIRE LIABILITY AND LICENSEE’S SOLE AND

EXCLUSIVE REMEDY UNDER THIS AGREEMENT, AND IS SUBJECT TO ALL LIMITATIONS

STATED IN SECTION 4.2.

5.3 Notices. All notices required to be sent hereunder will be in writing and will be deemed to

have been given when mailed by rst class mail to the address shown below:

LICENSE NOTICES:

Eaton Intelligent Power Limited

Eaton House,

30 Pembroke Road,

Dublin 4,

D04 Y0C2,

Ireland

5.4 Severability. If any provision of this Agreement is held to be invalid or unenforceable, the

remaining provisions of this Agreement will remain in full force.

5.5 Waiver. The waiver by either party of any default or breach of this Agreement will not

constitute a waiver of any other or subsequent default or breach. Failure to enforce or delay in

enforcing any provision of this Agreement will not constitute a waiver of any rights under any

provisions of this Agreement.

5.6 Entire Agreement. This Agreement constitutes the complete agreement between the

parties and supersedes all prior or contemporaneous agreements or representations, written

or oral, concerning the subject matter of this Agreement. This Agreement may not be modied

or amended except in a writing specically referencing this Agreement and signed by a duly

authorized representative of each party. No other act, document, usage or custom will be

deemed to amend or modify this Agreement. The Firmware, or portions thereof, may also

be subject to additional paper or electronic license agreements. In such cases, the terms of

this Agreement will be supplemental to those in the additional agreements, to the extent not

inconsistent with the additional agreements. If a copy of this Agreement in a language other

than English is included with the Firmware or Documentation, it is included for convenience and

the English language version of this Agreement will control.

5.7 Heirs, Successors, and Assigns. Each and all of the covenants, terms, provisions

and agreements herein contained will be binding upon and inure to the benet of the parties

hereto and, to the extent expressly permitted by this Agreement, their respective heirs, legal

representatives, successors and assigns.

5.8 Export Restrictions. Licensee agrees to comply fully with all relevant export laws and

regulations of the United States and all other countries in the world (the “Export Laws”) to

assure that neither the Firmware nor any direct product thereof are (I) exported, directly or

indirectly, in violation of Export Laws; or (ii) are intended to be used for any purposes prohibited

by the Export Laws. Without limiting the foregoing, Licensee will not export or re-export the

Firmware: (i) to any country to which the U.S. has embargoed or restricted the export of

goods or services (see http://www.treasury.gov/resource-center/sanctions/Programs/Pages/

Programs.aspx), or to any national of any such country, wherever located, who intends to

transmit or transport the Firmware back to such country; (ii) to any end user who Licensee

knows or has reason to know will utilize the Firmware in the design, development or production

of nuclear, chemical or biological weapons; or (iii) to any end-user who has been prohibited

from participating in U.S. export transactions by any federal agency of the U.S. government.

5.9 U.S. Government Restricted Rights. The Firmware is a “commercial item” as that term

is dened at 48 C.F.R. § 2.101, consisting of “commercial computer software” and “commercial

computer software documentation”, as such terms are used in 48 C.F.R. § 12.212, and is

provided to the U.S. Government only as a commercial end item. Consistent with 48 C.F.R.

§ 12.212 and 48 C.F.R. §§ 227.7202-1 through 227.7202-4, all U.S. Government End Users

acquire the Firmware with only those rights set forth herein. Contractor/manufacturer is Eaton

Corporation, 1000 Eaton Boulevard, Cleveland, Ohio 44122.

5.10 Third Party Intellectual Property Rights. The Firmware may contain components

(including open source software components) that are owned by third parties (“Third Party

Licensors”) and are provided with, incorporated into, or embedded in, the Firmware pursuant to

license arrangements between Eaton and such third parties. Third Party Licensor components

in the Firmware are not licensed or warranted under the terms of this document, but are instead

subject to the Third Party Licensors’ license agreements. Licensee will not modify, delete, or

obfuscate any copyright or other proprietary rights notices of Third Party Licensors contained

in the Firmware.

5.11 Indemnity. Licensee shall defend, indemnify and hold Eaton and its ofcers, directors,

employees, and agents harmless from and against all losses, damages, liabilities, claims,

actions, and associated costs and expenses (including reasonable attorneys’ fees and expenses)

by reason of injury or death to any person or damage to any tangible or intangible property arising

or resulting from the negligence or willful misconduct of the Licensee, its employees, contractors,

or agents, in connection with Licensee’s use of Firmware and Documentation.

Licensee shall be responsible for any breach of this Agreement by its ofcers, directors,

employees, contractors, or agents. Licensee shall defend, indemnify, and hold Eaton and

its ofcers, directors, employees, and agents harmless from and against any and all losses,

damages, liabilities, claims, actions, and associated costs and expenses (including reasonable

attorneys’ fees and expenses) arising out of or in connection with any breach of this Agreement.

5.12 Open Source Software. The Firmware may contain certain components owned by

Eaton that are provided with, incorporated into, linked to, or embedded in the Firmware that are

subject to third party open source licenses (“Eaton Open Source Components”). Eaton Open

Source Components are subject to the open source licenses corresponding to the particular

software component. To the extent there are any conicts between the terms of this Agreement

and any open source license corresponding to Eaton Open Source Components or additional

obligations by such open sources license that are not set forth in this Agreement, the terms of

the open source license will control.

5.13 Condentiality. Licensee acknowledges that condential aspects of the Firmware

(including any proprietary source code) are a trade secret of Eaton, the disclosure of which

would cause substantial harm to Eaton that could not be remedied by the payment of damages

alone and such condential aspects of the Firmware shall not be disclosed to third parties

without the prior written consent of Eaton. Accordingly, Eaton will be entitled to preliminary and

permanent injunctive and other equitable relief for any breach of this Section 5.13.

5.14 Note on JAVA Support. The Firmware may contain support for programs written in JAVA.

JAVA technology is not fault tolerant and is not designed, manufactured, or intended for use or

resale as online control equipment in hazardous environments requiring fail-safe performance,

such as in the operation of nuclear facilities, aircraft navigation or communications systems, air

trafc control, direct life support machines, or weapons systems, in which the failure of JAVA

technology could lead directly to death, personal injury, or severe physical or environmental

damage. EATON DISCLAIMS ALL DAMAGES INCLUDING DIRECT, INDIRECT AND

CONSEQUENTIAL DAMAGES RELATING TO THE FAILURE OF ANY SOFTWARE

INCLUDING JAVA PROGRAMS AND/OR JAVA TECHNOLOGY.

5.15 Governing Law. This Agreement will be interpreted and enforced in accordance with the

laws of Ireland, without regard to choice of law principles. Any claim or suit with respect to this

Agreement shall be brought in the Courts of Ireland, unless mandatory law imposes otherwise.

