Page 1

9376

MTL Trunk Surge Module

DRAFT - 28 July 2014

January 2017

INS9376 Rev 2

Instruction sheet

MTL fieldbus networks

1

Eaton Electric Limited,

Great Marlings, Butterfield, Luton

Beds, LU2 8DL, UK.

Tel: + 44 (0)1582 723633 Fax: + 44 (0)1582 422283

E-mail: mtlenquiry@eaton.com

www.mtl-inst.com

© 2017 Eaton

All Rights Reserved

Publication No. INS9376 Rev 2

January 2017

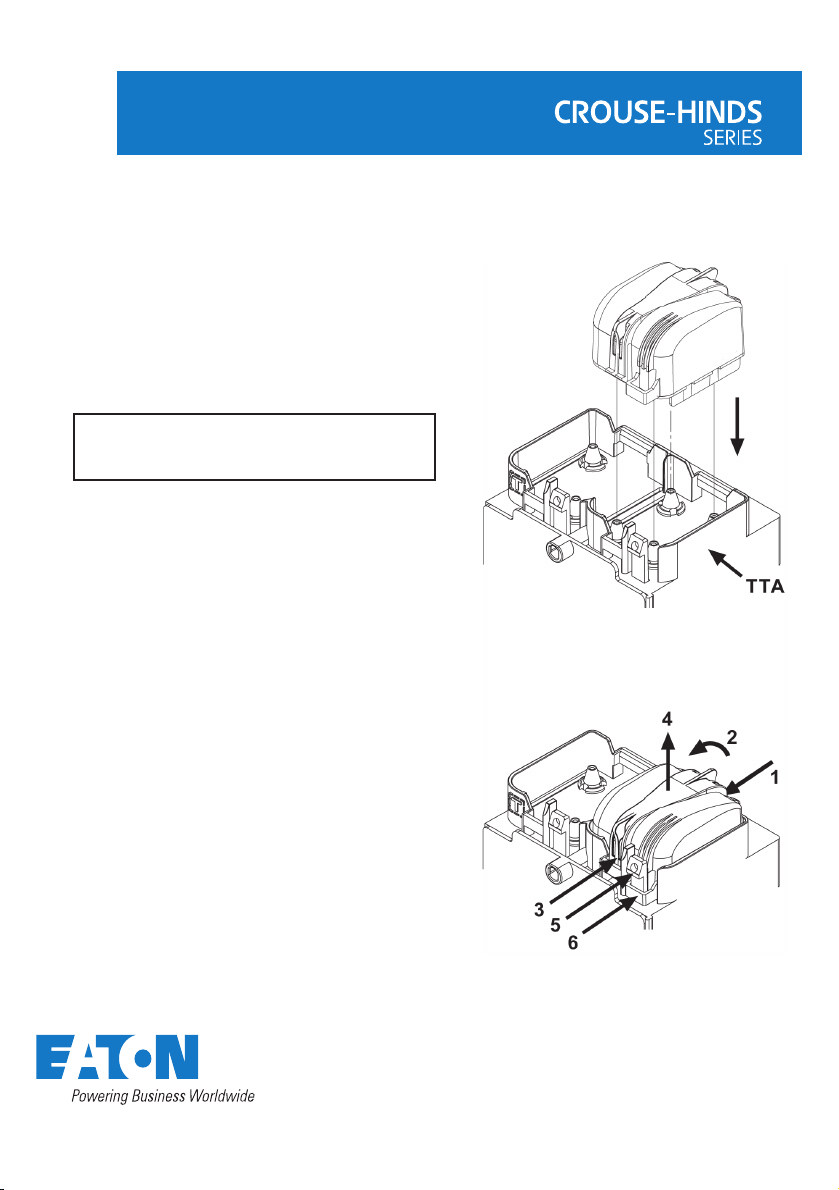

Introduction

T

he 9376-SP Trunk Surge module is designed to protect the 9370FB range of Fieldbus Barrier System from voltage and current

surges that could occur on the trunk wiring, and must be used only

with this equipment.

See the 9 376- SP technic al datash eet for full product details.

It is a 4- pin module that pl ugs into the upper end fa ce of the Trunk

Terminator A ssembl y (T TA) and is provided wi th pin conn ectors

that will p revent an ignition spa rk when the m odule is installed o r

removed.

The 9376-SP modul e may be in stal led or r emoved

with out is olati ng the t runk po wer.

READ SAFETY INFORMATION OVERLEAF

Inst alli ng a module

Remove the m odule fro m any packa ging provi ded.

