Eastman Kodak 81507E2537 User Guide

3

Troubleshooting

Correcting Errors

Occasionally errors (malfunctions), such as film jams, may occur in the

imager during print operations. You can easily correct minor problems. If

more serious malfunctions occur, you should contact a trained Authorized

Service Provider of Kodak products (see “Calling for Support” on

page 3-17).

Error and Alarm

Indications

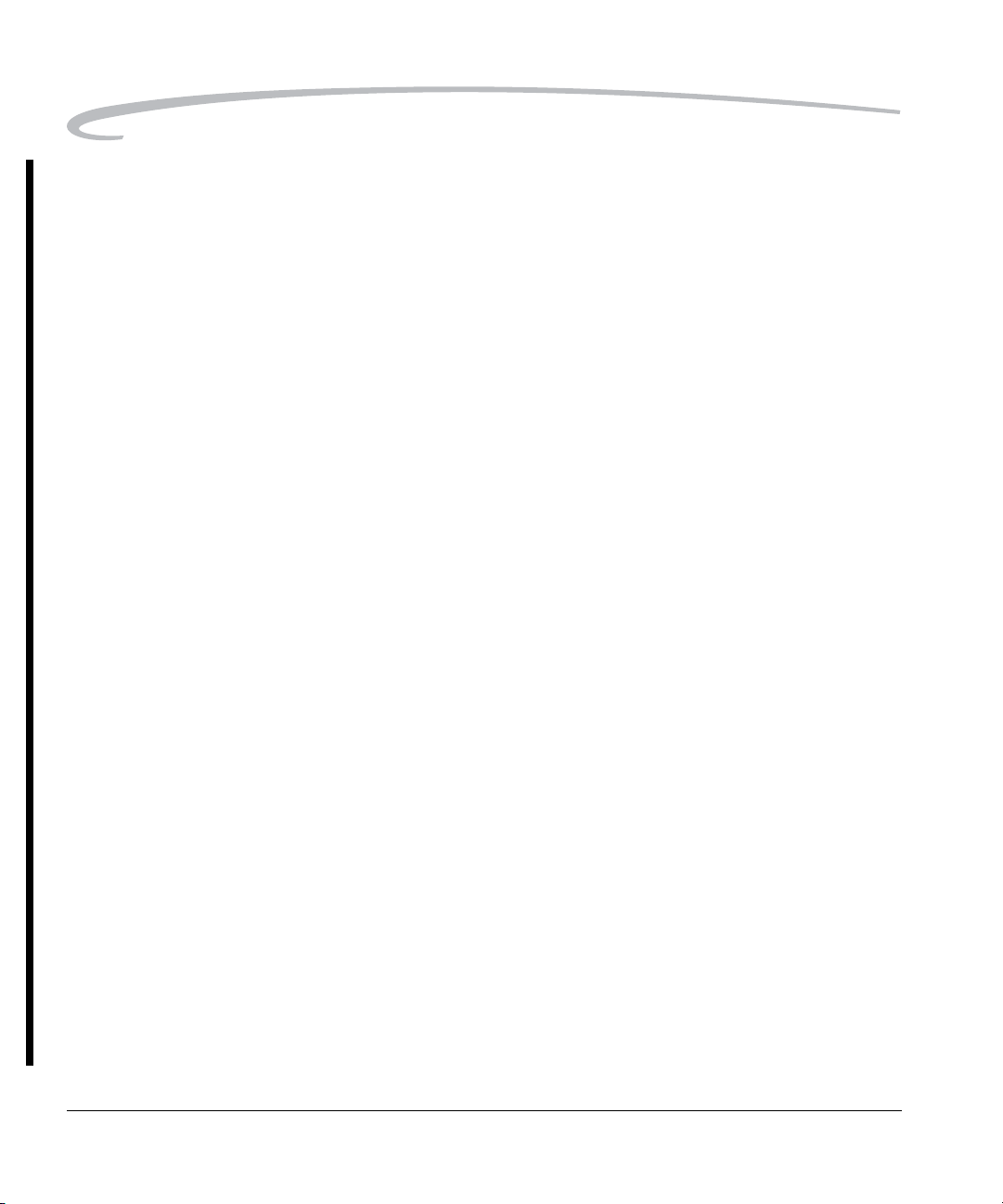

Home Screen Status

Messages

The Imager can detect malfunctions and other conditions that require

operator action. The Local Panel reports the presence of these errors or

abnormal conditions in several ways:

• Error Message screen

• Current Errors screen

• Current Errors notice on the Home screen

• Home screen status messages

For a description of the status information reported on the Home screen,

see “Home Screen Status Line” on page 2-14. Most of these status messages

do not report errors or abnormal conditions, but they do give information

about the current state of the Imager that may be useful for troubleshooting.

Status information about the film supply and film tray is displayed within the

Film Tray button on the Home screen. For a description, refer to “Film

Supply Button Status Information” on page 2-12.

September 30, 2004 7F3319 3-1

Troubleshooting

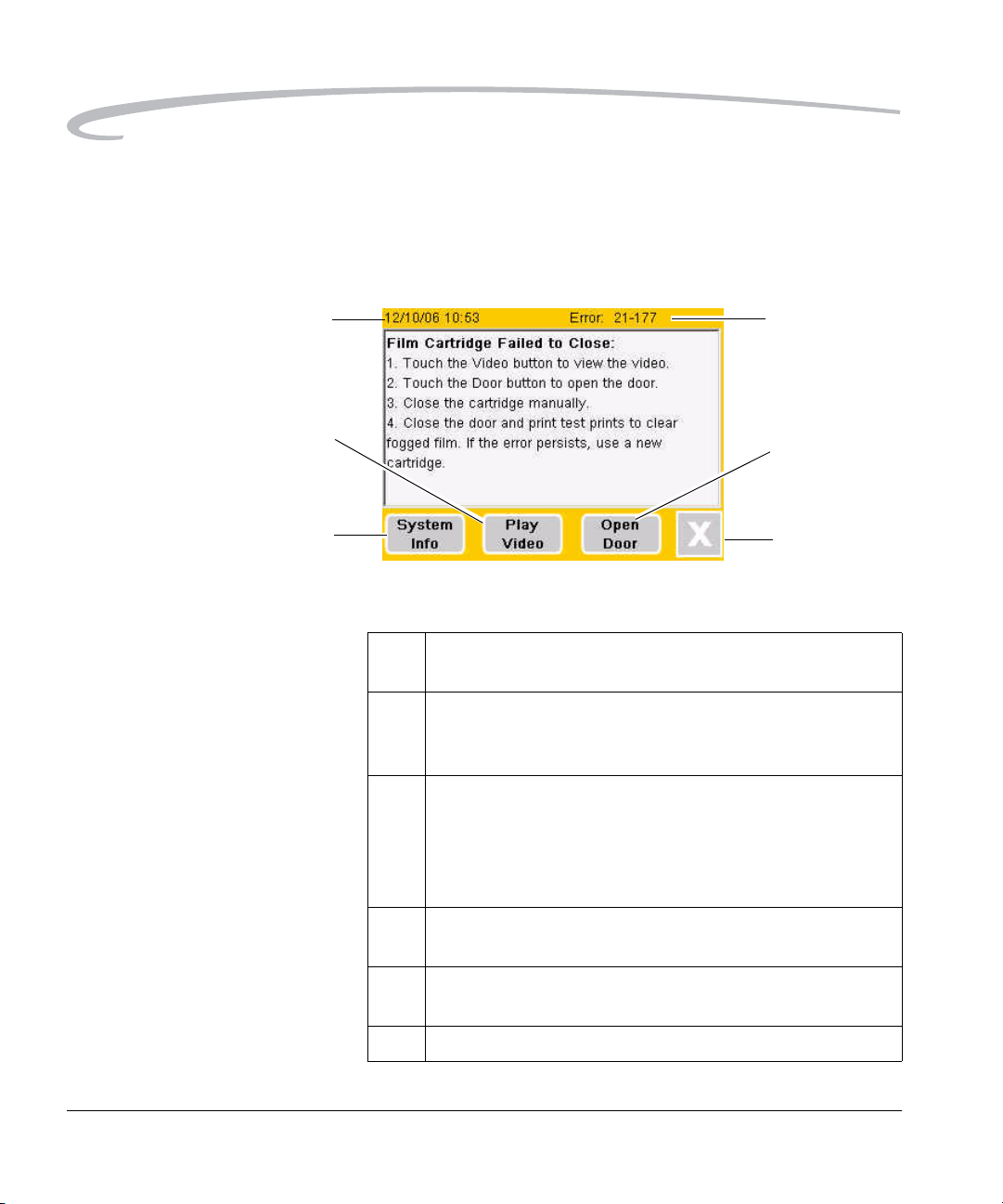

Error Message Screen The Error Message screen is the main error reporting mechanism for the

Imager. When the Imager detects an error, an alarm sounds and the Local

Panel displays an Error Message screen that describes the error and gives

a corrective action. Touch anywhere on the screen to silence the alarm.

6

5

4

Error Message Screen

Error Message Screen Details

1

2

1 Error Code. Identifies the type of error. Refer to this code when

calling for service.

2 Open Door button. Unlatches the front door. This button will

appear when the front door must be opened to correct the

reported error.

3X button. Closes the Error Message screen and moves to the

Current Errors screen, which lists any uncorrected errors in the

Imager. (See “Current Errors Screen” on page 3-4.) If you have

not corrected the error when you press

X, the error will be listed

on the Current Errors screen.

3

4 System Info button. Opens the System Information menu

screen. (See “System Information Menu” on page 2-26.)

5 Play Video button. Plays a short video that explains how to

correct the error. A video is not available for all errors.

6 Date and Time. When the error occurred.

3-2 7F3319 September 30, 2004

NOTE: If you close an Error Message screen without correcting the

current error, you can recall the Error Message from the

Current Errors screen. (See “Current Errors Screen” on

page 3-4.)

Operator Action When an error message is displayed:

1. Silence the alarm by touching anywhere on the Error Message

screen.

2. Perform the corrective action recommended on the screen. If this

does not clear the error, call for service. (See “Calling for Support” on

page 3-17.)

Note the error code and error message before you call for service.

The error message may direct you to perform one of the following actions:

• Restart the Imager.

1. Go to the Home screen.

2. Press the Power Off button.

3. Wait for the Local Panel to go blank.

4. Turn off the power switch on the back of the Imager and then turn it

back on.

• Open the front door manually. See “Opening the Front Door Manually”

on page 2-49.

• Close the film cartridge. See “Manually Closing the Film Cartridge” on

page 3-9.

