INSTALLATION AND OPERATING

INSTRUCTIONS FOR EASY HEAT IN-LINE

PIPE HEATING CABLE

Your heating cable has been designed to prevent water supply pipes from

freezing in winter. In addition, the heating cable has been designed for a quick,

easy and professional installation. State-of-the-art plumbing ttings, electrical

controls and heating cable have been provided to ensure a safe,economical

and long-lasting water line freeze protection.

These heating cables are primarily designed for use in water supply lines for

residential and commercial applications. Do not use this heating cable for other

types of applications without rst contacting Easy Heat Ltd. for professional

advice.

We recommend that the heating cable kit be installed by persons with adequate

knowledge of plumbing and electrical installations.

CAUTION – READ THIS BEFORE ATTEMPTING INSTALLATION

For 1.25” diameter Polyethylene

Water Pipes

Read carefully and follow these instructions for an efcient, safe and economical

installation. It is important that you assemble the proper tools and other supplies

(e.g. insulation, plumbing ttings, etc.) prior to beginning your heating cable

installation.

With proper installation, this heating cable will provide many years of trouble free

service. We recommend you retain these instructions for future reference.

USA

2 Connecticut South Drive

East Granby, CT 06026

www.easyheat.com

11001-062 Rev. 6 ©2015 Easy Heat

Tel: 800-537-4732

Fax: 800-541-7451

Canada

99 Union Street

Elmira, ON N3B 3L7

Tel: 800-794-3766

Fax: 800-361-4574

INSTALLATION AND OPERATING

INSTRUCTIONS FOR EASY HEAT

IN-LINE PIPE HEATING CABLE

LIMITED WARRANTY AND LIABILITY

Easy Heat warrants that if there are any defects in material or workmanship in this product

during the rst year after the date of its purchase, we will replace the product with an equivalent

model, not including any labor or other installation costs.

Our obligation to replace the product as described above is conditioned upon (a) the installation

of the product conforms to the specications set forth in our installation instructions and (b) the

product not having been damaged by unrelated mechanical or electrical activities.

Product replacement as described above shall be your sole and exclusive remedy

for a breach of this warranty. This limited warranty does not cover any service costs

relating to repair or replacement.

We shall not be liable for any incidental, special or consequential damages as a result of

any breach of this warranty or otherwise, whether or not caused by negligence. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

The warranty above is exclusive and makes no other warranties with respect to description or

quality of the product. No afrmation of fact or promise made by us, by words or action, shall

constitute a warranty. If any model or sample was shown to you, the model or sample was

used merely to illustrate the general type and quality of the goods and not to represent that the

goods would necessarily be of that type or nature. No agent, employee or representative of

ours has authority to bind us to any afrmation, representation or warranty concerning

the goods sold unless such afrmation, representation or warranty is specically

incorporated by written agreement.

Any implied warranty of merchantability or tness for particular purpose that may arise

in connection with the sale of this product shall be limited in duration to one year from

the date of purchase. We disclaim all other implied warranties, unless we are prohibited

by law from doing so, in which case all such implied warranties shall expire at the earliest

time permitted by applicable law. Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.

This warranty gives you specic legal rights, and you may also have other rights which vary

from state to state or province to province.

To obtain a replacement under this warranty any inoperative product or component must

be returned, with proof of purchase, to Easy Heat at the addresses noted herein. Buyer is

responsible for all costs incurred in removal and re-installation of product and must pre-pay

shipment to factory or point of purchase.

In Canada In USA

Heating Cable Warranty Department Heating Cable Warranty Department

99 Union Street 2 Connecticut South Drive

Elmira, ON N3B 3L7 East Granby, CT 06026

CAUTION – READ THIS BEFORE ATTEMPTING INSTALLATION

1. Do not attempt to pull the cable by the end connector; this connector

prevents the inltration of water into the cable, and excessive force could

damage this seal. The cable has been provided with a pull cord to ensure

that the cable is not damaged when being pulled through the piping.

2. The heating cable cannot be altered in length. Any attempt to physically

alter the heating cable will void the warranty. Once cut, the heating cable

cannot be repaired.

3. If the heating cable is insufciently exible to facilitate installation, perhaps

due to cold temperature, first completely uncoil the cable and then plug it

into a 120 VAC outlet until it is warm and pliable. The cable can then be

installed in the pipe. NEVER PLUG IN THE HEATING CABLE WHILE IT

IS COILED. If the heating cable touches itself while plugged in, as would

be the case if the cable is coiled, the outer PVC jacket will melt. This could

result in a loss of electrical insulation and, as the cable cools after it is

unplugged, the jacket will fuse together and the cable then could not be

uncoiled. A cable damaged in this manner must be discarded and is not

warranted.

4. Do not install heating cable in pipes that are heated to above 66°C

(155°F).

5. If the Ground Fault Circuit Interrupter (GFCI) trips during normal operation,

and cannot be reset, then there is likely a fault in the cable and the heating

cable system should not be energized. UNDER NO CIRCUMSTANCES

SHOULD THE GFCI BE BYPASSED.

6. The cable has been pre-assembled and sealed to the T-coupling; do not

alter the T-coupling connection as damage to the cable and/or coupling

could result.

WARNING

The plastic tting surrounding the black power supply cord is factory

tightened. If additional tightening of the tting is required to stop

leakage, do so in 1/8 turn increments. Overtightening may damage the

cord and result in electrical failure.

7. The heating cable must be installed straight inside the pipe and must not

touch, cross, or overlap itself at any point inside the water pipe, as this

could cause the cable to overheat and melt the cable (and/or the plastic

pipe). This could then result in a ground fault or short circuit, which would

require replacement of the cable.

