Easton Archery EASTON TUNE User Manual

.50

ID

TUNING

. . . . . . .

. . . . .

A

A

C

C

. . . . .

2 Arrow Tuning and Maintenance Guide

INTRODUCTION

Successful tuning can only be achieved by using a properly spined arrow shaft. Start with a shaft recommended

on Easton’s Arrow Shaft Selection Chart, available on the

Easton web site at www.eastonarchery.com, in the Easton

Target and Bowhunting catalogs, and on the Easton Shaft

Selector “Plus” software program. Final verification is

achieved during the tuning process. Problems caused by

an improperly spined shaft will become evident during

tuning. Before tuning, be sure that shafts are straight,

properly fletched, and have perfectly aligned nocks.

Choose Your Shooting Style.

Tuning procedures for the three most popular shooting

setups are described and abbreviated throughout this

guide as follows:

◆ recurve bows, using finger release (RF)

◆ compound bows, using finger release (CF)

◆ compound bows, using a release aid (CR)

Some of the techniques of bow tuning apply to all types of

bow setups and others apply to just one or two types.

When separate tuning procedures are required for specific

setups, find your setup within the topic and follow those

specialized instructions.

Install All Accessories

Before starting any bow tuning, be sure to install on your

bow all the items you intend to use when shooting. This

includes the correct bowstring, bow sight, stabilizers,

arrow rest, cushion plunger, bow quiver, etc. Any adjustments made to the bow or changes in bow components can

affect the tune of your equipment. Remember, when tuning,

it is very important to change only one variable at a time!

The first phase in achieving well tuned equipment is good

preliminary equipment setup. If the initial setup is done

correctly, bow tuning can be an easy process. By following

the bow setup guidelines in the initial preparation of your

equipment, you can eliminate most or all of the possible

disturbances that cause tuning problems, including false

tuning indicators. An example of a false tuning indicator

would be having a high nocking point indication when the

problem is actually poor clearance.

Install the Nocking Point

Install a moveable nocking point on the bowstring. Clampon types are ideal. Initially, position the nocking point on

the bowstring about 1/2" (1.3 cm) above square for RF and

CF and approximately 1/4" above square (0.63 cm) for CR.

See Fig. 1.

Fig. 1

90°

1

/2" RF, CF

1

/4" CR

Nocking

Point

Position

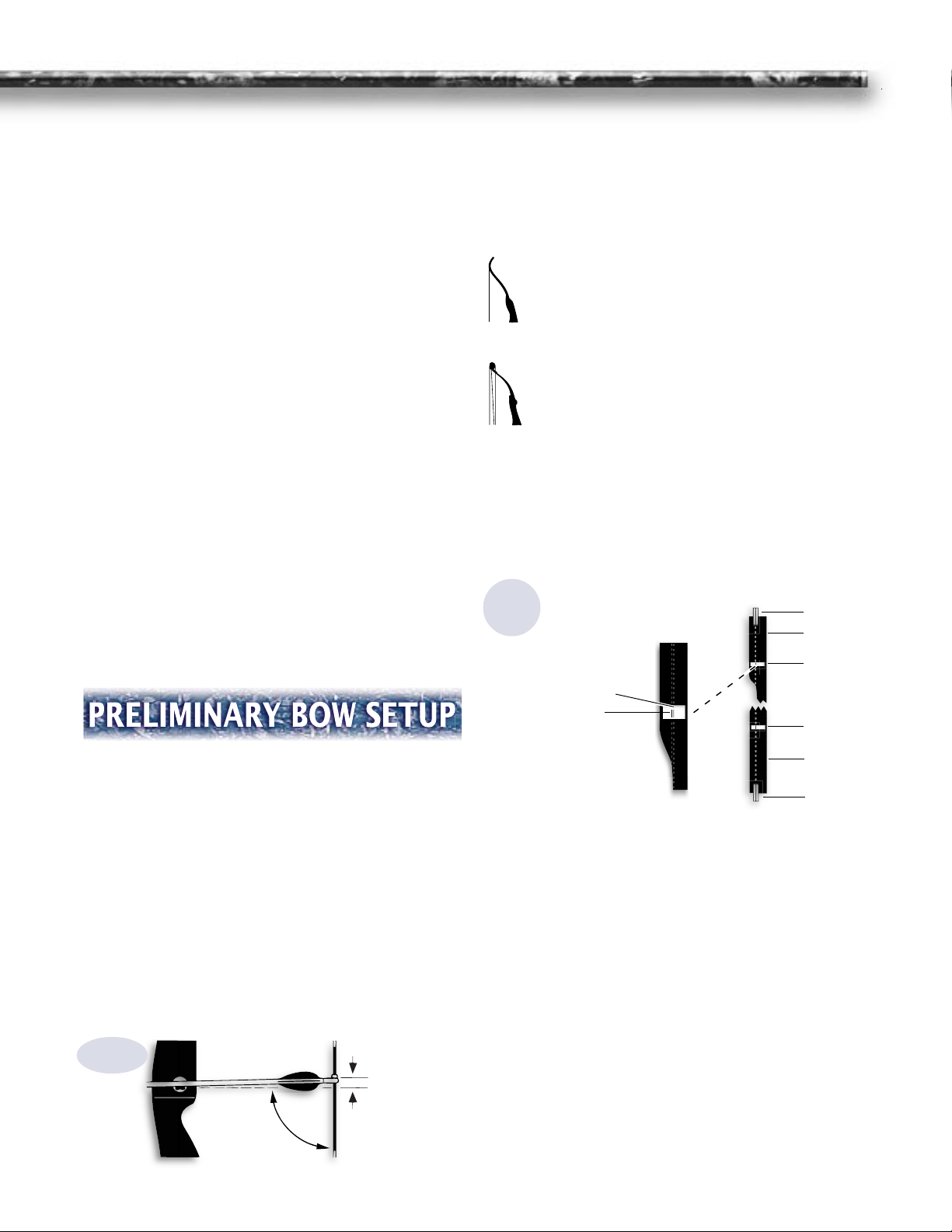

Find the Limb Centers

In order to have a reference point from which to adjust the

arrow's left/right position on the bow, it is necessary to find

and mark the exact center of the limbs on a recurve bow,

or what is termed the “balanced limb center” on a compound bow, as defined below.

Recurve Bows

To find the limb center for recurve bows, place a

piece of masking tape across the inside of each limb

near the riser. Measure the width of the limbs, and

make a small vertical mark on the tape in the exact

center of each limb.

Compound Bows

To find the balanced limb center location for the

preliminary setup of your compound bow, place a

piece of masking tape across the inside of each limb

near the riser. Measure the width of the limbs, and

make a small vertical mark on the tape in the exact center

of each limb. Next, measure 3/16" (4.8 mm) to the left of the

mark (for right-handed archers) and make a larger vertical

mark on the tape. (Left-handed archers place a larger mark

3

/16" (4.8 mm) to the right of the limb center mark.) This

second mark will be used for arrow centering. (See Fig. 2.)

This procedure is done to compensate for the amount the

eccentric wheel or cam is offset from the actual center of

Fig.

2

the limb. The 3/16" (4.8 mm) measurement is an average

“offset” difference for most compound bows and does not

need to be a precise measurement in the preliminary setup

stage, as you will locate the true balanced limb center

when performing the fine-tuning procedures.