Eaton EULA

P-110000654-001 Revised: December 21st, 2018

TTaabbllee ooff CCoonntteennttss

11 IInnttrroodduuccttiioonn....................................................................................................................................................................................................................................................................................................11

1.1 UPS Standard Features . ... ... .......... ... ....... ... ... .......... ... ............. .......... ... ... .......... ... ....... ... ... .......... ... ............. . 1

1.1.1 Installation Features .... ... .......... ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... ......... 1

1.1.2 Control Panel . .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .......... ... .......... . 3

1.1.3 Customer Interface . ....... ... ... ... ....... ... .......... ... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... ...3

1.1.4 Energy Saver System Mode.. ... .......... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... . 3

1.1.5 Internal Redundancy.... .......... ... ... .......... ............. ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... .. 3

1.1.6 UL 924 Auxiliary Lighting and Power Equipment Certification .... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... . 3

1.1.7 Advanced Battery Management.. ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... ....... ... .......... ... ... ......... 3

1.2 Options and Accessories..... ............. ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ... .......... .......... . 4

1.2.1 Integrated Battery Cabinet . ... .......... ... .......... ... ... .......... .......... ... ... .......... ... .......... ... .......... ... ... .......... ....... 4

1.2.2 Integrated Accessory Cabinet-Distribution... ... .......... ... .......... ... ... .......... ... .......... ... .......... ... ... .......... .......... . 4

1.2.3 Integrated Accessory Cabinet-Power Distribution ...... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... . 4

1.2.4 Sidecar Integrated Accessory Cabinet-Bypass... ... ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... ...4

1.2.5 Sidecar Integrated Accessory Cabinet-Tie .... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... .......... .......... 5

1.2.6 Sidecar Integrated Accessory Cabinet-Tie Bypass..... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... .. 5

1.2.7 Integrated Accessory Cabinet-Tie . ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ... .......... ... ....... . 5

1.2.8 Parallel System .... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ..... 5

1.2.9 Top Entry Wiring Sidecar ...... ... .......... ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ............. ... . 5

1.2.10 Monitoring and Communication ... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... ......5

1.2.11 Additional Output Surge Protection . ... .......... ... ... .......... .......... ... ... .......... ... ............. .......... ... ... .......... ... .... 6

1.3 Battery System . ... ....... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... .......... ... ....... ... ... .......... ... ............. . 6

1.4 Basic System Configurations...... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... ... ....... ... .......... ... ... .. 6

1.5 Using This Manual .... ... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... .......... ... ............. ... . 6

1.6 Conventions Used in This Manual ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... ....... ... .......... 7

1.7 Symbols, Controls, and Indicators ....... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... .......... 7

1.8 For More Information ... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. . 8

1.9 Getting Help.. ... ....... ... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... .......... ... ............. ... . 9

1.10 Equipment Registration... ... .......... ... ............. .......... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... .......... 9

22 SSaaffeettyy WWaarrnniinnggss.................................................................................................................................................................................................................................................................................... 1111

33 UUPPSS IInnssttaallllaattiioonn PPllaann aanndd UUnnppaacckkiinngg ........................................................................................................................................................................................................................ 1133

3.1 Creating an Installation Plan ...... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... .......... ... . 13

3.2 Preparing the Site ......... ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... . 13

3.2.1 Environmental and Installation Considerations ... ... .......... ... ... .......... ............. ... .......... ... ... ....... ... .......... ... ... 13

3.2.2 UPS System Power Wiring Preparation .... ... ....... ... ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... . 24

3.2.3 External Parallel UPS System Power Wiring Preparation... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... . 25

3.2.4 UPS System Interface Wiring Preparation ..... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... ... ... .... 35

3.3 Inspecting and Unpacking the UPS Cabinets .......... .......... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .... 37

Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07 v

Table of Contents

44 UUPPSS SSyysstteemm IInnssttaallllaattiioonn .............................................................................................................................................................................................................................................................. 3399

4.1 Preliminary Installation Information..... .......... ... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... .......... ... ......... 39

4.2 Unloading the UPS Cabinet from the Pallet......... ... .......... ... .......... ... .......... ... ... .......... ............. ... .......... ... ........ 39

4.3 Integrated Battery Cabinet Installation...... ............. ... .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... . 43

4.4 Sidecar Integrated Accessory Cabinet-Bypass Wiring Installation..... ... .......... ... ............. ... ....... ... ... .......... ... ......... 44

4.5 Sidecar Integrated Accessory Cabinet-Tie Wiring Installation....... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... 44

4.6 Sidecar Integrated Accessory Cabinet-Tie Bypass Wiring Installation .......... ... ... .......... .......... ... ... .......... ... .......... .. 44

4.7 Integrated Accessory Cabinet-Tie..... ... .......... ... .......... ... ... .......... ... ....... ... ... .......... ... ............. .......... ... ... ........ 44

4.8 Integrated Accessory Cabinet-Distribution ...... ... .......... ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... . 44

4.9 External AC Power Wiring Installation ...... ... .......... ... ... .......... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... . 45

4.10 Battery Power Wiring... ... ... ....... ... ............. ... ....... ... ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... . 50

4.11 Installing Interface Connections ....... ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ... .......... ... ...... 51

4.11.1 Installing Building Alarm and Relay Contact Connections .......... ............. ... .......... ... ... ....... ... .......... ... ... ....... 51

4.11.2 Installing Battery Detect Interface Connections ...... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... 55

4.11.3 Installing Battery Shunt Trip Interface Connections.... ... ............. ... ....... ... ... ... ....... ... .......... ... ... ....... ... ........ 57

4.11.4 Generator Interface Connections . ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... ....... ... ........ 60

4.11.5 Installing External Parallel CAN Control Wiring and Connections..... ... ............. ... ....... ... ... .......... ... .......... ... ... 61

4.11.6 Installing External Parallel Pull Chain Control Wiring and Connections..... ... ............. ... ....... ... ... ... ....... ... ......... 64

4.11.7 Installing Minislot Interface Connections . ... .......... ... ... .......... .......... ... ... .......... ... ............. .......... ... ... ........ 66

4.12 Installing a REPO Switch .... ... ............. ... ....... ... ... ... ....... ... .......... ... ... ....... ... ... .......... ... ....... ... ... ... ....... ... ..... 67

4.13 Initial Startup.... .......... ... ... .......... ............. ... .......... ... ... .......... .......... ... ... .......... ... .......... ... .......... ... ... ........ 70

4.14 Completing the Installation Checklist...... ... .......... ... .......... ... ... .......... .......... ... ... .......... ... ............. .......... ... ... . 71

55 UUnnddeerrssttaannddiinngg UUPPSS OOppeerraattiioonn ............................................................................................................................................................................................................................................ 7733

5.1 UPS System Overview ... ... .......... ... ... .......... ............. ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... 73

