Eaton 150 VCP-WL, 50 VCP-WL, 75 VCP-WL Instructions For Installation, Operation And Maintenance

Instructions for Installation, Operation and Maintenance

IB131021EN

of Type VCP-WL Vacuum Circuit Breakers

Effective Mar 2018

THIS PAGE INTENTIONALLY LEFT BLANK

Effective Mar 2018

IB131021EN

IB13 1020EN Pag e ii

WARNING

IMPROPERLY INSTALLING OR MAINTAINING THESE

PRODUCTS CAN RESULT IN DEATH, SERIOUS

PERSONAL INJURY, OR PROPERTY DAMAGE.

READ AND UNDERSTAND THESE INSTRUCTIONS

BEFORE ATTEMPTING ANY UNPACKING, ASSEMBLY,

OPERATION OR MAINTENANCE OF THE CIRCUIT

BREAKERS.

INSTALLATION OR MAINTENANCE SHOULD BE

ATTEMPTED ONLY BY QUALIFIED PERSONNEL. THIS

INSTRUCTION BOOK SHOULD NOT BE CONSIDERED

ALL INCLUSIVE REGARDING INSTALLATION OR

MAINTENANCE PROCEDURES. IF FURTHER

INFORMATION IS REQUIRED, YOU SHOULD CONTACT

EATON.

WARNING

THE CIRCUIT BREAKER ELEMENTS DESCRIBED IN

THIS BOOK ARE DESIGNED AND TESTED TO

OPERATE WITHIN THEIR NAMEPLATE RATINGS.

OPERATION OUTSIDE OF THESE RATINGS MAY

CAUSE THE EQUIPMENT TO FAIL, RESULTING IN

DEATH, BODILY INJURY AND PROPERTY DAMAGE.

ALL SAFETY CODES, SAFETY STANDARDS AND/OR

REGULATIONS AS THEY MAY BE APPLIED TO THIS

TYPE OF EQUIPMENT MUST BE STRICTLY ADHERED

TO.

THESE CIRCUIT BREAKER ELEMENTS ARE DESIGNED

TO BE INSTALLED PURSUANT TO THE AMERICAN

NATIONAL STANDARDS INSTITUTE (ANSI). SERIOUS

INJURY, INCLUDING DEATH, CAN RESULT FROM

FAILURE TO FOLLOW THE PROCEDURES OUTLINED

IN THIS MANUAL. THESE CIRCUIT BREAKER

ELEMENTS ARE SOLD PURSUANT TO A NONSTANDARD PURCHASING AGREEMENT WHICH LIMITS

THE LIABILITY OF THE MANUFACTURER.

All possible contingencies which may arise during installation, operation or maintenance, and all details and

variations of this equipment do not purport to be covered by these instructions. If further information is desired

by purchaser regarding his particular installation, operation or maintenance of particular equipment, contact an

Eaton representative.

Effective Mar 2018

TABLE OF CONTENTS

SECTION 1: INTRODUCTION....................................................................................................................................................................................1

1-1 PRELIMINARY COMMENTS AND SAFETY PRE- CAUTIONS..................................................................................................................................1

1-2 GENERAL INFORMATION...................................................................................................................................................................................1

1-3 TYPE VCP-WL VACUUM CIRCUIT BREAKER ELEMENT RATINGS.........................................................................................................................2

1-4 OUTLINES AND DIMENSIONS.............................................................................................................................................................................3

SECTION 2: SAFE PRACTICES...................................................................................................................................................................................5

2-1 RECOMMENDATIONS.........................................................................................................................................................................................5

SECTION 3: RECEIVING, HANDLING AND STORAGE..................................................................................................................................................6

3-1 GENERAL............................................................................................................................................................................................................6

3-2 RECEIVING..........................................................................................................................................................................................................6

3-3 HANDLING..........................................................................................................................................................................................................6

3-4 STORAGE............................................................................................................................................................................................................6

3-5 TOOLS AND ACCESSORIES..................................................................................................................................................................................7

3-6 TYPE VCP-WL VACUUM CIRCUIT BREAKER ELEMENT WEIGHTS........................................................................................................................7

SECTION 4: INITIAL INSPECTION AND INSTALLATION............................................................................................................................................ 14

4-1 INTRODUCTION................................................................................................................................................................................................14

4-2 VACUUM INTERRUPTER INTEGRITY.................................................................................................................................................................14

4-3 INSULATION.....................................................................................................................................................................................................14

4-4 PRIMARY CIRCUIT RESISTANCE........................................................................................................................................................................14

4-5 NAMEPLATE.....................................................................................................................................................................................................14

4-6 ELECTRICAL OPERATION AND MECHANICAL OPEN CHECK..............................................................................................................................14

4-7 CIRCUIT BREAKER/STRUCTURE INTERFACING.................................................................................................................................................21