List of Components

The following components are included in your in-line pipe heating cable kit:

• heating cable pre-assembled to T-coupling **Warning: The heating cable

has been pre-assembled and sealed to the T-coupling at the factory – do

not adjust these connections as damage to the T-coupling, cable and/or

seal may occur.

• stainless steel end connector clip.

• power control enclosure (SL1-G or SL2-G), includes thermostat and GFCI

receptacle.

• two tie-wraps (to attach thermostat sensor to pipe).

The longer lengths of heating cables are supplied on a convenient spool.

DO NOT REMOVE THE HEATING CABLE/T-COUPLING FROM THE CABLE

SPOOL.

In addition, you will require insulation and protective covering (to reduce wind chill

effect) for any exposed areas of pipe, an assortment of tools (e.g. electrician’s

sh tape), plumbing supplies, etc., depending on your specic installation.

Preparation for Installation of Heating Cable

This heating cable has been designed to prevent water supply pipes from

freezing. It is expected that the cable will be entirely inserted into 11/4” diameter,

buried and/or insulated, polyethylene water piping. In addition, if the cable is

being installed in a pressurized pipe, it is recommended that the maximum

system pressure be less than 60 psig. The heating cable life expectancy can

be extended if the cable is installed in non-pressurized piping. For example, the

installation of a check valve at the suction port of a jet pump will ensure that the

suction piping is not pressurized; hence, a heating cable in the suction piping

will not be subjected to system pressure.

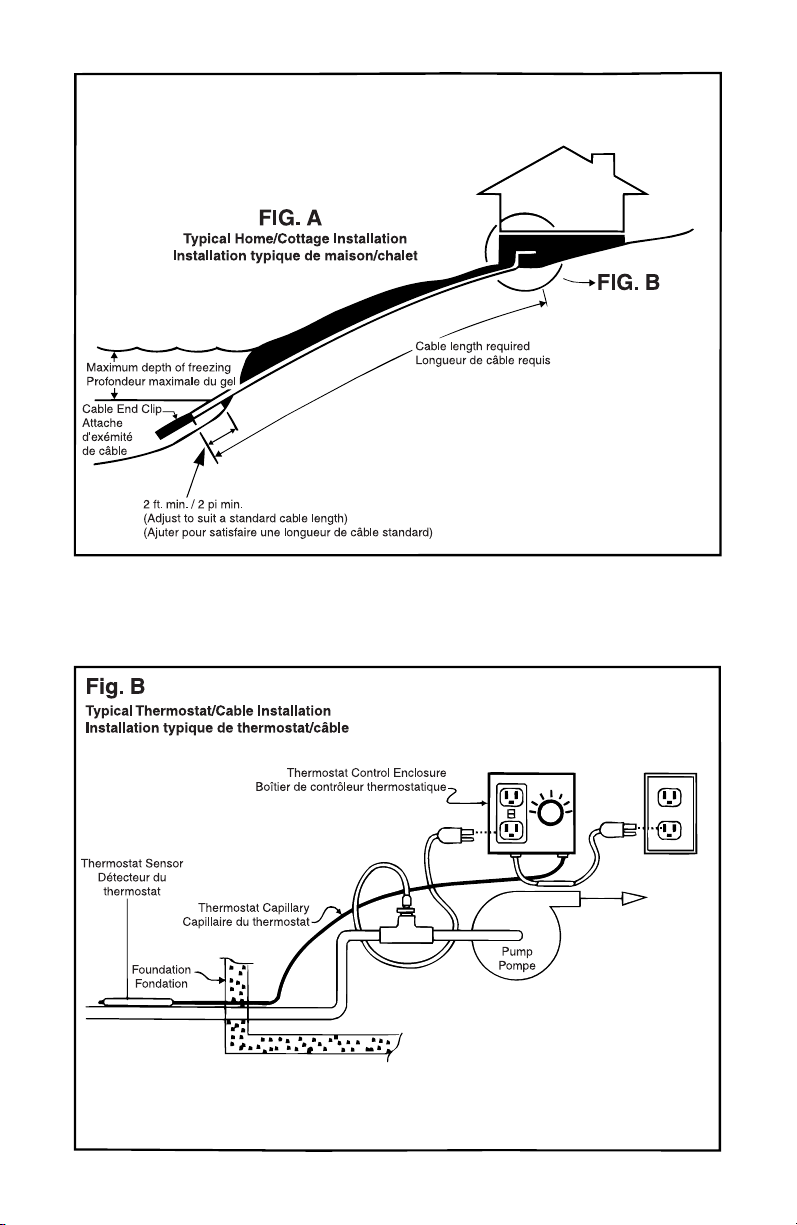

The heating cable inside the pipe should extend beyond the furthest point of

the pipe, which would, if unheated, be expected to freeze in winter. The pipe

itself can, if necessary, further extend beyond the end of the cable. Refer to

Figure A.

It is not possible to alter the length of the cable to accommodate a nonstandard

length of piping. These heating cables are available in a wide variety of standard

lengths; ensure that the cable you have chosen for your installation is of

appropriate length.

The insulation of the complete length of the outdoor piping is optional, except

in areas of extreme cold. Insulation of the piping is best accomplished by the

use of a maximum of 1/2” thick polyethylene foam (PEF) insulation, such as

the “Tundra®” insulation available at most hardware stores. (Unlike berglass,

polyethylene foam insulation is not affected by water). The addition of the 1/2”

thick PEF jacket will greatly improve the freeze protection capability and energy

efciency of any installation; the associated energy savings and enhanced pipe

freeze protection will more than offset the small cost of that insulation.

WARNING: Never use more than ½” thick polyethylene foam (PEF) or other

equivalent non-ammable insulation. Over insulation can cause the heating

cable to overheat and cause serious re hazard or electrical shock.

