Eaton 10250T/91000T, E34 Installation Instructions And Operation Manual

Effective February 2018

Supersedes July 2011

Instructions and Operation P20442

Heavy Duty Oiltight Selector Switch

Units - 10250T/91000T or E34

®

Underwriters Laboratories Listed

For use on a flat surface of Type

1, 2, 3, 3R, 4, 4X, 12 and 13

enclosures. IP 65

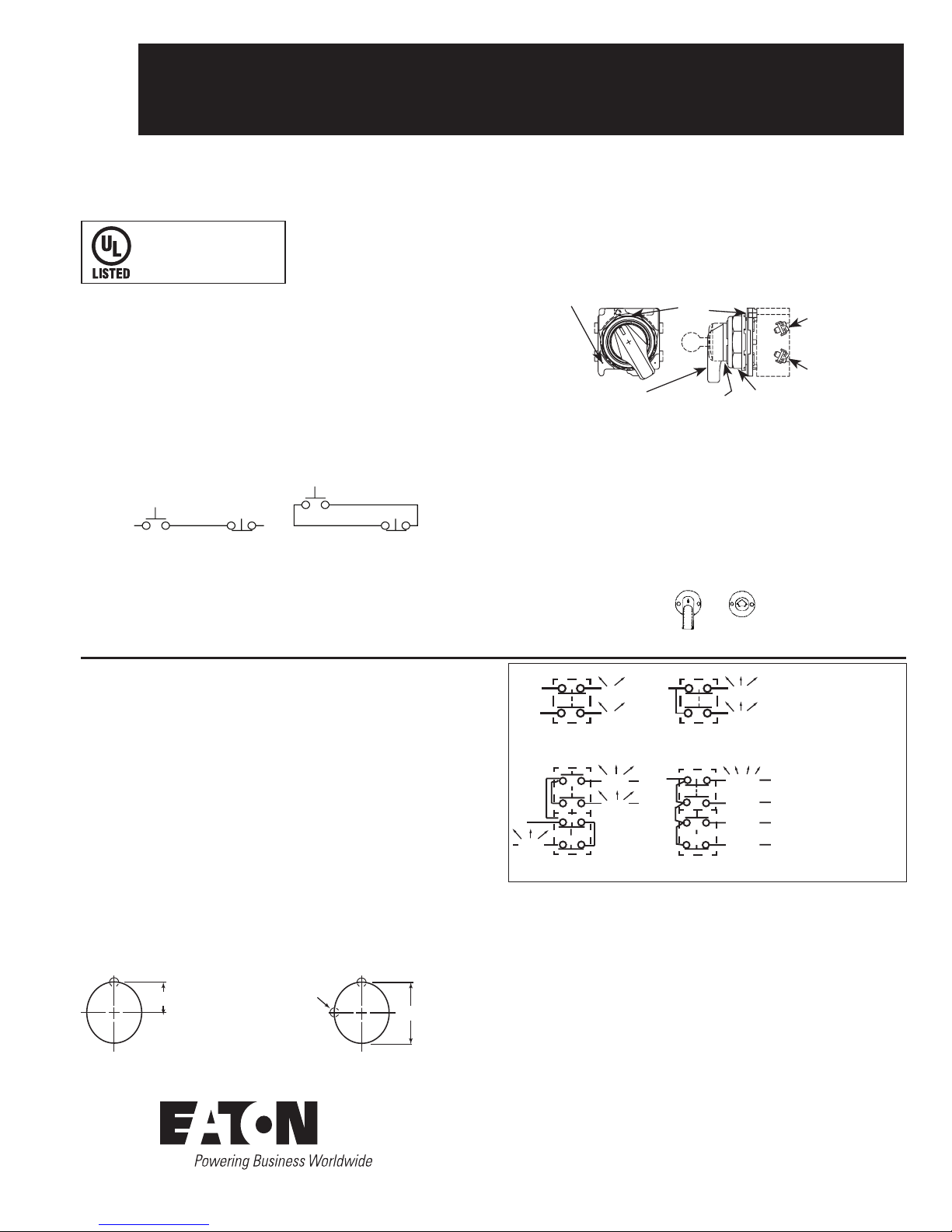

ASSEMBLY INSTRUCTIONS

1. Select the desired schematic circuit function from the chart below and

note in your cam column the type of contacts, N.O. or N.C., the “A” and

“B” circuit locations, and any series or parallel jumper connections the may

be required.