Troubleshooting

September 30, 2004 7F3319 3-3

Troubleshooting

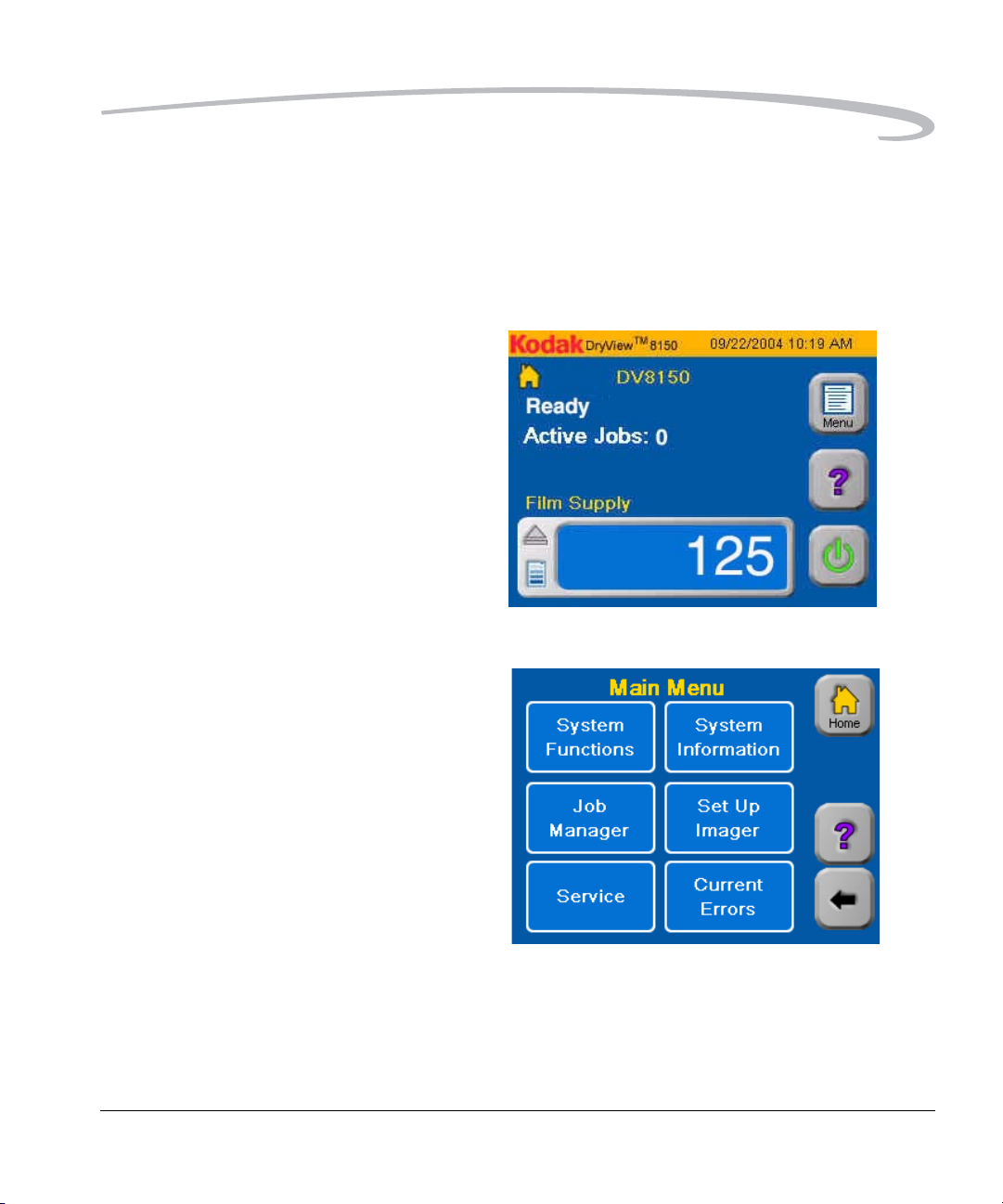

Current Errors Screen The Current Errors screen shows a list of uncorrected errors in the Imager.

To display this screen:

1. Press the Menu button.

2. On the Main Menu screen, press Current Errors.

The Current Errors screen appears:

List of Errors

Current Errors Screen

To see detailed information about any of the errors:

1. Highlight the error using the Up or Down arrow.

2. Touch Select.

The Error Message screen displays the error message for the error

you selected. (See “Error Message Screen” on page 3-2.)

3-4 7F3319 September 30, 2004

Troubleshooting

Current Errors Notice on the

Home Screen

Current Errors

Notice

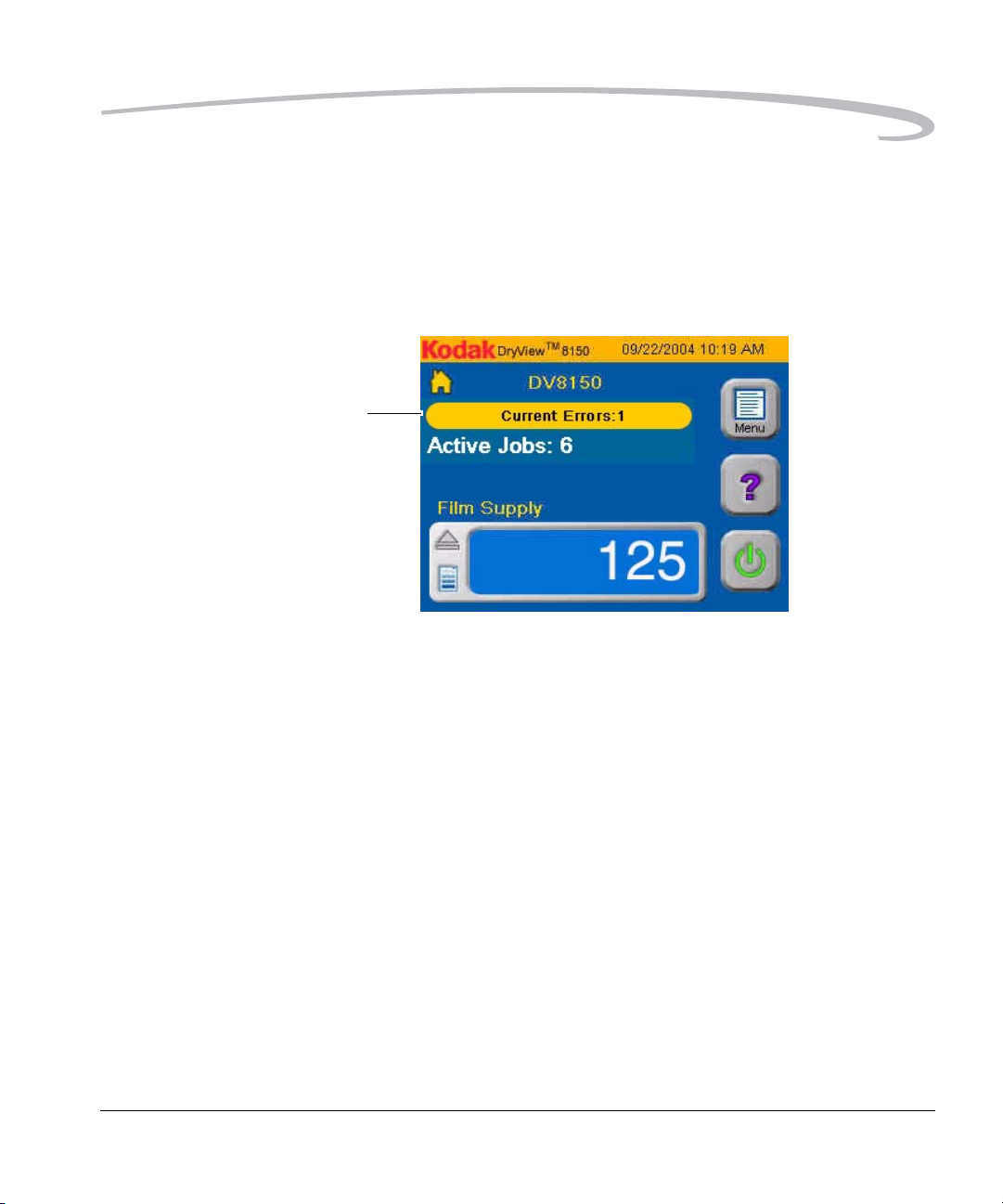

When there are one or more uncorrected errors in the Imager, the Home

screen displays a Current Errors notice that shows the number of

uncorrected errors in the Imager.

To see a list of the current errors, you can display the Current Errors

screen. (See “Current Errors Screen” on page 3-4.)

Home Screen

September 30, 2004 7F3319 3-5

Troubleshooting

Calibration Failure

Periodically the Imager must be calibrated to ensure that internal settings

match the characteristics of the film in the Imager. Calibration is performed

by running a calibration print. The Imager runs a calibration print when:

• A film cartridge containing film with new sensitometric characteristics

(speed, contrast) is loaded.

• The Imager has not printed film for 7 days.

• The Dpatch (density patch) printed on the film is out of range.

The operator can also request a calibration print from the Local Panel.

For more information on calibration, see “Running a Calibration Print” on

page 2-53.