If uninsulated, the water supply pipe should be buried in at least 3” of topsoil or

sand. Any sections of pipe exposed to the elements should be insulated and

protected from wind, as the “wind chill factor” can be a serious impediment to

the performance of the heating cable. For example, a large drainpipe can be

used to protect the water pipe from wind chill effects and from such damage as

may occur due to, for example, ice movement at the water shore.

Insulation of underwater piping can present signicant problems, primarily due to

the fact that PEF insulation is quite buoyant and will tend to make the water pipe

oat on the surface of the water. This can be overcome by attaching weights, such

as steel or concrete, to the insulated piping. In general, insulation of underwater

piping is probably not necessary below about the 1 foot water depth.

It is recommended that the in-line pipe heating cable system be energized at

all times during the winter season such that water supply pipes do not freeze.

(During warmer winter periods, the thermostat control will automatically

disconnect power from the heating cable to minimize energy consumption). In

the event that the water pipe freezes, such as might happen during an electrical

power interruption, it might take a few hours to thaw a frozen pipe once power is

restored, depending on the weather conditions, duration of power outage, etc.

It is not recommended that the cable be used to regularly thaw uninsulated

frozen pipes. If power outages of 24 hours or more are frequently expected,

or if the cable is to be used to regularly thaw frozen pipes, it is recommended

that the complete length of outdoor piping be insulated.

The heating cable must only be plugged into the receptacle in the power control

enclosure. Hence, the power control enclosure must be mounted in close

proximity to the cable exit from the T-coupling. Refer to Figure B. Ideally, the

power control enclosure should be located within 10 ft of the estimated coldest

point of the water pipe such that the thermostat sensor can be attached there.

This ensures that heat is always applied to the pipe as required to ensure that

the coldest point does not freeze.

If it is not possible to locate the power control enclosure within 10 ft of the

estimated coldest point of the water pipe, the thermostat adjustment capability

can compensate for this. In such a case, however, the thermostat sensor must

be installed onto a section of the piping, which is expected to be reasonably

cold. In a typical installation of a home/cottage located on a lake with a rocky

shoreline, the piping on the outside of the cottage/home foundation could usually

be expected to be reasonably cold, even though not as cold, perhaps, as the

piping at the rocky lakeshore. Attaching the thermostat sensor to the piping

immediately outside the building foundation and increasing the thermostat

setpoint will still enable the thermostat control to keep the coldest section of

piping from freezing while minimizing energy consumption. Refer also to the

section “Operation of the Heating Cable”.

It is recommended that the power control enclosure and the T-coupling be

mounted in a dry area where no damage will occur to the water line heating

system connections. The T-coupling should be located as close as possible to

the pump, but more importantly, in close proximity to the location of the power

control enclosure. It is suggested that the pumping system be located in a

heated area, as the pump and associated downstream piping must also be

protected from freezing.

Another factor in establishing the location for the power control enclosure should

be the requirement to regularly test the GFCI. Also, the possibility of the heating

cable becoming inadvertently unplugged should be considered. The power

control enclosure contains a GFCI, and hence it is not necessary for this control

to be connected to a GFCI protected outlet. However, it is possible to plug the

power control enclosure into a GFCI protected receptacle, if convenient.

It is recommended that the heating cable be the only load on the circuit supplying

electrical power to the cable.

Installing the Heating Cable

1. Check Piping

Before installing the heating cable, ensure that all joints and inside surfaces

of the pipe are free from any sharp edges or other restrictions which would

inhibit pulling the cable through the pipe or which may damage the heating

cable jacket.

2. Prepare Cable

For cables supplied on spools, remove the power control enclosure from the

center of the spool. (You may nd it benecial to mount the spool on some

convenient axle, such as a broom handle, for easier dispensing).

For cables supplied without spools, uncoil and straighten.

3. Lubricate Cable

You will nd installation easiest in straight lengths of piping; piping with

several 90 degree turns will signicantly restrict the threading of the cable

through the piping; a pull force exceeding 30 lbs. could damage the cable.

Similarly, long piping runs exceeding about 100 feet may also require

excessive force to pull the cable; in such situations, it is recommended that

the piping be lled with water as this provides excellent lubrication for pulling

the cable through the pipe. As an alternate, the cable can be lubricated with

petroleum jelly; do not use any other type of lubricant, as this could

damage the cable and/or result in contamination of the water flowing

through the pipe. It is also advantageous to keep the heating cable as

straight and free from twists and kinks as possible.

4. Thread Cable

Thread heating cable through any plumbing ttings, which may be necessary

to connect the T-coupling to the piping. Refer to Figure C.

5. Attach Pull Cord

Attach the heating cable pull cord to a strong cord or electrician’s sh-tape

which has been threaded through the pipe. It is recommended that tape

be applied around the cable end connector and cord to ensure the end

connector does not get snagged on the inside of the pipe. Do not loop

the heating cable back onto itself for pulling purposes, as this could

damage the heating elements inside the cable. Refer to Figure C. Do

not attach the fish tape directly to the cable end connector.

6. Pull Cable

Gently pull (maximum pull force of 30 lbs) the heating cable through the

water pipe. Remove the T-coupling from the spool hub when the cable is

fully uncoiled from the spool. Disconnect the sh-tape or cord.

7. Secure End Connector

Secure the cable end connector to the piping using the stainless steel clip

provided. Refer to Figure D. Insert the clip through the hole in the cable

end connector. Note that the pull cord does not have to be removed from

the heating cable; the cord and shrink sleeve are “food grade” quality and

can be safely left inside the pipe.

DO NOT ATTEMPT TO REMOVE THE HEAT SHRINK FROM THE CABLE

AS DAMAGE TO THE CABLE MAY RESULT. If desired, the cord can

be cut at either end of the shrink sleeve. Complete associated plumbing

connections.

