Eaton 350 Series Technical Instructions

Dual Path Mobile Pump

Technical Manual

350 Series

350 Series Mobile Pump

Introduction ........................................................................................................................................................................................2

Features, Controls, Applications and Specifications ..........................................................................................................................3

Model Code......................................................................................................................................................................................4-5

Dimensional Drawings

Manual Servo Displacement Control ..........................................................................................................................................6-7

Solenoid Displacement Control..................................................................................................................................................8-9

Hydraulic Remote Control............................................................................................................................................................10

Magnetic Speed Sensor ..............................................................................................................................................................11

2 EATON Dual Path Mobile Pump E-PUPI-TM005-E July 2006

The 350 Series mobile pump

is an advanced, closed circuit,

servo controlled, axial piston

design offered as either a single or dual pump (two pumps

in one housing) for medium

duty hydrostatic circuits.

These pumps can be combined with an Eaton motor to

transfer and control hydraulic

power in many different ways.

An efficient, reliable and

durable rotating piston group

allows the 350 series pump to

maintain continuous pressures to 280 bar (4000 psi)

and 380 bar (5500 psi) rated

levels. This pressure capability, coupled with high allowable input speed (3600 RPM),

along with a compact package

means superior power density

in the market place.

*Not yet released

High load, taper roller bearings and a stiff drive shaft help

provide long bearing life at

rated mobile conditions,

reducing operating costs and

extending operating life.

350 Series pumps feature a

needle bearing under the

swash plate. This feature provides for better temperature

and contamination resistance.

The swash plate bearing

offers low control hysteresis

when matched with Eaton

control technologies.

The 350 series pump offers

the latest design in Eaton technologies for closed circuit piston pumps along with a wide

variety of responsive controls.

These controls include

mechanically or electricallyactuated feedback controls,

hydraulic or electronic proportional controls and a three

position (Forward-NeutralReverse) electric control.

A large input shaft diameter

allows more through put power,

even with an integral charge

pump. When the 350 series

pump is fully loaded as much as

56 kW (75 hp) of through put

power is av ailable for auxiliary

hydraulic pow er needs from the

SAE B auxiliary mounting pad.

350 Series pumps operate at

a level of quietness that

exceeds the requirements of

today's demanding work conditions. Another pump feature

- a serviceable, bimetal valve

plate - improves pump filling

characteristics which, in turn,

reduces fluid-borne noise and

extends pump life. A highly

engineered pump housing and

swash plate also minimizes

noise and vibration.

Mounting flanges are offered

in SAE B and C configurations

and ports are offered in SAE,

ISO tube and flange and STC

direct port versions. Opposite

or same side port versions are

available to facilitate plumbing

and help the pump fit your

machine space needs. An integral gerotor charge pump can

be provided with up to four different displacement sizes allo wing for either remote or inlet

charge filter options.

The 350 series pump offers a

full range of product features

and has the ability to match

the needs of many different

customer platforms. It supports increased power

requirements in Agricultural,

Construction and Utility markets and allows for a wide variety of installation opportunities

for global machine design.

