Eaton 2075 Operation Manual

/'\

1

/~)

;:-1

VI/V

t:, <

OPERATION

EATON

2075

MANUAL

NOISE-GAIN

M B M T MESSTECHNIK

H A N D E L S G H B H

Auf

D - 2 7 2 1 1 B A S S U M

Tel.

ANALYZER

der

04241/3516

A 1 1 o g e

FAX

18

5516

II

_

.

~·

....,

..-.:.T•N

2U/5

~=·

·--··

-

NOISE-GAIN

~IW(O'ZER

'.!.

e .

--

·---~-~

(Y

..

~"

1

-,

1

1

'·

1

!llll•flfllT

--

- -

----~

- 7 8 9

..,,~ -~

~

• 4 5 6

0 1 2 3

~

-

- -

•

1

e

..,

!'oOSf

•<Gl,»~E

E..

:

0,

__

, - „

-.,

••

·-

REVISED

•

-

DECEMBER

1985

Eaton Corporation

Electronic Instrumentation Division

Los Angeles. California 90066

WARRANTY

Eaton

Corporation,

instrument

the

original

Re

pair

or

replacement

our

examination

Electron

Tran

tubes,

potentiometers

authorized

lf

the

instrument

negligence,

void.

This

warranty

IMPLIED

event

SELLER

WARRANTY

shall

neither

connection

With

respect

the

repaired

Electronic

tobe

free

from

purchaser

Electrical

satisfactorily

semiconductors,

are

by

the

factory.

or

any

or

if

any

serial

is in

lieu

the

SELLER

assumes,

with

sales

to

repairs,

portion.

Instrumentation

as

and

(at

defects

follows:

our

Electronic

in

option)

material

Measuring

without

indicates

batteries,

excluded

portion

number

of

all

OF

MERCHANTABILITY,

be

liable

nor

of

instruments

the

from

thereof,

or

other

for

authorizes

foregoing

REPAIR

has

seal

warranties,

INCi

manufactured

warranty

AND

Division,

and

workmanship,

Instruments

eh

arge

that

defects

fuses, lamps,

warranty

been

coverage.

abused, misused,

has

been

express

or

DENTAL

any

person

shall

MAINTENANCE

(SELLER)

effective

...... 1 Year

( F.O.

B.

factory)

are

due

to

workmanship

thermoelements,

Warranty

removed

fitness

OR

CONSEOUENTIAL

to

assume

by

SELLER.

apply

or

or

implied

for a particular

for

for a period

warrants

will

be

returns

damaged

altered,

INCLUDING

it,

any

of

each

after

delivery

effected

or

materials.

and

must

by

accident

the

warranty

purpose.

damages.

other

liability

ninety

new

when

Ratio

first

THE

In

The

days

to

be

or

is

no

in

to

Instruments

the

factory.

instrument

Chargeable

Please

your

provide

instrument:

1.

2.

3.

4.

111

lnclude

data

relevant

data

Additional

and

Service

should

You

will

to

the

factory

repairs:

us

with

Model

Serial

Description

Approximate

was

placed

on

symptoms.

service

information

Centers:

be

returned

be

advised

prepaid.

lf

requested,

the

or

Type

Number

of

date

in

measurements

Elmhurst,

Fairfield,

Los

Oakton,

Sunnyvale,

only

of

detailed

Validity

an

following

trouble

instrument

operation.

taken.

can

be

IL

NJ

Angeles,

VA

on

prior

authorization

shipping

of

warranty

estimate

of

information

5.

(1) 6.

7.

suspected

locat1on

SERVICE

made

available

(312)

(201)

CA -

(213)

(703)

CA (408)

from

instructions

will

be

charges

in

order

will

to

expedite

Approximate

hours

in use.

Maintenance

requested

Other

ot

trouble.

by

calling

comments.

ma1ntenance

279-8220

227-8990

822-3061

620-5820

733-657

4

the

Representative

at

that

determined

be

made

the

number

action

or

performed

act1on

any

of

these

time.

Return

by

the

prior

to

processing

of

previously

taken

and

Eaton

or

the

factory.

repairs.

of

any

other

Sales

FRANCE • Argenteuil • Telephone:

UNITED

KINGOOM • Wokingham • Telephone:

GERMANY • Munich • Telephone:

(03)

(089)

99817

446

(0734)

794717

5233023-24

• Telex:

• Telex:

• Telex:

609036

847238

529420

EATON2075

TABLE OF CONTENTS

TABLE OF CONTENTS

Paragraph

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

SECTION

Scope and Organization

Introduction

Purpose and U se

Calibration Cycle

Equipment Supplied

Equipment Required But Not Supplied

Optional Accessories

Specifications

Safety Precautions

SECTION

Introduction

U npacking and Physical Inspection

AC Power Requirements

Operational Inspection

Operating Temperature

Selection

Equipment Mounting

Rack Mounting the Eaton 2075

Equipment Interconnections

Reference Card

Pre-Operational Adjustments

1-GENERAL

.........................................................

of

.....................................................

........................................................

....................................................

2-

INSTALLATION

.........................................................

of

Relay DC Voltage

......................................................

INFORMATION

of

the Manual

Equipment.

...................................................

..................................................

...............................................

.................................................

................................................

..................................................

.........................................

......................................

..........................................

..........................................

............................................

...........................................

Tide

....................................

....................................

1-1

.

.

1-2

1-2

.

.

1-2

.

1-3

1-3

.

.

1-3

.

1-4

.

1-7

.

2-1

.

2-1

.

2-1

.

2-3

.

2-5

.

2-3

.

2-5

.

2-5

.

2-7

.

2-8

.

2-8

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

3-14

3-15

3-16

3-17

SECTION 3 - OPERATION

Introduction

Capabilities

Controls and Indicators

Power-On Conditions, Preset, and Total System Reset

Continuous Measurement Mode and the Hold Function

Fixed Frequency Operation

Swept Frequency Operation

Uncorrected and Corrected Measurements

of

Entry

Selecting the

Procedure for Test Configuration 1

Procedure for Test Configuration 2 - Double Sideband

Procedure for Test Configuration 2 - Single Sideband

Procedure for Test Configuration

Procedure for Test Configuration

Procedure for Test Configuration

Procedure for Test Configuration

.........................................................

of

the Eaton 2075

Frequency and

Correct

Test Configuration

................................................

ENR

..........................................

.............................................

............................................

Values

.....................................

..................................

......................................

3-

Single Sideband

4-

Double Sideband

4-

Single Sideband

5-

Single Sideband

................................

.......................

......................

......................

.......................

.......................

......................

.......................

.......................

.

3-1

.

3-1

.

3-3

.

3-16

.

3-20

.

3-21

.

3-22

.

3-24

.

3-26

.

3-27

.

3-31

.

3-33

.

3-37

.

3-41

.

3-45

.

3-49

3-53

.

TABLE OF CONTENTS EATON 2075

TABLE OF CONTENTS (Continued)

Paragraph

3-18

3-19

3-20

3-21

3-22

3-23

3-24

3-25

3-26

3-27

3-28

3-29

3-30

3-31

3-32

3-33

3-34

3-35

3-36

3-37

3-38

3-39

3-40

3-41

3-42

3-43

3-44

3-45

3-46

3-47

3-48

3-49

3-50

3-51

Title

6-

Procedure for Test Configuration

of

Additional Types

Measurements

Single Sideband

.......................................

Effective Input Noise Temperature (Te) Measurement

Y-Factor (Y) Measurement

Operating Noise Temperature (T

Power (dB) Measurements

ENR

Measurement

...................................................

Noise Measure (M) Measurement

Manual Measurements

Manual Measurement

Manual Measurement

Calibrated Noise Source

Noise Drive Voltage and Indicator

ENR

Tables

Calibration

.........................................................

..........................................................

Frequency Calibration

Second Stage Calibration

Input Gain Selection

IF Attenuators Calibration

of

Selection

Sideband Parameters

Bandwidth Compensation

Determining the Bandwidth Ratio

For

Compensation

Tcold Compensation

Loss

...................................................

Oscilloscopes and Recorders to Display Data

Selecting an External Local Oscillator

Controlling External Local Oscillators

Writing a Custom Program

Special Functions

Error

Messages

.....................................................

......................................................

Store-Recall Registers

Smoothing Function

100

kHz Display Resolution

Software Revisions

...................................................

...................................................

.............................................

p) Measurement

0

..........................

.............................................

.......................................

.................................................

of

Noise Figure and Gain

of

Y-Factor

.......................................

............................

...............................................

.......................................

.................................................

..............................................

..................................................

.............................................

........................................

..............................................

of

the First and Second Stages

or

Gain

.........................................

..............................

....................................

....................................

For

Controlling a Local Oscillator

.................................................

............................................

.......................

.......................

..............

................

3-57

.

.

3-62

3-63

.

.

3-63

3-64

.

.

3-65

.

3-66

.

3-67

.

3-67

.

3-67

.

3-69

.

3-70

3-71

.

3-72

.

.

3-74

3-74

.

.

3-75

.

3-77

3-78

.

.

3-78

.

3-82

.

3-84

.

3-86

3-88

.

.

3-89

3-95

.

.

3-95

.

3-96

3-101

.

.

3-106

3-110

.

3-110

.

3-113

.

3-113

.

ii

EATON 2075

TABLE OF CONTENTS

TABLE OF CONTENTS (Continued)

Paragraph

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-11

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

SECTION

Introduction

GPIB General Information

GPIB Operating Modes

Setting the GPIB Address

GPIB Compatibility

Remote and Local Modes

GPIB Message Types

Interface Bus Messages

Device Messages

Data Messages

Status Messages

SECTION

Introduction

Test Equipment Required

Performance Verification Procedures

Power-On Test

Noise Drive Voltage Test

IF Attenuators Calibration

Final Detector Bias Test

Second Stage Calibration

Final Detector Linearity Test

Scope/Plotter Output Test

4-GPIB

.........................................................

5-

.........................................................

OPERATION

.............................................

................................................

..............................................

...................................................

..............................................

.................................................

................................................

.....................................................

.......................................................

......................................................

PERFORMANCE VERIFICATION TESTS

..............................................

.......................................................

...............................................

.............................................

...............................................

..............................................

...........................................

..........................

Title

.....................................

,

...................

.

4-1

.

4-1

.

4-3

.

4-3

.

4-3

.

4-4

.

4-4

.

4-4

.

4-8

.

4-12

.

4-16

.

5-1

.

5-1

.

5-2

.

5-2

.

5-2

.

5-3

.

5-3

.

5-4

.

5-5

.

5-7

iii

LIST OF ILLUSTRATIONS

EATON 2075

LIST OF ILLUSTRATIONS

Title

1-1

2-1

2-2

2-3

2-4

2-5

3-1

3-2

3-3

3-4

3-5a

3-5b

3-6

3-7a

3-7b

3-8a

3-8b

3-9a

3-9b

3-lOa

3-lOb

3-lla

3-1

lb

3-12a

3-12b

3-13a

3-13b

3-14a

3-14b

3-15a

3-15b

3-16

3-17

3-18

3-19

3-20

3-21

3-22

3-23

3-24

3-25

Eaton 2075 Noise Gain Analyzer

AC Voltage Selection Card

Extemal Relay Voltage Selection

of

Installation

Installation

GPIB Connector

Rack Mounts

of

Slide Mounts

.....................................................

Front Panel Controls and Indicators

Rear Panel Controls and lndicators

Uncorrected and Corrected Measurements

Test Configuration Downconversion Modes

1-

Test Configuration

Test Configuration

Calibration

1-

Extemal Relays for Calibration

........................................

.............................................

........................................

............................................

............................................

......................................

......................................

................................

...............................

.......................................

Test Configuration 1 - Extemal Relays for Calibration

Test Configuration 2 - Calibration - Double Sideband

Test Configuration

Test Configuration 2

Measurement-

-Calibration

Double Sideband

- Single Sideband

2-

Test Configuration 2 - Measurement - Single Sideband

Test Configuration 3

-Calibration

Test Configuration 3 - Measurement

.......................................

.....................................

Test Configuration 4 - Calibration - Double Sideband

4-

Test Configuration

Test Configuration

Test Configuration 4 Test Configuration 5

Test Configuration 5 - Measurement

Test Configuration

Test Configuration

P

Setup-Calibration

T

0

~P

T

ENR

ENR

Setup-

Measurement

Setup-Calibration

Setup-Measurement

Manual Y-Factor Measurement

of

Example

ENR

Calibrated Noise Source Data

Table

1,

2,

Setup With Extemal Relays for Calibration

Example 1 Sideband Selection

Example 2 Sideband Selection

Example 3 Sideband Selection

Example 4 Sideband Selection

Bandwidth Compensation Example 1

Bandwidth Compensation Example 2

Measurement - Double Sideband

4-

Calibration - Single Sideband

Measurement-

-Calibration

Single Sideband

.......................................

.....................................

6-

Calibration

6-

Measurement

.......................................

.....................................

................................................

..............................................

...............................................

.............................................

..........................................

.................................

or 3 ..................................................

................................

..........................................

..........................................

..........................................

..........................................

.....................................

.....................................

.......................

.......................

.......................

......................

........................

......................

.......................

......................

........................

......................

.

1-1

.

2-2

.

2-4

.

2-5

.

2-6

.

2-8

.

3-4

3-15

.

.

3-25

.

3-30

.

3-31

.

3-31

.

3-31

.

3-34

.

3-34

.

3-38

3-38

.

.

3-42

.

3-42

.

3-46

.

4-36

.

3-50

.

3-50

3-54

.

.

3-54

.

3-58

.

3-59

3-64

.

3-64

.

.

3-66

.

3-66

.

3-69

.

3-71

.

3-73

.

3-76

.

3-79

.

3-80

.

3-81

.

3-81

.

3-82

.

3-83

iv

EATON 2075

LIST OF ILLUSTRATIONS

LIST OF ILLUSTRATIONS (Continued)

Title

3-26

3-27

3-28

3-29

3-30

3-31

3-32

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

5-1

Insertion Loss Measurement With Power Meter

Insertion Loss Measurement With 2075

Loss Compensation

Error

Caused by

...................................................

Tcold

Deviation From 290 K

Test Pattern 2 Oscilloscope Display

...................................

......................................

Noise Figure and Gain Oscilloscope Display

Smoothing Indicator

General Purpose Interface Bus

Sample Data Output

Status Byte

..........................................................

..................................................

..........................................

..................................................

............................

..............................

...............................

Flowchart For Data Collection in Test Configuration 1 Using SRQ Data Ready

Programming Example For Data Collection in Test Configuration 1 Using SRQ

On Data Ready With HP 85 Controller

From

Sample Results

Program

Setup in Test Configuration 2

Flowchart For SRQ on Ready

of

...........................................

To

Flowchart For SRQ on Data Ready

Sample Program

Output Test Pattern 2

.....................................................

..................................................

...................................

Figure 4-5

Tune

..............................

...................................

......................................

..

3-84

.

.

3-85

.

3-87

.