8. Check Cable

Plug the cable into a 120 VAC outlet to ensure that the cable was not

damaged during installation; the cable should feel warm within one minute

of being energized. Once the cable warmth is detected, unplug the cable

and proceed with installation.

9. Connect T-coupling

Connect the T-coupling to the pipe and complete all plumbing connections,

ensuring that the cable inside the pipe does not touch, cross, or overlap

itself at any point inside the water pipe.

10. Check Cable

It is recommended that the continuity of the cable be tested at this time

to ensure that the cable was not damaged during the completion of the

plumbing connections. Do not plug in the cable in anticipation of sensing

the warming of the piping, as this could take a signicant amount of time

and may not even be noticeable, depending on the weather conditions,

pipe insulation, etc.

Installing the Power Control Enclosure

1. Mount

Mount the power control enclosure in a suitable location as noted in

“Preparation for Installation of Heating Cable” above. Using nylon tie wraps

supplied with the heating cable, attach the thermostat sensor to the pipe.

If this section of pipe is insulated, it is important that the sensor be placed

directly on the pipe and then covered by the insulation.

2. Pressurize

The water supply system should then be returned to normal operation and

all pipes completely lled with water. The power control enclosure can then

be plugged into a properly grounded electrical receptacle.

3. Energize

Plug the heating cable into the receptacle on the power control enclosure

and turn the thermostat control knob to the maximum setting.

4. Adjust

If you are certain that the thermostat sensor was located at the coldest

point of the piping, then set the thermostat temperature control knob to the

minimum setpoint. Otherwise, it is advisable to increase the thermostat

setting somewhat above the minimum setpoint.

Operation of the Heating Cable

Normally, the heating cable does not require any monitoring or adjustment;

the thermostat provided with the cable ensures that the cable is only turned on

when required, i.e. in winter. At all other times, the cable will not be energized

and, hence, minimum energy consumption is assured. Still, it is advisable to

unplug the cable in nonwinter seasons.

If an electrical power failure occurs for longer than a few hours, the water supply

pipe might freeze; this freezing will not damage the heating cable. If power

interruptions are expected to be longer than a few hours in duration, though, and

if such power failures are expected to occur frequently, increasing the thermostat

setpoint can, to some extent, help counteract the effect of power interruptions.

(The higher thermostat setpoint keeps the water in the pipe warmer, thereby

increasing the amount of time required to freeze the water in the pipe during

a power interruption).

If the water pipe should freeze during normal operation, then this likely means

that the thermostat sensor was not located at the coldest portion of the pipe;

this can usually be overcome by simply increasing the thermostat temperature

setting i.e. the thermostat sensor may not necessarily have to be relocated.

The GFCI receptacle contains a pilot light; this light is only illuminated when a

fault on the heating cable is detected.

To test if the power control enclosure is functioning properly and that 120 VAC

power is available, turn the thermostat control knob to the maximum setting,

plug in a 120 VAC powered device such as a light xture. The device should be

energized, in the case of a light xture illuminated.

It is recommended to inspect the thermostat control and its connection to the

electrical power source at the beginning of the heating season and monthly

during operation. Similarly, check the GFCI. Testing of the GFCI is dependent

upon the temperature of the capillary bulb.

a) If the ambient is below 21° C (69.8° F), turn the thermostat control knob

to the maximum setting; the GFCI will be energized. Push the “TEST”

button on the GFCI receptacle; a “ click “ sound should be heard and the

receptacle indicator light will turn on. Push the “ RESET “ button on the

GFCI receptacle to reset the power (the indicator light will turn off).

b) If the ambient temperature is above 22° C (71.6° C), you will need to

“cool down “ the capillary bulb to test the GFCI. It is recommended to wait

until the bulb is below 21° C (69.8° F) as in step a), however if this is not

possible you will need to submerge the capillary bulb in ice water for 10

minutes and then follow the instructions as described in a) above.

c) The GFCI will not be affected by power interruptions.

NOTES

INSTRUCTIONS D’INSTALLATION

ET DE FONCTIONNEMENT CÂBLE CHAUF-

FANT POUR CONDUIT EN LIGNE EASY HEAT

Ce câble chauffant a été spécialement conçu pour éviter que les conduits

d’amenée d’eau ne gèlent en hiver et pour permettre une installation rapide,

facile et professionnelle. Les raccords de tuyauterie, les contrôles électriques

et le câble chauffant dernier cri doivent procurer une protection sécuritaire,

économique et durable contre le gel des conduits d’eau.

La câble chauffant a surtout été conçu pour des applications résidentielles et

commerciales. Ne pas l’utiliser pour d’autres genres d’applications avant d’avoir

demandé des conseils aux experts de Easy Heat Ltd.

Nous recommandons l’installation de l’ensemble de câble chauffant par des

personnes ayant les connaissances appropriées dans les domaines de la

plomberie et des installations électriques.

ATTENTION – LIRE LES PRÉSENTES INSTRUCTIONS AVANT

L’INSTALLATION

Pour conduits d’eau en polyéthylène

diamètres de 1,25 po

Lire attentivement les instructions suivantes pour une installation efcace,

sécuritaire et économique. Il est important d’assembler les outils appropriés

et les autres fournitures (par ex., isolant, raccords de tuyauterie, etc.) avant

d’installer le câble chauffant.

S’il est installé comme il faut, ce câble chauffant fonctionnera longtemps, sans

le moindre problème. Veuillez garder ces instructions à titre de référence.