5.2 Single UPS.. ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... . 74

5.2.1 Modes.... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... .. 74

5.2.2 Energy Saver System Mode.. ... .......... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. .. 75

5.2.3 Normal Mode.... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ... .......... ... ...... 76

5.2.4 Bypass Mode.... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... ....... ... ... .......... ... ...... 77

5.2.5 Battery Mode.... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ... .......... ... ...... 78

66 UUPPSS OOnneelliinnee SScchheemmaattiiccss............................................................................................................................................................................................................................................................ 7799

77 UUPPSS OOppeerraattiinngg IInnssttrruuccttiioonnss.................................................................................................................................................................................................................................................... 8855

7.1 UPS Controls and Indicators... ... ... .......... ... .......... ... .......... ... ... .......... .......... ... ... .......... ... ............. .......... ... ... . 85

7.2 Using the Control Panel ...... ............. ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ... .......... ......... 85

7.2.1 Status Indicators.... .......... ... .......... ... .......... ... ... .......... ... ....... ... ... .......... ... ............. .......... ... ... .......... ... .. 86

7.2.2 System Events... .......... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... .......... ........ 87

7.2.3 Using the LCD Touch Screen....... ... ....... ... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... .......... ... ......... 87

7.2.4 Using the Menu... ... .......... ... ... ....... ... .......... ... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... . 88

7.2.5 Mimic Screen .... .......... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... .......... ........ 89

7.2.6 Display Menu Operation.. ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .... 89

vi Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07

Table of Contents

7.2.7 Sign In... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .......... ... .......... ... ... 95

7.2.8 System Controls... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .......... ... ... ....... ... ............. ... ... 97

7.3 Single UPS Operation ...... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... ....... 100

7.3.1 Starting the UPS in Double Conversion Mode .......... .......... ... ... .......... ... .......... ... .......... ... ............. ... ....... . 100

7.3.2 Starting the UPS in Bypass Mode... ... .......... ... .......... ... ... .......... ............. ... .......... ... .......... ... .......... ... ... .. 101

7.3.3 Starting the UPMs ... .......... ... ... .......... ... .......... ... .......... ... ... .......... ............. ... .......... ... ............. .......... . 101

7.3.4 Starting a Single UPM.. ... ....... ... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... ... ..... 101

7.3.5 Transfer from Double Conversion to Bypass Mode ...... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .. 102

7.3.6 Transfer from Bypass to Double Conversion Mode ...... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .. 102

7.3.7 Transfer from ESS Mode to Double Conversion Mode .... ... .......... ... ... .......... ... .......... ... .......... ... ... ....... ... ... 102

7.3.8 Transfer from Double Conversion Mode to ESS Mode .... ... .......... ... ... .......... ... .......... ... .......... ... ... ....... ... ... 103

7.3.9 Transfer from Double Conversion to Bypass Mode and Shut Down UPMs .. .......... ... ... .......... ............. ... ........ 103

7.3.10 Single UPM Shutdown ...... ... .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... ....... ... .......... ... . 103

7.3.11 Single UPM Restart ...... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... .. 104

7.3.12 UPS and Critical Load Shutdown .... ... .......... ... ... .......... .......... ... ... .......... ... ............. .......... ... ... .......... ... 104

7.3.13 Charger Control ..... .......... ... ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... . 104

7.3.14 Battery Test.. ....... ... ... .......... ... ............. ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... ...... 104

7.3.15 Using the UPS LOAD OFF Command..... .......... ... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... ......... 105

7.3.16 Using the Remote Emergency Power-off Switch ...... ... ............. ... ....... ... ... .......... ... .......... ... .......... ... ...... 105

7.4 Multiple External Parallel System Operation ...... ... ............. ... ....... ... ... .......... ... .......... ... .......... ... ... .......... ... .... 107

7.4.1 Starting the Parallel System in Double Conversion Mode...... ... ... ....... ... ............. ... .......... ... .......... ... .......... . 107

7.4.2 Starting the Parallel System in Bypass Mode .... ... ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... .. 107

7.4.3 Starting the Parallel System UPMs ...... ... ....... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... .......... ... 108

7.4.4 Starting a Single UPM.. ... ....... ... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... ... ..... 108

7.4.5 Transfer from Double Conversion to Bypass Mode ...... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .. 108

7.4.6 Transfer from Bypass to Double Conversion Mode ...... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .. 109

7.4.7 Transfer from ESS Mode to Double Conversion Mode .... ... .......... ... ... .......... ... .......... ... .......... ... ... ....... ... ... 109

7.4.8 Transfer from Double Conversion Mode to ESS Mode .... ... .......... ... ... .......... ... .......... ... .......... ... ... ....... ... ... 109

7.4.9 Transfer from Double Conversion to Bypass Mode and Shut Down all UPMs ............ ... ....... ... ... .......... ... ....... 109

7.4.10 Single UPM Shutdown ...... ... .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... ....... ... .......... ... . 110

7.4.11 Single UPM Restart ...... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... .. 110

7.4.12 Single UPS Shutdown ... ... ... .......... ... .......... ... ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... .. 110

7.4.13 Single UPS Restart ..... ... .......... ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ... .......... ... .... 111

7.4.14 Parallel System and Critical Load Shutdown... ... ... ....... ... .......... ... ... ....... ... ... .......... ... .......... ... ... ....... ... ... 111

7.4.15 Charger Control ..... .......... ... ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... . 112

7.4.16 Battery Test.. ....... ... ... .......... ... ............. ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... ...... 112

7.4.17 Using the LOAD OFF Command.... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .......... ... .......... ... . 112

7.4.18 Using the Remote Emergency Power-off Switch ...... ... ............. ... ....... ... ... .......... ... .......... ... .......... ... ...... 113

88 UUPPSS MMaaiinntteennaannccee..............................................................................................................................................................................................................................................................................111155

8.1 Important Safety Instructions ...... ... .......... ... ... .......... ............. ... .......... ... ... .......... .......... ... ... .......... ... .......... 115

8.2 Performing Preventive Maintenance .... ............. ... .......... ... .......... ... .......... ... ... .......... ............. ... .......... ... ...... 115

Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07 vii

Table of Contents

8.2.1 DAILY Maintenance ..... ............. .......... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .......... ... ....... 116

8.2.2 MONTHLY Maintenance . ....... ... ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... ..... 116

8.2.3 PERIODIC Maintenance.. .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... ....... ... .......... ... ... ..... 117

8.2.4 ANNUAL Maintenance.... .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... ....... ... .......... ... ... ..... 117

8.2.5 BATTERY Maintenance... .......... ... ... .......... .......... ... ... .......... ... ............. .......... ... ... .......... ... ....... ... ... ..... 117

8.3 Installing Batteries . .......... ... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... .......... ... ...... 118

8.4 Recycling the Used Battery or UPS.... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... .. 118

8.5 Maintenance Training . ... ....... ... ... .......... ... .......... ... ... ....... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... .. 118