3-89

.

3-91

.

3-92

.

3-111

.

4-2

.

4-14

.

4-17

.

4-18

.

4-19

.

4-21

.

4-21

.

4-23

.

4-26

.

4-28

.

5-8

V

LIST

OF T ABLES

LIST OF TABLES

EATON

2075

Table

1-1

1-2

1-3

1-4

2-1

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

4-1

4-2

4-3

4-4

4-5

Title

Equipment Supplied

Optional Accessories

Performance Specifications

Supplemental Specifications

GPIB Connector Pin-out

Front Panel Controls and Indicators

Rear Panel Controls and Indicators

Power-On, Preset, and Total System Reset Parameters

Selecting the

Additional Types

Output Display Special Functions

Control Programs For Externat Local Oscillators

ASCII Codes

Special Functions

Error

Messages

GPIB Functional Capabilities

GPIB Function Reference Table

Eaton 2075 GPIB Device Codes

Eaton 2075 GPIB Front Panel Codes

Selection

Correct

of

Data Message Contents

...................................................

..................................................

.............................................

............................................

...............................................

......................................

......................................

Test Configuration

of

Measurements

........................................

........................................................

.....................................................

......................................................

...........................................

.........................................

.........................................

..................................

.......................................

...........................

.....................................

......................................

.......................

.

1-3

.

1-3

.

1-4

.

1-6

.

2-8

.

3-5

.

3-15

.

3-18

.

3-29

.

3-62

.

3-90

.

3-95

.

3-99

.

3-102

.

3-107

.

4-4

4-6

.

.

4-9

4-11

.

4-12

.

vi

EATON

2075

GENERAL INFORMATION

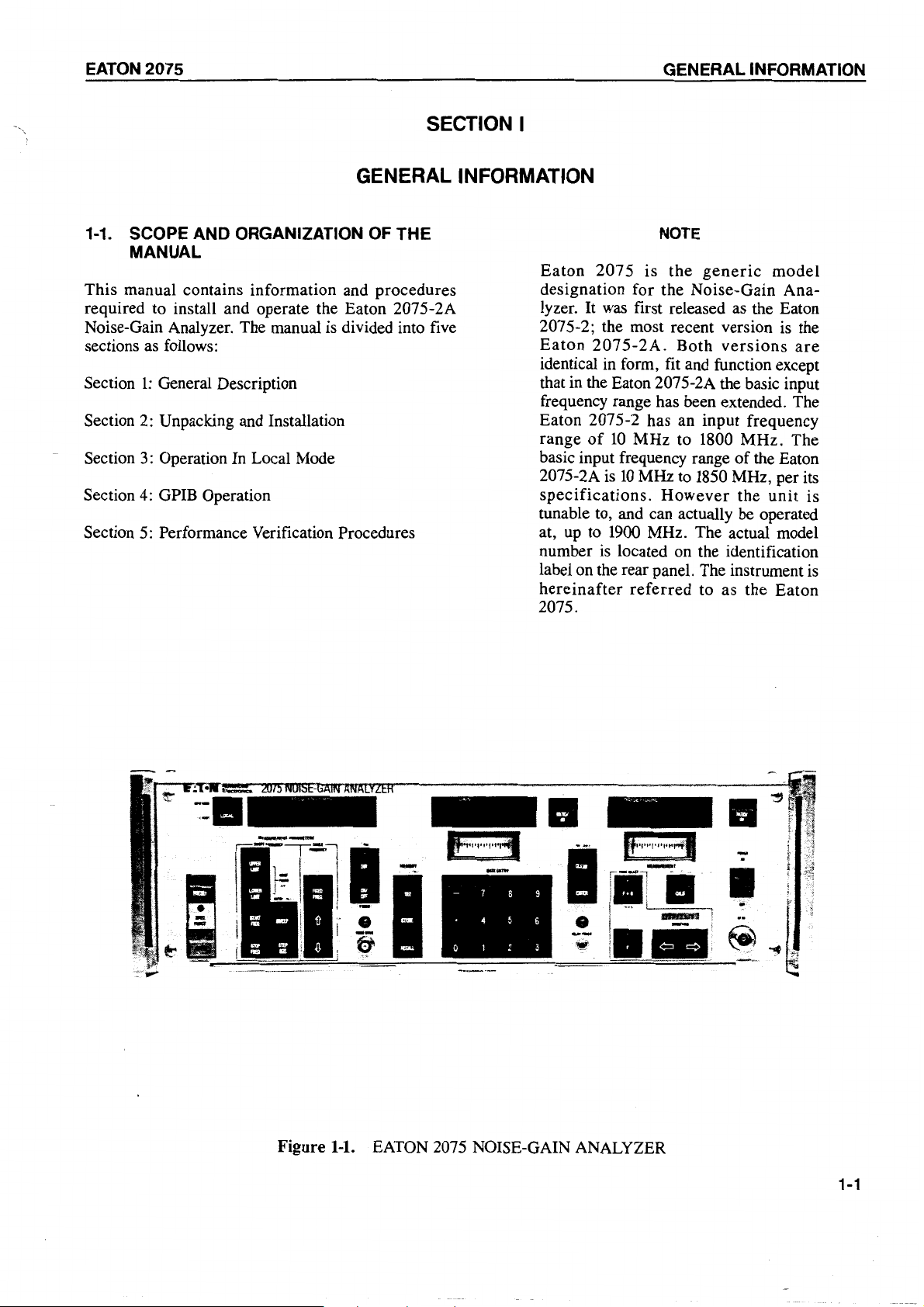

SECTION 1

GENERAL INFORMATION

1-1.

SCOPE AND ORGANIZATION OF THE

MANUAL

This manual contains information and procedures

required to install and operate the Eaton 2075-2A

Noise-Gain Analyzer. The rnanual is divided into five

as

sections

Section

Section

Section

follows:

1:

General Description

2:

Unpacking and Installation

3:

Operation In Local Mode

Section 4: GPIB Operation

5:

Section

Performance Verification Procedures

NOTE

Eaton

2075

is

the

generic

rnodel

designation for the Noise-Gain Ana-

lt

was

lyzer.

first released

as

the Eaton

2075-2; the most recent version is the

Eaton

identical in form,

2075-2A.

Both

versions

fit

and function except

are

that in the Eaton 207 5-2A the basic input

frequency range has been extended. The

Eaton 2075-2 has an input frequency

of

10

range

basic input frequency range

2075-2A

specifications.

MHz to 1800 MHz. The

of

the Eaton

is

10

MHz to

1850

However

MHz, per its

the

unit

is

tunable to, and can actually be operated

1900

at, up to

nurnber

is

MHz. The actual rnodel

located on the identification

label on the rear panel. The instrurnent is

hereinafter

referred

to as the Eaton

2075.

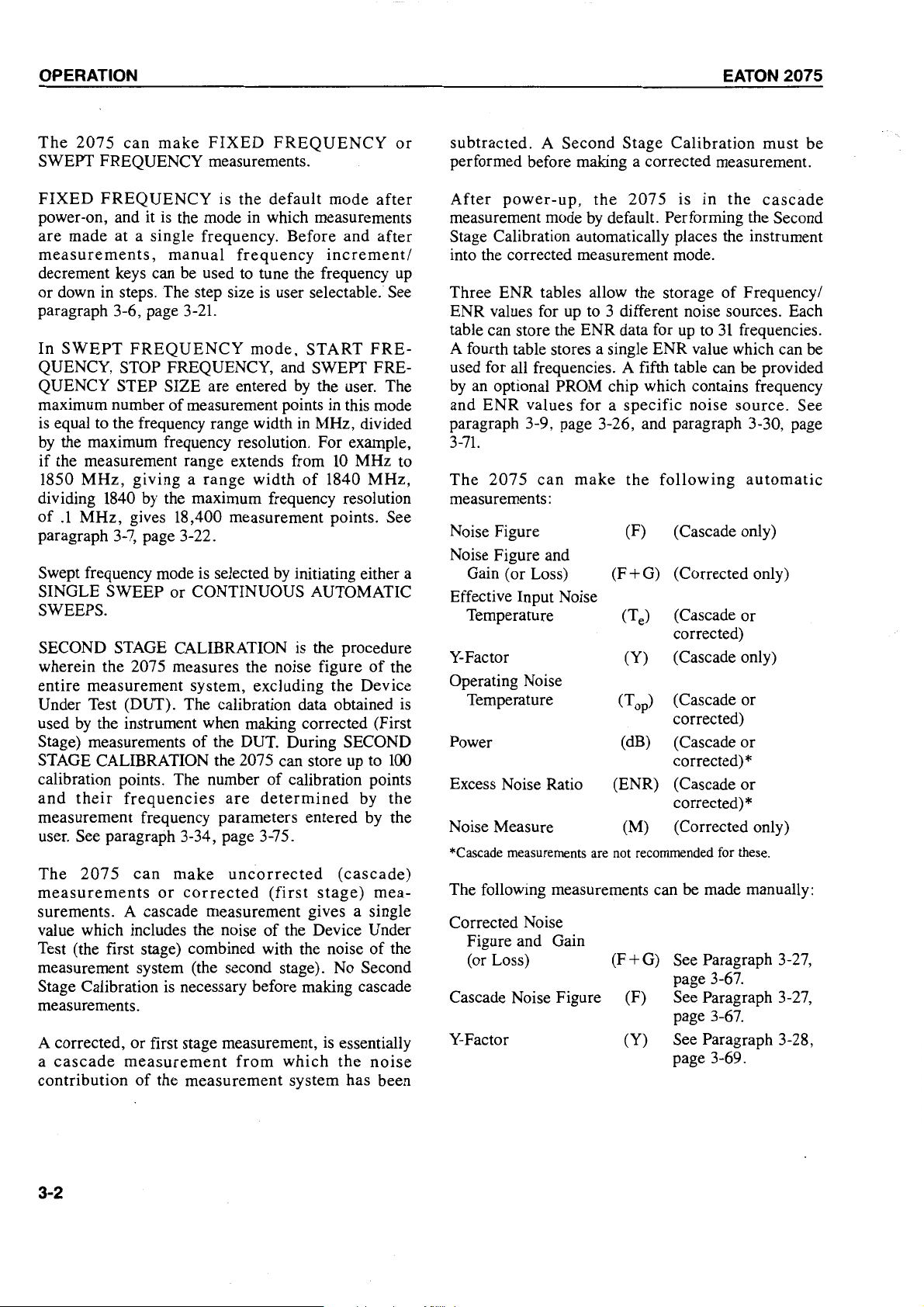

Figure

1-1.

EATON

- 7 8 9

• 4 5 6

0 1 2 3

2075 NOISE-GAIN ANALYZER

1-1

GENERAL INFORMATION

EATON

2075

This manual has been organized to allow the new user

of

the Eaton 2075 to quickly and easily begin test

to

operations. Read Section 1

the test instrument. Follow the procedures

obtain a familiarity with

of

Section 2

for installation.

The

Eaton

configurations,

2075

can

be

used

depending

on

in any

the

desired

of 6 test

test

application. Section 3 is organized to quickly bring the

user

to

the

correct

procedure. Figure

3-1

and Table

test

configuration

3-1

may

be studied to

and

its

obtain a familiarity with the controls and indicators.

Paragraph

3-10 and Table

3-4

guide

the

user

in

selecting the correct test configuration. Paragraphs 3-

11

through

3-18

are the procedures to

be

used with

each configuration. Each procedure includes the

keystroke sequences necessary for each step. The

remaining pages of Section 3 cover, in greater detail,

of

specific subjects relevant to operation

Section 4 covers operation when the 2075

by an

external

computer

via

a General

the 2075.

is

controlled

Purpose

Interface Bus.

Section 5 includes information and procedures used

verify that the 2075

1-2. INTRODUCTION

This

section

description

including:

of

purpose

is

performing correctly.

of

the

manual

contains a general

the Eaton 2075 Noise-Gain Analyzer

and

function,

equipment

to

requirements, available options, specifications, and

safety precautions.

The analyzer can make the following measurements:

Corrected Noise Figure and Gain

Uncorrected Noise Figure

(F

(F)*

+ G)*

Corrected Effective Input Noise

Temperature and Gain

Effective Input Noise Temperature

Corrected Effective Operating Noise

Temperature and Gain

Effective Operating Noise Temperature

(T

P + G)

0

(Top)

Noise Measure (includes Gain) (M)*

1900

(Y)*

(PWR

(ENR)*

of

the 2075

MHz. In

dB)*

its

Y Factor

Power

Excess Noise Ratio

in

dB

or

as

*Can be displayed

a dimensionless ratio

The specified input frequency range

10

extends from

is

actually tunable and operable to

MHz to

1850

MHz. However, the unit

simplest test configuration the analyzer will make

measurements of RF devices with output frequencies

in this range. More complex test configurations,

of

requiring one or two stages

s ion, allow measurements

as

high

as

frequencies

65.535 GHz. The 2075 has the

capability for controlling the local oscillator used

external downconver-

of

devices with output

in

the external downconversion process.

1-4. CALIBRATION

CYCLE

1-3. PURPOSE AND

USE

OF

EQUIPMENT

The 2075 Noise-Gain Analyzer is a programmable,

microprocessor-controlled

specifically to make precise measurements

and gain characteristics

in

can be controlled

controls,

or

controller via

its local mode using its front panel

in the remote mode, by an external

an

IEEE-488 GPIB (General Purpose

instrument

designed

of

of

RF devices. The analyzer

noise

Interface Bus).

1-2

At six month intervals the Performance Verification

of

Procedures in Section 5

performed

performance

to

ensure

of

the 207 5.

this manual should be

the

continued

optimum

At one year intervals the instrument should be fully

calibrated

using

the

alignment

and

adjustment

procedures from the maintenance manual. These

procedures

should

be

performed

by

qualified

personnel experienced in calibration and servicing of

electronic instrumentation.