SECTION 5: DESCRIPTION AND OP E R ATIO N ........................................................................................................................................................23

5-1 INTRODUCTION................................................................................................................................................................................................23

5-2 INTERRUPTER ASSEMBLY.................................................................................................................................................................................23

5-3 ELECTROMAGNETIC MECHANISM...................................................................................................................................................................26

5-4 CONTROL SCHEMES.........................................................................................................................................................................................29

5-5 INTERLOCKS AND INTERFACING......................................................................................................................................................................29

5-6 LEVERING MECHANISM...................................................................................................................................................................................29

5-7 OPERATIONS COUNTER....................................................................................................................................................................................30

5-8 GROUND CONTACT..........................................................................................................................................................................................30

5-9 MOC AND TOC SWITCH OPERATIONS..............................................................................................................................................................30

SECTION 6: INSPECTION, MAINTENANCE A N D TR O U BLES H O OTI N G .................................................................................................................31

6-1 INTRODUCTION................................................................................................................................................................................................31

6-2 FREQUENCY OF INSPECTION AND MAINTENANCE..........................................................................................................................................31

6-3 INSPECTION AND MAINTENANCE PROCEDURES.............................................................................................................................................33

6-4 VACUUM INTERRUPTER INTEGRITY TEST.........................................................................................................................................................34

6-5 CONTACT EROSION AND WIPE.........................................................................................................................................................................35

6-6 INSULATION....................................................................................................................................................................................................35

6-7 INSULATION INTEGRITY CHECK........................................................................................................................................................................35

6-8 PRIMARY CIRCUIT RESISTANCE CHECK.............................................................................................................................................................36

6-9 MECHANISM CHECK.........................................................................................................................................................................................36

6-10 LUBRICATION...................................................................................................................................................................................................36

6-11 TROUBLESHOOTING CHART (CONTINUED NEXT PAGE).........................................................................................................................................37

6-11 TROUBLESHOOTING CHART (CONTINUED)..........................................................................................................................................................38

6-12 END OF LIFE PROCEDURES...............................................................................................................................................................................39

6-13 FAILURE REPORTING........................................................................................................................................................................................39

6-14 REPLACEMENT PARTS......................................................................................................................................................................................39

