Easy-kleen Magnum 4000 Ultra, Magnum 4000 Plus, Magnum 4000 Gold, Magnum 4000 3600 User Manual

MAGNUM 4000 SERIES

OWNER’S MANUAL

ULTRA

GOLD

NEW

2014

PLUS 3600

Call 1-800-315-5533

Email sales@easyleen.com

Easy Kleen Pressure Systems

1-800-315-5533

This manual contains operational information that is specific for

Hot and Cold Water Pressure Washers.

Read the following instructions carefully before attempting to assemble,

install, operate or service this pressure washer. Failure to comply with the

instructions could result in personal injury and/or property damage.

CONTENTS

Safety Information

Introduction

Operating Instructions

Chemical Application

Winterization of Pressure Pump and Coil

General Maintenance Instructions

Maintenance Checklist

Glossary of Terms

Warranty

Pressure Washer Components Diagram

Troubleshooting Guide

** Hot Water Pressure Washers Only

SAFETY

WARNING

: To reduce the risk of

carefully before using.

WARNING

: Use protective

WARNING

: This machine

ear protection must be worn.

The safe operation of our pressure washing systems is the FIRST priority of Easy Kleen. This

will only be achieved by following the operation and maintenance instructions as explained in

this manual and all other enclosed manuals.

IMPORTANT SAFETY INFORMATION:

ALL

CAUTIONS

INJURY OR DAMAGE TO EQUIPMENT.

AND SAFETY WARNINGS MUST BE

FIR

S

FOLLOWED

T

TO AVOID

THIS EQUIPMENT IS TO BE USED ONLY BY TRAINED OPERATORS

ALWAYS BE ATTENDED DURING OPERATION.

injury, read operating instructions

Read the instructions in this manual carefully before attempting to assemble,

install, operate or service this pressure washer. Failure to comply with the

instructions could result in personal injury and/or property damage.

AND MUST

** Hot Water Pressure Washers Only

eyewear and clothing when

operating equipment in order

to avoid personal injuries.

exceeds 85db. Appropriate

IMPORTANT SAFETY INFORMATION

WARNING

:

Risk of explosion.

or torch is permitted.

WARNING

:

Flammable liquids can

WARNING

:

Risk of fire. Do not

WARNING

:

Keep water spray

WARNING

:

Risk of asphyxiation.

ventilated area.

WARNING

:

Risk of injection or

clear of nozzle spray.

Operate only where open flame

Use only #2 furnace oil or Diesel fuel in the burner fuel tank.

add fuel when operating machine.

Never use gasoline, crankcase draining, or waste oil in your burner fuel tank.

Never run pump dry or let the pump run with the trigger gun released for

more than 2 minutes. The minimum clearance to any combustible material is

12 inches.

away from electrical wiring.

All electrically powered equipment must be grounded at all times to prevent

fatal electric shots. Do not spray water on or near electrical components. Do not

touch electrical components while standing in water or when hands are wet.

Always make sure machine is disconnected from power source before servicing.

create fumes which can ignite, causing

property damage or severe injury.

** Hot Water Pressure Washers Only

Use this product only in a well

Use equipment in a well ventilated area to avoid carbon monoxide poisoning or

death. This machine must never be connected to a Type B gas vent.

severe injury to persons. Keep

High pressure spray can cause serious injuries. Never point pressurized spray

at any person or animal. Handle the spray assembly with care.

IMPORTANT SAFETY INFORMATION

WARNING

:

Risk of injury. Hot

WARNING

:

Hot discharge

WARNING

:

Trigger gun kicks

WARNING

:

Risk of injury

WARNING

:

Protect from freezing.

surfaces can cause burns.

back. Hold with both hands.

Hold firmly to the gun and wand during start up and operation of the machine.

Do not attempt to make adjustments while the trigger gun is in operation.

from falls when using ladder.

fluid. Do not touch or direct

discharge stream at persons.

Do not overreach or stand on anything unstable. Keep a good balance and

make sure to keep a steady footing at all times.

It is important to keep your machine from freezing in order to keep it in its best

working condition. Failure to protect your machine from freezing may cause

damages to the machine and personal injuries may occur as a result.