EATON

2075

GENERAL INFORMATION

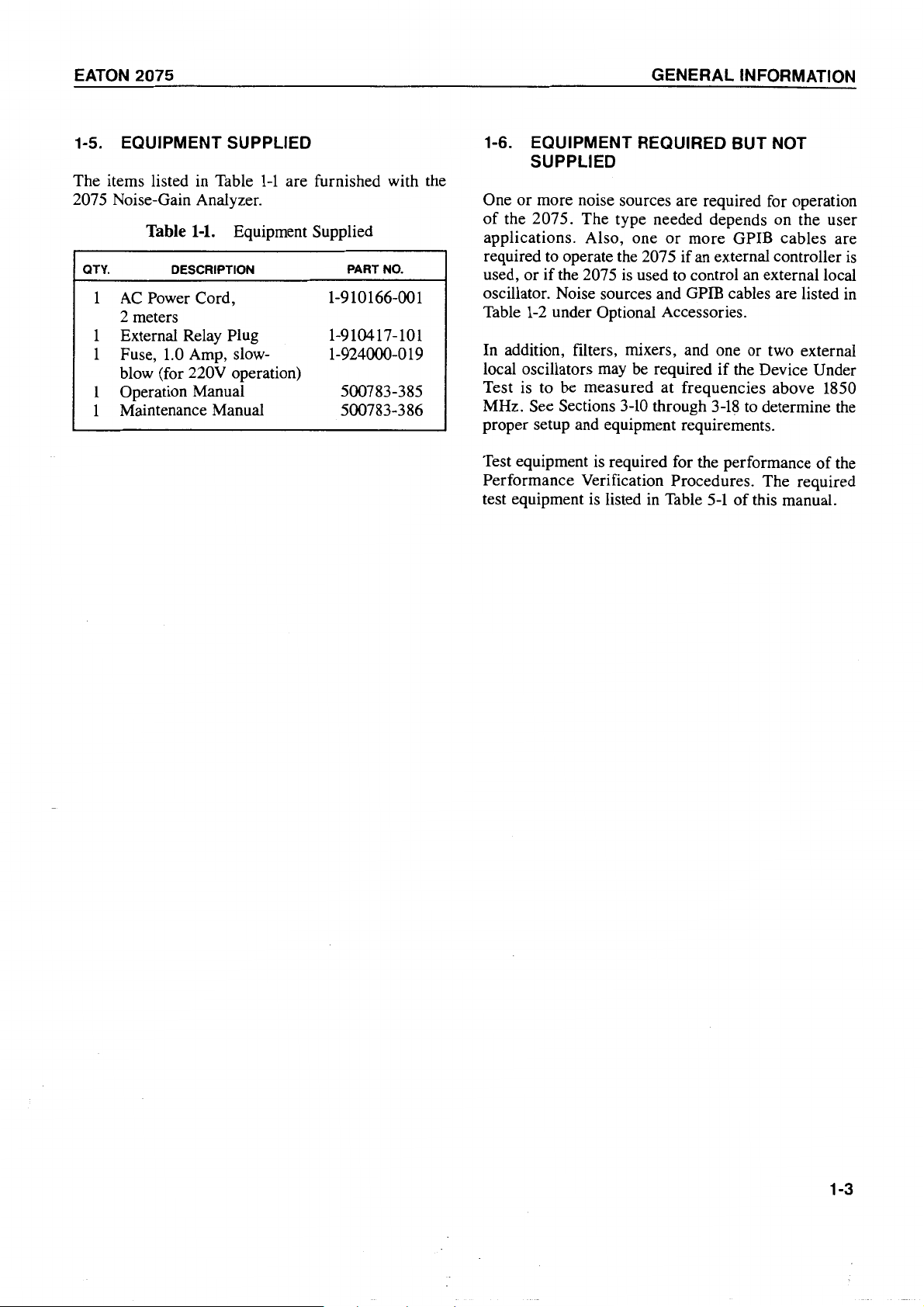

1-5. EQUIPMENT SUPPLIED

The items listed in Table

1-1

are furnished with the

2075 Noise-Gain Analyzer.

Table

QTY. DESCRIPTION PART NO.

1

AC

1-1.

Power Cord,

Equipment Supplied

1-910166-001

2 meters

External Relay Plug

1

1

Fuse,

1.

0 Amp, slow- 1-924000-019

1-910417-101

blow (for 220V operation)

Operation Manual 500783-385

1

Maintenance Manual 500783-386

1

1-6. EQUIPMENT REQUIRED BUT NOT

SUPPLIED

One or more noise sources are required for operation

of

the 207 5. The type needed depends on the user

applications. Also, one

required to operate the 2075

used, or

if

the 2075 is used to control an external local

oscillator. Noise sources and GPIB cables are listed

Table

1-2

under Optional Accessories.

In

addition, filters, mixers, and one or two external

local oscillators

may

be

required

or

more GPIB cables are

if

an external controller

if

the Device Under

is

in

Test is to be measured at frequencies above 1850

MHz. See Sections

3-10

through

3-18

to determine the

proper setup and equipment requirements.

Test equipment is required for the performance

of

the

Performance Verification Procedures. The required

test equipment is listed in Table

5-1

of

this manual.

1-3

GENERAL INFORMATION

EATON 2075

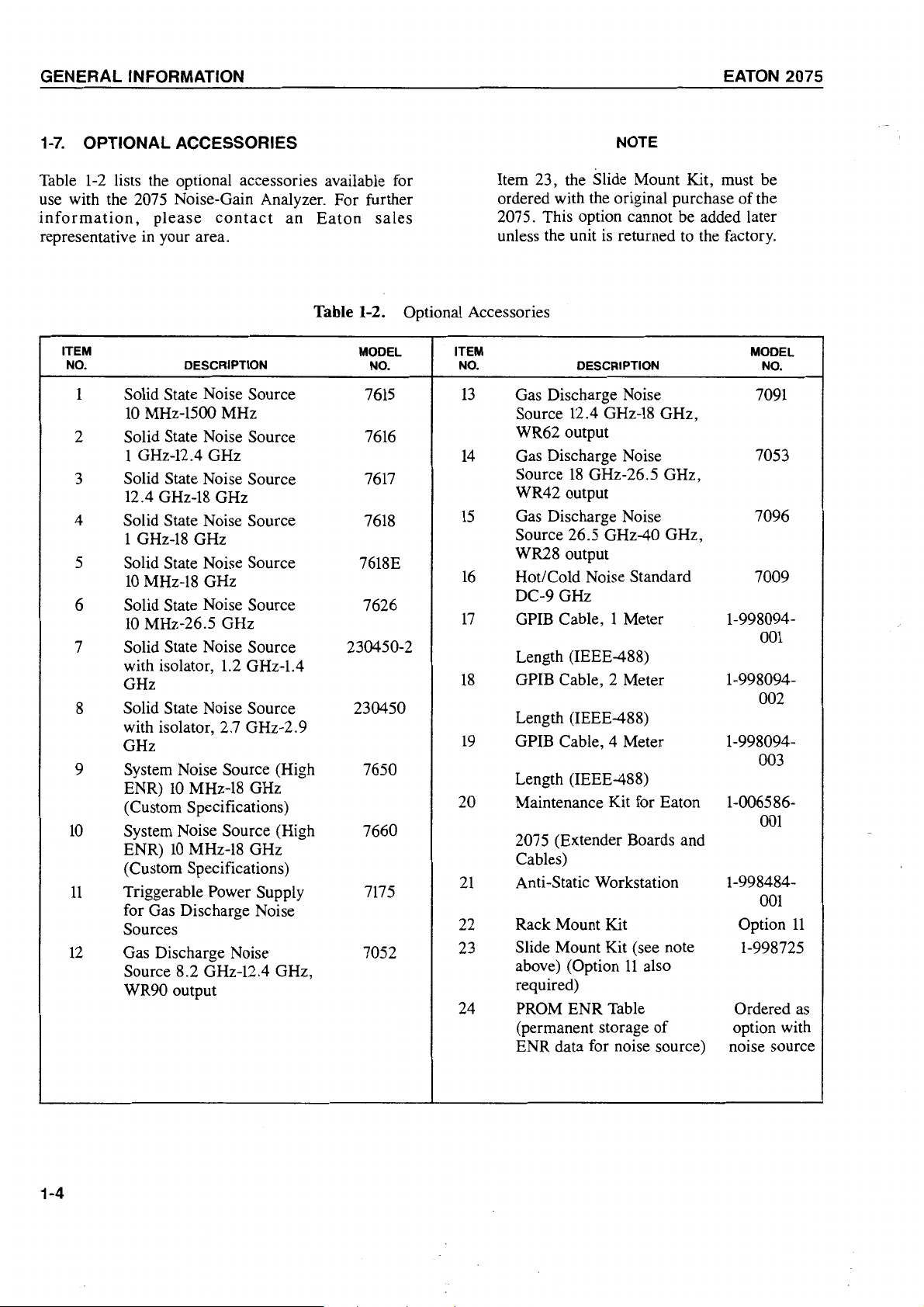

1-7.

OPTIONAL ACCESSORIES

Table

1-2

lists the optional accessories available for

use with the 2075 Noise-Gain Analyzer. For further

inforrnation,

please

contact

an

Eaton

sales

representative in your area.

Table 1-2. Optional Accessories

ITEM

NO.

1

Solid State Noise Source

10

DESCRIPTION

MHz-1500 MHz

2 Solid State Noise Source

MODEL ITEM MODEL

NO.

7615

7616

1 GHz-12.4 GHz

3 Solid State Noise Source

7617

12.4 GHz-18 GHz

4 Solid State Noise Source

1

5

6

7

GHz-18

Solid State Noise Source

10

MHz-18 GHz

Solid State Noise Source

10

MHz-26.5 GHz

Solid State Noise Source

with isolator,

GHz

1.2

GHz-1.4

7618

7618E

7626

230450-2

GHz

8 Solid State Noise Source 230450

with isolator, 2.7 GHz-2.9

GHz

9

System Noise Source (High 7650

10

ENR)

MHz-18 GHz

(Custom Specifications)

10

System Noise Source (High

ENR)

10

MHz-18 GHz

7660

(Custorn Specifications)

11

Triggerable Power Supply

7175

for Gas Discharge Noise

Sources

12

Gas Discharge Noise

7052

Source 8.2 GHz-12.4 GHz,

WR90 output

NOTE

Itern 23, the Slide Mount Kit, rnust be

ordered with the original purchase

2075. This option cannot be added later

unless the unit is returned to the factory.

NO.

13

Gas Discharge Noise

Source 12.4

DESCRIPTION NO.

GHz-18

GHz,

WR62 output

14

Gas Discharge Noise 7053

Source

18

GHz-26.5 GHz,

WR42 output

15

Gas Discharge Noise 7096

Source 26.5 GHz-40 GHz,

WR28 output

16

Hot/Cold Noise Standard 7009

DC-9 GHz

17

GPIB Cable, 1 Meter 1-998094-

Length (IEEE-488)

18

GPIB Cable, 2 Meter 1-998094-

Length (IEEE-488)

19

GPIB Cable, 4 Meter 1-998094-

Length (IEEE-488)

20

Maintenance Kit for Eaton

2075 (Extender Boards and

Cables)

21

22

23

Anti-Static Workstation 1-998484-

Rack Mount Kit Option

Slide Mount Kit (see note

11

above) (Option

also

required)

24

PROM ENR Table Ordered

(permanent storage

of

ENR data for noise source)

