Eaton 1MM, 37MM, 3MM, 35SS, 35MM Installation Instructions Manual

...

Installation Instructions for Type 1MM, 3MM, 35MM, 37MM,

35SS, and 37SS Modular Metering Centers

DANGER

H A Z A R D O U S V O LTA G E . W I L L C AUSE

SEV ER E I NJURY O R D EATH .

Tur n OFF pow er su ppl ying t his e qui pm en t bef ore wo rk in g

in sid e.

TEN SI ON DA N GER EU SE. PEU T CA USE R

DES BLE SSUR ES GR AV ES OU LA MO RT.

Co uper l ’al ime nt ati on é le ct ri que d e cet é qui pe me nt av ant

d’ y e ffe ctuer des trava ux.

)

PELIGRO

VO LTAJE PE LI GRO S O. CA USA HE RID AS

SEV ER AS O M UE RTE .

IN TER RUM PA el su min ist ro de e ner gia que a lim enta es te

e qu ip o an te s d e tr ab aj ar en e l in te ri or de l mi sm o.

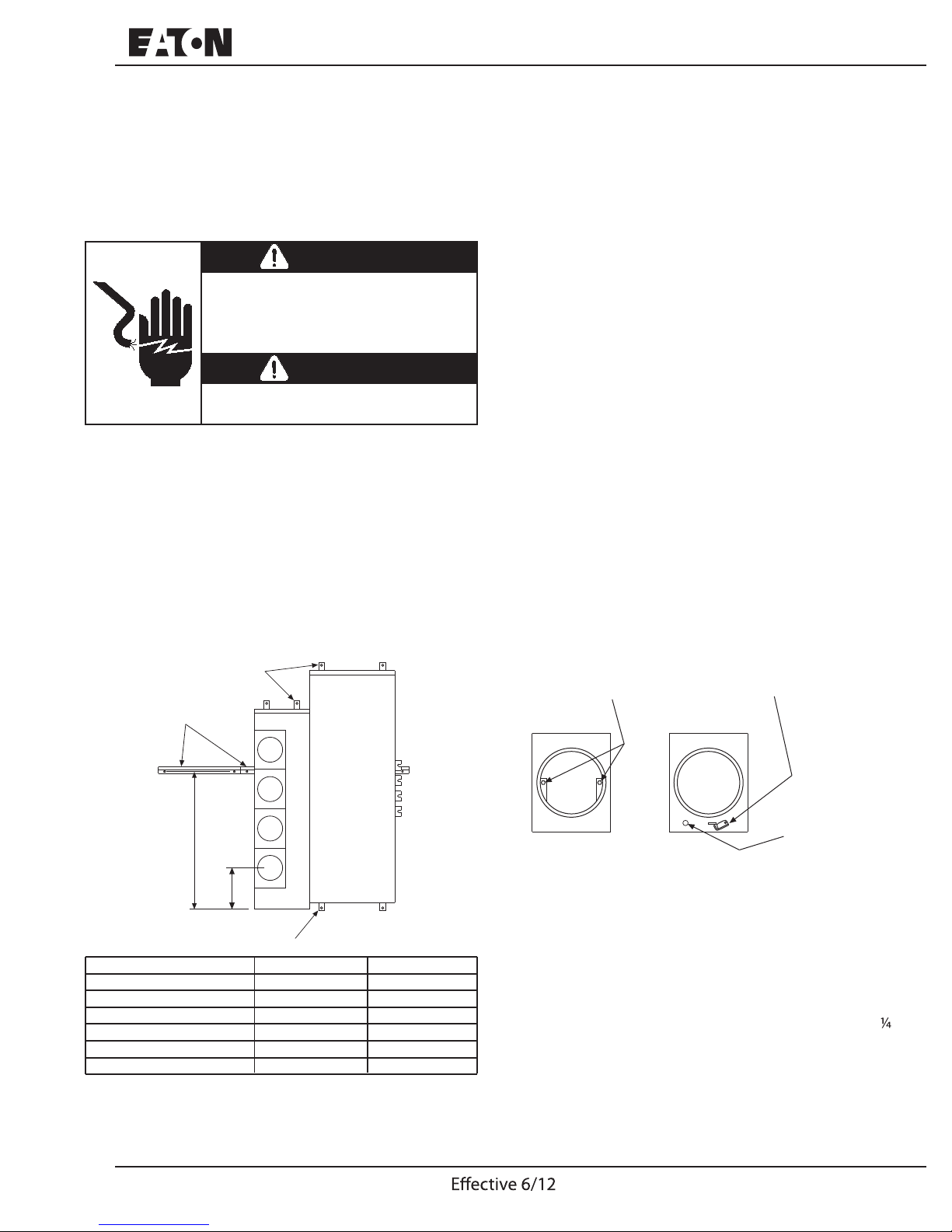

INSTALL MOUNTING RAILS ON WALL:

Establish the required height of the centerline of the bottom

meter socket, per the utility company specifications.