Pag e iv IB13 1021EN

FIGURES

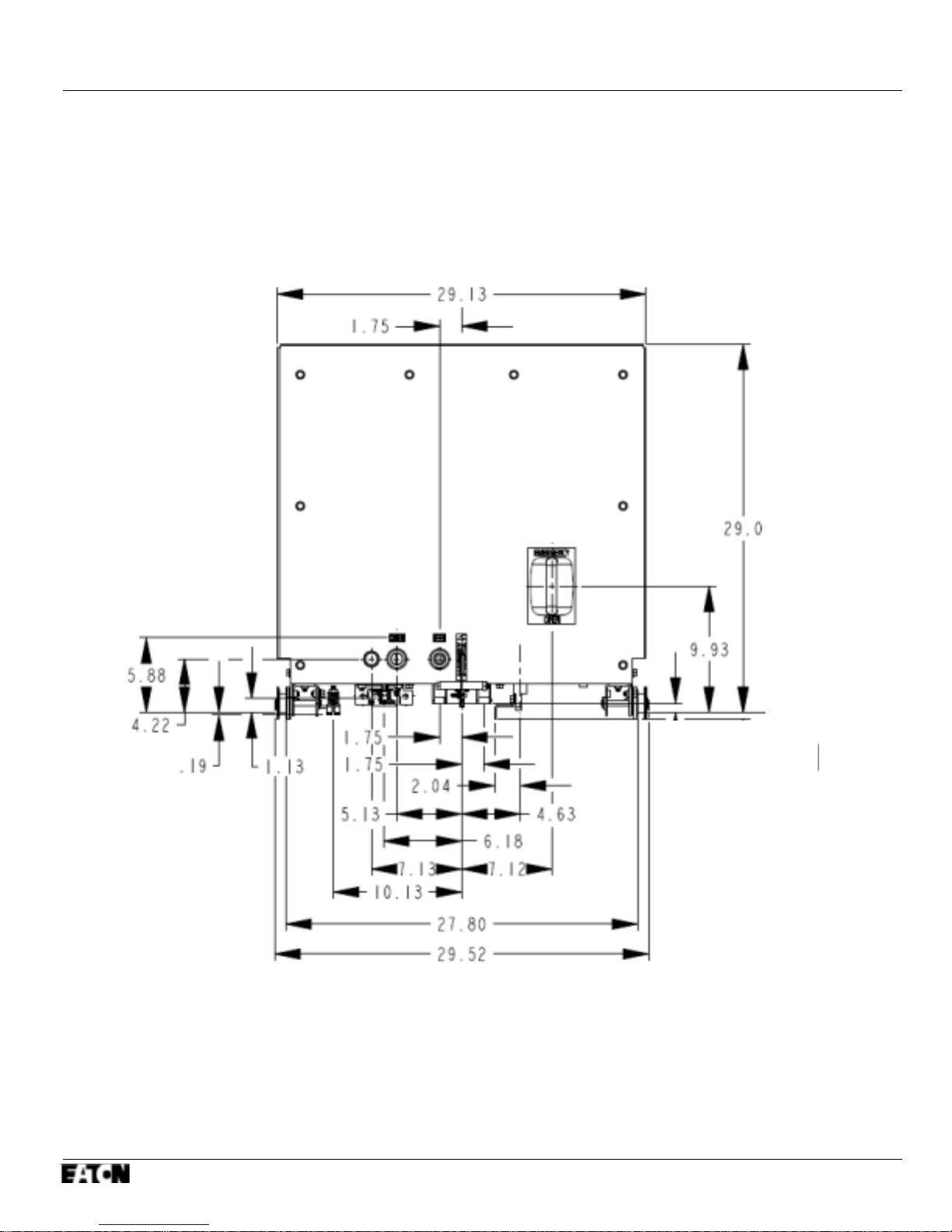

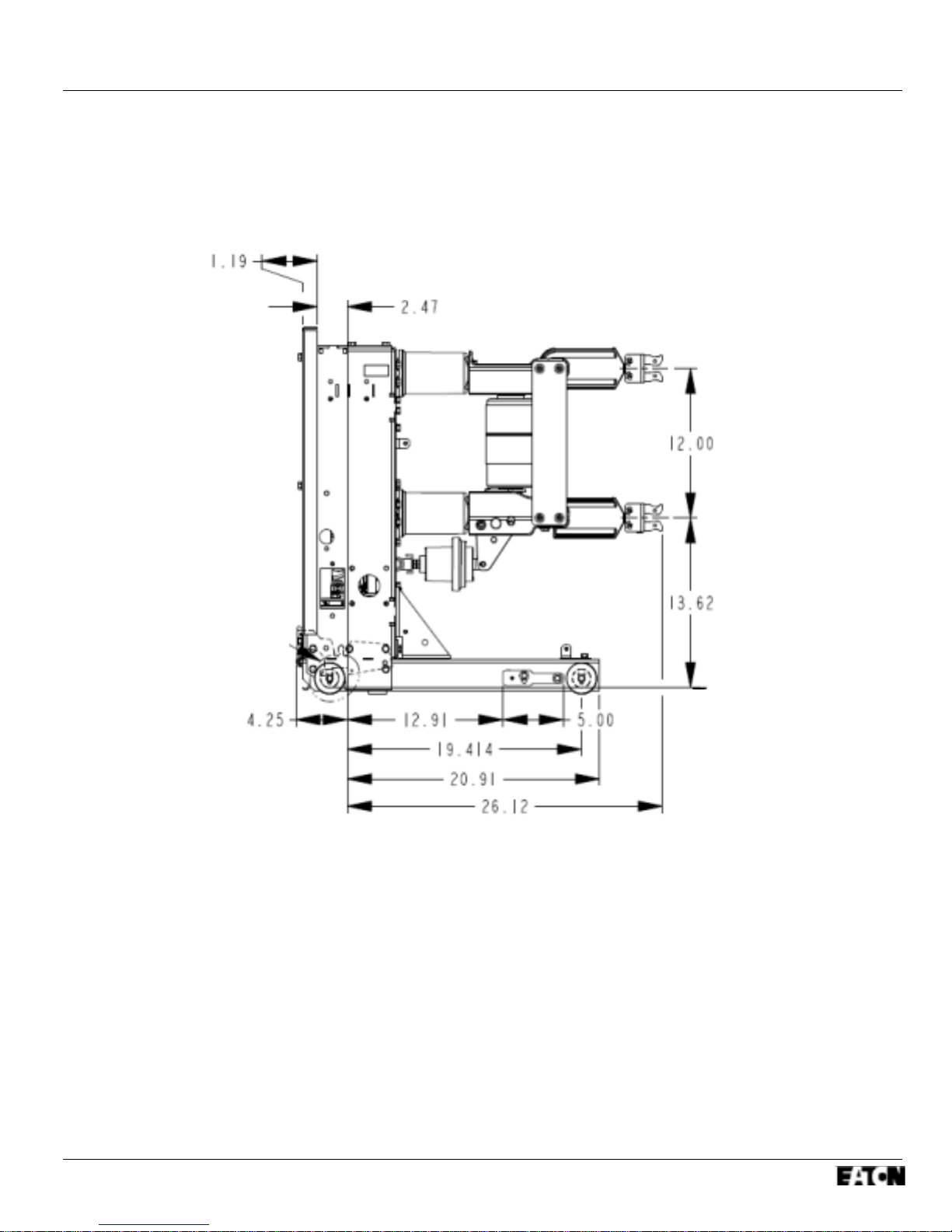

FIGURE 1-1 TYPE VCP-WL CIRCUIT BREAKER OUTLINES AND DIMENSIONS..........................................................................................3

