Page 1

Kodak DryView 8700/8500 Laser Imager

DRAFT

User Guide

8599110

41-1202-0176-3

3/01 Rev. B

Page 2

1

Page 3

Warnings and Cautions

Warnings and Cautions for

Kodak DryView 8700/8500 Laser Imager

Safety Instructions

Read and understand all instructions before using.

!

WARNING

This equipment is operated with hazardous voltage which can shock,

burn, or cause death.

Remove wall plug before servicing equipment. Never pull on cord to remove from

outlet. Grasp plug and pull to disconnect.

Do not operate equipment with a damaged power cord.

Do not use an extension cord to power this equipment.

Position the power cord so it will not be tripped over or pulled.

Connect this equipment to a grounded outlet.

Use only the power cord supplied with this equipment.

!

WARNING

For Continued Protection against Fire, Replace Fuses with only the Same Type and

Fuse Rating.

!

WARNING

This equipment contains moving parts that may be accessible to the user. Loose

clothing, jewelry, or long hair may cause minor personal injury or damage to the

equipment. Do not operate equipment with the covers open. Do not operate

equipment with any of the safety interlocks overridden.

!

WARNING

This equipment is not contained in a sealed cabinet. Therefore, it must not be used

in locations where it can come in contact with liquids, including bodily fluids.

2001 March Rev. B 8599110

i

Page 4

User Guide

!

CAUTION

Avoid Laser Beam

This equipment employs a 150 milliwatt laser. Laser radiation may be

present when the machine operates without panels or covers installed.

Use of controls or adjustments, or performance of procedures other than those

specified herein, may result in eye damage.

Covers shall be removed by authorized service personnel only.

!

CAUTION

Do not substitute or modify any part of this equipment without approval of Eastman

Kodak Company.

!

CAUTION

General External Cleaning: This equipment may be cleaned with a damp cloth

using water with mild detergent, or commercial electronic equipment cleaner.

Do not touch, Hot Surface!

!

CAUTION

ATTENTION:

Surface Chaude. Ne pas toucher!

ACHTUNG:

Nicht anfassen. Heisse Oberflache!

ATTENZIONE:

Non toccare. Superficie Calda!

CAUTION:

Do not touch. Hot surface!

ADVERTENCIA:

No tocar. Superficia Caliente!

OPGEPAST:

Niet aanraken. Heet Oppervlak!

U.S. Federal law restricts this device to the sale by, or on the order of, a licensed

health care practitioner.

ii

8599110 2001 March Rev. B

Page 5

Warnings and Cautions

!

CAUTION

This equipment is intended to connect to other medical devices. Only qualified

service personnel may perform installation and service maintenance. The laser in

the equipment is not a patient device. Therefore, the equipment must be installed no

closer than 1.83 meters from a patient bed or chair.

!

CAUTION

Do not use in the presence of flammable anesthetics, oxygen or nitrous oxide. This

equipment does not have a gas–sealed electronics enclosure and could ignite any

flammable or explosive gases present in its environment.

!

CAUTION

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC rules. Those limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC ID: PA4870085007E2620

2001 March Rev. B 8599110

iii

Page 6

User Guide

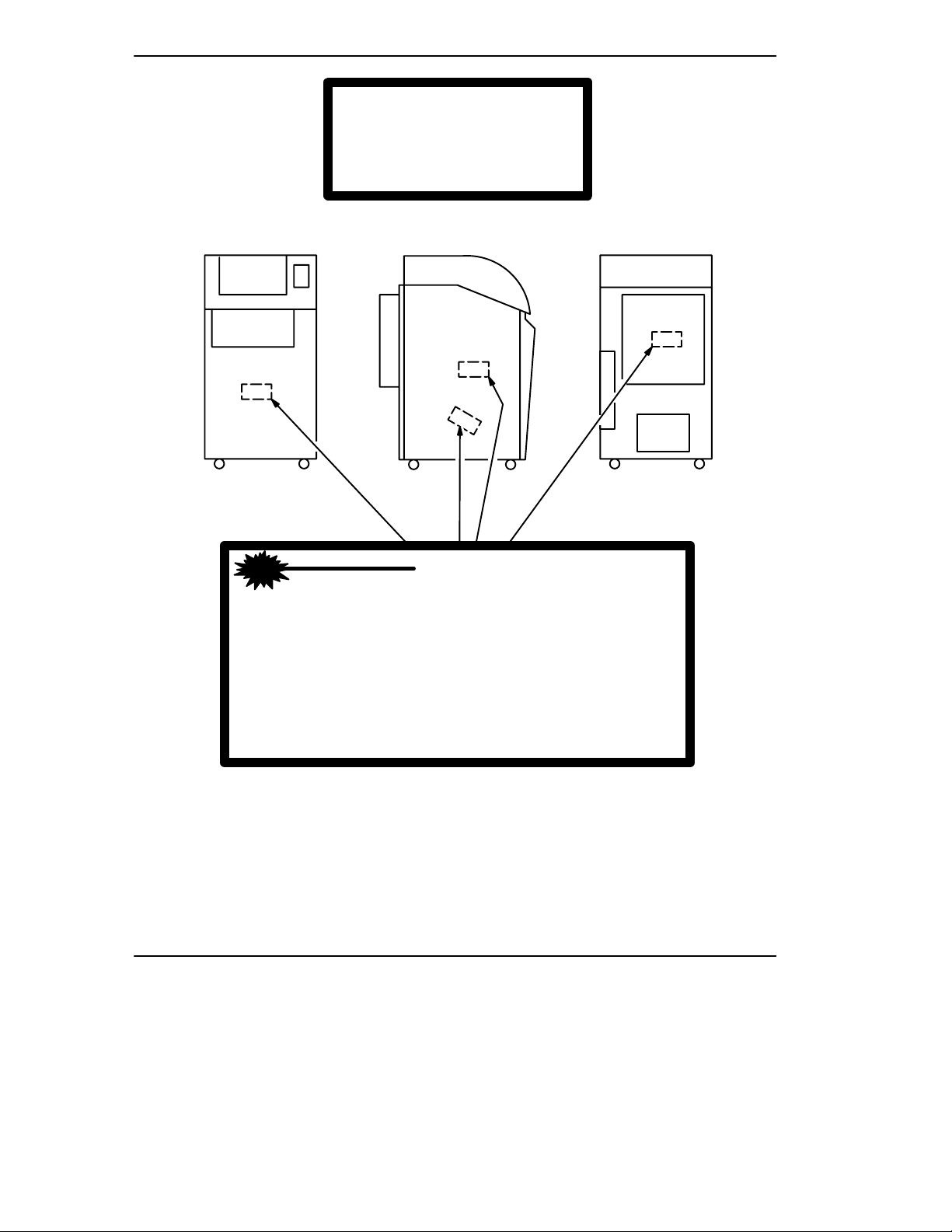

Class 1 Laser

Laser de catégorie 1

Laser-Klasse 1

Laser di Classe 1

Klass 1 Laser

Front

Left

DANGER - Invisible Laser Radiation When Open.

Avoid Direct Exposure to Beam.

ATTENTION - Rayonnement Laser Invisible En Cas

D’Ouverture. Exposition Dangereuse

Au Faisceau.

VORSICHT - Unsichtbare Laserstrahlung Wenn Abdeckung

Geöffnet. Nicht Dem Strahl Aussetzen.

VARNING - Osynlig Laserstrålning. Laserstråining När

Denna Del Ä Öppnad. Strålen Är Farlig.

Rear

iv

8599110 2001 March Rev. B

Page 7

Warnings and Cautions

WarningsandCautions

for External Interface Box Accessories

Read and understand all instructions before using.

Classifications

UL Classified

File Number E183646

Control Number 9R46

Medical Equipment

UL 2601-1 CAN/CSA No. 601.1

!

Classified by Underwriters Laboratories Inc.Ò With Respect to Electric Shock,

Fire, Casualty and Medical Hazards only in Accordance with UL 2601-1, CAN/CSA

C22.2 No. 601.1 and IEC 601.1.

!

WARNING

This equipment is operated with hazardous voltage which can shock,

burn or cause death.

¯ Remove wall plug before servicing equipment. Never pull on cord to remove from

outlet. Grasp plug and pull to disconnect.

¯ Do not operate equipment with a damaged power cord.

¯ Do not use an extension cord to power this equipment.

¯ Use only the power cord supplied with this equipment.

¯ Position the power cord so it will not be tripped over or pulled.

¯ Connect this equipment to a grounded outlet.

¯ Do not place a portable multiple--socket outlet (power strip) on the floor. Mount

the power strip on a wall or on the underside of a table.

2001 March Rev.B 8599110

v

Page 8

User Guide

!

WARNING

This equipment contains moving parts that may be accessible to the user. Loose

clothing, jewelry or long hair may cause minor personal injury or damage to the

equipment. Do not operate equipment with the covers open. Do not operate

equipment with any of the safety interlocks overridden..

!

WARNING

This equipment is not contained in a sealed cabinet. Therefore, it must not be used

in locations where it can come in contact with liquids, including bodily fluids.

!

WARNING

For Continued Protection against Fire, Replace Fuses with only the Same Type and

Fuse Rating.

!

CAUTION

Do not substitute or modify any part of this equipment without approval of Eastman

Kodak Company.

!

CAUTION

General External Cleaning: This equipment may be cleaned with a damp cloth

using water with mild detergent, or commercial electronic equipment cleaner.

Type B Applied Part

!

CAUTION

Do not use in the presence of flammable anesthetics, oxygen or nitrous oxide. This

equipment does not have a gas--sealed electronics enclosure and could ignite any

flammable or explosive gases present in its environment.

!

CAUTION

This equipment is intended to connect to other medical devices. Only qualified

service personnel may perform installation and service maintenance.

!

CAUTION

U.S. Federal law restricts this device to the sale by, or on the order of, a licensed

health care practitioner.

vi

8599110 2001 March Rev. B

Page 9

Read and understand all instructions before using.