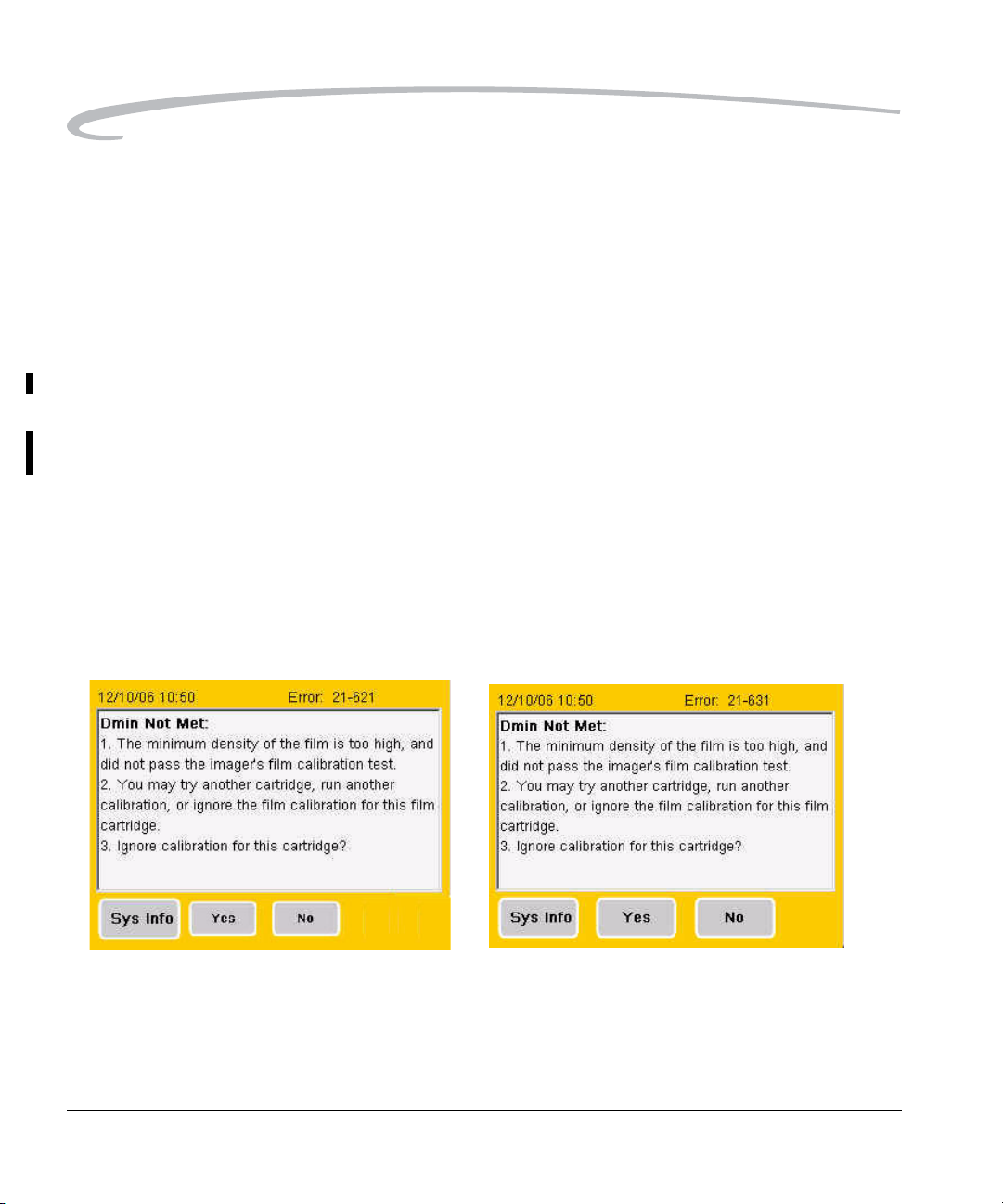

Occasionally, the Imager may fail calibration. When this occurs, the Local

Panel displays an error message screen. Depending on the cause of the

calibration failure, the Imager may or may not be able to continue

operating.

There are four conditions that cause calibration failure. The four error

message screens, below and on the next page, describe these error

conditions and show recommended operator actions.

These two errors indicate possible film aging. You can elect to continue

operation with the current film by touching Yes on the error screen.

3-6 7F3319 September 30, 2004

Troubleshooting

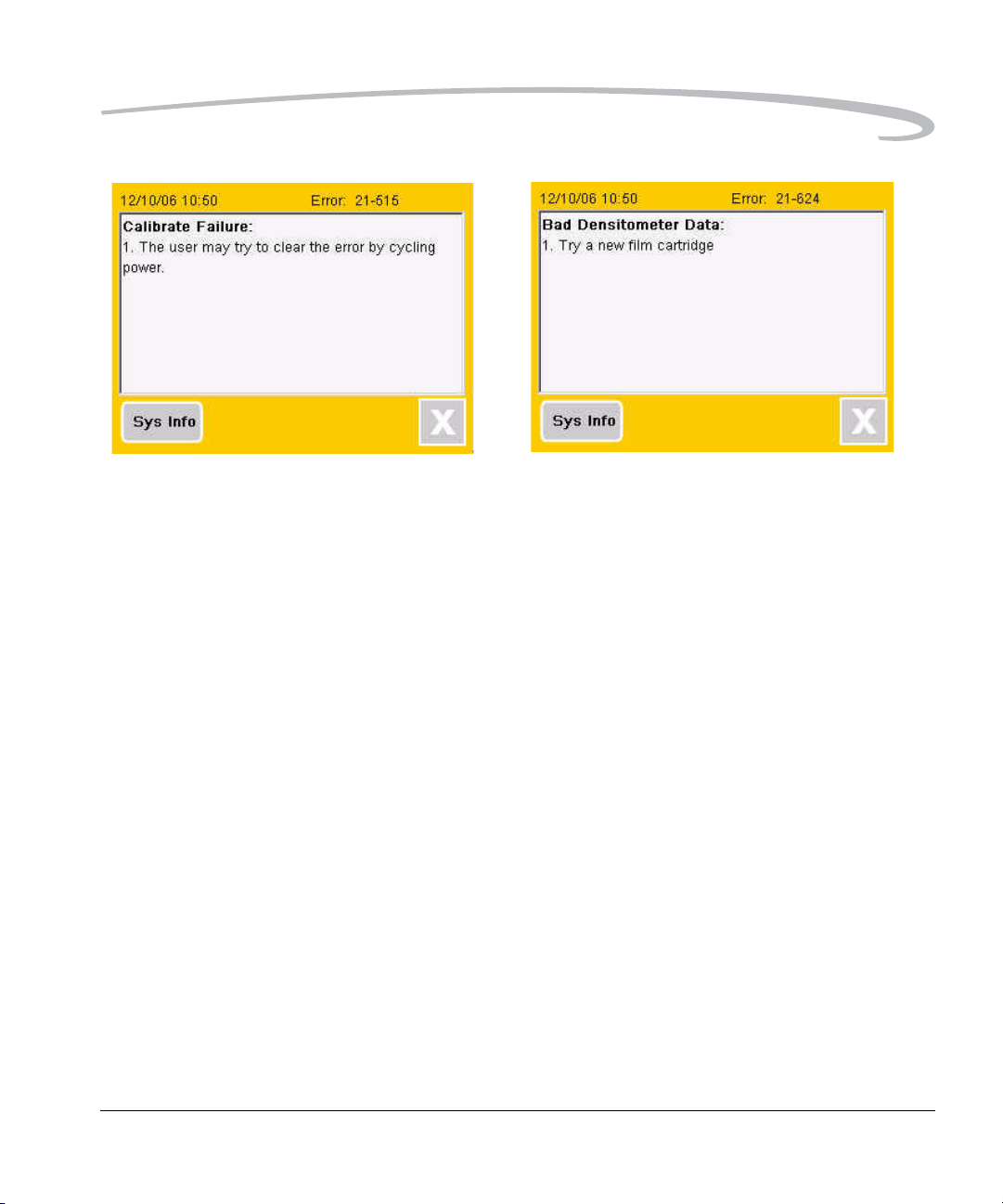

These two calibration errors indicate a major machine or film fault. The

Imager cannot continue to operate with the current film.

If you cannot restore normal operation by following the recommended

action on the error message screen, call for service. (See “Calling for

Support” on page 3-17.)