2. Choose contact blocks that have the required schematic circuits and

assemble in any convenient sequence that fullls the “A” and “B” circuit

location requirements.

NOTE: Single circuit contact blocks, if used, must be last in the stack and

positioned so that the plunger motion is transmitted through.

3. Make the indicated series or parallel jumper connections.

(10250T/91000TA70,TA71).

4. If this operator was received without an operating cap, assemble the

separately purchased cap, assemble the separately purchased cap and secure

with the screws provided.

NOTES: Single, double and 2NO-2NC contact blocks are available. Six contacts

can be stacked in each of the two circuit locations making a maximum of

twelve circuits possible.

For additional selector switch explanation ask for manual NU-118.

The two sections of the operating cam of this selector switch work

independently, so it is important that the contact blocks be oriented with

their plungers in the correct “A” and “B” circuit locations. The sketch below

identies these positions with respect to the locatin nib or marked top.

Sketch shows VERTICAL MOUNTING. For HORIZONTAL MOUNTING

loosen the set screw and assemble so that the locating nib is at the left.

ILLUMINATED GASKET INSTRUCTIONS This operator was shipped with

the gasket oriented for VERTICAL MOUNTING using lever lens and the

new type knob lens.

For HORIZONTAL MOUNTING (or VERTICAL MOUNTING using the old

type knob) carefully peel the lens gasket, rotate it 90°, and press onto the

operator. (Lens screws will now thread into alternate holes).

LAMB REMOVAL TOOL For Trans. Type Cat. No. 10250TA74 for Full Voltage

Type E30KV1.

1. Drill mounting hole for vertical or horizontal mounting per one of the gures

above.

2. ensure sealing gasket is in the place on the operator. Align location nib

of the operator with notch in the panel and insert operator through mounting hole.

3. Place legend plate and mounting nut over operator. Tighten mounting

nut. If applicable assemble buttons to operator. Tighten securely (5 ft-lbs)

(6.8 Nm).

4. Torque terminals to 12 in/lbs (1.4 Nm).

For ease of assembly, we recommend the following tools:

91000T/10250TA95 (for 10250T/91000T octagonal nut, E29 and E30 line)

E22CW (for 10250T/91000T octagonal nuts, E22, E30 and E34)

5. Torque contact block stacking screws to 5-7 in/lbs (0.57- 0.79 Nm)

The selector switch operator in this package may not be complete. A knob,

lever, coin slot or knob type lens operating cap is required wich may be

merchandised and packaged separately.

WIRING INSTRUCTIONS

The illustration shows the circuit conditions that result for each position of

the selector switch.

Heavy lines indicates

costumers connections.

Light lines are factory

installed jumpers

X=circuit closed

O=circuit open

L=Left

C=Center

R=Right

1-2-3-4=4 position switch

ASSEMBLY INSTRUCTIONS

US 60/75°C COPPER CONDUCTORS ONLY

LIGHT MODULE OF CONTACT BLOCK

Vertical Mounting

Lever

New

Knob

For Replacement Gasket Order PT #32-803

Grounding nibs Locating nib

or top

Set screw

Use 1/16”

Allen Wrench

Circuit

“A”

Circuit

“B”

Retaining Nut

To be changed in Coin

Slot Assembly

Operating cab

Knob, Lever, Coin, Slot, Key or Knob

Type Lense

1A

1B

X O

O X

L R

10250T/91000T20

SERIES OR E34

1A

1B

X O O

L C R

COM

10250T/91000T21

SERIES OR E34

O O X

10250T/91000T22

SERIES OR E34

X O O

O O X

COM

L C R

O X O

10250T/91000T46

SERIES OR E34

O O O X

O O X O

O X O O

X O O O

COM

1 2 3 4

.60 (15.2 mm)

1.20 (30.5 mm)

.136 (3.5 mm) dia. hole or

.180 (4.6 mm) rectangular

notch

VERTICAL MOUNTING

HORIZONTAL MOUNTING

4 Position

Combination

No.