Warnings and Cautions

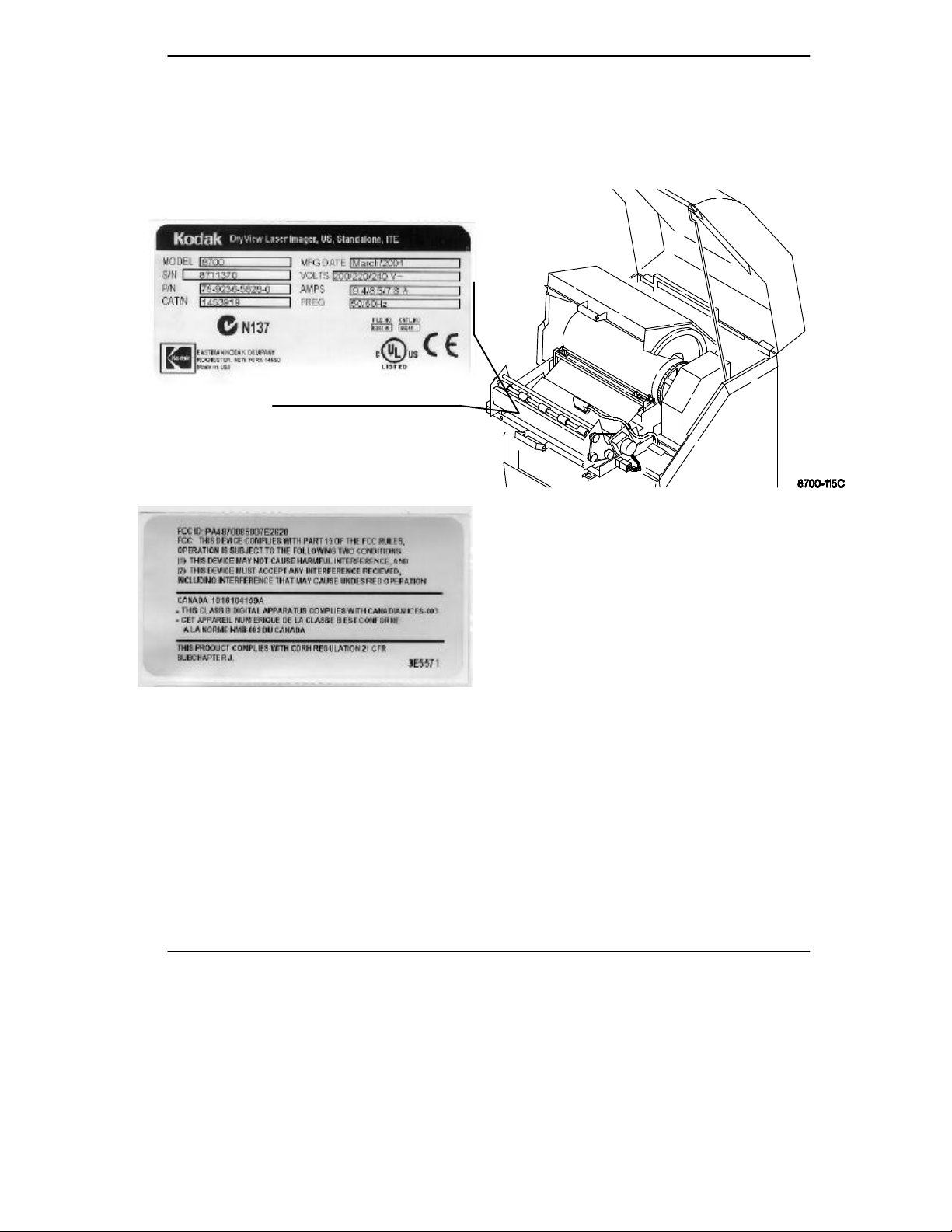

Label located on back of machine.

2001 March Rev.B 8599110

vii

Page 10

User Guide

BLANK PAGE

viii

8599110 2001 March Rev. B

Page 11

Agency, Regulatory and CE Marking Compliance

Agency, Regulatory and CE Marking Compliance

This equipment has been tested for and complies with the following Safety and

Emission Standards. Certificates of Compliance and Declarations of Conformity

have been issued as shown below.

Safety:

Canada:

C22.2 NO 950-95–CAN/CSA Safety for Information Technology Equipment,

Including Electrical Business Equipment

C22.2 NO 601.1–M90–CAN/CSA Medical Electrical Equipment – Part 1:

General Requirements for Safety

CSA–CS–03: Rules for Telecommunication Equipment

Europe:

EN60950: Safety of Information Technology Equipment, Including Electrical

Business Equipment (IEC 60950 : 1991, Modified) (Includes Amendment A1 and

A2: 1993)

EN60601–1–1: Medical electrical equipment – Part 1: General requirements for

safety – Section 1: Collateral standard: Safety requirements for medical electrical

systems

EN60825–1: Safety of laser products – Part 1: Equipment classification,

requirements and user’s guide

U.S.A.:

UL 1950: Safety of Information Technology Equipment, Including Electrical

Business Equipment DOD (Bi–National Standard) with UL 2601–1 Medical

Electrical Equipment, Part 1: General Requirements for Safety

21CFR1040.10 Class I: FDA CDRH Code of Federal Regulations Title 21,

Volume 8, Food and Drugs, Part 1040 Performance Standards For

Light–Emitting Products, Section 10 Laser Products

FDA Premarket Notification 510(K): Regulatory Requirements For Medical

Devices

47 CFR Part 68: FCC Rules for Telecommunication Equipment

2001 March Rev. B 8599110

ix

Page 12

User Guide

Rest of World:

IEC 950: Safety of information technology equipment

IEC 60601–1–1: Medical electrical equipment – Part 1: General requirements for

safety – Section 1: Collateral standard: Safety requirements for medical electrical

systems

IEC 60825–1: Safety of laser products – Part 1: Equipment classification,

requirements and user’s guide

EMC:

Canada:

CAN/CSA–C108.6–M91 Class A: Limits and Methods of Measurement of

Electromagnetic Disturbance Characteristics of Industrial, Scientific and Medical

(ISM) Radio–Frequency Equipment

Europe:

EN55022 (CISPR 22) Class B Group 1: Limits and Methods of Measurement of

Radio Interference Characteristics of Information Technology Equipment

EN300330: 1999 European Telecommunication Standard, Sections 7.2 and 7.4

Emission Requirements

EN300683: 1997 European Telecommunication Standard, Section 8 Emission

Requirements and Immunity Requirements

EN61000–3–2 (IEC 1000–3–2): 1995 Electromagnetic Compatibility (EMC) –

Part 3: Limits – Section 2: Limits for Harmonic Current Emissions (equipment

input current <= 16A per phase)

EN61000–3–3 (IEC 1000–3–3): 1995 Electromagnetic Compatibility (EMC) –

Part 3: Limits – Section 3: Limits for Voltage Flicker Emissions (equipment input

<– 16A per phase)

EN 61000–4–2 (IEC 1000–4–2): Electromagnetic Compatibility (EMC) – Part 4:

Testing and Measurement techniques – Section 2: Electrostatic Discharge

Immunity Test. Basic EMC Publication

EN 61000–4–3 (IEC 1000–4–3): Electromagnetic Compatibility (EMC) – Part 4:

Testing and Measurement Techniques – Section 3: Radiated, Radio–frequency,

Electromagnetic Field Immunity Test

EN 61000–4–4 (IEC 1000–4–4): Electromagnetic Compatibility (EMC) – Part 4:

Testing and Measurement techniques – Section 4: Electrical Fast Transient/Burst

Immunity Test. Basic EMC Publication

x

8599110 2001 March Rev. B

Page 13

Agency, Regulatory and CE Marking Compliance

EN 61000–4–5 (IEC 1000–4–5): Electromagnetic Compatibility (EMC) – Part 4:

Testing and Measurement Techniques – Section 5: Surge Immunity Test

EN 61000–4–6 (IEC 1000–4–6): Electromagnetic Compatibility (EMC) – Part 4:

Testing and Measurement Techniques – Section 6: Immunity to Conducted

Disturbances, Induced by Radio–Frequency Fields

EN61000–4–8 (IEC1000–4–8): Electromagnetic Compatibility (EMC) – Part 4:

Testing and Measurement Techniques – Section 8: Power Frequency Magnetic

Field

EN 61000–4–11 (IEC 1000–4–11): Electromagnetic Compatibility (EMC) –

Part 4: Testing and Measuring Techniques – Section 11: Voltage Dips, Short

Interruptions and Voltage Variations Immunity Tests

U.S.A.:

FCC Rules and Regulations, Title 47, Part 15, Subpart B, Class B: Radio

Frequency Devices: Unintentional Radiators; Part 15, Subpart C, Section 15.209

Radiated Emission Requirements

Rest of World:

CISPR 22 Class B Group 1: Limits and Methods of Measurement of Radio

Interference Characteristics of Information Technology Equipment

Directives:

EU:

73/23/EEC Council Directive on the Harmonization of the Laws of Member

States Relating to Electrical Equipment Designed for Use within Certain Voltage

Limits

89/336/EEC Council Directive on the Approximation of the Laws of the Member

States Relating to Electromagnetic Compatibility

93/42/EEC Council Directive Concerning Medical Devices

99/5/EEC Council Directive on Radio Equipment and Telecommunications

Terminal Equipment

2001 March Rev. B 8599110

0123

xi

Page 14

User Guide

CE Marking:

Documents concerning the conformance of this product to Council Directive

93/42/EEC of 14 June 1993 concerning Medical Devices can be obtained from the

Eastman Kodak Health Imaging Systems European Representative at:

Kodak AG

Quality Services

Product Safety

70323 Stuttgart

Germany

Phone: ++49 711 406 2993

Fax: ++49 711 406 3513

DOC:

Canada 1016104159A

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe A respecte toutes les exigences du Règlement

sur le matérial brouilleur du Canada.

xii

8599110 2001 March Rev. B

Page 15

T able of Contents

PLEASE NOTE

The information contained herein is based on the experience

and knowledge relating to the subject matter gained by Eastman

Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this

information without notice and makes no warranty, express or

implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special

damages, resulting from the use of this information, even if loss

or damage is caused by Kodak’s negligence or other fault.

Table of Contents

Description Page

Warnings and Cautions

for DryView 8700/8500 Laser Imager i. . . . . . . . . . . . . .

Warnings and Cautions

for External Interface Box Accessories iv. . . . . . . . . . .

Agency, Regulatory and CE Marking Compliance vi. . . . .

Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introducing the DryView 8700 and 8500 Laser Imagers 1-1

System Configurations 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Feature Comparison 1-3. . . . . . . . . . . . . . . . . . . . . . .

How the DryView 8700/8500 Laser Imager Works 1-4. . . .

Controls and Indicators 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DryView 8700/8500 Laser Imager 2-1. . . . . . . . . . . . . . . . . .

Local Panel 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Panel – Main Menu 2-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Local Panel – User Settings Menu (Applies to 8700/8500

DryView 8700/8500 Keypad (Used only on 8700/8500

Kodak Keypad (Used on 8700/8500 Standard and Plus

2001 March Rev. B 8599110

Standard and Plus systems.) 2-6. . . . . . . . . . . . . . . . . . .

Standard systems.) 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

systems and on Multi–Input/Dual Printer systems.) 2-10

xiii

Page 16

User Guide

Description Page

Kodak Keypad – Main Menu 2-12. . . . . . . . . . . . . . . . . . . . . . .

Kodak Keypad – Format Menu 2-14. . . . . . . . . . . . . . . . . . . . .