99 CCoommmmuunniiccaattiioonn ....................................................................................................................................................................................................................................................................................111199

9.1 Minislot Cards.... .......... ... ... .......... ............. ... .......... ... ... .......... .......... ... ... .......... ... .......... ... .......... ... ... ...... 119

9.2 Building Alarm Monitoring .... ... ............. ... .......... ... ... ....... ... .......... ... ... ....... ... ... .......... ... .......... ... ... ....... ... ... 120

9.3 General Purpose Relay Contact ...... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... .......... 120

9.4 PredictPulse Remote Monitoring and Management Service....... ... ............. ... ....... ... ... .......... ... .......... ... .......... .. 120

9.4.1 PredictPulse Service Features .... ... ... ....... ... .......... ... ... ....... ... ............. ... ....... ... ... ... ....... ... .......... ... ... ..... 120

9.4.2 Installing PredictPulse ... .......... ... ............. .......... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... ...... 121

1100 PPrroodduucctt SSppeecciiffiiccaattiioonnss............................................................................................................................................................................................................................................................112233

10.1 Model Numbers .... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... . 123

10.2 Specifications.... ............. ... ....... ... ... ... ....... ... .......... ... ... ....... ... ............. ... ....... ... ... ... ....... ... .......... ... ... ..... 123

10.2.1 UPS Input... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .......... ... ... ....... ... ............. ... ........ 123

10.2.2 UPS Output ..... .......... ... .......... ... .......... ... ... .......... ... .......... ... .......... ... ... .......... .......... ... ... .......... ... ... 124

10.2.3 UPS Environmental .... .......... ... .......... ... ... .......... ............. ... .......... ... .......... ... .......... ... ... .......... .......... 124

1111 WWaarrrraannttyy....................................................................................................................................................................................................................................................................................................112255

viii Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07

LLiisstt ooff FFiigguurreess

Figure 1. Eaton 93PM UPS – 100 kW Frame ... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... ... ....... ... 2

Figure 2. Eaton 93PM UPS –100 kW Frame with Left or Right-Mounted Sidecar .... ... .......... ... ... ....... ... ............. ... ..... 2

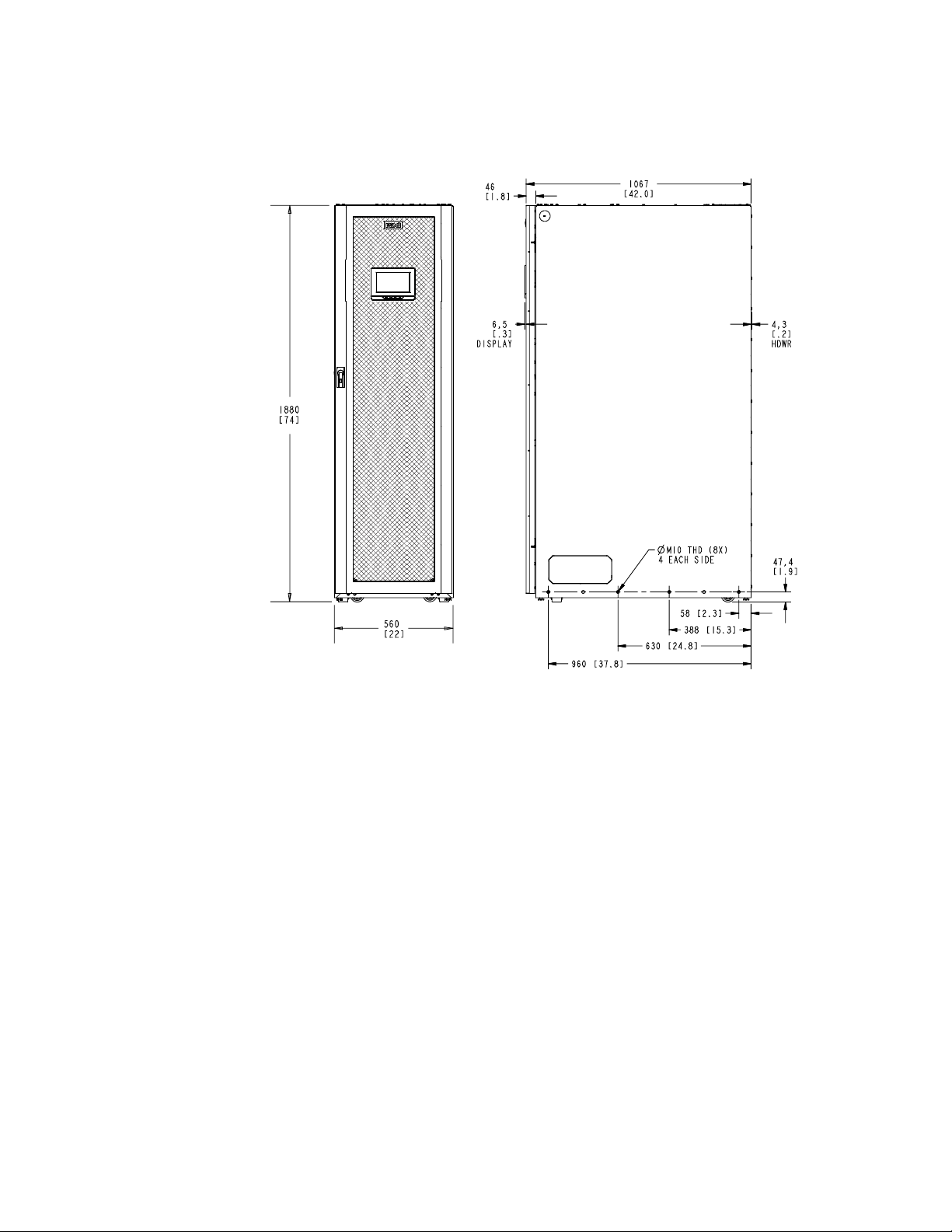

Figure 3. UPS Cabinet Dimensions (Front and Right Side Views)..... ... .......... ... .......... ... ... ....... ... ............. ... .......... 17

Figure 4. UPS Cabinet Dimensions (Top and Bottom Views) ...... ... ............. .......... ... ... .......... ... .......... ... .......... ... . 18

Figure 5. UPS Cabinet Front and Back Floor Mounting Bracket Mounting Dimensions (Back Views) .. ... ....... ... ............ 19

Figure 6. UPS Cabinet with Left or Right-Mounted Sidecar Dimensions (Front Views) ......... ... .......... ... .......... ... ... .... 20

Figure 7. UPS Cabinet with Left or Right-Mounted Sidecar Dimensions (Top and Bottom Views) ....... ... ... ....... ... ........ 21

Figure 8. UPS Cabinet Center of Gravity .... ... .......... ............. ... .......... ... .......... ... .......... ... ... .......... ............. ... ... 22