If you need further explanation of any of the information in this manual,

suspend any activity involving the equipment and call our toll free number

for assistance, 1-800-315-5533.

** Hot Water Pressure Washers Only

OPERATING INSTRUCTIONS

1. P

erform pre-start

the machine. This is essential for the safe, effecti

optimum performance from your system ONLY if these instructions and inspections are

followed. Any indication that the pressure washing system was not operated and maintained

according to these instructions may cancel the manufacturers’ warrant

maintenance inspection on all applicable systems prior to operating

ve and efficient operation. You will get

y.

Location – Gasoline

Controls – Make sure all

Pu mp – O il l ev el - Level the pressure washer. Be sure oil level in the pump is

correct on dip stick. If the level is low, add the correct oil to the

SAE 30 W NON-DETERGENT OIL OR HYDRAULIC 68. DO NOT OVER FILL.

Gas Engine - Gasoline level – The engine is a 4 cycle and uses

fuel. DO NOT USE MIXED FUEL. Refer to the engine operation manual included with

your

pressure-washing unit.

Gas Engine - Oil level – The engine is a 4 cycle and uses 10W30 detergent oil. Refer to

Glossar

**Oil Fired Burner - Oil Tank Level – #2 Furnace oil is

Hot Water Pressure

Diesel fuel may be used as an alternative. Do not overf

y or engine manual.

powered

controls

Washers.

machines must be outdoors in a well ventilated area.

turned to the off position.

proper level. USE ONLY

It burns cleaner

regular

recommended fuel for

and

the burner requires less

ill burner tank

octane, unleaded

Oil Fired

maintenance.

.

Visually inspect all e

Visually inspect all hoses, nozzles and guns to assure they are in

replacements

2. Attach the

Ensure that the quick disconnect connections are tightly locked t

pull on the hose to confirm.

Attach the wand nozzle specific to the task requirements (i.e. chemical or pressure wash).

[Quick Coupling Operation – Pull back sleeve end and insert male end into fitting, release

sleeve and confirm connection.]

** Hot Water Pressure Washers Only

high-pressure

lectrical components to assure they are in

no signs of exposur

are necessar

y they must be rated to withstand the machines operating

pressure and temperatur

hose to the outlet coupling on the coil heat exchange system.

e,

breakage or splicing.

es.

good condition, showing

good condition. If

ogether

. Apply a sharp

3. A

ttach the water

be attached with a good

Connect the male fitting into the female pump inlet swivel fitting, make sure that th

inlet

screen/filter

BE IN SUFFICIENT SUPPLY AND PRESSURE MUST BE BETWEEN 20 –

60 PSI TO ENSURE PROPER AND SAFE OPERATION. Specific attention should be

given if using a well water supply. Ensure water is flowing from end nozzle with the trigger gun

pulled. Deplete system of all air.

4. Start gas engine / electric motor and switch on burner

•

Gasoline engine - refer to the instructions in the Engine Manual MAKE SURE

THAT THE ENGINE EXHAUST IS NOT FACING ANY FLAMMABLE

MATERIALS. Adjust the burner thermostat control to ON at the desired temperature.

•

Electric Motor – Turn burner switch to PUMP, adjust the burner thermostat to desired

temperature, turn switch to BURNER.

source to the water inlet located on the pump. The water

quality standard

is intact and fitted correctly. Turn on the water source. WATER MUST

garden type hose, 1/2” minimum is required

source

must

.

e

5. **Burner

Be sure water is flowing through water heater coil before turning on burner switch. Turn

thermostat to desired temperature. Burner will ignite and remain in operation as long as there is

sufficient water flow to satisfy the pressure switch and temperature control.

To shut off burner, turn temperature switch to "Off". Allow the engine/motor to continue to run.

Pull the trigger gun to allow water flow to run through the coil for approximately 2 minutes prior to

completely shutting off the system. This process will allow coil to cool down.