USA

2 Connecticut South Drive

East Granby, CT 06026

www.easyheat.com

11001-062 Rev. 6 ©2015 Easy Heat

Tel: 800-537-4732

Fax: 800-541-7451

Canada

99 Union Street

Elmira, ON N3B 3L7

Tel: 800-794-3766

Fax: 800-361-4574

INSTRUCTIONS D’INSTALLATION

ET DE FONCTIONNEMENT CÂBLE CHAUF-

FANT POUR CONDUIT EN LIGNE EASY HEAT

GARANTIE ET RESPONSABILITÉ LIMITÉES

Easy Heat garantit que s’il y a des défauts de matériel ou de main-d’oeuvre dans ce produit

pendant la première année de son achat, il remplacera le produit avec un modèle équivalent,

sans inclure les coûts de main-d’oeuvre et d’installation.

Notre obligation de rembourser le produit comme décrit ci-dessus est conditionnée à (a)

l’installation du thermostat conformément aux spécications exposées dans nos directives

d’installation et (b) ce que le thermostat n’ait pas été endommagé par des activités mécaniques

ou électriques indépendantes.

Le remplacement du produit décrit ci-dessus sera votre seul et exclusif recours pour

une violation de cette garantie. Cette garantie limitée ne couvre aucun coût relatif à la

réparation ou au remplacement.

Nous ne serons pas responsable des dommages accessoires, spéciaux ou indirects,

à la suite de toute violation de cette garantie ou autrement, qu’ils soient causés par la

négligence ou non. Certains États ou provinces n’autorisent pas l’exclusion ou la limitation

des dommages accessoires ou indirects; par conséquent, la limitation ou l’exclusion ci-dessus

pourrait ne pas s’appliquer à vous.

La présente garantie ne fait aucune autre garantie en ce qui concerne la description ou la

qualité du produit. Aucune afrmation de fait ou de promesse verbale ou par acte ne constituera

une garantie. Si un modèle ou un échantillon vous a été montré, le modèle ou l’échantillon

a été utilisé simplement pour illustrer le caractère général des biens et non pour représenter

le fait que les biens seront nécessairement de ce type ou de cette nature.

Aucun de nos agents, employés ou représentants n’a le pouvoir de nous lier à toute

afrmation, représentation ou garantie concernant les biens vendus, à moins qu’une

telle afrmation, représentation ou garantie ne soit spéciquement incorporée dans

une entente écrite.

Toute garantie implicite de qualité marchande ou d’adéquation à des ns particulières,

qui pourrait survenir en relation avec la vente de ce produit, sera limitée en durée à un

an à partir de la date d’achat. Nous désavouons toute autre garantie implicite, à moins

que la loi ne nous l’interdise. Dans ce cas, toutes ces garanties implicites expireront au moment

le plus rapproché permis par la loi applicable. Certains États ou provinces n’autorisent pas

les restrictions sur la durée d’une garantie implicite; par conséquent la restriction ci-dessus

pourrait ne pas s’appliquer à vous.

Cette garantie vous accorde des droits spéciques reconnus par la loi, mais elle peut également

accorder d’autres droits, puisqu’ils varient d’un État ou d’une province à l’autre.

Pour obtenir un remboursement en vertu de cette garantie, veuillez retourner le produit ou

composant défectueux avec preuve d’achat, port payé, à Easy Heat aux adresses qui se

trouvent dans le présent document. L’acheteur est responsable pour tout coût encourru dans

l’enlèvement et la réinstallation du produit.

Au Canada aux États-Unis

Heating Cable Warranty Department Heating Cable Warranty Department

99 Union Street 2 Connecticut South Drive

Elmira, ON N3B 3L7 East Granby, CT 06026

ATTENTION – LIRE CES INSTRUCTIONS AVANT L’INSTALLATION

1. Ne pas essayer de tirer sur le câble par le connecteur d’extrémités;

ce connecteur empêche l’inltration d’eau dans le câble, et l’utilisation

excessive de force pourrait nuire à I’étanchéité. Le câble est muni d’une

corde pour éviter qu’il ne soit endommagé quand on tire sur lui pour le faire

passer à travers le conduit.

2. La longueur du câble chauffant ne peut être modifiée. Toute tentative

de modication physique du câble chauffant annule la garantie. Une fois

coupé, le câble chauffant ne peut plus être réparé.

3. Si le câble chauffant n’est pas sufsamment souple pour faciliter l’installation,

peut-être en raison de basses températures, d’abord dérouler le câble et

ensuite le brancher sur une prise de courant de 120 VCA jusqu’à ce qu’iI

soit chaud et exible. Le câble peut alors être instaIIé dans le conduit. NE

JAMAIS BRANCHER LE CÂBLE CHAUFFANT QUAND IL N’EST PAS

DÉROULÉ. Si une partie du câble chauffant touchait une autre partie du

même câble alors qu’iI est branché, comme ce serait le cas si le câble n’était

pas dérouIé, son enveloppe de PVC fondrait. Cela pourrait entraîner une

perte d’isolation électrique et, étant donné que le câble refroidit après être

débranché, I’enveloppe fond et le câble ne peut plus être déroulé. Si un

câble est endommagé ainsi, il faut s’en débarrasser. Dans ce cas, il n’est

pas garanti.

4. Ne pas installer le câble chauffant dans des conduits chauffés à plus

de 66°C (155°F).

5. Si l’interrupteur différentiel saute pendant le fonctionnement normal et qu’iI

ne puisse être remis en état, le câble est vraisemblablement défectueux

et le système ne peut être mis sous tension. EN AUCUN CAS, METTRE

HORS CIRCUIT L’INTERRUPTEUR DIFFÉRENTIEL.

6. Le câble a été préassemblé et sceIIé au raccord en T; ne pas modifier la

connexion du raccord en T vu que le câble et/ou le raccord pourraient

être endommagés.

ATTENTION

Le recouvrement de plastique, entourant le cordon électrique est ajusté

à l’usine. Si un ajustement additionnel est requis an d’arrêter une fuite,

tourner 1/8 de tour à la fois. Un serrement excessif peut endommager

le cordon et causer une panne électrique.

