MANUAL

E710

English

05-0461 Revision 13

System version 11.0

CONTENT

INTRODUCTION 1

Service and calibration 3

Travelling with your measurement system 4

DISPLAY UNIT 5

Reset the Display unit 5

Navigation buttons 6

OK buttons 6

Function buttons 6

Status bar 7

Screen dump 8

LED lights 8

Battery 9

Note! 9

Charge the Display unit 9

A PC via USB cable 9

Dry cell batteries 9

Charge the Detector/Measuring units 9

Calculator 10

Measurement le handling 11

Save le 11

File manager 11

Favourites 12

Open le as template 13

Copy le to USB memory 13

Barcode 13

Print le (Optional) 14

Report 14

Download le to PC 14

Control panel 15

Filter 15

Unit and resolution 16

Detector rotation 16

Date and time 16

Language 17

User 17

Backlight 17

Automatic power off 18

VGA 18

System update 18

License 20

Bluetooth® set up 21

CHOOSE PROGRAM 23

Preparations 23

PROGRAM VALUES 25

Tolerance 26

Zoom 26

Halve or Zero set value 27

Live values – colours 27

Automatic recording 28

Precision level E290 (Optional equipment) 28

Streaming values 29

Calibration check 30

HORIZONTAL 31

Adjust measuring units 32

Select machines 33

Enter distances 34

Measure using Easy Turn™ 35

Measure using Multipoint 36

Quality assessment 37

Measure using 9-12-3 38

Result and adjust 39

Live values 40

Thermal compensation 42

RefLock™ 43

Tolerance 44

SOFTFOOT 47

MACHINE TRAIN 49

Build machine train 50

Enter distances 52

Measure using EasyTurn™ 53

Measure using Multipoint 54

Measure using 9-12-3 55

Result 56

Result Machine view 56

Result Table view 57

Result Graph view 58

Lock feet pair 59

Best t and Manual t 59

Uncertain coupling 59

Adjust 60

Tolerance 62

VERTICAL 63

Preparations 63

Measure 64

Result 65

Adjust machine 66

CARDAN 67

Mount the units 67

Cone laser beam 68

Rough alignment 69

Measure 69

Result 70

Adjustment 70

STRAIGHTNESS 71

Show target 72

Show reference target 72

Measure 73

Quickmode 74

Add and delete points 75

Result 76

Tolerance 79

Calculation settings 80

Reference points 80

Best t operations 82

Waviness 83

Straightness settings 84

FLATNESS 87

Preparation 87

Enter distances 87

Measure 89

Result table 90

Result grid 91

Result 3D 91

Calculation settings 92

Reference points 92

Best t 92

TWIST 93

Measure 93

Result 94

FLANGE FLATNESS 95

Preparations 95

Measure 97

Result 98

Reference points 100

Custom reference points 100

Three reference points 100

Best t 101

Taper result 103

Tolerance 104

FLANGE FLATNESS SECTION 109

Preparations 110

Measure 111

Rotate ange 111

PARALLELISM A 113

Prism set up 114

Precision level 115

Calibrate the precision level 115

Measure 116

Measure vertical value 117

Measure horizontal value 118

Adjust roll live 119

Detector angle 119

Result 120

PARALLELISM B 123

Preparations 124

Calibrate the precision level

Calibrate E2 detector 125

Laser setup 126

Measure 127

Measure vertical value 127

Measure horizontal value 128

Switch measurement direction 128

129

Result

Move laser 132

124

BTA 133

Measure using Display unit 135

Measure without Display unit 138

VIBROMETER 139

Measure 140

Vibration level 141

Bearing condition value 142

OFFSET AND ANGLE 143

BATTERY PACKS 145

TECHNICAL DATA 147

Display unit E51 148

Measuring units 149

BTA E180 (Optional) 150

Vibrometer (Optional) 151

Precision level E290 152

INDEX 153

PARTIAL FLANGE FLATNESS 105

Measure 107

Result 108

INTRODUCTION

Damalini AB

Damalini AB develops, manufactures and markets Easy-Laser® measurement and

alignment equipment based on laser technology.

We have more than 25 years of experience from measurement tasks in the eld and

product development. We also provide measurement service, which means that we

ourselves use the equipment we develop, and continuously improve it. Because of this

we dare to call ourselves measurement specialists.

Do not hesitate to contact us about your measurement problems. Our expertise will

help you solve it in an easy way.

Declaration of conformity

Equipment: Easy-Laser® product range

®

Damalini AB declares that the Easy-Laser

manufactured in conformity with national and international regulations.

The system complies with, and has been tested according to the

following requirements:

EMC Directive 2004/108/EG

Low Voltage Directive 2006/95/EC

Laser Classication Europe: SS_EN 60825-1

USA: CFR 1040.10/11

RoHs Directive 2011/65/EU

WEEE Directive 2012/19/EU

The calibration of the equipment fully complies with ISO9001:2008 #7.6

®

For Bluetooth

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference

(2) this device must accept any interference received, including interference that may

It should be handed over to an applicable collection point for the recycling of electrical

and electronic equipment. By ensuring this product is disposed correctly, you will help

to prevent potential negative consequences to the environment and human health. For

more detailed information about the recycling of this product, please contact your local

city ofce, household waste disposal service or the retail store where you purchased

this product.

devices: This device complies with Part 15 of the FCC Rules.

cause undesired operation.

Disposal of old electrical and electronic equipment (Applicable through-

out the European Union and other European countries with separate collection programs)

This symbol, found on product or on its packing, indicates that this product should not be treated as household waste when disposed of.

product range is

Quality certicate

Damalini AB is ISO 9001:2008 certied. Certicate number 900958.

Damalini AB conrm, that our products are produced according to applicable national

and international regulations and standards. All components are checked before assem-

bly and nal products are tested in functionality and visually checked before delivery

The calibration of the equipment fully complies with ISO9001: 2008 #7.6

1

Introduction

Limited warranty

This product is manufactured under Damalini’s strict quality control system. Should

the product fail within two (2) years from the date of purchase under normal usage

conditions, Damalini will repair or replace the product free of charge.

1. Using new or refurbished replacement parts.

2. Exchange the product with a product that is new or which has been manufactured

from new or serviceable used parts and is at least functionally equivalent to the

original product.

Proof of purchase date should be conrmed, and sent together with a copy of the original purchase document.

Warranty is valid under normal usage described in the user’s manual appended with

the product. The warranty comprises failure on Easy-Laser

related to material and/or fabrication errors. The warranty is valid only in the country

of purchase.

The warranty is not valid in the following cases:

• If the product is broken due to mishandling or incorrect operation

• If the product has been exposed to extreme temperature, calamity, chock or high

voltage.

• If the product has been modied, repaired or disassembled by unauthorized per-

sonnel.

Compensation for possible damage due to failure on Easy-Laser

cluded in the warranty. Freight cost to Damalini is not included in the warranty.

®

product that could be

®

product is not in-

Note!

Before delivery of the product for warranty repair, it is the responsibility of the buyer

to backup all data. Data recovery is not included in the warranty service and Damalini is not responsible for data that may be lost or damaged during transit or repair.

Lithium Ion battery limited warranty

Lithium ion batteries inevitably lose power during their lifetimes, depending on usage

temperatures and the number of charging cycles. Therefore, the internal rechargeable

batteries used in the E-series are not included in our general 2-year warranty. There

is a 1 year warranty for the battery capacity not to fall below 70 % (a normal change

means that the battery must have more than 70 % capacity after more than 300 charging cycles). A 2 year warranty applies if the battery becomes unusable because of a

manufacturing fault or factors that Damalini AB could be expected to have control of,

or if the battery displays abnormal loss of capacity in relation to use.

Extended warranty

Easy-Laser® Measurement and Alignment Systems meet the highest quality standards!

For this reason, we have extended the warranty to you to a total of 3 years — free of

charge!

The prerequisite for a warranty extension is that you register your system parts on

the Internet within 6 months of purchase. The warranty period begins on the date of

purchase. The warranty extension applies to all products in accordance with the EasyLaser® Warranty requirements.

2

Safety precautions

Easy-Laser® is a laser instrument in laser class II

with an output power less than 1 mW, which

requires the following safety precautions:

• Never stare directly into the laser beam

• Never aim the laser beam at anyone else’s eyes.

Note!

Opening the laser units can result in hazardous radiation, and will invalidate the

manufacturer warranty.