Compound Bow

Balanced Limb

Center Location

Actual

limb center

(right mark)

Balanced

limb center

(left mark)

Measured 3/16"

from actual

center

Wheel

Bow limb

Tape

Tape

Bow limb

Wheel

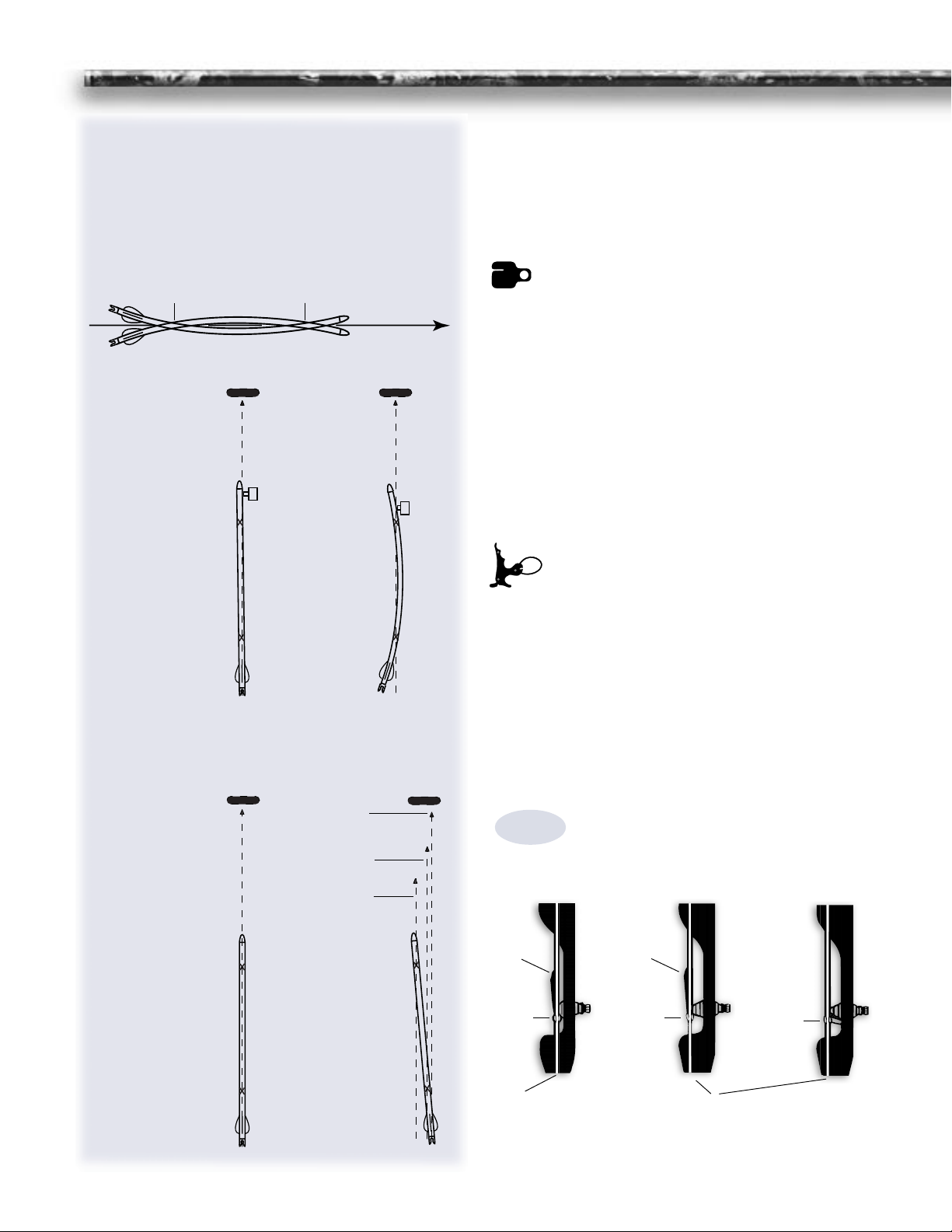

“Centering” the Arrow

The objective of arrow centering is to have the arrow leave

the “theoretical” or “balanced” limb center of the bow. In

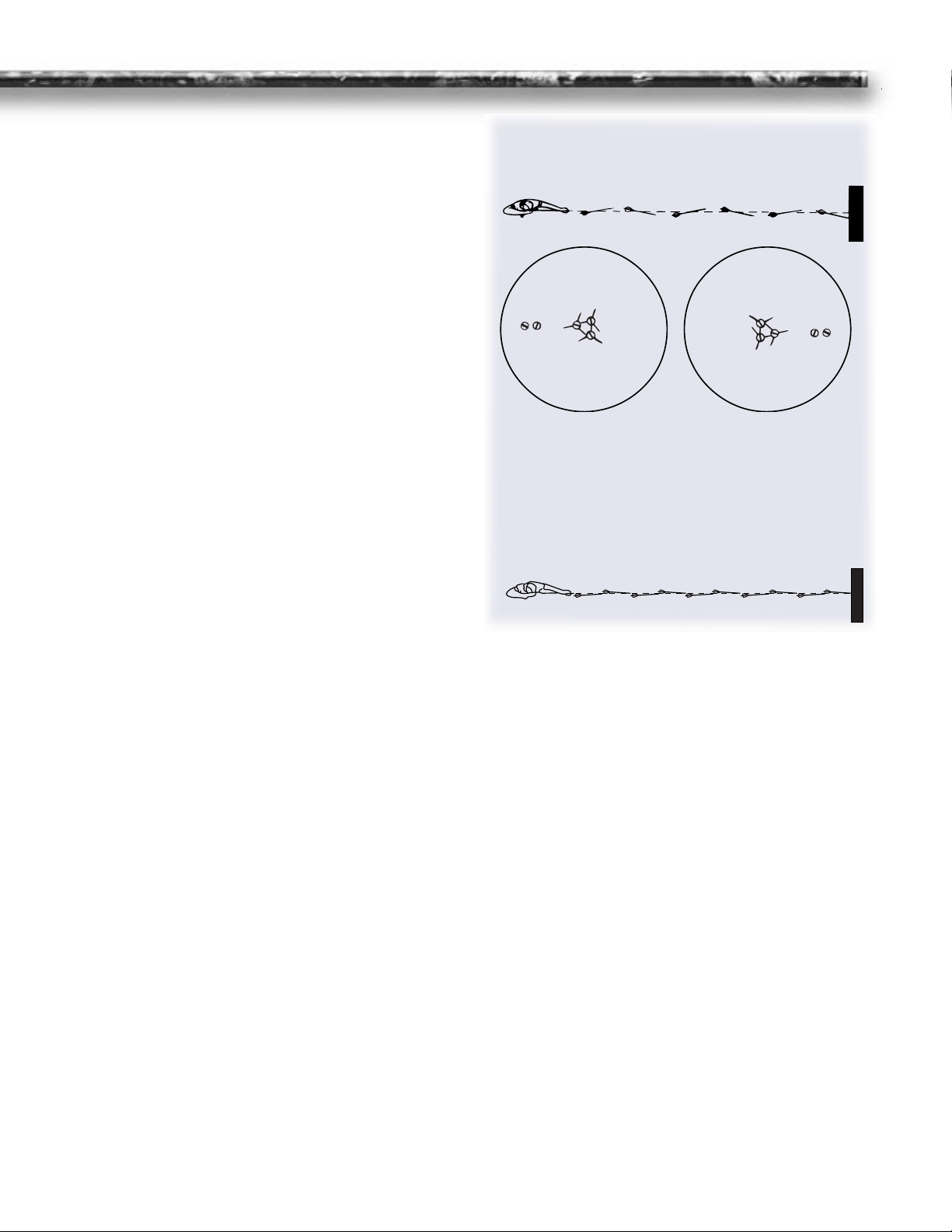

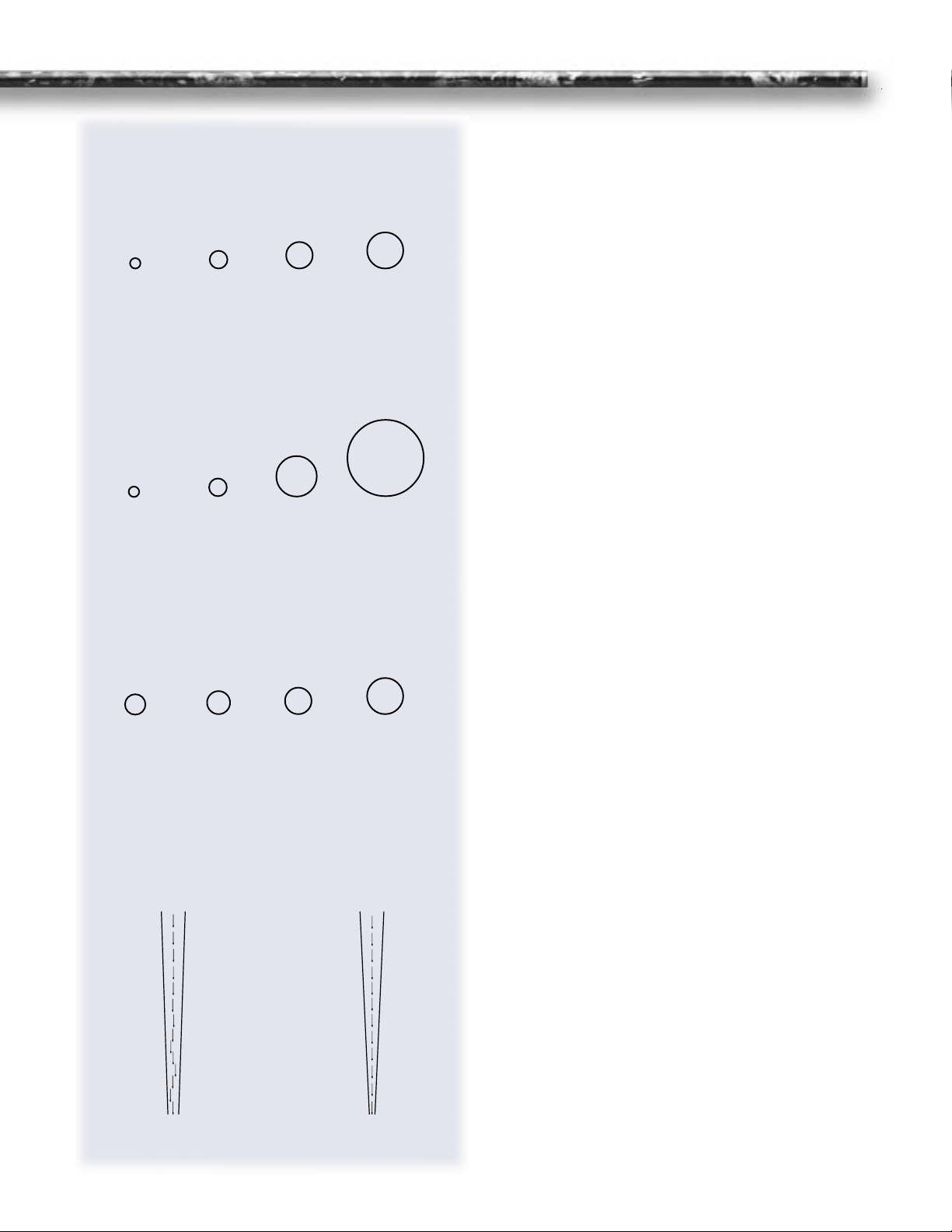

actuality, it is the two nodes (Fig. 3) of the arrow shaft that

should leave the center of the bow in direct alignment to

the target. Releasing the string with fingers creates a

horizontal bending motion within the arrow. Releasing

the string with a release aid causes a slight up/down

bending motion. Because of this, the arrows must be

positioned differently for each style of release. Adjust the

horizontal (in/out) position of the cushion plunger or

arrow rest assembly so that the tip (center) of the arrow

point is correctly aligned with the type of equipment you

shoot. (See Node Alignment diagram to the right).

Tuning—Bow Setup

3

Aligning the Nodes

Fig. 3 Nodes

Arrow Nodes - As the arrow oscillates, the nodes

remain in direct alignment to the target. This

diagram clearly illustrates the front and rear node

positions of the arrow. The front node is usually

closer to the front end of the arrow than the rear

node is to the nock end. This is due to the mass

weight of the point—nodes will always be located

closer to the heavier mass.

Front NodeRear Node

Direct Line

to Target

Top View of

Arrow

Fig. 4

Finger

Release

(RF, CF)

Line to target Line to target

When there is

no pressure

on the

cushion

plunger, the

fingerreleased

arrow nodes

are aligned

slightly

outside the

center of the

bowstring.

Fig. 5

Compound

Mechanical

Release (CR)

As the

cushion

plunger

compresses,

the nodes

of the arrow

come in

direct

alignment

to the

target.

Fig. 6

Misaligned Arrow

RF, CF, CR (Incorrect

Arrow Rest Position)

Adjust the Arrow's

Left/Right Position

Adjust the horizontal (in/out) position of the cushion

plunger or arrow rest assembly, so that the tip (center) of

the arrow point is correctly aligned with the type of