Desired Circuit

Operation

X Circuit Closed

O Circuit Open

Contact Blocks Required to

Accomplish Circuit Function

Combination

No.

Desired Circuit

Operation

X Circuit Closed

O Circuit Open

Contact Blocks Required to

Accomplish Circuit Function

Mounting Location Mounting Location

Top Plunger A Bottom

Plunger B

Top Plunger A Bottom

Plunger B

1 X O O O

10 X O X O

2 O X O O

3 O O X O

11 X X X O

4 O O O X

5 X O O X

12 O X X X

6 O X X O

7 O O X X

13 X O X X

8 X X O O

9 O X O X 14 X X O X

3 Position

Combination

No.

Desired Circuit

Operation

X Circuit Closed

O Circuit Open

Contact Blocks Required to Accomplish Circuit Function

(Jumpers must be installed where indicated)

Operator with Cam Code #2 Operator with Cam Code #3

Mounting Location Mounting Location

Top Plunger A Bottom Plunger B Top Plunger A Bottom Plunger B

1 X O O

2 X X O

3 X O X

4 O O X

5 O X X

6 O X O

2 Position

Combination

No.

Desired Circuit

Operation

X Contacts

Closed

O Contacts

Open

Contact Blocks Required

to Accomplish Circuit

Function

Top PlungerABottom

Plunger

B

1 X O

2 O X

2

Instructions and Operation P20442

Effective February 2018

Heavy Duty Oiltight Selector Switch

SWITCH UNITS-10250T/91000T OR E34

EATON CORPORATION www.eaton.com

GENERAL

With any electrical component there is the possibility an external factor (loose wire, moisture, etc.) can cause a short circuit between the component and

ground. If the device is adequately grounded, the condition causes the protective fuse or circuit breaker to open and remove the potential. If not, an electrical

hazard may remain unnoticed.

GROUNDING NIBS – 10250T

This 10250T device is designed to make direct metallic contact to the rear of the panel (with no interfere with component-to-panel ground continuity). As

a further aid in establishing an electrical ground, the device has 4 metal points, “grounding nibs” designed to penetrate most paint or other protective coatings.

Penetration of these nibs is dependent upon the torque applied to the mounting nut. Recommended torque is 5 ft.lbs (6.8Nm). More or less may be necessary

to penetrate the specic type of thickness of your panel coating. Test for continuity to ground after installation. If a short circuit to ground does occur, the

fault should be corrected and the device replaced.

GROUNDING KITS

For grounding 10250T devices to non-metallic panels or metal panels having excessive surface coating or for grounding E34 with any panel we offer the

following grounding kits which provide for a separate grounding circuit, daisy chained between components and then to ground. Use 10250TKG1.

EARTH TERMINALS- 91000T/E34

These devices are supplied with an earth/ground terminal incorporated. These devices have a 6-32 terminal screw and will accommodate ring type terminations

for bonding to international specications.

Select cam code giving

simplest contact block

arrangement for circuit(s)

required.

-Ordinarily, these operators should not be used with overlap and early closing contact

blocks (10250T/91000T55, T56, T57 and T58). Contact local EATON sales ofce on

specic application.

