Eaton 900, 950B Installation, Operation & Maintenance Manual

Installation, Operation & Maintenance Manual

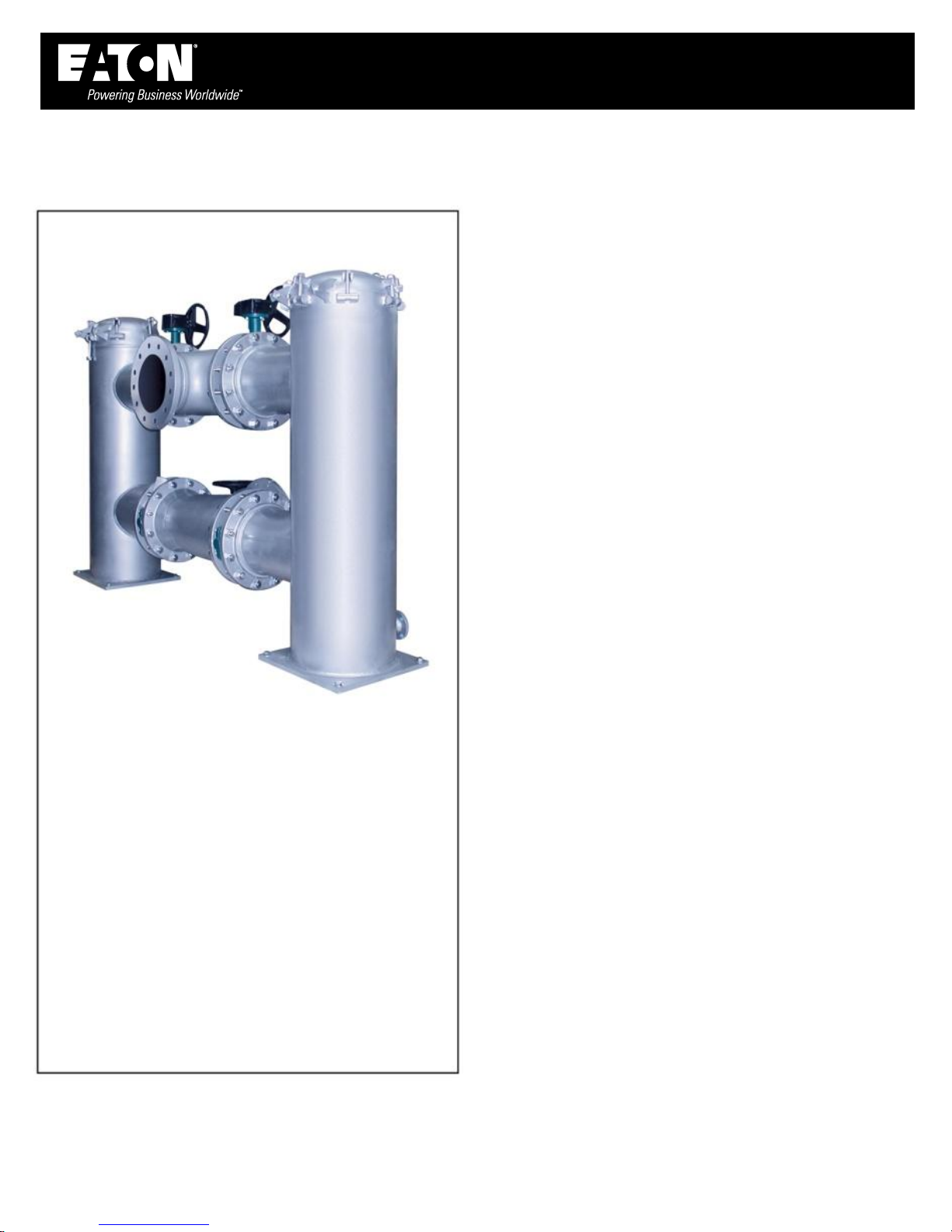

Model 900 & 950B Duplex Basket Strainer

Failure to comply with these instructions could result in bodily injury or property damage.

mdi - Manufacturers Distributor, Inc Phone: (727) 835 - 0665 | Fax: (813) 571 – 0422 Strainers.mdiSales.com | Sales@mdiSales.com

Read all the following information and instructions prior to installing and operating the equipment.