Determine the bottom line of the meter modules and main

devices. Use a “Z” dimension per the table below. That

is the distance from the bottom meter socket line to the

bottom of a meter module.

Measure up a distance “X” (see table) inches from the

bottom line of the meter modules to mounting holes for the

mounting rail. Strike a level line for the fasteners and attach

the mounting rails. (See Fig. 1 below).

MOUNTING FEET

MOUNTING RAIL(S)

MAIN DEVICE

Please read these instructions completely before installing

or removing device. Improper installation could be

hazardous to personnel and/or equipment.

Por favor lea estas instrucciones en su totalidad antes de

instalar o mover el aparato. Una instalacion inapropiada

puede ser peligrosa para el personal y/o el equipo.

Veuillez lire les présentes directives au complet avant

d’installer ou de retirer le dispositif. Une mauvaise installation

pourait causer des blessures au personnel et/ou

endommager l’equipement.

MOUNTING FEET:

Swivel the mounting feet at the top and bottom of the enclosures as shown (meter modules have two mounting feet

and main devices have four mounting feet). After marking

holes on the wall, the mounting feet may be moved away

for drilling of the holes. (See Fig. 1 below).

METER SOCKET COVERS:

Remove all the meter socket covers which are over the

horizontal main bus. Ring style covers are attached with

two screws inside the socket rim. Ringless style covers

are attached with an external movable latch. (See Fig. 2).

Ringless style covers have barrel lock provision K.O. To

use, remove knockout and apply kit 3MMBLKIT or 37MMBLK.

METER COVER

SCREWS

MOVABLE LATCH

“X”

“Z”

MOUNTING FEET

TYPE OF METER MODULE

1MM, 3MM - 125 AMP

1MM, 3MM - 200 AMP

35SS, 37SS - 1 METER

35SS, 37SS - 2,3 METER

35MM, 37MM - 1,3,4 METER

35MM, 37MM - 2 METER

“X” in.(mm)

34-7/32 (869.16)

34-7/32 (869.16)

17-1/16 (433.39)

35-3/16 (893.76)

30-11/16 (779.46)

30-11/16 (779.46)

Fig. 1 Locations of Mounting Feet, Rails, and Modules

I.L. 70-8306

“Z” in.(mm)

12-19/32 (319.88)

18-15/32 (469.11)

19-27/32 (504.03)

18-1/2 (469.90)

13 (330.20)

27 (685.80)