Do not use, o r attempt to re pair, a module that has any of the pins

on its und erside bent or dama ged, bec ause this m ight affect its

safety and invalidate the certification.

Orient ate the modu le so that the smaller front clip is fa cing the

user, then:

• lower the module so th at the safet y retainin g clip (5) on the

TTA hous ing fits into the loop ( 6) on the mo dule,

• locate the terminal pins into thei r contac t sockets on t he

TTA hous ing, and push the mod ule home unt il front and re ar

retainin g clips are en gaged.

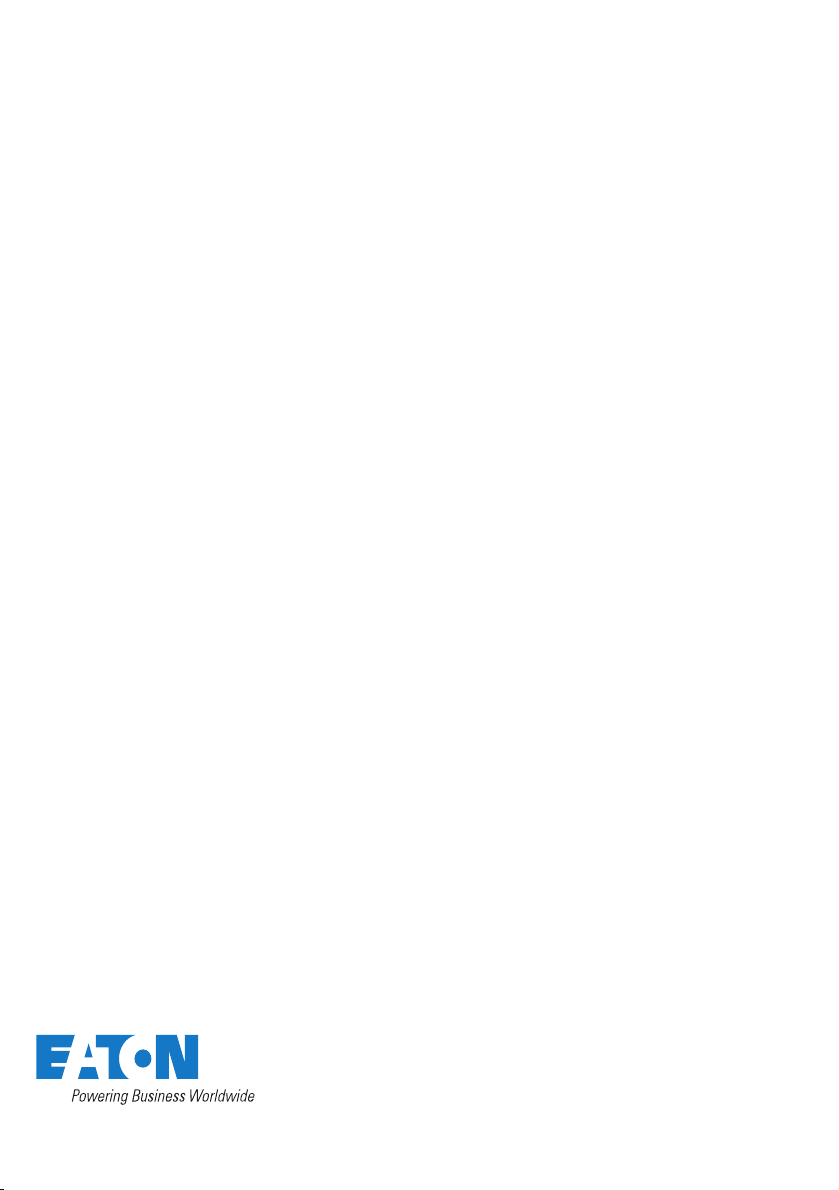

Remov ing a mod ule

Removal i s a two- step pro cess that f irst breaks the electrical

connec tion, foll owed by the ph ysical rem oval of the mo dule from

the TTA.

• Press the c lip at the rea r of the modu le (1) and lift th e rear of

the module (2) until the clip disengages.

• Press the f ront clip ( 3) and withdraw the mo dule from i ts

socket (4 ) until it is sto pped by the safety ret aining cli p (5).

• Press ag ainst the s afety clip enough to rel ease it and p ull the

module s traight ou t from the T TA body wi thout rot ating it.