If starting the machine to be measured would result in injuries, the possibility to unintentionally start it must be disabled before mounting the equipment, for example by

locking the switch in the off position or removing the fuses. These safety precautions

should remain in place until the measurement equipment has been removed from the

machine.

Note!

The system should not be used in explosive risk areas.

Introduction

Service and calibration

Our Service centres will quickly assist you if your measurement system need to be

repaired or when it is time for calibration.

Our main Service centre is located in Sweden. There are several local Service centres

that are certied to carry out limited service and repair. Contact your local Service

centre rst before sending your equipment for service or repair. All Service centres are

listed on our web site under Service and Calibration.

Before sending your measuring system to our main Service centre, please ll in the

online Service and Repair report. www.easy-laser-service.com

Manuals as PDF

You can download our manuals in pdf format from our website. The pdf’s are also

available on the USB memory stick that is delivered with most systems.

EasyLink

The new version of our database program EasyLink is available on the USB memory

stick that is delivered with most systems. You can always download the latest version

from damalini.com>download>software.

3

Introduction

Travelling with your measurement system

When travelling by airplane with your measurement system we strongly recommend

that you check which rules apply for each airline company. Some companies/countries

have limitations for checked baggage when it comes to items including batteries. For

information about Easy-Laser® batteries, please see system unit details in the end of

this manual. It is also good practice to remove the batteries from the equipment, when

possible, e.g. D22, D23 and D75.

Compatibility

The E-series is not compatible with previous analogue units from the D-series. You can

however continue to use previous brackets.

Disclaimer

Damalini AB and our authorized dealers will take no responsibility for damage to

machines and plant as a result of the use of Easy-Laser® measurement and alignment

systems.

Copyright

© Damalini 2015

We might change and correct the manual in later issues without further information.

Changes to the Easy-Laser

tion.

October 2015

®

equipment may also affect the accuracy of the informa-

Fredrik Eriksson

Quality Manager, Damalini AB

Damalini AB, PO Box 149, SE-431 22 Mölndal, Sweden

Phone: +46 31 708 63 00, E-mail: info@damalini.com

Web: www.damalini.com

4

DISPLAY UNIT

LED signals

OK buttons

Navigation buttons

Numeric buttons

Function buttons

A Connection for external power.

B Network connection. (Not available on all systems.)

C External connection. Use for projector for example. (Not available on all systems.)

D USB A (master). Use for USB memory.

E USB B (slave). Use for connecting to a PC.

F Connection for Easy-Laser® equipment.

G Protective cover.

Battery compartment

(Not available on all systems.)

Reset the Display unit

Press and hold the On/Off button to reset the Display unit.

A B C D E F

G

5

Display unit

Navigation buttons

To navigate on the screen, use the navigation buttons. The selected icon is marked with

a yellow frame. The navigation buttons are also used to move between the icons in a

submenu and to change the values in the elds.

Navigation buttons

OK button

Numerical buttons

Function buttons

OK buttons

There are two green OK buttons and they both work in the same way. Press to

select the currently selected icon for example.

Function buttons

The icons above the function buttons change depending on which view is currently

displayed on screen.

Below is a list of the most common icons.

Back to previous view. Press and hold to leave current program.

Back. There is no “previous view”. Leave the current program.

More. Contains a submenu with general functions,

such as

(Control panel) and (Save le).

Submenus

The icons formed as an arrow contain a submenu. Use the navigation buttons to navigate in a submenu. Press to select.

Function button with arrow contains submenu

6

Status bar

The Status bar contains additional information such as warning icon, current time and

Bluetooth® connection.

Measurement unit.

Change units via Settings.

The yellow arrow indicates

that there are sub-menus

There are also text messages regarding:

• The selected icon.

• Hints on what information you are expected to ll in.

Status bar icons

Warning. Select the function button to get additional information

regarding the warning.

Warning. Displayed when the coordinates has been rotated in the detector.

Go to Control panel to rotate coordinates.

Hourglass. The Display unit is in the middle of a task.

Display unit

Display unit charging. Indicating that a power adaptor is plugged in.

Display unit is low in battery.

Measurement progress. Time depending on which lter you have selected.

Selected lter.

Peripheral.

Indicates that a peripheral device is plugged in, such as a projector.

Bluetooth®. Indicates that the Bluetooth® functionality is activated.

The number beside indicates the number of Bluetooth® units connected.

Printing report on thermal printer. The thermal printer is optional equipment.

Printing performed OK.

Printing problem.

7

Display unit

Screen dump

It is possible to take screen dumps of what is currently displayed on screen. You can

e-mail the screen dump or use it for reports.

Take a screen dump

1. Press and hold the numeric button period (.) for 5 seconds.

2. An hour glass is displayed on the status bar.

3. The screen dump is saved in the le system as a .jpg le. It is named with current

date and time. Select

on page 11.

to open saved les. See “Measurement le handling”

LED lights

Right indicator

Yellow

Flashing: The internal battery in the Display unit is charging.

Left indicator

Left indicator has several functions and colours:

Red/Blue

Red

Blue

Green

Light blue

Quick ashing: Reprogramming the system.

Flashing: Warning, for example low battery.

Flashing: Searching for detectors equipped with Bluetooth®.

Fixed light: Connected to detectors equipped with Bluetooth

Flashing: Display unit is starting.

Fixed light: The internal battery in the Display unit is fully charged.

Flashing: Backlight is off, but the Display unit is still on. Press any

button to activate the Display unit.

®

.

8

Battery

Select to display the Battery view. This view gives you a good overview of the

battery status of all connected equipment.

Display unit

Dry cell batteries

(not available for all systems)

Detector or

Measuring unit

Battery pack

Serial number

Charging

The E-series is not compatible with units from the D-series.

Display unit

Note!

When nished working for the day, charge the whole system. Plug in the power adaptor to the Display unit and connect the measuring units by using cable.

Charge the Display unit

The Display unit can be used from -10ºC to +50ºC. Charge the Display unit within the

temperature range of ±0ºC to +40ºC.

Note!

If you shut the Display unit off while charging, it will charge faster.

Power adaptor

With the power adaptor plugged in, you can keep on working.

A PC via USB cable

While you have this connection, you can open the les in the Display unit via the

explorer in your PC. However, the Display unit is locked.

Dry cell batteries

When you get a battery warning, insert four R14 dry cell batteries in the battery compartment. This will prolong the power of

the Display unit so that you can nish your measurement. However, if the internal battery is completely empty, the dry cell

batteries do not have enough power to start up the Display unit.

USB

Charge the Detector/Measuring units

The Detectors and Measuring units are charged by the Display unit when connected by

cable. If you are using Bluetooth® units, switch to cable when the battery in the Detector/Measuring unit is low.

Charge the Bluetooth® units

The Bluetooth® units are powered by the Detector/Measuring units. To save energy, the

Bluetooth® units will only connect when you are using a measurement program. There

is no power switch on the unit. To switch off, simply unplug the unit.

See “Charge the Display unit” on page 9.

9

Display unit

Calculator

The calculator is found on the Start view and Control panel ( ).

1. Select

2. Use the numerical buttons and function buttons to enter values.

3. Use the

and to open the calculator.

button to compute.

Select to display sub-menu

Use OK button as equal sign (=)

Unit converter

The unit converter is found on the Start view and Control panel ( ).

1. Select

2. Select a category. Move using the navigation buttons up and down.

3. Press navigation button right. The result column is activated.

4. Select a unit to convert from.

5. Enter an amount. The other units are recalculated.

In the example below, one inch is selected.

and to open Unit converter.

Select category

Select unit and amount

10

Measurement le handling

Save le

1. Select and to save your measurement.

2. Enter a le name. The date and time will automatically be added to the le name.

The measurements that you save will be available to other users as well.

3. Press

File manager

Select (found on the start view and Control panel) to open saved measurements.

The File manager is displayed. Here you can easily when and from which program the

le was saved.