of

the

7091

001

002

003

1-006586-

001

001

11

1-998725

as

option with

noise source

1-4

EATON

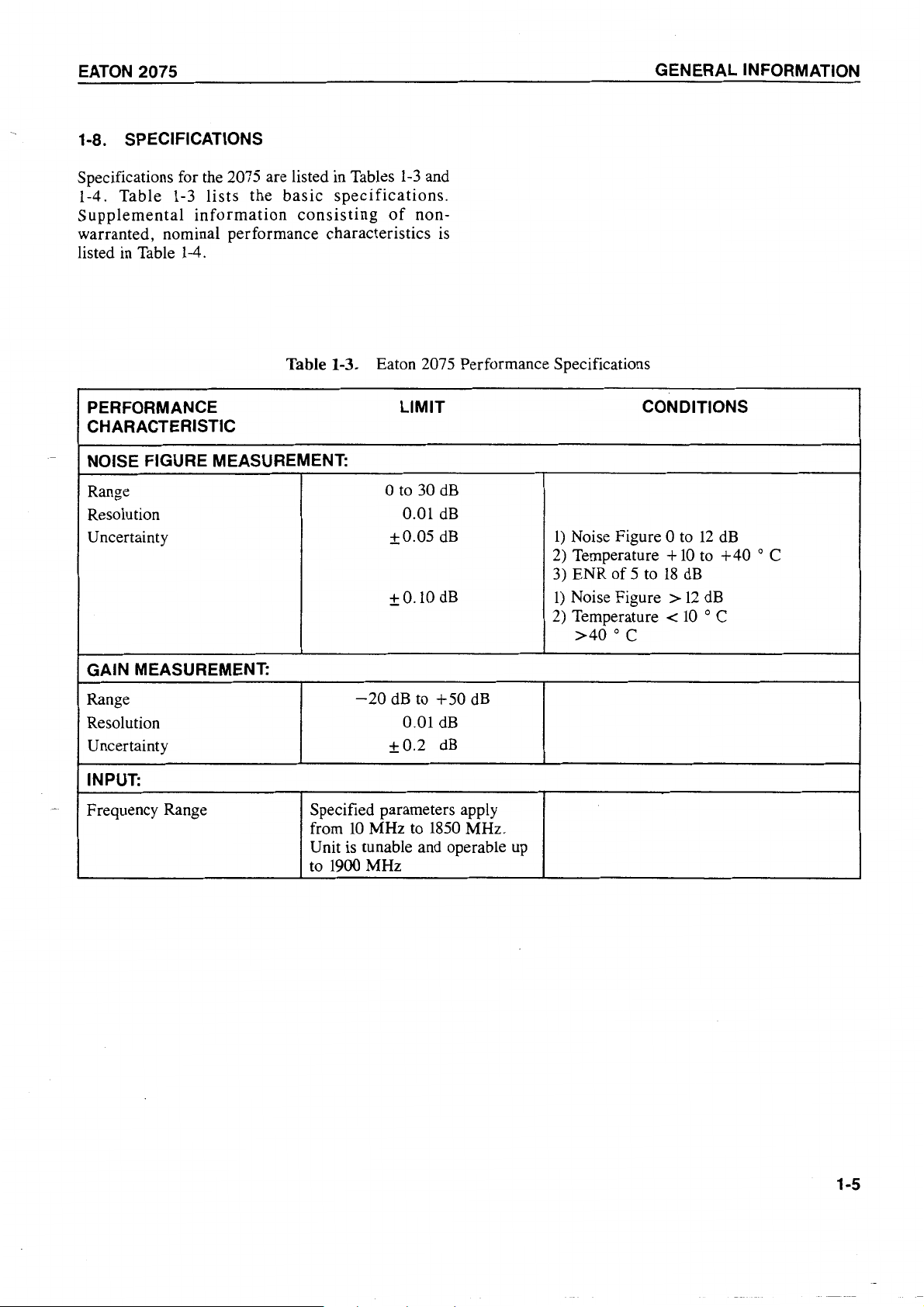

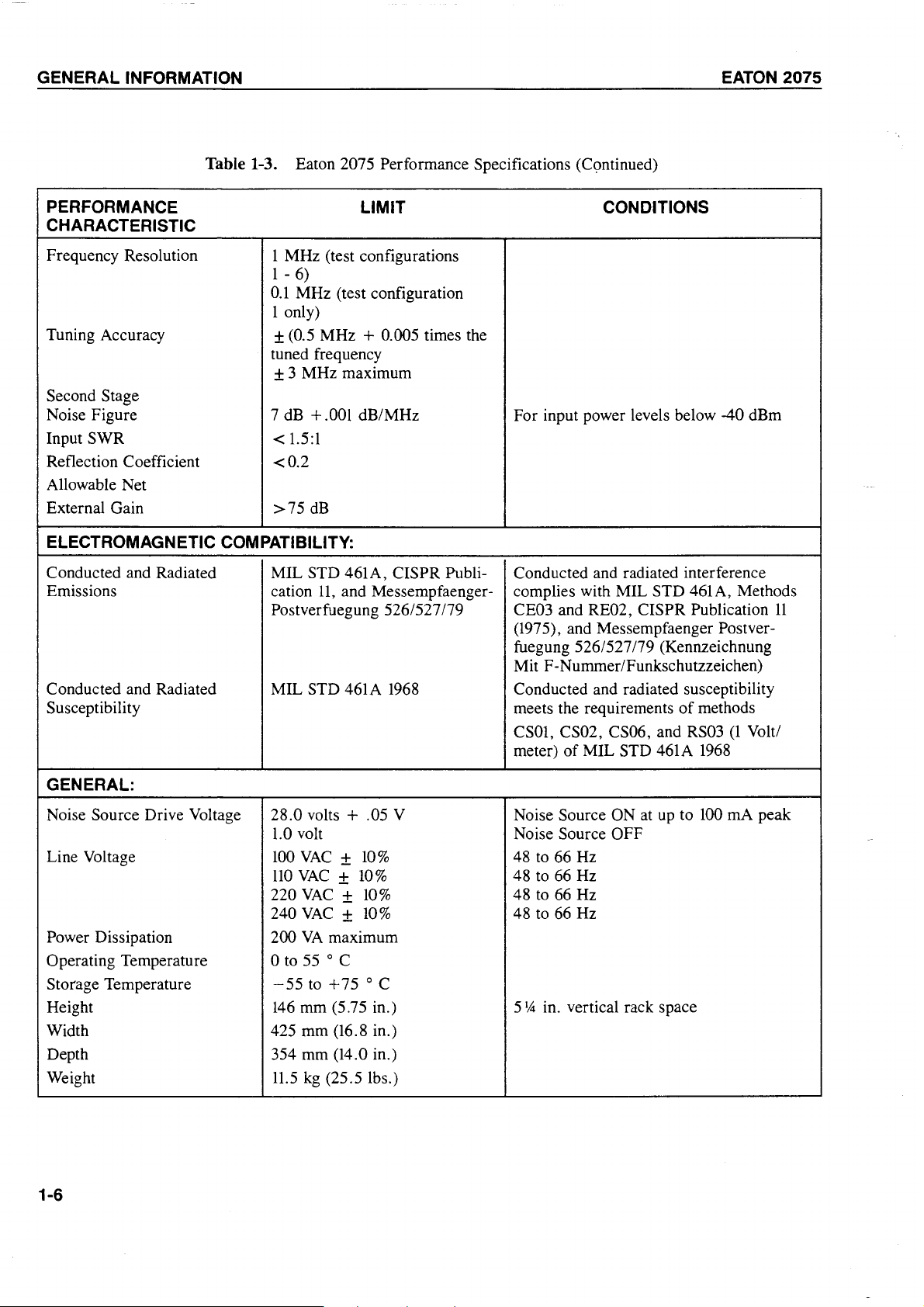

1-8. SPECIFICATIONS

2075

GENERAL

INFORMATION

Specifications for the 2075 are listed in Tables

1-4.

Table

Supplemental

1-3

lists

information

the

basic

specifications.

consisting

of

1-3

nonwarranted, nominal performance characteristics

listed in Table 1-4.

Table 1-3. Eaton 2075 Performance Specifications

PERFORMANCE

CHARACTERISTIC

NOISE FIGURE MEASUREMENT:

Range

Resolution

U ncertainty

LIMIT

0 to 30

0.01

±0.05

±0.10

and

is

dB

dB

dB

dB

CONDITIONS

1)

Noise Figure 0 to

2)

Temperature +

3) ENR of 5 to

1)

Noise Figure >

2)

Temperature <

>40

° c

18

10

dB

12

10

12

to

dB

° C

dB

+40

° C

GAIN MEASUREMENT:

Range

Resolution

U ncertainty

INPUT:

Frequency Range

-20

dB

to

+50

dB

dB

0.01

±0.2

dB

Specified parameters apply

from

10

MHz to

1850

MHz.

Unit is tunable and operable up

to 1900 MHz

1-5

GENERAL INFORMATION EATON

Table 1-3. Eaton 2075 Performance Specifications (Continued)

2075

PERFORMANCE

CHARACTERISTIC

Frequency Resolution

1 MHz (test configurations

1 -

6)

0.1

MHz (test configuration

LIMIT CONDITIONS

1 only)

Tuning Accuracy

± (0.5 MHz + 0.005 times the

tuned frequency

± 3 MHz maximum

Second Stage

Noise Figure

Input SWR

Reflection Coefficient

Allowable Net

External Gain

ELECTROMAGNETIC COMPATIBILITY:

Conducted and Radiated

Emissions

Conducted and Radiated

Susceptibility meets the requirements

+.

001

7 dB

1.5:1

<

dB/MHz For input power levels below -40 dBm

<0.2

>75

dB

MIL STD 461A, CISPR Publication

11,

and Messempfaenger-

Postverfuegung 526/527179

MIL STD 461A

1968

Conducted and radiated interference

complies with MIL STD 461A, Methods

CE03 and RE02, CISPR Publication

(1975), and Messempfaenger Postverfuegung 526/527 /79 (Kennzeichnung

Mit F-Nummer/Funkschutzzeichen)

Conducted and radiated susceptibility

CSOl, CS02, CS06, and RS03

meter)

of

MIL STD 461A

of

methods

1968

(1

11

Volt/

GENERAL:

Noise Source Drive Voltage

28.0 volts + .05 V Noise Source ON at

1.0 volt Noise Source OFF

Line Voltage

Power Dissipation 200

Operating Temperature 0 to

Storage Temperature

Height

100

VAC ± 10%

110

VAC ± 10%

VAC ± 10%

220

240

VAC ± 10%

VA

maximum

55

° C

-55

to

+75

° C

146

mm (5.75 in.) 5

Width 425 mm (16.8 in.)

Depth 354 mm (14.0 in.)

Weight

1-6

11.5

kg

(25.5 lbs.)

up

48 to 66 Hz

48 to 66 Hz

48 to 66 Hz

48 to 66 Hz

1

A in. vertical rack space

to

100

mA

peak

EATON

2075 GENERAL INFORMATION

CHARACTERISTIC

Bandwidth

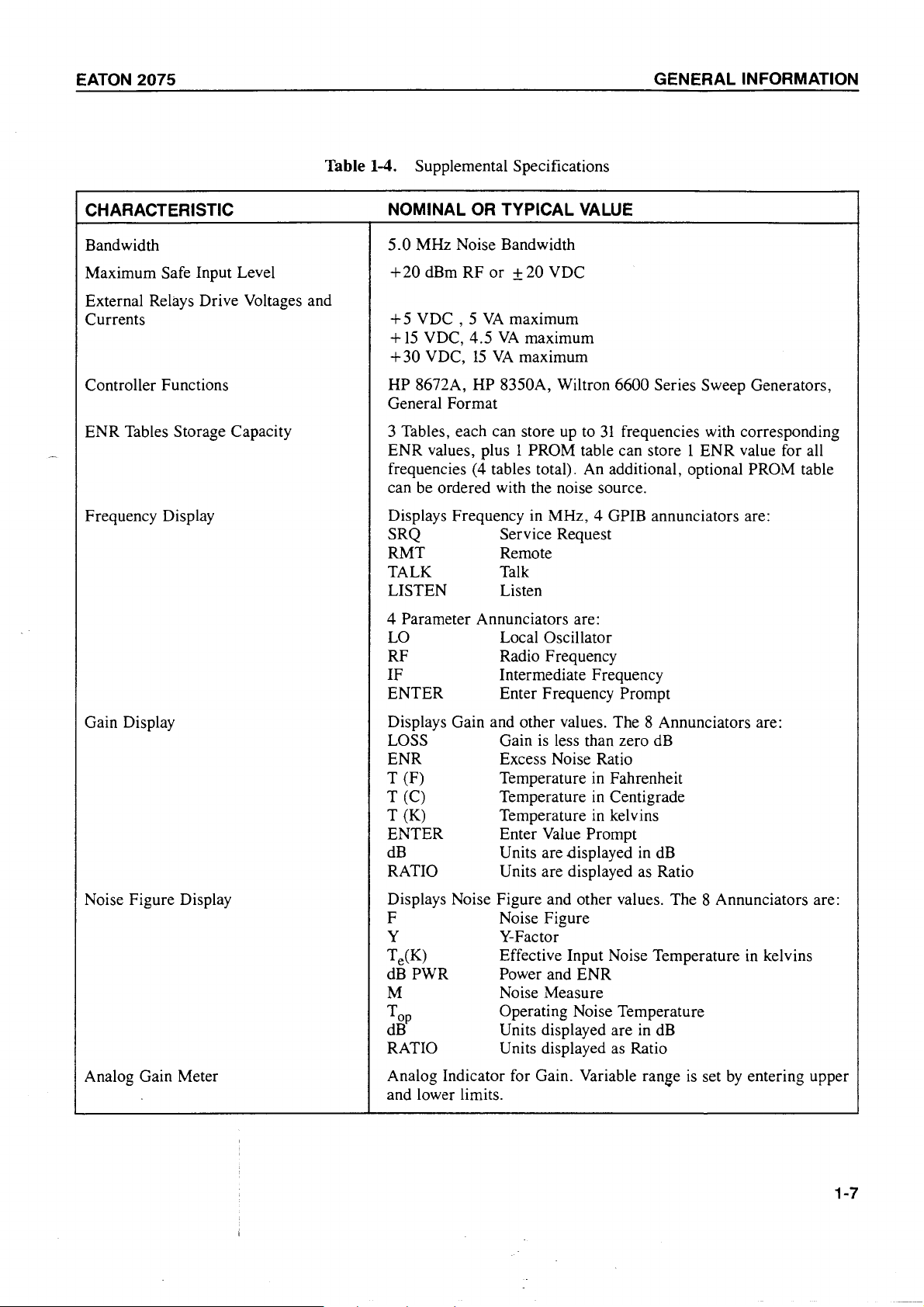

Table 1-4. Supplemental Specifications

OR

NOMINAL

5.0

MHz Noise Bandwidth

TYPICAL

VALUE

Maximum Safe Input Level

+20

dBm RF or

±20

VDC

External Relays Drive Voltages and

Currents

VDC, 5 VA

+

15

VDC,

+30

VDC,

4.5

15

maximum

VA

maximum

VA

maximum

+5

Controller Functions HP 8672A, HP 8350A, Wiltron 6600 Series Sweep Generators,

General Format

31

ENR Tables Storage Capacity 3 Tables, each can store up to

frequencies with corresponding

ENR values, plus 1 PROM table can store l ENR value for all

frequencies (4 tables total). An additional, optional PROM table

can be ordered with the noise source.

Frequency Display

Displays Frequency in MHz, 4 GPIB annunciators are:

SRQ

Service Request

RMT Remote

TALK Talk

LISTEN Listen

4 Parameter Annunciators are:

LO Local Oscillator

RF Radio Frequency

IF

Intermediate Frequency

ENTER Enter Frequency Prompt

Gain Display

Displays Gain and other values. The 8 Annunciators are:

LOSS Gain

is

less than zero

dB

ENR Excess Noise Ratio

T (F)

(C)

T

T (K)

Temperature in Fahrenheit

Temperature

Temperature

in

Centigrade

in

kelvins

ENTER Enter Value Prompt

dB

RATIO

Units are .displayed in

dB

Units are displayed as Ratio

Noise Figure Display

Analog Gain Meter

Displays Noise Figure and other values. The 8 Annunciators are:

F Noise Figure

y

Te(K)

dBPWR

Y-Factor

Effective Input Noise Temperature

Power and ENR

in

kelvins

M Noise Measure

Top

dB

Operating Noise Temperature

Units displayed are

in

dB

RATIO Units displayed as Ratio

Analog Indicator for Gain. Variable range

is

set

by

entering upper

and lower limits.

1-7

GENERAL INFORMATION

EATON

2075

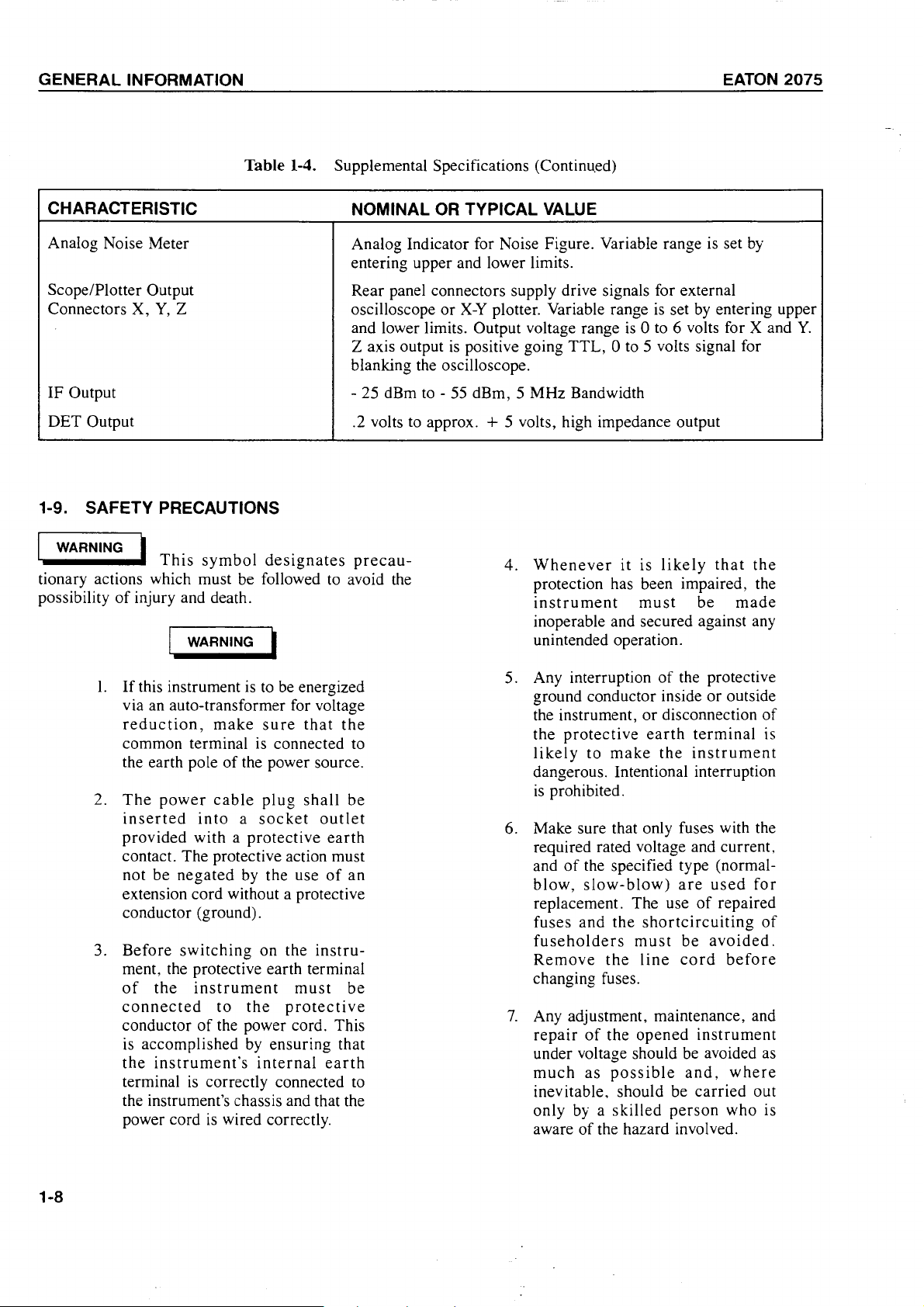

Table 1-4.