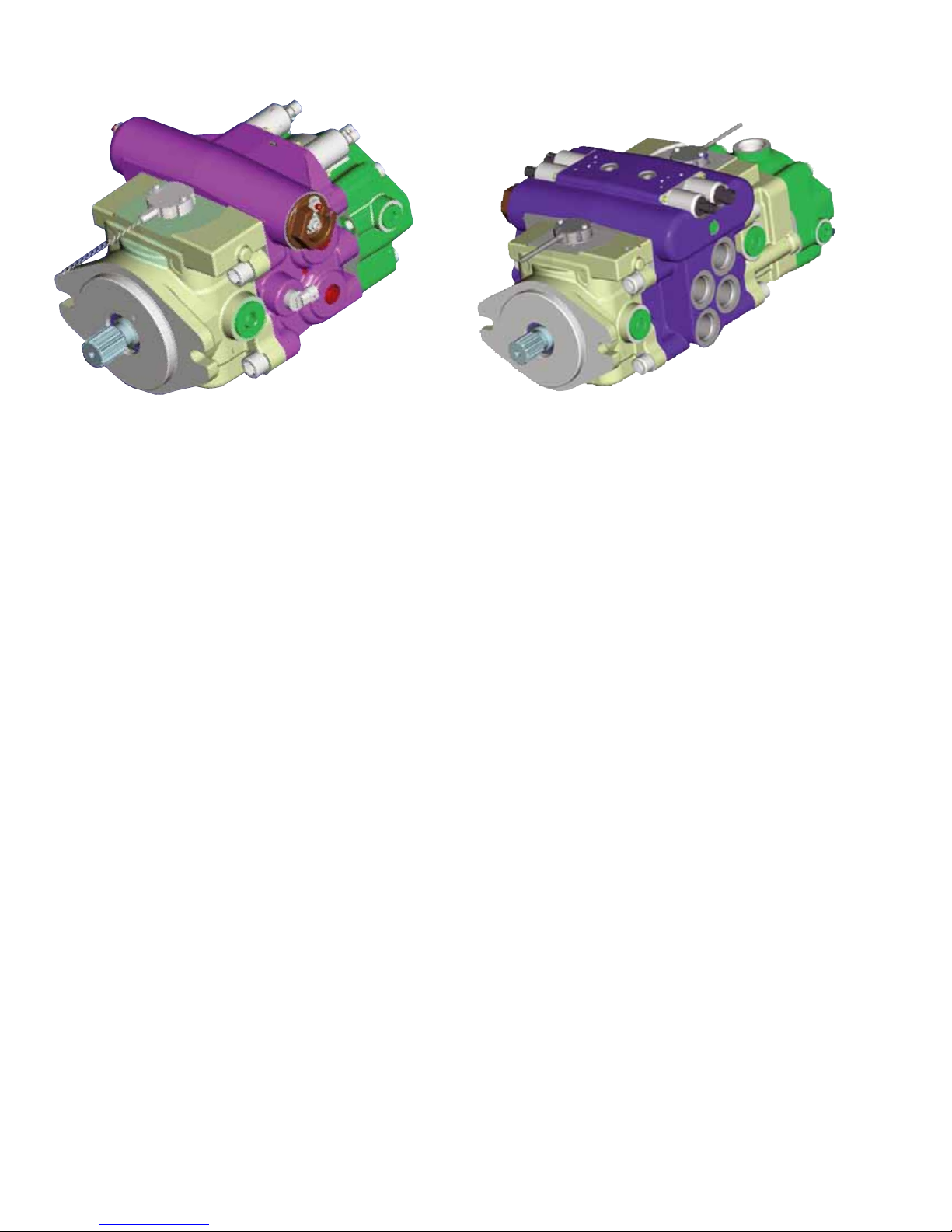

Single Assembly* Dual Path Assembly

Table of Contents

350 Series

Mobile Pump

Introduction

3

EATON Dual Path Mobile Pump E-PUPI-TM005-E2 September 2007

Features,

Controls,

Applications and

Specifications

Controls

• Mechanical servo and

Hydraulic (non-feedback)

• Electro-proportional “EP”

• Proportional valve control

with electronic swash

plate feedback

- Non-contacting sensor

- Fast response, precise,

real-time pump control

- Best electro-hydraulic con-

trol for mobile hydrostatic

transmissions available on

the market today*

* Interface requires proprietary

Eaton electronic control or

control algorithms

Features

• Symmetrical 4-Bolt design

• Polyacrylate Shaft Seal

• 15-Tooth splines, 14-Tooth

splines, Taper Input Shafts

• Case Drains location

(one connection needed)

• Shaft mounted on Tapered

roller bearings

• Optional Speed Pickup

Location

• Swash plate bearings

• Same Side or Opposite

Side Main Work Ports

Typical Applications

• Pavers, Rollers

• T elescopic Booms

• Boring Machines

• T renc hing Machines

• Sweepers

• Small Sprayers

• T elehandlers

• Stump Grinders

• Compact Wheel Loaders

• Rough Terrain Fork Lifts

• Material Handling

Equipment

• Skid Steer Loaders

• Windrowers/Sprayers

UNITS 41 49 62

Displacement cc/rev (cid) 41 (2.50) 49 (3.00) 62 (3.80)