Press

to save the le.

to open a measurement le.

xml

A measurement le.

jpg

“Screen dump” on page 8

Display unit

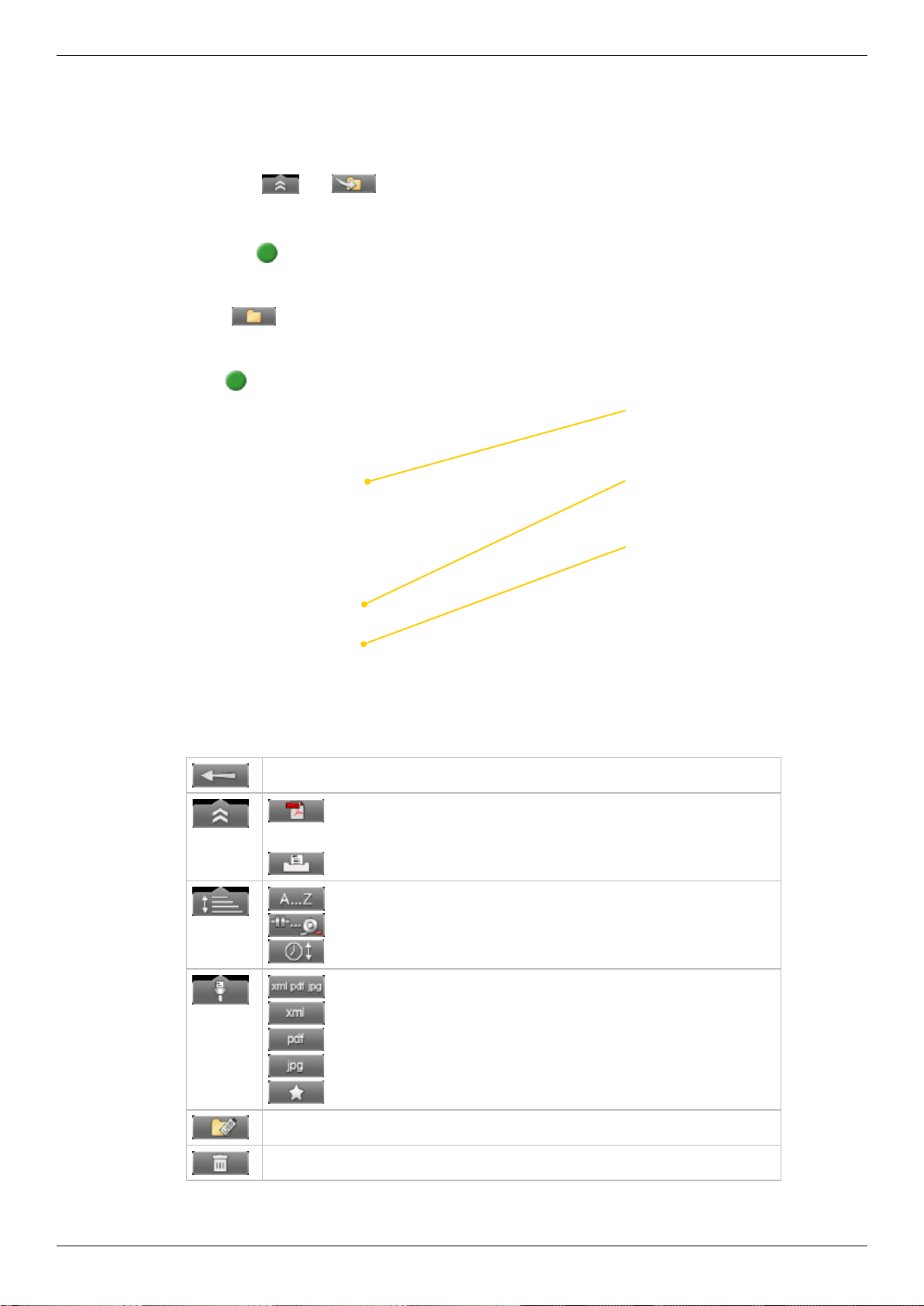

Function buttons

Back to previous view.

“Copy le to USB memory” on page 13.

PDF

A report. The PDF report can not be

opened in the Display unit.

PDF is not available for E420.

“Report” on page 14.

“Open le as template” on page 13.

“Print le (Optional)” on page 14.

Sort les alphabetically.

Sort les by measurement program.

Sort by time.

Show all les.

Show only xml les.

Show only pdf les.

Show only jpg les.

Show only Favourites. See “Favourites” on page 12.

Delete les. Delete all displayed les or only selected le.

11

Display unit

Favourites

It is possible to save a measurement as a Favourite. A Favourite can be used for exam-

ple when you have many anges or machines with the same dimensions. This way you

do not have to enter the same distances or tolerances every time. When you have saved

as Favourite, a new icon is displayed on the start screen.

Create a favourite

1. Select to open the File manager and select a le.

2. Select

3. Go to the start screen and select

4. Press

and to save the selected le as a Favourite.

to see all favourites.

to open a Favourite. All distances are lled in.

Import favourites

The favourite les are saved in the folder Favourites in the Display unit.

1. Plug in the Display unit to a PC and open the Favourites folder.

2. Copy the .FAV (favourite) le to the root of an USB memory stick.

3. Connect the USB stick to a Display unit and select

and to import.

Delete favourite

1. Select to open the File manager and select a le.

2. Select

3. Select a le and

and to show all Favourite les.

.

Show Favourite

Import Favourites

from USB

Create Favourite

12

Open le as template

You can open a saved measurement and use it to make a new measurement. This is

very useful when you have many anges or machines with the same dimensions for

example. This way you do not have to enter the same distances every time.

1. Select

displayed.

2. Select a le in the list and select

3. Change distances if needed and proceed to measuring view.

(found on the Start view and Control panel). The File manager is

. The Edit distance view is displayed.

Copy le to USB memory

You can easily copy a saved measurement or other les to a USB memory.

1. Insert a USB memory.

2. Select the le you want and select

3. A folder is automatically created on the USB memory. The le is saved in the

folder \Damalini\archive\.

.

Barcode

Save le with barcode

The barcode scanner is not included in all systems. The rst time you measure a

machine, you stick a barcode on the machine and save the measurement together with

the scanned barcode. Next time you align the same machine, all you need to do is scan

the barcode and all machine data is read.

1. Scan the barcode on the machine.

2. Enter a le name.

3. Press

data is saved together with the barcode.

The barcode number is added to the le name.

When you connect the Display unit to a PC the whole le name is shown:

to save the le. All measurement

File name

Barcode number

Display unit

File name Barcode numberDate and time User Barcode reader

Open le with barcode

• Start the Display unit and scan the barcode. The latest measurement that was

made and saved with this barcode is automatically opened.

OR

• Select

ments saved with this barcode are shown.

to open File view. Scan the barcode on the machine. All measure-

13

Display unit

Print le (Optional)

Part no. 03-1004

The thermal printer is optional equipment.

1. Save the measurement. To print from a Shaft program, you need to

open a saved measurement before you can print a report.

2. Connect the thermal printer and select

3. The progress is displayed on the status bar.

Printing report on thermal printer.

Printing performed OK.

Printing problem.

You can also save a measurement, download the pdf-report to your PC and print the

pdf-report.

and .

Report

A report is generated and saved in the ling system. You can not open an old measurement and save it again (program Machine train is an exception to this). You can

however generate a new report from an opened le. This means you can for example

change the language and make a new report from the opened measurement. You can

download the report to a PC and print it.

Company logo

You can replace the logo on the report with your own .jpg le.

1. Name your logo logo.jpg. The default logo has the proportions of 230x51

pixels.

2. Connect the Display unit to your PC using the USB-cable.

3. Place your image in the Display unit’s folder Damalini/custom/reports/

logo.

File extensions (for example .jpg) are often hidden in the Explorer window. To dis-

play le extensions do the following: Open an Explorer window and press Alt to show

menu. Select Tools > Folder options. Click the View tab > Advanced settings > Clear

the Hide extensions for known le types check box.

Date format

By default, the date and time format is set to Central European Time (CET).

You can change the date and time format used in your PDF reports.

See “Date and time” on page 16.

Download le to PC

1. Start the Display unit.

2. Connect the USB cable between the Display unit and PC.

3. While you have this connection, the Display unit is blocked.

4. View and/or copy the les to the PC.

14

EasyLink

You can also use our database program EasyLink to view the les on your PC.

EasyLink is available on the USB memory stick that is delivered with

most systems. You can always download the latest version from damalini.

com>download>software.

Control panel

Select and to open the Control panel. Some of the settings are personal

and will be default next time you start the system.

Note!

All settings are not available

for all systems.

Filter

Select to open the Filter view.

The lter you select on the Filter view will be saved as a personal setting.

If the laser beam passes through air with varying temperature, this may inuence the

direction of the laser beam. If measurement values uctuate, this could mean unstable

readings. Try to reduce air movements between laser and detector by, for instance,

moving heat sources, closing doors. If the readings remain unstable, increase the lter

value (more samples will become available to the statistical lter).