Kodak Keypad – Imager Menu 2-16. . . . . . . . . . . . . . . . . . . . .

Kodak Keypad – Contrast, Density, & Count Menu 2-18. . . .

Kodak Keypad – Keypad Menu 2-20. . . . . . . . . . . . . . . . . . . . .

Operation and Maintenance 3-1. . . . . . . . . . . . . . . . . . . . . . . . .

System Power Up 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Format/Acquire/Print – DryView 8700/8500 Keypad 3-2. .

Format/Acquire/Print – Kodak Keypad 3-3. . . . . . . . . . . . . . .

Density/Contrast Selection – Local Panel

(Applies to 8700/8500 Standard and Plus systems.) 3-4

Density/Contrast Selection – Kodak Keypad

(Applies to 8700/8500 Standard and Plus systems and

Multi–Input/Dual Printer systems.) 3-5. . . . . . . . . . . . . . .

Moving Stored Images – Kodak Keypad 3-6. . . . . . . . . . . . .

Erasing Stored Images – DryView 8700/8500 Keypad 3-7

Erasing Stored Images – Kodak Keypad 3-7. . . . . . . . . . . .

Deleting a Job from the Print Queue – DryView 8700/8500

Keypad 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting a Job from the Print Queue – Kodak Keypad 3-8.

Loading/Unloading Film 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Platen 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Developer Filter 3-12. . . . . . . . . . . . . . . . . . . . .

xiv

Troubleshooting 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Panel and Keypad Message Types 4-1. . . . . . . . . . . .

Local Panel Error Message Table 4-2. . . . . . . . . . . . . . . . . . .

Kodak Keypad Error Message Table 4-4. . . . . . . . . . . . . . . .

DryView 8700/8500 Keypad Error Message Table 4-5. . . .

Removing Jams from Area 1 4-6. . . . . . . . . . . . . . . . . . . . . . .

Removing Jams from Area 2a 4-7. . . . . . . . . . . . . . . . . . . . . .

Removing Jams from Area 2b 4-8. . . . . . . . . . . . . . . . . . . . . .

Removing Jams from Area 3 4-9. . . . . . . . . . . . . . . . . . . . . . .

8599110 2001 March Rev. B

Page 17

T able of Contents

Description Page

Removing Jams from Area 4 4-10. . . . . . . . . . . . . . . . . . . . . . .

Removing Jams from Area 5 4-12. . . . . . . . . . . . . . . . . . . . . . .

Manually Closing the Film Cartridge 4-13. . . . . . . . . . . . . . . . .

Unlocking the Left Door and Supply Door Via Mechanical

Releases 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Environment 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Effects 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DryView 8700/8500 Laser Imager Storage

Environment 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Control 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DryView 8700/8500 Keypad 5-2. . . . . . . . . . . . . . . . . . . . . . .

Kodak Keypad 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Information 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spectral Sensitivity 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Quality 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Image Quality Control 6-2. . . . . . . . . . . . . . . . . . .

Less Impact on the Environment 6-3. . . . . . . . . . . . . . . . . . .

Storage and Handling of Undeveloped Film 6-4. . . . . . . . . .

Handling of Developed Film 6-4. . . . . . . . . . . . . . . . . . . . . . . .

Archivability of Developed Film 6-5. . . . . . . . . . . . . . . . . . . . .

Exposure to Moisture 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Odor Dissipation 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat Dissipation 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Film Recycling 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT NOTICE TO PURCHASER 6-6. . . . . . . . . . . .

2001 March Rev. B 8599110

xv

Page 18

User Guide

BLANK PAGE

xvi

8599110 2001 March Rev. B

Page 19

Introduction

Introduction

Introducing the Kodak DryView 8700 and 8500 Laser Imagers

The Kodak DryView 8700 Laser Imager (8700 Laser Imager) and the Kodak

DryView 8500 Laser Imager (8500 Laser Imager) are continuous–tone laser

imagers with an integrated photothermographic film developer.

The two imagers are nearly identical except for film size. The 8700 Laser Imager

uses only 14” x 17” (35 x 43 cm) Kodak DryView Laser Imaging Film (DryView film).

The 8500 Laser Imager also uses DryView film but accepts only 11 in. x 14 in.

(28 x 35 cm) film sheets.

Both film sizes are available in clear or blue base, packaged in 125-sheet Kodak

Instant Daylight Load Film Cartridges.

The 8700/8500 Laser Imagers are both available in three different configurations,

with two different remote keypads, described later in this manual.

Figure 1-1. Kodak DryView 8700/8500 Laser Imager

2001 March Rev. B 8599110

1-1

Page 20

User Guide

System Configurations

The 8700/8500 Laser Imagers are both available in three different configurations.

Key features of each configuration are:

8700/8500 Laser Imager Standard System

Supports up to two inputs (can be upgraded to support multiple inputs).

Provides up to 64 megabytes of image memory, in 16 megabyte increments.

Uses copper cable for external connections.

Image acquisition and printing are accomplished via host control, Kodak

DryView 8700/8500 Keypad, or Kodak Keypad.

8700/8500 Laser Imager Plus System

Supports up to two inputs (can be upgraded to support multiple inputs).

Provides up to 128 megabytes of image memory, in 32 megabyte increments.

Uses fiber optic cable for external connections.

Image acquisition and printing are accomplished via host control or Kodak

Keypad.

Multi-Input/Dual Printer System

Consists of an 8700 or 8500 Dual Printer connected to a Kodak DryView 8800

Multi-Input Manager (8800 Multi–Input Manager) or 969 HQ Laser Imager.

Supports up to eight inputs.

Provides 32 or 64 megabytes of image memory per input.

Uses fiber optic cable for external connections.

Image acquisition and printing are accomplished via host control or Kodak

Keypad.

The 8800 Multi–Input Manager can provide output connects for one or two laser

printers. Connects to any of the following printers:

– Kodak DryView 8700 Laser Imager

– Kodak DryView 8500 Laser Imager

– Kodak DryView 8300 Laser Imager

– 969 HQ Laser Imager

If dual printers are connected, the two printers can be the same or mixed.