IF

YOU

BURNER! EXCESS FUEL AND VAPORS MAY HAVE ACCUMULATED AND THE

CHAMBER MAY BE HOT. THE UNIT

BE A

TTEMPTE

Warning: Condensation on Coil

When cold water is being pumped through the heater coil and the burner is firing, condensation

may form at times on the coil and drip down into the burner compartment. This can be

particularly noticeable on cold, humid days giving the false appearance of a leaking coil.

operation

EXPERIENCE

D.

IGNITION FAILURE, DO NOT ATTEMPT TO RESTART

MUST COOL DOWN BEFORE RESTART CAN

** Hot Water Pressure Washers Only

Eec

trically

and provide the necessary power

must be g

YOUR EXISTING ELECTRICAL SYSTEM IN ORDER TO

PRESSURE WASHER, THEY MUST BE PERFORMED

ELECTRICIAN AND BE COMPLETED

Operated

rounded

Burners

– Some models generate 12V from the gasoline engine

for the burner.

Others utilize a 120v connection which

. IF YOU REQUIRE UPGRADES OR

IN ACCORDANCE TO ALL A

MODIFICATIONS TO

OPERATE YOUR

BY A LICENSED

PPLICABLE

CODES IN YOUR AREA OF OPERATION. The power supply must be adequate for

your specific unit. Make sure to verify the data plate for your machine’s specific

requirements (i.e. voltage, amperage, etc).

WARNING:

All electrically powered units must be provided with suitable overload a

overcurrent protection in accordance with the Canadian Electrical

Code part 1.

Confirm the GFCI (Ground Fault Circuit Interrupter) is in good working order.

6.

Pressure

diagram). It

regulator

Turning the

adjustment - The pressure regulator (unloader) is located on the pump (see

controls

may be adjusted to the desired pressure by

adjustment

the pressure being generated by the

turning

knob clockwise will

increase

the

pressure washer.

the

adjustment

pressure.

NEVER

This

knob.

OPERATE

SYSTEM AT A HIGHER P S I THAN THE MAXIMUM RATING. This machine has

been adjusted to operate at a specific maximum pressure as per the machine

specifications. Pressure may be reduced

for

lighter use by

turning

the

Pressure

Regulator/Unloader counter clockwise.

7.

You are now ready to start the cleaning operation

- Pull trigger on the pressure wand

assembly to start cleaning. To stop the pressurized water, release the trigger. DO NOT

LEAVE

8. **

To stop Burner operation – Turn the burner control switch to off (or PUMP for

electric machines) and

UNIT RUNNING WHEN NOT IN USE.

run

pump for two minutes with the trigger gun pulled to allow

the coil to cool down. After the cooling period is complete, turn off main

power

reli

to engine/motor. Squeeze and release the trigger for the second time in order to

eve the pump system of pr

essur

e.

n

d

9.

Prior to storage

– Inspect the pressure washer for any damage

or

required

maintenance. If your machine needs to be exposed to cold weather, please refer to the

winterization instructions found in this manual. If possible, d

o not allow unit to remain

outside in the elements.

10.

Warning – If unit is left running while not in use, pump damage may occur.

not leave unit running while not in use!

11.

Battery Specifications for electric start systems only

– Rating: 165CCA,

190 CA or better, dimensions: 8” x 5” x 6”.

** Hot Water Pressure Washers Only

Do

CHEMICAL A

PPLICATION

DOWNSTREAM CHEMICAL INJECTION – STANDARD

N

OTE: Do not remove back

the potable water source. Ensure the black nozzle is properly fitted at the

end of the wand. The chemical injector will not function if this nozzle is

not correctly in place.

flow

preventer as chemical may

flow

back into

1. Chemical

cleaning task.

instructions. The volume of chemical being used may be adjusted at th

valve located on the chemical injector.

2. Insert the intake hose, located on the chemical injector at the pump,

the chemical being used.

3. Turn the

OR when single lance is used, black nozzle will need to be used

wand.

4. To apply chemical, engage the trigger on the pressure wand assembly.

Turn the chemical injector’s nipple to adjust flow.