equipment you shoot, as described below.

Finger Release (RF,CF)

Align the “tip” of the arrow point 1/16" to 1/8" (1.6-

3.2 mm) or less outside the bowstring with the

bowstring properly centered according to Fig. 7. The

arrow tip is placed slightly outside the string to provide

compensation for the amount the cushion plunger or side

loading device compresses into the bow when the arrow is

released. See Fig. 4.

With a finger release, the arrow bends horizontally, first

bending in toward the bow, then bending away from the

bow, which causes the arrow shaft to leave the arrow rest.

In the next bending sequence, the arrow nock disengages

from the bowstring. The arrow is then on its way, freely

oscillating all the way to the target. The amount of oscillation

decreases as the arrow travels farther from the bow.

Mechanical Release (CR)

Align the “tip” of the arrow point down the

center of the bowstring. See Fig. 5. The center

line (axis) of the arrow must start out in a direct

line with the bowstring when the bowstring is aligned to

the balanced limb center. See Fig. 7.

When using a release, the arrow most often bends vertically,

rather than horizontally. Therefore, there is no need for an

inward compression device such as a cushion plunger.

Follow the bow tuning methods in the Fine Tuning and

Micro Tuning sections on pages 12-14 to find the best

in/out position for your arrow shaft, which allows the

arrow nodes to be in direct alignment to the target.

The diagrams in Fig. 7 indicate the correct in/out arrow

position for your shooting style.

Line to

target

The arrow tip is

aligned down

the center of the

bowstring.

Nodes of the

arrow are in

alignment to the

target. (Since the

arrow bends

vertically when

using a release,

the nodes stay in

alignment with

the center of the

bowstring.)

Bowstring

to target

alignment

Rear node

position

Front node

position

The arrow is

not

positioned

to leave the

center of the

bow—it is

out too far.

Nodes are

not in

alignment to

the target.

Fig. 7 Arrow Centering

Recurve Bow

Finger Release

Arrow

Tip Out

1

/16"-1/8"

Nock

Bowstring

aligned

with limb center

Compound Bow

Finger Release

Arrow

Tip Out

1

/16"-1/8"