September 30, 2004 7F3319 3-7

Troubleshooting

Film Transport Problems

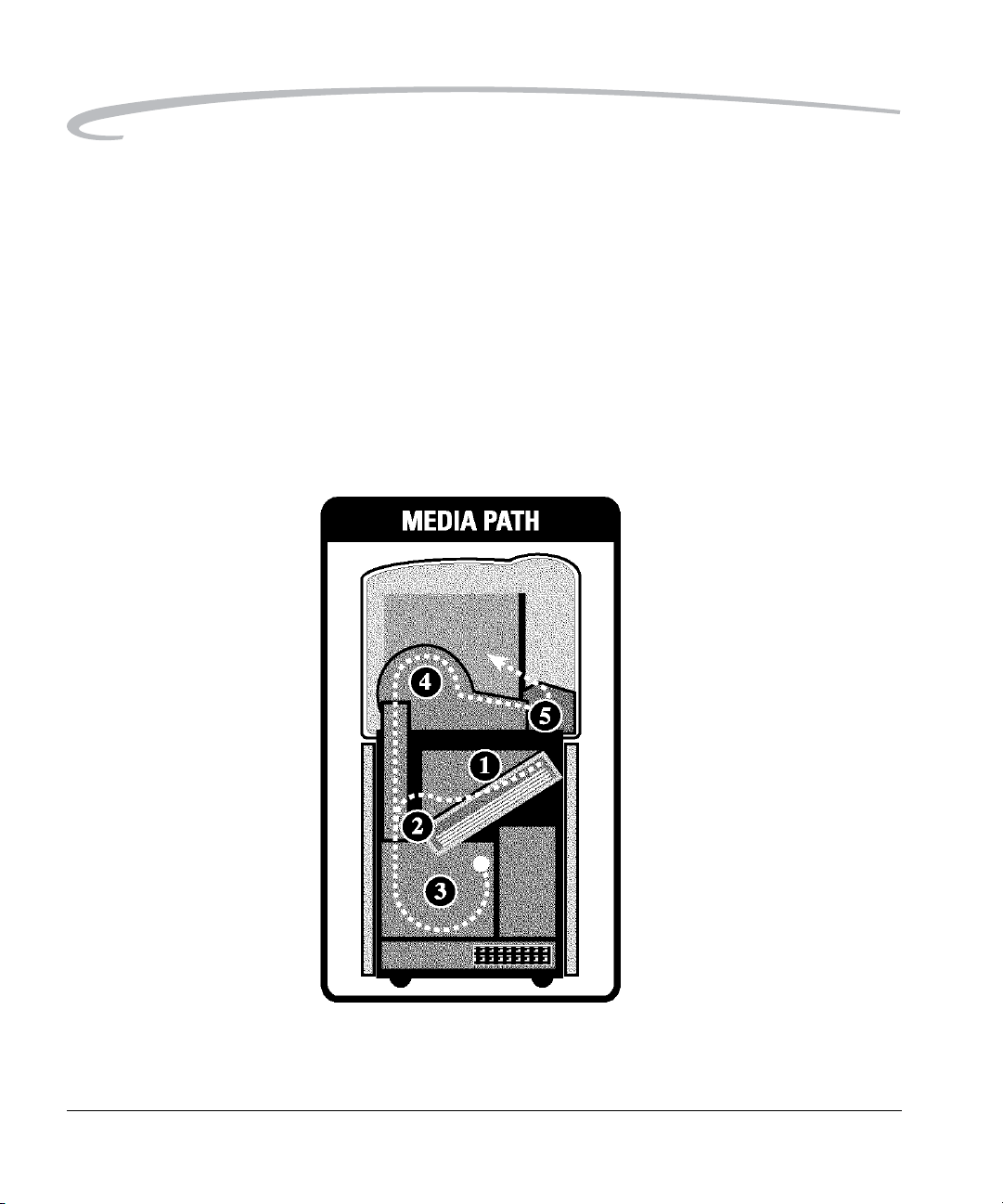

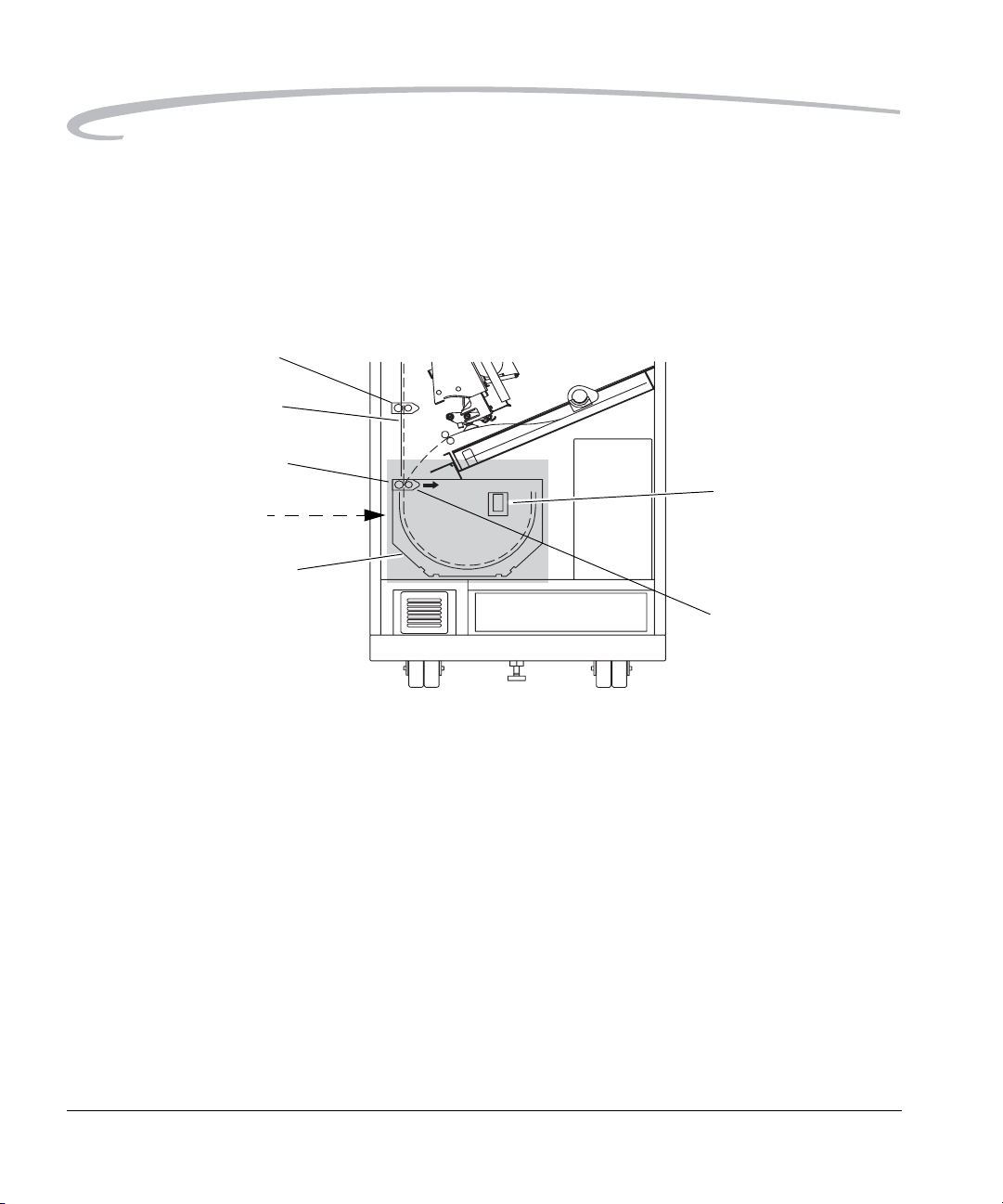

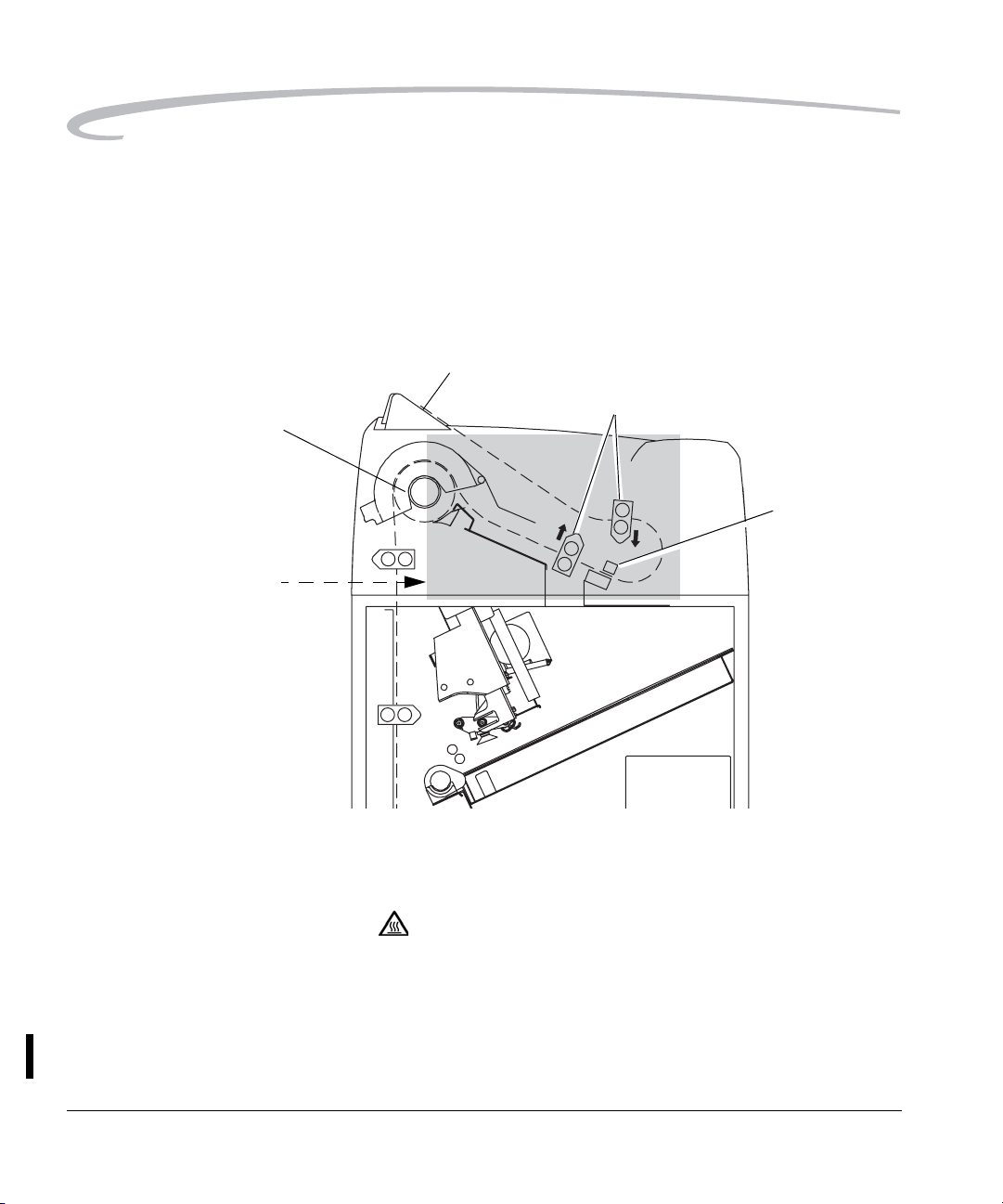

The illustration below shows the path that film travels through the Imager

after the operator requests a print. The numbers in the illustration identify

key areas on the path through the five major areas in the Imager:

Area 1 – Film pickup from the cartridge

Area 2 – Film feed into the exposure area

Area 3 – Film feed out of the exposure area

Area 4 – Film feed into the processor

Area 5 – Film feed out of the processor and into the film tray

H188_1063GC

Film Drive Path

3-8 7F3319 September 30, 2004

Films may occasionally jam at various points along the film path. When a

film jam or film feed error occurs, an error message appears. The error

message identifies the area where a jam has occurred and recommends a

corrective action. The following information supplements the advice given

in the error messages for film feed problems.

