Eaton 50 VCP-T16, 50 VCP-T20, 50 VCP-T25, 50 VCP-TR20, 50 VCP-T32 Instructions For The Use

...

Instructions for the Use, Operation and Maintenance of

Types VCP-T and VCP-TR Vacuum Circuit Breakers

IB131016EN Effective November 2017

VCP-TR Fixed (up to 25kA)

VCP-TR Fixed (up to 40kA)

VCP-T Drawout (up to 25kA)

VCP-T Drawout (up to 40kA)

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page iii

WARNING

IMPROPERLY INSTALLING OR MAINTAINING

THESE PRODUCTS CAN RESULT IN DEATH,

SERIOUS PERSONAL INJURY, OR PROPERTY

DAMAGE.

READ AND UNDERSTAND THESE INSTRUCTIONS

BEFORE ATTEMPTING ANY UNPACKING,

ASSEMBLY, OPERATION OR MAINTENANCE OF

THE CIRCUIT BREAKERS.

INSTALLATION OR MAINTENANCE SHOULD BE

ATTEMPTED ONLY BY QUALIFIED PERSONNEL.

THIS INSTRUCTION BOOK SHOULD NOT BE

CONSIDERED ALL INCLUSIVE REGARDING

INSTALLATION OR MAINTENANCE

PROCEDURES. IF FURTHER INFORMATION IS

REQUIRED, YOU SHOULD CONTACT EATON

Eaton Corporation

Moon Township, PA. 15108

WARNING

THE CIRCUIT BREAKER ELEMENTS DESCRIBED

IN THIS BOOK ARE DESIGNED AND TESTED TO

OPERATE WITHIN THEIR NAMEPLATE RATINGS.

OPERATION OUTSIDE OF THESE RATINGS MAY

CAUSE THE EQUIPMENT TO FAIL, RESULTING IN

DEATH, BODILY INJURY AND PROPERTY

DAMAGE.

ALL SAFETY CODES, SAFETY STANDARDS

AND/OR REGULATIONS AS THEY MAY BE

APPLIED TO THIS TYPE OF EQUIPMENT MUST BE

STRICTLY ADHERED TO.

SERIOUS INJURY, INCLUDING DEATH, CAN

RESULT FROM FAILURE TO FOLLOW THE

PROCEDURES OUTLINED IN THIS MANUAL.

THESE CIRCUIT BREA K ER E LE M EN TS A RE S OL D

PURSUANT TO A NON-STANDARD PURCHASING

AGREEM ENT WHICH LIMITS THE LIABILITY OF

THE MANUFACTURER.

All possible contingencies which may arise during installation, operation or maintenance, and all details and

variations of this equipment do no purport to be covered by these instructions. If further information is

desired by purchaser regarding his particular installation, operation or maintenance of particular equipment,

contact an Eaton representative .

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Page iv Effective: November 2017

TABLE OF CONTENTS

SECTION 1: INTRODUCTION

1-1 VCP-T and VCP-TR Vacuum Circuit Breaker Ratings .................................................................................................................................. 1

1-2 Types VCP-T and VCP-TR Outlines and Dimensions ................................................................................................................................. 4

SECTION 2: SAFE PRACTICES

SECTION 3: RECEIVING, HANDLING AND STORAGE

3-1 Receiving ..................................................................................................................................................................................................... 12

3-2 Handling ....................................................................................................................................................................................................... 12

3-2.1 Unpacking .................................................................................................................................................................................. 12

3-2.2 Lifting (up to 25kA) ..................................................................................................................................................................... 13

3-2.3 Lifting (up to 40kA) ..................................................................................................................................................................... 13

3-3 Storage ....................................................................................................................................................................................................... 14

3-4 Typical Breaker and Cassette Weights ...................................................................................................................................................... 15

SECTION 4: INSTALLATION AND WIRING

4-1 Initial Inspection ......................................................................................................................................................................................... 22

4-2 Electrical Clearances ................................................................................................................................................................................. 22

4-3 Interphase Barriers ...................................................................................................................................................................................... 22

4-4 Front Cover ................................................................................................................................................................................................ 22

4-5 Installing Fixed Circuit Breaker .................................................................................................................................................................. 22

4-5.1 Fixed Mechanical Interfaces ...................................................................................................................................................... 22

4-5.2 Fixed Electrical Interfaces ......................................................................................................................................................... 22

4-6 Installing Drawout Circuit Breaker ............................................................................................................................................................... 23

4-6.1 Drawout Mechanical Interfaces ................................................................................................................................................. 23

4-6.2 Circuit Breaker Positioning ........................................................................................................................................................ 24

4-6.3 Drawout Electrical Interfaces ..................................................................................................................................................... 26

4-6.4 Levering Circuit Breaker ............................................................................................................................................................ 28

SECTION 5: DESCRIPTION AND OPERATION

5-1 Introduction ................................................................................................................................................................................................ 31

5-2 Vacuum Interrupter Assembly .................................................................................................................................................................... 31

5-2.1 Contact Erosion Indicator (up to 25kA) ...................................................................................................................................... 34

5-2.2 Contact Wipe and Stroke (up to 25kA) ...................................................................................................................................... 34

5-2.3 Contact Wipe and Erosion (up to 40kA) ..................................................................................................................................... 34

5-3 Stored Energy Mechanism ......................................................................................................................................................................... 35

5-3.1 Manual Operation ...................................................................................................................................................................... 35

5-3.2 Electrical Operation ................................................................................................................................................................... 36

5-3.3 Trip Free Operation ................................................................................................................................................................... 36

5-3.4 Anti-Pump Feature .................................................................................................................................................................... 36

5-3.5 Latch Check Switch ................................................................................................................................................................... 36

5-3.6 Mechanical Interlocks ................................................................................................................................................................ 36

5-4 Connection Diagrams ................................................................................................................................................................................... 37

5-4.1 Timing ......................................................................................................................................................................................... 37

5-4.2 Sensors ........................................................................................................................................................................................ 37

5-5.4 Trip Actuator ............................................................................................................................................................................... 37

5-6 Accessory Devices Secondary Connections ................................................................................................................................................ 43

5-5 Electronic Tripping System .......................................................................................................................................................................... 43

5-5.1 Microprocessor-Based Trip Unit .................................................................................................................................................. 44

5-5.2 Rating Plug ................................................................................................................................................................................. 44

5-5.3 Current ......................................................................................................................................................................................... 45

5-6.1 Plug-in Electrical Accessories...........................................................................................

5-6.2 Internal Electrical Accessories ..................................................................................................................................................... 47

5-6.3 Mechanical Accessories ............................................................................................................................................................. 49

SECTION 6: INSPECTION AND MAINTENANCE

6-1 Introduction .................................................................................................................................................................................................. 50

6-2 Frequency of Inspection and Maintenance ................................................................................................................................................. 50

........................................................... 46

Page

For more information visit: www.Eaton.com IB131016EN

Instruction Book

Effective: November 2017 Page v

6-3 Vacuum Interrupter Integrity Test ................................................................................................................................................................. 49

6-4 Contact Erosion (up to 25kA) ....................................................................................................................................................................... 51

6-5 Contact Wipe (up to 25kA) ........................................................................................................................................................................... 51

6-6 Insulation ...................................................................................................................................................................................................... 54

6-7 Insulation Integrity Check .............................................................................................................................................................................. 54

6-8 Primary Circuit Resistance Check ............................................................................................................................................................... 54

6-9 Mechanism Check ....................................................................................................................................................................................... 54

6-10 Lubrication ................................................................................................................................................................................................... 54

6-11 Troubleshooting ........................................................................................................................................................................................... 54

6-14 End of Life Procedures…………………………………………………………………………………………………………………………………..59

6-15 Failure Reporting………………………………………………………………………………………………………………………………………….59

SECTION 7: RENEWAL PARTS

7-1 General ........................................................................................................................................................................................................ 59

7-2 Ordering Instructions ..................................................................................................................................................................................... 59

7-3 Mechanism and Related Parts ..................................................................................................................................................................... 60

7-4 Current Path .................................................................................................................................................................................................. 61

7-5 Electrical Attachments .................................................................................................................................................................................. 62

7-6 Other Breaker Related Parts ......................................................................................................................................................................... 65

7-7 Trip Unit and Related Parts ........................................................................................................................................................................... 68

LIST OF FIGURES

1-1 VCP-TR Fixed Breaker Outlines (except 25kA, 2000/2500A and all 31.5/40kA) ................................................................................... 4

1-2 VCP-T Drawout Breaker Outlines (except 25kA, 2000A and all 31.5/40kA) ......................................................................................... 5

1-3 VCP-T Breaker Cassette Outlines (except 25kA, 2000A and all 31.5/40kA) ......................................................................................... 6

1-4 VCP-TR Fixed Breaker Outlines (25kA, 2000/2500A and all 31.5/40kA) .............................................................................................. 7

1-5 VCP-T Drawout Breaker Outlines (25kA, 2000A and all 31.5/40kA) ..................................................................................................... 8

1-6 VCP-T Breaker Cassette Outlines (25kA, 2000A and all 31.5/40kA) .................................................................................................... 9

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

3-1 Fixed Breaker Shown Mounted on Pallet ............................................................................................................................................. 12