Display unit

which lter you have selected.

Select lter

Use as short a time as possible that still produces acceptable stability

during the measurement. Default is set to 1. Normally you will use a

lter value of 1-3. If you set the lter type to 0, no lter will be used.

Use the numerical buttons 3, 6 and 9 to set the lter. In the Filter view

but also when you are using a measuring program.

Current noise level in

the system before and

after ltering

Press function button 6

to test how long the measurement progress is

Selected lterMeasurement progress. Time is depending on

Use numerical buttons to select lter

Currently selected lter

Use numerical but-

tons to set lter.

Button 6 will restart

the lter

Graph shows ltered

noise level over time

15

Display unit

Unit and resolution

Personal setting

Select

to open the Units and resolution view. Use the navigation buttons to

move between the elds. Set Metric or Imperial and which resolution you want to use.

Default is set to 0.01 mm (0.4 mil). The selected unit is shown on the Status bar.

Note!

It is possible to select 0.0001mm only in

the E940 system.

For E420, only 0.01mm is possible.

Detector rotation

Personal setting

The coordinate system can be rotated 90º. Select

view. When you have rotated the coordinates, a warning is displayed on the Status bar.

Detector rotation will only affect detectors with two axis.

to open the Detector rotation

Warning displayed on

Status bar

Detector rotation view

Date and time

Select to open the Date and Time view. Set the date and time. Default is set to

Central European Time. (CET)

Date and time view

Select to set the date format used in your PDF reports.

Date and time used in PDF reports

16

Language

Personal setting

Display unit

Select

buttons to select a language. Press to save changes.

to open the Language view. Default is set to English. Use the navigation

Language view

User

Select to open the Users view. A user account is used for storing your personal

settings.

Use the function buttons to add or remove users. To switch user, simply select the user you would like to switch to and press .

User view

Backlight

Personal setting

Select

the elds. Press to save changes. When backlight is off, the left LED signal will

ash to indicate that the Display unit is still on.

Backlight level

Adjust the backlight to make it easier to read in bright sunlight. Remember however

that a high contrast consume more battery power. Default is set to 50%.

Reduce after

Set time before backlight reduction as a way to save energy. The Display unit will be

dimmed, but is still on. Default is set to Never.

Off after

Set time before backlight off. Default is set to Never.

to open the Backlight view. Use the navigation buttons to move between

Backlight view

17

Display unit

Automatic power off

Personal setting

Select

power off. Use the navigation buttons to select. Press to save changes.

to open the Automatic off view. Select how much time before automatic

Automatic power off view

Note!

Measurements in progress will not be saved in the event of an Automatic power off.

Information

Select to display the information regarding serial number and version of the

equipment.

Information view

VGA

(Not available on all systems.)

Makes it possible to show display unit screen image with a projector, for example in a

training context. Must be factory installed on order.

Select

to open the VGA view.

18

System update

Download update le

1. Go to www.damalini.com > Download > Software >

E series Display unit Firmware Update.

2. Download the update le to your PC.

3. Unzip the le.

4. Copy the .elu le to the root of a USB memory.

Install update le

1. Start the Display unit. Make sure that the internal battery of the Display unit is charged. The battery symbol

should be at least yellow.

2. Insert the USB memory in the Display unit. Do not

remove the USB memory until the update is nished.

Display unit

Save .elu le on a USB memory.

3. Select

and to display the System

update view.

4. Select the update le and press

5. Select

. The installation starts.

.

Select the .elu le.

6. The Display unit will automatically restart when

the installation is nished and the Main menu is

displayed.

Note!

During restart, the screen turns black for up to one

minute. When the main menu is displayed, it can

“freeze” (no response when you press buttons). If

this happens, press the On/Off button for at least 15

seconds to restart the Display unit.

Main menu is automatically displayed after restart.

Font package

Some of the early E-series systems was not installed with Unicode fonts. To install the

latest system updates, you need to install the font package with Unicode fonts.

Check if you need to install:

1. Select

and to display the Language view.

2. Check if you have Chinese installed. If Chinese is

installed, you already have the correct Font package.

If not, please go to www.damalini.com > Download >

Software > Eseries Display unit Font package update

and follow the instructions above to install.

Chinese installed?

No need to update with Font package.

19

Display unit

License

It is easy to upgrade your Display unit.

®

1. Contact your Easy-Laser

2. An e-mail will be sent to you with information on how to download the update

le.

3. Save the le to the root of the le system to a USB memory stick or directly to the

Display unit.

Save le on USB

1. Save the downloaded license le to a USB memory stick.

2. Insert the USB memory stick in the Display unit.

3. Select

and to display the License view.

distributor if you wish to upgrade your Display unit.

4. Select

5. Press

to search for licenses.

to import license.

Save le to Display unit

1. Connect the Display unit to a PC.

2. Save the license le to the root of the Display unit’s storage.

3. Select and to display the License view.

4. Select

5. Disregard the text and select

is achieved.

to search for the new license le. A window is displayed.

. The license le is installed and full functionality

20

Bluetooth® set up

Bluetooth® wireless technology makes it possible for Display unit and Detector to

exchange data without using cables.

®

Some detectors have built-in Bluetooth

unit that you attach to the detector. Please see Technical data for more

information.

Set up

This is only necessary when adding new Bluetooth® units to the list.

1. Select

2. Select

3. The view is updated with the Easy-Laser

to open the Bluetooth® view.

to search for Bluetooth® units.

Searching for Bluetooth® units

, others have a separate Bluetooth

®

Bluetooth® units you can connect to.

Display unit

4. Select the unit you want to connect to and select . The unit will automatically be connected when you start a measurement program.

5. Press

to save changes and to leave the Bluetooth® view.

6. Enter a measurement program. The Display unit will connect to the selected units.

While connecting, the left LED indicator is ashing with a blue light which will

turn to a xed blue light once connected.

7. An icon on the status bar will indicate how many

®

Bluetooth

units are connected.

One Bluetooth® unit connected

Function buttons

Back to Control panel. Changes made in the table are saved.

Search for Bluetooth® units.

Cancel search. Use if your Bluetooth® unit is already found.

Remove a Bluetooth® unit from the list.

Connect the unit. The unit will automatically connect when you start a

measurement program.

Disconnect the unit. The unit will remain in the list.

Note!

Do not use a Bluetooth® unit and a cable at the same time.

21

Display unit

Use only one Bluetooth® unit

Many of our systems are delivered with two Measuring units. In some cases you might

want to use only one unit together with a laser transmitter. By default both units are set

to “Connect

trying to connect to it, even if it is not plugged in.

1. Attach the Bluetooth unit to the detector.

2. Select

”. If the unused unit is set to “Connect ”, the system will keep on

to open the Bluetooth® view.

3. Set the Bluetooth® unit you want to use to

4. Make sure that the other units are set to

5. Enter a measuring program.

The Display unit will connect to the selected unit. This may take a couple of minutes.

.

.

Note!

Remove Bluetooth® unit from the Measuring unit before putting the equipment in the

carrying case. If attached, it will discharge the Measuring unit.

Bluetooth® information

This device contains

FCC ID: PVH0925

IC: 5325A-0925

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions;

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

22

CHOOSE PROGRAM

Preparations

Before starting a measurement, there are several things that are good to check to

ensure a good and accurate measurement.

• Ensure a good measurement environment. Strong sunlight, warning lights, vibrations and temperature gradients can affect the readings.

• Make sure the surfaces are clean.

• Ensure that the foundation of the machine is stable.

• Check for play and clearance in the bearing.

Values

Shows live readings from S and M units.

Horizontal

For alignment of horizontal machines.

Vertical

For alignment of vertically mounted machines.

Cardan

For alignment of cardan-shaft-coupled/centreoffset machines.

Machine train

For machine trains with two or more couplings.

Straightness

For straightness measurement of machine

bases, bearing journals, machine tools, etc.

Flatness

Program to measure atness of machine bases,

machine tables, etc.

Flange Flatness

Measure 1 to 5 circles on a ange.

Twist

Measure twist on an object by taking two diagonal measurements.

BTA

For alignment of belt and chain drives.

VIbrometer

Shows the vibration level in “mm/s” and

bearing condition value in “g”.

Offset and Angle

Shows centre offset and angular error between

two shafts, for example.

Softfoot

Check to ensure that the machine is resting

evenly on all its feet.