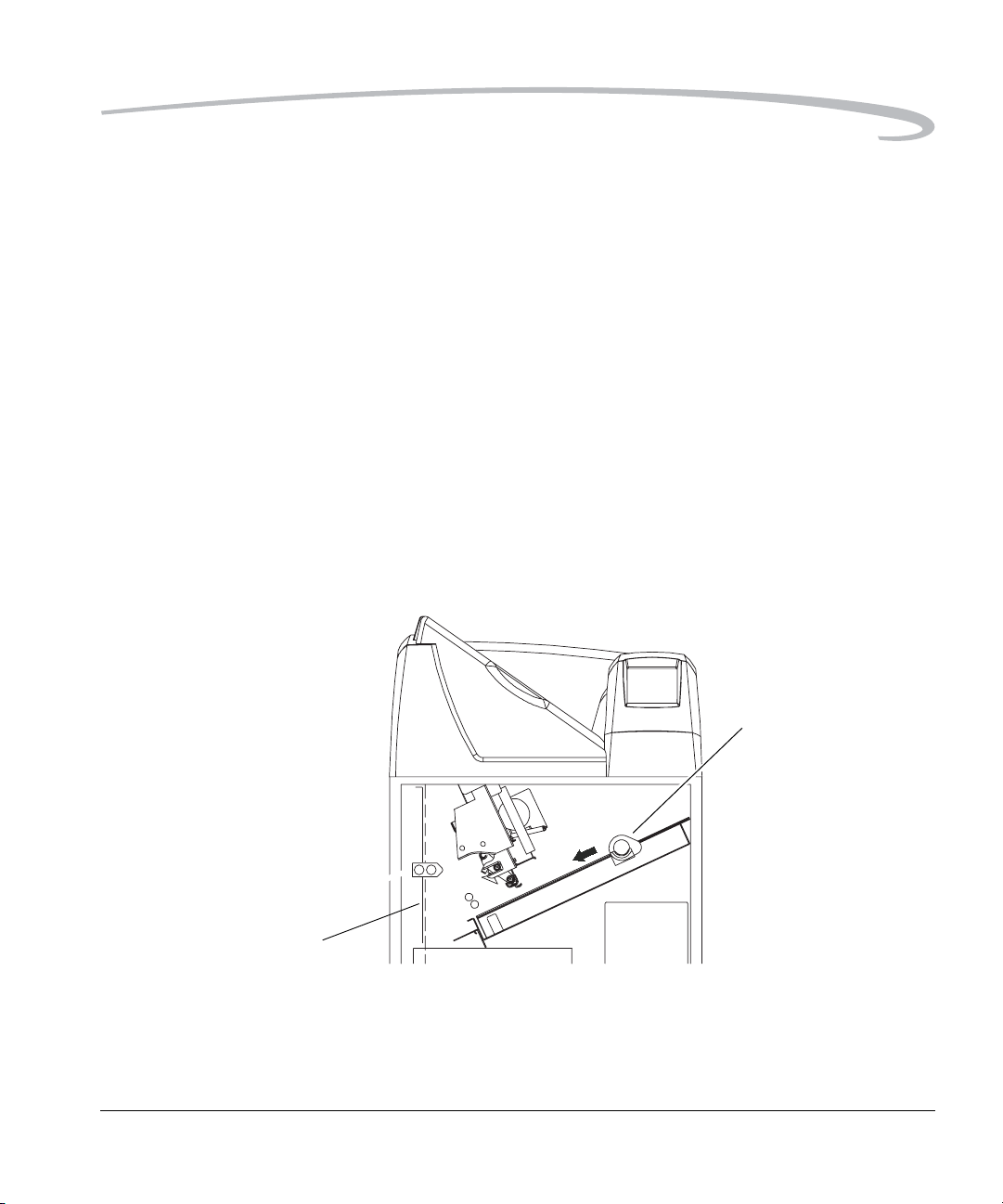

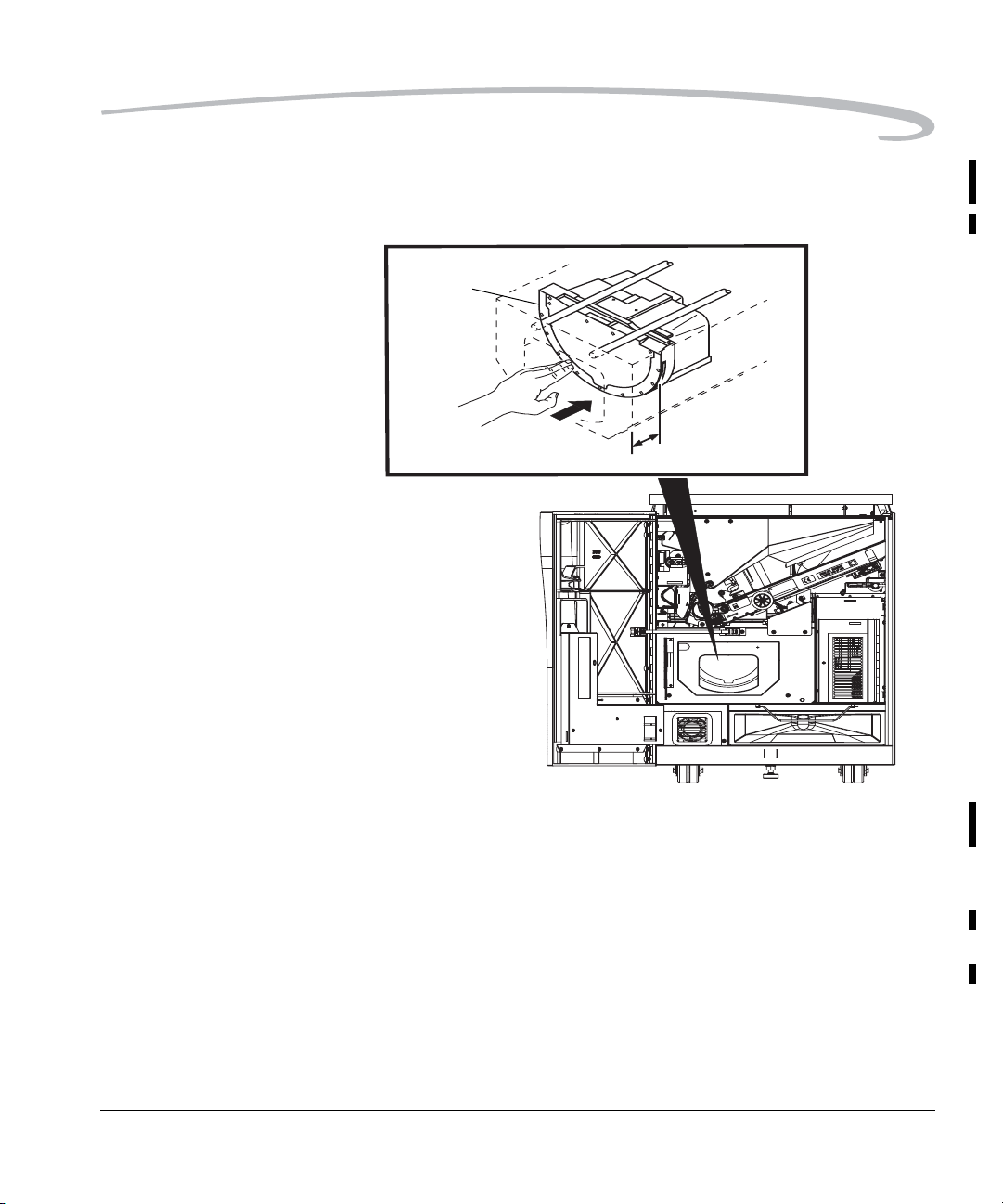

Manually Closing the Film Cartridge

When clearing film jams you may have to close the film cartridge manually.

Normally the Imager automatically closes the film cartridge when you press

the Open Front Door button. When a film jam occurs, the Imager may be

unable to close the cartridge. The front door then will not open.

When the film cartridge fails to close, an error message appears. Press the

Door Open button on the Error Message screen to unlock the front

door.

NOTE: If you open the front door when the film cartridge is open, the top

sheets of film in the cartridge are exposed. Before opening the

door, make the room as dark as possible to minimize exposure.

Troubleshooting

Rollback

Knob

Film Path

(dashed line)

