Eaton 145406, 145407, Airflex qrv 9100, 146506, 145141 Installation, Operation And Maintenance Manual

QRV 9100

Installation, Operation

and Maintenance of

Forward this manual to the person responsible

for Installation, Operation and Maintenance of

the product described herein. Without access to

this information, faulty Installation, Operation or

Maintenance may result in personal injury or

equipment damage.

Airflex

Quick Release

Valve

Note: This manual pertains to the AIRFLEX

DIAPHRAGM OPERATED QUICK RELEASE

VAVLE which is identified by its silver housing. If

your valve housing is anodized green, service it

according to manual QRV 9090 or replace the entire

valve with the diaphragm style.

®

Use Only Genuine Airflex® Replacement Parts.

The Airfiex Division of Eaton Corporation recommends

the use of genuine Airfiex replacement parts. The use of

non-genuine Airflex replacement parts could result in

substandard product performance, and may void your

Eaton warranty. For optimum performance, contact

Airflex:

In the U.S.A. and Canada:(800) 233-5926

Outside the U.S.A. & Canada: (216) 281-2211

Internet: www.airflex.com

October, 1987

(Revised : November, 2006)

203977

©Copyright Eaton Corp., 2006. All rights reserved.

AIRFLEX® QUICK RELEASE VALVE

Figure 1 : Quick Release Valve

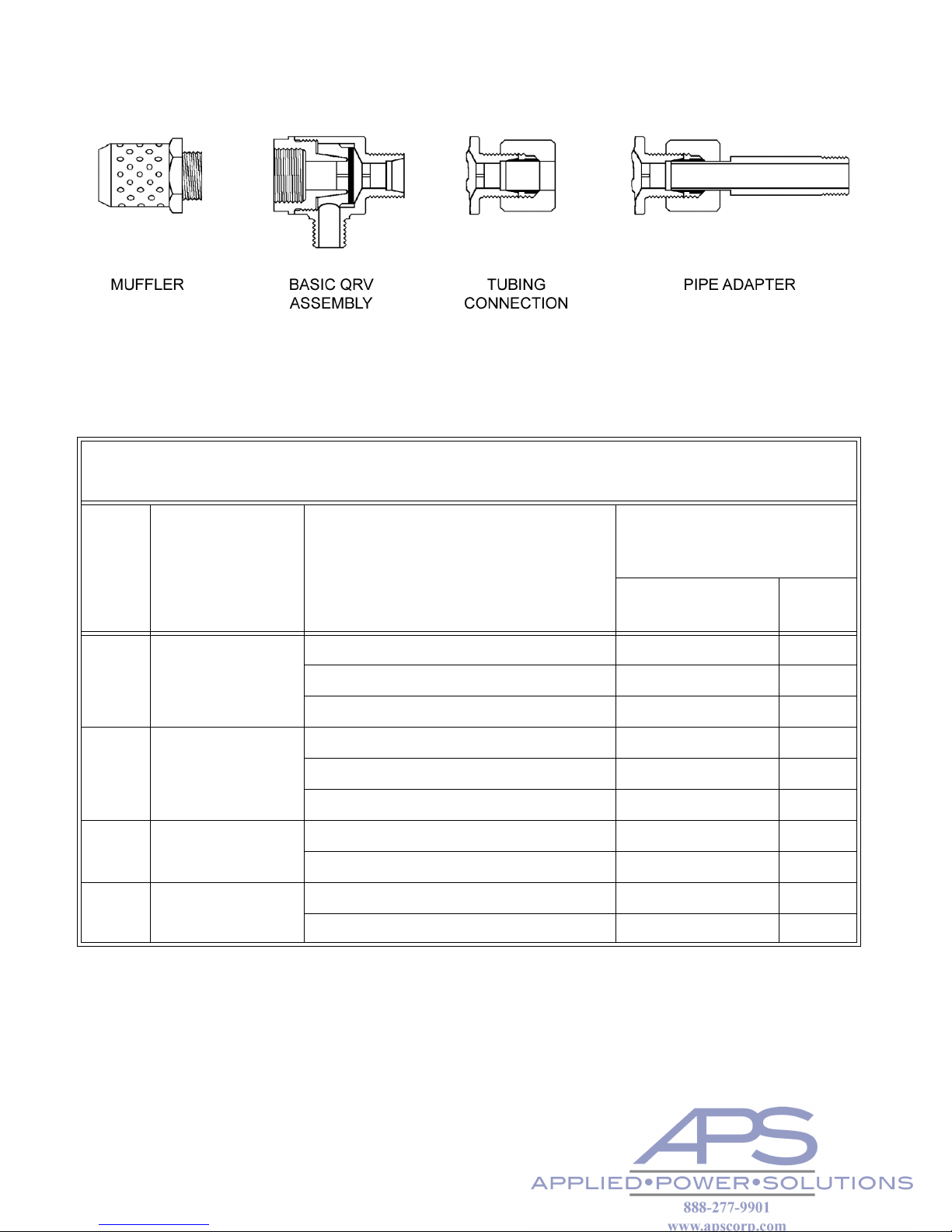

TABLE 1:

QRV MODEL and KIT NUMBERS

QRV

SIZE

BASIC QRV

MODEL and KIT

NUMBER

3/8 145406

1/2 145407

3/4 145141

1” 146506

QRV OPTIONS and KITS

OPTION and KIT

DESIGNATION***

3/8", 1/2" and 3/4" Size 1"

w/Metal Sleeve DE BD

w/Rubber Sleeve DF

w/Inlet Pipe Thread DG

w/Metal Sleeve & Muffler** DS BE

w/Rubber Sleeve & Muffler** DR

w/Inlet Pipe Thread & Muffler** DT

w/Metal Sleeve & Pipe Adapter DL BR

w/Metal Sleeve & 1/4 Pipe Adapter* DM

Diaphragm & End Cap Kit DP DP

Diaphragm, Muffler & End Cap Kit DQ DQ

1/4 NPT adapter for 3/8 QRV only.

*

** Mufflers are not factory-assembled to QRV. See Installation section.

***

The option and kit designation letters must be added as a suffix to the basic model number to completely