5. Chemical can now be applied through the pressure wand assembly. It will

take 5 – 15 seconds for the chemical to travel to the spray nozzle. Volume

of chemical being used or water being supplied may be

Chemical Injector.

preparation

Prepare

adjustment

– Select the

the dilution

knob on the wand or lance to the open positio

detergent/chemical

according

to the manufacturer

that best suits

adjusted

at the

’s

on

int

n

your

e

o

6. For best results apply chemical from bottom to top, allow the c

proper penetration time prior to rinsing. Do not allow the chemical to

dry. Rinse from the top to the bottom.

7.

Optional high pressure chemical injection systems available. Plea

contact Easy Kleen.

** Hot Water Pressure Washers Only

hemical

se

NTER PUMP/COIL

WI

PROTECTIO

N

The following

unit is stored at

1. All water must be

Connect a short piece of male fitted ½” garden type hose on to th

female inlet on the pump.

2. Place the open end of the hose into a wide mouthed container of full

strength,

RATED FOR MINIMUM -40°C.

3. Connect the pressure wand

4. Start the engine and engage the trigger on the pressure gun. Operat

the system until the fluid runs the same color as the windshield washing

fluid. Your machine is now

procedure

temperatures

winter rated, vehicle windshield washing fluid or Anti-Freeze,

MUST be used when the pressure washing

below freezing.

drained

or blown (via compressed air) from

a

ssembly.

prepared

for storage.

system.

e

e

5. Blow out,

** Hot Water Pressure Washers Only

disconnect

fluid supply & pump out

excess

or cap

end

GENERAL MAINTENANCE

**BURNER

Repair of the burner is to be done by authorized and trained burner professionals only.

GENERAL MAINTENANCE AND CARE

If the water heater is likely to be exposed to freezing weather then it should be

winterized with anti-freeze. Circulation of an anti-freeze solution through the coil by means of

the pumping module is the most fail-safe method and should be used. Alternate methods may

not completely protect the components. Damage from freezing is not a warrantable item.

Water Condition

mineral content. The advantages of soft water are very beneficial: prevents scale buildup in heater

coil, cleans better with considerably less detergent, prevents streaking on painted surfaces and

glass when rinsing.

**Descaling Heater Coil

as excessive scale in heater coil will reduce efficiency of the unit and affect recovery capacity.

Descaling via use of acid may be hazardous and is thus not recommended.

MAINTE

Use a softener on your water system if local water is known to be high in

NANCE

If heater coils develop excessive scale buildup it should be replaced

** Hot Water Pressure Washers Only

MAINTENANCE CHECKLIST

PUMP

D

AILY

1. Check oil for proper level and adjust accordingly.

2. Examine the quality of the oil.

3. Check pump for oil and/or water leaks.

4. Inspect and clean inlet filters.

WEEKLY

1. Examine all fittings, components, hoses, connections,

loose parts, or leaks. – Replace accordingly—

RECOMMENDATION FOR OIL CHANGES AND COMPONENT REPLACEMENTS

1. Change the oil in the pump after the first 50 hours and every 500 hours after the

initial oil change. Use SAE 30 W Non-Detergent for GP Pumps and Hydraulic 68 for

EK Pumps.

2. Change all other components on the pump as needed.

and nozzles for damages,

GASOLINE ENGINE

DAILY

1.

Check oil for proper level and adjust accordingly.

2. Examine the quality of the oil.

3. Examine the air cleaner element.

WEEKLY

1. Examine engine components for damages, loose parts, or leaks.

RECOMMENDED SCHEDULE FOR OIL CHANGES AND COMPONENT REPLACEMENTS

1. Change the engine oil after the first 5 hours and eve

change. Use 10W-30 engine oil.

2. Replace the spark plug every 100 hours.

3. Change the air cleaner element every 100 hours.

4. Check fuel filters every 300 hours.

5. Change all other components on the engine as needed.

ry 100 hours after the initial oil

GLOSSARY OF

PSI

– Pounds per square inch. Pressure washers are designed and rated to operate at a specific

PSI. Operating at pressures exceeding the maximum rating could result in damage to the unit

and/or SEVERE PERSONAL INJURY.

GPM

– Gallons per minute. The orifice on the pressure wand assembly has been selected to

deliver up to the maximum GPM for your machine.

TE

RM

S

PRESSURE WAND ASSEMBLY

PUMP

assembly.