FIGURE 3-1 TYPICAL VCP-WL TOOLS AND ACCESSORIES......................................................................................................................8

FIGURE 3-2 TYPICAL FRONT VIEW VCP-WL VACUUM CIRCUIT BREAKER .....................9

FIGURE 3-3 TYPICAL VCP-WL VACUUM CIRCUIT BREAKER ELEMENT WITH FRONT COVER REMOVED.................................................10

FIGURE 3-4 VCP-WL MECHANISM DETAILS.......................................................................................................................................11

FIGURE 3-5 TYPICAL REAR VIEW VCP-WL VACUUM CIRCUIT BREAKER ELEMENT................................................................................12

FIGURE 3-6 TYPICAL VCP-WL VACUUM CIRCUIT BREAKER FRONT COVER ARRANGEMENT................................................................. 13

FIGURE 4-1A INSERTION OF THE DRAWOUT EXTENSION RAILS.........................................................................................................15

FIGURE 4-1B LIFTING AND SETTING THE BREAKER IN THE HOUSING..................................................................................................15

FIGURE 4-1C BPI PAN ASSEMBLY......................................................................................................................................................17

FIGURE 4-2 ENGAGING EXTENSION RAILS IN A LOWER CIRCUIT BREAKER COMPARTMENT................................................................19

FIGURE 4-3 TYPICAL VCP-WL CIRCUIT BREAKER BOTTOM VIEW........................................................................................................20

FIGURE 4-4 ENGAGING LEVERING-IN CRANK....................................................................................................................................21

FIGURE 5-1 VCP-WL POLE UNIT AND VACUUM INTERRUPTER...........................................................................................................23

FIGURE 5-2 GRAPHIC REPRESENTATION OF ARC INTERRUPTION.......................................................................................................24

FIGURE 5-3 MEASUREMENT OF CONTACT STROKE...........................................................................................................................25

FIGURE 5-4 LOOSENING THE DRIVE ROD HOUSING JAM NUT............................................................................................................25

FIGURE 5-5 MEASUREMENT OF CONTACT OPEN GAP.......................................................................................................................25

FIGURE 5-5 TYPICAL VCP-WL CONTROL SCHEME..............................................................................................................................29

Effective Mar 2018

IB13 1021EN P ag e v

TABLES

TABLE 1-1 (ANSI STANDARDS) TYPE VCP-WL VACUUM CIRCUIT BREAKER...........................................................................................2

TABLE 3-1 VCP-WL ANSI RATED BREAKER WEIGHTS............................................................................................................................7

TABLE 6.1 TORQUE GUIDELINES.......................................................................................................................................................32

TABLE 6.2 (INSULATION & VACUUM INTEGRITY) TEST VOLTAGE.......................................................................................................34

TABLE 6.3 TYPICAL RESISTANCE MEASUREMENTS.............................................................................................................................36

INTRODUCTIONSECTION 1:

PRELIMINARY COMMENTS AND SAFETY PRE- 1-1

CAUTIONS

This technical document is intended to cover most aspects

associated with the installation, operation and maintenance

of Type VCP-WL Vacuum Circuit Breakers. It is provided

as a guide for authorized and qualified personnel only.

Please refer to the specific WARNING and CAUTION in

Paragraph 1-1.2 before proceeding past Section 1. If

further information is required by the purchaser regarding a

particular installation, application or maintenance activity,

an Eaton representative should be contacted.

WARRANTY AND LIABILITY FORMATION1-1.1

NO WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OF MERCHANTABILITY, OR

WARRANTIES ARISING FROM COURSE OF DEALING

OR USAGE OF TRADE, ARE MADE REGARDING THE

INFORMATION, RECOMMENDATIONS AND

DESCRIPTIONS CONTAINED HEREIN. In no event will

Eaton be responsible to the purchaser or user in contract,

in tort (including negligence), strict liability or otherwise for

any special, indirect, incidental or consequential damage

or loss whatsoever, including but not limited to damage or

loss of use of equipment, plant or power system, cost of

capital, loss of power, additional expenses in the use of

existing power facilities, or claims against the purchaser or

user by its customers resulting from the use of the

information and descriptions contained herein.

WARNING

THE WARNINGS AND CAUTIONS INCLUDED AS PART

OF THE PROCEDURAL STEPS IN THIS DOCUMENT

ARE FOR PERSONNEL SAFETY AND PROTECTION OF

EQUIPMENT FROM DAMAGE. AN EXAMPLE OF A

TYPICAL WARNING LABEL HEADING IS SHOWN

ABOVE IN REVERSE TYPE TO FAMILIARIZE

PERSONNEL WITH THE STYLE OF PRESENTATION.