identify the QRV model or kit. Diaphragm and end cap kit contains a diaphragm, end cap and sealant. Diaphragm, muffler and end cap kit contains diaphragm, end cap, muffler and sealant.

QRV 9100 (PDF FORMAT) 1

1.0 INTRODUCTION

1.1 Description

Throughout this manual there are a number of

HAZARD WARNINGS that must be read and

adhered to in order to prevent possible personal

injury and/or damage to equipment. Three signal words “DANGER”, “WARNING” and

“CAUTION” are used to indicate the severity of

a hazard, and are preceded by the safety alert

symbol

Denotes the most serious hazard, and is

used when serious injury or death WILL

result from misuse or failure to follow specific instructions.

Used when serious injury or death MAY

result from misuse or failure to follow specific instructions.

The Airflex® QRV is a quick release valve that

facilitates the release of air from a pressurized

chamber i.e., air cylinders, clutches, brakes or

other pneumatic devices. In essence it provides

an exhaust port at the chamber rather than

exhausting through long supply lines and control components. The function they perform is

especially important in high speed cycling

equipment. They prevent sluggish operation,

overlap and excessive wear. Their importance

in an air control system cannot be overemphasized.

QRV’s are available in four sizes for direct connection to 3/8, 1/2, 3/4 and 1 inch pipe. Models

are also available which permit 1/2, 5/8 and 3/4

inch outside diameter tubing connections to the

QRV inlet port.

Exhaust noise from the valve can be reduced

by using a muffler, which threads into the

tapped hole in the end cap.

1.2 How It Works

Used when injury or product/equipment

damage may result from misuse or failure to

follow specific instructions.

It is the responsibility and duty of all personnel

involved in the installation, operation and maintenance of the equipment on which this device

is used to fully understand the:

procedures by which hazards can be avoided.