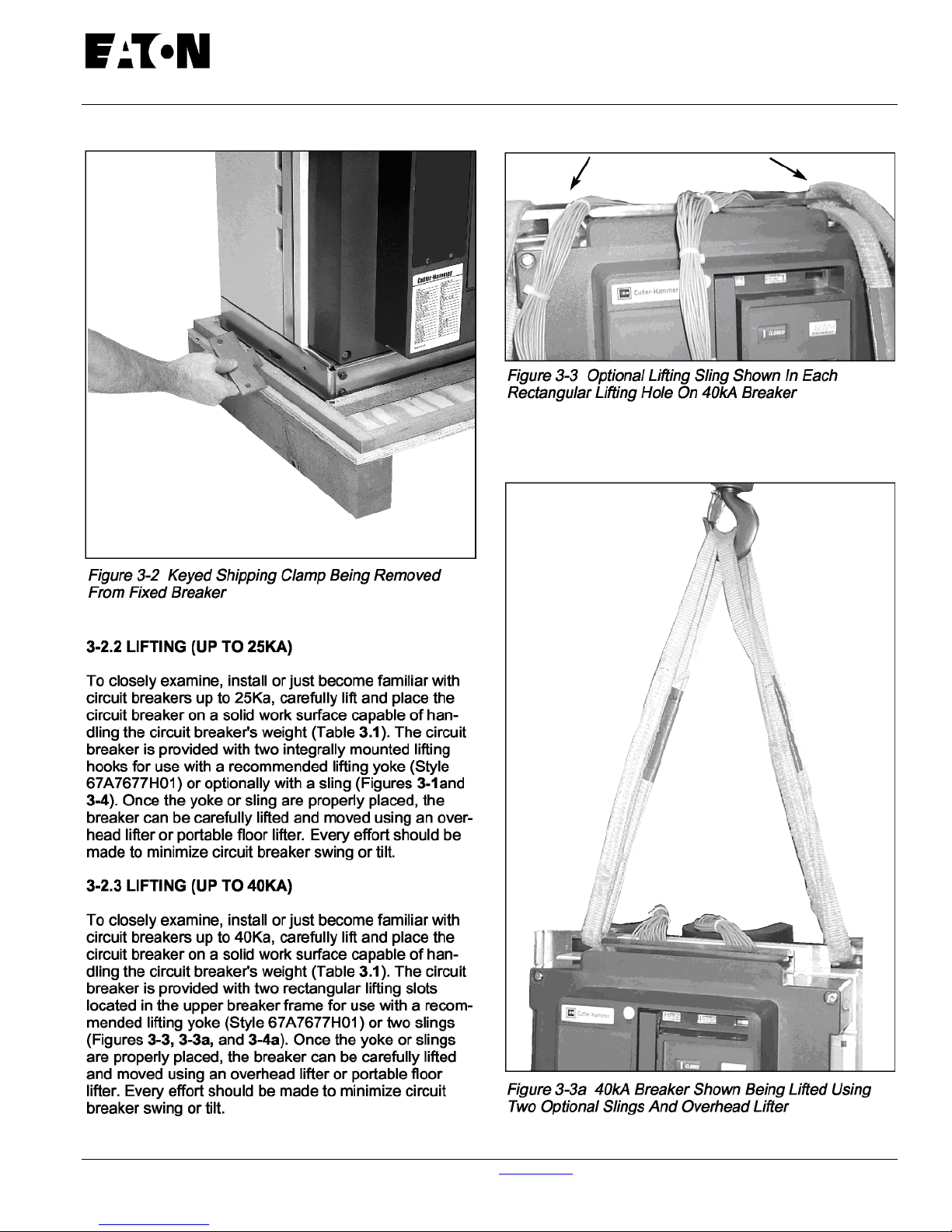

3-2 Keyed Shipping Clamp Being Removed from Fixed Breaker .............................................................................................................. 13

3-3 Optional Lifting Sling Shown on 40kA Breaker .................................................................................................................................... 13

3-3a 40kA Breaker Shown Being Lifted with Optional Lifting Slings ............................................................................................................ 13

3-4 Preferred Lifting Method Using Lifting Yoke To Lift 25kA Breaker ....................................................................................................... 14

3-4a Preferred Lifting Method Using Lifting Yoke To Lift 40kA Breaker ....................................................................................................... 14

3-5 Front and Rear Views All VCP-TR Fixed (except 25kA, 2000/2500A and all 31.5/40kA) .................................................................... 16

3-6 Front and Rear Views All VCP-T Drawout (except 25kA, 2000A and all 31.5/40kA) .......................................................................... 17

3-7 Front and Rear Views Drawout Cassette (except 25kA, 2000A and all 31.5/40kA) ............................................................................ 18

3-8 Front and Rear Views VCP-T Drawout Breaker (25kA, 2000A and all 31.5/40kA) .............................................................................. 19

3-9 Front and Rear Views Drawout Cassette (25kA, 2000A and all 31.5/40kA) ......................................................................................... 20

3-10 Typical VCP-T Front Cover ................................................................................................................................................................... 21

4-1 Typical Fixed Non-Automatic VCP-TR 15KV Circuit Breaker ............................................................................................................... 23

4-2 Bottom View of VCP-TR Circuit Breaker showing Mounting Holes ..................................................................................................... 23

4-3 Cassette Rejection Interlock Pin Positioning ....................................................................................................................................... 24

4-4 Position Circuit Breaker with Lifter on Removable Extension Rails ..................................................................................................... 25

4-5 Breaker Shoot Bolts Against Cassette .................................................................................................................................................. 25

4-6 Shoot Bolt Handle in Up (Locked) Position ........................................................................................................................................... 25

4-7 Shoot Bolt Handle Shown in Position “C” - Shoot Bolts Protrude Fully from Cradle ............................................................................ 26

4-8 Shoot Bolt Handle Shown in Position “B” - Shoot Bolts Protrude Partially from Cradle ....................................................................... 26

4-9 Shoot Bolt Handle Shown in Position “A” - Shoot Bolts Retracted Fully Inside Cradle ........................................................................ 26

4-10 Circuit Breaker Umbilical Cord Shown Connected to Breaker Prior to Breaker Insertion .................................................................... 27

4-11 Secondary Connector Viewed from Rear of Breaker ............................................................................................................................ 27

4-12 Cassette Secondary Connector and Interlock Lever ........................................................................

4-13 Drawout Cassette with Primary Safety Shutters Open Showing Fixed Primary Stabs ........................................................................ 28

4-14 Circuit Breaker Shown in Levered Out (DISCONNECT) Position - Correct for Breaker Positioning ................................................... 28

4-15 Circuit Breaker Shown in Levered In (CONNECT) Position - Incorrect for Breaker Positioning........................................................... 28

................................................... 27

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Page vi Effective: November 2017

4-16 Cradle Mounted Levering Mechanism ..................................................................................................................................................... 29

4-17 Levering Circuit Breaker .......................................................................................................................................................................... 29

4-18 Circuit Breaker Connected as Indicated by Fully Connected Position Label ........................................................................................... 29

4-19 Circuit Breaker Shown in CONNECT Position with Secondary Connections Made ................................................................................ 30

4-20 Primary Safety Shutters Shown in Open Position with Fixed Primary Stabs Exposed ............................................................................. 30

4-21 Padlocking Device on Side of Cassette ................................................................................................................................................... 30

5-1 Rigid Frame Construction ........................................................................................................................................................................ 31

5-2 VCP-TR Fixed Non-automatic Circuit Breaker (Front Cover Removed) .................................................................................................. 32

5-3 VCP-T Drawout Circuit Breaker (Front Cover Removed) ........................................................................................................................ 33

5-4 Typical Fixed 50 VCP-TR Interrupter Assembly ...................................................................................................................................... 34

5-5 Typical Drawout 150 VCP-T Interrupter Assembly .................................................................................................................................. 34

5-6 Breaker Closing Springs Being Manually Charged ................................................................................................................................... 35

5-7 Motor Operator Shown Installed .............................................................................................................................................................. 36

5-8 Typical Cover Mounted Key Interlock ...................................................................................................................................................... 36

5-9 Typical Mechanical Cable Interlock ......................................................................................................................................................... 37

5-10 VCP-T and VCP-TR Non Trip Unit Connection Diagram ......................................................................................................................... 38

5-11 VCP-T and VCP-TR with 520V Trip Unit Connection Diagram ................................................................................................................. 39

5-12 VCP-T and VCP-TR with 1150V Trip Unit Connection Diagram ............................................................................................................... 40

5-12A VCP-T and VCP-TR with 520MCV Trip Unit Connection Diagram ........................................................................................................... 41

5-13 VCP-T Drawout Umbilical Cord and Connector Wiring Diagram ............................................................................................................. 42

5-14 Secondary Connectors Shown Mounted without Secondary Protective Hood in Place .......................................................................... 37

5-15 Top View Secondary Connectors ............................................................................................................................................................ 43

5-16 Secondary Male Connector with Female Pins ......................................................................................................................................... 43

5-17 Optional Terminal Block ........................................................................................................................................................................... 43

5-18 AMP Secondary Wiring Removal Tool (AMP#305183) ........................................................................................................................... 43

5-19 Digitrip RMS 1 150Vi Programmable Trip Unit Installed in VCP-T Circuit Breaker................................................................................... 44

5-20 Hand Held Tester ...................................................................................................................................................................................... 44

5-21 Through-The-Window Electrical Accessories .......................................................................................................................................... 46

5-22 Shunt Trip Device .................................................................................................................................................................................... 46

5-23 Spring Release Device ............................................................................................................................................................................ 46

5-24 Undervoltage Release Device ................................................................................................................................................................. 47

5-25 Rugged Motor Operator ............................................................................................................................................................................ 48

5-26 Auxiliary Switch ........................................................................................................................................................................................ 48

5-27 Pushbutton Cover Mounted ..................................................................................................................................................................... 49

5-28 Door Escutcheon and Gasket .................................................................................................................................................................. 49

6-1 Contact Erosion Mark Visible on Stem .................................................................................................................................................... 53

6-2 Contact Wipe Inspection Area ................................................................................................................................................................. 53

6-3 Satisfactory Contact Wipe Condition with Breaker Closed ...................................................................................................................... 53

6-4 Unsatisfactory Contact Wipe Condition with Breaker Closed .................................................................................................................. 53

6-5 Contact Wipe Measurement 40kA Breaker ............................................................................................................................................... 54

6-6 40kA Breaker Contact Wipe Graphic ....................................................................................................................................................... 54

6-7 Circuit Breaker Lubrication ....................................................................................................................................................................... 58

6-8 Drawout Cassette Lubrication .................................................................................................................................................................. 59

LIST OF TABLES

Table Title Page

1.1 VCP-T and VCP-TR Ratings ...................................................................................................................................................................... 2

3.1 Circuit Breaker and Cassette Weights ..................................................................................................................................................... 15

4.1 Cassette Rejection Interlock Pin Locations ............................................................................................................................................... 23

5.1 Digitrip Trip Units ..................................................................................................................................................................................... 44

5.2 Current Sensors and Matching Rating Plugs ........................................................................................................................................... 45

5.3 Shunt Trip Ratings ................................................................................................................................................................................... 47

5.4 Spring Release Ratings ........................................................................................................................................................................... 47

5.5 Undervoltage Release Ratings ................................................................................................................................................................ 47

5.6 Motor Operator Ratings ........................................................................................................................................................................... 48

5.7 Auxiliary Switch Contacts Interrupting Capacities ..................................................................................................................................... 48

6.1 Inspection and Maintenance Procedures ................................................................................................................................................. 51

6.2 Test Voltage .............................................................................................................................................................................................. 52

6.3 Typical Resistance Measurements .......................................................................................................................................................... 55

6.4 Troubleshooting Guide .............................................................................................................................................................................. 56

For more information visit: www.Eaton.com IB131016EN

Instruction Book

Effective: November 2017 Page 1

SECTION 1: INTRODUCTION

The purpose of this book is to provide instructions for

unpacking, storage, use operation and maintenance

of VCP-T drawout type and VCP-TR fixed type

Vacuum Circuit Breakers. VCP-T and VCP-TR are

compact vacuum interrupting elements designed for

applications such as: mine power centers, portable

power stations, fixed breaker or drawout switchgear

and portable generators, all without compromising

metal clad expectations. VCP-T and VCP-TR

breakers were specifically designed to provide proven

reliable performance in a small package. The circuit

breakers are available in voltage classes of 4.76, 8.25

and 15.0 kV. They are tested in accordance with ANSI

C37.04 and C37.09 (Table 1.1).