Input Speed Min RPM 500 500 500

Max RPM 3600 3600 3600

Continuous Pressure Bar (psi) 280 (4000) 280 (4000) 280 (4000)

Rated Pressure Bar (psi) 380 (5500) 380 (5500) 380 (5500)

Charge Pressure Bar (psi) 15-31 (220-450) 15-31 (220-450) 15-31 (220-450)

Flow at Rated Speed LPM (GPM) 139 (37) 166 (44) 210 (56)

Mounting 2-Bolt SAE B 2-Bolt SAE B

4-Bolt SAE C 4-Bolt SAE C 2-Bolt SAE C

2-Bolt SAE C 2-Bolt SAE C 4-Bolt SAE C

Specifications:

Continuous Pressure:

280 Bar (4000 psi)

Rated Pressure:

380 Bar (5500 psi)

Displacements:

41cc (2.50 cid), 49 cc (3.00

cid), 62 cc (3.8 cid).

Estimated weight for a 350 series pump

with opposite side main ports with charge

pump - 81.8 Kg (181 lbs).

2. Symmetrical

4 Bolt Design

9. Swash Plate

Position Sensors

1. Solenoid

Displacement

Control

3. Polyacrylate

Shaft Seal

4. 15-Tooth Splines

14-Tooth Splines

Taper Input Shafts

Shaft Mounted on

Tapered Roller Bearings

5. Case Drains Location

(one connection needed)

7. Same Side or Opposite

Side Main Work Ports

8. Swash Plate

Bearings

6. Optional Speed

Pickup Location

9

1

9

2

3

4

8

5

6

7

5

Feature Locations

4 EATON Dual Path Mobile Pump E-PUPI-TM005-E2 September 2007

Model Code

Code Title

AED – Dual Servo Controlled

Variable Displacement Axial

Piston Pump

Displacement & Rotating

Kit- Front

1 – 41.0 cm3/r [2.50 in3/r]

2 – 49.2 cm

3

/r [3.00 in3/r]

3 – 62.3 cm

3

/r [3.80 in3/r]

4 – 35.0 cm

3

/r [2.10in3/r]

Destroked from -

41.0 cm

3

/r [2.50 in3/r]

5 – 45.0 cm

3

/r [2.75 in3/r]

Destroked FROM -

49.2 cm

3

/r [3.00 in3/r]

6 – 54.0 cm

3

/r [3.30 in3/r]

Destroked FROM -

62.3 cm

3

/r [3.80 in3/r]

Input Shaft Rotation

L – Left hand rotation (CCW)

R – Right hand rotation (CW)

Front Mounting

A – 2 Bolt C (SAE J744-127-2)

B – 4 Bolt C (SAE J744-127-4)

C – 2 Bol t B (S AE J744-101-2 )

Input Shaft

A – Taper shaft 1.0 dia 1.5 taper

B – 14 Tooth 12/24 Pitch Spline

Shaft

C –15 Tooth 16/32 Pitch Spline

Shaft

D –19 Tooth 16/32 Pitch Spline

Shaft

Valve Plate - Front

A – Type 1- Standard

Relief Setting for Front

Main Port A - Front

0 – None, no relief valve or

check valve

A – Check valve only

J – 207 bar [3000 lbf/in

2

]

K – 224 bar [3250 lbf/in

2

]

L – 241 bar [3500 lbf/in

2

]

M – 259 bar [3750 lbf/in

2

]

N – 280 bar [4000 lbf/in

2

]

R – 310 bar [4500 lbf/in

2

]

T – 345 bar [5000 lbf/in

2

]

U – 362 bar [5250 lbf/in

2

]

V – 380 bar [5500 lbf/in

2

]

Relief Setting for Front

Main Port B - Front

0 – None, no relief valve or

check valve

A – Check valve only

J – 207 bar [3000 lbf/in

2

]