7. Le câble chauffant doit être installé dans le conduit de façon droite et ne

peut se toucher, se croiser ni se chevaucher à aucun endroit dans le

conduit d’eau parce qu’iI pourrait surchauffer et ainsi fondre (et/ou faire

fondre le conduit en plastique). Cela pourrait entraîner un défaut à la terre

ou un courtcircuit, ce qui nécessiterait le remplacement du câble.

Liste d’articles

Voici une liste des articles que comprend la trousse du câble chauffant pour

conduit en ligne:

• câble chauffant préassembIé au raccord en T. ** Attention : le câble chauffant

a été préassembIé et scelIé au raccord en T à l’usine; ne pas essayer

de rajuster ces connexions parce que le raccord en T, le câble ou le joint

d’étanchéité pourraient être endommagés.

• attache d’extrémité du câble en acier inoxydable.

• boîtier de commande mécanique (SL1-G) : comprend le thermostat et la

prise de courant de l’interrupteur différentiel.

• deux attaches autoblocantes (pour xer le détecteur du thermostat au

conduit).

Les câbles chauffants longs sont fournis en bobine.

NE PAS ENLEVER LE CÂBLE CHAUFFANT OU LE RACCORD EN T DE

LA BOBINE.

De plus, il vous faudra du matériau isolant et un revêtement protecteur (an de

réduire l’effet du facteur éolien) pour toute partie de conduit qui est exposée

aux intempéries, ainsi qu’un jeu d’outils (par exemple, un ruban de tirage), des

accessoires de plomberie, etc., selon l’installation.

Préparation de l’installation du câble chauffant

Ce câble chauffant a été spécialement conçu pour empêcher les conduits

d’amenée d’eau de geler. Pour cela, on suppose que le câble est entièrement

introduit dans des conduits d’eau enfouis et/ou isolés, en polyéthylène, d’un

diamètre de 1,25 po. De plus, si le câble est installer dans un conduit sous

pression, nous recommandons une pression maximale inférieure à 60 lb/po2.

La durée de vie du câble chauffant peut être prolongée s’il est instalIé dans des

conduits qui ne sont pas mis sous pression. Par exemple, l’installation d’une

soupape de retenue à l’orice d’aspiration d’une pompe à injection assure que

les tuyaux d’aspiration ne sont pas mis sous pression; en conséquence, le

câble chauffant des tuyaux d’aspiration ne sera pas assujetti à de la pression

d’alimentation.

Le câble chauffant dans le conduit doit dépasser le point le plus recuIé du

conduit, qui, s’il n’est pas chauffé, pourrait geler en hiver. Le conduit même

peut dépasser, au besoin, I’extrémité du câble. Voir g. A.

Il est impossible de modier la longueur du câble pour I’adapter à un conduit

d’une longueur non standard. Ces câbles chauffants sont vendus en plusieurs

longueurs standard; s’assurer que le câble choisi a la longueur appropriée,

pour l’installation.

L’isolation d’un conduit pour l’extérieur sur toute sa longueur est facultative, sauf

pour des endroits où il fait extrêmement froid. Le conduit est isoIé le mieux au

moyen d’un demi-pouce (au maximum) de mousse isolante en polyéthylène,

comme l’isolant « Tundramd » vendu dans la plupart des quincailleries.

(Contrairement à la bre de verre, la mousse isolante en polyéthylène résiste

à l’eau.) L’ajout de l’enveloppe en mousse isolante en polyéthylène, d’une

épaisseur de 1/2 po, augmentera de beaucoup la protection du gel et le

rendement énergétique de toute installation; les économies d’énergie et la

protection améliorée du conduit contre le gel compense amplement le coût

modique de l’isolant.

MISE EN GARDE : N’utiliser jamais un d’isolation de mousse de polyéthylène

(DEP) ou autre équivalent non inammables isolation a une épaisseur excédant

1/2 pouces. Plus d’isolation peut causer le câble chauffant à se surchauffer et

causer un sérieux risque de choc électrique et d’incendie.

S’il n’est pas isolé, le conduit d’amenée d’eau doit être enfoui dans au moins

3 po de terre ou de sable. Toute partie exposée aux intempéries doit être isolée

et protégée contre le vent, vu que le facteur éolien peut réduire considérablement

le rendement du câble chauffant. Par exemple, on peut utiliser un gros tuyau de

drainage pour protéger le conduit d’eau des effets du vent et des dommages

causés par exemple par le mouvement des glaces sur le rivage.

L’isolation de conduits submergés peut poser de sérieux problèmes, surtout

parce que la mousse isolante en polyéthylène otte assez bien et aura tendance

à faire monter le conduit d’eau à la surface. Pour y remédier, on peut attacher

des poids, comme de I’acier ou du béton, au conduit isolé. En général, il se

peut que l’isolation d’un conduit submergé ne soit pas nécessaire s’il se trouve

à une profondeur de plus d’un pied.

Nous recommandons qu’en hiver, le câble chauffant du conduit en ligne soit

mis sous tension en tout temps pour que les conduits d’amenée d’eau ne

gèlent pas. (En hiver, pendant des périodes relativement chaudes, le contrôleur

thermostatique débranchera automatiquement le câble chauffant an de réduire

au minimum la consommation d’électricité.) Au cas où un conduit d’eau gèlerait,

par exemple pendant des pannes d’électricité, le dégel d’un tel conduit pourrait

prendre quelques heures une fois la panne réparée, selon les conditions

atmosphériques, la durée de la panne, etc. L’utilisation régulière du câble pour

dégeler des conduits gelés non isolés n’est pas recommandée. Si l’on s’attend

à des pannes d’électricité fréquentes de 24 heures ou plus ou si le câble est

utilisé régulièrement pour dégeler des conduits gelés, nous recommandons

l’isolation des conduits se trouvant à l’extérieur sur toute leur longueur.