Parallelism A

Measure roll parallity using a penta prism and a

precision level.

Parallelism B

Measure roll parallity using an angle detector

and a precision level.

Partial Flange Flatness

Measure only a part of a large ange.

Flange Section

Use for large anges. The ange is divided into

four sections.

23

24

PROGRAM VALUES

With the program Values, you can see live readings from the detectors.

As default, a target and a table is displayed.

Press OK to register values.

Live values, vertical and horizontal.

Detector or Measuring unit

Serial number

Unit two (out of two connected)

Target

Tolerance area

Laser point

(becomes a line when

using spinning laser)

Current range

Function buttons

Registered values

Use the navigation

buttons to scroll

the list

Back, leave program.

See “Control panel” on page 15.

See “Tolerance” on page 26.

See “Zoom” on page 26.

Save le. See “Measurement le handling” on page 11.

See “Automatic recording” on page 28.

Delete registered values.

Print report on thermal printer (optional equipment).

See “Streaming values” on page 29.

Set current value to zero.

Halve displayed value.

Return to absolute value.

Only available after zeroing or halving.

Choose how to display values. Use left and right navigation button to

switch between two or more detectors when only one target is displayed.

25

Program values

Tolerance

1. Select and to set tolerance.

It is possible to set different tolerance in vertical

and horizontal direction.

2. Use navigation buttons to move between the

elds and to change the tolerance.

3. Press OK.

Live values and marking displayed in

green when within tolerance.

Live values displayed in red when

outside tolerance.

Zoom

1. Select and to zoom.

2. Select a zoom factor between 1–5. Use navi-

gation buttons to increase or decrease zoom

factor.

3. Press OK.

Default view Zoom factor is set to 2

26

Edge warning

When the laser beam is close to the edge, the edge is “lit up” as a warning. It is not

possible to register values when you see the edge warning.

Halve or Zero set value

Halve value

Select to half

displayed value.

Zero point of the PSD

moves halfway towards the

laser point.

Zero set value

Select to zero set

displayed value.

Zero point of the PSD

moves to the laser point.

Absolute value

Select to return to

the absolute value.

Zero point of the PSD

returns to the PSD centre.

Program values

Note the change of the current range

Live values – colours

Live values are normally yellow Loss of signal, laser beam

Green when within

tolerance

Red when outside

tolerance

interrupted for example

27

Program values

Automatic recording

In Values, it is possible to make automatic recording of values. This is very useful

when you want to register values during a longer time period for example.

1. Select

2. Set Interval.

3. Press navigation button “right”.

4. Set Duration.

5. Press OK. The recording will start and you can follow

the progress on screen.

Icon indicates that values are being recorded

and to start automatic recording.

Views

You can decide how to display the current values. As default a target and a table is

displayed, but you can choose to show only target for example.

Select

to display the different layout options, see image below.

Note!

Use left and right navigation button to switch between two or more detectors when

only one target is displayed.

Precision level E290 (Optional equipment)

Connect the Precision level via Bluetooth, see “Bluetooth® set up” on page 21.

For calibration, see “Precision level E290” on page 223 For calibration, see “Preci-

sion level E290” on page 152

When measuring a shaft using the

Precision level, we recommend that

the shaft is no larger than 100 mm in

diameter.

28

Max Ø100 mm

Program values

Streaming values

With the Streaming value functionality, you can transfer data from the Display unit.

For this to work, you need a USB to USB Null Modem Cable, the USB cable delivered

with the system does not work for streaming values.

1. Connect the Display unit to the PC using a USB to USB Null Modem Cable.

The USB-to-USB null modem

cable shows up as a Virtual

Serial Port with the following

properties:

19200 bps, 8n1 without ow

control.

The port number can, for example, be found using the Device Manager. See ‘USB Serial Port’ under ‘Ports (COM and LPT)’.

2. Click Open.

3. Start the program Values in the Display unit.

4. Select

5. To stop, select

and to start streaming values.

.

In this example, PuTTY

is used to show the

streamed data

Data format

The data is sent as lines with semi colon separated values. Each line begin with a

detector identication, S, M, Vib or BTA, followed by the detector serial number. The

unit and resolution depends on the settings in the user prole.

Data from Vib: Vib;serial;LP;HP;G;

Data from BTA: BTA;serial;PSD1X;PDF2X;PDF3X;X axis angle;Y axis angle;Z axis

angle;

Data from S: S;serial;PSD X; PSD Y; X axis angle;Y axis angle;Z axis angle;

Data from M: M;serial;PSD X; PSD Y; X axis angle;Y axis angle;Z axis angle;

29

Program values

Calibration check

Use the program Values to check if the detector readings are within

specied tolerances.

Quick check

1. Set the tolerance to 0.01 mm (0.5mil).

2. Select

3. Select

4. Place a shim under the magnet base to lift the Munit 1mm (100mils). The M-unit’s reading shall

correspond to the movement within 1% (1mil ±

1digit) (0.01mm ± 1 digit).

5. Remove the shim from the M-unit.

6. Select

7. Make a mark to mark out the position of the detector.

8. Place the shim under the magnet base of the S-unit.

The S-unit’s reading shall correspond to the movement within 1% (1mil ± 1digit) (0.01mm ± 1 digit).

and show targets for both M- and S-unit.

to zero set value.

Make sure that the distance is kept

to zero set value.

Parallel lift to a known distance.

Shim exactly 1mm.

Note!

The shim must be exactly 1 mm. In this example it is only the M-unit that is checked.

Select to show both targets. Zero set value

Precision check

1. Fasten one unit in a machine tool.

2. Select

3. Move the units a known distance is to use the movement of a machine tool spindle.

4. The fastened unit’s reading shall correspond to the

movement within 1% (1mil ± 1digit) (0.01mm ± 1 digit).

to zero set value.

30

Note!

In this example it is only the unit fastened in the machine that is checked.

HORIZONTAL

For horizontally mounted machines.

Select between three different measuring methods:

EasyTurn

Start anywhere on the turn. The three measuring positions can be registered with as little as 20º between positions. By default, the EasyTurn

program is shown.

See “Measure using Easy Turn™” on page 35.

Horizontal Multipoint

Start anywhere on the turn. Register as many points as you wish.

See “Thermal compensation” on page 42

9-12-3

The measuring positions are registered at positions 9, 12, 3 o’clock. The

inclinometers are not used.

“Measure using 9-12-3” on page 38.

TM

Note!

Measurements made with older versions of the Horizontal program are opened with

the older version of the program. For information regarding the previous program version, please see corresponding manual.

Work ow

Preparations Adjust/Result

1. Mount units

2. Enter distances

3. Rough alignment

Measure

EasyTurn™

Multipoint

9-12-3

Live any angle

Live 9, 12, 3 or 6

Live 9 o’clock

Live 3 o’clock

Live 12 o’clock

Live 6 o’clock

31

Horizontal

Mount the units

1. Mount the S-unit on the stationary machine and the M-unit on the movable machine.

2. Mount the units facing each other. Make sure they are at the approximately same

rotational angle and radius.

Rod

Laser adjustment knob

Connectors for cables or

Bluetooth

Locking knob

Laser adjustment knob

Hook for the chain

Chain tension knob

Mounted measuring units

®

unit

Connect cables or Bluetooth® units

Cable

The measuring units has two connectors that are used for cables or Bluetooth® units.

1. Connect a cable to the Display unit. Connect the other end to any of the

measuring units.

2. Connect the second cable between the measuring units.

Bluetooth

The Display unit is equipped with Bluetooth® wireless technology, which makes it possible for the Display unit to receive data without using cables. For more information, see

“Bluetooth® set up” on page 21.

®

Adjust measuring units

When making a new installation, a rough alignment can be necessary. Place the Measuring units on the rods, make sure they are at the approximately same rotational angle and

radius. Also make sure that the adjustment knob is adjustable in both directions.

1. Place the Measuring units at 9 o’clock. Aim the laser beams at the centre of the

targets.

2. Turn the shaft to position 3 o’clock. Note where the laser beams hit.

3. Adjust the laser beams half way to the centre of targets. Use the adjustment knobs.

4. Adjust the movable machine until the laser beam hits the centre of targets.

32

12

1

The example shows the S-unit, but the procedure is made on both units.

9 3

6

2

3

4

Select machines

Before measuring your machines, you need to dene what kind of machines you have.

1. Use navigation buttons to select Basic or Custom.

2. Press

Custom

Select this option if you want to select machine types. There are several machine types

to choose from. You can also dene as many feet pairs as you need on the machines.