Nock

Compound

Bow

Mechanical

Release Aid

Arrow

Tip in

line

with

bowstring

Nock

Bowstring aligned with

balanced limb center

4 Arrow Tuning and Maintenance Guide

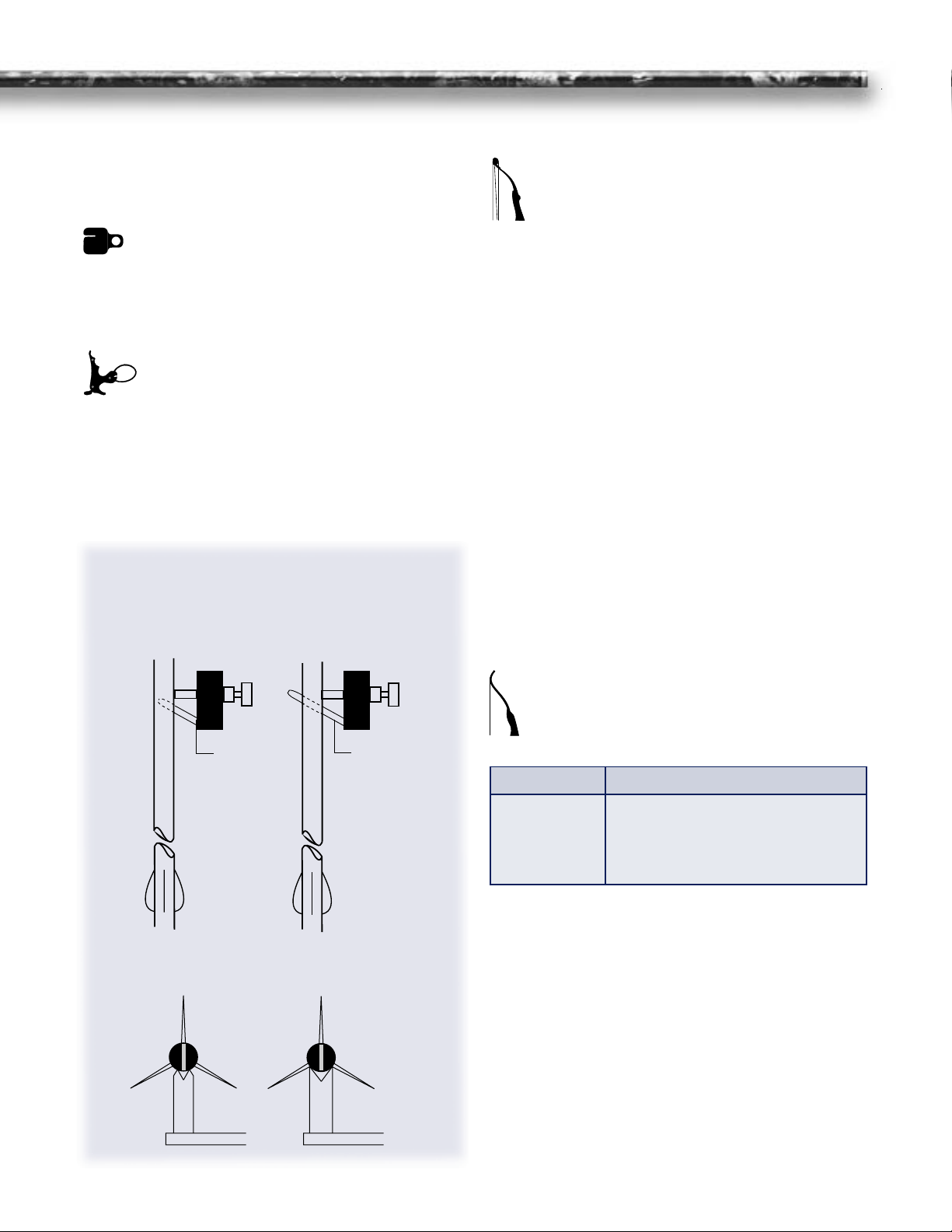

Adjust the Arrow Rest

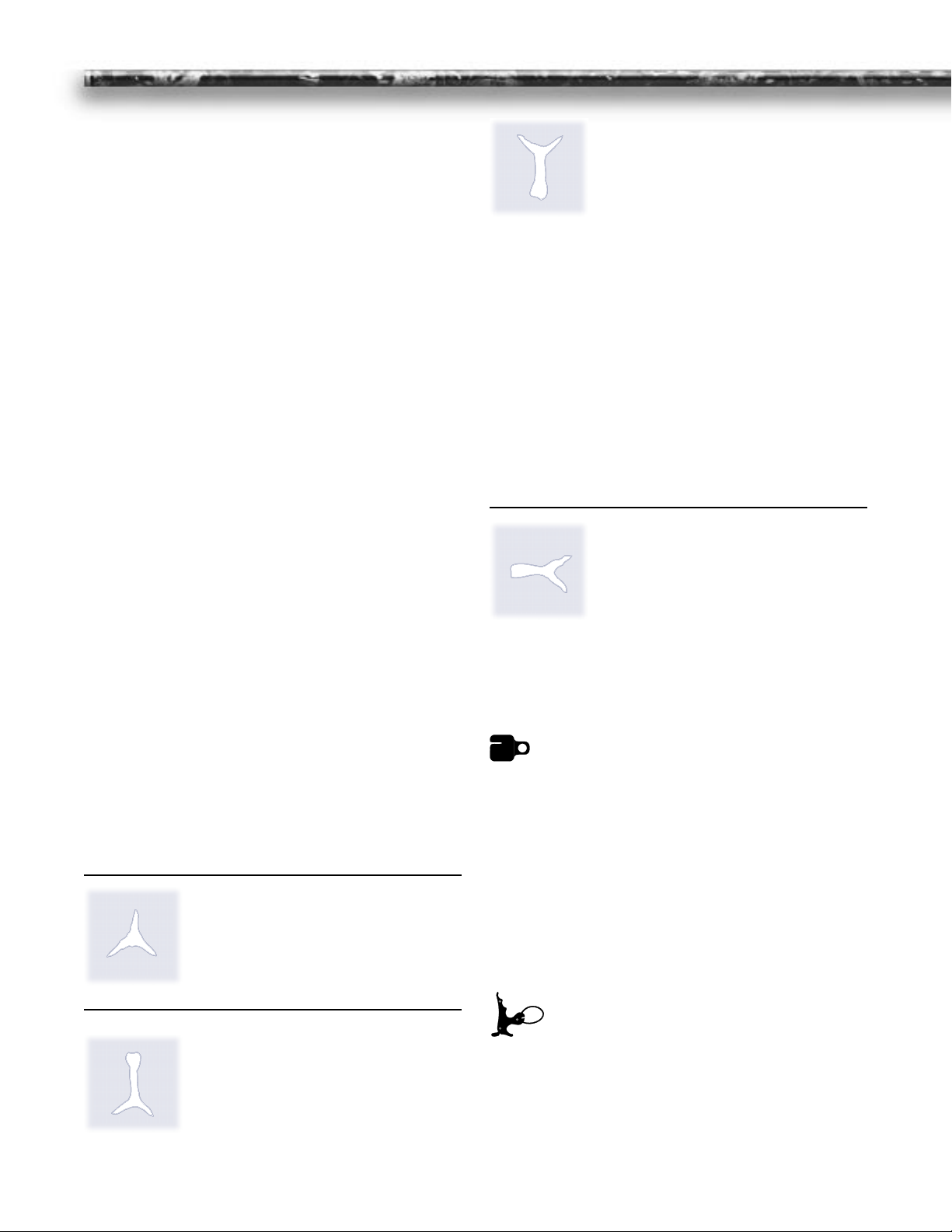

(Recurve and Compound)

The arrow rest support arm position is critical to achieving

good arrow clearance.

Finger Release (RF, CF)

Most flipper/rest setups have an adjustable arm for

the arrow rest. If this adjustment is available on the

rest you're using, the arrow rest support arm should

be adjusted so that it is not visible past the outside of the

arrow shaft when observed from an overhead view. See

Fig. 8.

Mechanical Release (CR)

On launcher type rests, commonly used on

compound bows with release aids, be sure that

the arrow support arm is narrow enough to allow

the two lower vanes to pass over the rest without making

contact. (See the Fig. 9.) This is very important for archers

using release aids because the arrow is most often supported on the rest for its full length of forward travel. For

the smaller diameter aluminum/carbon or carbon shafts

with less space between vanes, it may be necessary to

significantly reduce the width of the launcher blade.

Fig. 8

Arrow Rest - Overhead View (RF,

CF)

Correct Position Incorrect Position

BOW

Arrow rest

NOTE:

Be sure

enough of

the flipper

arm is

extended to

safely hold

the arrow on

the rest.

Fig. 9

Arrow Rest - Back View, Vane Clearance

(CR)

Correct Good Vane

Clearance

(out too far)

BOW

Arrow rest

NOTE:

Be sure that the

arrow rest has

enough height

above the

arrow shelf to

allow for vane

clearance.

Incorrect Poor Vane

Clearance

Adjusting for Outsert

Components (CR)

When using carbon arrow shafts with externally

fitted nocks, it may be necessary to adjust your

nocking point up slightly to allow the nock to clear

the arrow rest. (The nock diameter is larger than the

shaft diameter.) A slightly higher nocking point lifts the

arrow off of the arrow rest and keeps the nock from

contacting it, eliminating a potential clearance problem.

Internal-fit nock systems do not have this problem.

RISER-MOUNTED CLICKERS (RF, CF)

For shooters using a clicker, be sure that the arrow is well

supported on the rest and not held in place only by the

tension of the clicker. Draw the bow a few times without

the clicker to make sure the arrow can be drawn and let

down without the arrow falling off the arrow rest.

ALIGN THE BOW-SIGHT PIN

Initially, set the sight pin on your bow sight over the

centerline of the arrow shaft.