1-1 VCP-T and VCP-TR Vacuum Breaker Ratings

Refer to Tables 1.1 and 1.2 on pages 2 and 3.

The circuit breaker's nameplate provides complete

rating information. Reliable control and protection for

medium voltage equipment and circuits are achieved

through the use of VCP-T and VCP-TR Vacuum

Breakers.

WARNING

SATISFACTORY PERFORMANCE OF THESE

BREAKERS IS CONTINGENT UPON PROPER

APPLICATION, CORRECT INSTALLATION AND

ADEQUATE MAINTENANCE. THIS INSTRUCTION

BOOK MUST BE CAREFULLY READ AND

FOLLOWED IN ORDER TO OBTAIN OPTIMUM

PERFORMANCE FOR LONG USEFUL LIFE OF THE

CIRCUIT BREAKERS.

VCP-T and VCP-TR CIRCUIT BREAKERS ARE

PROTECTIVE DEVICES, AS SUCH, THEY ARE

MAXIMUM RATED DEVICES. THEREFORE, THEY

SHOULD NOT UNDER ANY CIRCUMSTANCES BE

APPLIED OUTSIDE THEIR NAMEPLATE RATINGS.

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page 2

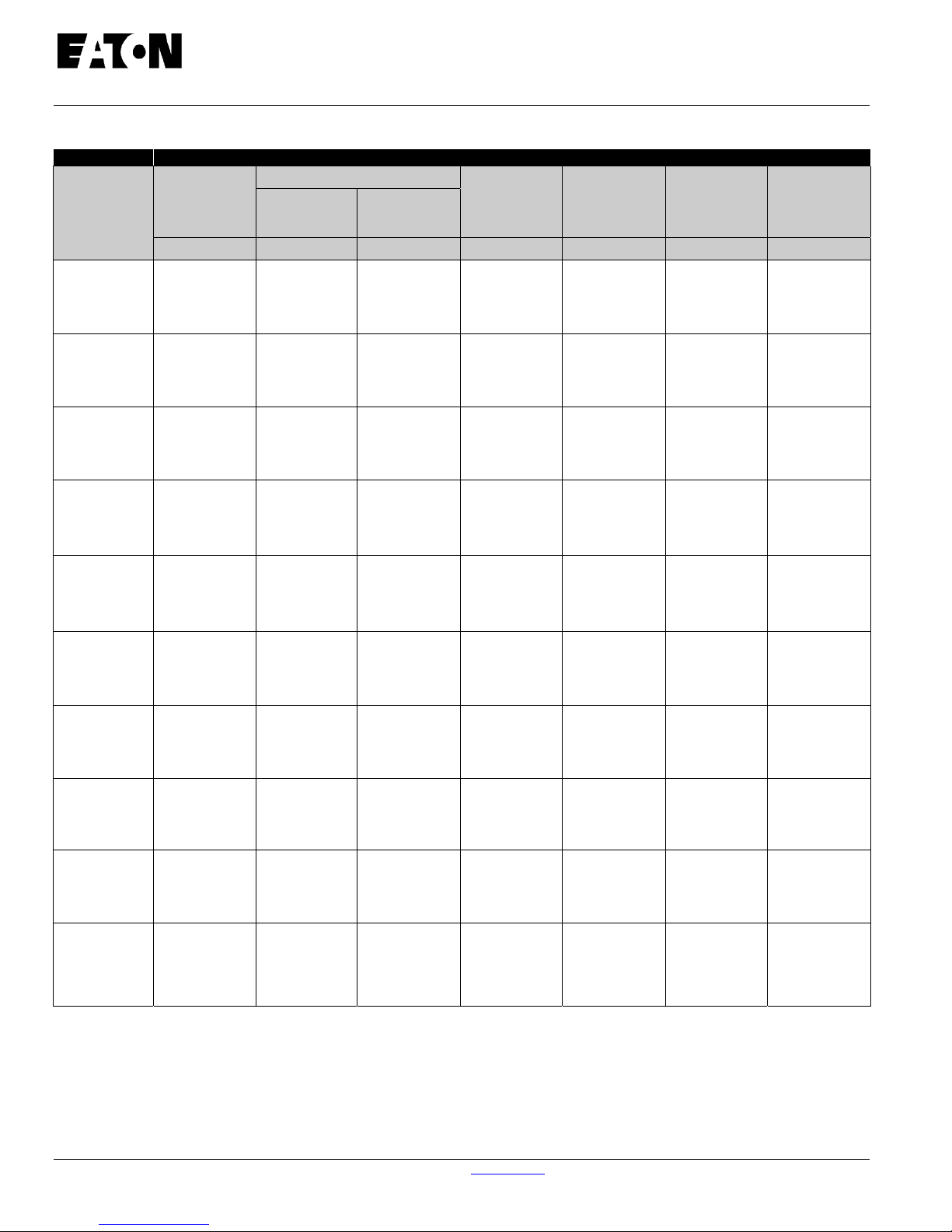

Table 1.1 VCP-T and VCP-TR Ratings (ANSI C37. 04 and C37. 09) (continued on next page)

Identification Rated Values

Circuit

Breaker

Type

Insulation Level

Voltage

Class

Power

Frequency

Impulse

Withstand

kV rms kV rms kV Peak

Continuous

Current

Amperes

Short Circuit `

Breaking

Current

kA rms

Short Circuit

Making

Current

Mechanical

Endurance

C - O

kA Peak Operations

50 VCP-T16

and

50 VCP-TR16

50 VCP-T20

and

50 VCP-TR20

50 VCP-T25

and

50 VCP-TR25

50 VCP-T32

and

50 VCP-TR32

50 VCP-T40

and

50 VCP-TR40

75 VCP-T16

and

75 VCP-TR16

75 VCP-T20

and

75 VCP-TR20

4.76 19 60

4.76 19 60

4.76 19 60

4.76 19 60

4.76 19 60

8.25 20

8.25 20

60

60

600

1200

1600

600

1200

1 600

600

1200

1600

2000

2500

600

1200

2000

2500

600

1200

2000

2500

600

1200

1600

600

1200

1600

16 42

20 52

25 65

31.5 82

40 104

16 42

20 52

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

75 VCP-T25

and

75 VCP-TR25

75 VCP-T32

and

75 VCP-TR32

75 VCP-T40

and

75 VCP-TR40

Use 15kV Breaker and Cassette when 95kV Impulse Withstand required Also 2 Second Short Time Current Rating