TABLE OF CONTENTS

Introduction ...................................................................... 1

Receiving, Handling, and Inspection ................................. 2

Installation ......................................................................... 2

Start Up ............................................................................. 2

Basket Removal, Cleaning, and Replacement ................... 3

Shut Down ......................................................................... 4

Recommended Spare Parts ............................................... 4

INTRODUCTION

A duplex strainer is a device installed in a pipeline to

remove dirt and other unwanted debris from fluids.

Straining is accomplished by directing the fluid through

sized openings in a basket. Duplex strainers are installed

where fluid flow cannot be interrupted while the basket

is removed for cleaning. Duplex strainers are designed to

withstand the rated pressure of the piping system.

Standard Model 900 and 950B strainers up to and

including 14” pipe sizes ship fully assembled. Secure the

strainer before moving and move as a single unit. Model

900 and 950B strainers sizes 26” and larger are shipped

disassembled. See Sales Drawing for assembly

arrangement

IOM 900 & 950B 06/2011 REV A. Page 1 of 4

Installation, Operation & Maintenance Manual

Model 900 & 950B Duplex Basket Strainer

CAUTION: Before installation, review the

application and chemical compatibility of the

process fluid to all the materials of construction

and components of the strainer.

CAUTION: Strainers are not designed to be

anchor supports in the pipeline. Be sure to

properly support process piping on both sides

of the strainer. Use care to prevent piping

forces and movements from acting on the strainer

connections. Damage may occur to strainer if improperly

connected.

CAUTION: To protect the operator when

draining and venting, the fluid must be piped to

a safe area. This is a requirement for all fluids

and for water with a temperature above 120˚F.

The operator should wear appropriate protective

equipment (goggles, gloves, vest, clothing etc.) consistent with

the process fluid for strainer operation and servicing.

mdi - Manufacturers Distributor, Inc Phone: (727) 835 - 0665 | Fax: (813) 571 – 0422 Strainers.mdiSales.com | Sales@mdiSales.com

RECEIVING, HANDLING, AND INSPECTION

1. After unpacking, inspect strainer for damage incurred

during transit. Report any damage to the carrier

immediately. If the strainer is not to be installed

immediately, store indoors in a clean, dry environment and

replace protective wrap, flange protectors, etc. which may

have been removed during receiving, handling and

inspection.

2. Remove preservative with solvent-dampened cloth.

Exercise care when using solvent and follow solvent

manufacturer’s instructions.

3. Check to be sure the rated pressure and temperature on

the strainer nameplate is not less than the maximum

pressure and temperature of the installation. The rated

pressure shown on the nameplate is the maximum

pressure, including shock, at which the strainer may be

operated.

4. Open the strainer covers (removing the cover nuts, Bolted

Cover; loosening bolt nuts, Quick Opening Cover—see

manufacturer’s instructions.) Lift or swing the cover away

until it is free of basket well.

5. Verify each basket handle has sufficient height that it is

compressed when the cover is bolted closed. Remove

basket and flange/nozzle protectors and check the inside

of the body for any foreign or loose material that could be

carried down stream when fluid is introduced into the

strainer. Remove this material and replace basket.

6. Close and bolt covers (cover nuts & studs, Bolted Cover;

bolt nuts, Quick Opening Cover.) Ensure that the sealing

surfaces are clean. The gasket or O-ring is to be seated

properly before tightening the cover hardware.

INSTALLATION

2. Standard Model 900 strainers up to and including 14” pipe

size ship fully assembled. Ensure the strainer is secured

before moving and move as a single unit. Strainers 16” and

larger are shipped disassembled. See Sales Drawing for

assembly arrangement. Position strainer components in

place and secure with strainer hardware. Use standard

piping practice for assembly.

3. Position the strainer in the pipeline so that the fluid enters

the connection marked “IN” or “INLET.” Be sure sufficient

clearance is provided for easy opening of the covers and

removal of strainer baskets. Refer to the Sales Drawing for

removal clearances. Support the strainer firmly in place.

4. Connect the strainer line flanges to the piping. Be sure to

use the same type flange faces. Do not bolt a raised face

flange to a flat face flange. Be sure flange gaskets are in

place and fasteners are tight. On strainers with other line

connections, use standard piping practice when installing.

5. Pressure gauges near the strainer inlet and outlet are

required to determine differential pressure across the

strainer and cleaning frequency. Pressure gauges are

essential for the safe operation of the strainer.

START UP

1. Remove protective wraps, caps, plugs etc. before installing

the strainer into operation after storage. Be sure to inspect

cover gasket or O-ring for possible damage and replace as

required.

IOM 900 & 950B 06/2011 REV A. Page 2 of 4

Loading...

Loading...