UNLOADER VALVE

into the bypass when the trigger gun is shut off. It also reduces the load on pump when gun is off.

OIL, PUMP

30 W Non Detergent (GP Pump) or Hydraulic 68 (EK Pump) in the pump (see diagram).

OIL, GASOLINE ENGINE

appropriate lubricant. Use 10W30 detergent oil.

BURNER

and may be powered by furnace oil or diesel fuel.

BACK FLOW PREVENTER

MAXIMUM WORKING PRESSURE The water heater coils are designed to operate safely at

normal working pressures of 4000 PSI. Each machine is equipped with a safety pressure relief

valve which prevents over pressurization of the high pressure system. It is an important safety

device and must not be tampered with in any way.

– The pump moves the water through the system and delivers it to the

– Is a valve located at the head of the pump for unloading water back

– The oil used within the pump to lubricate its operation. Important to use only SAE

– The burner heats the water in hot water pressure washers. It is located under the coil

– This refers to the gun, wand, and nozzle.

pressure wand

– Machines which are powered by gasoline engines need

– Device to prevent flow backwards into potable water supply.

TEMPERATURE CONTROL-

shuts down the burner in the event of excessive outlet temperature caused by insufficient water

flow through the heater coil. Do not set thermostat above 195˚F

HIGH PRESSURE SWITCH -

the burner control system (see diagram).

The water heater is equipped with a temperature control which

A high pressure switch is used to control the burner. It is part of

OFF

– PUMP

– BURNER Switch

Pressure S

witch

Site Glass

Electric Motor

Moteur Électrique

10 Gal.

Fuel Tank

Réservoir à Fuel

10 Gal.

Coil

EK

Pump

Oil Cap

Water Inlet

Entrée pour l’Eau

Hot Water Outlet

Sortie d’Eau Chaude

Unloader

Régulateur à Pression

13” Pneumatic Tires

Pneus 13”

High Pressure Connector Hose

Tuyau Connecteur à Haute Pression

General Pump Also Available

(GP)

Interrupteur “Arrêt – Pompe – Brûleur”

Serpentin

Pompe “General Pump” Aussi Disponible (GP)

Type of Oil needed for Pumps:

EK Pump – Hydraulic 68 (650ml)

GP Pump – SAE 30 Non-Detergent

Type d’Huile pour les Pompes:

Pompe EK – Hydraulique 68 (650ml)