1600A and 2500A available as fixed VCP-TR circuit breaker only

8.25 20

8.25 20

8.25 20

For more information visit: www.Eaton.com IB131016EN

600

60

60

60

1200

1600

2000

2500

600

1200

2000

2500

600

6040

1200

2000

2500

25 65

31.5 82

40 104

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

Instruction Book

Effective: November 2017 Page 3

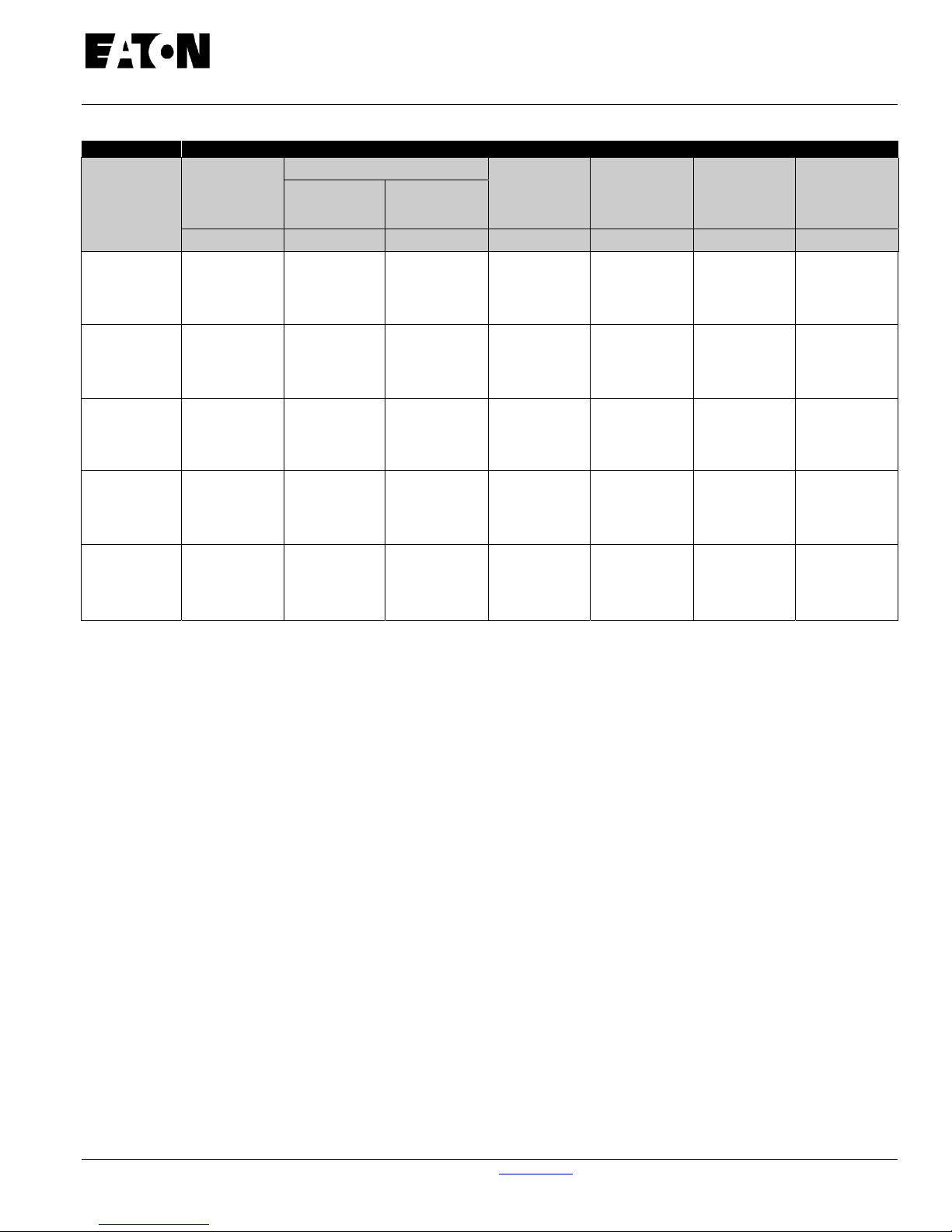

Table 1.1 VCP-T and VCP-TR Ratings (ANSI C37. 04 and C37. 09) (continued from previous page)

Identification Rated Values

Circuit

Breaker

Type

Insulation Level

Voltage

Class

Power

Frequency

Impulse

Withstand

kV rms kV rms kV Peak

Continuous

Current

Amperes

Short Circuit `

Breaking

Current

kA rms

Short Circuit

Making

Current

Mechanical

Endurance

C - O

kA Peak Operations

150 VCP-T16

and

150 VCP-TR16

150 VCP-T20

and

150 VCP-TR20

150 VCP-T25

and

150 VCP-TR25

150 VCP-T32

and

150 VCP-TR32

150 VCP-T40

and

150 VCP-TR40

Use 15kV Breaker and Cassette when 95kV Impulse Withstand required Also 2 Second Short Time Current Rating

1600A and 2500A available as fixed VCP-TR circuit breaker only

Tested for capacitor switching capabilities. “General Purpose” to ANSI C37: Cable charging = 25A. "Definite Purpose" to ANSI C37:

Back-to-back equals 250A and 1000A. Ratings of 250 and 1000A cover capacitor bank applications from 75 to 1000A.

Inrush current and frequency rating = 18 kApk at 2.4 kHz.

15 36 95

15 36 95

15 36 95

15 36 95

15 36 95

600

1200

1600

600

1200

1600

600

1200

1600

2000

2500

600

1200

2000

2500

600

1200

2000

2500

16 42

20 52

25 65

31.5 82

40 104

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

10000

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page 4

1-2 Types VCP-T and VCP-TR Outlines and Dimensions (Circuit Breakers and Drawout Cassettes)

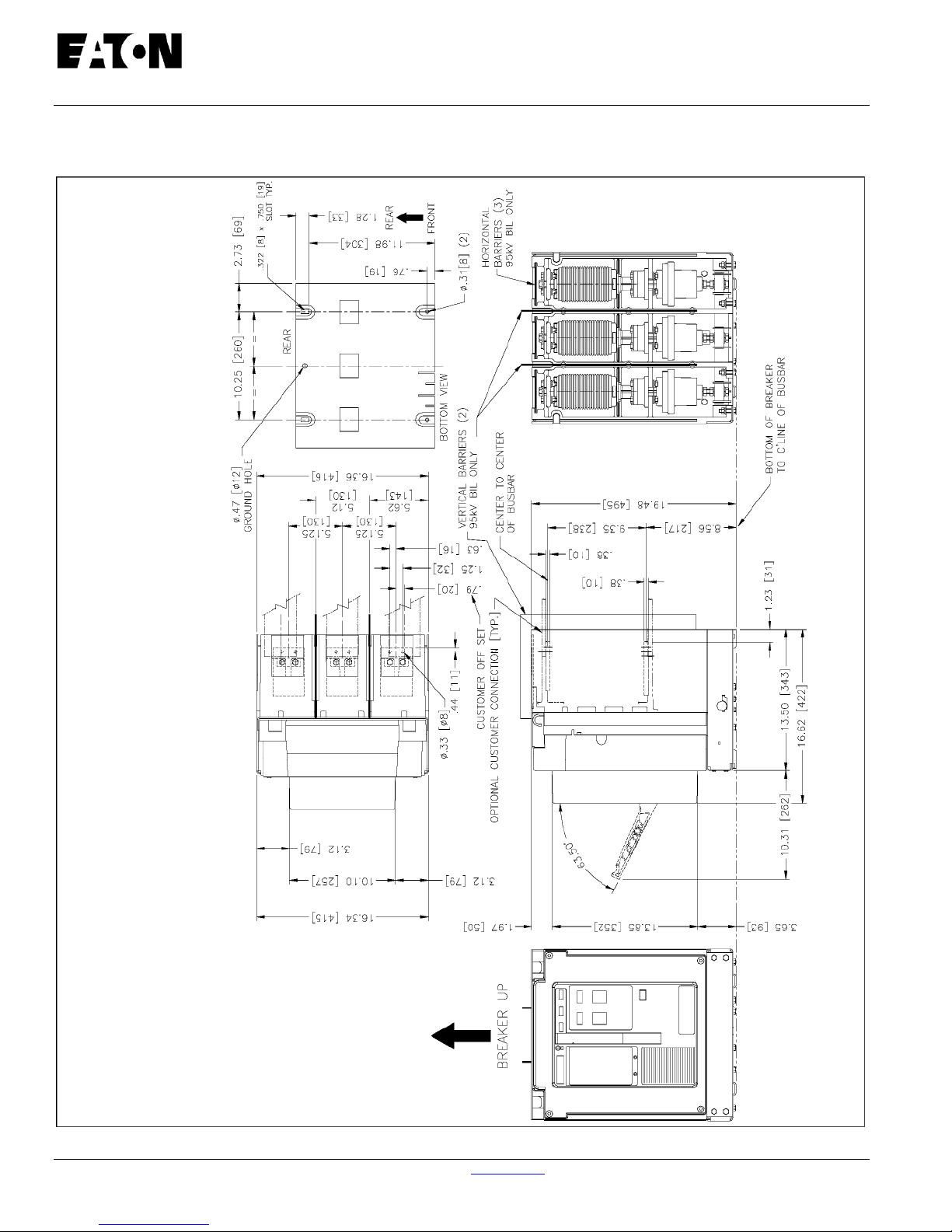

Figure 1-1 VCP-TR Fixed Breaker Outlines in inch es [mm] (e xcept 25kA, 2000/2500A and all 31.5/40kA)