Manually Closing the Film Cartridge

H200_0004da

1. Darken the room.

2. Open the front door.

September 30, 2004 7F3319 3-9

Troubleshooting

3. Clear any films that may be jammed in the film cartridge area.

4. Turn the rollback knob counterclockwise to close the cartridge.

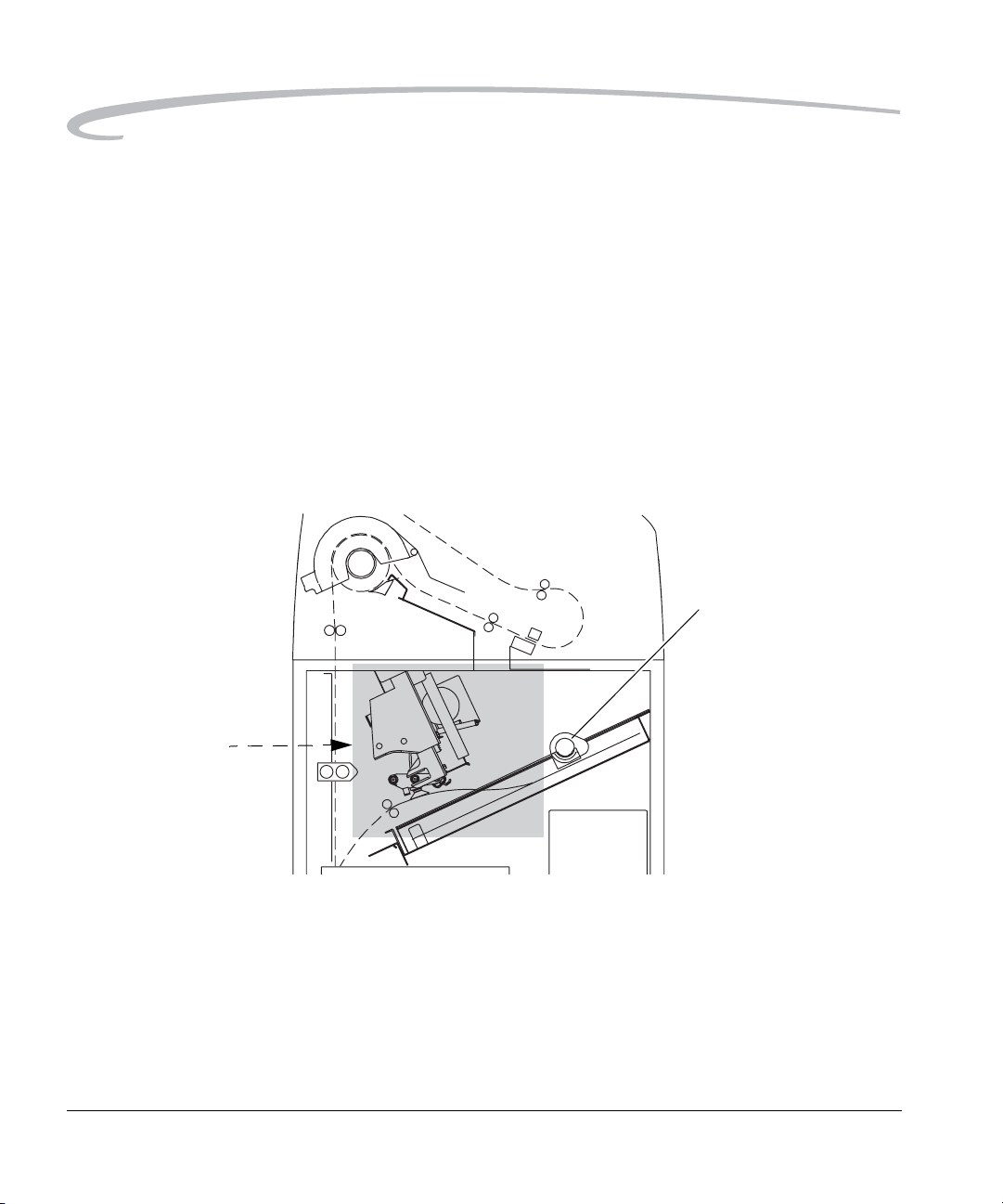

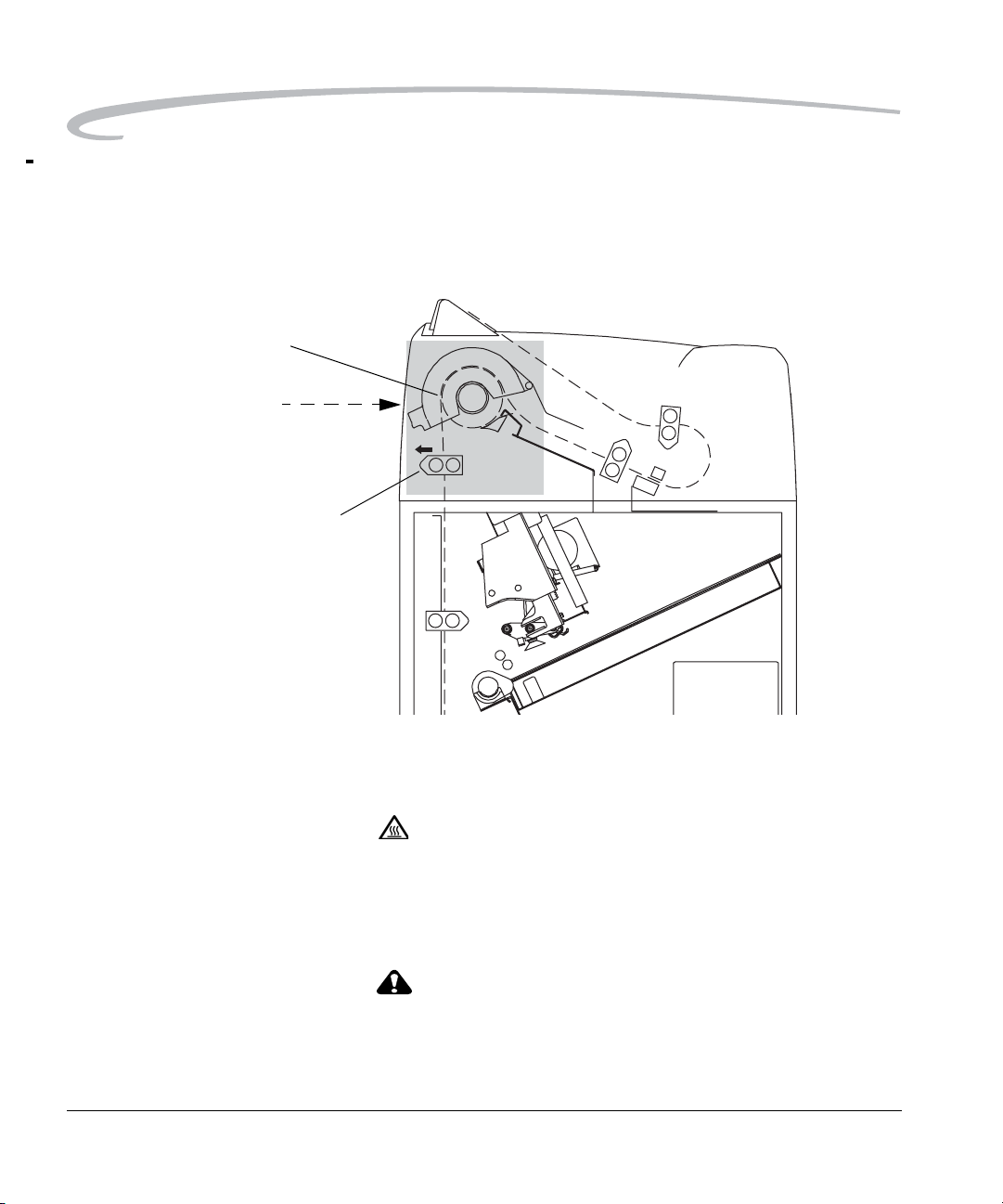

Film Pickup Problems in Area 1

Area 1 is the location where film is removed from the film cartridge and

positioned to be sent by drive rollers toward the exposure area. If the

Imager cannot properly pick up a sheet of film and position it for drive,

error 21-116 (Pickup Fail) is declared. Error 21-177 (Cartridge Failed to

Close) also relates to Area 1.

NOTE: When problems occur in Area 1, the film cartridge is left open.

When you open the front door, the top sheets of film in the

cartridge will be exposed. Before opening the door, make the

room as dark as possible to minimize exposure.

Rollback

Knob

Area 1

Film Area 1

1. Press Door Open on the Error Message screen.

2. Remove any film outside the cartridge.

3. Turn the rollback knob counterclockwise to manually close the

cartridge lid.

4. Close the front door.

5. If you cannot resolve the problem, call for service. (See page 3-17.)

3-10 7F3319 September 30, 2004

Removing Film Jams from Area 2

Area 2 in the Imager includes the path between the film pickup assembly

and the exposure platen.

NOTE: When jams occur in Area 2, the film cartridge is left open. When

you open the front door, the top sheets of film in the cartridge will

be exposed. Before opening the door, make the room as dark as

possible to minimize exposure.

Film Pickup

Assembly

Area 2

Exposure

Platen

Troubleshooting

Rollback Knob

H200_0006da

Jam Area 2

1. Press Door Open on the Error Message screen.

2. Remove the jammed film.

3. Turn the rollback knob counterclockwise to manually close the

cartridge lid.

4. Close the front door.

September 30, 2004 7F3319 3-11

Troubleshooting

Removing Film Jams from Area 3

Area 3 includes the exposure platen. Jams in this area occur as film is

entering the platen before exposure, or as film is leaving the platen after

exposure. In rare cases, film may stall in the transport area above the

platen.

Plastic Thumb

Tab 2

Vertical

Transport

Platen Feed

Rollers

Area 3

Exposure

Platen

Platen Door

Latch

Plastic Thumb

Tab 1

H200_0007da

Jam Area 3

1. Open the front door.

NOTE: When film jams in this area, the cartridge may not close. If it does

not close, the front door will not unlock normally. You may have to

open the door manually (see “Opening the Front Door Manually”

on page 2-49). When the front door opens, the top sheets of film

in the cartridge will be exposed. Before opening the door, make

the room as dark as possible to minimize exposure.

2. If the film cartridge is open, turn the rollback knob counterclockwise

to manually close the cartridge lid.

3. Clear the jammed film, if it is accessible.

4. If the film is not accessible:

a. Open the platen door by sliding the door latch to the left and pulling

out the platen door.

3-12 7F3319 September 30, 2004

Troubleshooting

b. Push the optics module toward the rear of the imager slowly and

smoothly.

Optics

Module

10 cm (4 in.)

c.Clear the film from inside the platen. If film is caught in the platen

feed rollers, pull Plastic Thumb Tab 1 (inside the platen door) to the

right. This opens the rollers and frees the film.

d. After clearing the jam, close the platen door.

5. If film is stalled in the vertical transport area, pull Plastic Thumb Tab 2

in this area to the right to open the rollers and free the film.

6. Close the front door.

September 30, 2004 7F3319 3-13

Troubleshooting

Removing Film Jams from Area 4

Area 4 includes the film processor.

When a jam occurs in this area all films in the Imager must be removed.

Processor

Drum

Area 4

Plastic Thumb

Tab

H200_0008da

Jam Area 4

1. Open the hood.

CAUTION

:

Drum and rollers inside the processor are hot. Exercise

caution when removing jammed film from the processor.

2. Release the two clamps at the left of the processor and open the drum

cover. (See the following figure).

CAUTION

:

To prevent damage to the surface of the processor drum, do

not use any type of tool to remove jammed film.

3-14 7F3319 September 30, 2004

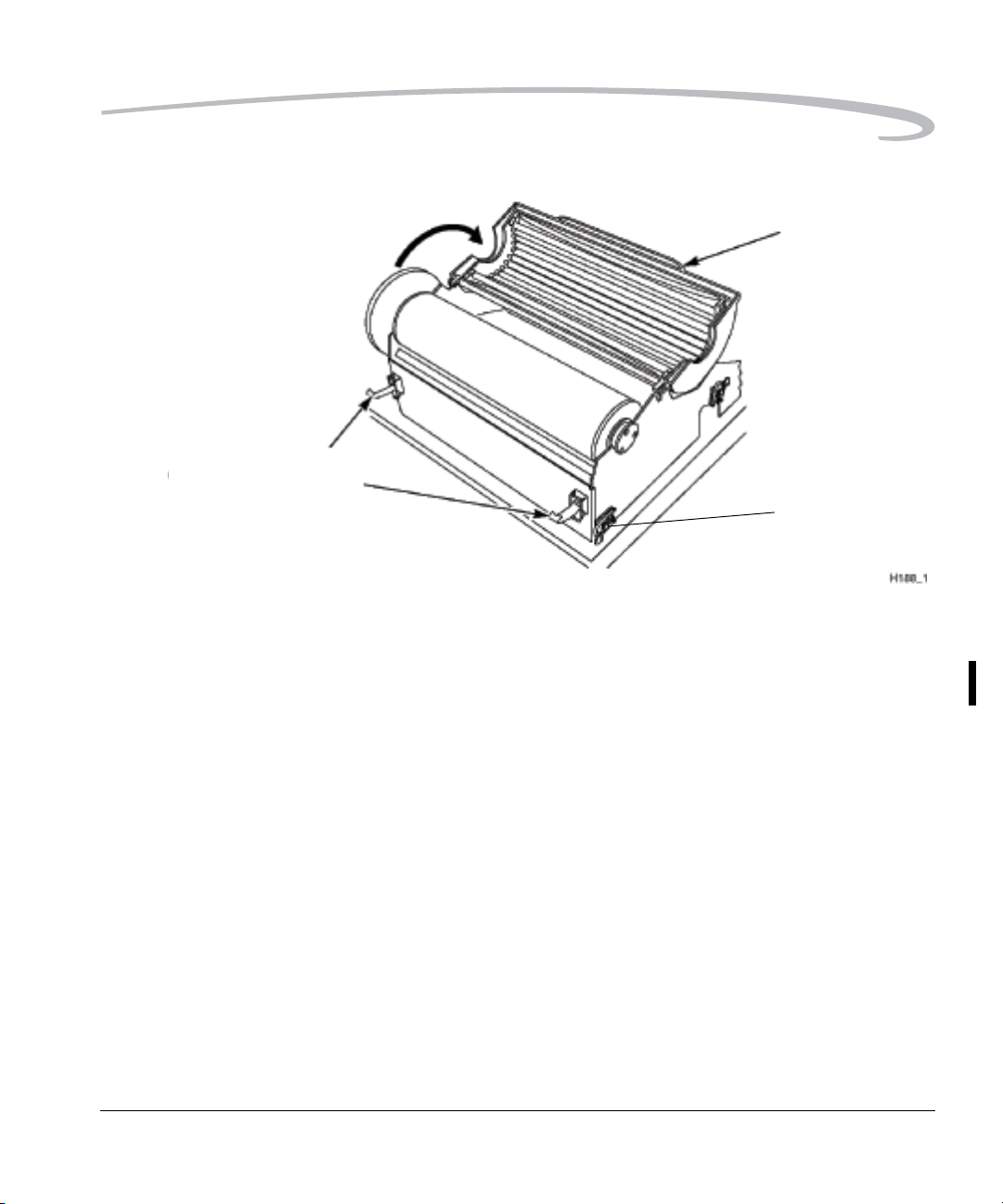

Open

Clamps

Troubleshooting

Open Drum

Cover

Plastic Thumb

Tab

Opening the Drum Cover

3. Clear the jammed film from the processor area (there may be more

than one sheet). If film is jammed in the drive rollers, pull the Plastic

Thumb Tab to the left to open the rollers and free the film.

4. Close the drum cover and secure it with the two clamps.

5. Remove any films in Area 5. (See page 3-16.)

6. Open the front door.

7. Remove all films in the lower part of the Imager.

8. Close the front door.

9. Close the hood.

The processor will have to warm to operating temperature before the

imager can resume printing.