CHARACTERISTIC

Analog Noise Meter

Supplemental Specifications (Continu.ed)

NOMINAL

OR

TYPICAL

VALUE

Analog Indicator for Noise Figure. Variable range is set by

entering upper and lower limits.

Scope/Plotter Output

Y,

Connectors X,

Z

Rear panel connectors supply drive signals for external .

or

X-Y

oscilloscope

plotter. Variable range is set by entermg upper

and lower limits. Output voltage range

z axis output

is

positive going

TTL,

0 to 5 volts signal for

blanking the oscilloscope.

IF Output - 25 dBm to - 55 dBm, 5 MHz Bandwidth

DET Output

.2 volts to approx.

+ 5 volts, high impedance output

1-9. SAFETY PRECAUTIONS

WARNING 1 . l d .

1

tionary actions which must be followed to avoid the

possibility

Th1s

of

injury and death.

symbo

es1gnates

precau-

Whenever

4.

protection has been impaired, the

instrument

inoperable and secured against any

1 WARNING 1

unintended operation.

is

0 to 6 volts for X and

it

is

likely

must

be

that

made

Y.

the

1.

If

this instrument is to be energized

via an auto-transformer for voltage

reduction,

make

sure

common terminal is connected to

of

the earth pole

The

2.

power

inserted

provided with a

the power source.

cable

plug

into a socket

protective

contact. The protective action must

not be

negated

by the use

extension cord without a protective

conductor (ground).

3.

Before

switching

on the

ment, the protective earth terminal

of

the

instrument

connected

conductor

to

of

the power cord. This

is accomplished

the

instrument's

terminal

is

correctly connected to

the

by

must

protective

ensuring that

internal

the instrument's chassis and that the

is

power cord

wired correctly.

that

shall

outlet

earth

of

instru-

earth

the

be

an

be

of

5. Any interruption

ground conductor inside

the instrument,

the

protective

likely

to

make

the protective

or

or

disconnection

earth

terminal

the

instrument

outside

of

is

dangerous. Intentional interruption

is

prohibited.

6. Make sure that only fuses with the

required rated voltage and current,

of

and

blow,

replacement. The use

fuses

fuseholders

Remove

the specified type (normalslow-blow)

and

the

the

are

used

of

repaired

shortcircuiting

must

line

be

cord

avoided.

before

for

of

changing fuses.

7.

Any adjustment, maintenance, and

repair

of

the

opened

instrument

under voltage should be avoided as

much

inevitable, should be

only by a

aware

as

possible

skilled

of

the hazard involved.

and,

person

where

carried

who is

out

1-8

EATON 2075

8.

Exercise

servicing the unit. High voltages

are used.

9. Capacitors inside the instrument

may still be charged even

instrument has been disconnected

from its source.

extreme

care

when

if

the

GENERAL INFORMATION

3. Any interruption

of

the protective

(grounding) conductor inside

outside the instrument is likely

cause damage to the instrument.

avoid damage, this instrument and

all line powered devices connected

to it must be connected to the same

earth ground.

or

to

To

+++++++++++

! CAUTION !

•••••••••••

tionary actions which must be followed to avoid

damage to all or part

1.

2. Verify that the socket for the power

This

symbol

of

the instrument.

+++++++++++

! CAUTION !

+++++++++++

designates

precau-

Verify that the line voltage selector

rear

card on the

panel is in the

correct position before connecting

the power.

line cord is provided with a protective earth contact.

4. Make sure that only fuses with the

required

specified

replacement.

given

on

rating,

type,

Fuse

the

rear

and

are

ratings

panel

of

used

of

the

for

are

the

instrument near the fuseholder.

To

5.

avoid the possibility

of

damage

to test equipment, read completely

through

each

section

before

starting it. Make any preliminary

control

settings

necessary

for

correct test equipment operation.

6. Do not torque the RF connector

more than 2

V2

inch-pounds.

to

1-9

EATON

2075

INSTALLATION

SECTION 2

INSTALLATION

2-1.

INTRODUCTION

This

section

required for unpacking, inspecting, and installing the

Eaton 2075 Noise-Gain Analyzer.

2-2. UNPACKING AND PHYSICAL

INSPECTION

Examine

unpacking the equipment.

damaged, have the carrier's agent present when the

equipment is removed from the carton. Retain the

shipping carton and padding material for the carrier's

inspection

it has been unpacked.

of

the manual contains information

the

shipping

if

damage to the equipment is evident after

carton

If

for

the

damage

carton

before

has been

•••••••••••

! CAUTION !

•••••••••••

Exercise

instrument from its shipping container to

ensure that

time.

See that the equipment is complete as listed on the

packing slip. Visually examine the 2075 for any

evidence

evident,

immediately notify the carrier and also your local

Eaton sales office. After completing the physical

inspection, the Performance Verification Procedures

in

Section 5

operational or electrical inspection.

of

or

care

when

no

damage

physical

if

the

of

this manual should be performed

damage.

contents

removing

is

incurred at this

If

any

are

not

the

damage

complete,

as

an

is

2-3.

Prior

configured for operation using

Refer

steps

configuration:

AC

POWER REQUIREMENTS

to

shipping, the 2075

VAC,

120

60 Hz line power. The unit is easily re-

to

Figure

to

Observe all the safety precautions listed

in

determine that the line voltage selector

card is set to its correct position.

necessary to change the card setting, use

the following procedure .

For units with serial numbers 286 and

up,

unit

Likewise,

whether the unit

240

2-1

verify,

paragraph

it

is

VAC.

or

makes

configured for

below and perform the following

no

it

is

to

change,

WARNING 1

1-9. In

NOTE

difference whether the

makes

is

configured for 220

configured to operate on

100,

220,

or

240

VAC.

the

line

voltage

particular,

If

it is

100

or

120

VAC.

no

difference

or

2-1

INSTALLATION

EATON

2075

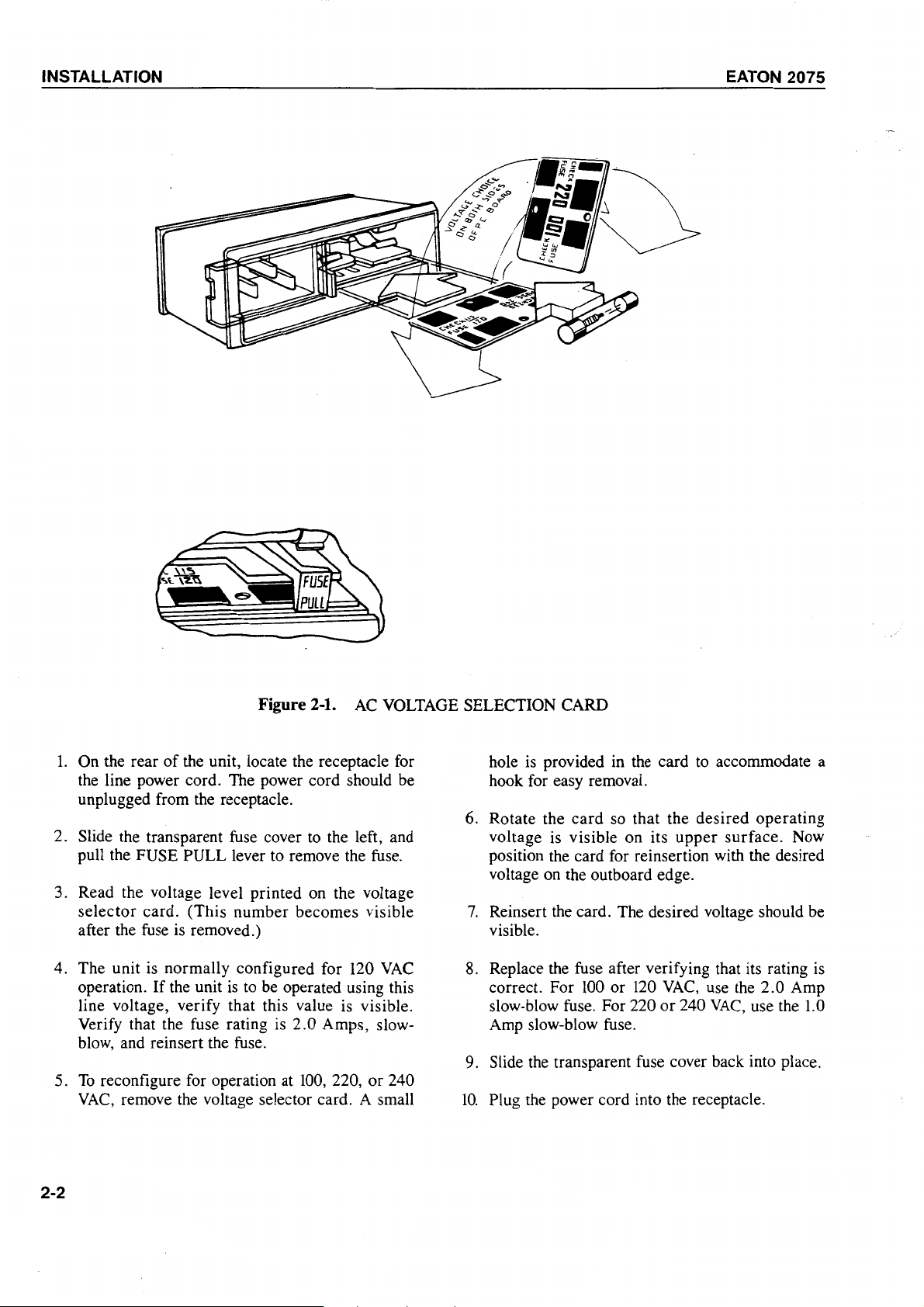

1.

On the rear

of

the unit, locate

Figure 2-1.

the

AC

VOLTAGE

receptacle for

SELECTION CARD

the line power cord. The power cord should be

unplugged from the receptacle.

6.

2.

Slide the transparent fuse cover

to

the left, and

pull the FUSE PULL lever to remove the fuse.

3. Read the voltage level printed on the voltage

selector card. (This number becomes visible

7.

after the fuse is removed.) visible.

120

4. The unit is normally configured for

operation.

If

the unit

is

to

be operated using this

VAC

8.

line voltage, verify that this value is visible.

Verify that the fuse rating is 2.0 Amps, slowblow, and reinsert the fuse.

9.

5.

To

reconfigure for operation at

VAC,

remove

the

voltage selector card. A small

100,

220, or 240

10.

hole is provided in the card to accommodate a

hook for easy removal.

Rotate the card so that the desired operating

voltage is visible on its upper surface. Now

position the card for reinsertion with the desired

voltage on the outboard edge.

Reinsert

Replace the fuse after verifying that its rating

correct. For

slow-blow fuse. For 220 or 240

the

card. The desired voltage should be

100

or

120

VAC,

use the

VAC,

2.0

use the

is

Amp

1.0

Amp slow-blow fuse.

Slide the transparent fuse cover back into place.

Plug the power cord into the receptacle.

2-2

EATON

2075

INSTALLATION

WARNING 1

The power line cord

to

ensure that the instrument chassis

connected

conditions

interrupted,

tobe

used.

to

the main ground. Under

is this

or

is

a 3 wire assembly

is

no

ground

a 2 wire extension cord

lead

to be

•••••••••••

! CAUTION !

•••••••••••

Observe all the safety precautions given

in

paragraph

2-4. OPERATIONAL INSPECTION

After verifying that the 2075 is configured for the

correct line voltage, the unit should be subjected

Performance Verification Tests in Section 5

manual. After completion

ready for bench-top operation.

1-9.

of

these tests, the unit

to

of

the

this

is

Operation outside this range for extended periods will

result in degradation

eventual malfunction.

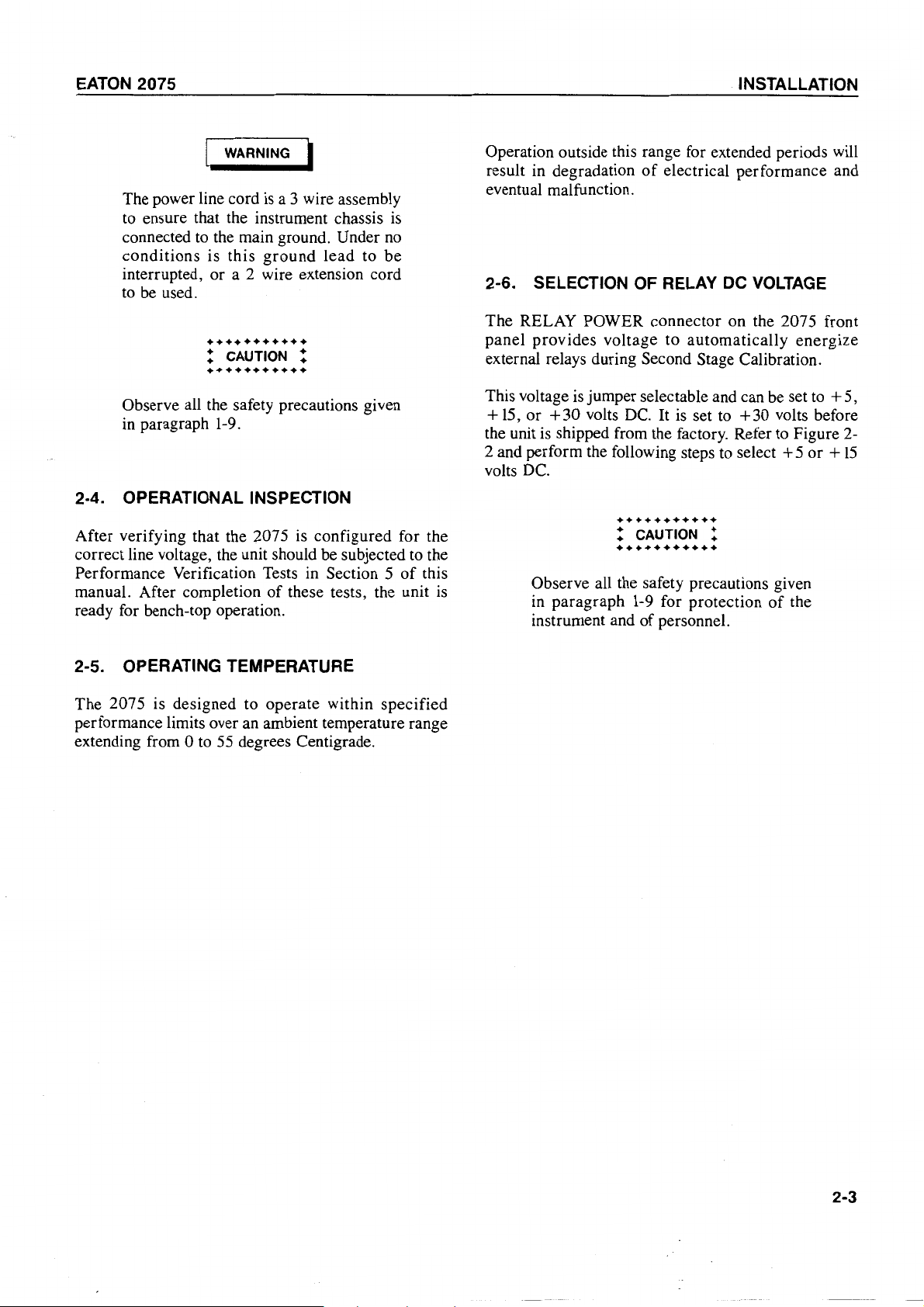

2-6. SELECTION

The RELAY POWER connector on the 2075 front

panel provides voltage to automatically energize

external relays during Second Stage Calibration .