Figure 9. UPS Cabinet with Left or Right-Mounted Sidecar Center of Gravity..... ... ....... ... ... ... ....... ... .......... ... ... ....... 23

Figure 10. Remote EPO Switch Dimensions ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... ... 24

Figure 11. 93PM External Parallel Wire Length .... ... .......... ... .......... ... .......... ... ............. .......... ... ... .......... ... ......... 26

Figure 12. UPS Cabinet as Shipped on Pallet . ... .......... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .. 38

Figure 13. UPS Cabinet with Left-Mounted or Right-Mounted Sidecar as Shipped on Pallet....... ... ............. ... .......... ... . 38

Figure 14. Removing the Pallet Skids and Supports – Eaton 93PM UPS ....... ... ............. ... ....... ... ... .......... ... ....... ... ... 40

Figure 15. Removing the Sidecar Pallet Skids and Supports – Eaton 93PM UPS...... ... .......... ... ............. ... ....... ... ... .... 41

Figure 16. Removing the Sidecar Rear Shipping Bracket – Eaton 93PM UPS .... ... ............. ... .......... ... ... ....... ... ......... 43

Figure 17. UPS Conduit and Wire Entry Locations .... ... .......... ... .......... ... .......... ... ... .......... ... ....... ... ... .......... ... ..... 46

Figure 18. Sidecar Conduit and Wire Entry Locations .... ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... . 47

Figure 19. UPS Inter-Cabinet Wiring Access Location... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .. 48

Figure 20. Power Terminal Locations... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .......... ... 49

Figure 21. Power Terminal Detail......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... .......... ... .......... ... ...... 50

Figure 22. Interface Terminal Locations.... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... ... ......... 52

Figure 23. Interface Terminal Detail............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .. 52

Figure 24. Bottom Access Interface Wiring Location.. ... ....... ... ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... . 53

Figure 25. Wire Tie Anchors .... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... ... ....... ... .......... ... ... ....... 54

Figure 26. Building Alarm Terminal Block Connector Assignments..... .......... ... ... .......... ... ....... ... ... .......... ... ............ 55

Figure 27. Relay Contact Terminal Block Connector Assignments...... .......... ... ... .......... ... ....... ... ... .......... ... ............ 55

Figure 28. Battery Shunt Trip Location .... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... ... ... .... 58

Figure 29. Battery Shunt Trip Terminal Detail... ... .......... ... ....... ... ... .......... ... ............. .......... ... ... .......... ... ....... ... ... 59

Figure 30. Battery Shunt Trip Terminal Assignments.. ... ....... ... ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... . 60

Figure 31. External Parallel CAN Wiring . .......... ... ... ....... ... ............. ... .......... ... .......... ... .......... ... ... .......... ............ 63

Figure 32. External Parallel Terminal Block . .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... .......... ........ 63

Figure 33. External Parallel Pull Chain Wiring . .......... ... ... .......... .......... ... ... .......... ... ............. .......... ... ... .......... ... .. 65

Figure 34. REPO Switch .... ....... ... ............. ... .......... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .. 68

Figure 35. REPO Terminal Block Connector Assignments ...... ... .......... ... ... ....... ... .......... ... ... .......... ... .......... ... ...... 69

Figure 36. Normally-Open REPO Switch Wiring .... ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... ........ 69

Figure 37. Normally-Closed REPO Switch Wiring ... .......... ... ... .......... ............. ... .......... ... ... ....... ... .......... ... ... ....... 70

Figure 38. Main Elements of the UPS System ...... ... ....... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... ........ 73

Figure 39. Path of Current Through the UPS in Energy Saver System Mode...... ... ............. .......... ... ... .......... ... ......... 75

Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07 ix

List of Figures

Figure 40. Path of Current Through the UPS in Normal Mode...... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... .. 76

Figure 41. Path of Current Through the UPS in Bypass Mode...... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .. 77

Figure 42. Path of Current Through the UPS in Battery Mode...... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... .. 78

Figure 43. Eaton 93PM UPS System Oneline .... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... ... ....... . 80

Figure 44. Eaton 93PM UPS System with Two-Breaker Bypass Oneline...... ... ....... ... ... ... ....... ... ............. ... ....... ... ... . 81

Figure 45. Eaton 93PM UPS System with Three-Breaker Bypass Oneline..... ... .......... ... .......... ... ... .......... .......... ... ... 82

Figure 46. Eaton 93PM UPS System with Four-Breaker Bypass Oneline ...... ... .......... ... .......... ... ... .......... .......... ... ... 83

Figure 47. UPS Controls and Indicators .... ... .......... ............. ... .......... ... ... ....... ... .......... ... ... .......... ... .......... ... ...... 85

Figure 48. UPS Control Panel.. ....... ... ............. ... .......... ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... . 86

Figure 49. Parts of the LCD ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... ... ....... ... ......... 88

Figure 50. Main Menu and Mimic Screen .... ... .......... ... .......... ... .......... ... ............. .......... ... ... .......... ... .......... ... ... 89

Figure 51. Typical Meters Summary Screen ...... .......... ... ... .......... ... .......... ... .......... ... ............. .......... ... ... .......... . 91

Figure 52. Typical Active Events Screen ..... ............. ... .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... . 92

Figure 53. Typical System Log Screen ... ... .......... ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... ... ........ 92

Figure 54. Typical Settings User Screen .... ... ....... ... ... .......... ... .......... ... .......... ... ... .......... ... ....... ... ... .......... ... ..... 93

Figure 55. Typical Information Screen.. ....... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .......... ... 93

Figure 56. Typical About Screen ..... .......... ... .......... ... ... ....... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... . 94

Figure 57. Typical Settings Configuration 1 Screen .... ... .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... . 94

Figure 58. Typical Settings Configuration 2 Screen .... ... .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... . 95

Figure 59. Typical Statistics Screen . ....... ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... ... . 95

Figure 60. Sign In Password Screen .... ... .......... ... .......... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... .......... 96

Figure 61. Sign In Keypad.... .......... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .......... ... ... .......... . 96

Figure 62. Typical System Control Screen ..... .......... ... ... ....... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... . 98

Figure 63. Typical UPS Control Screen ...... .......... ... ... .......... ... .......... ... .......... ... ... .......... .......... ... ... .......... ... ..... 98

Figure 64. Typical UPM Select Screen ... ............. ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... ........ 99

Figure 65. Typical UPM Control Screen ..... ... ....... ... ... .......... ... .......... ... .......... ... ... .......... ... ....... ... ... .......... ... ..... 99

Figure 66. Typical EAA Control Screen ...... ... ....... ... ... .......... ... .......... ... ... ....... ... ... .......... ... ....... ... ... .......... ... ... 100

Figure 67. REPO Operation .... .......... ............. ... .......... ... ... ....... ... .......... ... ... .......... ............. ... .......... ... ... ...... 106

Figure 68. Air Filter Location .... ... ....... ... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... ... ... .. 117