Pompe GP – SAE 30 Non-Détergente

Vitrine à Niveau

Bouchon d’Huile

Pompe EK

Pressostat

Chemical Injector

Injecteur de Produits Chimique

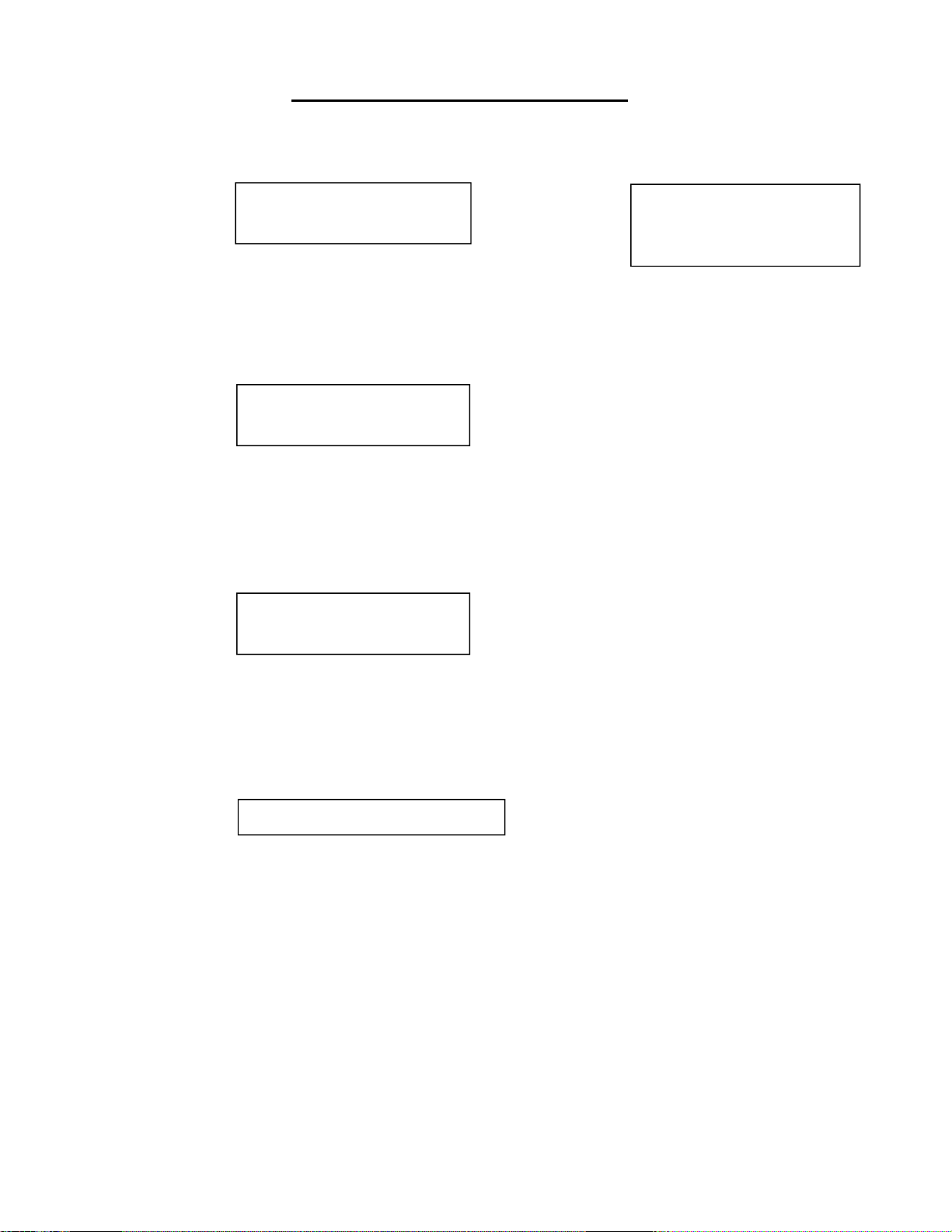

Site Glass

Pressure Switch

Coil

Serpentin

10 Gal Fuel Tank

Electric Starter

Démarreur Électrique

Gasoline Engine

Oil Cap

Unloader

Régulateur à Pression

Hot Water Outlet

Water Inlet

Entrée pour l’Eau

EK Pump

High Pressure Connector Hose

Tuyau Connecteur à Haute Pression

Pressure Relief Valve

Rectifier

Thermostat Knob

Règlage du Thermostat

Type of Oil needed for Pumps:

EK Pump – Hydraulic 68 (650ml)

GP Pump – SAE 30 Non-Detergent

Type d’Huile pour les Pompes:

Pompe EK – Hydraulique 68 (650ml)

Pompe GP – SAE 30 Non-Détergente

General Pump Also Available (GP)

Pompe “General Pump” Aussi Disponible (GP)

Moteur à Gaz

Réservoir à Fuel 10 Gal.

Bouchon d’Huile

Vitrine à Niveau

Pressostat

Valve de Décharge à Pression

Chemical Injector

Injecteur de Produits Chimique

Pompe EK

Rectificateur

Electric Motor

Moteur Électrique

Water Inlet

En

trée pour l’Eau

Hot Water Outlet

Hot Water Outlet

Sortie d’Eau Chaude

Water Inlet

Entrée pour l’Eau

Fold Down Handle

General Pump Also Available (GP)

EK Pump

Gasoline Engine

EK Pump

Unloader

Régulateur à Pression

Unloader

Régulateur à Pression

Pompe “General Pump” Aussi Disponible (GP)

Poignée Dépliante

Pompe EK

Moteur à Gaz

Type of Oil needed for Pumps:

EK Pump – Hydraulic 68 (650ml)

GP Pump – SAE 30 Non-Detergent

Type d’Huile pour les Pompes:

Pompe EK – Hydraulique 68 (650ml)