Page 2

DRAFT - 28 July 2014

The given dat a is only intended as a prod uct

descriptio n and should not be regard ed as a legal

warranty of pr operties or guara ntee. In the interest

of further technical developments, we reserve the

right to make desig n changes.

2

MTL trunk surge module

January 2017

Eaton Electric Limited,

Great Marlings, Butterfield, Luton

Beds, LU2 8DL, UK.

Tel: + 44 (0)1582 723633 Fax: + 44 (0)1582 422283

E-mail: mtlenquiry@eaton.com

www.mtl-inst.com

© 2017 Eaton

All Rights Reserved

Publication No. INS9376 Rev 2 170117

January 2017

EUROPE (EMEA):

+44 (0)1582 723633

mtlenquiry@eaton.com

THE AMERICA

S:

+1 800 835 7075

mtl-us-info@eaton.com

ASIA-PACIFIC:

+65 6 645 9888

sales.mtlsing@eaton.com

ATEX and IECEx Safety Instructions for 9376-SP Trunk Surge

Module

The following infor mation is in accordance with t he

Essential Health and Safety Requirements (Annex II) of the

EU Direct ive 2014/34/EU [the ATEX D irective - safet y of apparatu s]

and is provided for tho se locat ions where such requirements are

applicable.

General

a) This module must on ly be installed, op erated an d

maintained by competent personnel. Such personnel shall

have unde rgone training, which included instruction on t he

various types of p rotectio n and insta llation practice s, the

relevant rules and regulations, and on the general principles

of area cla ssification. Appropri ate refresher training shall be

given on a re gular bas is. [See clause 4. 2 of EN 60 079 -17].

b) This module has be en design ed to provid e protection

against all the relevant additional hazards referred to in

Annex II of t he directive, such as those in clau se 1.2.7.

c) This module has been de signed to meet the requi rements of

EN 60 079 -0, E N 600 79-1, EN 6 0079-7, EN 60 079 -18.

Installation

d) The install ation must comply w ith the app ropriate Eu ropean,

national and local regulations, which may include referenc e

to the IEC co de of prac tice IEC 6 007 9-14. In addition ,

parti cular ind ustries o r end users m ay have spec ific

requirements relating to the safety of their installations and

these req uirements s hould als o be met. For t he majori ty of

install ations the Directi ve 1999 /92 /EC [the ATEX Directive safety of i nstalla tions] is als o applic able.

e) This module can be mounted in a Safe are a or a Zone 2 or

Zone 1 haz ardous are a. When mo unted in a Zon e 2 or Zone

1 locati on the mod ule must be p rovided w ith an encl osure,

which of fers an add itional d egree of protection ap propri ate

to the area classification.

f) Unless al ready protected by de sign, this m odule mus t be

protecte d by a suitab le enclos ure agains t:

i) mechanical and thermal stresses

in excess of th ose noted in t he certi fication docume ntation

and the product specification.

ii) aggressive substances, excessive dust, moisture and other

contaminants.

Read also the Schedule of Limitations (below) for any additional or

more specific information.

Schedule of Limitations

1) The 93 76- SP Trunk Surg e Protector must be housed in an

approp riately certifi ed Ex e enclosure.

2) The 93 76- SP Trunk Surg e Protecto r must plug in to

equipm ent that use s the socket part of the c onnector

covered by c ertificate TU V09 ATEX5 553 54U.

3) Due to the pre sence of tr ansient protection c omponents

between the fieldbus and earth connections, the

9376 -SP Trunk Surge Prote ctor will n ot withst and a 50 0V

a.c. dielectric s trength te st. This mu st be taken into account

during installation.

4) The ambient temper ature must not exeed +75°C.

5) The 93 76- SP Trunk Surg e Protecto r shall only be powered

from supp lies confo rming to IEC 61158.

6) The 93 76- SP Trunk Surg e Protecto r shall only be connec ted

into equip ment that c auses the se condary latching

connec tor to limit movement befor e the live -dem ateable

connec tor plug and socket meta l parts s eparate by over

1.9 mm.

Inspection and maintenance

Inspection and maintenance should be carried out in accordance

with European, nat ional and l ocal regulations w hich may refe r to

the IEC st andard IE C 600 79-17. In addit ion spec ific industries or

end users m ay have spe cific requirements w hich shou ld also be

met.

Repair

This module cannot be repaired by the user and must be

replaced with an equivalent certified product.

Marking

Each module is marked in compliance with the above

Directive and CE marked with the Notified Body

Identification Number.

This information applies to modules manufactured during or after

the year 2010.

Loading...

Loading...