This voltage

+

15,

or + 30 volts DC.

the unit

2 and perform the following steps to select + 5 or +

volts

DC.

is

jumper selectable and can be set

is

shipped from the factory. Refer

of

electrical performance and

OF

RELAY

lt

is

DC

VOLTAGE

set

to

+ 30 volts before

to

to

+ 5,

Figure

215

•••••••••••

! CAUTION !

•••••••••••

Observe all the safety precautions given

in paragraph

instrument and

1-9

for protection

of

personnel.

of

the

2-5. OPERATING TEMPERATURE

The 2075 is designed to operate within specified

performance limits over an ambient temperature range

extending from 0

to

55 degrees Centigrade.

2-3

INSTALLATION

Top

Partition

,

,

,

,

,

,

,.

,

,

,

,

,

,

,

,

,

,

,

,

A4

DUEi

BDES

BOARD

. } .

.

.

EATON

2075

view

of

2075

1.

Remove the

on the rear

2. Remove the single 6-32 screw which secures the

top cover panel. Slide the cover to the rear

unit and remove it.

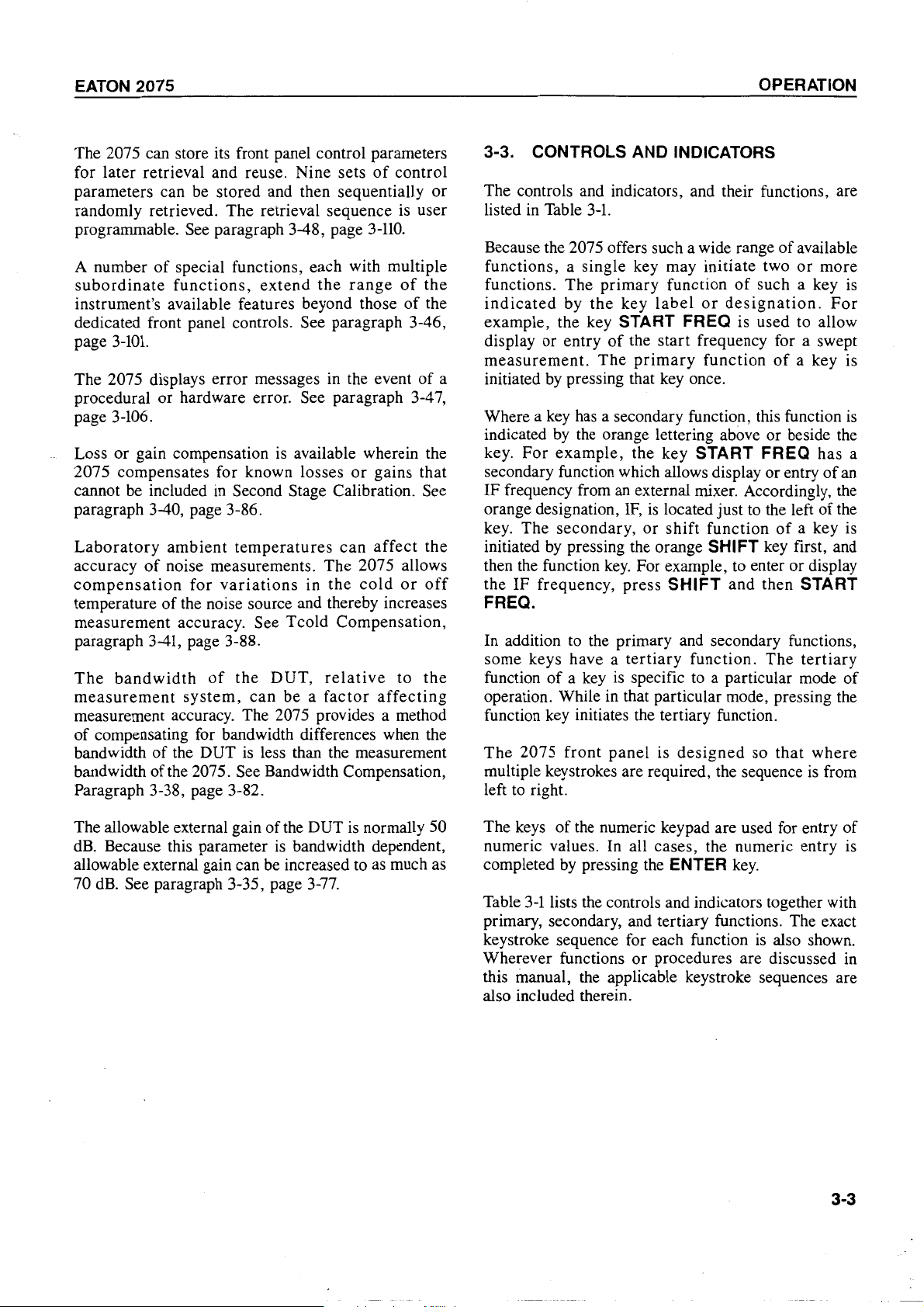

3. Two internal covers are exposed. Remove the Figure 2-2 above. A jumper

nine 4-40 screws which secure the right side pins E3 and E4, selecting

internal cover (the RF Deck Cover) and remove

the cover.

4.

Locate the

Figure 2-2 above.

5. Remove the three board holding screws which

are located along the top edge

AC

of

the 207 5.

A4

board. Its position is shown in jumper between pins E 1 and E2.

A4

Board

front

Figure 2-2. EXTERNAL RELAY

power cord from its receptacle 6. Unplug the connectors located near the top edge

of

the board.

.,,,.

of

,,.""'

the

.,,,.

.,,,.

.,,,.

.,,,.

.,,,.

.,,,.

.,,,.

.,,,.

VOLTAGE

of

be removed.

connector.

Locate

7.

located in the center

8.

To

pins

9.

To

in

SELECTION

the board,

the

select + 5 volts, connect the jumper between

E5

and E6.

reassemble the unit perform steps 1 through 6

reverse.

as

necessary, so that the board can

Lift

the

board

pins

E 1

through

of

the board as shown in

+ 30 volts.

To

select +

free

of

its edge

E6.

These

is

installed between

15

volts, connect the

are

2-4

EATON

2075

INSTALLATION

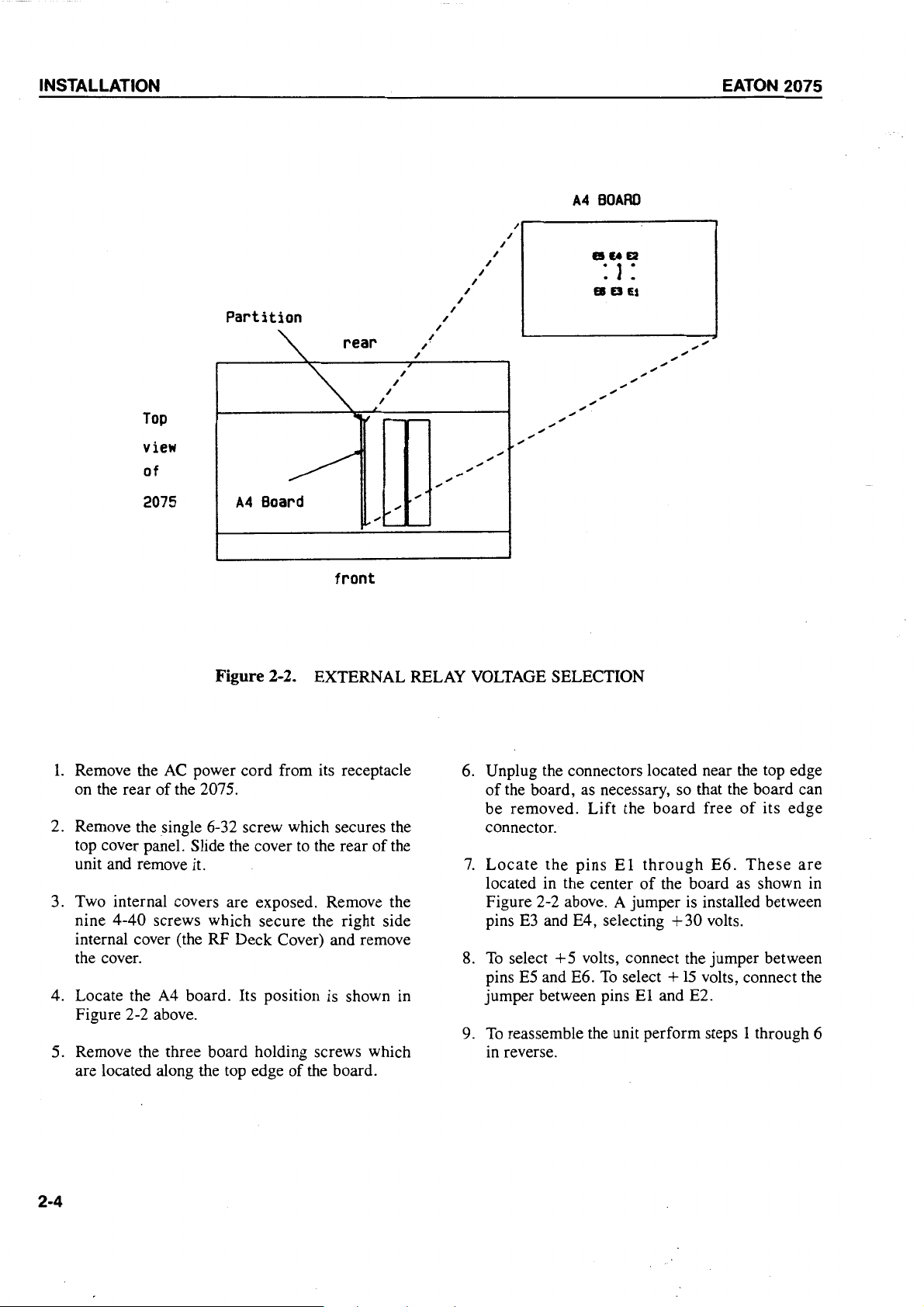

2-7.

EQUIPMENT MOUNTING

The 2075 comes equipped with four supporting feet

allow bench-top operation. The unit may also be

mounted in a standard

angled support brackets

The rack mounting kit, Option

panel brackets and the necessary screws for attaching

the brackets to the 2075.

The Slide Mount Kit, part number 1-998725, consists

of

the two slide mount assemblies and the required

mounting screws. Both kits are required for mounting

the unit on slides.

brackets, only Option

19

inch equipment rack on

or

on sliding mounts.

11,

For

rack

mounting on angled

11

is required.

consists

of

two front

to

NOTE

The Slide

ordered

purchased. The unit

slide mounts installed.

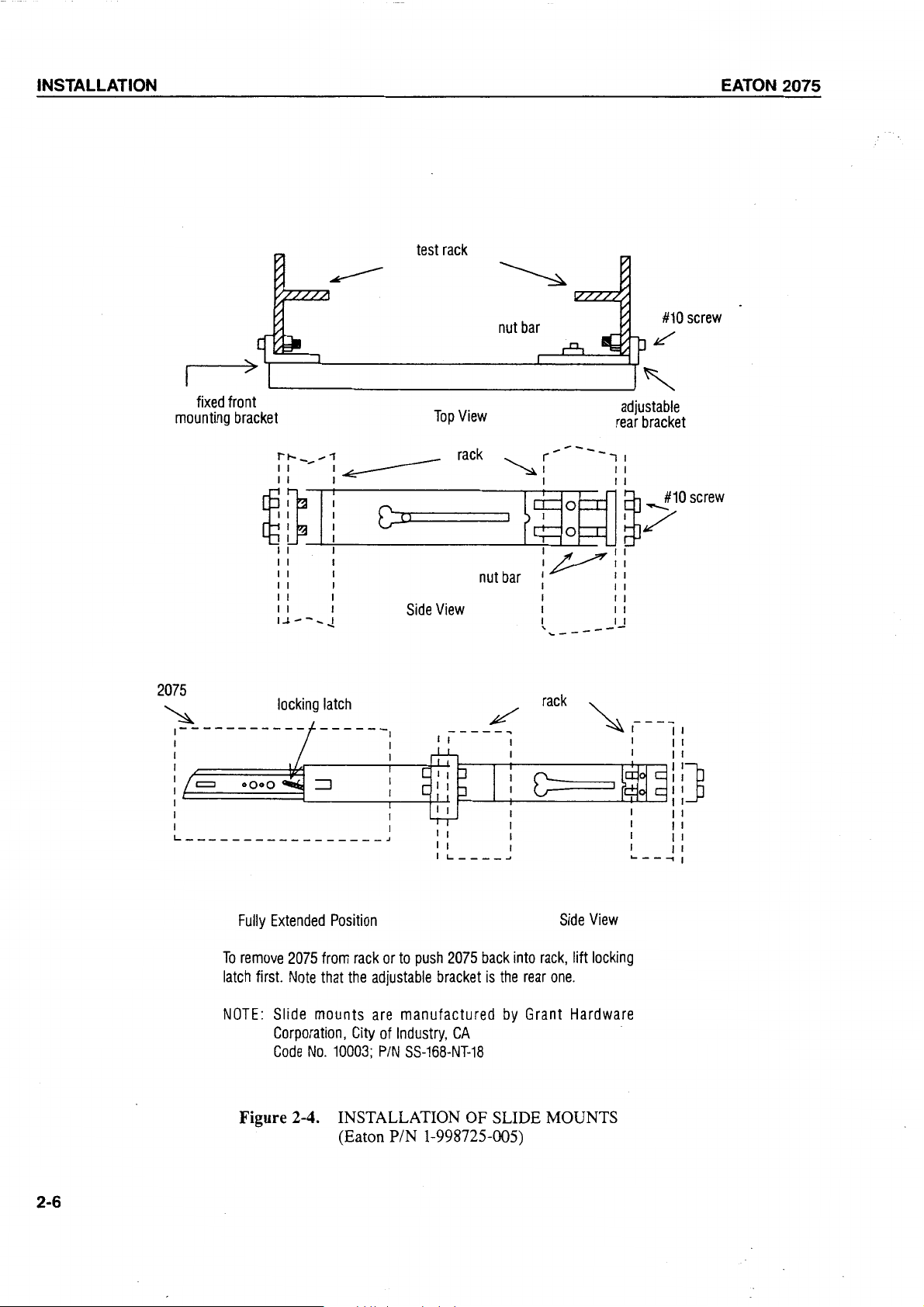

2-8. RACK-MOUNTING THE 2075

Refer to Figure 2-3 to attach the rack mount brackets

to the 2075. Refer to Figure 2-4 for installation

2075

on

slide mounts in a standard equipment rack.