Pompe GP – SAE 30 Non-Détergente

Pompe EK

22

Burner fan starts up when the machine

QUICK DIAGNOSTIC AND SOLUTIONS GUIDE

(FOR MORE INFORMATION, PLEASE CALL 1-800-315-5533)

TYPE OF OIL

Pump 30W Non-Detergent

Gas Engine 10W30

PROBLEM POSSIBLE CAUSES SOLUTIONS

PRESSURE

No pressure

or

Very low pressure

Pressure too high

Burner fan does not shut down

or

- Metal in oil

- Dirt in water

- Wrong nozzle size

- Wrong nozzle size

- Unloader adjusted improperly or damaged

LOSS OF BATTERY CHARGE (12 VOLT SYSTEM)

- Thermostat is stuck or damaged - Make sure the thermostat is working properly. Take dial off thermostat button. Turn the

- Examine the oil in the pump to see if there is metal in the oil.

- If you find traces or pieces of metal, your pump has damaged components.

- Verify if there is dirt in the nozzle tip or in the valves in the pump.

- If the nozzle is plugged, clean it or replace it.

- If the valves in the pump are clogged, clean the valves.

- If the valves in the pump are dammaged, replace the valves.

- Make sure you have the right nozzle size. The black nozzle will drop the pressure in

order to use the chemical injector. If you are not using soap, try using a different color.

- Make sure you have the right nozzle size.

- Check the pressure of the pump with a pressure guage and adjust to desired pressure.

- If you cannot reduce the pressure, replace the unloader.

2 screws about a quater of a turn to the left (counterclockwise). Put dial back on. Try to

shut off thermostat.

- If you don’t hear a click when you turn the dial completely over, replace the

thermostat.

is not in use

NOTE : The newer 12 volt models now have an on/off swtich that is designed to cut off

the current between the battery and the burner in order to preserve the battery’s charge. If

you have a model that does not have this switch, please call us for more info.

23

BURNER

pressure switch by unscrewing the 4 screws on the front part of the switch (switch is located on the

IN ORDER TO AVOID SERIOUS INJURIES, PLEASE DO NOT ATTEMPT TO REPAIR YOUR MACHINE IF THE PROBLEMS YOU ARE FACING ARE GREATER T

HAN

TAKE THE NECESSARY

STEPS TO AVOID ELECTRIC S

HOCKS AND OTHER INJURIES.

FOR THESE STEPS, PLEASE MAKE SURE THE MACHINE IS NOT RUNNING. PLEASE ALSO

No hot water

- Dead battery

- Damaged thermostat

- Damaged pressure switch

- Dam

aged ignitor

- Make sure your battery is fully charged.

If the battery’s charge is not full, please replace or re-charge your battery.

-

- Make sure the thermostat is connected properly.

- If the burner fan does not come on when you turn the thermostat dial, replace the

thermostat.

- If the burner fan comes on, check the pressure switch.

- Make sure the pressure switch is connected properly to the burner unit. Take the cover off the

pump). Without touching the contacts that conduct current, push on the little button found on the

mirco switch (the button is located directly above the part that attaches directly into the pump).

- If the burner comes on, replace the pressure switch.

- If the burner does not come on, make sure there is current going through the swtich

(consult a professional for this if you do not know how to do this properly as you can get

severly injured by the electrical current connected to your machine)

. If current properly flows through the pressure switch to the burner, check the ignitor.

- Please call a repair center or PowerJet’s service line for help to conduct tests on the ignitor.

- If you see vapor coming out the top of the coil when you try to turn the burner on while

the machine is in use, fuel is passing through the system properly but the ignitor is unable

to produce a spark. Replace the ignitor.

- I

f you don’t see vapor, check the fuel line.

- Plugged filter or no fuel

- Make sure you have enough fuel in the tank.

- If you have fuel, make sure the filter and fuel line are not plugged or damaged.

YOUR CAPABILITY TO HANDLE SAFELY. PLEASE CALL EASY KLEEN OR A PROFESSIONAL REPAIR CENTER IF YOU NEED HELP WITH YOUR MACHINE.

Loading...

Loading...