Figure 69. Optional Minislot Cards ..... .......... ... ....... ... ... .......... ... ............. .......... ... ... .......... ... .......... ... .......... .. 119

x Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07

LLiisstt ooff TTaabblleess

Table 1. Air Conditioning or Ventilation Requirements During Full Load Operation.......... ... ....... ... ... .......... ... ............ 15

Table 2. UPS Cabinet Weights . .......... ... ... ....... ... ............. ... .......... ... ... ....... ... .......... ... ... .......... ... .......... ... ...... 16

Table 3. UPS Cabinet Clearances ... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... 16

Table 4. Input/Output Ratings and External Wiring Recommendations: Eaton 93PM-100-1 and 93PM-100-2 (N

+1) ......... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .......... ... ... ....... ... ............. ... ... 27

Table 5. Input/Output Ratings and External Wiring Recommendations: Eaton 93PM-100-2 and 93PM-100-3 (N

+1) ......... ... ... .......... ... .......... ... ... ....... ... ............. ... .......... ... .......... ... .......... ... ... ....... ... ............. ... ... 28

Table 6. UPS External Power Cable Terminations .... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .... 29

Table 7. Power Cable Conduit Recommendations: Eaton 93PM-100-1 and Eaton 93PM-100-2 (N+1) .. .......... ... ... ....... . 30

Table 8. Power Cable Conduit Recommendations: Eaton 93PM-100-2 and Eaton 93PM-100-3 (N+1) .. .......... ... ... ....... . 31

Table 9. Recommended Input and Bypass Circuit Breaker Ratings ...... ... ... .......... ... ....... ... ... .......... ... ............. ...... 32

Table 10. Recommended Output Circuit Breaker Ratings.. ... ... ....... ... .......... ... ... ....... ... ............. ... .......... ... ... ....... . 33

Table 11. Recommended DC Input Battery Disconnect Circuit Breaker Ratings (216 Cell) ... ....... ... ... .......... ... ....... ... ... 34

Table 12. Recommended DC Input Battery Disconnect Circuit Breaker Ratings (240 Cell) ... ....... ... ... .......... ... ....... ... ... 35

Table 13. Building Alarm Connections and Wire Terminations ....... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... 54

Table 14. Relay Contact Connections and Wire Terminations ......... ... .......... ... ... ....... ... .......... ... ... .......... ............. .. 55

Table 15. Battery Shunt Trip Connections and Wire Terminations ...... ... .......... ... ............. ... ....... ... ... .......... ... ......... 59

Table 16. External Parallel CAN and Pull Chain Connections..... ............. ... .......... ... ... .......... .......... ... ... .......... ... ..... 62

Table 17. External Parallel CAN and Pull Chain Terminal Block Terminations... ... ... .......... ... .......... ... ... ....... ... ............ 62

Table 18. Normally-Open REPO Connections and Wire Terminations..... ... ... ....... ... .......... ... ... ....... ... ... .......... ... ...... 69

Table 19. Normally-Closed REPO Connections and Wire Terminations .... ... .......... ... ... .......... .......... ... ... .......... ... ..... 70

Table 20. Status Indicators ... .......... ... ... .......... ............. ... .......... ... .......... ... .......... ... ... .......... ............. ... .......... 87

Table 21. Display Function Menu Map .... ... .......... ... ....... ... ... ... ....... ... ............. ... ....... ... ... .......... ... ....... ... ... ... .... 89

Table 22. Display Menu Operation ... ... ....... ... ... .......... ... .......... ... ... ....... ... ............. ... ....... ... ... .......... ... .......... ... 90

Table 23. Controls Menu Operation . ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... .......... ... .......... ... .......... ... . 97

Table 24. Typical System Status Messages... ... ....... ... ... .......... ... ....... ... ... .......... ... ............. ... ....... ... ... .......... ... .. 97

Table 25. IRC-MS Default Triggers .... .......... ... ... .......... ... .......... ... .......... ... ... .......... .......... ... ... .......... ... .......... 119

Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07 xi

List of Tables

xii Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07

CChhaapptteerr 11 IInnttrroodduuccttiioonn

The Eaton®93PM 480V Three-Wire - 100 kW Frame uninterruptible power supply (UPS) is a true online,

continuous-duty, transformerless, double-conversion, solid-state, three-phase system, providing conditioned

and uninterruptible AC power to protect the customer's load from power failures.

The Eaton 93PM UPS online power protection system is used to prevent loss of valuable electronic

information, minimize equipment downtime, and minimize the adverse effect on production equipment due to

unexpected power problems.

The Eaton 93PM UPS continually monitors incoming electrical power and removes the surges, spikes, sags,

and other irregularities that are inherent in commercial utility power. Working with a building's electrical

system, the UPS system supplies clean, consistent power that sensitive electronic equipment requires for

reliable operation. During brownouts, blackouts, and other power interruptions, batteries provide emergency

power to safeguard operation.

The Eaton 93PM – 100 kW Frame UPS is available with one, two, or three Uninterruptible Power Modules

(UPMs) integrated in one cabinet. Each UPM is rated for a maximum of 50 kW. The system maximum rating is

100 kW. To deliver greater reliability, UPS with two or three UPMs can provide N+1 redundancy up to a

maximum of 50 kW and 100 kW respectively. Should one UPM become unavailable or require servicing, the

remaining UPM supplies the load instead of transferring to bypass.

The UPS is housed in a single free-standing cabinet, with safety shields behind the door for hazardous voltage

protection. Power wiring is installed through the bottom of the cabinet with an optional sidecar available for top

entry wiring. Figure 1 shows the Eaton 93PM - 100 kW Frame UPS and Figure 2 shows the

Eaton 93PM - 100 kW Frame UPS with a left or right-mounted sidecar.

NOTE Startup and operational checks must be performed by an authorized Eaton Customer

Service Engineer, or the warranty terms specified on the product's resources page

become void. See Chapter 11 Warranty for details. This service is offered as part of the

sales contract for the UPS. Contact an Eaton service representative in advance (a

minimum two-week notice is required) to reserve a preferred startup date.

11..11 UUPPSS SSttaannddaarrdd FFeeaattuurreess

The UPS has many standard features that provide cost-effective and consistently reliable power protection. The

descriptions in this section provide a brief overview of the UPS standard features.

