Eaton 30R Operating Instructions Manual

Web: www.

Eaton Filtration, LLC

44 Apple Street, Tinton Falls, NJ 07724

Phone:

E-Mail: filtration@eaton.com

732-212-4700 Fax: 952-906-3706

eaton.com/filtration

Model 30R Simplex

Operating

Instructions

Basket Strainers

Read all instructions before installation or operation of equipment. Failure to comply

with these instructions could result in bodily injury and/or property damage.

Installation

Each strainer is shipped completely assembled and ready for installation. Note that the “Inlet ” must be

correctly oriented during service. Although all Eaton Strainers are 100% hydrostatically tested at the factory, it is recommended that you inspect all strainer closures prior to putting the strainer into service.

Check that all hardware is secure and that the gaskets and/or o-rings seal properly.

Operation

Be sure the cover and drain are tightly closed. Open the valve on the outlet side of the strainer.

Slowly open the valve on the inlet side of the strainer (to prevent damage from water hammer). The

strainer is now in service.

Basket Cleaning

Close the valve on the inlet and outlet side of the strainer and open the drain. To remove the basket from

the strainer, loosen the cover clamp T-bolt and remove the cover from the top of the strainer.

The basket handle will protrude slightly out of the strainer well. (This unique design offers both a means

of removing the basket easily and also allows the basket to be firmly seated around the machined seating

surface when closed.) Remove the basket from the well by pulling straight up on the basket handle.

Clean the basket by using a brush or by soaking in a solvent or cleaning solution. Avoid striking baskets

to loosen their contents. This will dent them out of shape and eventually break the welds. Baskets

should be cleaned as soon as possible after removal from the strainer. Otherwise, the contents may

harden and become difficult to remove. It is recommended that one spare basket be kept on hand at all

times. When changing baskets for cleaning, we suggest that the spare or cleaned basket be installed in

the strainer so your start up is not delayed cleaning the used basket.

Install the basket in the strainer. Be sure the cover O-ring is on the cover. The basket should be properly centered in the well and firmly seated. Replace the cover. The cover should be centered before the

T-bolt is tightened. Tighten only until a seal is made between the cover and the strainer body. The Oring should be periodically inspected for nicks and tears. A spare O-ring should also be kept on hand.

Check the O-ring seating surface, it should be kept free of dirt and grit. The strainer is now ready to be

put back in operation. Follow the steps listed above under “Operation”

Recommended Spare Parts

1 Eaton Replacement Screen and 1 Eaton Replacement Gasket or O-Ring.

Always use genuine Eaton replacement parts for guaranteed fit and performance. When ordering parts

specify all nameplate data as well as the description and quantity of the parts.

Visit our web site www.

eaton.com/filtration for more information about Eaton Strainers.