SET CUSHION PLUNGER

Not every type of bow setup uses a cushion plunger. For

example, many archers use a Springy™ rest, and some

traditional archers use other styles of arrow rests that do

not have side pressure tension adjustments. If your setup

incorporates a cushion plunger, start with the spring

tension set at medium.

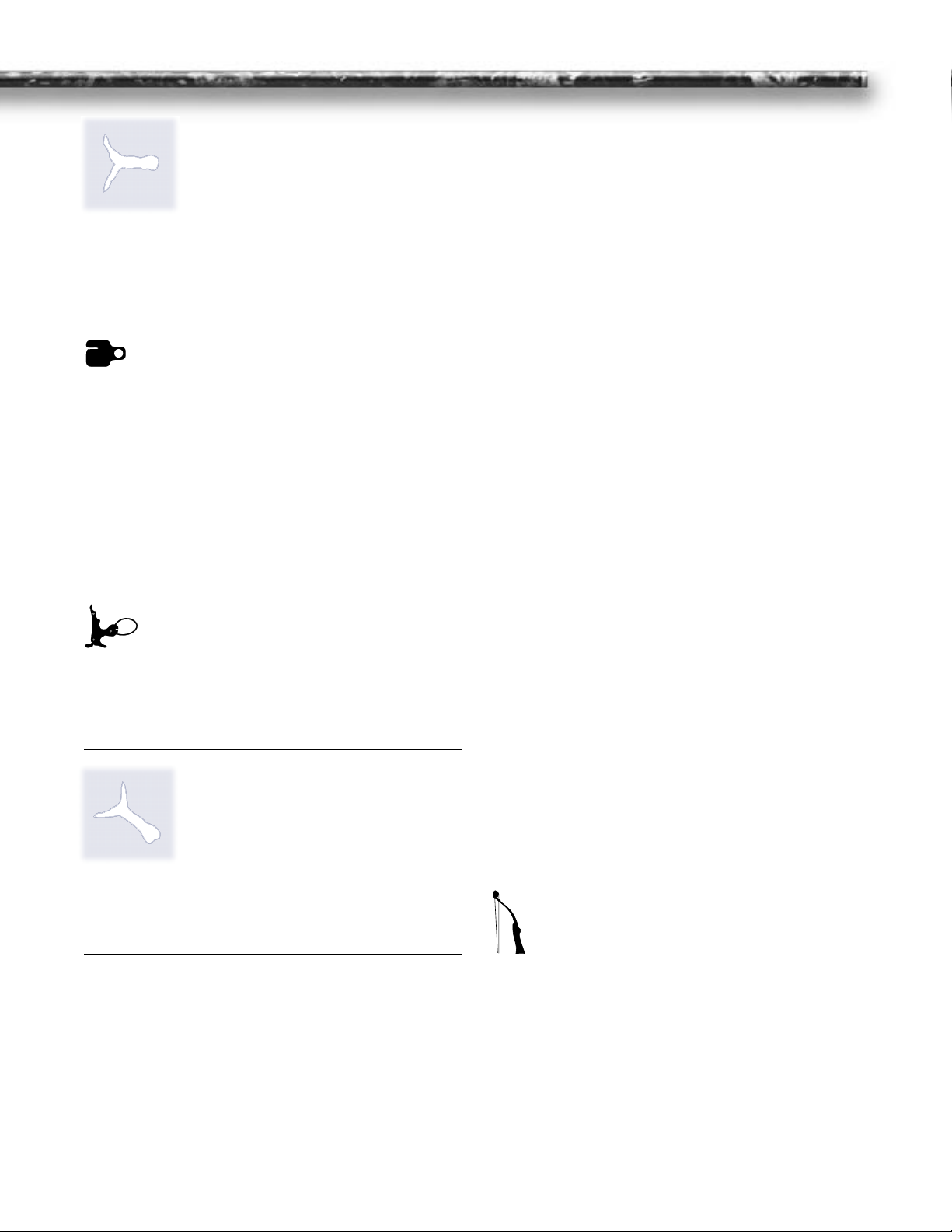

Set Brace Height

(Recurve bows)

Start with the brace height at the lower end of the

manufacturer’s recommendation or use the following chart. To locate the optimum brace height for

your particular bow, “twist up” the bowstring to

make it shorter. This raises the brace height.

BOW LENGTH

64" 8 1/4" - 8 1/2" (21.0 cm - 21.6 cm)

66" 8

68" 8

70" 8

All bows are different, even bows of the same make and

model can have small variations. Therefore, it is important

to locate a brace height that fits your particular bow and

shooting style. Shoot a few arrows at the suggested

beginning brace height, then unstring the bow, add 3-4

twists to the bowstring and shoot again. Continue this

process until the bow feels smoothest and quietest when

shooting.

If the bowstring is too short to allow a brace height at the

lower setting, use a slightly longer string. If the string is too

long to allow a higher brace height (and starts to knot-up

from too many twists), try a slightly shorter bowstring.

There are many custom bowstring makers who produce

strings to your exact specifications including length, type

of material, type and color of serving, etc.

BEGINNING BRACE HEIGHT

3

/8" - 8 5/8" (21.3 cm - 21.9 cm)

1

/2" - 8 3/4" (21.6 cm - 22.2 cm)

5

/8" - 8 7/8" (21.7 cm - 22.5 cm)

Standard Tuning—Bare Shaft Planing Test

5

The brace height determines the specific point at which

the arrow separates from the bowstring and the amount of

bend the arrow has when the separation occurs. The best

brace height for your recurve or compound bow is one that

allows the most compatible launch position for the arrow

at the end of the bow’s “power stroke.” Locating the best

brace height for your bow can significantly improve arrow

grouping and shooting consistency.

Set the Brace Height

(Compound bows)

Brace height is set by the compound bow manufacturer. Sometimes changing the brace height to a

slightly higher or lower position will improve arrow

flight and grouping. This can be accomplished by

changing the length of the string, as described previously

for recurve bows. Remember, however, that changing the

brace height of a compound bow affects the draw weight

and draw length of the bow.

Nock-to-Bowstring Tension

The nock tension (“snap fit”) necessary to separate the

nock from the bowstring serving can be very critical,

especially on light draw-weight bows (30 lbs. and under).

Nock tension should be tight enough so the arrow can

easily support its own weight when the arrow is hanging

vertically on the bowstring (nock against the nocking

point). To check this, hang your arrow vertically from the

bowstring, and give the string a sharp tap with your finger

on the serving about 1-2" (2.5-5 cm) from the arrow nock.

The arrow should separate from the string. If it does not,

the nock is probably too tight for most target archery. For

hunting, a tighter nock-to-bowstring fit is often preferred.

To accommodate this, Easton designs nocks in several

string groove widths. Easton's Super Nock is designed

with the tight press fit bowhunters need to keep an arrow

on the string in all types of hunting conditions. The 3-D

Super Nocks feature a snap fit with slightly less string

tension, and a nockset détente for shorter bows. The "G"

nock is available in two string groove widths.

Arrows that do not fly well and do not group tightly are

usually affected by one or more of the following problems:

1. They may PORPOISE in flight.

2. They may FISHTAIL in flight.

3. They may not CLEAR the bow properly as the arrow

leaves the bowstring. They may also MINNOW in

flight (a specific type of clearance problem).

1. Porpoising

It is important to correct for porpoising first. If the arrow

leaves the bowstring with the nock too high or too low, a

motion known as porpoising occurs. Porpoising is caused

by an incorrect nocking point location. Use the Bare Shaft

Planing Test to find the correct nocking point location.

Shoot at least three fletched shafts at a distance of 15 to 20

yards (or meters). Then shoot two identically-aimed

unfletched shafts. Once you get the bare shafts to impact

close to the fletched arrows at 20 yards (or meters), you

may want to try shooting 25-30 yards (or meters) for a finer

tuning indication.

If the unfletched shafts impact above the identicallyaimed fletched shafts, move the nocking point up on the

bowstring until both fletched and unfletched shafts strike

at the same elevation. See Fig. 10.

If the unfletched shafts impact below the identicallyaimed fletched shafts, move the nocking point down on

the bowstring until the unfletched shafts hit at the same

elevation or slightly lower than the fletched shafts.*

To assure you have eliminated porpoising, repeat the test,

shooting first the fletched, then the unfletched shafts, and

make adjustments to the nocking point until both fletched

and unfletched shafts impact at the same elevation.