For more information visit: www.Eaton.com IB131016EN

Instruction Book

Effective: November 2017 Page 5

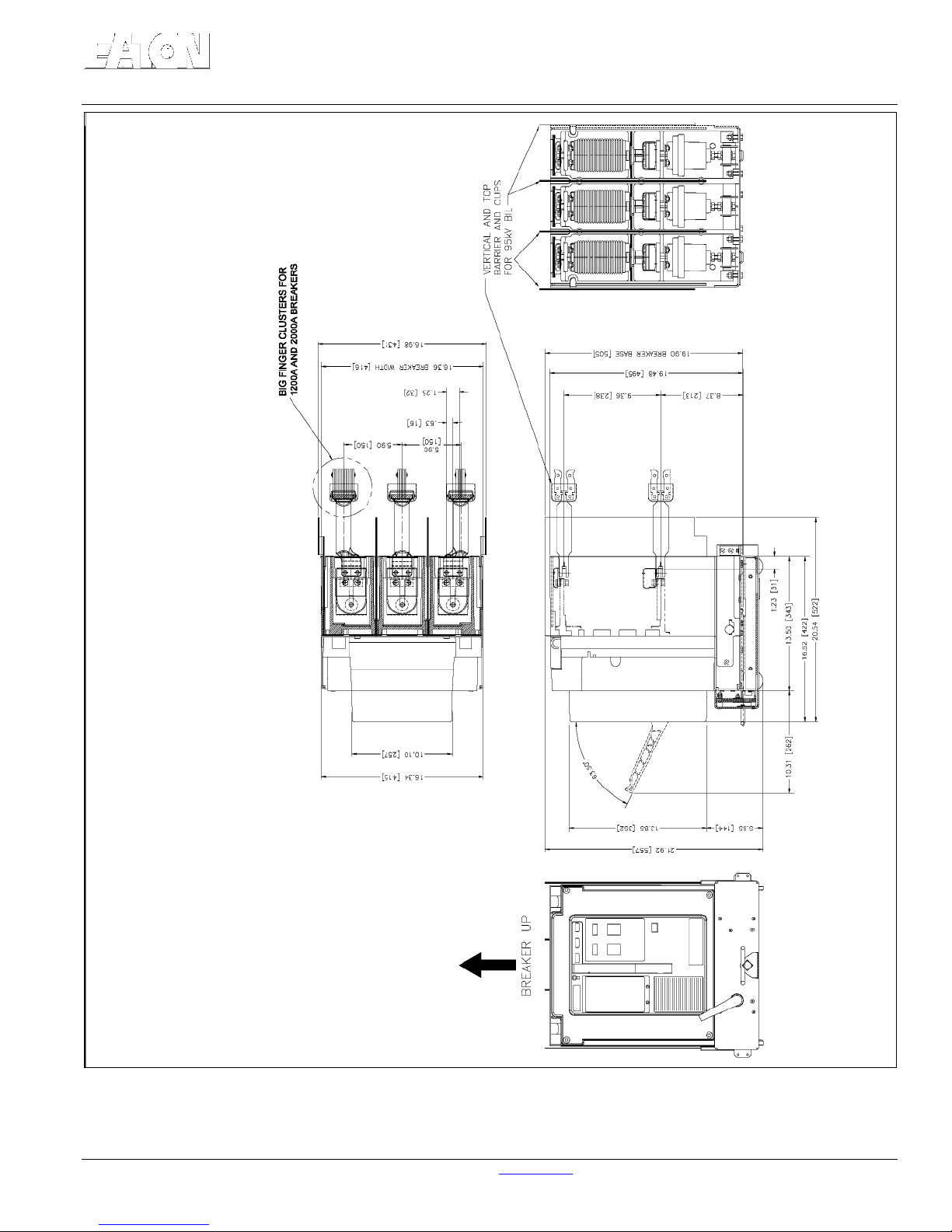

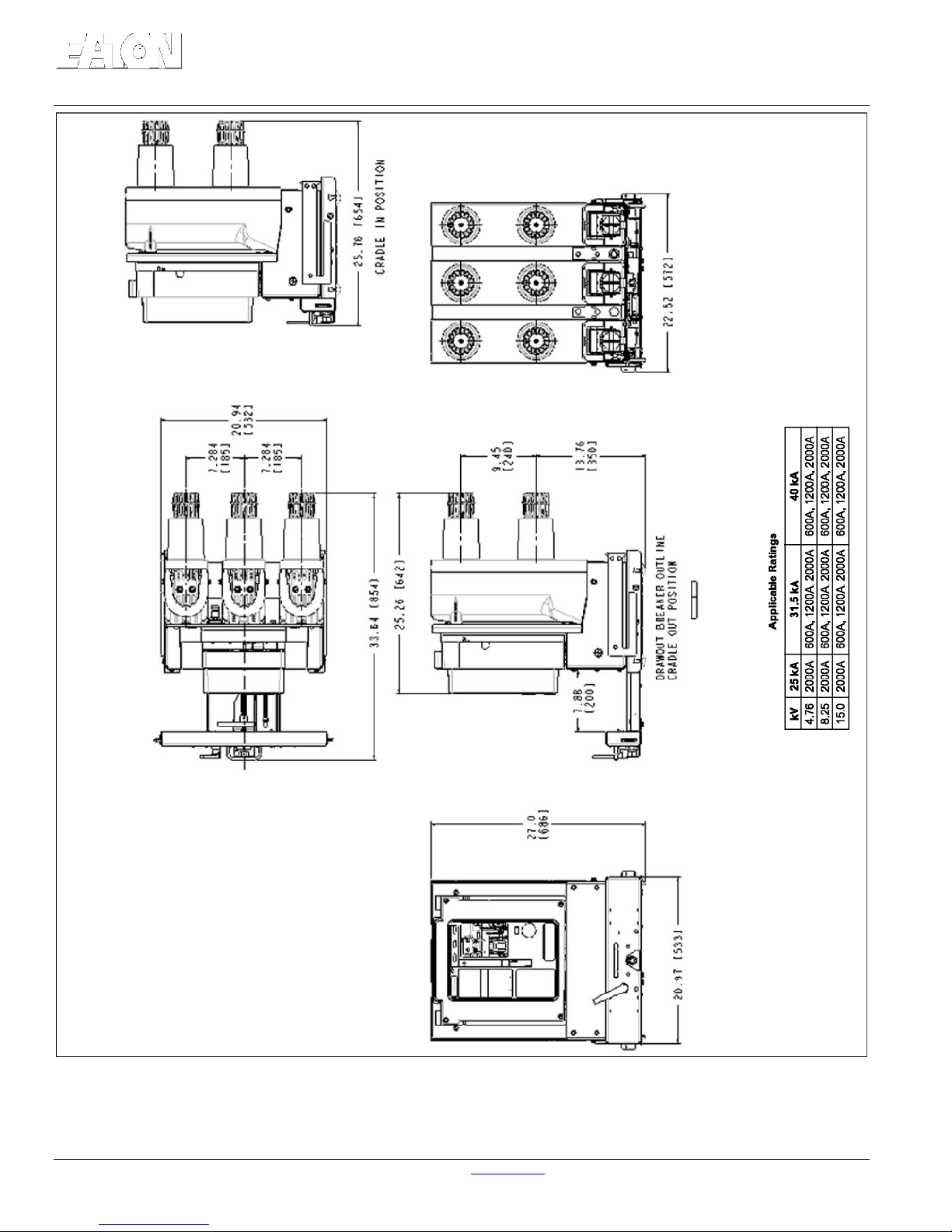

Figure 1-2 VCP-T Drawout Breaker Outlines in inches [mm] (except 25kA, 2000A and all 31.5/40kA)

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page 6

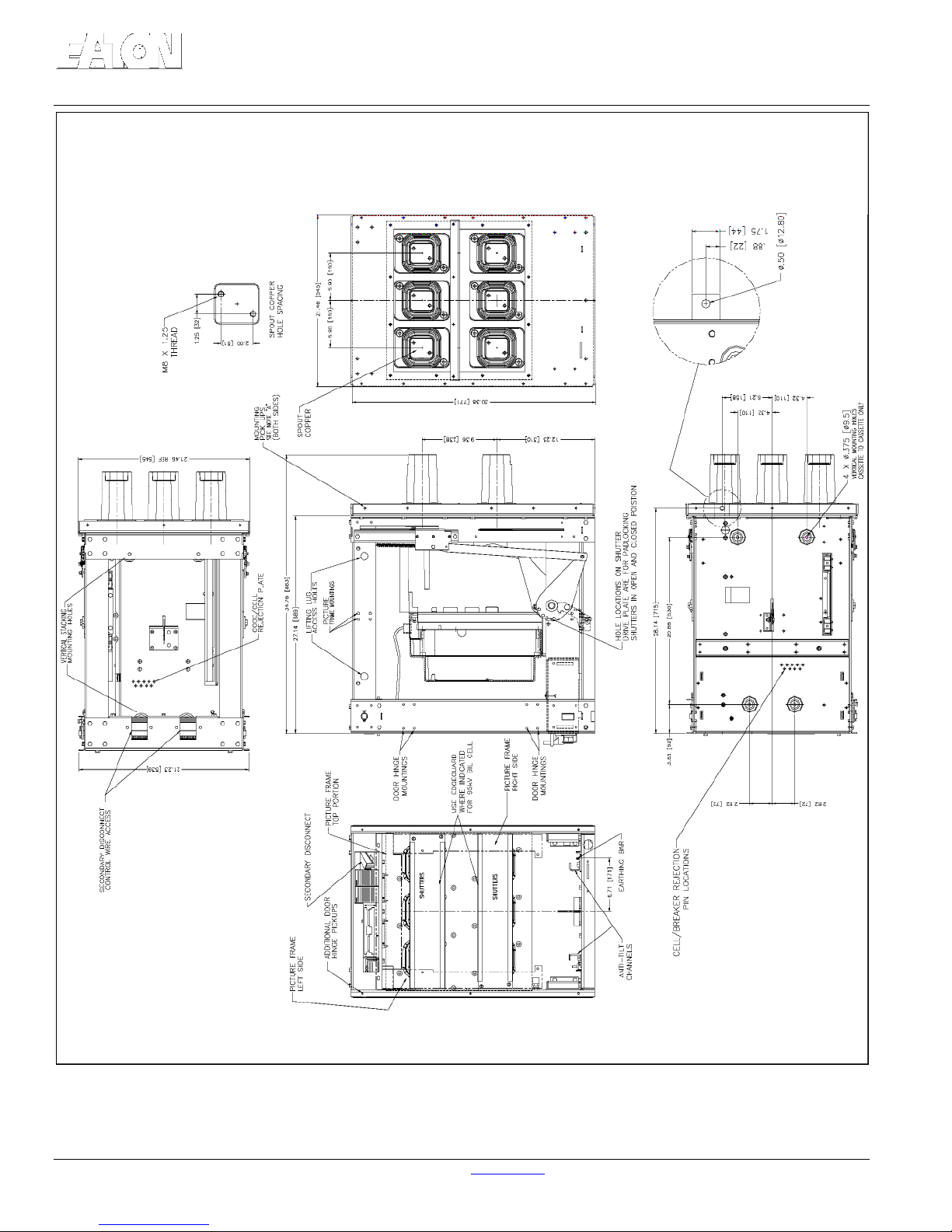

Figure 1-3 VCP-T Breaker Cassette Outlines in inches [mm] (except 25kA, 2000A and all 31.5/40kA)