September 30, 2004 7F3319 3-15

Troubleshooting

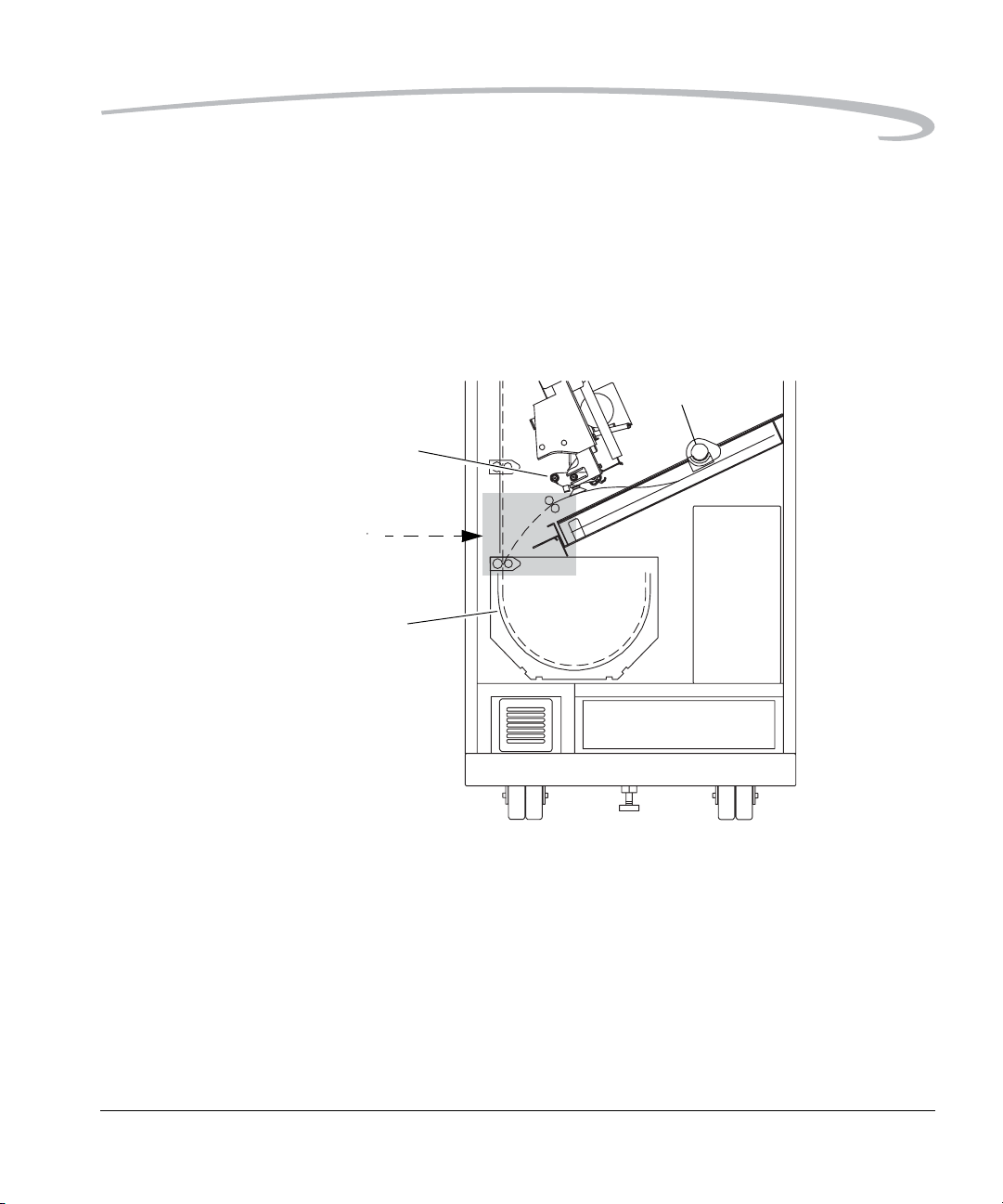

Removing Film jams from Area 5

Area 5 consists of the components between the processor drum and the film

exit tray. Jams can occur in this area between the drum and the

densitometer, or in the densitometer. See the figure below.

When a jam occurs in this area all films in the imager must be removed.

Exit Tray

Processor

Drum

Area 5

Plastic Thumb Tabs

H200_0009da

Jam Area 5

1. Open the hood.

CAUTION

:

Drum and rollers inside the processor are hot. Exercise

caution when working in the drum area.

Densitometer

2. Clear the jammed film from the processor area (there may be more

than one sheet). If film is jammed in the drive rollers, pull the Plastic

Thumb Tab to open the rollers and free the film.

3-16 7F3319 September 30, 2004

Calling for Support

Troubleshooting

3. Remove any films in the processor. (See page 3-14.)

4. Close the hood.

5. Open the front door.

6. Remove all films in the lower part of the Imager.

7. Close the front door.

The processor will have to warm to operating temperature before the

imager can resume printing.

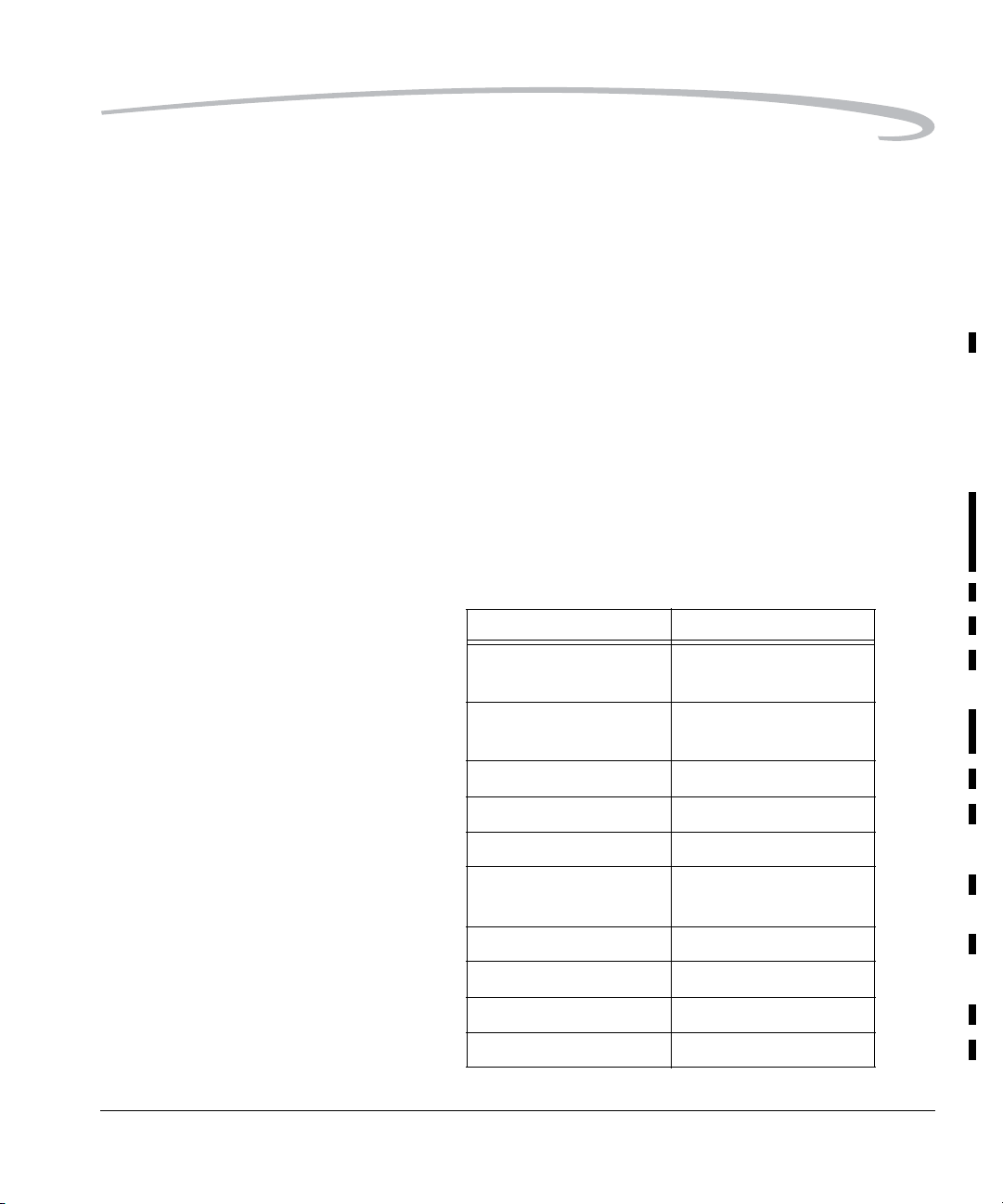

If you cannot correct a malfunction and need help, call for support (see the

following table). Before you call, have the following information ready:

• Model number: 8150

• K-number: Displayed on the Local Panel System Information Screen

• Error code and error message if they are displayed on the Local Panel

Service Phone Numbers

Country Phone Number

Argentina 54-3327-458-195

54-3327-458-163

Austrailia 1 800 034 487

1 800 805 290

Austria 43.800291332

Azerbaijan 00 99412 410856

Belgium 32.27194116

Bolivia 54-3327-458-195

54-3327-458-163

Brazil 0800 15003

Canada 1-800-268-1567

Peoples Republic of China 800 820 5800

Cyprus 00 352 497777

September 30, 2004 7F3319 3-17

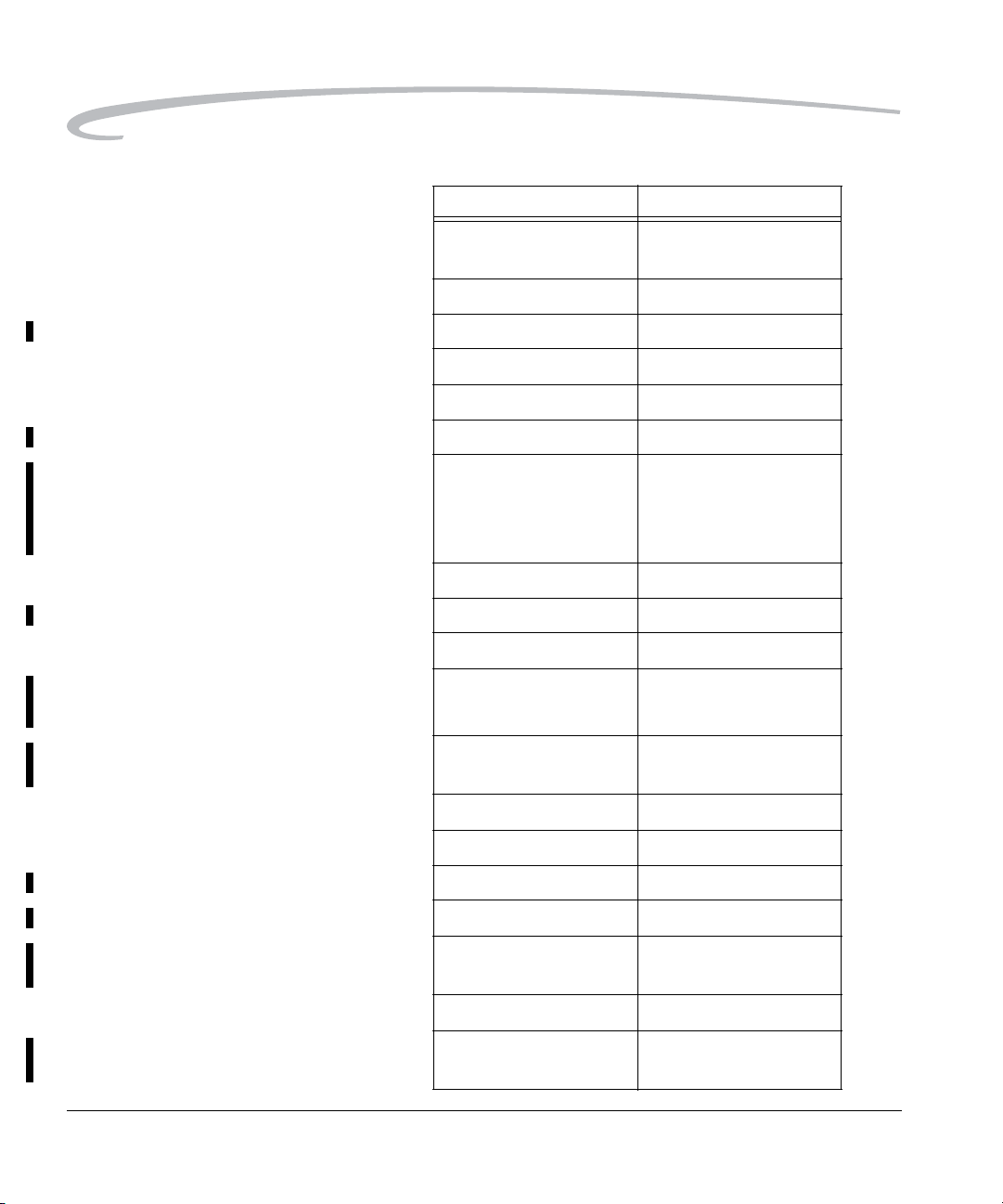

Troubleshooting

Service Phone Numbers

Country Phone Number

Czech Republic 420 236 100 307

420 62 335 426

Denmark 45 70206129

Finland 35.88001214

France 01 4001 4705

Germany 49.0180.3000.307

India 1600 118989

Iran 00 98 216 950821

00 98 216 402105

00 98 21 256 9741

00 98 21 256 9097

Ireland 44.01442 845775

Israel 00 972 3 9254040

Italy 39.02.66028000

Japan

0120-45-1881

Jordan 00 962 6 4545845

00 962 6 4543354

Netherlands 31.347.363900

Norway 47.66 81 80 80

Pakistan 00 92 21 2638881

Palistinian Territory 00 970 92387421

Paraguay 54-3327-458-195

54-3327-458-163

Portugal 351 21 414 7642

Qatar 00 974 4469 830

00 974 4360 820

3-18 7F3319 September 30, 2004

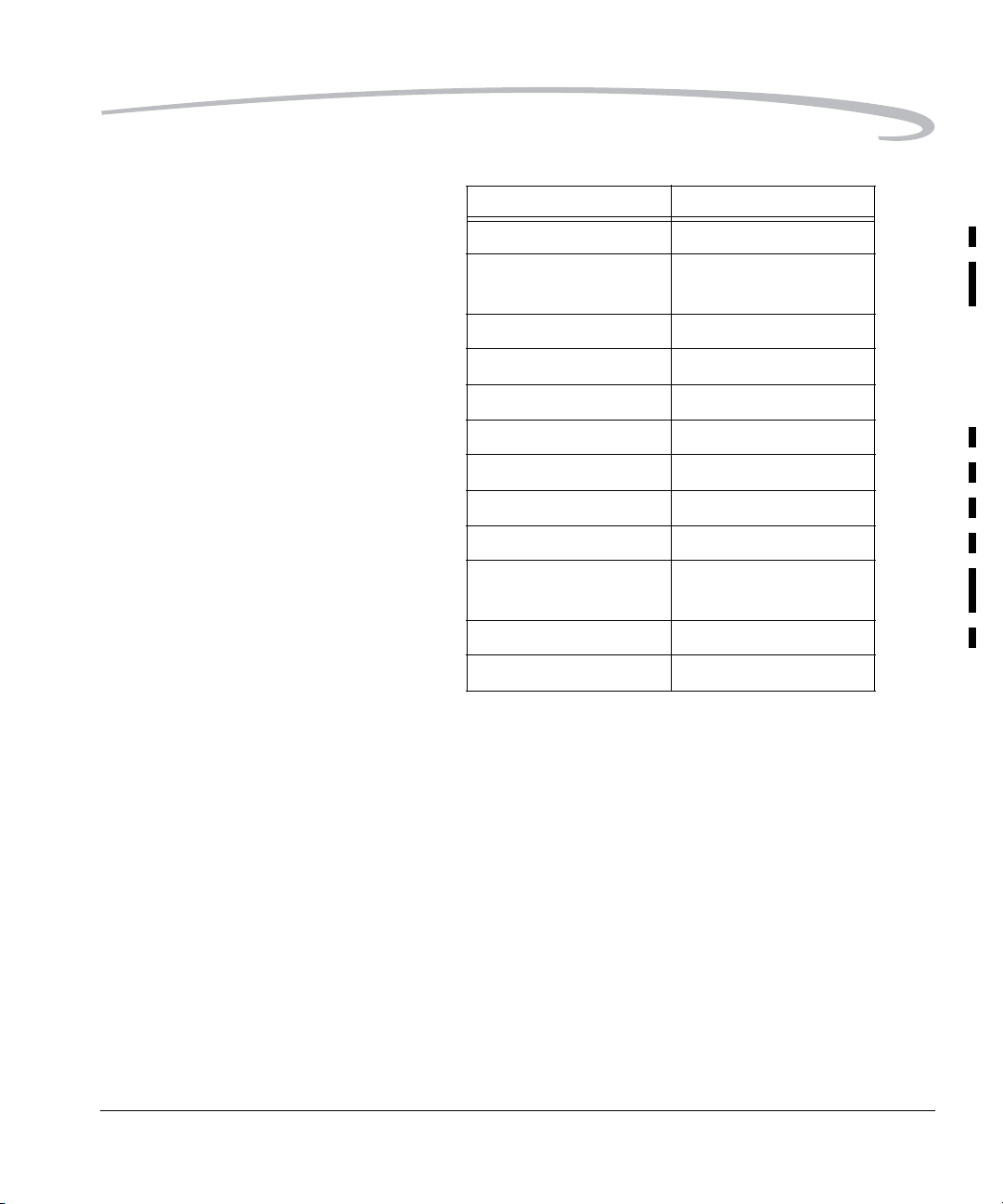

Troubleshooting

Service Phone Numbers

Country Phone Number

Romania 00 40 1210 3854

Saudi Arabia 00 966 2 682 8219

00 966 1 464 5064

Spain 902 19 03 99

Sweden 46.200.119.494

Switzerland 41.0800.804807

Syria 00 963 112128600

Tajikistan 00 90 216 578 2600

Turkey 90 216 572 54 33

Turkmenistan 00 90 216 578 2600

United Arab Emirates 00 971 6 746 6751

00 971 6 746 6285

United Kingdom 44 0442 84 6855

United States 800-328-2910

September 30, 2004 7F3319 3-19

Blank Page

4

Adding a Modality

After the Imager has been placed into service, you can later configure the

Imager to print images from additional modalities. The Imager is capable of

receiving images from twelve DICOM-compatible modalities concurrently.

Adding a modality involves adjusting some of the image quality settings in

the Imager to match the new modality. The following procedure explains

how to add one new modality.

NOTE: You must have the Service Passcode to perform this

Preparing to Add a Modality

• Before you begin, make sure that the new modality has been set up to

print to the Imager. The Imager must be available as a print destination

in the modality print command.

• You will need the following information about the modality:

– The modality manufacturer

– The modality type (CT, MR, etc.)

– The modality model designation

– The type and size of film to be used

– Is the modality GSDF-compliant?

– If GSDF-compliant, does the modality use PLUTs for all images it

sends or only for some images?

• You should also decide on a screen name for the modality. This name

will be used only on the Imager Local Panel to identify the modality

procedure.

September 30, 2004 7F3319 4-1

Adding a Modality

Modality-Related Parameters

The Imager must be configured to print from each connected modality. In

the Imager a set of modality-specific parameters must be created for each

modality that will print to the Imager.

For many modalities, the required parameters can be taken from the

"Modality Preferences Database" (MPDB). This internal database, within

the Imager, contains tested parameter sets for many commonly used

modalities.

Modality configuration is accomplished in three ways:

• First Print - When a modality prints to the Imager for the first time, the

Imager automatically attempts to identify the type of modality from

information included in the print job. If the Imager identifies the

modality, it searches for a parameter set in the MPDB. If an appropriate

parameter set is not found, the Imager assigns a universal set of

parameters to the modality. If the parameter set does not produce

acceptable prints, the installer can go on to the

"Manufacturer/Model/Type" procedure.

• Manufacturer/Model/Type - If the automatic search in the MPDB is

not successful, the installer can enter the Manufacturer, Model and Type

of the modality on the Local Panel. The Imager uses this information to

search the MPDB again for a set of parameters. A universal parameter

set is applied if an approprialte parameter set is not found. If the

parameter set is not acceptable, the Installer must use the Manual Entry

method.

• Manual Entry - The installer can enter or adjust individual modality

parameter values on several modality configuration screens.

For each of the above methods, the user must print a clinical image and

check image quality to determine if the parameter set is acceptable.

The user can use a combination of manual entry and one of the other two

methods. For example, the user may accept the "First Print" parameter set

but adjust one or two of the parameters manually to suit local preferences.

The parameter set selected using the above methods is placed in a

"Connection Database" in the Imager and used to print all images from the

modality. The Connection Database contains a separate parameter set for

each modality associated with the Imager.

4-2 7F3319 September 30, 2004

Configuration Procedure

The modality setup procedure is performed on the Imager Local Panel.

Adding a Modality

1. Be sure that the proper film size and type required for the modality is

loaded in the Imager.

2. Start from the Home screen.

3. Press Menu.

4. Touch Setup Imager.

September 30, 2004 7F3319 4-3

Loading...

Loading...