THIS WILL HELP TO INSURE THAT PERSONNEL ARE

ALERT TO WARNINGS, WHICH MAY APPEAR

THROUGHOUT THE DOCUMENT. IN ADDITION,

CAUTIONS ARE ALL UPPER CASE AND BOLDFACE

AS SHOWN BELOW.

CAUTION

COMPLETELY READ AND UNDERSTAND THE

MATERIAL PRESENTED IN THIS DOCUMENT BEFORE

ATTEMPTING INSTALLATION, OPERATION OR

APPLICATION OF THE EQUIPMENT. IN ADDITION,

ONLY QUALIFIED PERSONS SHOULD BE PERMIT-TED

TO PERFORM ANY WORK ASSOCIATED WITH THE

EQUIPMENT. ANY WIRING INSTRUCTIONS

PRESENTED IN THIS DOCUMENT MUST BE

FOLLOWED PRECISELY. FAILURE TO DO SO COULD

CAUSE PERMANENT EQUIPMENT DAMAGE.

1-2 GENERAL INFORMATION

1-1.2 SAFETY PRECAUTIONS

All safety codes, safety standards and/or regulations must

be strictly observed in the installation, operation and

maintenance of this device.

Effective Mar 2018

The purpose of this book is to provide instructions for

unpacking, storage, use, operation and maintenance of

Type VCP-WL Vacuum Circuit Breakers. These circuit

breakers are horizontal drawout type removable

interrupting elements designed for use in VacClad-W MetalClad Switchgear and appropriate VCP-WL modules. The

Type VCP-WL Vacuum Circuit Breakers are designed to

operate as a roll-in replacement for Type VCP-W Vacuum

Circuit Breakers. They provide reliable control and

protection for medium voltage electrical equipment and

Pag e ii IB13 1021EN

circuits. All VCP-WL circuit breaker elements are designed

to ANSI Standards for reliable performance, ease of

handling and simplified maintenance.

WARNING

SATISFACTORY PERFORMANCE OF THESE

BREAKERS AND OR MINIMOD IS CONTINGENT UPON

PROPER APPLICATION, CORRECT INSTALLATION

AND ADEQUATE MAINTENANCE. THIS INSTRUCTION

BOOK MUST BE CAREFULLY READ AND FOLLOWED

IN ORDER TO OBTAIN OPTIMUM PERFORMANCE FOR

LONG USEFUL LIFE OF THE MINIMOD. EQUIPMENT

TO FAIL, RESULTING IN DEATH, BODILY INJURY AND

PROPERTY DAMAGE.

ALL SAFETY CODES, SAFETY STANDARDS AND/OR

REGULATIONS AS THEY MAY BE APPLIED TO THIS

TYPE OF EQUIPMENT MUST BE STRICTLY ADHERED

TO.