1

IOM 30R 01/06

More From Eaton Filtration

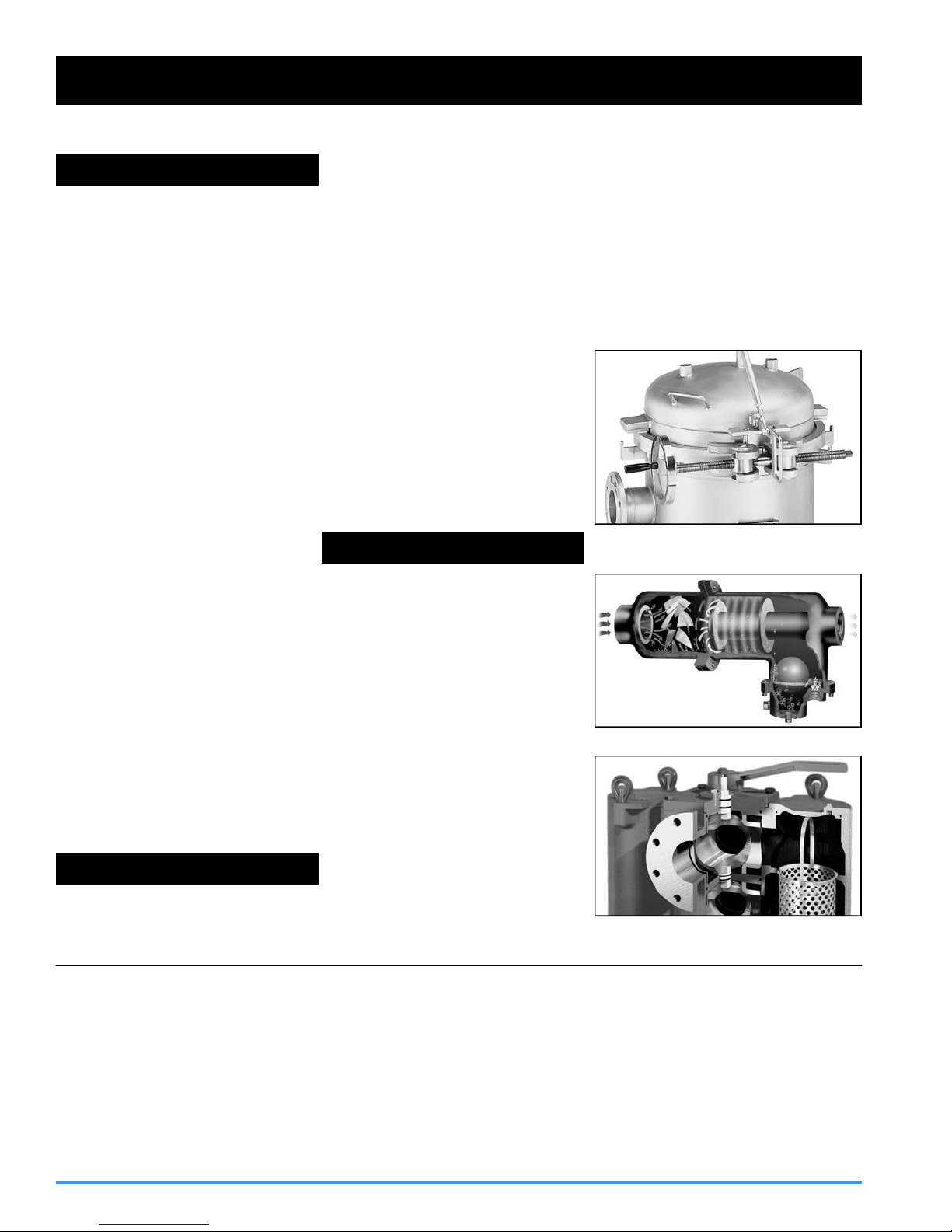

Pipeline Strainers

Eaton provides the most complete

range of standard cast pipeline

strainers for coarse filtration available

from any manufacturer. These include Simplex, Duplex and Y Type

Strainers, in Iron, Bronze, Carbon

and Stainless Steel. For ultra-pure

applications, strainers of all plastic

construction are available. Cast

Pipeline Strainers range in size from

1/2” to 36” and larger.

When a cast strainer won’t meet the

applications requirements because of

size, weight or design Eaton offers

standard fabricated strainers to meet

exact customer requirements. without

any trade-offs. When a standard design fabricated strainer will not meet

an application’s requirements Eaton’s

design team can work with customers to create a unique one that will.

Eaton also offers Automatic SelfCleaning strainers. These are motorized strainers designed for the continuous removal of entrained solids

from liquids in pipeline systems. The

strainer operates un-attended and

the system flow never has to be shut

down for strainer element cleaning.

These strainers are available in both

cast and fabricated types.

Find out more on the web at:

www.Eaton.co

m/filtration

Gas/Liquid Separators

Eaton’s Gas/Liquid Separators have

been the “Industry Standard” for over

100 years. Nobody knows more

about gas/liquid separation than us.

Eaton Gas/Liquid Separators are

used to remove 99% of damage

causing moisture and particulate

matter from air, gas and steam pipelines. They protect valuable system

components like air compressors and

turbines from damage.

Eaton has a wide selection with hundreds of different Gas/Liquid Separators. When a standard model isn’t

right for an application, Eaton Engineers can work with customers to

create a custom fabricated model

that fits the application requirements

exactly.

Find out more on the web at:

www.Eaton.co

m/filtration

Filtration Systems

With Eaton Fi

your choice of high grade investment

cast construction or engineered fabricated construction in stainless steel

or carbon steel. Or, for extremely

corrosive or ultra-pure services, you

can choose all-plastic construction.

You can be sure Eaton Filter Housings will meet specifications because

they are all made to ISO 9001:2000

Standards. Eaton has representatives in over 40 countries, experienced professionals to provide the

filtration help you need, when and

where you need it.

Choosing the correct filter bag is critical to the success of you application.

Don’t trust anything less than a filter

bag from Eaton. They’re made under

ISO 9001:2000 Standards to ensure

lter Housings you have

the consistent, reliable performance

that you demand. Eaton Filter Bags

fit all Eaton Filter Housings and the

housings of most other manufacturers as well.

Find out more on the web at:

www.Eaton.co

m/filtration

Eaton Filtration warranties its products against defective material and workmanship only. Eaton assumes no responsibility for damage or injury

resulting from improper installation, abuse, or misapplication of any product. Eaton assumes no responsibility for damage or injury resulting

from chemical incompatibility between its products and the process fluids to which they are subjected. The end user should always test to determine application suitability. Contact your Eaton Representative for complete warranty information.

44 Apple Street, Tinton Falls NJ 07724 Tel: 732-212-4700 Fax: 952-906-3706

E-Mail: filtration@eaton.

Eaton Filtration, LLC

©Copyright 2013 Eaton Filtration, All rights reserved.

com Web: www.

2

eaton.com/filtration

Loading...

Loading...