1-2

8599110 2001 March Rev. B

Page 21

Introduction

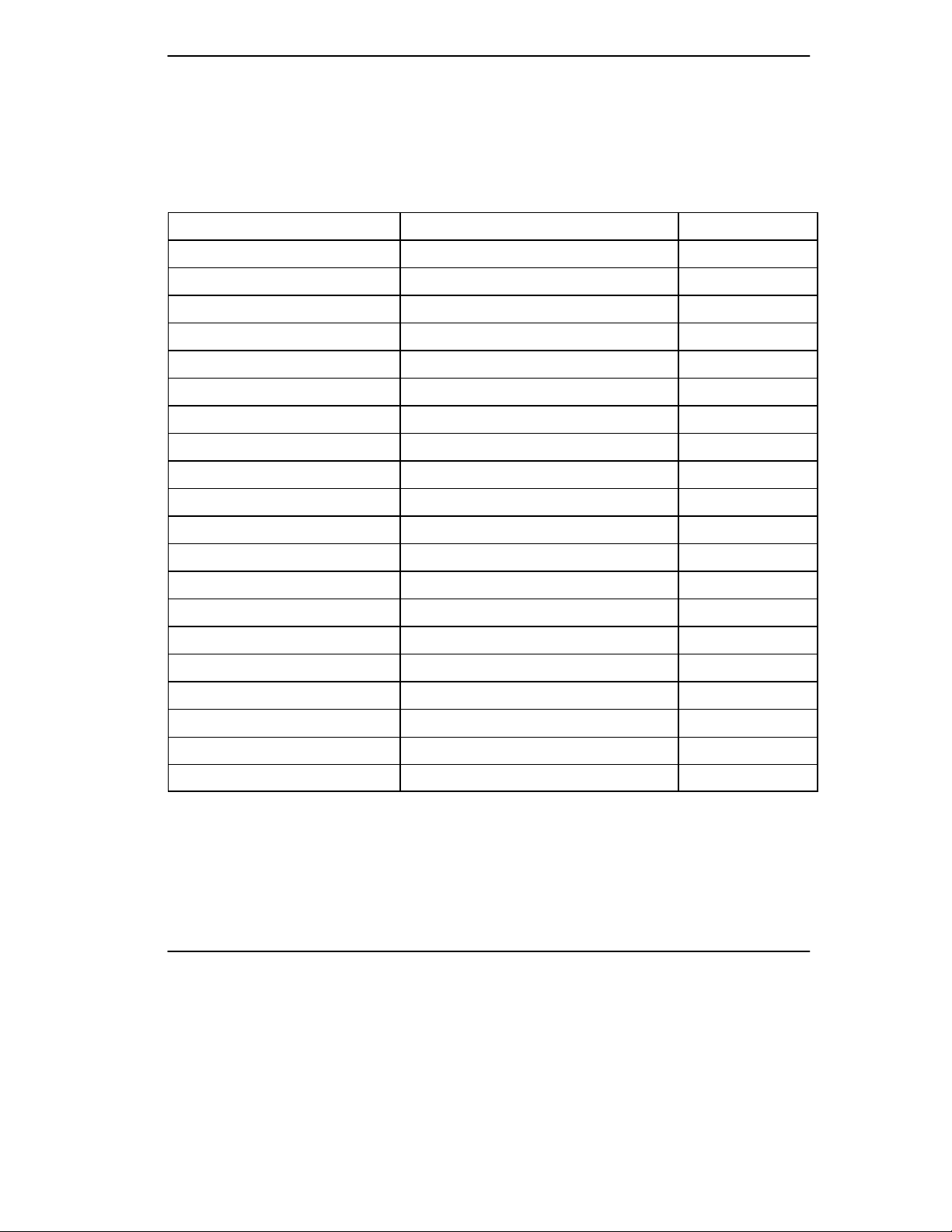

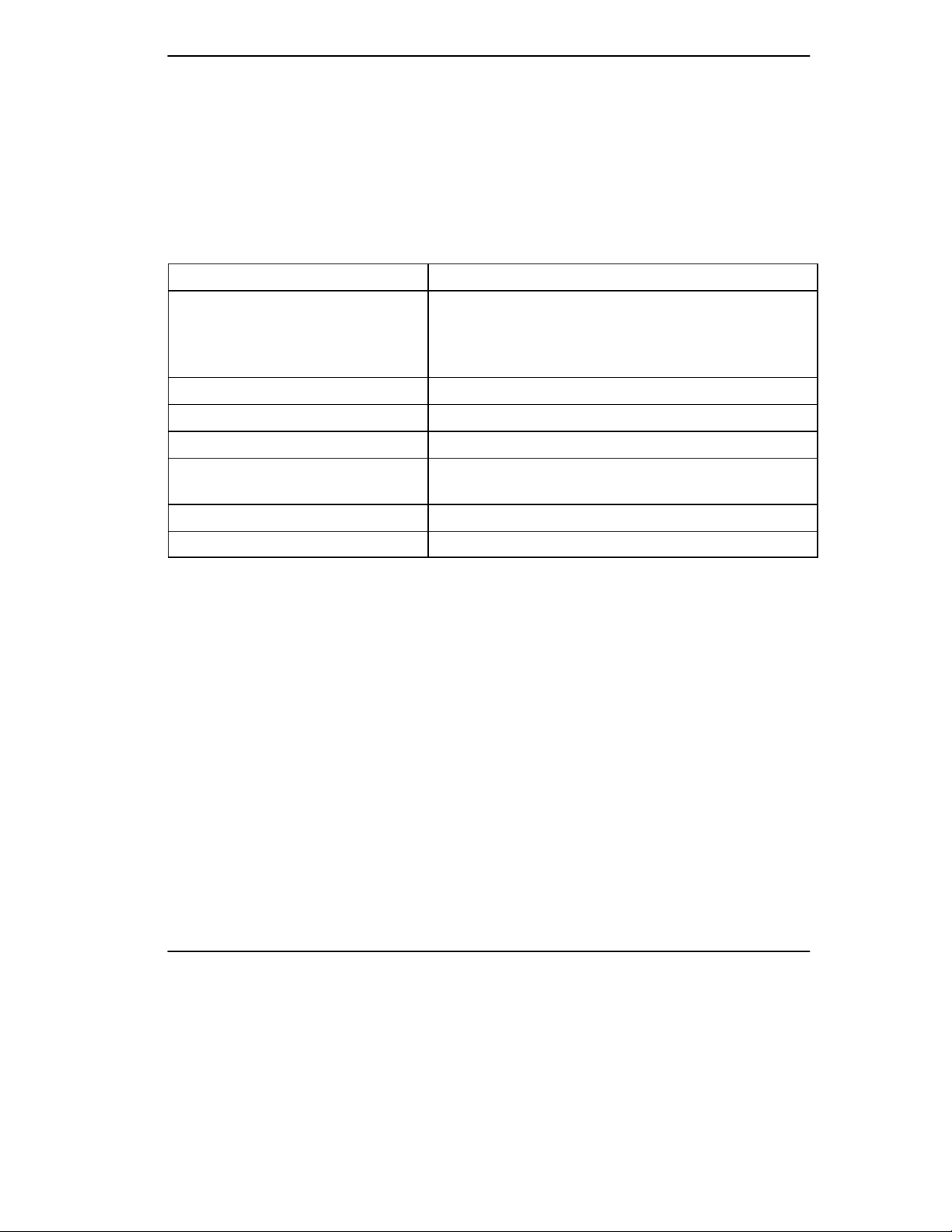

Keypad Feature Comparison

This table compares the features provided by the DryView 8700/8500 Keypad and

the Kodak Keypad. Note that the Kodak Keypad is available with all DryView

8700/8500 Laser Imager systems, but the DryView 8700/8500 Keypad is available

only with the DryView 8700/8500 Laser Imager Standard system.

Feature

DryView 8700/8500 Keypad Kodak Keypad

Format Select Yes Yes

Custom Formats No Yes

Multiple Copies Setting Yes Yes

Sequential Image Acquire Yes Yes

Random Image Acquire No Yes

Sequential Image Erase Yes Yes

Random Image Erase No Yes

Move Acquired Image No Yes

Print Yes Yes

Stop Print Yes Yes

Density or Dmax Setting No * Yes

Contrast Setting No * Yes

Print Density Test No * Yes

Print Contrast Test No * Yes

Smooth/Sharp Select No Yes

Image Polarity Select No Yes

Image Framing Select No Yes

Auto-Print Select No ** Yes

Auto-Format Select No ** Yes

Alarm Volume Setting No Yes

* Can be set at the imager’s local panel.

** Can be set by service personnel during installation.

2001 March Rev. B 8599110

1-3

Page 22

User Guide

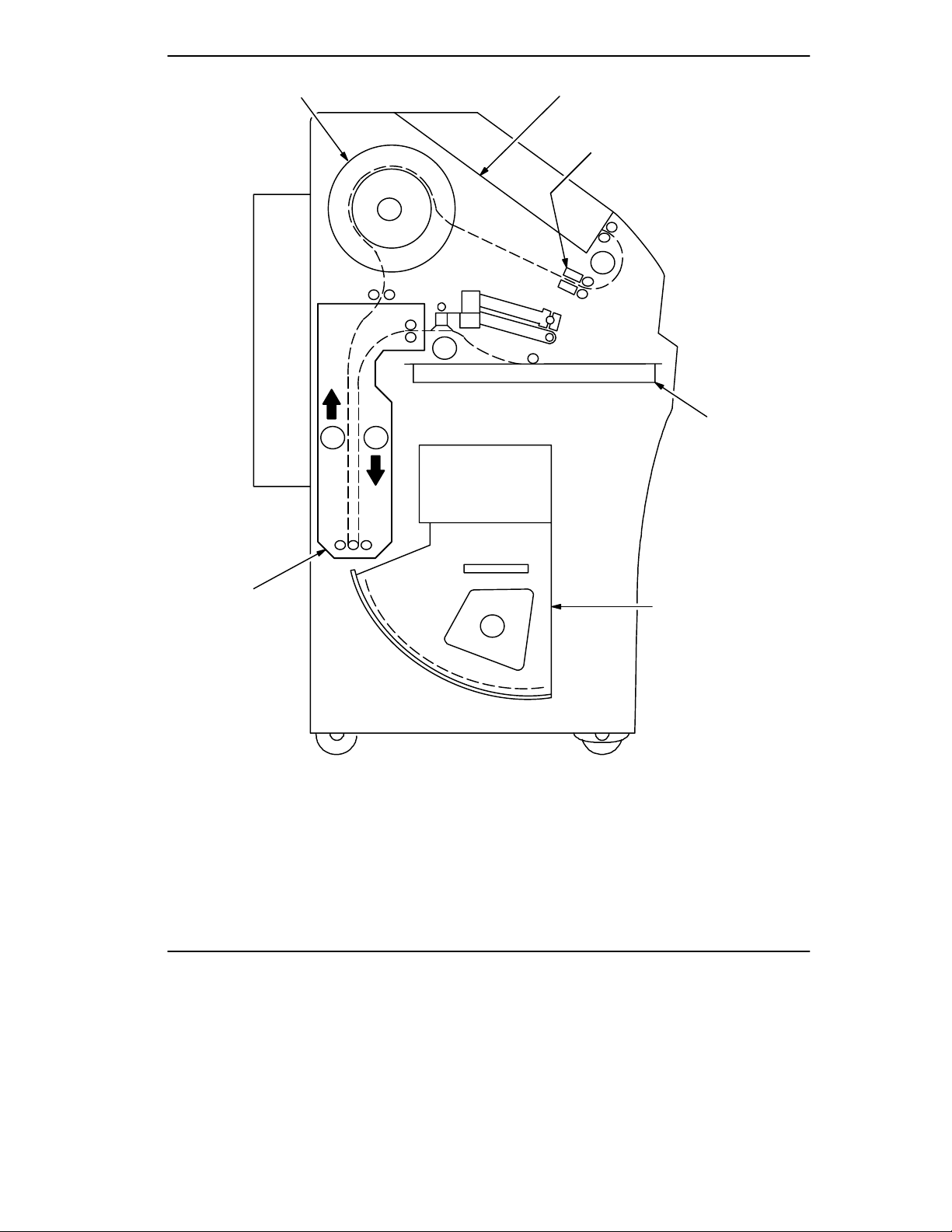

How the 8700/8500 Laser Imager Works

The following sequence occurs each time the 8700/8500 Laser Imager receives a

print command. The circled numbers in Figure 1-2 correspond to the numbered

steps below. Dashed lines indicate the film path.

1. Suction cups in the pickup area lift a single sheet of film out of the supply

cartridge and feed it into the film transport rollers.

2. The film transport drives the film down into the exposure module.

3. The film is exposed by a laser beam and then fed back into the film transport.

4. The film transport drives the film up into the film developer.

5. As the film passes over the film developer drum, the heat generated by the drum

develops the film.

6. The film transport drives the film out of the film developer, through the

densitometer, and out to the receive tray. The densitometer is a key element in

the Kodak Automatic Image Quality Control (AIQC) process, which allows the

imager to automatically adjust image processing parameters to ensure optimum

image quality.