CONTACT BLOCK SELECTION CHART

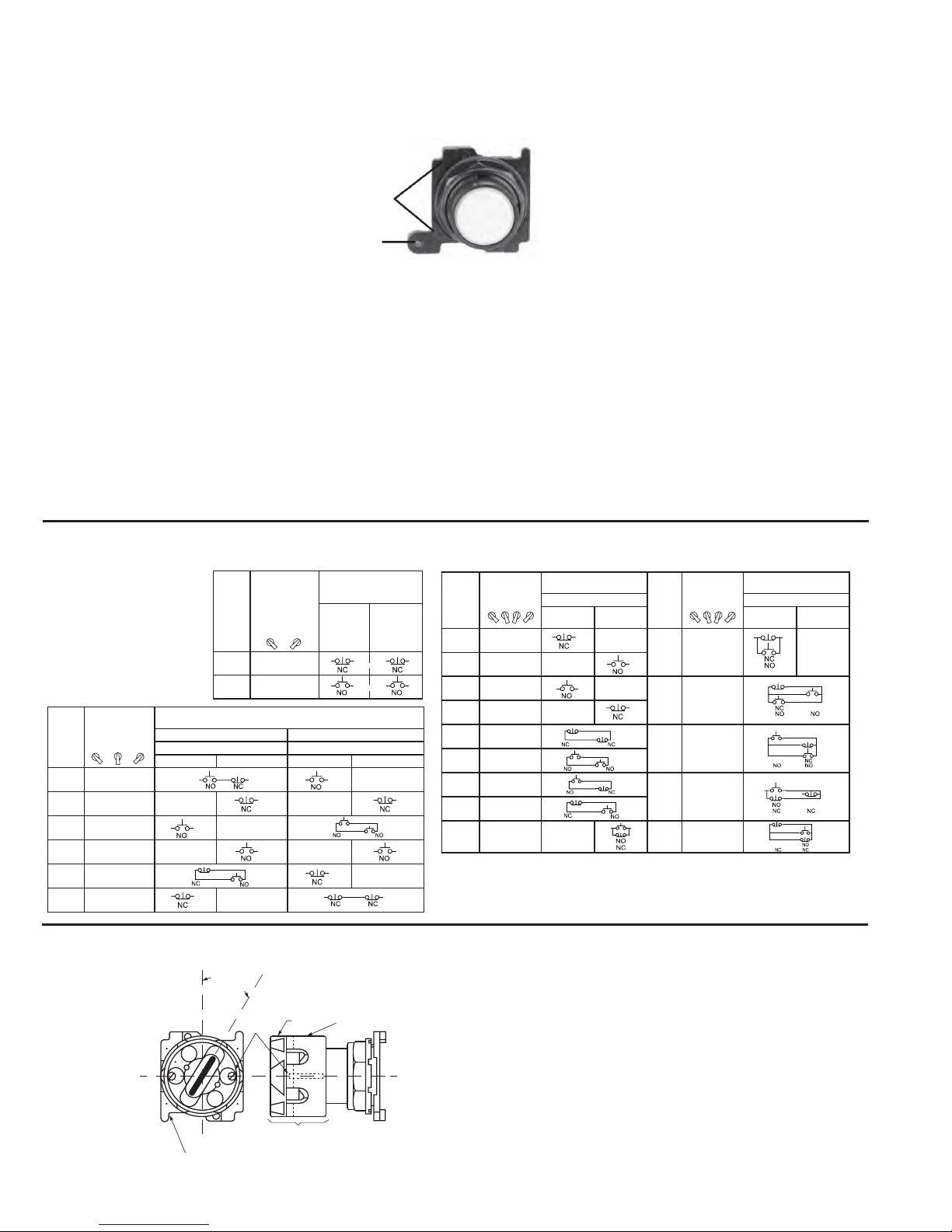

INSTRUCTIONS FOR THE ASSEMBLY OF THE PADLOCK ATTACHMENT E34TA11, 10250T/91000TA11

TO KNOB OPERATED HEAVY DUTY OIL TIGHT SELECTOR SWITCH OPERATORS

1. With the knob of the selector positioned per dimension “A”, place the

padlock attachment over the knob with the mounting screws located as

shown in the illustration.

2. Tighten the mounting screws alternately and uniformly to prevent the

attachment from being assembled skewed.

3. The outer lock ring can now be turned to any desired selector position.

there are provisions for 5 padlocks.

Dimension “A”- For 2 or 3 position selector switch operators. Locate the

knob half way between clockwise and center positions.

GROUNDING OF 10250T/91000T AND E34

COMPONENTS

Nib

Earth

Terminal

FOR HORIZONTAL MOUNTED UNITS THIS BASE IS TURNED 90 DEG.

HOWEVER, KNOB POSITION AND ASSEMBLY INSTRUCTIONS SHOWN

HERE APPLY

PADLOCK

ATTACHMENT

FOR ASSEMBLING SEE ITEM

2 INSTRUCTIONS

SELECTOR

KNOB

POSITION

DIM “A”

MOUNT-

ING

SCREWS

OUTER

LOCK RING

INTER LOCK

RING

OR

OR

OR

Loading...

Loading...