Effective Mar 2018

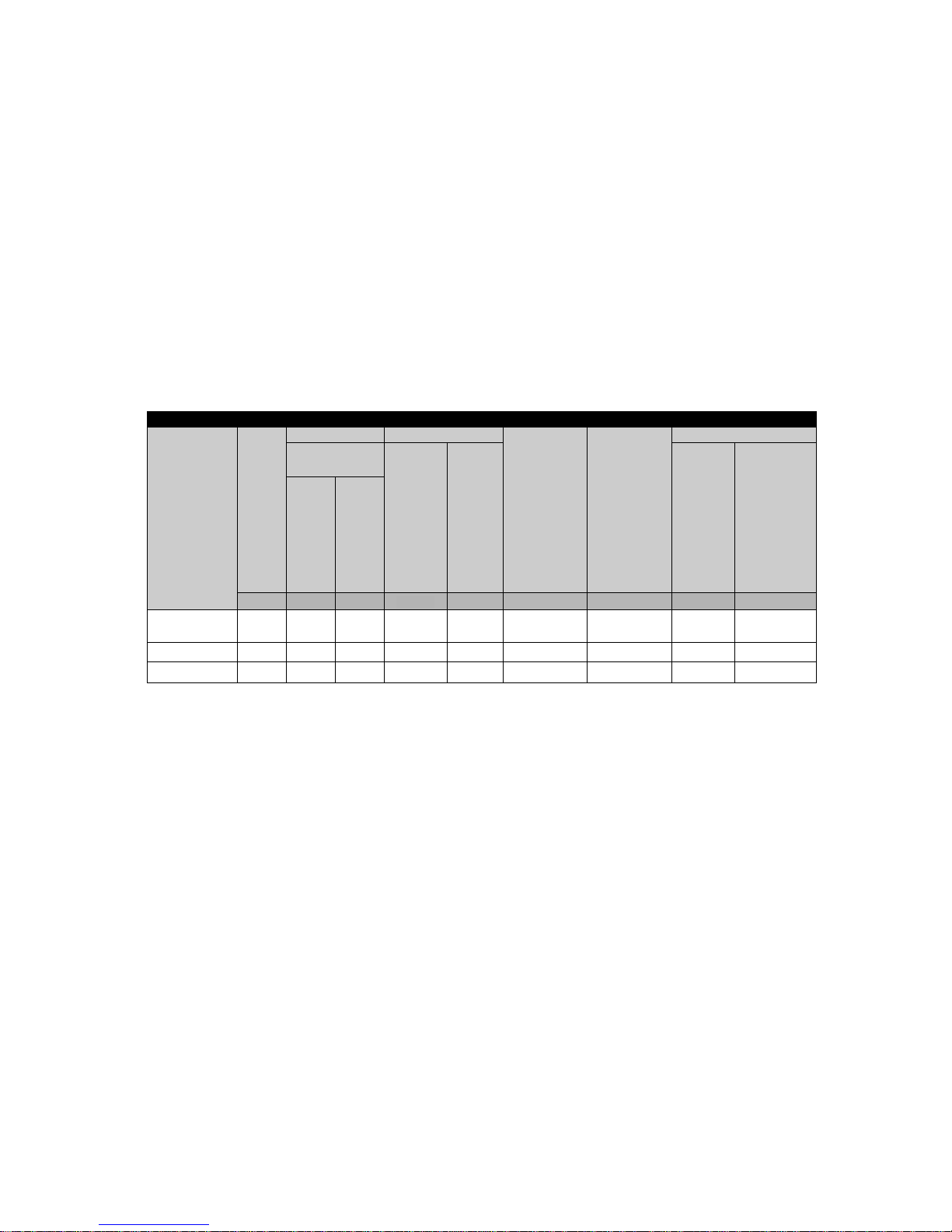

TYPE VCP-WL VACUUM CIRCUIT BREAKER ELEMENT RATINGS1-3

Rated Values

Circuit

Breaker

Type

Nominal

Voltage

Class

Insulation Level Current

Interrupting

Time

Permissible

Tripping

Delay

Y

Current Values

Withstand Test

Voltage

Continuous

Current

at 60 Hz

Short

Circuit

Current

(at Rated

Max. kV)

I

Closing

and

Latching

Capability

2.7 K

Times

Rated

Short

Circuit

Current

Closing

and

Latching

Capability

Momentary

1.6 K

Times

Rated

Short

Circuit

Current

Power

Frequency

(1 Min.)

Impulse

kV kV rms Amperes kA rms Cycles Seconds kA Peak kA rms

150 VCP-WL 15 36 95 1200 25 3 or 5 2 65 39

75 VCP-WL 8.25 36 95 1200 25 3 or 5 2 65 39

50 VCP-WL 4.76 36 95 1200 25 3 or 5 2 65 39

Table 1-1 (ANSI Standards) Type VCP-WL Vacuum Circuit Breaker Through 15 kV Rated Symmetrical Current Basis

Identification

Pag e iv IB13 1021EN

OUTLINES AND DIMENSIONS1-4

Figure 1-1 Type VCP-WL Circuit Breaker Outlines and Dimensions

Effective Mar 2018

Front View

IB13 1021EN P ag e v

SECTION 2: SAFE PRACTICES

Effective Mar 2018

Side View

2-1 RECOMMENDATIONS

Type VCP-WL Vacuum Circuit Breaker Elements are

equipped with high speed, high energy operating

mechanisms, and are designed with several built-in inter-

Pag e vi IB13 1021EN

locks and safety features to provide safe and proper

operating sequences.

WARNING

TO PROTECT THE PERSONNEL ASSOCIATED WITH

INSTALLATION, OPERATION, AND MAINTENANCE OF

THESE CIRCUIT BREAKER ELEMENTS, THE

FOLLOWING PRACTICES MUST BE FOLLOWED:

Only qualified personnel, as defined in the local

electrical code, who are familiar with the installation and

maintenance of medium voltage circuits and equipment,

should be permitted to work on these circuit breaker

elements.

Read these instructions carefully before attempting

any installation, operation or maintenance of these

breakers.

Always remove the breakers from the enclosure before

performing any maintenance. Failure to do so could

result in electrical shock leading to death, severe

personal injury or property damage.

tripping. Carelessness could cause the circuit breaker to

fall from the rails resulting in personal injury to those in the

area.

Do not work on a closed breaker or a breaker with

capacitor bank charged. The capacitor bank should be

discharged and the main contacts open before working

on the breaker. The capacitor bank will discharge after

control power is removed. Failure to do so could result in

severe injury or death.