K – 224 bar [3250 lbf/in

2

]

L – 241 bar [3500 lbf/in

2

]

M – 259 bar [3750 lbf/in

2

]

N – 280 bar [4000 lbf/in

2

]

R – 310 bar [4500 lbf/in

2

]

T – 345 bar [5000 lbf/in

2

]

U – 362 bar [5250 lbf/in

2

]

V – 380 bar [5500 lbf/in

2

]

Displacement & Rotating

Kit - Rear

1 – 41.0 cm3/r [2.50 in3/r]

2 – 49.2 cm

3

/r [3.00 in3/r]

3 – 62.3 cm

3

/r [3.80 in3/r]

4 – 35.0 cm

3

/r [2.10in3/r]

Destroked from -

41.0 cm

3

/r [2.50 in3/r]

5 – 45.0 cm

3

/r [2.75 in3/r]

Destroked FROM -

49.2 cm

3

/r [3.00 in3/r]

6 – 54.0 cm

3

/r [3.30 in3/r]

Destroked FROM -

62.3 cm

3

/r [3.80 in3/r]

Valve Plate - Rear

A – Type 1- Standard

Relief Setting For Front

Main Port A - Rear

Ref Position 9 for options

Relief Setting For Front

Main Port B - Rear

Ref Position 10 for options

Charge Pump

0 – No Charge Pump

1 – 13.9 cm

3

/r [.85in3/r],

1.3125-12 UN-2B SAE O-Ring

Suction Inlet Port (S)

2 – 17.4 cm

3

/r [1.06 in3/r],

1.3125-12 UN-2B SAE O-Ring

Suction Inlet Port (S)

3 – 21.0 cm

3

/r [1.28 in3/r],

1.3125-12 UN-2B SAE O-Ring

Suction Inlet Port (S)

4 – 23.1 cm

3

/r [1.41 in3/r],

1.3125-12 UN-2B SAE O-Ring

Port for Suction Inlet (S)

Charge Relief Setting

0 – No Charge Relief Setting

1 – 17.2 - 20.7 bar [250-300 lbf/in

2

]

Relieved to Case

2 – 20.7 - 24.1 bar [300-350 lbf/in

2

]

Relieved to Case

3 – 24.1 - 27.6 bar [350-400 lbf/in

2

]

Relieved to Case

4 – 27.6 - 31 bar [400-450 lbf/in

2

]

Relieved to Case

5 – 13.8 - 1 7.2 bar [400-450 lbf/in

2

]

Relieved to Case

Charge Port Location

0 – None

1 – Inlet Right Side C2 (Only

with Main Ports opposite side)

2 – Inlet Left Side C1

3 – Inlet Bottom C3 (Only with

Main Ports Same Side, No

Bypass Valv e)

Auxiliary (Rear) Mount &

Output Shaft

A – 2 Bol t B (S AE J744-101-2 )

Accepts 13T, 16/32 Pitch

Spline

B – 2 Bolt B (SAE J744-101-2)

Accepts 15T, 16/32 Pitch

Spline

C – 2 Bolt A (SAE J744- 82-2)

Accepts 11T, 16/32 Pitch

Spline

D – 2 Bolt A (SAE J744-82-2)