1-4

8599110 2001 March Rev. B

Page 23

Introduction

Film Developer

Receive Tray

Densitometer

5

6

1

2

4

Supply

Cartridge

Film

Transport

2001 March Rev. B 8599110

3

Figure 1-2. Print Sequence

Exposure

Module

1-5

Page 24

User Guide

BLANK PAGE

1-6

8599110 2001 March Rev. B

Page 25

Controls and Indicators

Controls and Indicators

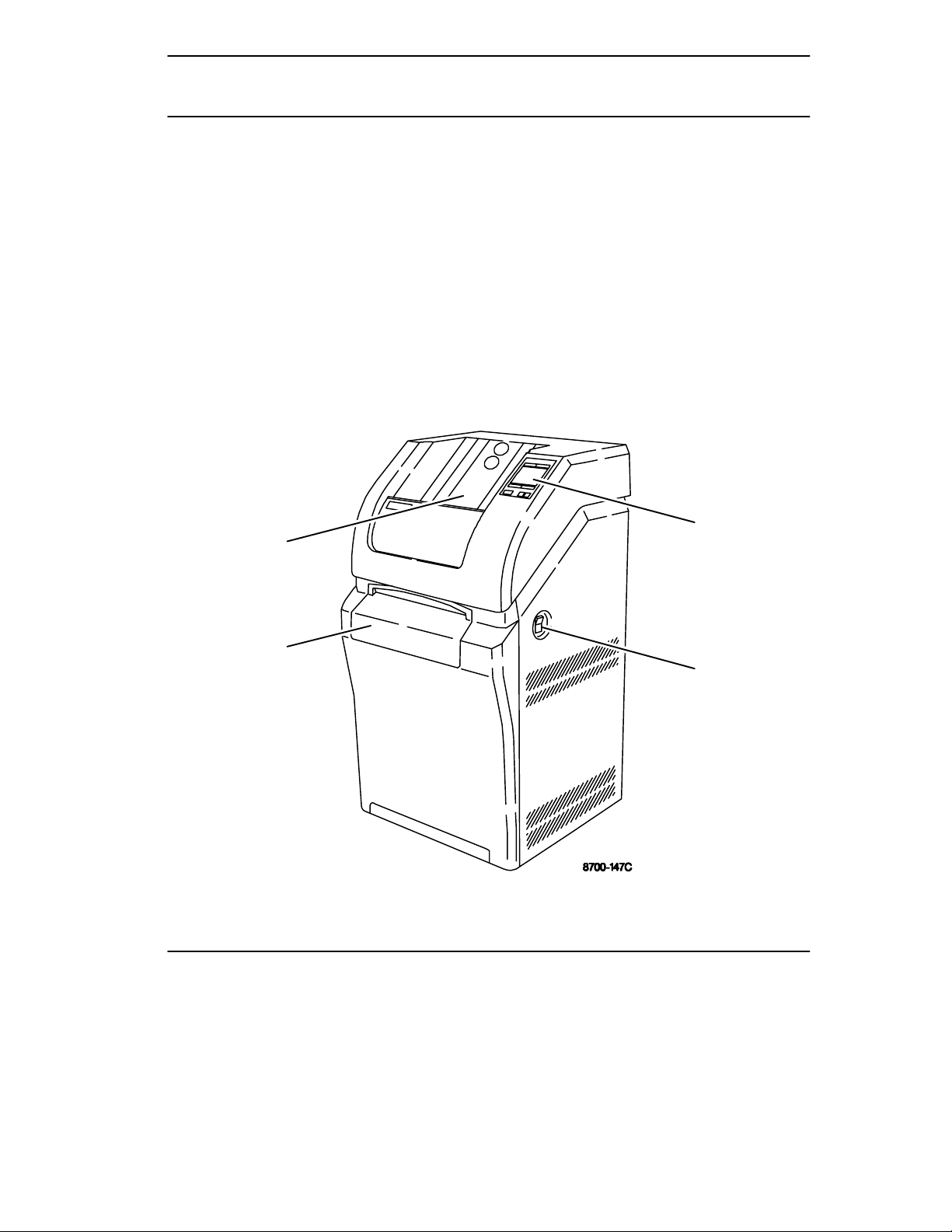

Kodak DryView 8700/8500 Laser Imager

The controls and indicators for the Kodak DryView 8700/8500 Laser Imager

(8700/8500 Laser Imager) are identified in the figure. The numbered descriptions

correspond to the numbered callouts in Figure 2-1.

1. Local Panel – Includes a message display, status indicator lights, and push

button controls. For more detailed description, refer to Local Panel in this

section.

2. Power Switch – Controls power to the imager.

3. Supply Door – Enables access to the film cartridge.

4. Receive Tray – Collects developed film.

4

3

Figure 2-1. 8700/8500 Laser Imager – Controls and Indicators

2001 March Rev. B 8599110

1

2

2-1

Page 26

User Guide

Local Panel

The numbered descriptions correspond to the numbered callouts in Figure 2-2.

1. Attention Light – Indicates a condition that may affect imager operation (e.g.,

imager warming or film low). Check the display for a related message.

2. Power Light – Indicates the imager is powered up.

3. Next Button –

Main Menu displayed: Used to scroll through status/error messages.

User Settings menu displayed: Used to move from one parameter to the

next.

4. Display – Displays messages, menus, and button labels.

5. User 2/+ Button –

Main Menu displayed: Used to access the User 2 Settings menu.

User Settings menu displayed: Used to increase the contrast or density

setting .

Note

The User 2/+ button has no function on Multi-Input/Dual Printer systems. Refer to

the 8800 Multi–Input Manager User Guide for instructions on setting contrast and

density and for printing test films on Multi-Input/Dual Printer systems.

6. Calibration Button – Initiates a calibration film is printing.

7. Light Control Button – Disables the indicator lights and display backlighting.

8. Supply Button – Opens the supply door.

9. User 1/–/Print Button –

Main Menu displayed: Used to access the User 1 Settings menu.

User Settings menu displayed: Used to decrease the contrast or density

setting, or to initiate printing of a contrast or density test sheet.

Note

The User 1/–/Print button has no function on Multi-Input/Dual Printer systems. Refer

to the 8800 Multi–Input Manager User Guide for instructions on setting contrast and

density and for printing test films on Multi-Input/Dual Printer systems.

2-2

8599110 2001 March Rev. B

Page 27

Controls and Indicators

10. Test/Return Button –

Multi–Input/Dual Printer systems: Used to initiate a test print.

User Settings menus on Standard and Plus systems: Used to return to

the Main Menu.

11. Ready Light – Indicates the imager is ready to begin its next operation.

12. Alarm Light – Indicates an error condition exists (e.g., film jam or door open),

and imager operation can not continue until the error is cleared. Check the

display for a related message.

12

11

10

1

2

3

Next

Laser Imager Ready

14 x 17 Blue

4

Supply: 123

Printed: 9870

User 1 User 2

9

5

68

2001 March Rev. B 8599110

7

Figure 2-2. Local Panel Controls

2-3

Page 28

User Guide

Local Panel – Main Menu

The center box displays system status and error messages. The four smaller boxes

display labels that indicate the function of the buttons immediately above and below

the display. Note that the functions of the buttons vary depending on the type of

system. Figure 2-3 shows the labels displayed for Standard and Plus systems.

Figure 2-4 shows the labels displayed for Multi-Input/Dual Printer systems.

Next

Laser Imager Ready

14 x 17 Blue

Supply: 123

Printed: 9870

User 1 User 2

2-4

Figure 2-3. Local Panel Main Menu – Standard and Plus Systems

8599110 2001 March Rev. B

Page 29

Controls and Indicators

NextTest

Laser Imager Ready

14 x 17 Blue

Supply: 123

Printed: 9870

Figure 2-4. Local Panel Main Menu – Multi-Input/Dual Printer Systems

The Test button is not displayed or available on an 8500 Dual Printer.

Pressing the Test button on an 8700 Dual Printer initiates a density test film print

containing a SMPTE test pattern.

2001 March Rev. B 8599110

2-5

Page 30

User Guide

Local Panel – User Settings Menu

Note

The Local Panel User Settings Menu applies only to 8700/8500 Standard and Plus

systems. For Multi–Input 8700/8500 Dual Printer systems, refer to the 8800

Multi–Input Manager User Guide for instructions on setting contrast and density and

printing test films.

The center box on the User Settings Menu displays a menu. The currently selected

menu item is surrounded by a rectangle.

The four smaller boxes display labels that indicate the function of the buttons

immediately above and below the display. The two bottom labels depend on which

menu item is currently selected:

If Contrast or DMAX is selected, the + and – labels are displayed. Refer to

Figure 2-5.

If Contrast Test or Density Test is selected, the Print label is displayed. Refer to

Figure 2-6.

Each menu item is described below:

Contrast – When selected, pressing the + or – buttons increases or decreases

the contrast setting (range: 1 to 15 for positive contrast and –1 to –15 for

negative contrast).

DMAX – When selected, pressing the + or – buttons increases or decreases the

density setting. If AIQC (Automatic Image Quality Control) is active, the selected

Dmax setting is displayed (range: 1.70 – 3.10). If AIQC is not active, the selected

density setting is displayed (range: 1 – 16).

Contrast Test – When selected, pressing the Print button initiates a contrast test

film print. The last image stored is printed 15 times using 15 different contrast

settings. On either an 8700 or 8500 Standard or Plus system, the 15 images

may be printed on a single film sheet or the 15 different contrast images may be

printed on multiple–film sheets, depending on the acquired image size.

Density Test – When selected, pressing the Print button initiates a density test

film print containing a SMPTE test pattern.

2-6

8599110 2001 March Rev. B

Page 31

Controls and Indicators

NextReturn

User 1

Menu Items

Contrast: 8

DMAX: 2.90

Selected Item

Contrast Test

Density Test

–+

Figure 2-5. User Settings Menu – Contrast Setting Selected

NextReturn

Menu Items

Figure 2-6. User Settings Menu – Contrast Test Selected

2001 March Rev. B 8599110

User 1

Contrast: 8

DMAX: 2.90

Contrast Test

Density Test

Print

Selected Item

2-7

Page 32

User Guide

DryView 8700/8500 Keypad

Note

The DryView 8700/8500 Keypad is used only on 8700/8500 Laser Imager Standard

systems.

The numbered descriptions correspond to the numbered callouts in Figure 2-7.

1. Display – Displays system status information.

2. Stop Key – Stops the most recently queued print job. The job, including any

unprinted multiple copies, is deleted from the print queue.

3. Copies Key – Sets the copy count (range: 1 – 9).

4. Print Key – Places a print request in the print queue.

5. Format Keys – Used to select the desired image format.

6. Acquire Key – Used to acquire and store images in sequential order, starting in

the top row and working from left to right in each row.

7. Light Key – Adjusts the brightness of the display backlighting.

8. Erase Key – Deletes images in reverse order, starting with the last image stored.

2-8

8599110 2001 March Rev. B

Page 33

READY

Film:125 Queue:90

Next:1/20 Copies:9

––––––––––––––––––––

Controls and Indicators

1

8

Erase Light Copies Stop

7

Print

1246

2

3

4

5

9121520

Acquire

6

Figure 2-7. DryView 8700/8500 Keypad

2001 March Rev. B 8599110

2-9

Page 34

User Guide

Kodak Keypad

Note

The Kodak Keypad is used on 8700/8500 Laser Imager Standard and Plus systems

and on Multi–Input/Dual Printer systems.

The numbered descriptions correspond to the numbered callouts in Figure 2-8.

1. Touch Screen – Displays a variety of menus used for system configuration and

operation. These menus are described later in this section.

2. Print Button – Places a print request in the print queue.

3. Store Buttons – Used to acquire and store images in specific positions for

printing. LEDs above each button indicate used (red) and available (green)

storage locations.

4. Sequential Store Button – Used to acquire and store images in sequential

order, starting in the top row, and working from left to right in each row.

5. Erase Button – Used to enter Erase Image mode, which allows random erasure

of any or all stored images.

2-10

8599110 2001 March Rev. B

Page 35

Controls and Indicators

1

5

2

3

4

Figure 2-8. Kodak Keypad

2001 March Rev. B 8599110

2-11

Page 36

User Guide

Kodak Keypad – Main Menu

The numbered descriptions correspond to the numbered callouts in Figure 2-9.

1. Attention Message Area – Displays system status and error messages.

2. Imager Information Area #1 – Indicates the status (active or OFF) of Automatic

Image Quality Control (AIQC) and the percentage of free image memory.

3. Imager Information Area #3 – Indicates the number of films remaining in the

supply cartridge, the number of prints in the print queue, and the total number of

completed prints.

4. Copy Count Set Buttons – Used to increase or decrease the copy count

(range: 1 – 99).

5. Stop Print Button – Stops the most recently queued print job. The job, including

any unprinted multiple copies, is deleted from the print queue.

6. Format Menu Button – Used to access the Format Menu.

Note

When in Erase Image mode, the Erase All Images button is displayed in place of the

Format Menu button. The Erase All Images button is used to erase all stored images

from the current format.