For more information visit: www.Eaton.com IB131016EN

Instruction Book

Effective: November 2017 Page 7

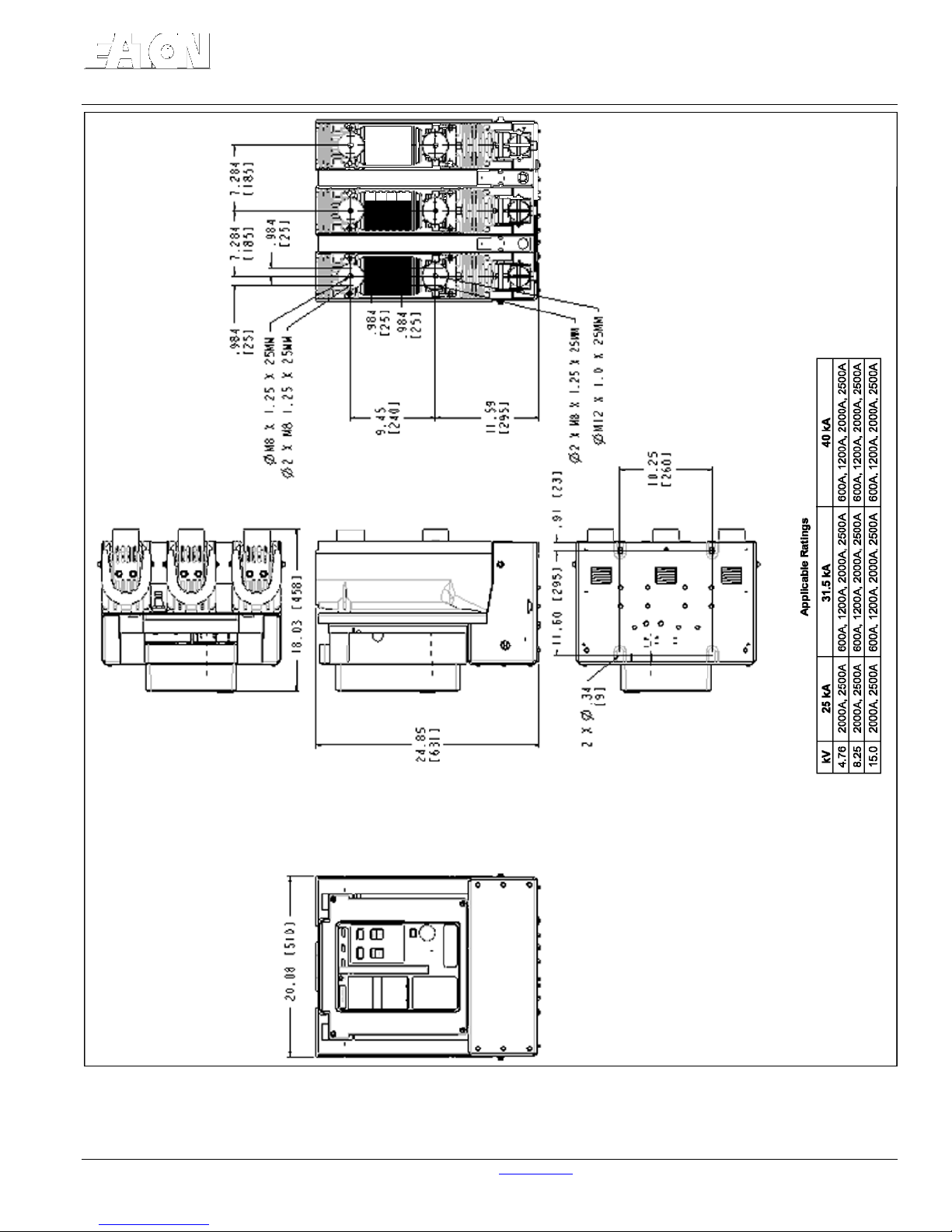

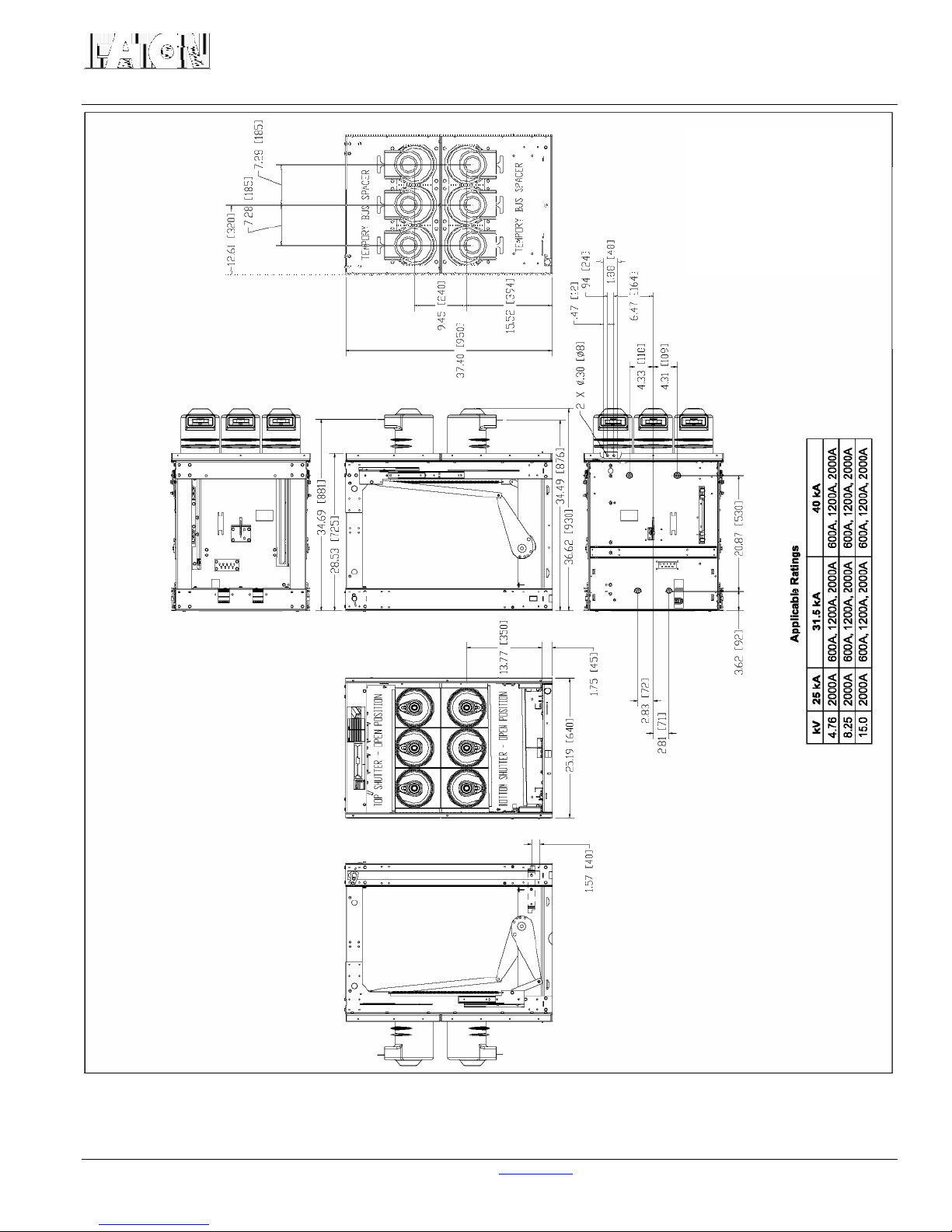

Figure 1-4 VCP-TR Fixed Breaker Outlines in inches [mm] (Refer to above Applicable Ratings Table)

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page 8

Figure 1-5 VCP-T Drawout Breaker Outlines in inches [mm] (Refer to above Applicable Ratings Table)

For more information visit: www.Eaton.com IB131016EN

Instruction Book

Effective: November 2017 Page 9

Figure 1-6 VCP-T Breaker Cassette Outline s in inch es [mm ] (Re fer to abo ve Applicab le Ra tings Ta ble)

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page 10

REFER TO IL131031EN FOR:

VCP-T/T-VAC 31.5kA, 40kA 2000A Cassette Bus Bar

Assembly Instructions

For more information visit: www.Eaton.com IB131016EN

Instruction Book

Effective: November 2017 Page 11

SECTION 2: SAFE PRACTICES

The circuit breakers are equipped with high speed,

high energy operating mechanisms. They are

designed with built-in safety interlocks to provide for

safe operation. In addition, other optional interlocks

are available depending upon the application. Refer to

Section 5 for additional inter lock informatio n. It is the

customers’ responsibility to insure that appropriate

interfaces with the breakers are provided and tests

conducted to adequately prove proper installation and

functioning.

WARNING

TO PROTECT THE PERSONNEL ASSOCIATED

WITH INSTALLATION, OPERATION, AND

MAINTENANCE OF THESE BREAKERS, THE

FOLLOWING PRACTICES MUST BE FOLLOWED:

Always make sure that primary and secondary

power are disconnected from a fixed breaker

before performing any maintenance. Failure to do

so could result in electrical shock leading to death,

severe personal injury and/or property damage.

Do not work on a closed breaker or a breaker with

closing springs charged. The closing springs

should be discharged and the main contacts open

before working on the breaker. Failure to do so

could result in cutting or crushing injuries.

Do not use a circuit breaker by itself as the sole

means of isolating a high voltage circuit. As

appropriate, use an isolation means and follow all

lock-out and tagging rules of the Local Electrical

Codes and any and all applicable codes,

regulations and work rules.

Only qualified persons, as defined in the Local

Electrical Codes, who are familiar with the

installation and maintenance of medium voltage

circuits and equipment, should be permitted to

work on these breakers.

Read these instructions carefully before

attempting any installation, operation or

maintenance of these breakers.

Always remove drawout type breakers from their

enclosure before performing any maintenance.

Failure to do so could result in electrical shock

leading to death, severe personal injury and/or

property damage.

Always ensure that drawout circuit breakers are in

one of their designed cell positions, such as

Connect, Test/Disconnect or Remove. A circuit

breaker permitted to remain in an intermediate

position could result in control circuits being

improperly connected resulting in electrical failures.

Breakers are equipped with safety interlocks. Do

Not defeat them. This may result in death, bodily

injury and/or equipment damage.

Do not work on a circuit breaker while

suspended from a lifting means. Maintenance

work should be performed on a properly

supported cart or table.

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page 12

3-2.1 UNPACKING

SECTION 3: RECEIVING, HANDLING

AND STORA GE

VCP-T and VCP-TR circuit breakers are subjected to

complete factory production tests and inspection

before being packed. They are shipped in packages

designed to provide maximum protection to the

equipment during shipment and storage and at the

same time to provide convenient handling.

3-1 RECEIVING

Until the breaker is ready for use, it is best NOT to

remove it from its container. If the breaker is to be

placed in storage, maximum protection can be obtained

by keeping it packed as shipped.

Upon receipt of the equipment, inspect the containers

for any signs of damage from rough handling and/or

external damage incurred during the transportation

phase. Record any observed damage for reporting to

the transportation carrier and Eaton. All reports should

be as specific as possible and include the order

number and other applicable nameplate information.

Every effort is made to ensure that circuit breakers

arrive at their destination undamaged and ready for

installation. Care should be exercised, however, to

protect the breakers from impact at all times. Do not

remove protective packaging until the circuit breakers

are ready for inspection, testing and/or installation.

Before beginning to unpack new circuit breakers, read

and understand the directions. Unpacking a fixed circuit

breaker is described in the next paragraph in detail.

Unpacking a drawout circuit breaker is also simple to

accomplish and is not described here in detail. Just

proceed by carefully removing all packing material used

for protection during shipment and the fa steners used

to secure the drawout circuit breaker to its shipping

pallet.