Do not use a circuit breaker by itself as the sole means of

isolating a high voltage circuit. Remove the breaker to the

DISCONNECT position and follow good lockout and

tagging rules, as well as all applicable codes, regulations

and work rules.

Do not leave the breaker in an intermediate position in

the cell. Always have the breaker either in the TEST or

CONNECTED position. Failure to do so could result in a

flash over and possible death, personal injury or property

damage.

Breakers are equipped with safety interlocks. Do not

defeat them. This may result in death, bodily injury or

equipment damage.

BE EXTREMELY CAREFUL while the circuit breaker is

on the extension rails. Use provided rail clamps to firmly

hold the circuit breaker on the extension rails while

performing such activities as charging, closing and

SECTION 3: RECEIVING, HANDLING AND

STORAGE

Effective Mar 2018

IB13 1021EN P ag e vii

3-1 GENERAL

Type VCP-WL Vacuum Circuit Breaker Elements are

subjected to complete factory production tests and

inspection before being packed. They are shipped in

packages designed to provide maximum protection to the

equipment during shipment and storage and at the same

time to provide convenient handling.

3-2 RECEIVING

If the circuit breaker element is not to be used immediately

but is to be placed in storage; maximum protection can be

obtained by keeping it packed as shipped.

Upon receipt of the equipment, inspect the containers for

any signs of damage or rough handling. Open the

containers carefully to avoid any damage to the con-tents.

Use a nail puller rather than a crow bar when required.

When opening the containers, be careful to save any loose

items or hardware that may be otherwise discarded with

the packing material. Check the contents of each package

against the packing list.

Examine the circuit breaker element for any signs of

shipping damage such as broken, missing or loose

hardware, damaged or deformed insulation and other

components. File claims immediately with the carrier if

damage or loss is detected and notify the nearest Eaton

Office.

breaker element side openings with the lifting hole toward

the interrupters. Once the lifting yoke is securely seated in

the holes, the breaker element can be carefully lifted and

moved.

3-4 STORAGE

If the circuit breaker element is to be placed in storage,

maximum protection can be obtained by keeping it packed

as shipped. Before placing it in storage, checks should be

made to make sure that the breaker element is free from

shipping damage and is in satisfactory operating condition.

The circuit breaker element is shipped with its contacts

open and capacitor bank discharged. The indicators on the

front panel should confirm this.

Outdoor storage of the breaker element is NOT

recommended. If unavoidable, the outdoor location must

be well drained and a temporary shelter from sun, rain,

snow, corrosive fumes, dirt, falling objects and excessive

moisture must be provided. Containers should be arranged

to permit free circulation of air on all sides and temporary

heaters should be used to minimize condensation.

Moisture can cause rusting of metal parts and deterioration

of high voltage insulation. A heat level of approximately

400 watts for each 100 cubic feet of volume is

recommended with the heaters distributed uniformly

throughout the structure near the floor.

Indoor storage should be in a building with sufficient heat

and air circulation to prevent condensation. If the building is

not heated, the same general rule for heat as for outdoor

storage should be applied.

3-3 HANDLING

CAUTION

DO NOT USE ANY LIFTING DEVICE AS A PLATFORM

FOR PERFORMING MAINTENANCE, REPAIR OR

ADJUSTMENT OF THE BREAKER OR FOR OPENING,

CLOSING THE CONTACTS OR CHARGING THE

SPRINGS. THE CIRCUIT BREAKER ELEMENT MAY

SLIP OR FALL CAUSING SEVERE PERSONAL INJURY.

ALWAYS PERFORM MAINTENANCE, REPAIR AND

ADJUSTMENTS ON A SOLID WORK SURFACE

CAPABLE OF SUPPORTING THE BREAKER

ELEMENT.

When a breaker element is ready for installation, a lifting

yoke in conjunction with an overhead lifter or portable floor

lifter can be used to move a breaker element. When a

breaker element is to be lifted, position the lifting yoke over

the breaker element and insert the lifter tabs into the

Effective Mar 2018

3-5 TOOLS AND ACCESSORIES

Tools and accessories, both standard and optional are

available for use with the circuit breaker element

(Figure 3-1).