.

Basic: Contains a pump and a motor. These

predened machines have two feet pair each.

Custom: Select this option if you want to select

machine types.

Horizontal

More than three feet pairs are visualized as one solid

foot on the machine.

Switch M and S

1. Use navigation buttons up and down to nd the machine you want.

2. Press

When you are done, select

. The next machine becomes active.

to continue to Enter distance view.

Select number of feet pair

If you want to change the number of feet pair on the machine, simply enter the number

you want on the numerical buttons.

Function buttons

Leave program.

See “Control panel” on page 15.

Open table to rename the machines and change the number of feet pairs.

Switch on which machine you will place the S (stationary) and

M (movable) measuring unit.

Continue to Measure view.

33

Horizontal

Enter distances

Conrm each distance with .

4

Distance between rst and second feet pair. Optional, select

1

Distance between second feet pair and S-unit. Optional, select

2

Distance between S-unit and M-unit. Measure between the rods.

3

Distance between S-unit and centre of coupling.

4

Distance between M-unit and feet pair one.

5

7

2

1

6

5

3

to activate eld.

to activate eld.

Distance between feet pair one and feet pair two.

6

Coupling diameter. Optional, select

7

Function buttons

Leave program.

See “Control panel” on page 15.

See “Tolerance” on page 44.

See “Thermal compensation” on page 42.

Select to enter distances of the S-machine.

Toggle between showing Distance view in 3D or 2D.

Diameter. Select to enter coupling diameter. This is necessary if you want

the result based on the gap of the coupling instead of angle.

Toggle button. Show movable machine to the left or the right.

Continue to Measure view. Available when you have entered the manda-

tory distances.

to activate eld.

34

Measure using Easy Turn™

Preparations

Follow the preparations as described in the previous pages.

1. Mount the measuring units.

2. Enter distances, conrm each distance with

3. If needed, perform a rough alignment.

4. If needed, perform a Softfoot check.

Measure

It is possible to measure with as little as 40º spread between the measurement points.

However, for an even more accurate result, try to spread the points as much as possible. The colours indicates where the optimum positions to measure are.

1. Adjust laser to the centre of the targets. If needed, adjust the units on the rods,

then use laser adjustments knobs.

2. Press

A red marking is displayed.

3. Turn shafts outside of the red 20º marking.

4. Press

5. Turn shafts outside of the red markings.

6. Press

to register rst position. The rst position is automatically set to zero.

to register second position.

to register third position. The Result and adjust view displayed.

Angle warning. Shown if the angle between M and S is

greater than 2 degrees.

.

Horizontal

S-unit

Red 20º marking

Laser point

Green indicates best

measurement position

Edge warning

Detector values

Function buttons

Edge warning

When the laser beam is

close to the edge, the edge

is “lit up” as a warning. It

is not possible to register

values when you see the

edge warning.

Back. Measure previous position or back to Distance view.

See “Control panel” on page 15.

Switch to the EasyTurn™ method.

Switch to the 9-12-3 method.

Switch to the Horizontal Multipoint method.

See “SOFTFOOT” on page 47.

35

Horizontal

Measure using Multipoint

Preparations

Follow the preparations as described in the previous pages.

1. Mount the measuring units.

2. Enter distances, conrm each distance with

3. If needed, perform a rough alignment.

4. If needed, perform a Softfoot check.

Measure

1. Select and to switch to Horizontal Multipoint.

2. Adjust laser to the centre of the targets. If needed, adjust the units on the rods, then use

laser adjustments knobs.

3. Press

4. Press

5. Select

39.

to register rst position. The rst position is automatically set to zero.

to register as many points as you wish. After three points a result is available.

to display the Result and adjust view. See “Result and adjust” on page

.

Spread the measurement points

For a more accurate result, try to spread the points as much as possible. The colours indicates where the optimum positions to measure are. The colour bar indicates a statistical

accuracy of the measurement.

Registered

measurement point

Green = best place to

measure!

First position is auto-

matically set to zero

Edge warning

Quality assessment

Green = a good spread of the

measurement points.

Function buttons

Edge warning

When the laser beam is

close to the edge, the edge

is “lit up” as a warning. It

is not possible to register

values when you see the

edge warning.

36

Back. Measure previous position or back to Distance view.

See “Control panel” on page 15.

Switch to the EasyTurn™ method.

Switch to the 9-12-3 method.

Switch to the Horizontal Multipoint method.

See “SOFTFOOT” on page 47.

Continue to the Result and adjust view. Available after registering three

positions with a minimum spread of 40º.

Quality assessment

Not available for the US market!

Horizontal

From the result view, select

and to show the Quality assessment view

Attainable accuracy

Many measurement points that also have a good spread, will statistically ensure a high

accuracy. This is the same indicator as on the measurement view. If the attainable accuracy is low, try to spread the points as much as possible.

Acquired accuracy

Actual measured values from the units. If the acquired accuracy is low, it may depend

on for example air turbulence or bearing clearance.

Temperature stability

Measured temperature variation in the measuring units. If the stability is low, remeas-

ure when the temperature has stabilized.

Measurement direction

Indicates if you have changed measurement direction. It is better to move the measurement units in the same direction.

Quality assessment

A sum of the four quality factors. Also available in the pdf report.

37

Horizontal

Measure using 9-12-3

Preparations

Follow the preparations as described in the previous pages.

1. Mount the measuring units.

2. Enter distances, conrm each distance with

3. If needed, perform a rough alignment.

4. If needed, perform a Softfoot check.

Measure

1. Select and to switch to 9-12-3.

2. Adjust laser to the centre of the targets. If needed, adjust the units on the rods,

then use laser adjustments knobs.

3. Turn shafts to 9 o’clock.

4. Press

5. Turn shafts to 12 o’clock.

6. Press

7. Turn shafts to 3 o’clock.

8. Press

“Result and adjust” on page 39.

to register rst position. The rst position is automatically set to zero.

to register second position.

to register third position. The Result and adjust view is displayed. See

.

First position is auto-

matically set to zero

Edge warning

Function buttons

Edge warning

When the laser beam is

close to the edge, the edge

is “lit up” as a warning. It

is not possible to register

values when you see the

edge warning.

Back. Measure previous position or back to Distance view.

See “Control panel” on page 15.

Switch to the EasyTurn™ method.

Switch to the 9-12-3 method.

Switch to the Horizontal Multipoint method.

38

Result and adjust

Offset, angle and feet values are clearly displayed. Both horizontal and vertical direction are shown live, which makes it easy to adjust the machine. Values within tolerance

are green.

Horizontal

Thermal compensation

has been set

Feet values.

Yellow frame indicates live values.

Add shims

Remove shims

Function buttons

Vertical offset and angle

Horizontal offset and angle

Back to measure view.

See “Control panel” on page 15.

Save, see “Measurement le handling” on page 11.

See “Tolerance” on page 44.

See “Thermal compensation” on page 42.

Show target. This is a quick way to see where the laser beam hits the

target and how the measuring units are positioned.

Print report on thermal printer (optional equipment). Available when

you open a saved measurement.

Edit distances. Press to conrm changes. The result is recalculated.

See “Quality assessment” on page 37.

RefLock, lock feet. Note! Not available for E420.

See “Live values” on page 40.

Toggle button. Show/hide Position indicator. See “Position indicator”

on page 41.

Toggle button. Switch between to show gap and show angular error per 100 mm.

For this to work you need to set the coupling diameter.

39

Horizontal

Live values

When reading the values, face the stationary machine from the movable machine.

Positions for measuring units as seen from the movable machine.

Live values are marked with yellow frame.

12

9

3

6

Face the stationary machine (S) from the movable machine (M). Then 9 o’clock is to the left, as in the measuring programs.

Offset and angle values

The offset and angle value indicate how well the machine is aligned at the coupling.

They appear in both horizontal and vertical direction.

These values are important to get within tolerance.

Offset

The centre lines of two axis are not concentric but parallel.

This is measured at the coupling centres.

In this example, a positive offset is shown.

Angular misalignment

The centre lines of two axis are not parallel.

In this example, a negative angle is shown.

Offset and angular misalignment

Misalignment is often a combination of both offset and angular

misalignment.

40

Show live values for EasyTurnTM and Multipoint

The inclinometer can be used to show live values at all angles.

Show live values at any angle.

Inclinometer controls when to show live values.