11..11..11 IInnssttaallllaattiioonn FFeeaattuurreess

• Line-up-and-match or standalone configurations

• Power wiring can be routed through the bottom of the cabinet

• Battery wiring can be run internally through the left or right sides of the UPS cabinet in line-up-and-match

configurations

• Easily accessible mechanical terminals located at the bottom front of the cabinet reduce installation time

• Control wiring can be routed through the top or bottom of the UPS cabinet, or through the left or right

sides of the UPS cabinet in line-up-and-match configurations

• Built-in casters for easy cabinet placement

• Cabinet bolt holes are provided for permanently mounting the UPS using optional front and back or left and

right side floor mounting bracket kits

Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07 1

UPS with Left-Mounted Sidecar UPS with Right-Mounted Sidecar

Introduction

Figure 1. Eaton 93PM UPS – 100 kW Frame

Figure 2. Eaton 93PM UPS –100 kW Frame with Left or Right-Mounted Sidecar

2 Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07

Introduction

11..11..22 CCoonnttrrooll PPaanneell

The control panel, located on the front of the UPS, contains a color liquid crystal touch screen display (LCD) and

a horizontal row of LED indicators to control the operation of the UPS and to display the status of the UPS

system. See Chapter 7 UPS Operating Instructions.

11..11..33 CCuussttoommeerr IInntteerrffaaccee

• Building Alarm Monitoring – Up to five inputs in the UPS are available to connect the facility's alarm

system contacts. Some system configurations may limit the number of inputs available. The UPS uses

these inputs to monitor the building alarms in addition to the UPS status. See Chapter 9 Communication.

• Alarm Contact – One alarm contact is provided for connection to equipment at the facility, such as a light,

an audible alarm, or a computer terminal. The equipment connected to this contact alerts you to a UPS

alarm. See Chapter 9 Communication.

• Minislot Communication Bays – Four communication bays are standard equipment. One to four optional

Minislot

the front of the UPS and are hot-pluggable. See Chapter 9 Communication.

11..11..44 EEnneerrggyy SSaavveerr SSyysstteemm MMooddee

The 93PM Series UPS offers an Energy Saver System (ESS) mode that maximizes efficiency by eliminating

unnecessary power conversion when the commercial power source is within acceptable voltage and frequency

limits. In this mode, the UPS is actively monitoring the critical bus and instantly and seamlessly transitions to

double-conversion mode (inverter online) if a commercial electrical power brownout, blackout, overvoltage,

undervoltage, or out-of-tolerance frequency condition occurs. See Chapter 7 UPS Operating Instructions for

additional information.

®

connectivity cards can be installed in the UPS at any time. Minislot cards are quickly installed at

11..11..55 IInntteerrnnaall RReedduunnddaannccyy

To deliver greater reliability, the Eaton 93PM UPS can be configured for internal redundancy. When configured,

the UPS automatically becomes redundant if the load is at or below the capacity of the UPMs minus the

capacity of one UPM. Under normal conditions the UPMs in the UPS share the load equally. If one or more

UPMs becomes unavailable and the load is at or below the capacity of remaining UPMs, the remaining UPMs

supply the load instead of transferring to bypass.

11..11..66 UULL 992244 AAuuxxiilliiaarryy LLiigghhttiinngg aanndd PPoowweerr EEqquuiippmmeenntt CCeerrttiiffiiccaattiioonn

93PM models are complementary listed for “UL 924 Auxiliary Lighting and Power Equipment”, which allows

alternative battery runtimes to be used.

WARNING

Emergency Power Off (EPO) and Remote Emergency Power Off (REPO) functionality is disabled for UPS

systems configured for UL 924 auxiliary lighting. To remove power from the system, a LOAD OFF command

(see paragraph 7.3.15 Using the UPS LOAD OFF Command or 7.4.17 Using the LOAD OFF Command) must be

given using the front panel controls and all breakers opened.

11..11..77 AAddvvaanncceedd BBaatttteerryy MMaannaaggeemmeenntt

Advanced Battery Management (ABM) technology uses sophisticated sensing circuitry and a three-stage

charger. The charger is a high-frequency, IGBT-based power conversion stage that extends the useful service

life of UPS batteries by isolating the battery from the electrical environment, except for periodic charging or

reserve mode operation. ABM also protects batteries from damage due to high current charging and inverter

ripple currents. Charging at high currents can overheat and damage batteries.

ABM extends battery life by keeping the batteries charged and performing periodic battery testing. The battery

test checks the batteries by transferring to battery mode. During the test the battery voltage is constantly

monitored to determine Battery Health. ABM is intended for VRLA style batteries.

Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07 3

Introduction

An ABM charging cycle starts with the charger driving the battery voltage at maximum current limit, to a

battery charge level of 2.30volts/cell. The time it takes for the voltage to reach the battery charge level is saved

as the battery charge time. If the battery charge time exceeds 24 hours, an alarm sounds.

When the battery reaches the float level, the battery is charged at the float level for 48 hours. Due to charger

capability, some battery cabinet configurations extend float level to 72 hours. Twenty-four hours into the float

period, a series of battery tests are performed to check the battery health. The float level charge continues

after a successful test.

After initial startup, the battery run time on the front panel display indicates two minutes. After the 24-hour float

charging period and automated battery testing, the actual battery run time is determined and the actual battery

run time is displayed.

After the float period is completed, the charger is disconnected and the batteries are allowed to rest for up to

672 hours (28 days) maximum rest time. If the battery voltage falls below the opportunity charge level of 2.1V/

cell during the first 240 hours (10 days) of the rest period, an alarm sounds.

An ABM charge cycle is initiated whenever one of these four conditions occurs since the last charge cycle:

• The batteries have rested over the maximum rest time of 672 hours.

• Accumulated discharge time is over a maximum battery discharge time of 20 seconds.

• Battery voltage is under the opportunity charge level of 2.1 volts/cell and the cabinet has been in rest mode

for longer than 240 hours.

• A Battery Test command has been initiated.

11..22 OOppttiioonnss aanndd AAcccceessssoorriieess

Contact an Eaton sales representative for information about the following options.

11..22..11 IInntteeggrraatteedd BBaatttteerryy CCaabbiinneett

Battery backup protection with additional runtime can be provide by equipping the UPS system with up to four

Integrated Battery Cabinets (IBCs) containing sealed lead-acid, maintenance-free batteries. The IBCs are

housed in single, free-standing cabinets designed for line-up-and-match installation, but may be installed

separate from the UPS cabinet. An external battery disconnect switch or tie point must be used when three or

four IBCs are located separate from the UPS cabinet. The IBCs may be installed on either the right or left side

of the UPS cabinet. The recommended installation location for adjacent battery cabinets is on the right side of

the UPS cabinet.

11..22..22 IInntteeggrraatteedd AAcccceessssoorryy CCaabbiinneett--DDiissttrriibbuuttiioonn

The Integrated Accessory Cabinet-Distribution (IAC-D) provides power distribution with up to 2 42-pole

distribution panels or up to five 3-pole 100- 250A adjustable subfeed breakers. The IAC-D is housed in a single,

free-standing cabinet designed for line-up-and-match installation, but may be installed separate from the UPS

cabinet. The recommended installation location for an adjacent IAC-D is to the left of the UPS cabinet.