Pag e viii IB13 1021EN

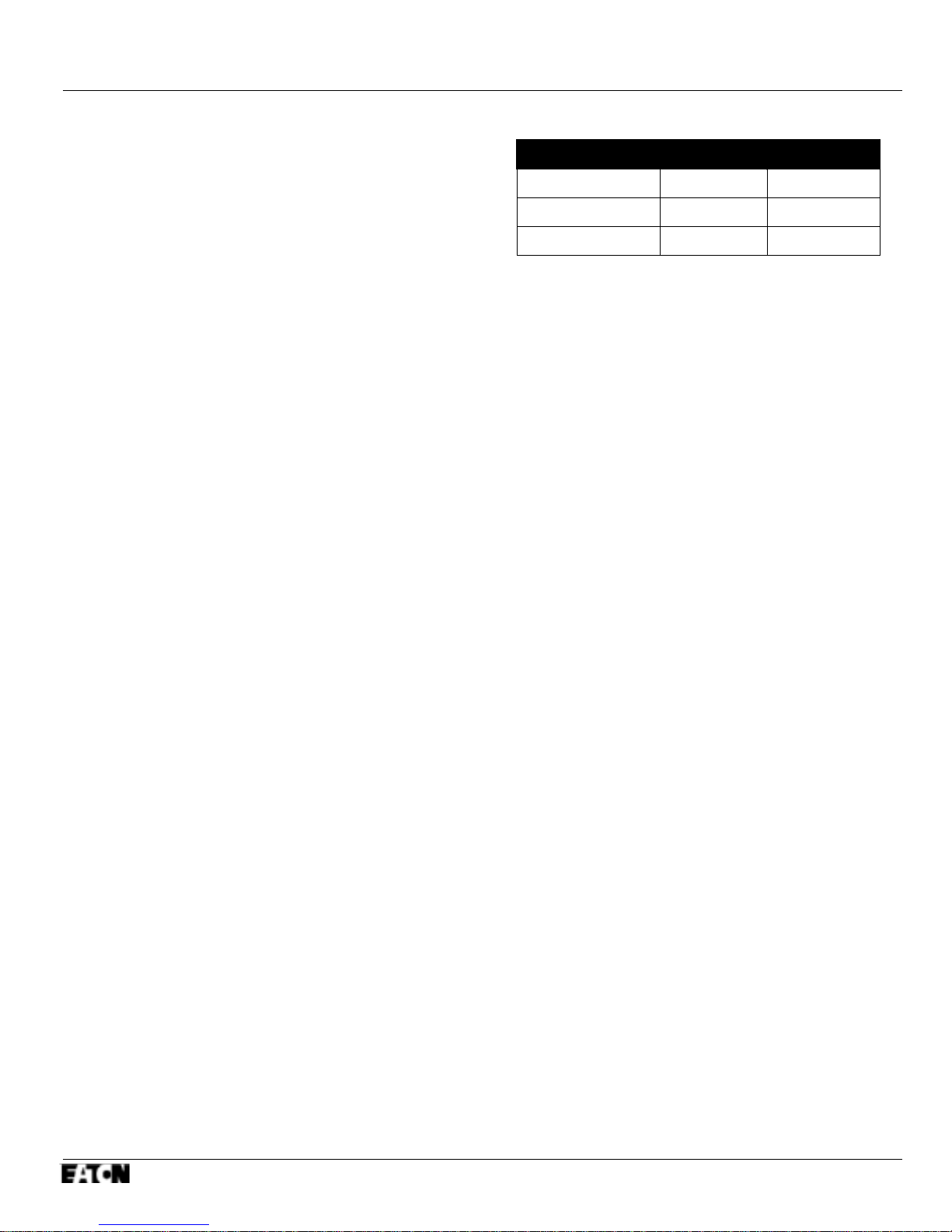

Amperes Lbs. (kg)

50VCP-WL25 1200 350

75VCP-WL25 1200 350

150VCP-WL25 1200 350

Spin-Free Levering-In Crank: Used to crank breaker

between TEST and CONNECTED positions (Style

701B601G11).

Extension Rails: Permits breaker to be withdrawn from its

compartment (Style 7813C41G03 for VCP-WL).

Rail Clamps: Used to secure breaker to extension rails

(Style 6511C83G11 for VCP-WL).

Lifting Yoke: Used to lift breaker (Style 691C607G11 for

VCP-WL).

Drawout Ramp: Used to insert or withdraw breaker from

lower compartment without portable lifter (Style

1C14163G02 for VCP-WL).

Table 3-1 VCP-WL ANSI Rated Breaker Weights

Rating

Does not include shipping carton

①

Portable Lifter: Used to lift breaker to or from extended

rails (Style 1C14504H01).

Docking Transport Dolly: Used to insert or withdraw

breaker from lower compartment without portable lifter or

move breaker from one location to another (Style

6510C71G11 for VCP-WL).

Electrical Levering-In Device: Used to electrically move

breaker between TEST and CONNECTED positions (Style

1A30257G01).

Test Jumper: Used to operate breaker electrically while

breaker is on extension rails or transport dolly (Style

6526C23G11 for VCP-WL).

Test Cabinet: Used to provide power to operate breaker

outside its compartment (Styles 8346A28G21 – G23 for

VCP-WL depending on voltage requirements).

3-6 TYPE VCP-WL VACUUM CIRCUIT BREAKER

ELEMENT WEIGHTS (TABLE 3.1)

Effective Mar 2018

Loading...

Loading...