Eaton 600 A 15 kV class, Cooper Power Series, 600 A 25 kV class Installation Instructions Manual

Deadbreak Connectors

COOPER POWER

SERIES

Catalog Data

CA650060EN

Effective May 2015

Supersedes 600-43 June 1997

600 A 15/25 kV class insulated

protective cap

Description

Eaton meets the full requirements of IEEE Std

386™-2006 standard – Separable Insulated

Connector Systems, and provides insulated, fully

shielded submersible protection for energized

15 and 25 kV class deadbreak interfaces with

its Cooper Power™ series 600 A, 15/25 kV class

insulated protective cap. The cap is required

for temporary or permanent installation on

15/25kV deadbreak bushings, junctions and other

accessories having interfaces that conform to IEEE

Std 386™-2006 standard.

The cap design includes a semiconducting EPDM

insert for stress relief and high quality peroxide

cured EPDM insulation. The molded EPDM semiconducting shield maintains ground potential

on the cap’s surface when the drain wire is

connected to a common ground.

(Top image on left shows standard insulated

protective cap. Bottom image shows U-OP™/

T-OP™ II connector insulated protective cap.)

Installation

No special tools are required. A hotstick tool is

used to place the protective cap on a de-energized

bushing. Refer to Service Literature S600-63-1

15, 25, and 35 kV Protective Cap Installation

Instructions for further information.

Production tests

Tests are conducted in accordance with IEEE Std

386™-2006 standard.

•

ac 60 Hz 1 Minute Withstand

• 40 kV

•

Minimum Corona Voltage Level

• 19 kV

Tests are conducted in accordance with Eaton

requirements.

•

Physical Inspection

•

Periodic Dissection

•

Periodic Fluoroscopic Analysis

Catalog Data CA650060EN

Effective May 2015

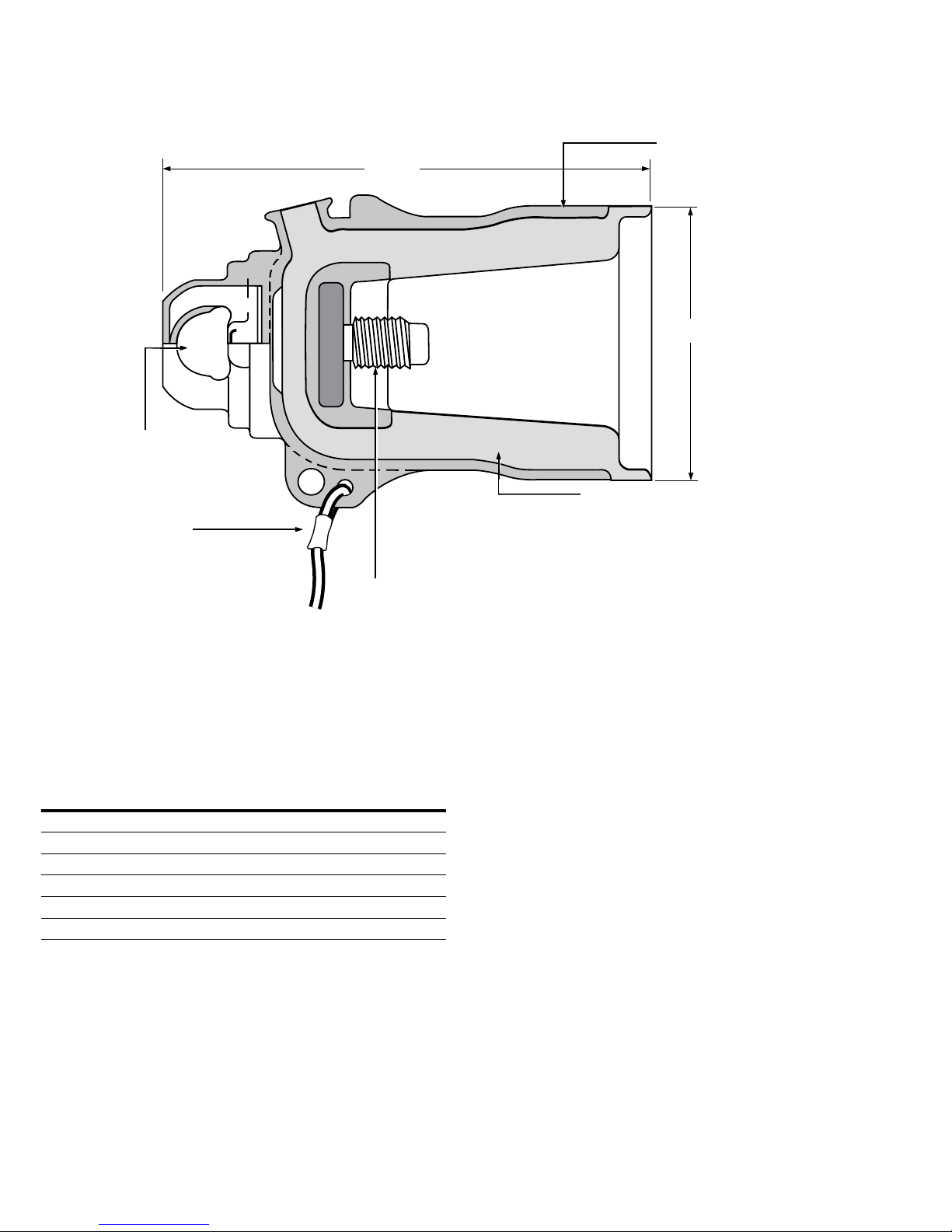

PULLING EYE

Stainless Steel Reinforced

Pulling Eye ensures high

strength for hotstick operation.

DRAIN WIRE AND

GROUNDING EYE

30-inch, #14 AWG Stranded Tin

Plated Copper Drain Wire prevents

low energy discharge from the

molded semi-conducting shield.

5.8"

(147 mm)

5/8" – 11 UNC

2A BRASS

THREAD

600 A 15 kV and 25 kV class insulated protective cap

SEMI-CONDUCTIVE SHIELD

Molded Semi-Conductive

EPDM Shield meets requirements

of IEEE Std 592™-2007 standard.

3.25"

(83 mm)

EPDM INSULATION

High Quality Peroxide Cured

EPDM Insulation is mixed and

formulated in-house for

complete control of raw rubber

characteristics.

Figure 1. Cutaway illustration of standard cap with drain wire shows design detail and dimensions.

ote:N Dimensions given are for reference only.

Table 1. Voltage Ratings and Characteristics

Description kV

Standard Voltage Class 25

Maximum Rating Phase-to-Ground 15.2

ac 60 Hz 1 Minute Withstand 40

dc 15 Minute Withstand 78

BIL and Full Wave Crest 125

Minimum Corona Voltage Level 19

Voltage ratings and characteristics are in accordance with IEEE Std 386™-2006 standard.

2

www.eaton.com/cooperpowerseries

Loading...

Loading...