Le câble chauffant peut uniquement être branché sur la prise de courant du

boîtier de commande mécanique. En conséquence, le boîtier de commande

mécanique doit être monté près de l’endroit où le câble sort du raccord en T.

Voir g. B. Idéalement, le boîtier de commande mécanique devrait être situé

à moins de 10 pieds de l’endroit du conduit d’eau considéré comme étant le

plus froid, de sorte que le détecteur du thermostat peut y être xé. Ainsi, l’on

s’assure que le conduit est toujours sufsamment chaud pour que la partie la

plus froide ne gèle pas.

S’il n’est pas possible d’installer le boîtier de commande mécanique à moins de

10 pieds de l’endroit du conduit d’eau considéré comme étant le plus froid, le

pouvoir d’ajustement du thermostat peut y remédier. En tel cas, cependant, le

détecteur du thermostat doit être installé sur la partie du conduit dont on prévoit

qu’elle sera raisonnablement froide. Prenons comme exemple une maison ou

un chalet construit près d’un lac à rivage rocheux. L’on pourrait s’attendre à

ce que les conduits à l’extérieur de la fondation du chalet ou de la maison soit

raisonnablement froids, mais peut-être pas aussi froids que les conduits sur le

rivage rocheux. Si l’on xe le détecteur du thermostat au conduit immédiatement

à l’extérieur de la fondation du bâtiment et que l’on augmente la valeur de

consigne du thermostat, le contrôleur thermostatique pourra empêcher le gel de

la partie la plus froide du conduit, tout en consommant le minimum d’électricité.

Se reporter aussi à la partie intitulée « Fonctionnement du câble chauffant ».

Il est recommandé que le boîtier de commande mécanique et le raccord en T

soient montés dans un endroit sec où les connexions du système de chauffage

en ligne ne peuvent être endommagées. Le raccord en T doit se situer le plus

près possible de la pompe, mais, qui plus est, près de l’emplacement du boîtier

de commande mécanique. Nous suggérons que le système de pompage soit

situé dans un endroit chauffé, vu que la pompe et la tuyauterie montée en aval

qui y est liée doivent également être protégées du gel.

D’autres facteurs à considérer quant au choix de l’emplacement du boîtier de

commande mécanique devraient être la vérication régulière de l’interrupteur

différentiel ainsi que la possibilité de débrancher le câble chauffant par

inadvertance. Le boîtier de commande mécanique contient un interrupteur

différentiel, et, en conséquence, ce contrôleur n’a pas besoin d’être connecté

à une prise de courant protégée par un interrupteur différentiel. Au besoin, il

est cependant possible de brancher le boîtier de commande mécanique sur

une prise de courant protégée par un interrupteur différentiel.

Nous recommandons que le câble chauffant soit la seule charge du circuit qui

fournisse de l’électricité au câble.

Installation du câble chauffant

1. Vérifier les conduits

Avant d’installer le câble chauffant, s’assurer qu’aucun joint et aucune

surface intérieure du conduit ne présentent un angle aigu ou d’autres

obstacles qui empêcheraient le passage du câble dans le conduit ou qui

pourraient endommager l’enveloppe du câble chauffant.

2. Préparer le câble

Pour ce qui est des câbles en bobine, enlever le boîtier de commande

mécanique du milieu de la bobine. (Pour rendre le déroulement plus facile,

vous pourriez peut-être installer la bobine sur une axe, comme le manche

d’un balai.)

Dérouler les câbles fournis sans bobine et les rendre droits.

3. Lubrifier le câble

L’installation se fera plus facilement dans les parties droites du conduit; il

sera considérablement plus difcile de tarauder le câble dans un conduit

qui a plusieurs coudes de 90°. Une tension dépassant 30 lb pourrait

endommager le câble. De même, si la longueur du conduit excèdait 100 pi,

il se pourrait qu’on soit obligé d’exercer un excès de tension sur le câble;

en tel cas, nous vous recommandons de remplir le conduit d’eau, vu que

celle-ci a un excellent effet lubriant, ce qui aide pour faire passer le câble à

travers le conduit. Le câble peut également être lubrié avec de la vaseline.

Ne pas utiliser d’autres genres de lubrifiants, car ceux-ci pourraient

endommager le câble ou contaminer l’eau qui passe par le conduit.

Il est également utile de garder le câble aussi droit que possible et sans

tour ni nœud.

4. Tarauder le câble

Tarauder le câble chauffant à travers tous les raccords de tuyauterie dont

on pourrait avoir besoin pour connecter le raccord en T au conduit. Voir

g. C.

5. Attacher une corde

Fixer la corde du câble chauffant à une corde solide ou à un ruban de

tirage, taraudé à travers le conduit. Nous recommandons l’application de

ruban adhésif autour du connecteur d’extrémité de câble et de la corde,

pour éviter qu’il accroche dans le conduit. Ne pas enrouler le câble

chauffant pour mieux pouvoir tirer, car cela pourrait endommager

les éléments chauffants du câble. Voir fig. C. Ne pas fixer le ruban de

tirage directement au connecteur d’extrémité de câble.

6. Tirer sur le câble

Tirer le câble chauffant avec prudence (force maximale de 30 lb) à travers

le conduit d’eau. Enlever le raccord en T de l’axe de la bobine lorsque le

câble est complètement déroulé. Détacher le ruban de tirage ou la corde.

7. Fixer le connecteur d’extrémité

Fixer le connecteur d’extrémité du câble au conduit à I’aide de l’attache

d’acier inoxydable. Voir g. D. Introduire I’attache dans le trou du connecteur

d’extrémité du câble. N.B. : La corde n’a pas besoin d’être enlevée

du câble chauffant; la corde et le manchon rétractable sont de qualité

« catégorie alimentaire » et peuvent être laissés à l’intérieur du conduit.