Mount

when the 2075 is

Kit option must be

is

shipped with the

originally

of

the

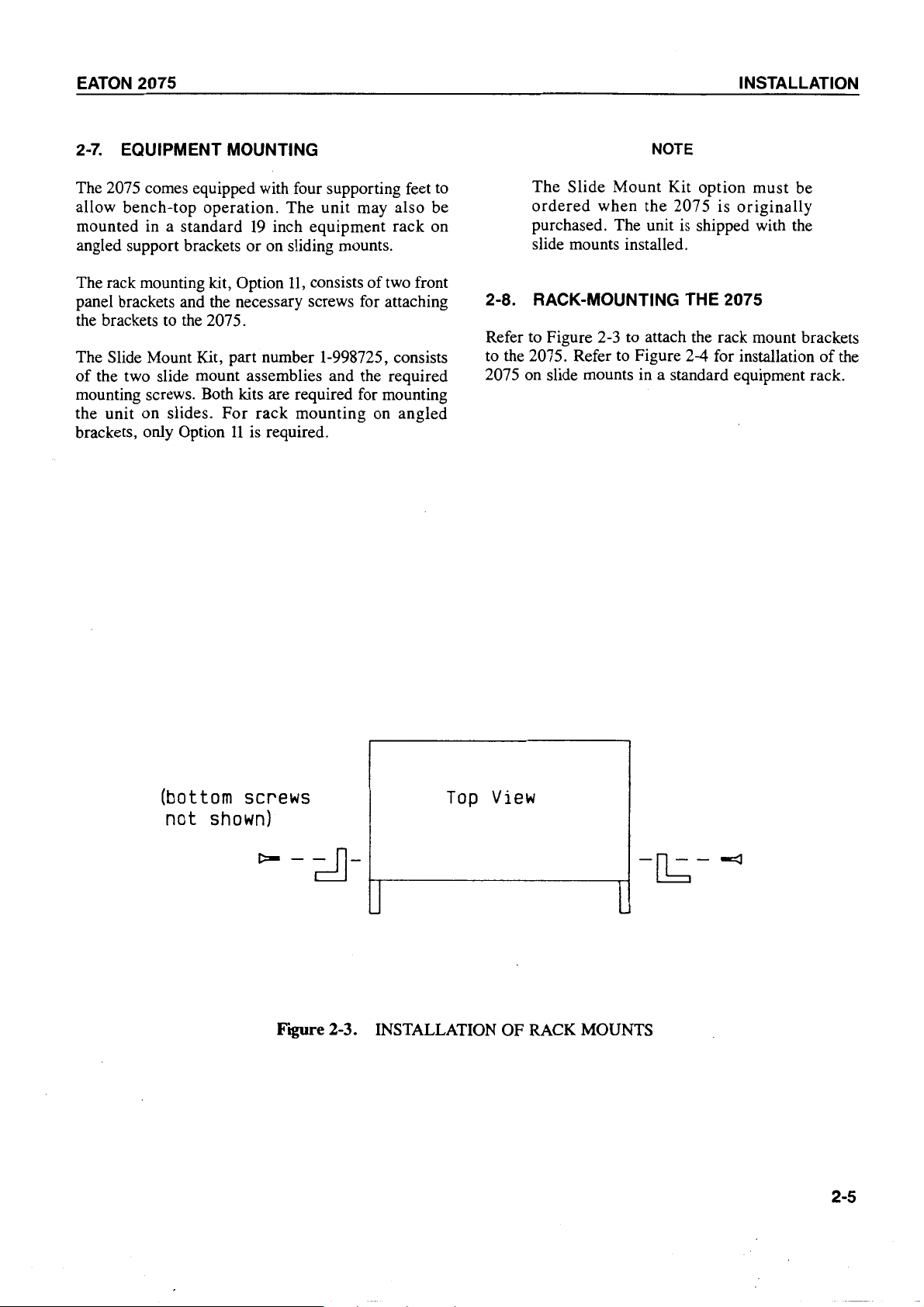

(bot

not

tarn

shown)

screws

- 2]-

Figure 2-3. INSTALLATION

i----------1

Top

View

OF

RACK MOUNTS

2-5

INSTALLATION

fixed

mounting

front

bracket

test

rack

Top

View

nut

bar

#10

/

adjustable

rear

bracket

screw

EATON

2075

fi---;

II

~

~----=-----1

II

1 1 1 1 1 1

i i i

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1

l.J---..!

~

1 1 1 1

j

_G:x...____i_

1

Side

rack

~

(----;:

~_'