Fig. 10

Porpoising

Now that you have completed the preliminary adjustments,

you can start the tuning process. Four methods of bow

tuning are described on pages 5 through 14: the Bare Shaft

Planing Test, the Paper Tuning Arrow Test, Short Distance

Tuning, and Broadhead Tuning.

Bare Shaft Planing Test

(Finger release - RF, CF)

In addition to tuning, the bare shaft test is also

useful for determining if the correct shaft has been

selected. If the left/right adjustments outlined under “Fishtailing” do not cause the unfletched shafts to

group with or very near the fletched shafts, then a weaker

or stiffer spined shaft (based on where the arrows have

impacted) must be selected.

Nocking point too low* Nocking point too high*

* It is sometimes desirable to have the bare shaft impact just slightly

below the identically-aimed fletched shafts. Bare shafts that impact above

identically-aimed fletched shafts indicate a low nocking point. If the

nocking point is too low, it may force the arrow fletching down into the

arrow rest, creating Clearance problems.

6 Arrow Tuning and Maintenance Guide

2. Fishtailing

If the arrow leaves the bow with the nock end leaning to

one side or the other, fishtailing occurs. The nock end of

the arrow will appear to move from side to side as the

arrow follows its flight path. See Fig. 11.

Use the Bare Shaft Planing Test to correct fishtailing. Shoot

three fletched shafts at a distance of 15 to 20 yards (meters),

then shoot two identically-aimed, unfletched shafts. If the

unfletched shafts impact left (stiff) of the fletched shafts, as

seen in Fig. 11 (for a right-handed archer), either decrease

the spring tension on the cushion plunger, increase bow

weight slightly (if your bow weight is adjustable), or

increase arrow point weight.

If the unfletched shafts impact right (weak) of the identicallyaimed, fletched shafts, as seen in Fig. 11 (for a right-handed

archer), increase the spring tension on the cushion plunger,

decrease bow weight slightly (if your bow weight is

adjustable), or decrease arrow point weight.

Your equipment is basically tuned when the bare shafts

and fletched shafts impact at the same or very near the

same location. Once you have completed the finer tuning

methods listed for Fine Tuning and Micro Tuning on

pages 12-14, do not be surprised if the bare shaft impact

changes. It is common on a well-tuned bow to have the

bare shaft impact a little low and slightly stiff (to the left of

the fletched shafts for a right-handed archer). Occasionally,

a good tune may be achieved with the bare shaft impacting

slightly weak (to the right of the fletched shafts for righthanded archers), but this is less common.

When correcting fishtailing using the Bare Shaft Planing

Test, you may have a problem adjusting the unfletched

shaft's impact to that of the fletched shaft. Your arrows

might be too weak (the unfletched shaft impacts to the

right of the fletched shaft for right-handed archers) or too

stiff (the unfletched shaft impacts to the left of the fletched

shaft for right-handed archers). If, after completing this

test, the bare shaft impact is more than 6 inches (15 cm) to

the right (weak) or left (stiff) of the fletched shafts at 20

yards (18 m), you will need to change shaft size, or make

some modifications to the equipment to achieve a better

tune. Follow the suggestions on how to better match the

arrow to your bow in the “Adjusting the Bow and Arrow

System” section on page 10.

Fig. 11

Fishtailing

Stiff Arrow

Unfletched shafts

impact left

(RH archer, opposite

for LH)

Fig. 12

Minnowing

If you are not achieving good arrow clearance, and the

arrow fletching and bow make contact, optimum grouping

cannot be achieved. By examining the areas where the dry

powder spray is scraped off, the nature of any interference

can be determined, and the position of the fletching as the

arrow leaves the bow can be identified.

Minnowing, like fishtailing or porpoising, indicates a

specific arrow flight disturbance. Minnowing will appear

to look much like fishtailing except that the tail of the

arrow appears to move from side to side more quickly, and

the amount of side swing is usually much less than in

fishtailing. (See Fig. 12.) Minnowing indicates inadequate

clearance and is caused by the rear portion of the arrow

(usually fletching) contacting the arrow rest assembly.

Weak Arrow

Unfletched shafts

impact right

(RH archer, opposite

for LH)

3. Clearance

Proper clearance is absolutely essential for optimum grouping, consistency and accuracy. This is especially true with

ultra-light weight arrows like the UltraLite aluminum, the

A/C/E, A/C/C and A/C/C HyperSpeed shafts.

After you have performed the Bare Shaft Planing or Paper

Tuning Arrow Test, it is a good idea to check for adequate

clearance. To check for clearance, use dry powder foot

spray, dry deodorant spray or similar product, applied to

the last quarter of the arrow shaft, fletching, arrow rest

assembly and sight window near the arrow rest. Do not

disturb the powder sprayed on the arrow and bow while

preparing to shoot. The arrow should be shot into a firm

target so that it will not penetrate to the fletching.

Correcting Clearance Problems

The following procedures can help you correct clearance

problems that cause minnowing:

1. If the arrow fletching is hitting the arrow rest, try

rotating your arrow nock 1/32 of a turn. Continue

rotating the nock in 1/32-turn increments until clearance

is achieved.

2. Make sure your arrow rest support arm does not

protrude past the outside of the arrow shaft when the

arrow is resting on the support arm and is lying against

the cushion plunger or side loading device. See Fig. 8.

3. Choose a lower profile fletching.

4. Follow the procedures for Tuning Adjustments within

Standard Tuning—Paper Tuning Arrow Test

7

the Bow and Arrow System on page 10 for equipment

modifications to achieve a better tune.

5. Move the cushion plunger or side loading device

slightly out from the bow to help increase clearance if

the other tuning modifications have no effect.

Paper Tuning Arrow Test

(Recurve or compound - RF, CF, CR)

Archers using mechanical release aids (CR) should review

the following reminder notes before starting the Paper

Tuning Test.

1. Align the arrow down the center of the bowstring with

the tip of the arrow point correctly positioned as

indicated in Fig. 7, page 3.

2. Initially position the sight pin over the centerline of the

arrow.

3. When using a release aid the arrow normally bends

more vertically than horizontally, so good clearance is

essential. Usually, the entire arrow contacts the rest

when it is shot and the fletching must be positioned to

clear the rest.

“SHOOT-THROUGH” RESTS - It may be necessary to

adjust the width of the arrow rest support arm(s) so the

fletching will pass cleanly over or through.

“SHOOT-AROUND” RESTS - Vane-to-nock indexing is

very important and should be adjusted to achieve

maximum clearance.

The Paper Tuning Arrow Test is the most commonly used

bow tuning test for archers using compound bows with

release aids. This test also works well for a finger release:

1. Firmly attach a sheet of paper to a picture frame type

rack approximately 24" X 24" (60 x 60 cm).

2. Position the center of the paper about shoulder height

with a target mat about 6 feet behind the paper to stop

the arrows.

3. Stand approximately 4 to 6 feet (1.2-1.8 m) from the

paper.

4. Shoot a fletched arrow through the center of the paper

with the arrow at shoulder height (parallel to the floor).

5. Observe how the paper is torn.

This tear indicates good arrow flight. The

point and fletching enter the same hole.

This tear indicates a low nocking point.

To correct, raise the nocking point 1/16"

(1.6 mm) at a time and repeat the procedure until the low vertical tear is eliminated.

This tear indicates a high nocking point,

clearance problem, or a very weak arrow

if you are using a release aid. To correct,

lower the nocking point 1/16" (1.6 mm) at

a time until the high tear is eliminated. If

the problem is unchanged after moving

the nocking point a few times, the disturbance is most

likely caused by a lack of clearance or by an arrow that is

too weak (if using a release aid). To identify a clearance

problem, check to see if the arrow fletching is hitting the

arrow rest. (See “Clearance Problems,” page 6.)

CR - If no clearance problem exists and you are using a

mechanical release, try:

1. A more flexible arrow rest blade if using a launcher

type rest or reduce downward spring tension on adjustable tension launcher rests.

2. Decreasing peak bow weight if there is an indication

the arrow spine is too weak.

3. Reducing the amount the shaft overhangs the contact

point on the arrow rest.