Accepts 9T, 16/32 Pitch Spline

Control Assembly -

Front

SA – Solenoid Control -

12 Volt With Non-Contact

Feedback Sensor with MetriPak Electrical Connectors

SB – Solenoid Control 12 Volt

SC – Solenoid Control 12 Volt

HA – Hydraulic Remote - Non

Feedback, 5-15 bar [72-217

lbf/in2] Pilot Pressure

MA – Manual Control,Wide

Band Neutral

MB – Manual Control,

Standard

MC – Manual Control, High Gain

MD – Manual Control,

Wide Band Neutral, Neutral

Lockout switch

ME – Manual Control, Standard,

Neutral Lockout switch

MF – Manual Control, High

Gain, Neutral Lockout switch

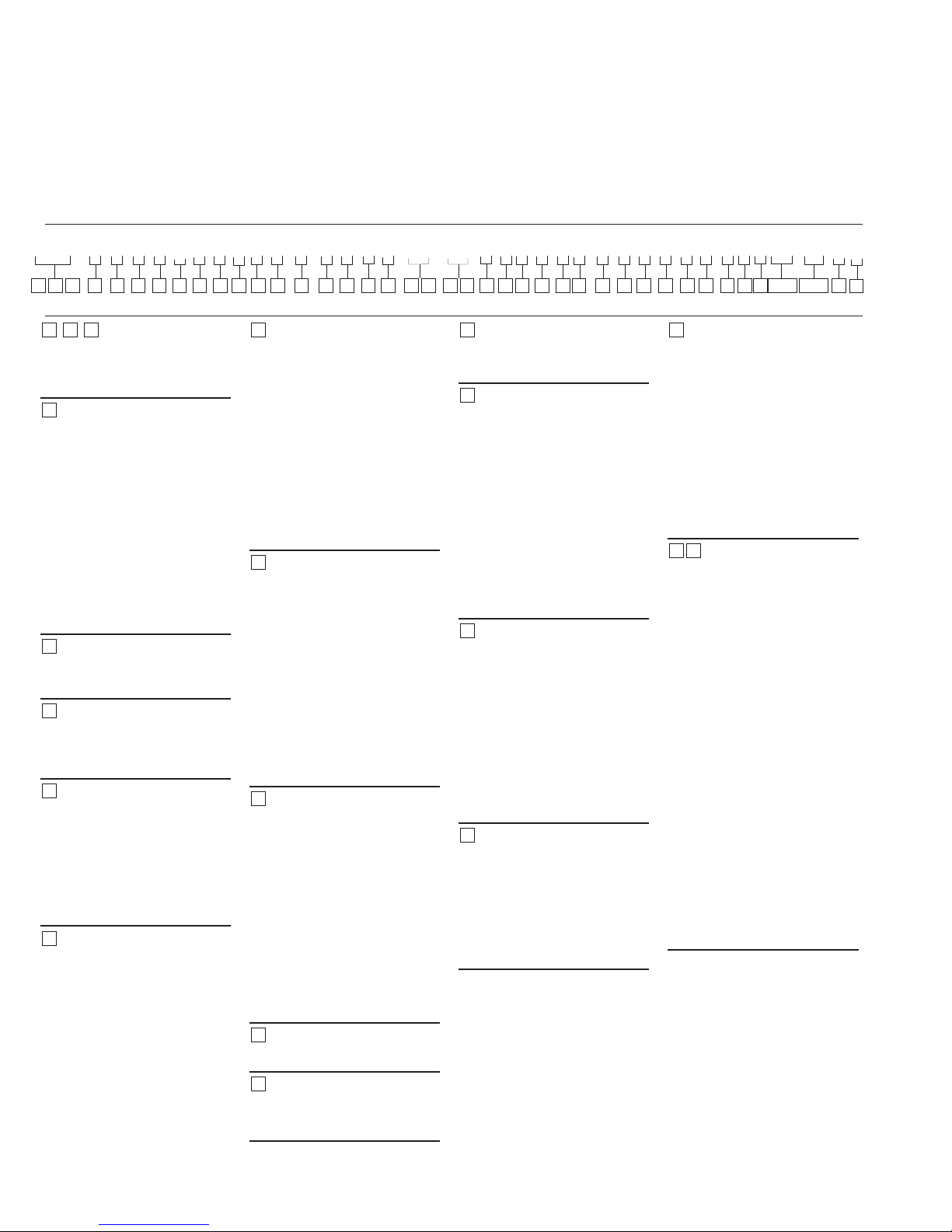

19 20

14 18

16

17

15

13

12

932

4

11

10

8

7

6

5

1

AED * * * * A * * * * * * * * * * ** ** * * * 0 * * * * * * * * * * * ** ** A A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35

38,39 40,41 42

43

36 37

Loading...

Loading...