View

nut

"'"---'---'---f

~~~

1~11

bar

i i i

1 1 1

t __

IJ

~~o

screw

"----

rack

2-6

Fully

Extended

To

remove

latch

first.

NOTE:

Slide

Corporation,

Code

Figure 2-4. INSTALLATION OF

2075

Note

No.

Position

from

rack

or

to

push

that

the

adjustable

mounts

are

City

of

10003;

P/N

(Eaton PIN 1-998725-005)

bracket

manufactured

lndustry,

SS-168-NT-18

2075

CA

back

is

the

by

SUDE

into

rear

Grant

rack,

Side

View

lift

locking

one.

Hardware

MOUNTS

EATON

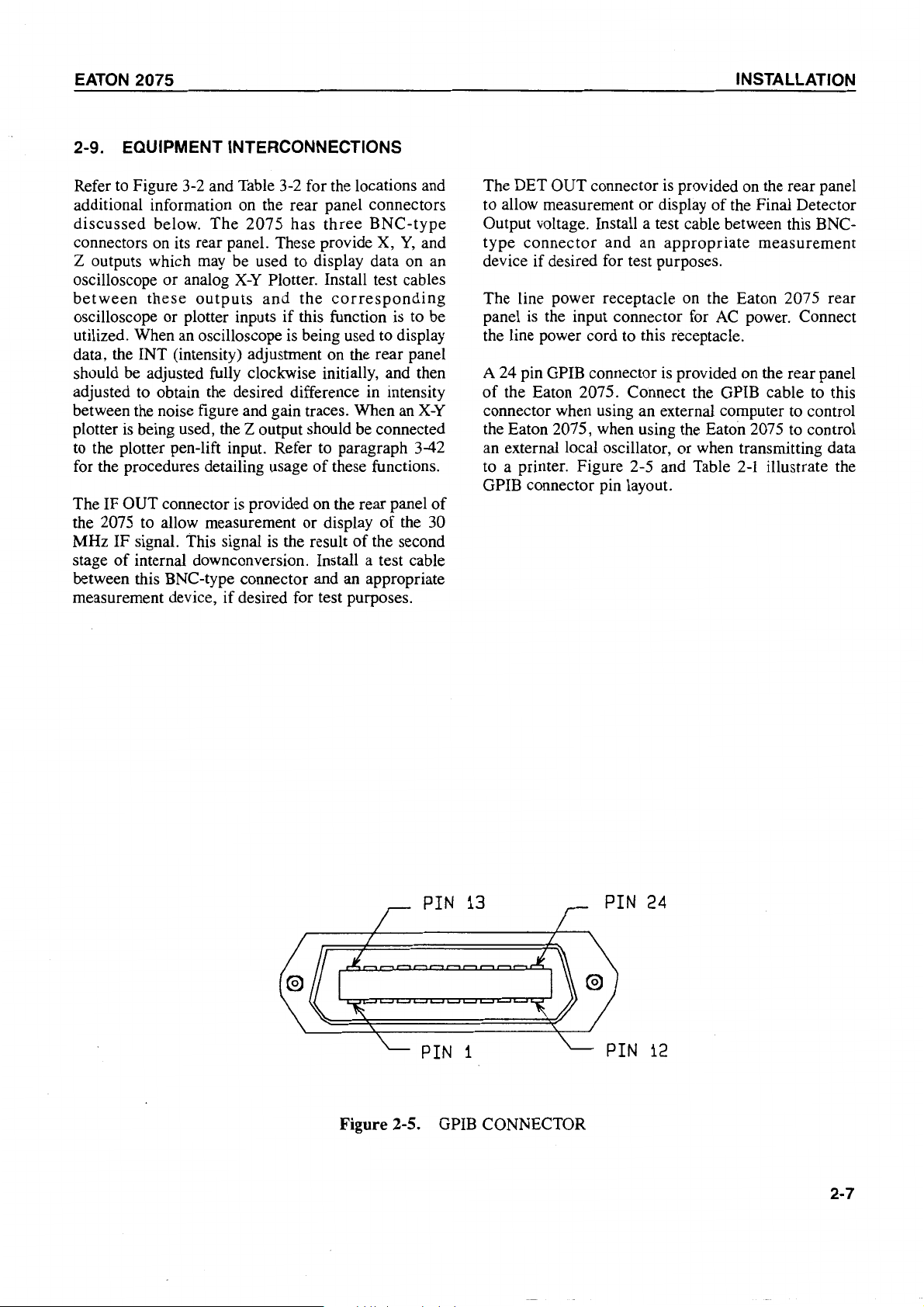

2-9. EQUIPMENT INTERCONNECTIONS

Refer

additional information on the rear panel connectors

discussed

connectors

Z outputs which may be used to display data on

oscilloscope or analog

between

oscilloscope or plotter inputs

utilized. When an oscilloscope is being used to display

data, the !NT (intensity) adjustment on the rear panel

should be adjusted fully clockwise initially, and then

adjusted to obtain the desired difference in intensity

between the noise figure and gain traces. When an

plotter

to the plotter pen-lift input. Refer to paragraph 3-42

for the procedures detailing usage

The IF OUT connector is provided on the rear panel

the 2075 to allow measurement or display

MHz IF signal. This signal is the result of the second

stage

between this BNC-type connector and an appropriate

measurement device,

2075

to

Figure 3-2 and Table 3-2 for the locations and

below. The 2075 has

on

its rear panel. These provide X,

X-Y

Plotter. Install test cables

these

is

being used, the Z output should be connected

of

internal downconversion. Install a test cable

outputs

and

if

desired for test purposes.

three

the

corresponding

if

this function

of

these functions.

BNC-type

is

of

Y,

and

an

to be

X-Y

of

the 30

INSTALLATION

The DET OUT connector

to allow measurement or display

Output voltage. Install a test cable between this BNCtype connector and an appropriate measurement

device if desired for test purposes.

The line power receptacle on the Eaton 2075 rear

is

panel

the line power cord to this receptacle.

A 24 pin GPIB connector

of

connector when using an external computer to control

the Eaton 2075, when using the Eaton 2075 to control

an external local oscillator, or when transmitting data

to a printer. Figure 2-5 and Table

GPIB connector pin layout.

the input connector for

the Eaton 2075. Connect the GPIB cable to this

is

provided on the rear panel

of

the Final Detector

AC

power. Connect

is

provided on the rear panel

2-1

illustrate the

PIN

13

PIN

1

Figure 2-5. GPIB CONNECTOR

PIN

PIN

24

12

2-7

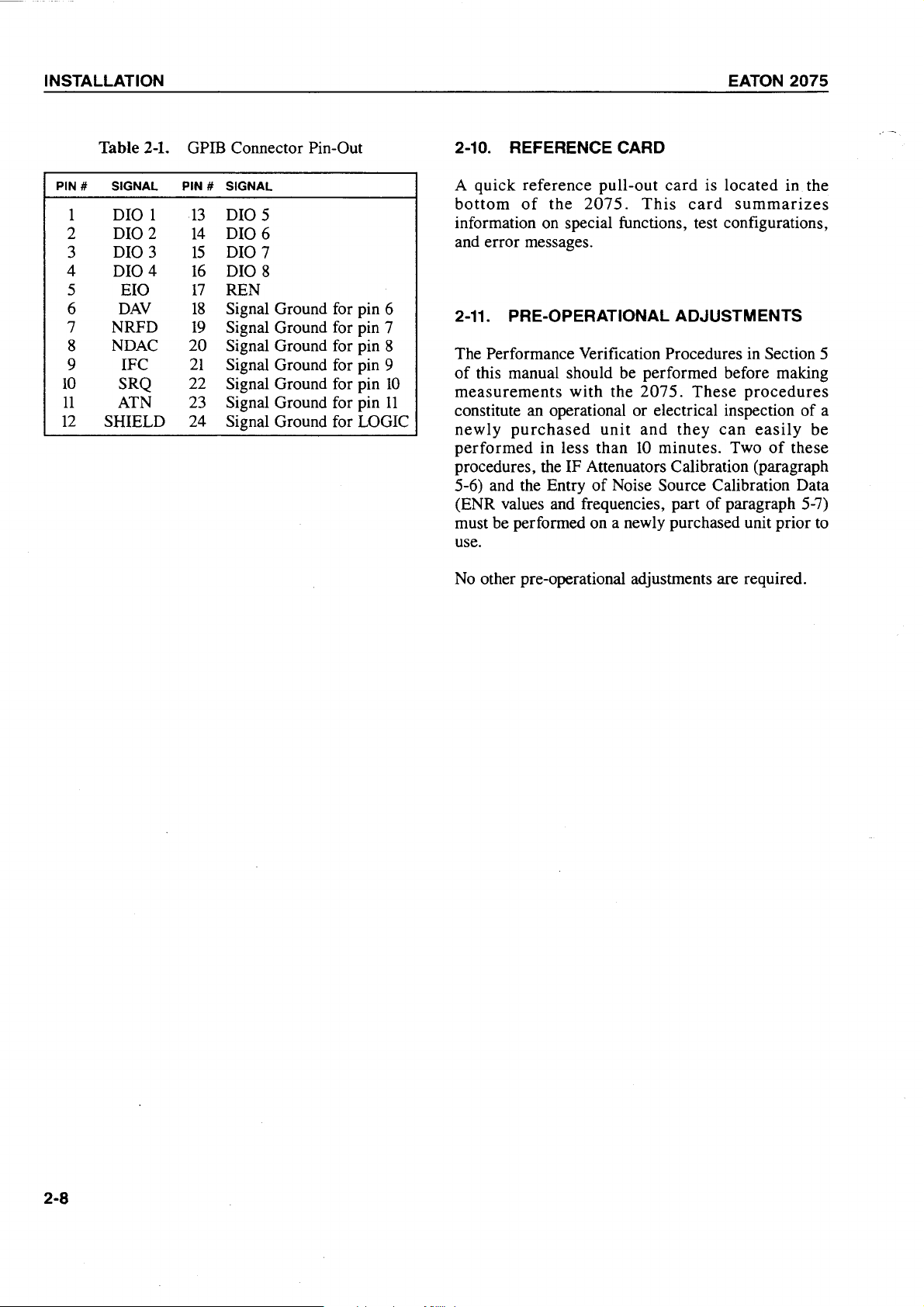

INSTALLATION

Table

2-1.

GPIB Connector Pin-Out

2-10. REFERENCE CARD

EATON

2075

PIN # SIGNAL

1 DIO 1

DI02

2

3 DIO 3

0104

4

5

6

EIO

DAV

7 NRFD

NDAC

8

9 IFC

10

11

12

SRQ 22

ATN 23 Signal Ground for pin

SHIELD

PIN

# SIGNAL

DIO 5

13

14

DI06

15

DIO 7

16

DIO 8

17

REN

18

Signal Ground for pin 6

19

Signal Ground for pin 7

20

Signal Ground for pin 8

21

Signal Ground for pin 9

Signal Ground for pin

10

11

24 Signal Ground for LOGIC

A quick reference pull-out

bottom

of

the

2075.

card

This

is located in the

card

summarizes

information on special functions, test configurations,

and error messages.

2-11.

PRE-OPERATIONAL ADJUSTMENTS

The Performance Verification Procedures in Section 5

of

this manual should be performed before making

measurements

with the

207

5.

These

procedures

constitute an operational or electrical inspection of a

newly

performed

procedures, the IF Attenuators

5-6) and the Entry

(ENR values and frequencies, part of paragraph

purchased

in less than

unit

and

they

can

easily

10

minutes. Two

Calibrati~n

of

Noise Source Cahbrat1on Data

of

(p~agraph

be

these

5-7)

must be performed on a newly purchased unit prior to

use.

No other pre-operational adjustments are required.

2-8

EATON

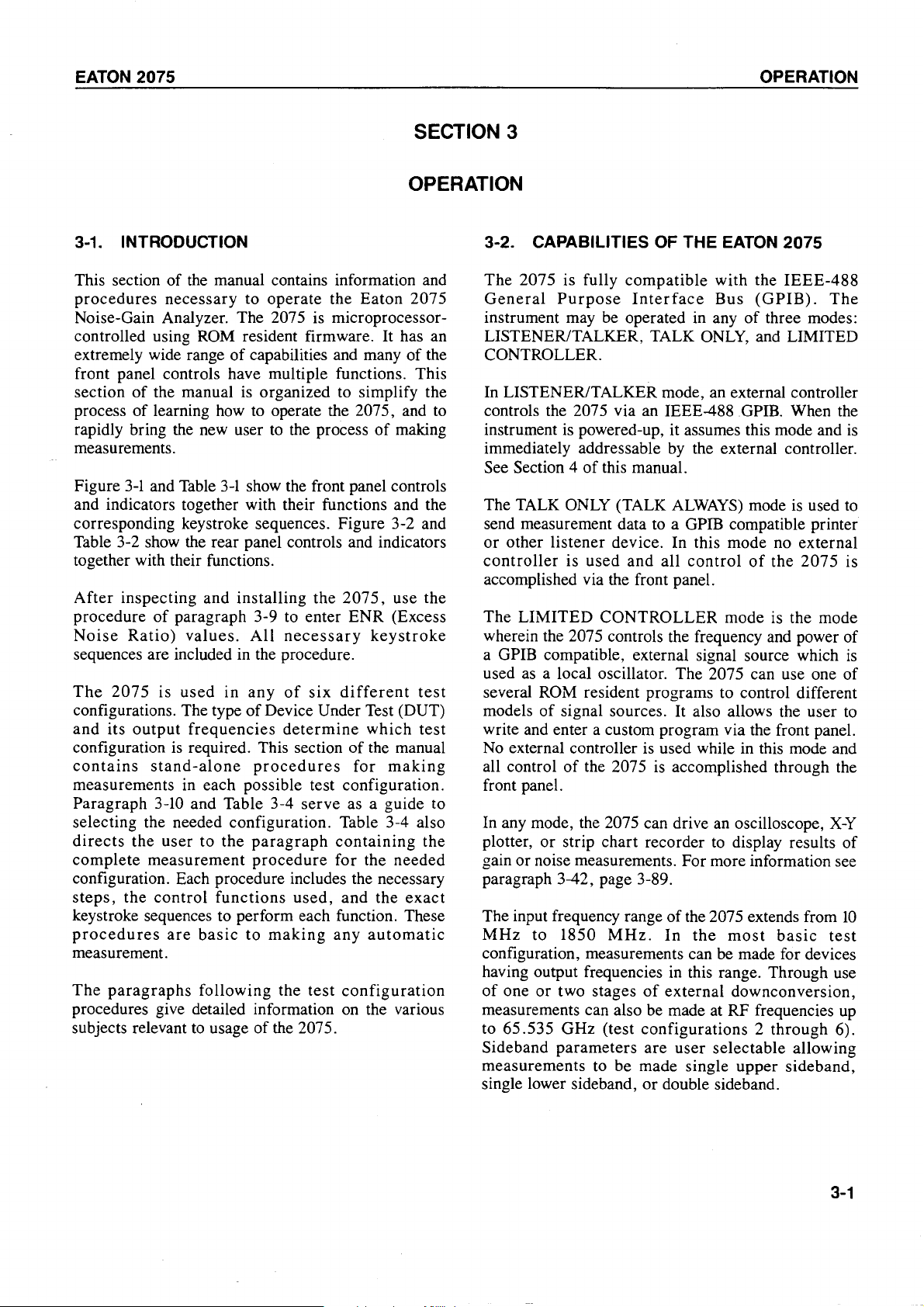

3-1.

2075 OPERATION

INTRODUCTION

SECTION 3

OPERATION

3-2. CAPABILITIES OF THE

EATON

2075

This section

procedures

Noise-Gain Analyzer. The 2075 is microprocessorcontrolled using

extremely wide range

front panel controls have multiple functions. This

section

process

rapidly bring the new user to the process

measurements.

Figure

and indicators together with their functions and the

corresponding keystroke sequences. Figure 3-2 and

Table 3-2 show the rear panel controls and indicators

together with their functions.

After

procedure

Noise

sequences are included in the procedure.

The

2075

configurations. The type

and

its

configuration

contains

measurements in each possible test configuration.

Paragraph

selecting the needed configuration. Table 3-4 also

directs

complete measurement

configuration. Each procedure includes the necessary

steps,

keystroke sequences to perform each function. These

procedures

measurement.

The

paragraphs

procedures give detailed information on the various

subjects relevant to usage

of

the manual contains information and

necessary to operate the Eaton 2075

ROM

resident firmware.

of

capabilities and many

of

the manual is organized to simplify the

of

learning how to operate the 2075, and to

3-1

and Table

inspecting and installing the

of

Ratio)

is used in any

output

is

stand-alone

3-10

the

user

the

control

are

3-1

show the front panel controls

2075,

paragraph 3-9 to enter ENR (Excess

values.

frequencies

required. This section

and Table 3-4 serve as a guide to

to the

basic

following the

All

of

Device Under Test (DUT)

procedures

paragraph

procedure

functions

to

making

of

the 2075.

necessary

of

six

different

determine

of

containing

for the needed

used,

and

any

test

configuration

keystroke

which

the manual

for

automatic

lt

has an

of

of

making

use the

making

the

exact

the

test

test

the

The 2075 is fully compatible with the

General

instrument may be operated in any

LISTENER/TALKER, TALK

CONTROLLER.

In LISTENER/TALKER mode, an external controller

controls the 2075 via an IEEE-488 GPIB. When the

instrument is powered-up, it assumes this mode and

immediately addressable by the external controller.

See Section 4

The TALK ONLY (TALK

send measurement data to a GPIB compatible printer

or

other listener device. In this mode no external

controller

accomplished via the front panel.

The LIMITED CONTROLLER mode is the mode

wherein the 2075 controls the frequency and power

a GPIB compatible, external signal source which

used

several ROM resident programs to control different

models

write and enter a custom program via the front panel.

No

external controller

all control

front panel.

In any mode, the 2075 can drive an oscilloscope,

plotter, or strip chart recorder to display results

gain or noise measurements. For more information see

paragraph 3-42, page 3-89.

The input frequency range

MHz

configuration, measurements can be made for devices

having output frequencies in this range. Through use

of

one

measurements can also be made at RF frequencies

to 65.535 GHz (test configurations 2 through 6).

Sideband parameters are

measurements to be made single upper sideband,

single lower sideband,

Purpose

of

is used

as

a local oscillator. The 207 5 can use one

of

signal sources.

of

the 2075

to 1850

or

two stages

Interface

this manual.

ALWAYS)

and

all

lt

is

used while in this mode and

is

accomplished through the

of

MHz.

In

of

external downconversion,

user

or

double sideband.

Bus

ONLY,

control

also allows the user

the 2075 extends from

the

most

selectable allowing

IEEE-488

(GPIB).

of

three modes:

and LIMITED

mode is used to

of

the

basic

The

2075

X-Y

test

up

is

is

of

is

of

to

of

10

3-1

OPERATION

The

2075

can

make

FIXED

FREQUENCY

SWEPT FREQUENCY measurements.

or

EATON

2075

subtracted. A Second Stage Calibration must be

performed before making a corrected measurement.

FIXED

power-on, and it

are made at a single frequency. Before and

measurements,

FREQUENCY

is

the mode in which measurements

manual

is the default mode

frequency

increment/

after

after

decrement keys can be used to tune the frequency up

or down

paragraph 3-6, page

In

in

SWEPT

steps. The step size is user selectable. See

3-21.

FREQUENCY

mode,

START

FRE-

QUENCY, STOP FREQUENCY, and SWEPT FRE-

by

QUENCY STEP SIZE are entered

the user. The

maximum number of measurement points in this mode

is

equal to the frequency range width in MHz, divided

by

the maximum frequency resolution. For example,

if

the measurement range extends from

MHz,

1850

dividing

of

.1

MHz, gives 18,400 measurement points. See

paragraph

Swept frequency mode is selected

1840

3-7,

giving a

by

range

width

the maximum frequency resolution

page 3-22.

by

10

MHz to

of

1840

MHz,

initiating either a

SINGLE SWEEP or CONTINUOUS AUTOMATIC

SWEEPS.

SECOND STAGE CALIBRATION is the procedure

of

wherein the 2075 measures the noise figure

the

entire measurement system, excluding the Device

Under Test (DUT). The calibration data obtained is

by

used

Stage) measurements

STAGE CALIBRATION the 2075 can store up to

the instrument when making corrected (First

of

the DUT. During SECOND

100

calibration points. The number of calibration points

and

their

measurement frequency parameters entered

frequencies

are

determined

by

by

the

the

user. Seeparagraph 3-34, page 3-75.

The

2075

measurements

can

make

or

corrected

uncorrected

(first

(cascade)

stage)

mea-

surements. A cascade measurement gives a single

of

value which includes the noise

Test (the first stage) combined with the noise

measurement system (the second stage).

is

Stage Calibration

necessary before making cascade

the Device Under

of

the

No

Second

measurements.

A corrected, or first stage measurement, is essentially

cascade

a

contribution

measurement

of

the measurement system has been

from

which

the

noise

After

measurement mode

power-up,

the

2075

by

default. Performing the Second

is in

the

cascade

Stage Calibration automatically places the instrument

into the corrected measurement mode.

of

Three ENR tables allow the storage

up

ENR values for

to 3 different noise sources. Each

table can store the ENR data for up to

Frequency/

31

frequencies.

A fourth table stores a single ENR value which can be

used for all frequencies. A fifth table can be provided

by

an

optional PROM chip which contains frequency

ENR

and

values for a specific noise source. See

paragraph 3-9, page 3-26, and paragraph 3-30, page

3-71.

The

2075

can

make

the

following

automatic

measurements:

Noise Figure

(F)

(Cascade only)

Noise Figure and

Gain (or Loss)

(F+G)

(Corrected only)

Eff ective Input Noise

Temperature

(Te)

(Cascade or

corrected)

Y-Factor

(Y)

(Cascade only)

Operating Noise

Temperature

(Top)

(Cascade or

corrected)

Power

(dB)

(Cascade or

corrected)*

Excess Noise Ratio

(ENR)

(Cascade or

corrected)*

Noise Measure

*Cascade

measurements

are

(M)

not

(Corrected only)

recommended

for

these.

The following measurements can be made manually:

Corrected Noise

Figure and Gain

+G)

(or Loss) (F

See Paragraph 3-27,

page 3-67.

Cascade Noise Figure (F) See Paragraph 3-27,

3-67.

page

Y-Factor (Y) See Paragraph 3-28,

page 3-69.

3-2

EATON

2075

OPERATION

The 2075 can store its front panel control parameters

of

for later retrieval and reuse. Nine sets

parameters can be stored and then sequentially

control

or

randomly retrieved. The retrieval sequence is user

programmable. Seeparagraph 3-48, page

A number

subordinate

of

special functions, each with multiple

functions,

extend

the

instrument's available features beyond those

3-110.

range

of

of

the

the

dedicated front panel controls. See paragraph 3-46,

page

3-101.

The 2075 displays error messages in the event

procedural

page

Loss

2075 compensates for known losses

or

hardware error. See paragraph 3-4

3-106.

or

gain compensation

is

available wherein the

or

of

7,

gains that

cannot be included in Second Stage Calibration. See

paragraph 3-40, page 3-86.

Laboratory

accuracy

compensation

temperature

ambient

of

noise measurements. The 2075 allows

of

the noise source and thereby increases

temperatures

for

variations

can

in the

affect

cold

or

the

off

measurement accuracy. See Tcold Compensation,

paragraph

The

measurement

3-41,

bandwidth

system,

page 3-88.

of

the

can

DUT,

be a

relative

factor

to

the

affecting

measurement accuracy. The 2075 provides a method

of

compensating for bandwidth differences when the

of

bandwidth

bandwidth

the DUT is less than the measurement

of

the 2075. See Bandwidth Compensation,

Paragraph 3-38, page 3-82.

3-3. CONTROLS AND INDICATORS

The controls and indicators, and their functions, are

listed

in

Table

3-1.

Because the 2075 offers such a wide range

functions, a single key may initiate two

functions. The primary function

indicated

by

the

key

example, the key START

display

measurement.

initiated by pressing that key once.

a

or

entry

of

The

label

FREQ

the start frequency for a swept

primary

of

such a key is

or

designation.

is used to allow

function