4. Choosing a stiffer arrow shaft.

This tear indicates a stiff arrow reaction for

right-handed archers using finger release

(RF, CF). Left-handed finger release

archers will have an opposite pattern. This

is an uncommon tear for right-handed

compound archers using a mechanical

release (CR). However, it can occur and

generally indicates that the arrow rest position is too far to

the right or that there is possible vane contact on the inside

of the launcher rest.

Finger Release (RF, CF)-–To correct:

1. Increase bow weight/peak bow weight.

2. Use a heavier arrow point and/or insert combi-

nation.

3. Use a lighter bowstring (less strands or lighter material,

like Fast Flight®).

4. Use a weaker spine arrow.

5. Decrease cushion plunger tension or use a weaker

spring on “shoot around” rests.

6. CF only - Move the arrow rest slightly in toward the

bow.

Mechanical Release Aid (CR)–To

correct:

1. Move the arrow rest to the left. Continue

moving the rest to the left in small increments

until the right tear is eliminated.

2. Make sure the arrow has adequate clearance past the

cable guard and cables.

3. Make sure the bow hand is relaxed, to eliminate

excessive bow hand torque.

8 Arrow Tuning and Maintenance Guide

This tear indicates a weak arrow reaction

or clearance problem for right-handed

finger release (RF, CF) archers. Left-handed

finger release archers will have the opposite

pattern. For right-handed compound

archers using mechanical releases (CR), the left tear is

common and usually indicates a weak arrow reaction

and/or clearance problem. If a high-left tear exists, (see

next tear illustration) make sure you correct the nocking

point first before proceeding further.

Finger Release (RF, CF)–To correct:

1. Check for Clearance (See page 5).

2. Decrease bow weight/peak bow weight.

3. Use a lighter arrow point and/or insert combination.

4. Use a heavier bowstring (more strands or heavier

material).

5. Use a stiffer spine arrow.

6. Increase cushion plunger tension or use a stiffer spring

on “shoot around” rests.

7. CF only - Move the arrow rest slightly out, away from

the bow.

Mechanical Release Aid (CR)–To

correct:

1. Move the arrow rest to the right. Continue to

move the rest to the right in small increments

until the left tear is eliminated.

2. Make sure the bow hand is relaxed to eliminate exces-

sive bow hand torque.

3. Decrease peak bow weight.

4. Choose a stiffer spine arrow.

This tear shows a combination of more

than one flight disturbance. Use the

procedures that apply to the tear pattern

for your style of shooting, and combine the

recommendations, correcting the vertical

pattern (nocking point) first, then the

horizontal. If you experience a tuning

problem (especially with the nocking point location) and

are unable to correct a high/low tear in the paper, have

your local pro shop check the “timing” (roll-over) of your

eccentric wheels or cams.

For archers using release aids, it may, in some cases, be

necessary to apply adjustments opposite from those

described. The type of arrow rest and release aid

combination used can alter the dynamic flex of the arrow

to produce tear patterns contrary to those indicated

(although it is uncommon).

Once you have achieved a good tune at 4 to 6 feet (1.2-1.8

m), move back 6 feet (1.8 m) more and continue to shoot

through the paper. This ensures that the tune is correct and

that the arrow was not just in a recovery position when it

passed through the paper at the first distance.

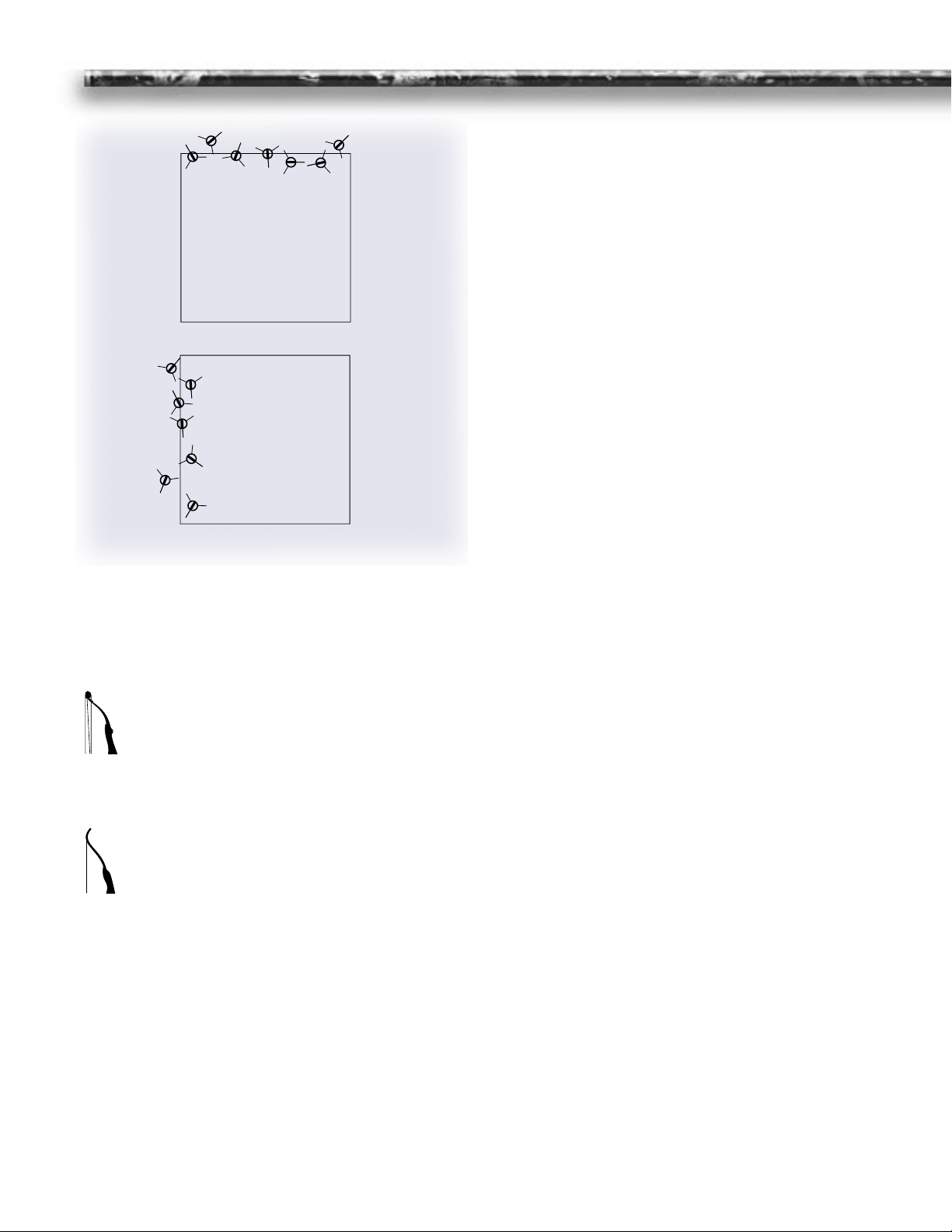

SHORT DISTANCE TUNING

(

Recurve and compound - RF, CF, CR)

Many times it is not possible to shoot long distances when

your equipment needs to be tuned. The following method

results in a very good equipment tune at short distances.

Use this tuning method after you have completed one of

the basic bow-tuning methods—either the Bare Shaft Planing

or Paper Tuning Arrow Test.

Start at approximately 12 to 15 yards (meters) from the

target. Use a 40 cm or 60 cm target face and place it with

the face side in so you are shooting at a plain white target.

Up-Down Impact

Using fletched arrows only, shoot approximately 6 to 8

arrows along the top edge of the target face. This step

determines if your nocking point is correct. See Fig. 13.

Normally, small tuning problems show up at close range,

because the arrow has its maximum oscillation at short

distance. This test assists you in identifying these arrow

flight problems and makes it possible to make finer

adjustments than with the previous tuning procedures.

If you are unable to consistently hit the top edge of the

target face, there is probably a small tuning disturbance in

the equipment. To correct, make a 1/32" (.8 mm) nocking

point adjustment either up or down and shoot again.

Continue making nocking point adjustments in 1/32" (.8 mm)

increments (no more than 1/32" (.8 mm) at a time).