7. Keypad Menu Button – Used to access the Keypad Menu.

8. Imager Menu Button – Used to access the Imager Menu.

9. Imager Information Area #2 – Indicates the status of the auto print and auto

format functions (ON or OFF).

2-12

8599110 2001 March Rev. B

Page 37

Main Menu

Controls and Indicators

Laser Imager 1 Status:

Ready

Imager 1

Automatic Image Quality Control Active

Memory Free 100%

Auto Print ON

9

8

7

Auto Format ON

Imager

Menu

Keypad

Menu

ERASE

Media: 14 X 17

Supply: 125

Queued: 10

Printed: 1231

Format

Menu

Copies: 2

Stop

Print

PRINT

1

2

3

4

5

6

Figure 2-9. Kodak Keypad – Main Menu

2001 March Rev. B 8599110

2-13

Page 38

User Guide

Kodak Keypad – Format Menu

The numbered descriptions correspond to the numbered callouts in Figure 2-10.

1. Attention Message Area – Displays system status and error messages.

2. RETURN Button – Used to return to the Main Menu without selecting a format.

3. Format Select Buttons – Used to select the desired image format. Buttons are

only displayed for those formats that are currently available. The available

formats include:

Nine fixed formats (1:1, 2:1, 4:1, 6:1, 9:1, 12:1, 15:1, 16:1, and 20:1).

Up to four custom formats. Custom formats (also referred to as mixed

formats) are set up by service personnel based on operator input.

– For custom formats on 8700 and 8500 Laser Imager Standard and Plus

systems, images within each row must all be the same size. Image size

can vary from row to row.

– For custom formats on Multi–Input/Dual Printer systems, the images can

be different sizes and randomly arranged on the film.

2-14

8599110 2001 March Rev. B

Page 39

Format Menu

Controls and Indicators

Laser Imager 1 Status:

Ready

CUSTOM

FORMAT

A

1246

CUSTOM

FORMAT

B

CUSTOM

FORMAT

C

CUSTOM

FORMAT

D

1

3

9 121516

20 RETURN

2

Figure 2-10. Kodak Keypad – Format Menu

2001 March Rev. B 8599110

2-15

Page 40

User Guide

Kodak Keypad – Imager Menu

The numbered descriptions correspond to the numbered callouts in Figure 2-11.

1. Attention Message Area – Displays system status and error messages.

2. Contrast, Density, & Count Menu Button – Used to access the Contrast,

Density, & Count Menu.

3. Print Density Test Button – Initiates a density test film print containing a

SMPTE test pattern.

4. Image Polarity Button – Selects positive or negative image polarity.

5. RETURN Button – Used to return to the Main Menu.

6. Image Framing Button – Sets image framing to ON or OFF. When set to ON, a

one pixel frame is printed around each image.

7. Output Button – Selects the desired output destination (Imager 1 or Imager 2).

This button is not displayed if the keypad is connected to a Standard or Plus

system.

8. Image Processing Button – Selects smooth or sharp image processing. (The

choice depends on the personal preference of the viewer.)

9. Print Contrast Test Button – Initiates a contrast test film print. The last image

stored is printed 15 times using 15 different contrast settings. On either an 8700

or 8500 Laser Imager Standard or Plus system, the 15 images may be printed on

a single film sheet or the 15 different contrast images may be printed on multiple

film sheets depending on the acquired image size.

2-16

8599110 2001 March Rev. B

Page 41

Imager Menu

Controls and Indicators

Laser Imager 1 Status:

Ready

Contrast,

Density,

& Count

Menu

Print

Contrast

Test

Image

8

Processing

SMOOTH

Output

Imager 1

ERASE

Image

Framing

ON

Print

Density

Test

Image

Polarity

POSITIVE

RETURN

PRINT

1

2

39

4

57

Figure 2-11. Kodak Keypad – Imager Menu

2001 March Rev. B 8599110

6

2-17

Page 42

User Guide

Kodak Keypad – Contrast, Density, & Count Menu

The numbered descriptions correspond to the numbered callouts in Figure 2-12.

1. Attention Message Area – Displays system status and error messages.

2. Reset Printed Count Button – Resets the printed count value to zero (displayed

in Imager Information Area #3 on the Main Menu).

3. Density Set Buttons – Used to increase or decrease the density setting. If

Automatic Image Quality Control (AIQC) is active, the selected Dmax setting is

displayed (range: 1.70 – 3.10). If AIQC is not active, the selected density setting

is displayed (range: 1 – 16).

4. RETURN Button – Used to return to the Imager Menu.

5. Contrast Set Buttons – Used to increase or decrease the contrast setting

(range: 1 through 15).

2-18

8599110 2001 March Rev. B

Page 43

Contrast, Density, & Count Menu

K190:

Changing the contrast and/or

density will affect image quality.

Reset

Printed

Count

DMAX 2.10Contrast 12

Controls and Indicators

1

2

5

RETURN

ERASE

PRINT

3

4

Figure 2-12. Kodak Keypad – Contrast, Density, & Count Menu

2001 March Rev. B 8599110

2-19

Page 44

User Guide

Kodak Keypad – Keypad Menu

The numbered descriptions below correspond to the numbered callouts in

Figure 2-13.

1. Attention Message Area – Displays system status and error messages.

2. Display Brightness Set Buttons – Sets the keypad display brightness.

3. Alarm Beep Volume Set Buttons – Sets the keypad alarm beep volume.

4. RETURN Button – Used to return to the Main Menu.

5. Auto Print Button – Sets the auto print function to ON or OFF. When set to ON,

a print is automatically queued after the last image is stored (the Print button

does not have to be pressed).

6. Auto Format Button – Sets the auto format function to ON or OFF. When set to

ON, a new format is automatically displayed after a print is queued (i.e., the

LEDs above the store buttons change from red to green).

7. Key Beep Volume Set Buttons – Sets the key beep volume.

8. Color Blind Mode Button – Sets the color blind feature to ON or OFF. When set

to ON, the red LEDs above the Store buttons (which indicate used storage

locations) blink instead of staying on constantly. This allows the red LEDs to be

differentiated from the constant green LEDs (which indicate available storage

locations).

Note

When in Erase Image mode, the red LEDs blink regardless of whether the color

blind feature is ON or OFF.

2-20

8599110 2001 March Rev. B

Page 45

Keypad Menu

Controls and Indicators

Laser Imager 1 Status:

Ready

Color

8

Blind

Mode

OFF

Display

Brightness

1

2

Key Beep

Volume

7

Auto

6

Format

ON

ERASE

Auto

Print

ON

Alarm Beep

Volume

RETURN

PRINT

3

4

5

Figure 2-13. Kodak Keypad – Keypad Menu

2001 March Rev. B 8599110

2-21

Page 46

User Guide

BLANK PAGE

2-22

8599110 2001 March Rev. B

Page 47

Operation and Maintenance

Operation and Maintenance

System Power Up

1. Set the imager power switch to ON.

The Power light on the local panel comes on.

The imager performs a series of self-diagnostic tests and begins a warmup

cycle. The time required for warmup varies based on how long the imager

has been turned off.

After the diagnostic tests and warmup cycle are complete, the local panel

displays “Laser Imager Ready”.

Note

Images can be acquired during the warmup cycle, but no printing will occur until the

ready message is displayed.

Figure 3-1. Power Switch and Local Panel

2001 March Rev. B 8599110

Local Panel

Power Switch

3-1

Page 48

User Guide

Format/Acquire/Print – DryView 8700/8500 Keypad

1. Set the imager power switch to ON.

2. On the keypad, press Copies to select the number of copies desired.

3. Press the appropriate Format key to select the desired format.

4. Press Acquire to acquire images.

5. After the images are acquired, press Print to place a print request in the print

queue.

Note

If the auto–print function is enabled, a print request is automatically placed in the

print queue after the last image in the format has been acquired (the Print button

does not have to be pressed).

Note

For the DryView 8700/8500 Keypad, the auto–print function is enabled or disabled

by service personnel during installation. The user cannot change this setting.

3-2

8599110 2001 March Rev. B

Page 49

Operation and Maintenance

Format/Acquire/Print – Kodak Keypad

1. Set the imager power switch to ON.

2. On the keypad’s Main Menu, press Copy Count Set to select the number of

copies desired.

3. Press Format Menu to access the Format Menu.

4. Press the appropriate Format Select button to select the desired format.

5. Press the appropriate Store buttons to acquire images.

6. After the images are acquired, press Print to place a print request in the print

queue.

Note

If the auto–print function is ON, a print request is automatically placed in the print

queue after the last image in the format has been stored.

7. Select a new format and/or acquire and store more images, as desired.

If the auto–format function is ON, a new format is automatically displayed,

allowing you to acquire more images.

If the auto–format function is OFF, new images cannot be acquired until a

new format is selected or the currently stored images are erased using the

Erase Image function.

2001 March Rev. B 8599110

3-3

Page 50

User Guide

Density/Contrast Selection – Local Panel

Note

This procedure applies only to 8700/8500 Laser Imager Standard and Plus Systems.

For Multi–Input 8700/8500 Dual Printer systems, refer to the 8800 Multi–Input

Manager User Guide for instructions on setting contrast and density and for printing

test films.

1. Display an image on the user’s console.

2. From the console, adjust the window and level controls to achieve the desired

image quality on the display monitor.

3. Acquire the displayed image.

4. Press User 1 or User 2 on the Local Panel to display the appropriate User

Settings Menu.

5. Press Next, as required, to select Contrast Test Print.

6. Press Print to initiate a contrast test film print. The last image stored is printed 15

times, using 15 different contrast settings. On either an 8700 or 8500 Standard

or Plus system, the 15 different contrast images may be printed on a single film

sheet or on multiple film sheets, depending on the acquired image size.

7. Examine the test sheet(s) to determine if the maximum density is acceptable.

If the maximum density is acceptable, skip to Step 11.

If the maximum density is not acceptable, continue to Step 8.

8. Press Next, as required, to select DMAX.

9. Press Increase/Decrease, as required, to change the density setting.

10. Repeat steps 5 through 9 until the desired maximum density is achieved.

11. Examine the 15 images on the contrast test sheet and select the image with the

most appropriate contrast. Note the value printed next to this image.

12. Press Next, as required, to select Contrast.

13. Press Increase/Decrease, as required, to change the contrast setting to the

value of the selected image (step 11). You can select either positive or negative

contrast. Use settings 1 through 15 for positive contrast images. Use settings –1

through –15 for negative contrast images.

14. Press Return to return to the Main Menu.

3-4

8599110 2001 March Rev. B

Page 51

Operation and Maintenance

Density/Contrast Selection – Kodak Keypad

Note

This procedure applies only to 8700/8500 Laser Imager Standard and Plus systems

and Multi–Input/Dual Printer systems.