RING STYLE

COVER

RINGLESS STYLE

COVER

Fig. 2 Ring Type and Ringless Covers

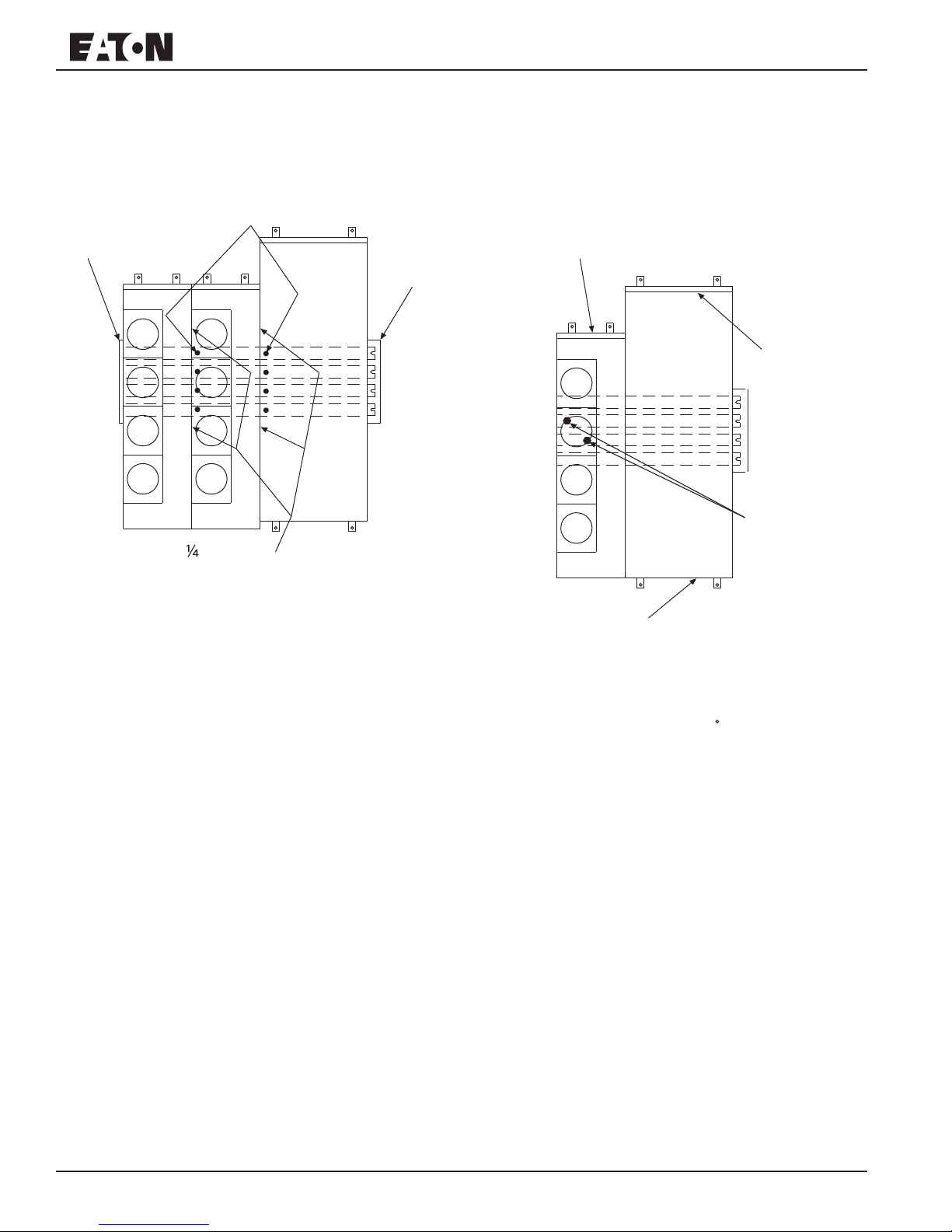

METER MODULES:

Hang meter modules on the mounting rails, loosen all of

the main bus joint bolts, and slide the meter modules

together.

Fasten the enclosures together, in order to bond devices

together and provide suitable ground path, with the (2) # 20 screws supplied with each module.

Torque to 26 lb-in (2.94 N-m).

Torque each main bus joint bolt to 300 lb-in (33.90 N-m).

Secure mounting feet to the wall. (See Fig. 3 on Page 2).

1

BUS END CAPS:

Install the bus end caps on the left hand side of the far left

meter module in the assembly and the far right meter

module in the assembly. End caps are supplied on the

main switch, main circuit breaker, or main terminal box

(one flush cap and one extended cap). (See Fig. 3 below).

MAIN BUS

FLUSH

END CAP

JOINT BOLTS

MAIN

DEVICE

EXTENDED

END CAP

PROVISIONS FOR HUBS OR KNOCKOUTS (CONT’D):

- Bottom Connection (1MM & 3MM)

Indoor and outdoor applications use knockouts that are

provided in bottom of meter modules or main devices.

- Bottom Connection (35MM, 37MM, 35SS, 37SS)

Indoor and outdoor applications use knockouts that are

provided in bottom of meter modules or main devices.

TOP KNOCKOUT PLATE

OR RAINTIGHT PLATE

MAIN

DEVICE

RAINTIGHT

PLATE

PHASE

CONNECTORS

#

-20 SCREWS

Fig. 3 Meter Module Assembly and End Cap Locations

PROVISIONS FOR HUBS OR KNOCKOUTS:

- Top Connections - Outdoor Application (1MM & 3MM)

Knockouts are not provided in top endwall. Punch proper

holes as required. Install raintight hubs on outdoor

devices.

- Top Connections - Indoor Application (1MM & 3MM)

Use the knockouts in top of module as required.

- Top Connections - Indoor or Outdoor Applications

(35MM, 37MM, 35SS, 37SS)

Remove raintight plate and punch proper holes for

installing raintight hubs. Reinstall raintight plate and

install raintight hubs into the raintight plate.

- Top Connections - Indoor or Outdoor Applications

(MTB, MFS, MCB, MHCB, or BPS)

Knockouts are not provided in top endwall. Punch proper

holes as required. Install raintight hubs on outdoor

devices.

- Backwall Connection (1MM & 3MM)

Knockouts are provided in Meter Modules. Remove

selected knockouts and pull wire through knockout

openings.

- Backwall Connection (35MM, 37MM, 35SS, 37SS)

Knockouts are provided in Meter Modules. Remove

selected knockouts and pull wire through knockout

openings.

BOTTOM

KNOCKOUT

PLATE

Fig. 4 Knockout Locations and Phase Connections

PHASE BALANCING, 3 PHASE SYSTEM (3MM ONLY):

Phase connectors are factory installed on the A Phase &

B Phase bus. Remove appropriate phase connectors and

balance for Phase A-B, B-C, or A-C, as needed, across

several meter modules in a complete installation. Torque

all phase connectors to 60 lb-in (6.78 N-m). (See Fig. 4

above).

INSTALL AND WIRE TENANT CIRCUIT BREAKERS:

Use only the circuit breakers listed on the meter module.

Check amperage and interrupting capacity for the

application.

TESTING AND INSPECTION:

- Recheck all main bus joint bolts for tightness. Torque to

300 lb-in. (33.90 N-m).

- Recheck all phase connectors for tightness. Torque to

60 lb-in. (6.78 N-m) minimum.

- Check all wire and cable terminations for proper installation

and tightness of lugs.

- Clean interiors of all units to remove foreign construction

material.

- Reinstall all meter socket covers and tenant breaker

covers.

2

I.L. 70-8306

Loading...

Loading...