Show live values for 9-12-3

The inclinometer is not used. You can manually show in which position your measurement units are.

Select

to show the live options.

Force live to 6 o’clock.

Force live to 12 o’clock.

Force live to 3 o’clock.

Force live to 9 o’clock.

Adjust

Adjust the machine if needed.

1. Shim the machine according to the vertical feet values.

2. Adjust the machine sideways according to the live horizontal values.

3. Tighten the feet.

4. Select

Position indicator

To adjust, you need to place the measuring units in live position (9, 12, 3 or 6 o’clock).

Select

to remeasure.

to show the Position indicator.

Position indicator

Horizontal

Function buttons

Toggle button. Show/hide position indicator manually.

Toggle button. Select to display the position indicator automatically when you move the measuring units.

Save

You can save a measurement and open it later to continue to measure. When you save

the measurement again, it will not overwrite the earlier version.

When you save a measurement, a pdf is automatically generated.

See “Measurement le handling” on page 11.

41

Horizontal

Thermal compensation

During normal operation, machinery is inuenced of different factors and forces. The

most common of these changes is the change in the temperature of the machine. This

will cause the height of the shaft to increase. This is called thermal growth. To compensate for thermal growth, you enter values for cold condition compensation.

Select

and from the result and

distance view. The Thermal compensation view is

displayed.

Example

It can be necessary to place the cold machine a bit

lower to allow thermal growth. In this example

we assume a thermal growth of +5mm in HOT

condition. Therefore we compensate with -5mm in

COLD condition.

Before thermal compensation.

1

Set thermal compensation.

2

Indicates that the compensation values

are set for cold (ofine) condition.

Vertical offset and

angle for movable machine.

1

2

Thermal compensation set. When you

3

have set thermal compensation and

return to the result view, the values have

changed. When the machine becomes

warm, the thermal growth will make it

perfectly aligned.

Indicates that thermal

compensation has been set

Feet values

1. On the distance view, enter distances for the

S-machine.

2. Select

.

3. Set thermal compensation values based on

feet values. The coupling values are recalcalculated. If there are more than two feet

pairs, you enter values for the rst and last

feet pair.

Note!

Only the coupling values are visible in the PDF

report and the printed report.

3

42

RefLock™

From the result view, you can select the function RefLock™. Here you can choose any

two feet pairs as locked and thus choose which machine is to be used as stationary and

which as adjustable. If you want to lock feet pair on the stationary machine, you need

to enter distances.

Horizontal

1. Select

2. The RefLock graph view is displayed. Navigate using the left and right navigation

button.

3. Select

4. Select

and .

to lock the selected feet pair or to unlock.

to continue to the result view.

Stationary machine

Movable machine

Selected feet pair

Locked feet pair

Note!

RefLock™ is available when using the program Horizontal. Not available for programs Vertical or Cardan.

43

Horizontal

Tolerance

1. Select and . The tolerance window is displayed.

2. Select a tolerance and press

GAP values

.

Add user dened tolerance

Function buttons

Close T olerance view.

See “Control panel” on page 15.

Edit user dened tolerance.

Delete user dened tolerance.

Add new tolerance

You can add your own user dened tolerance.

1. Select the row “Add new tolerance”. Press

2. Enter name and tolerance.

3. Press

. The new tolerance is added to the list.

.

Tolerance in result views

The tolerances are clearly displayed in the result views.

Green = within tolerance

Red = not within tolerance

44

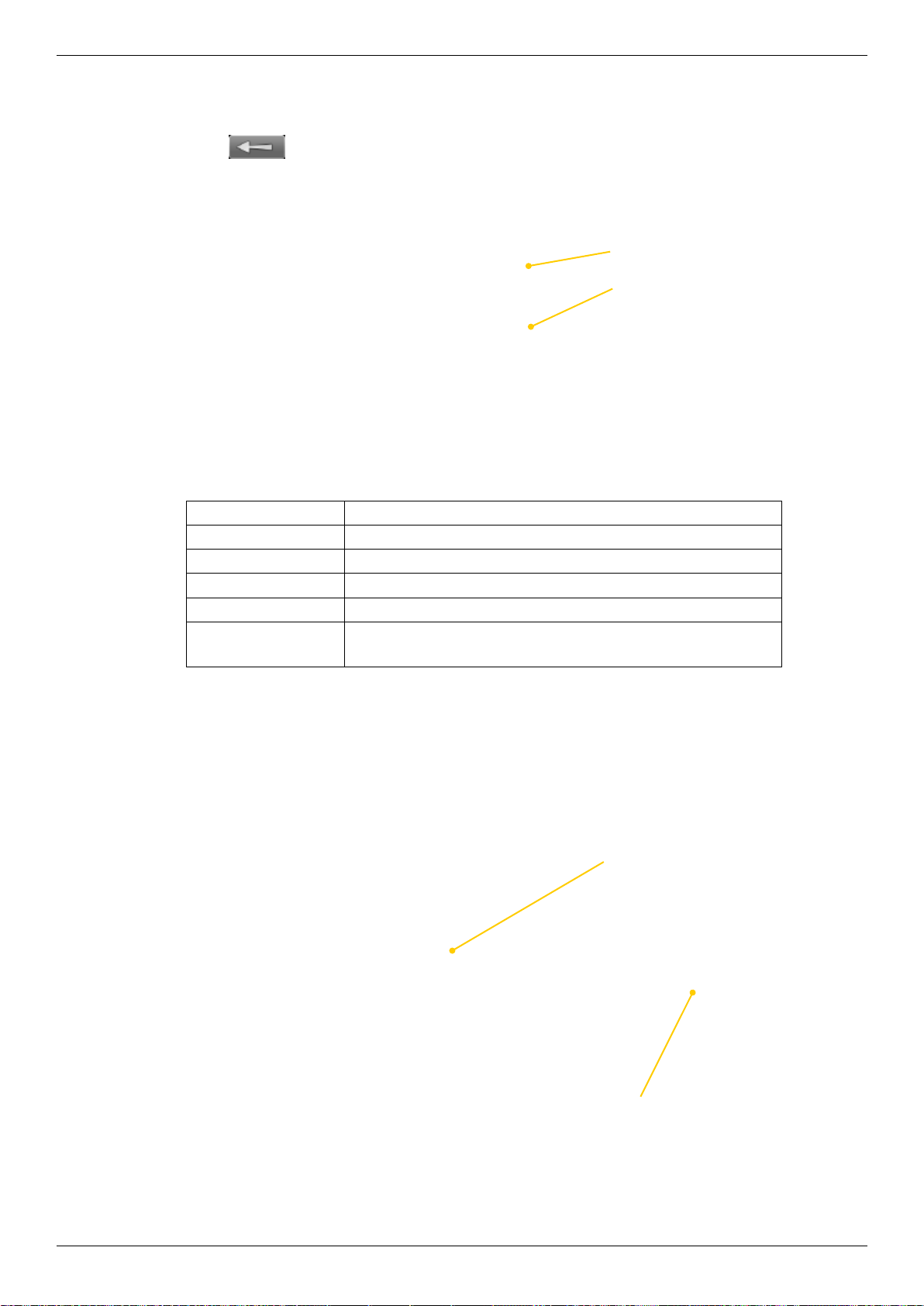

Tolerance table

The rotation speed of the shafts will decide the demands on the alignment. The table

on this side can be used as a guidance if no other tolerances is recommended by the

manufacturer of the machines.

The tolerances is set to the maximum allowed deviation from accurate values, with no

consideration to if that value should be zero or compensated for thermal growth.

Offset misalignment

Excellent Acceptable

rpm mils mm mils mm

0000-1000 3.0 0.07 5.0 0.13

1000-2000 2.0 0.05 4.0 0.10

2000-3000 1.5 0.03 3.0 0.07

3000-4000 1.0 0.02 2.0 0.04

4000-5000 0.5 0.01 1.5 0.03

5000-6000 <0.5 <0.01 <1.5 <0.03

Horizontal

Angular misalignment

Excellent Acceptable

rpm mils/’’ mm/100mm mils/’’ mm/100mm

0000-1000 0.6 0.06 1.0 0.10

1000-2000 0.5 0.05 0.8 0.08

2000-3000 0.4 0.04 0.7 0.07

3000-4000 0.3 0.03 0.6 0.06

4000-5000 0.2 0.02 0.5 0.05

5000-6000 0.1 0.01 0.4 0.04

The higher the rpm of a machinery is, the tighter the tolerance must be. The acceptable

tolerance is used for re-alignments on non-critical machinery. New installations and

critical machines should always be aligned within the excellent tolerance.