1. Display an image on the user’s console.

2. From the console, adjust the window and level controls to achieve the desired

image quality on the display monitor.

3. From the Main Menu, press Format Menu, then press any Format Select button

on the Format Menu.

4. Press any lighted Store button or Sequential Store to acquire the image.

5. From the Main Menu, press Imager Menu.

6. Press Print Contrast Test. The imager prints the acquired image in a 15:1

format on a single sheet, using each of the 15 different contrast settings.

7. Examine the test sheet to determine if the maximum density is acceptable.

If the maximum density is acceptable, skip to Step 11.

If the maximum density is not acceptable, continue to Step 8.

8. From the Imager Menu, press Contrast, Density, & Count Menu, then press OK

on the Confirmation Menu.

9. Press Density Set, as required, to change the density setting. When the desired

density value is displayed, press RETURN.

10. Repeat steps 6 through 9 until the desired maximum density is achieved.

11. Examine the 15 images on the contrast test sheet and select the image with the

most appropriate contrast. Note the value printed next to this image.

12. From the Imager Menu, press Contrast, Density, & Count Menu, then press OK

on the Confirmation Menu.

13. Press Contrast Set, as required, to change the contrast setting of the selected

image. When the desired contrast value is displayed, press RETURN.

14. From the Imager Menu, press Image Polarity to select either positive or

negative image contrast.

15. From the Imager Menu, press RETURN to return to the Main Menu.

2001 March Rev. B 8599110

3-5

Page 52

User Guide

Moving Stored Images – Kodak Keypad

The move function let you move a previously stored image to any available

non-stored position (i.e., any Store button with a green LED). To enable the move

function, press the Store button of the image you want moved. To complete the

move, press the Store button for the desired image position.

The move function is exited as soon as the image is stored at its new location.

To exit the move function without moving the image, press the image’s Store

button again (or press the Store button of any other stored image).

Erasing Stored Images – DryView 8700/8500 Keypad

Press Erase to erase images in reverse order, starting with the most recently

acquired image.

Erasing Stored Images – Kodak Keypad

Press Erase Image to enter Erase Image mode. While in Erase Image mode, any or

all stored images can be erased.

To erase a specific image, press Store for that image. Once all the desired

images are erased, press Erase Image to exit the Erase Image mode.

To erase all stored images, press Erase All Images on the Main Menu. After

erasing of the stored images, the keypad automatically exits Erase Image mode.

Note

When in Erase Image mode, the Erase All Images button is displayed in place of the

Format Menu button.

3-6

8599110 2001 March Rev. B

Page 53

Operation and Maintenance

Deleting a Job from the Print Queue – DryView 8700/8500 Keypad

To stop the most recently queued print job, press Stop. The job, including any

unprinted multiple copies, is deleted from the print queue.

Note

You cannot delete multiple jobs from the print queue by pressing the Stop key

multiple times.

Deleting a Job from the Print Queue – Kodak Keypad

To stop the most recently queued print job, press Stop Print on the Main Menu. The

job, including any unprinted multiple copies, is deleted from the print queue.

Note

You cannot delete multiple jobs from the print queue by pressing the Stop Print

button multiple times.

2001 March Rev. B 8599110

3-7

Page 54

User Guide

Loading/Unloading Film

1. If the supply door is not already open, press Supply on the local panel.

2. To remove the film cartridge, lift the edge of the cartridge slightly, then slide the

cartridge out of the imager.

3. To install the film cartridge, set the leading edge of the cartridge on the cartridge

guides, then slide the cartridge into the imager to engage the detents in the

bottom of the cartridge.

4. Close the supply door.

3-8

Leading Edge

Detents

Figure 3-2. Loading/Unloading Film

8700-43A

8599110 2001 March Rev. B

Page 55

Operation and Maintenance

Cleaning the Platen

The platen is the inside bottom surface of the exposure module. Over time, this

surface can collect dust. This dust can create artifacts on printed images.

Supplies Required

3M Auto-Pak Tack Cloth (60-9800-0888-6)

Procedure

1. From the local panel, press Supply to close the film cartridge and open the

supply door.

2. Remove the film cartridge.

!

Warning

When the power cord is plugged in, hazardous voltages are present in some areas

of the imager. These voltages can cause severe injury or death.

3. Turn off the imager and unplug its power cord.

4. Open the left door via its mechanical release (see page 4-14).

5. Open the platen access door (turn the handle counterclockwise and push in the

door).

!

Caution

The anti-reflective surface of the platen is easily damaged by fingernails and jewelry.

Before cleaning the platen, remove any jewelry (rings, bracelets, watches, etc.)

which may accidentally come in contact with the platen.

If the Auto-Pak cloth catches on parts inside the exposure module, take care not to

damage the parts when removing the cloth. Check for and remove any torn pieces of

cloth.

6. Use an Auto-Pak cloth to wipe the surface of the platen, as well as the inside

surfaces close to the bottom of the exposure module.

Note

The Auto-Pak cloth will not remove large particles. Use a flashlight and fingers to

remove large particles.

2001 March Rev. B 8599110

3-9

Page 56

User Guide

7. Close the platen access door after cleaning. Turn the handle fully clockwise to

latch the door.

8. Install the film cartridge.

9. Close the left door and supply door.

10. Plug in the power cord and power up the imager.

3-10

Handle

Platen Access Door

Figure 3-3.

8599110 2001 March Rev. B

Page 57

Operation and Maintenance

Replacing the Developer Filter

Kodak DryView Laser Imaging Film emits a slight odor when it is developed. The

developer filter absorbs and neutralizes this odor. As the filter ages, it becomes

slightly less effective. If odor becomes noticeable, replace the filter as follows:

1. Unlatch and open the filter housing.

2. Remove the old filter.

3. Install the new filter. See the instructions on the filter package.

4. Close and latch the filter housing.

Filter

Figure 3-4. Replacing the Developer Filter

2001 March Rev. B 8599110

3-11

Page 58

User Guide

BLANK PAGE

3-12

8599110 2001 March Rev. B

Page 59

Troubleshooting

Troubleshooting

Local Panel and Keypad Message Types

The local panel and keypads display three types of messages.

Status

Status messages are strictly informational and require no operator action.

Note

The DryView 8700/8500 Laser Imager displays a local panel status message (P550)

when preventive maintenance and cleaning are recommended. Preventive

maintenance and cleaning ensure optimum imager performance. The P550

message will not interfere with normal operation. The intent is to let the operator

schedule a convenient time for preventive maintenance and cleaning by a certified

technician.

Action

Action messages indicate that operator action is required before imager operation

can continue. If an action message does not clear after performing the indicated

action, call for service.

Error

Error messages indicate an error condition within the imager. In some cases, error

messages can be cleared by operator action, but in most cases a service call will be

required.

Error message tables list error messages (for the DryView 8700/8500 Keypad) or

error message numbers (for the local panel and Kodak Keypad), along with the

operator action that may clear the error.

2001 March Rev. B 8599110

4-1

Page 60

User Guide

Local Panel Error Message Table

This table lists all local panel error message numbers. When an error message is

displayed on the local panel, perform the operator action listed next to the message

number. If the listed action does not clear the error message, call for service.

This table does not include status or action messages. Status messages require no

operator action. Action messages include the required operator action.

Message

Number

Operator Action

P116 Open and close the supply door. Press Supply on the local panel.

P121

P122

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

P123

P126

P138 If pressing Supply does not unlock the door, use the mechanical

release (refer to page 4-14). Darken the room before opening the

door to expose as few sheets of media as possible.

P151

P154

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

P173 Close the platen access door.

P177 Close the cartridge manually (refer to page 4-13).

P178 Close the top cover.

P203

P204

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

P205

P206

P208 Use the mechanical release to open the left door (refer to page

4-14).

P221

P222

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

P223

P224

P225

P226

P227

4-2

8599110 2001 March Rev. B

Page 61

Troubleshooting

Message

Number

Operator Action

P228 Open the left door. Grasp the transport handle and slide the

transport out of the imager, then slide it back in until it latches.

P229 Use the mechanical release to open the supply door (refer to page

4-14).

P301

P302

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

P303

P501

Open and close the top cover of the imager to reset the developer.

P506

P507

P509

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

P551

P552

P553

P554

P561 If this error is caused by a film jam, clearing the jam should clear

the error. If not, turn the imager OFF, wait five seconds, then turn

the imager back ON.

P601

P602

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

P603

P604

P605

P620

P622

P623

P624

P625

Insert a different film cartridge and press Calibration on the local

panel.

P631

P632

P633

P634

P910

P913

2001 March Rev. B 8599110

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

4-3

Page 62

User Guide

Kodak Keypad Error Message Table

This table lists all Kodak Keypad error message numbers. When an error message

is displayed on the Kodak Keypad, perform the operator action listed next to the

message number. If the listed action does not clear the error message, call for

service.

This table does not include status or action messages. Status messages require no

operator action. Action messages include the required operator action.

Message

Number

K1

K3

Turn the imager OFF, wait five seconds, then turn the imager back

ON.

Operator Action

K4

K9

K58 Select a format with fewer images.

K73 Refer to local panel message.

K85 Wait for some images to be printed.

K183 Check for objects laying on the keypad or footswitch.

K184 Call for service.

K202 Refer to local panel message.

K203 Call for service.

K209

Refer to local panel message.

K215

K230 Insert a different film cartridge and press the calibration button on

the local panel.

4-4

8599110 2001 March Rev. B

Page 63

Troubleshooting

DryView 8700/8500 Keypad Error Message Table

This table lists all DryView 8700/8500 Keypad error messages. When an error

message is displayed on the DryView 8700/8500 Keypad, perform the operator

action listed next to the message. If the listed action does not clear the error

message, call for service.

This table does not include status or action messages. Status messages require no

operator action. Action messages include the required operator action.

Message

Acquire Failure – 59

Try acquiring again.

Operator Action

Acquire Failure – 65

Acquire Failure – 68

Acquire Failure – 72

Cover Open Refer to local panel message.

Error – Check Imager Refer to local panel message.

Media Jam Refer to local panel message.

Memory Full Wait for some images to be printed, then

continue acquiring.

No Cassette Refer to local panel message.

Supply Out Refer to local panel message.

2001 March Rev. B 8599110

4-5

Page 64

User Guide

Removing Jams from Area 1

Note

When jams occur in Area 1, the film cartridge does not close. If the left door is

opened, the top sheets of film in the cartridge will be exposed. To minimize the

number of exposed sheets, darken the room before opening the left door.

1. From the local panel, press and hold Supply for five seconds to unlock the left

door and supply door.