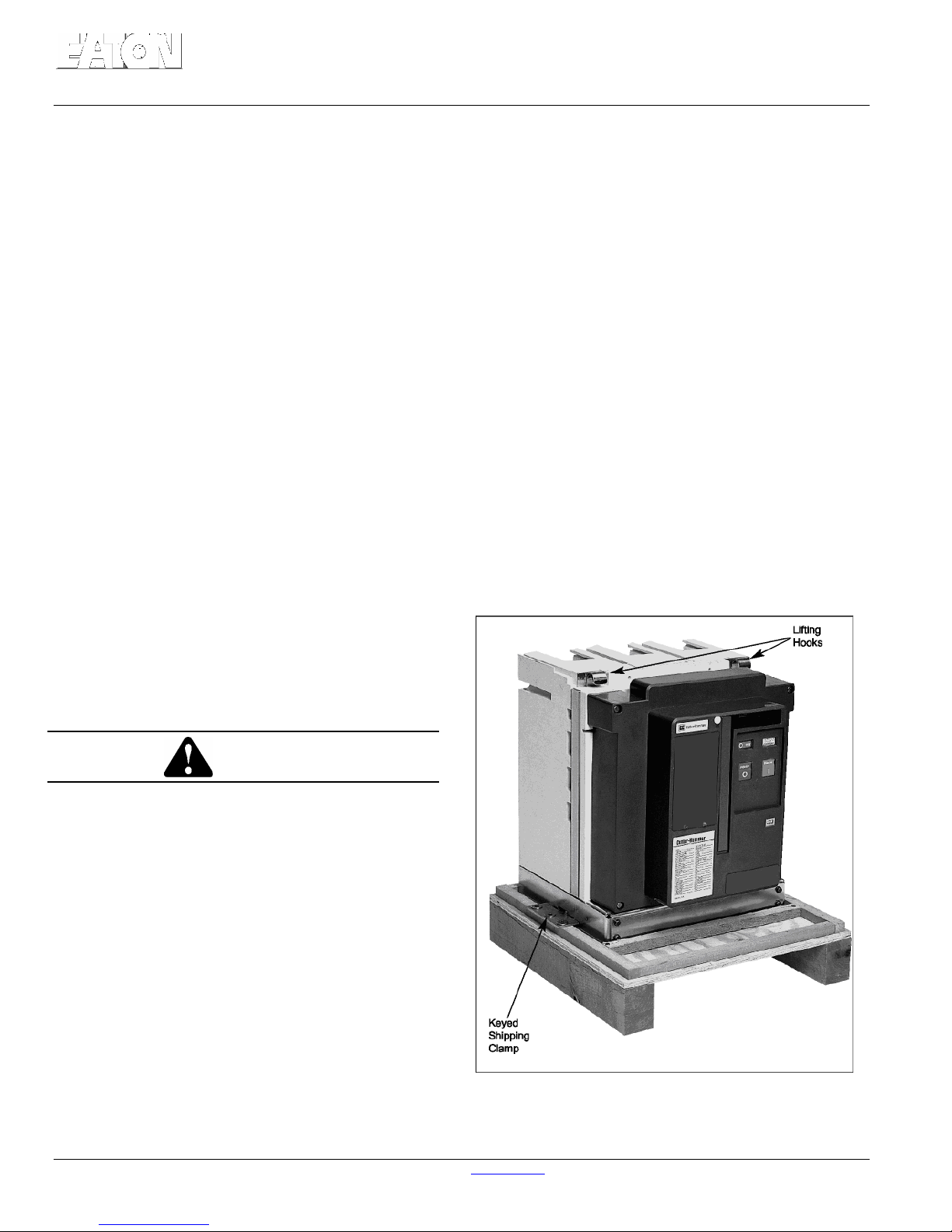

When ready to inspect and install the circuit breaker,

carefully remove any banding straps and lift off the

cardboard box. Remove any additional packing material

and internally packed documentation. The circuit

breaker is mounted to a wooden shipping pallet. A

keyed metal clamp is used on each side of the circuit

breaker to hold it to the wooden pallet (Figure 3-1).

Remove the screws from the wooden pallet on each

side and lift up and out on the keyed metal clamps for

removal (Figure 3-2). The circuit breaker is now ready

to be rem ov e d f r o m i ts s hi p ping pallet. Save all

shipping hardware and packaging material for any

future shipments of the circuit breaker.

3-2 HANDLING

WARNING

DO NOT USE ANY LIFTING DEVICE AS A

PLATFORM FOR PERFORMING MAINTENANCE,

REPAIR OR ADJUSTMENT OF THE BREAKER,

FOR OPENING OR CLOSING THE CONTACTS OR

CHARGING THE SPRINGS. THE BREAKER MAY

SLIP OR FALL CAUSING SEVERE PERSONAL

INJURY. ALWAYS PERFORM MAINTENANCE,

REPAIR AND ADJUSTMENTS ON A WORKBENCH

CAPABLE OF SUPPORTING THE BREAKER.

Shipping containers are designed to be handled either

by use of a sufficiently strong rope sling and overhead

lifting device or by a fork lift truck. If containers must

be skidded for any distance, it is preferable to use

roller conveyors or individual pipe rollers.

Figure 3-1 Fixed Breaker Shown Mounted on Pallet

For more information visit: www.Eaton.com IB131016EN

Instruction Book

Effective: November 2017 Page 13

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page 14

3-3 STORAGE

WARNING

THE CUSTOMER SHOULD READ AND

UNDERSTAND THE MATERIAL PRESENTED AND

ANY WARNINGS OR CAUTIONS OFFERED IN

THE INSTRUCTION BOOK BEFORE ANY

ATTEMPT IS MADE TO INTERFACE WITH THIS

CIRCUIT BREAKER.

IT IS IMPERATIVE THAT ALL APPLICABLE ANSI

STANDARDS BE COMPLIED WITH IN EVERY

RESPECT AND THAT NO COMPROMISES ARE

MADE WITH RESPECT TO THE ANSI

GUIDELINES OR INTENT.

UNDER NO CIRCUMSTANCES SHOULD

ALTERATIONS BE MADE TO EATON SUPPLIED

VCP-T OR VCP-TR CIRCUIT BREAKERS UNLESS

THE ALTERATION IS SPECIFICALLY ADDRESSED

IN AND PERMITTED BY THIS INSTRUCTION

BOOK.

If the circuit breaker is to be placed in storage,

maximum protection can be obtained by keeping it

packed as shipped. Before placing it in storage,

checks should be made to make sure that the breaker

is fre e from shipping damage and is in satisfactory

operating condition.

Outdoor storage is NOT recommended. If

unavoidable, the outdoor location must be well

drained and a temporary shelter from sun, rain, snow,

corrosive fumes, dust, dirt, falling objects, excessive

moisture, etc. must be provided. Containers should be

arranged to permit free circulation of air on all sides

and temporary heaters should be used to minimize

condensation. Moisture can cause rusting of metal

parts and deterioration of high voltage insulation. A

heat level of approximately 400 watts for each 100

cubic feet of volume is recommended with the heaters

distributed uniformly throughout the structure near the

floor.

Indoor storage should be in a building with sufficient

heat and circulation to prevent condensation. If the

building is not heated, the same general rule for heat as

for outdoor storage should be applied.