11..22..33 IInntteeggrraatteedd AAcccceessssoorryy CCaabbiinneett--PPoowweerr DDiissttrriibbuuttiioonn

An Integrated Accessory Cabinet-Power Distribution (IAC-PD) provides power distribution options for servers,

racks, and other equipment via distribution panelboards, or distributes power to larger loads via distribution

subfeed circuit breakers. The distribution options are customer configurable, enabling adaptation and expansion

without costly electrical rework.

11..22..44 SSiiddeeccaarr IInntteeggrraatteedd AAcccceessssoorryy CCaabbiinneett--BByyppaassss

A Sidecar Integrated Accessory Cabinet-Bypass (SIAC-B) provides maintenance bypass functions. The SIAC-B

is available in two, three, or four breaker configurations enabling power to completely bypass the UPS. The

UPS can then be safely serviced or replaced without interrupting power to critical systems. The four breaker

configuration provides a convenient method for removing power from the UPS when using the maintenance

4 Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07

Introduction

bypass to supply the load. The SIAC-B is housed in a cabinet attached to the UPS cabinet. The SIAC-B may be

installed on either the right or left side of the UPS cabinet. The SIAC-B can also be used for top entry wiring

access.

11..22..55 SSiiddeeccaarr IInntteeggrraatteedd AAcccceessssoorryy CCaabbiinneett--TTiiee

A Sidecar Integrated Accessory Cabinet-Tie (SIAC-T) provides the ability to parallel up to four UPSs together for

increased capacity and/or redundant capability. The SIAC-T is housed in a cabinet attached to the UPS cabinet.

The SIAC-T may be installed on either the right or left side of the UPS cabinet. The SIAC-T can also be used for

top entry wiring access.

11..22..66 SSiiddeeccaarr IInntteeggrraatteedd AAcccceessssoorryy CCaabbiinneett--TTiiee BByyppaassss

A Sidecar Integrated Accessory Cabinet-Tie Bypass (SIAC-TB) provides the ability to parallel two UPSs together

for increased capacity and/or redundant capability. In addition, maintenance bypass functions enable power to

completely bypass the UPS power module. The SIAC-TB is housed in a cabinet attached to the UPS cabinet.

The SIAC-TB may be installed on either the right or left side of the UPS cabinet. The SIAC-TB can also be used

for top entry wiring access.

11..22..77 IInntteeggrraatteedd AAcccceessssoorryy CCaabbiinneett--TTiiee

An Integrated Accessory Cabinet-Tie (IAC-T) provides the ability to parallel up to four UPSs together for

increased capacity and/or redundant capability. The IAC-T is housed in a single, free-standing cabinet designed

for line-up-and-match installation, but may be installed separate from the UPS cabinet. The recommended

installation location for an adjacent IAC-D is to the left of the UPS cabinet.

11..22..88 PPaarraalllleell SSyysstteemm

NOTE All UPSs in a parallel system must have the same battery configuration. Each UPS

requires a separate battery cabinet.

A parallel UPS system with up to eight UPSs can be installed to provide a parallel capacity and/or redundant

system. This load sharing system provides more capacity than a single UPS, and can provide backup,

depending on the load and configuration. In addition, when one UPS is taken out of service for maintenance or

is not operating properly, a redundant UPS continues to supply uninterrupted power to the critical load. A builtin Controller Area Network (CAN) provides connectivity for system metering and operational mode control. The

parallel system consists of two to four UPSs each with a parallel CAN, and an IAC-T, SIAC-T, or SIAC-TB to act

as a tie point and to control the output.

11..22..99 TToopp EEnnttrryy WWiirriinngg SSiiddeeccaarr

If required, a sidecar is available for top entry power wiring. The sidecar performs the function of a wireway

routing the wires to the terminals mounted at the bottom of the UPS cabinet. The sidecar can be installed on

the left or right side of the UPS cabinet.

11..22..1100 MMoonniittoorriinngg aanndd CCoommmmuunniiccaattiioonn

Minislot Cards – Optional Minislot cards support several protocols, such as SNMP, SMTP, HTTP, Modbus®,

and TCP/IP. See Chapter 9 Communication, for additional information on monitoring and communication

features.

Remote Monitoring Device (RMD) – An optional RMD contains a touch screen status display and a local

audible alarm, allowing monitoring of the operational status and alarm condition of the UPS from virtually any

location within the facility, up to 300 feet from the UPS. Refer to the Eaton Remote Monitoring Device (RMD)

Installation and Operation Manual, listed in paragraph 1.8 For More Information, for additional information.

Eaton 93PM UPS 480V Three-Wire – 100 kW Frame Installation and Operation Manual 164000227—Rev 07 5

Introduction

PredictPulse™ Remote Monitoring and Management Service – PredictPulse is a subscription monitoring

and management service from Eaton that collects and analyzes data from connected power infrastructure

devices, providing us with the insight needed to make recommendations and take action on your behalf. It’s

also powered by CA Technologies, bringing together the best in hardware and software. Like a second set of

eyes on your power infrastructure, PredictPulse provides 24/7 remote monitoring of alarms and system

performance (load, temperature/humidity, battery health, energy savings and service level) to reduce downtime

risk and expedite repairs. PredictPulse also shares real-time status and trend information via an online

dashboard and smartphone mobile app (Apple and Android), giving subscribers insights about past and current

performance, a list of all active alarms, and asset management data (i.e., battery date codes, last and next

scheduled service dates, firmware versions). The service notifies customers of critical alarms, supports remote

diagnostics, and facilitates smart dispatch of technicians. PredictPulse requires a Power Xpert

Minislot (PXGMS) connectivity card in an Minislot communication bay and an Environmental Monitoring Probe

(EMP) for battery temperature/humidity monitoring. See Chapter 9 Communication, for additional information

on monitoring and communication features.

®

Gateway

11..22..1111 AAddddiittiioonnaall OOuuttppuutt SSuurrggee PPrrootteeccttiioonn

The Eaton 93PM UPS complies with ANSI 62.41 for line surges. However, if added security is required an

additional Surge Protection Device (SPD) can be installed. For this application, a 480V Delta Style SPD Type 1 or

Type 2 installed on the load side is recommended. The SPD must meet the Maximum Continuous Operating

Voltage (MCOV) for a 480V Delta Style SPD. Eaton offers a variety of SPD solutions including the Eaton SPD

Series with various kA ratings options.

11..33 BBaatttteerryy SSyysstteemm

Although not provided with the UPS, a battery system is required to provide emergency short-term backup

power to safeguard operation during brownouts, blackouts, and other power interruptions. The battery system

should be equipped with lead-acid batteries. An external battery disconnect switch or tie point must be used

when battery systems are located separate from the UPS cabinet and wiring exceeds the number of battery

terminals available.

A supplemental 48 Vdc shunt trip signal for the battery disconnect device is provided by the UPS, but is not

required for normal operation.

11..44 BBaassiicc SSyysstteemm CCoonnffiigguurraattiioonnss