2. Swing open the left door.

3. Reach into the pickup area and remove the jammed film.

4. Close the left door and supply door.

4-6

Pickup Area

Figure 4-1. Removing Jams from Area 1

8599110 2001 March Rev. B

Page 65

Troubleshooting

Removing Jams from Area 2a

1. Open the left door (the imager automatically unlocks the door).

2. Squeeze the transport handle and slide the assembly out of the imager.

3. Push in the lever at the bottom of the transport. The film should drop out of the

transport; if not, reach through the access holes and push the film down and out

of the transport.

4. After removing the jam, slide the transport assembly in until it latches (do not

squeeze the transport handle), then close the left door.

Handle

Figure 4-2. Removing Jams from Area 2a

2001 March Rev. B 8599110

Access Holes

Lever

4-7

Page 66

User Guide

Removing Jams from Area 2b

1. Open the left door (the imager automatically unlocks the door).

2. Squeeze the transport assembly handle and slide the assembly out of the

imager.

3. Turn the knob on the side of the transport clockwise to drive the film out the top

of the transport.

4. After removing the jam, slide the transport assembly in until it latches (do not

squeeze the transport handle), then close the left door.

4-8

Handle

Knob

Figure 4-3. Removing Jams from Area 2b

8599110 2001 March Rev. B

Page 67

Troubleshooting

Removing Jams from Area 3

1. Open the left door (the imager automatically unlocks the door).

2. Open the platen access door (turn the handle counterclockwise and push the

door in).

3. Reach into the platen and remove the jammed film.

Note

If there is no film in the platen, check for the film in Area 2a (refer to page 4-7).

4. Close the platen access door. Turn the handle fully clockwise to latch the door.

5. Close the left door.

Platen Access Door

Figure 4-4. Removing Jams from Area 3

2001 March Rev. B 8599110

Handle

4-9

Page 68

User Guide

Removing Jams from Area 4

1. Raise the top cover to its highest position, then lower it slightly to engage the

support rod.

2. Grasp the developer/exit assembly handle and lift up to unlatch it, then slide the

assembly out of the imager.

3. Grasp the developer cover handle. Raise the cover to its highest position, then

lower it slightly to engage the support arm.

!

Caution

The drum and rollers inside the developer are hot. Use caution when removing

jammed film from the developer.

To prevent damage to the surface of the developer drum, do not use any type of

tool to remove jammed film.

4. Remove the jammed film.

5. Lift the developer cover slightly, pull the support arm forward, then carefully close

the cover.

6. Push down the release lever on the right side of the developer/exit assembly,

then slide the assembly into the imager until the handle latches.

7. Raise the the top cover slightly, push the support rod backward, then carefully

close the cover.

4-10

8599110 2001 March Rev. B

Page 69

Developer Cover

Troubleshooting

Top Cover

Support Arm

Support Rod

Release Lever

Figure 4-5. Removing Jams from Area 4

2001 March Rev. B 8599110

4-11

Page 70

User Guide

Removing Jams from Area 5

1. Raise the top cover to its highest position, then lower it slightly to engage the

support rod.

2. Remove the jammed film.

3. Raise the the top cover slightly, push the support rod backward, then carefully

close the cover.

Top Cover

Area 5

Support Rod

Figure 4-6. Removing Jams from Area 5

4-12

8599110 2001 March Rev. B

Page 71

Troubleshooting

Manually Closing the Film Cartridge

The imager automatically closes the film cartridge when Supply is pressed, when

the cartridge is empty, and when film jams occur in the expose or transport areas. If

the imager cannot close the cartridge, a P177 error message is displayed.

Note

If doors are opened when the film cartridge is open, the top sheets of film will be

exposed. To minimize the number of exposed sheets, darken the room before

opening the doors.

Press and hold Supply for five seconds to unlock the left door and supply door. If

the imager cannot unlock the door(s), use their mechanical releases (refer to

page 4-14).

To close the cartridge, turn the rollback knob counterclockwise.

Figure 4-7. Manually Closing the Film Cartridge

2001 March Rev. B 8599110

Rollback Knob

4-13

Page 72

User Guide

Unlocking the Left Door and Supply Door Via Mechanical Releases

Note

When the left door is unlocked via its mechanical release, the film cartridge stays

open, and the top sheets of film in the cartridge are exposed. To minimize the

number of exposed sheets, darken the room before opening the left door.

Left Door

The imager automatically unlocks the left door if a film jam occurs in the expose or

transport areas. If the imager cannot unlock the door, the local panel displays a

P208 error message. If this occurs, unlock the left door by lifting up the mechanical

release located below the left side of the imager.

Supply Door

The imager automatically unlocks the supply door when the film cartridge is empty or

when Supply is pressed on the local panel. If the imager cannot unlock the door, the

local panel displays a P229 error message. If this occurs,unlock the supply door by

pushing in the mechanical release located inside the left door.

4-14

8599110 2001 March Rev. B

Page 73

Left Door Release

Troubleshooting

Supply Door Release

Figure 4-8. Left Door and Supply Door Mechanical Releases

2001 March Rev. B 8599110

4-15

Page 74

User Guide

BLANK PAGE

4-16

8599110 2001 March Rev. B

Page 75

Specifications

Dimensions

Height: 1279 mm (50.4 in.) – Top Cover closed

1641 mm (64.6 in.) – Top Cover open

Width: 661 mm (26.0 in.) – Left Side Door closed

1218 mm (47.9 in.) – Left Side Door open

Depth: 813 mm (32.0 in.) – Supply and Filter Doors closed

1392 mm (54.9 in.) – Supply and Filter Doors open

Weight: 250 kg (550 lbs)

Electrical

Voltage: 200/220/240 VAC " 10%

50/60 Hz " 3%

Current Draw: 9 Amperes (maximum)

Power Consumption: 2000 V.A. (maximum)

Specifications

Operating Environment

Temperature: 15° to 35°C (59° to 95°F)

Humidity: 20% to 85% RH, Noncondensing

Vibration: 0.01 Gs (maximum)

Magnetic Field: v 100 Gauss

Environmental Effects

Heat Load: 300 BTU/Hr (average)

Floor Load: 220 lb/ft

Acoustical Noise: 55 dB at one meter (70 dB momentarily)

2001 March Rev. B 8599110

2

(1065 kg/m2)

5-1

Page 76

User Guide

DryView 8700/8500 Laser Imager Storage Environment

Temperature: –35° to 60°C (–31° to 140°F)

Humidity: 10% to 90% RH, Noncondensing

Host Control

RS232 or RS422 (jumper selectable) connection to imager or UKEIB.

Can be located up to one kilometer (3280 feet) from imager when using a

UKEIB and fiber cable.

DryView 8700/8500 Keypad

Available image formats include 1:1, 2:1, 4:1, 6:1, 9:1, 12:1, 15:1 and 20:1.

Images are acquired and stored in sequential order, from left to right and top

to bottom.

Can be located up to 60 meters (198 feet) from imager (copper cable).

Kodak Keypad

Nine fixed formats are available – (1:1, 2:1, 4:1, 6:1, 9:1, 12:1, 15:1, 16:1

and 20:1).

Up to four custom formats can be set up. Custom formats (also referred to as

mixed formats) are set up by service personnel based on operator input.

– For 8700 and 8500 Standard and Plus systems, images within each row

must be all the same size. Image size can vary from row to row.

– For Multi–Input/Dual Printer systems, the images can be different sizes

and randomly arranged on the film.

Images can be acquired and stored in random or sequential order.

Can be located up to one kilometer (3280 feet) from imager (fiber cable).

5-2

8599110 2001 March Rev. B

Page 77

T echnical Information

Technical Information

Description

Kodak DryView Laser Imaging (DryView Laser Imaging) film is a high-resolution,

infrared-sensitive, photothermographic film designed specifically for the family of

DryView Laser Imaging systems.

DryView Laser Imaging film delivers the same diagnostic image quality you get with

your current silver halide laser films – but it requires no “wet” chemistry, no “wet” film

processors, and no darkroom procedures. This means there is no need for special

plumbing, wet chemistry disposal procedures, or modifications to your facility.

DryView Laser Imaging film is packaged in daylight load packages and is available

in 14” x 17”, 11” x 14”, and 8” x 10” sizes. All sizes are available in blue or clear, 7 mil

polyester base.

Spectral Sensitivity

DryView Laser Imaging Film is infrared sensitive and has been sensitized to the

infrared laser diode of DryView Laser Imaging systems. When handled according to

instructions on the film package, safelights are not needed. It is not recommended,

but if you remove undeveloped film from the daylight load package, you will need a

darkroom setting and a green safelight, such as the Kodak IR Safelight.

DENSITY

2001 March Rev. B 8599110

Sensitometric Characteristics

3.5

3

2.5

2

1.5

1

0.5

0

0 0.5 1 1.5 2 2.5 3

RELATIVE LOG EXPOSURE

6-1

Page 78

User Guide

Image Quality

DryView Laser Imaging film delivers diagnostic-quality, continuous-tone images

along with sharp alphanumerics and optimum contrast. This high-quality silver-based

film provides radiologists with the same diagnostic information they are accustomed

to viewing – including the spatial resolution, contrast, and gray levels. Plus, because

it is a totally dry imaging process, there is no image quality variability due to “wet”

chemistry.

Automatic Image Quality Control

DryView Laser Imaging film is system-matched for Kodak’s unique Automatic Image

Quality Control (AIQC) technology. This fully automated system, which is a standard

feature of DryView Laser Imaging systems, is designed to ensure that contrast,

density, and other image quality parameters meet preset user preferences,

film-to-film, lot-to-lot.

When using the Kodak DryView 8700/8500 Laser Imager, information on each film

cartridge will allow the system to automatically determine film type, the number of

sheets remaining, and the film manufacturing lot. The AIQC uses this information to

automatically calibrate the imager’s electronics and optimize image quality without

operator intervention.

The AIQC also reads a special density patch printed on each 14” x 17” or 11” x 14”

sheet of DryView Laser Imaging film as it passes through a built-in densitometer.

Slight density variations are corrected automatically.

6-2

8599110 2001 March Rev. B

Page 79

T echnical Information

Less Impact on the Environment

Disposal regulations and procedures for “wet” processing chemistry are

time-consuming and expensive. And even with the most exacting procedures, the

potential to discharge hazardous materials into the environment exists.

Tests show that DryView Laser Imaging film is not considered hazardous to the

environment. As a result, you can develop, recycle, and dispose of films with less

impact on the environment than if you were using wet developed silver halide films.

DryView Laser Imaging Film

Environmental Regulations Comparison

Wet Silver Halide DryView

Developer Fixer Wash Film Film

Product

Regulation

OSHA

DOT

Use Permits

Disposal *

Regulation

EPA

DOT

MSDS

Hazardous

Local

Hazardous

Hazardous

MSDS

Hazardous

Local

Hazardous

Hazardous

Not Required

No Limits

None