If your arrows are hitting the top edge of the paper more

consistently and you are achieving a straight, horizontal

line of arrows across the top of the paper, you are correcting

the disturbance. If the horizontal line of arrow impact is

widening, go back to your original nocking point position

and start making 1/32" (.8 mm) nocking point adjustments

in the opposite direction. This will provide you with the

correct nocking point position.

Left-Right Impact

Once you have achieved the straightest horizontal line of

arrows that your ability will allow, you are ready to tune for

left/right arrow impact. Shoot 6 to 8 arrows at the left edge

of the paper in a vertical line. See Fig. 14.

To improve the left/right impact for CR and CF

archers, move the in/out position of your arrow rest.

This is done to compensate for the effect of the

eccentric wheel. The offset of the eccentric wheel on

compound bows does not always compensate for

the degree of natural torque generated in the bow. The

wheel often torques or leans over slightly as it reaches the

full draw position. This is common and is nothing to be

concerned about. At full draw, the “limb center” you

started with in the preliminary setup may not really be the

true balanced center. Therefore, through some trial and

error, you must locate the best in/out position for the

arrow to obtain maximum accuracy.

Make a 1/32" (.8 mm) adjustment either in or out and shoot

again. Continue making 1/32" (.8 mm) adjustments until

Short Distance Tuning—Trouble Shooting

Fig. 13

Up-Down Impact

Fig. 14

Left-Right Impact

you achieve the best possible vertical impact line of

arrows. If the vertical line widens, go back to your original

arrow rest position and move it 1/32" (.8 mm) in the

opposite direction. If the vertical line narrows, continue

1

/32" (.8 mm) adjustments in that direction until you achieve

the straightest line possible.

CF archers using cushion plungers should make the

necessary arrow rest adjustments and then try a

second tuning adjustment using the cushion plunger's

spring tension. Increase or decrease spring tension

1

/8-turn at a time. Again, if the vertical line becomes

wider, return to the original spring tension setting and

make 1/8-turn adjustments in the opposite direction until

you achieve a narrow vertical impact line.

RF archers should make cushion plunger spring

tension adjustments only, increasing or decreasing

the spring tension 1/8-turn at a time. If the vertical line

becomes wider, return to the original spring tension

setting and make 1/8-turn adjustments in the opposite

direction until you achieve a narrow vertical impact line.

Do not move the in/out position of your arrow. The position of

your arrow to the centerline of the bow has already been

established in the preliminary equipment setup.

9

causes poor arrow grouping. What follows here is information that will help you perform the fine tuning adjustments

necessary to eliminate most or all of the minute tuning

problems.

Many archers have experienced one or all of the following

arrow grouping/arrow flight combinations:

◆ Poor arrow flight and good grouping - This is commonly the result of a stiff arrow. The arrow yaws

slightly as it leaves the bow, but usually recovers

quickly and often produces very acceptable grouping.

◆ Good arrow flight and poor grouping - Although this

seems contradictory, the phenomenon is somewhat

common and relates to the tuning method you use.

Having a perfect bullet hole through paper using the

Paper Tuning Arrow Test, or having the bare shafts

impact exactly with the fletched shafts using the Bare

Shaft Planing Test, does not always mean your arrows

will group well; it only indicates you have good arrow

flight. For this reason, Easton has developed the Fine

Tuning and Micro Tuning methods, to assist you in

obtaining optimal grouping from your equipment.

◆ Poor arrow flight and poor grouping - This is most often

a problem of mismatched arrow spine or untuned

equipment. The information and tuning procedures in

this bulletin should help you correct this problem.

◆ Good arrow flight and good grouping - This should be

the end result of your efforts!

Arrow grouping patterns often reveal probable arrow

flight problems. Two of the most common grouping

indicators for determining arrow flight problems are

described below. The examples provided are shown in

FITA distances, although they easily correlate to any longand short-distance shooting. Fig. 15 illustrates good

grouping patterns at the distances indicated.

Excessive Drag

The grouping examples in Fig. 16 show a large pattern at

long distances (90 m) but the grouping is within acceptable

limits at closer distances. This pattern implies the arrow

has too much drag. Excessive drag will cause the arrow to

become unstable due to the rapid decay of its forward

velocity. When forward velocity drops too quickly, instability occurs. This unstable flight causes poor grouping at

long distances and extreme vulnerability to wind drift. On

lightweight arrows, it is very important to reduce drag to

a minimum to maintain maximum downrange velocity.

This can be done by reducing the size (height and/or

length) of the fletching or by reducing the angle of the

fletching, or both.

TROUBLE-SHOOTING

ARROW GROUPS

You may have heard people say, “If your arrows group

well at 20 yards, they will group at any distance,” or, “If

your arrows group at long distances, they will group at

short distances.” In some cases, neither statement is true.

There may be a minute disturbance in the equipment that

affects the equipment's potential for superior accuracy and

Insufficient Clearance

The grouping patterns in Fig. 17 show acceptable grouping at the two long distances. However, the shorter distance groups are not reduced in size proportionately to the

longer distance groups. (Compare to Fig. 15 on page 10).

This usually indicates a clearance problem or micro disturbance within the bow and arrow system. To correct, see

the section on Clearance on page 5 or the Fine Tuning and

Micro Tuning sections on pages 12-14.

10 Arrow Tuning and Maintenance Guide

Fig. 18 illustrates why you may have problems with closedistance grouping while long-distance groups are good.

Fig. 15

Good grouping patterns show

progressively increasing grouping sizes

as shooting distances increase.

30 m 50 m 70 m 90 m

When an arrow is shot, it is at its maximum bending as it

leaves the bow. As the arrow travels farther, the amount of

flexing reduces (dampens). If the flexing reduces, then so

does the magnitude of any original disturbance. The

example shows that the arrow has some disturbance and

close range grouping is poor, although the arrow stabilizes

at longer range and provides acceptable groups. Micro

disturbances and clearance problems usually cause these

disturbances.

Fig. 19 shows the path of the arrow when it leaves the bow

without any disturbance. This is the path you are trying to

achieve in the Fine Tuning and Micro Tuning processes.

Fig. 16

Excessive Drag

30 m 50 m 70 m 90 m

Fig. 17

Insufficient Clearance

30 m 50 m 70 m 90 m

Fig. 18

Poor close range

grouping Acceptable

long range grouping

Fig. 19

Path without

disturbance

ADJUSTING THE BOW

AND ARROW SYSTEM

If you are having problems tuning your bow, you will need

to make some modifications to your equipment to achieve

a better tune. Here are some suggestions:

Bow Weight Adjustment

Virtually all compound bows, as well as some recurve

bows, have an adjustable draw weight. If your arrow

reaction is too stiff, increase the draw weight. If your arrow

reaction is too weak, decrease the draw weight.

Bowstring

Bowstring “weight” can have a significant effect on arrow

spine. Increasing or decreasing the number of strands in

the bowstring can influence the arrow's dynamic spine

enough to require a shaft size change of one full size

weaker or stiffer. If your arrow reaction is too stiff, decrease the number of strands in your bowstring. If your

arrow reaction is too weak, increase the number of strands.

Serving weight (center serving) can also produce the same

effect. For example, monofilament center serving will

cause the arrow to react stiffer than lighter weight nylon

center serving. Simply changing from a metal nocking

point to a “tie-on” nocking point can have a noticeable

effect on arrow spine, due to the weight difference between the two styles of nocking points.

90 m

80 m

70 m

60 m

50 m

40 m

30 m

20 m

10 m

0 m

Point and Insert Weight

Easton and Beman arrows can be tuned by using various

point and/or insert/outsert weight combinations. If your

arrow is too weak, go to a lighter insert or point. If your

arrow is too stiff, try a heavier insert or point. Continue to

change insert and/or point weights within the acceptable

balance point range (7-16% F.O.C.).

Brace Height

For recurve bows, another way of altering arrow spine is

with the brace height. By increasing or decreasing the

distance from the bowstring to the pivot point of the grip,

the dynamic spine of the arrow can be made slightly

weaker or stiffer. Increasing brace height will make the

arrow shoot weaker, and decreasing brace height will

make the arrow shoot stiffer.

Loading...

Loading...