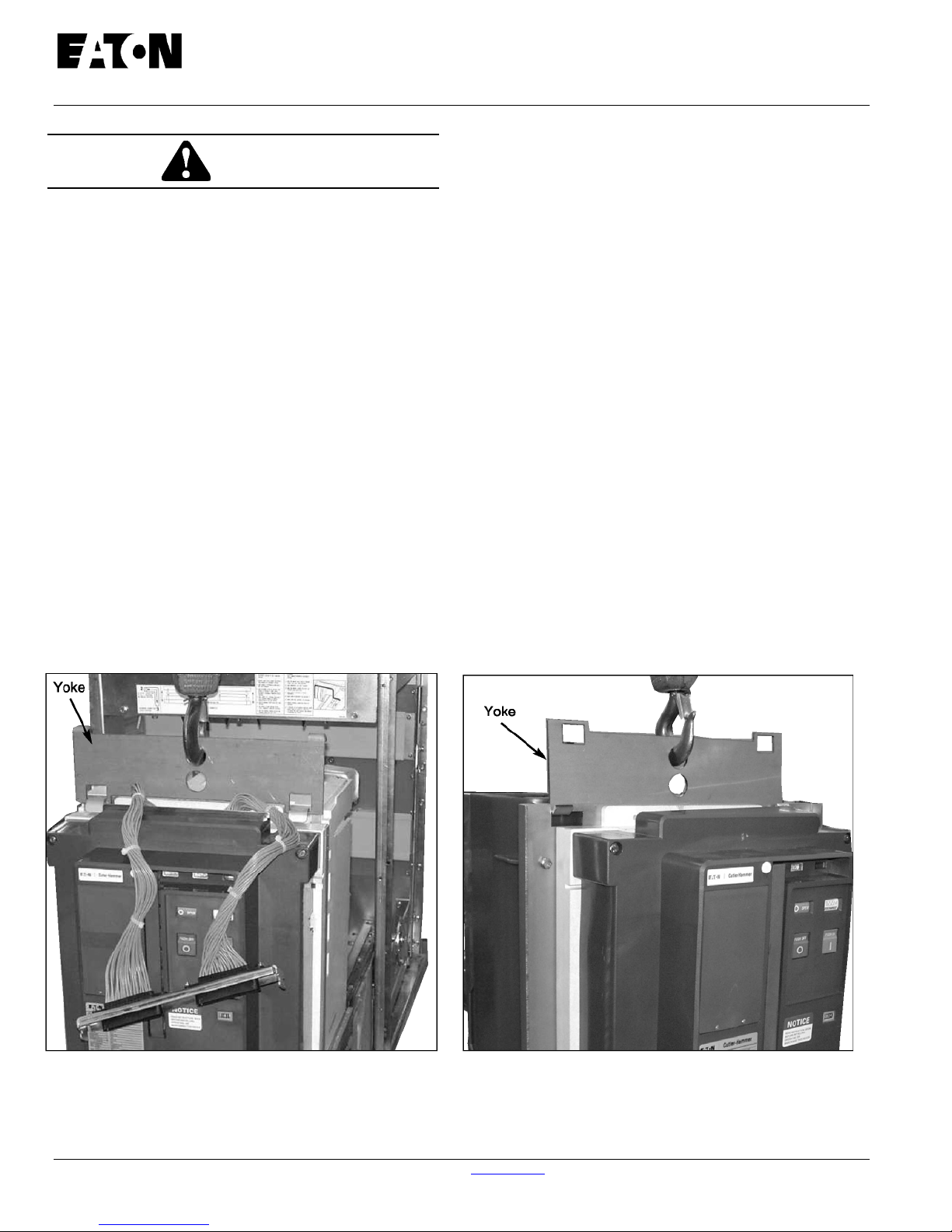

Figure 3-4 Preferred Lifting Method Using Lifting Yoke

To Lift 25kA Breaker

For more information visit: www.Eaton.com IB131016EN

Figure 3-4a Preferred Lifting Method Using Lifting

Yoke To Lift 40kA Breaker

Instruction Book

Effective: November 2017 Page 15

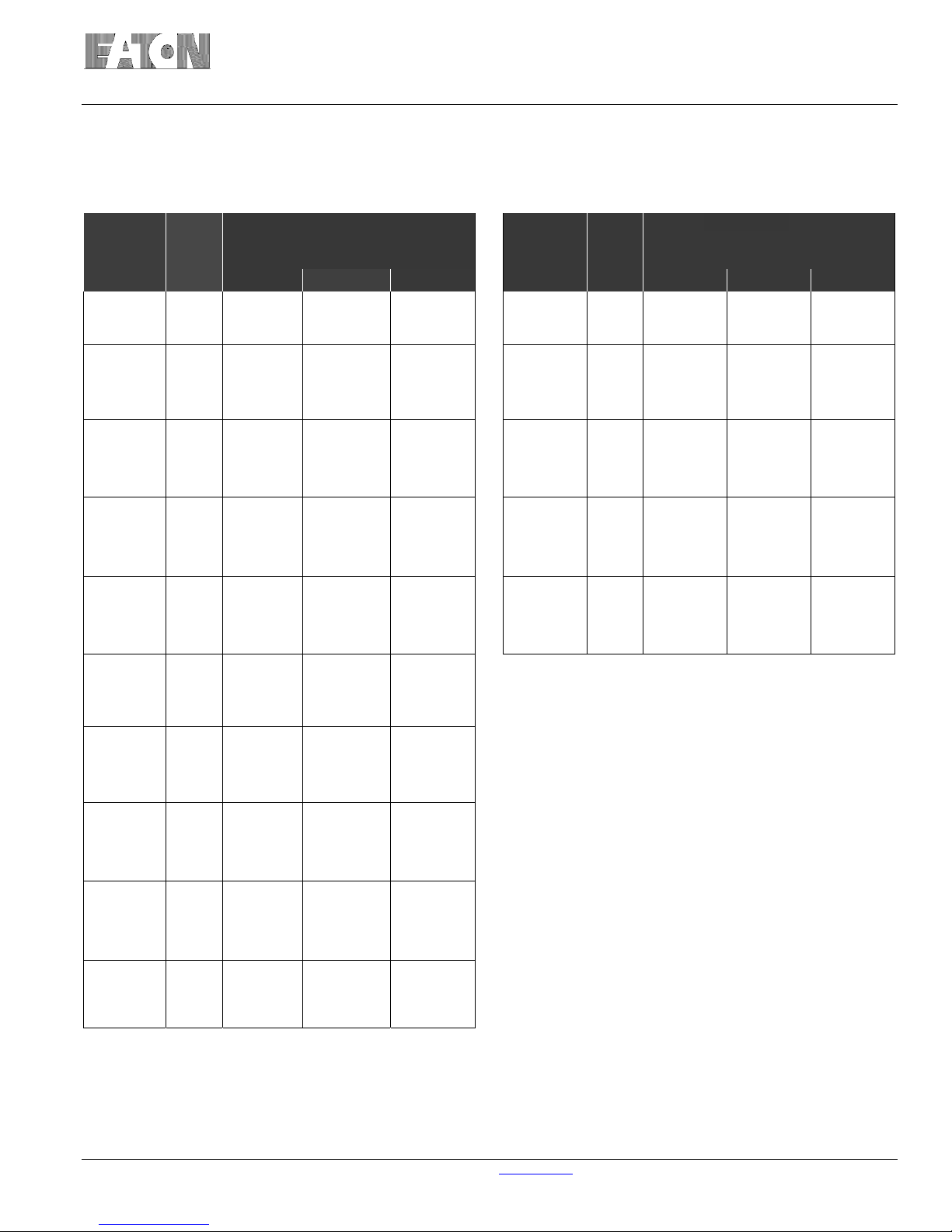

3-4 TYPICAL BREAKER AND CASSETTE WEIGHTS

Table 3.1 Circuit Breaker and Cassette Weights Table 3.1 (Continued)

Circuit

Breaker

Type

50 VCP-TR16

and

50 VCP-T16

50 VCP-TR20

and

50 VCP-T20

50 VCP-TR25

and

50 VCP-T25

50 VCP-TR32

and

50 VCP-T32

50 VCP-TR40

and

50 VCP-T40

Current

Rating

(Amps)

600

1200

1600

600

1200

1600

600

1200

1600

2000

2500

600

1200

1600

2000

2500

600

1200

1600

2000

2500

Approximate Weight

(lb)

Fixed Drawout Cassette Fixed Drawout Cassette

153

155

157

159

161

163

166

168

170

338

342

329

329

333

338

342

333

333

338

342

346

232

234

237

237

239

241

243

245

247

428

NA

419

419

424

428

NA

424

424

428

432

NA

157

157

157

157

157

157

157

157

157

157

NA

301

301

301

301

NA

301

301

301

301

NA

Circuit

Breaker

Type

150 VCP-TR16

150 VCP-T16

150 VCP-TR20

150 VCP-T20

150 VCP-TR25

150 VCP-T25

150 VCP-TR32

150 VCP-T32

150 VCP-TR40

150 VCP-T40

and

and

and

and

and

Current

Rating

(Amps)

600

1200

1600

600

1200

1600

600

1200

1600

2000

2500

600

1200

1600

2000

2500

600

1200

1600

2000

2500

Approximate Weight

(lb)

155

157

159

161

163

166

168

170

172

342

346

333

333

338

342

346

338

338

342

346

350

234

237

239

239

241

243

245

247

249

432

NA

424

424

428

432

NA

428

428

432

436

NA

161

161

161

161

161

161

161

161

161

161

NA

301

301

301

301

NA

301

301

301

301

NA

75 VCP-TR16

and

75 VCP-T16

75 VCP-TR20

and

75 VCP-T20

75 VCP-TR25

and

75 VCP-T25

75 VCP-TR32

and

75 VCP-T32

75 VCP-TR40

and

75 VCP-T40

600

1200

1600

600

1200

1600

600

1200

1600

2000

2500

600

1200

1600

2000

2500

600

1200

1600

2000

2500

155

157

159

161

161

163

166

168

170

342

346

333

333

338

342

346

333

333

338

342

346

232

234

237

239

241

243

245

247

249

432

NA

424

424

428

432

NA

424

424

428

432

NA

161

161

161

161

161

161

161

161

161

161

NA

301

301

301

301

NA

301

301

301

301

NA

IB131016EN For more information visit: www.Eaton.com

Instruction Book

Effective: November 2017 Page 16

8. Secondary Disconnect with Protective

Hood

9. Vacuum Interrupter (Part of Replacement

Pole Unit Assembly - 67A3158 or

67A3159 or 67A3160, depending on kA

and AMP rating.

10. Primary Conductor Interface or

Bottom Conductor – 69C3008H03

11. Drive Insulator with Internal Contact

Loading Spring (Wipe Spring)

16kA – 69C3053G01

25kA - 69C3053G03

12. Vacuum Interrupter Movable Stem

13. Rear Customer Mounting Holes

69C3010G01 – Base Plate

14. Customer Earth Connection

69C3010G01 - Base Plate

1. Horizontal Phase Barrier (95kV BIL Only)

68B3016H02

2. Vertical Phase Barrier (95kV BIL Only)

69C3027G01

3. Integral Lifting Hook

67A3137H01

4. Front Cover (Figure 3-10 for details)

69C3056G01

5. 3mm Earthed Steel Barrier

69C3104H03

6. Pole Unit Molding 70D3001G01

7. Trip Unit Location (Non-Automatic Breaker

Shown)

Figure 3-5 Front and Rear Views All VCP-TR Fixed (except 25kA, 2000/2500A and all 31.5/40kA)

For more information visit: www.Eaton.com IB131016EN

Instruction Book

Effective: November 2017 Page 17

1. Horizontal Phase Barrier – 95kV BIL Only 68B3106H02

2. Vertical Phase Barrier – 95kV BIL Only 69C3027G01

3. Integral Lifting Hook 67A3137H01

4. Front Cover 69C3056G01

5. 11 Gauge Grounded Steel Barrier 69C3104H03

6. Pole Unit Molding 70D3001G01

8. Secondary Disconnect Protective Hood (Umbilical Cord Shown)

Umbilical Harness Assembly 69C3261G01

9. Vacuum Interrupter (This is part of the Pole Unit Assembly)

67A3158, 67A3159, or 67A3160 (Depending on the kA and AMP Rating)

(Contact your Eaton Sales or Local Eaton Rep. for more information).

10. Primary Disconnect Finger Cluster (1200/1250A Shown)

1200/1250A – 68B3031G01 600/630A - 68B3031G02

11. Drive Insulator with Internal Contact Loading Spring (Wipe Spring).

16kA – 69C3053G01 25kA – 69C3053G03

12. Vacuum Interrupter Movable Stem

13. Cradle with Levering Mechanism 25kA – 69C3305G01 40kA – 69C3305G11

14. Shoot Bolt Handle – Part of 69C3305

15. Shoot Bolt - Part of 69C3305

16. Push/Pull Handle – Part of 69C3305

17. Racking Screw Lock Plate – Part of 69C3305

18. Levering Drive Nut – Part of 69C3305

19. Integral Wheel – Wheel 67A3201H01 Wheel Axle (Pin) – 67A3202H02

20. Shutter Operator – 69C3213H05

21. Primary Disconnect Cup (95kV BIL Only) – 68B3303H01

Figure 3-6 Front and Rear Views All T-VAC Draw out (except 25kA, 2000A and all 3 1.5/40

IB131016EN For more information visit: www.Eaton.com

Loading...

Loading...