Note!

Consider these tables as guidelines. Many machines must be aligned very accurately

even if they have a lower rpm. For example gearboxes.

45

Horizontal

46

Perform a softfoot check to ensure that the machine is resting evenly on

all its feet. A softfoot can be angular and/or parallel, see image.

Softfoot can be caused by:

• Twisted machinery foundations.

• Twisted or damaged machinery feet.

• Improper amount of shims under machine feet.

• Dirt or other unwanted materials under machine feet.

Start Softfoot from main shaft menu

1. Select and .

2. Enter distances. Select “Custom” if you want to

select other machine images and/or more than three

feet pair.

3. Select

to continue.

Start Softfoot from Horizontal program

1. Select and to open Horizontal program.

2. Enter distances. Conrm each distance

with

enter distances between the feet pairs. The measure

view is displayed.

3. Select

have registered any measurement points.

. To perform a Softfoot check, you need to

. Softfoot is only available before you

SOFTFOOT

Angular softfoot Parallel softfoot

Function buttons

Leave program.

See”Control panel” on page 15.

Enter distance for S-machine. Makes it possible to perform a soft-

foot measurement on the S-machine.

Toggle between 3D and 2D view.

Add a feet pair. Only available for E530. In E710 you select machines and

optional number of feet when you select custom.

Toggle button. Show movable machine to the left or the right.

Continue to Measure view. Available when you have entered the distances.

Filter

When you measure Softfoot, the detector lter is increased by three steps (maximum

to lter 7). If you measure with a higher lter than 7, that lter will remain. When the

Softfoot measurement is done, the lter is restored.

47

Softfoot

Measure softfoot

1. Tighten all feet bolts.

2. Turn the measuring units to 12 o’clock.

3. Adjust laser to the centre of targets. If needed, adjust the units on the rods, then use laser

adjustments knobs.

Turn the measuring units to 12 o’clock.

Adjust laser point to centre of target.

4. Press . The Softfoot measure view is displayed. The rst bolt is marked with yellow.

5. Loosen and then retighten the rst bolt.

6. Press

7. Register values on all four feet. The result is displayed.

8. Shim the foot with the largest movement.

9. Do a Softfoot check again.

Measure:

Loosen and retighten bolt before register value.

to register value.

Result:

Arrow indicating that the machine is tilting in this direction.

48

Note!

If the largest movement is opposite from the smallest it is not a conventional softfoot and you

will be asked to check the foundation.

Function buttons

Leave Softfoot.

See “Control panel” on page 15.

Save. Only available when you have started Softfoot from the main menu.

Zero value of selected foot.

Toggle button to switch machine. To check Softfoot, distances between feet pairs

are necessary. If needed, the Enter distance view is displayed. Not available for

E420.

Remeasure Softfoot.

Continue to Measure view, only available when you have started Softfoot from the

program Horizontal.

MACHINE TRAIN

Use for machines mounted in a train with two or more couplings.

Work ow

Build machine train

Adjust

Enter distances

Measure

Result

s

g

n

i

l

p

u

o

c

l

l

a

d

e

r

u

s

a

e

m

e

v

a

h

u

o

y

l

i

t

n

u

e

u

n

i

t

n

o

C

49

Machine train

Build machine train

Before measuring your machines, you need to dene what kind of machines you have.

1. Use navigation buttons to select Basic or Custom.

2. Press

.

Basic: Three predened machines.

Custom: Build a custom train.

Basic

The basic machine train contains a pump, a gearbox and a motor. These three pre-

dened machines all have two feet pair each.

Navigation buttons

OK button, illustrated with .

Numerical buttons

50

Custom

Select this option if you want to build a custom machine train. You build the train from

left to right. There are several machine types to choose from and you can add as many

as you need to your machine train. You can also dene as many feet pairs as you need

on the machines.

Machine train

Select machine

1. Use navigation buttons up and down to nd the machine you want.

2. Press

3. Add as many machines as you need. When you are done, select

. The next machine becomes active.

to continue

to Measure view.

Select number of feet pair

If you want to change the number of feet pair on the machine, simply enter the number

you want on the numerical buttons.

More than three feet pairs are visualized

as one solid foot on the machine.

Machine with two feet pairs

Build train table

Select to open a table view. In this table

you can rename the machines and change the

number of feet pairs.

51

Machine train

Enter distances

Conrm each distance with .

7

3

1

Distance between rst and second feet pair.

1

Distance between second feet pair and S-unit.

2

Distance between S-unit and centre of coupling.

3

Distance between S-unit and M-unit. Measure between the rods.

4

Distance between M-unit and feet pair one.

5

Distance between feet pair one and feet pair two.

6

Coupling diameter. Optional, select

7

Function buttons

Leave program.

4

to activate eld.

See “Control panel” on page 15.

6

52

52

See “Tolerance” on page 62.

See “Thermal compensation” on page 42.

Diameter. Select to enter coupling diameter. This is necessary if you want

the result based on the gap of the coupling instead of angle.

Continue to Measure view.

When there are more than three feet

pairs, a table is displayed where you

enter the distances.

Measure using EasyTurn™

It is possible to measure with as little as 40º spread between the measurement points.

However, for an even more accurate result, try to spread the points as much as possible. The colours indicates where the optimum positions to measure are.

1. Adjust laser to the centre of the targets. If needed, adjust the units on the rods,

then use laser adjustments knobs.

2. Press

A red marking is displayed.

3. Turn shafts outside of the red 20º marking.

4. Press

5. Turn shafts outside of the red markings.

6. Press

7. The result is displayed. You can show the result as graph, table or machine view.

See chapter Result.

8. From the result view, select

the coupling, select the machine you want to adjust and press . See chapter

Adjust.

to register rst position. The rst position is automatically set to zero.

to register second position.

to register third position. The Result and adjust view displayed.

to measure next coupling. If you want to adjust

Machine train

S-unit

Red 20º marking

Laser point

Green indicates best

measurement position

Edge warning

Detector values

Function buttons

Angle warning. Shown if the angle between M and S is

greater than 2 degrees.

Edge warning

When the laser beam is

close to the edge, the edge

is “lit up” as a warning. It

is not possible to register

values when you see the

edge warning.

Back. Measure previous position or back to Distance view.

See “Control panel” on page 15.

Switch to the EasyTurn™ method.

Switch to the 9-12-3 method.

Switch to the Horizontal Multipoint method.

See “SOFTFOOT” on page 47.

53

Machine train

Measure using Multipoint

1. Select and to switch to Horizontal Multipoint.

2. Adjust laser to the centre of the targets. If needed, adjust the units on the rods,

then use laser adjustments knobs.

3. Press

4. Press

available.

5. Select

graph, table or machine view. See “Result” on page 56.

6. From the result view, select

the coupling, select the machine you want to adjust and press . See “Adjust” on

page 60.

Spread the measurement points

For a more accurate result, try to spread the points as much as possible. The colours

indicates where the optimum positions to measure are. The colour bar indicates how

statistical accurate the measurement is.

to register rst position. The rst position is automatically set to zero.

to register as many points as you wish. After three points a result is

to display the Result and adjust view. You can show the result as

to measure next coupling. If you want to adjust

Registered

measurement point

Green = best place to

measure!

First position is auto-

matically set to zero

Edge warning

Colour bar

Green = a good spread of the

measurement points.

Function buttons

Edge warning

When the laser beam is

close to the edge, the edge

is “lit up” as a warning. It

is not possible to register

values when you see the

edge warning.

Back. Measure previous position or back to Distance view.

See “Control panel” on page 15.

Switch to the EasyTurn™ method.

Switch to the 9-12-3 method.

Switch to the Horizontal Multipoint method.

See “SOFTFOOT” on page 47.

54

Continue to the Result and adjust view. Available after registering three

positions.

Measure using 9-12-3

1. Select and to switch to 9-12-3.

2. Adjust laser to the centre of the targets. If needed, adjust the units on the rods,

then use laser adjustments knobs.

3. Turn shafts to 9 o’clock.

4. Press

5. Turn shafts to 12 o’clock.

6. Press

7. Turn shafts to 3 o’clock.

8. Press

Current machines

to register rst position. The rst position is automatically set to zero.

to register second position.

to register third position.

selected

S-unit

Machine train

Target

Laser point

Edge warning

Detector values

Return to enter distances