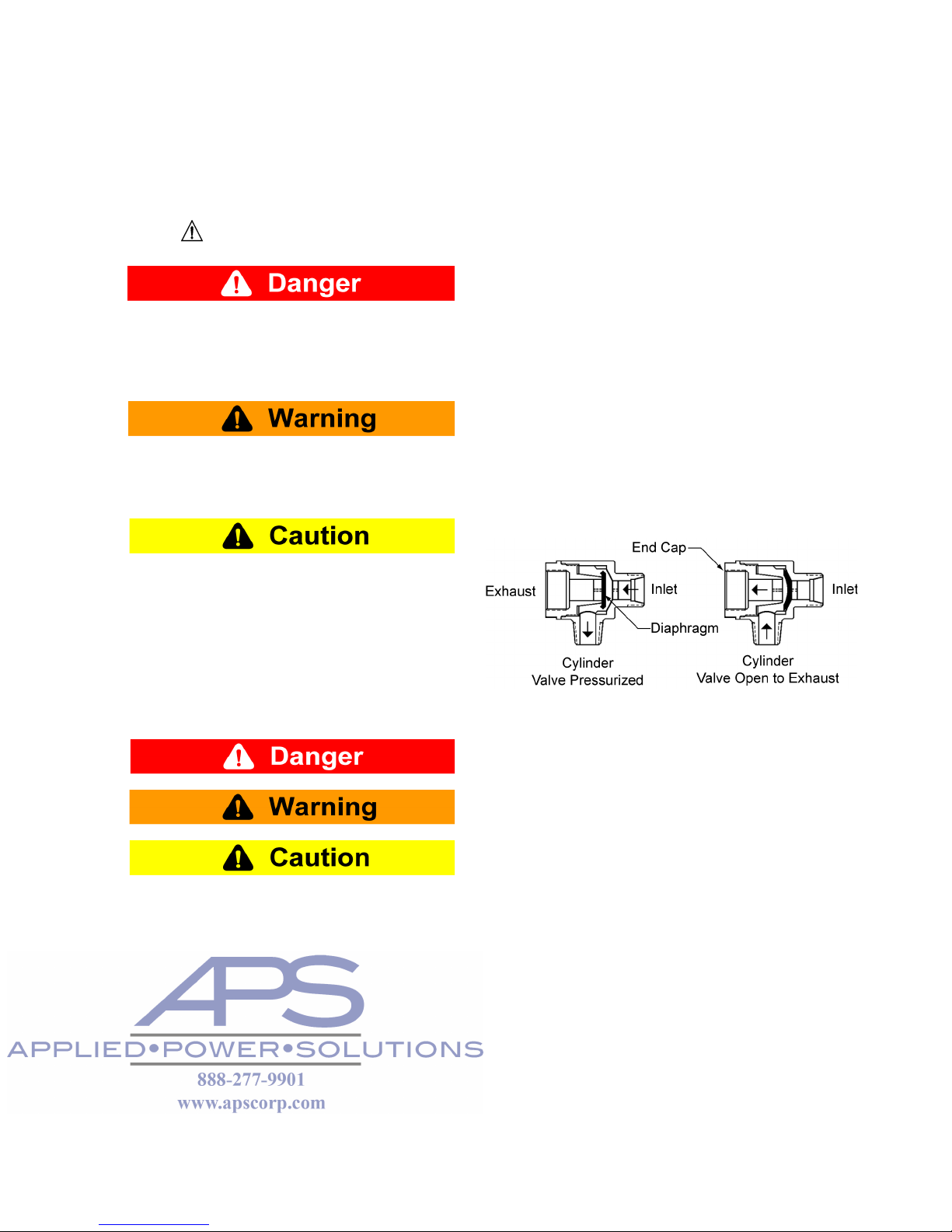

Figure 2

The Airflex QRV contains a diaphragm

designed to function on a pressure differential.

Air pressure at the valve inlet seats the diaphragm on the end cap, closing the exhaust

port. Applied pressure, acting on the outer

unsupported diaphragm area, deflects it and

allows air to flow to the cylinder port. See Fig-

ure 2.

When a pressure drop occurs in the air supply,

the pressure differential lifts the diaphragm from

the exhaust port and seats it on the inlet port.

Air from the pressurized device can now flow

freely to atmosphere through the valve’s

exhaust port.

If the cylinder pressure falls below the inlet

pressure, the pressure differential on the diaphragm will close the exhaust port, preventing

further exhaust.

QRV 9100 (PDF FORMAT) 2 © Copyright Eaton Corp. 2006, All Rights reserved.

Loading...

Loading...