NE PASESSAYER D’ENLEVER LE TUBE THERMORÉTRÉClSSABLE DU

CÂBLE ÉTANT DONNÉ QUE CELUI-Cl POURRAIT ÊTRE ENDOMMAGÉ.

Au besoin, l’on peut couper la corde des deux côtés du manchon rétractable.

Faire les connexions des tuyaux associés.

8. Vérifier le câble

Brancher le câble sur une prise de courant de 120 VCA pour voir si le câble

n’a pas été endommagé pendant l’installation; le câble devrait chauffer dans

la minute qui suit sa mise sous tension. Une fois que le câble commence

à chauffer, le débrancher et continuer l’installation.

9. Connecter le raccord en T

Connecter le raccord en T au conduit et faire les connexions des tuyaux,

en s’assurant que le câble à l’intérieur du conduit ne se touche ni se croise

ni se chevauche à aucun endroit dans le conduit d’eau.

10. Vérifier le câble

Nous recommandons à ce moment-là la vérication de la continuité du

câble pour voir si le câble n’a pas été endommagé quand on avait fait

les connexions des tuyaux. Ne pas brancher le câble en prévision du

chauffage du conduit. Cela pourrait prendre beaucoup de temps, voire ne

pas être perceptible, selon les conditions atmosphériques, l’isolation du

conduit, etc.

Installation du boîtier de commande mécanique

1. Montage

Monter le boîtier de commande mécanique à l’endroit approprié (voir la

section « Préparation de l’installation du câble chauffant » ci-dessus). À

I’aide des attaches autoblocantes en nylon fournies avec le câble chauffant,

xer le détecteur du thermostat au conduit. Si cette partie du conduit est

isolée, il est très important que le détecteur se situe directement sur le

conduit et soit ensuite couvert par l’isolant.

2. Mise sous pression

Ensuite, le système d’amenée d’eau doit de nouveau fonctionner

normalement et les conduits devraient être complètement remplis d’eau.

Le boîtier de commande mécanique peut alors être branché sur une prise

de courant électrique bien mise à la terre.

3. Mise sous tension

Brancher le câble chauffant sur la prise de courant du boîtier de commande

mécanique et tourner le bouton de réglage du thermostat au maximum.

4. Ajustement

Si vous êtes sûr que le détecteur du thermostat se trouvait à l’endroit le

plus froid du conduit, tourner le bouton de réglage de la température du

thermostat au minimum. Sinon, nous vous conseillons d’augmenter la

valeur de consigne du thermostat, quelque peu au-dessus de la valeur

minimale.

Fonctionnement du câble chauffant

Normalement, le câble chauffant n’a besoin ni de surveillance ni d’ajustement;

le thermostat fourni avec le câble assure que celui-ci ne fonctionne qu’en cas de

besoin, c.-à-d. en hiver. Autrement, le câble ne sera jamais mis sous tension et, en

conséquence, la consommation d’électricité est réduite au minimum. Nous vous

conseillons cependant de débrancher le câble pendant les autres saisons.

Si une panne d’électricité s’étend sur plusieurs heures, le conduit d’amenée d’eau

pourrait geler; ce gel n’endommagera cependant pas le câble chauffant. Si l’on

s’attend toutefois à des pannes plus longues et fréquentes, l’augmentation de la

valeur de consigne du thermostat pourrait, dans une certaine mesure, contrecarrer

l’effet des pannes d’électricité. (La valeur de consigne plus élevée du thermostat

garde l’eau du conduit plus chaude. Pendant une panne d’électricité, l’eau gèlera

donc moins vite.)

Si le conduit d’eau devait geler pendant son fonctionnement normal, il est

vraisemblable que le détecteur du thermostat ne se trouvait pas à l’endroit le plus

froid du conduit; habituellement, l’on peut y remédier en augmentant la valeur de

consigne du thermostat, c.-à-d. qu’on n’a pas nécessairement besoin de déplacer

le détecteur du thermostat.

La prise du disjoncteur de fuite de terre comporte un voyant qui ne s’allume qu’en

cas de détection de défaillance de câble chauffant.

Pour déterminer la fermeture appropriée de la commande d’alimentation et qu’un

courant de 120 V c.a. est disponible, tourner la commande du thermostat à la position

maximale, brancher un appareil de 120 V c.a., comme une lampe. L’appareil devrait

être alimenté, ou s’allumer s’il s’agit d’une lampe.

On recommande d’inspecter la commande du thermostat et son raccordement à la

source d’alimentation électrique au début de la saison de chauffage et tous les mois

pendant le fonctionnement. Vérier également le disjoncteur de fuite de terre. Le test

du disjoncteur de fuite de terre dépend de la température du bulbe capillaire.

a) Si la température ambiante est inférieure à 21 °C (69.8° F), tourner la

commande du thermostat au maximum ; le disjoncteur de fuite de terre sera

excité. Pousser le bouton « TEST » de la prise du disjoncteur de fuite de

terre ; un « clic » se fait entendre et le voyant de la prise s’allume. Pousser

le bouton « RESET » de la prise du disjoncteur de fuite de terre pour rétablir

le courant (le voyant s’éteint).

b) Si la température ambiante est supérieure à 22 °C (71.6° C), il faut «

refroidir » le bulbe capillaire pour tester le disjoncteur de fuite de terre.

On recommande d’attendre que la température du bulbe soit inférieure à

21 °C (69.8° F) comme à l’étape a) ; cependant, si c’est impossible, il faut

submerger le bulbe capillaire dans l’eau glacée pendant 10 minutes, puis

suivre les instructions décrites au paragraphe a) ci-dessus.

c) Le disjoncteur de fuite de terre ne sera pas touché par les interruptions

de courant.

NOTES

Loading...

Loading...