Page 1

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

Owner’s Manual Model TG32P12

0

Page 2

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

PREFACE

Thank you for purchasing products from EASTERNTOOLS & EQUIPMENT, INC. We

appreciate your business. The following manual is only a guide to assist you and is not a

complete or comprehensive manual of all aspects of maintaining and repairing your

generator. The equipment you have purchased is a complex piece of machinery. We

recommend that that you consult with a dealer if you have doubts or concerns as to your

experience or ability to properly maintain or repair your equipment. You will save time and

the inconvenience of having to go back to the store if you choose to write or call us

concerning missing parts, service questions, operating advice, and/or assembly questions.

Our gasoline generators have some of the following features:

.Lightweight construction

.Air cooled

.Four-stroke gasoline internal combustion engine

.Recoil starter

.Large fuel tank

.Automatic voltage stabilizer

.NFB circuit protector

.AC outputs

.Low oil level sensor

The ETQ air-cooled gasoline generators are widely used when electrical power is scarce.

Our generators provide a portable mobile solution in supplying power for field operations

during project construction.

This manual will explain how to operate and service your generator set.

If you have any questions or suggestions about this manual, please contact your local

dealer or us directly. Consumers should notice that this manual might differ slightly

from the actual product as more improvements are made to our products. Some of

the pictures in this manual may differ slightly from the actual product as well.

Eastern Tools and Equipment, Inc. reserves the right to make changes at any time

without notice and without incurring any obligation.

1

Page 3

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

TABLE OF CONTENTS

Page

TECHNICAL SPECIFICATIONS AND DATA 3

EQUIPMENT DESCRIPTION & KNOWING YOUR GENERATOR 4

PACKAGE CONTENTS 5

ASSEMBLY 6

SAFETY PRECAUTIONS 9

Danger 9

Electric shock and short circuit 9

Prevention from accidental burns 9

Refueling precautions 9

Engine safety precautions 10

Generator safety 10

PREPARATION BEFORE OPERATION 10

Engine oil 10

Gasoline 11

Air cleaner 11

GROUNDING THE GENERATOR 12

OPERATING THE GENERATOR 12

Starting the engine 12

Connecting electrical loads and electrical capacity 13

Stopping the engine 14

RECEPTACLES 15

MAINTENANCE 16

Cleaning the generator 17

Spark Plug 17

Storage 18

TROUBLESHOOTING 19

Wiring Diagram 20

PARTS LISTING 21

EXPLODED GENERATOR VIEW 21

CRANKCASE 24

PUSH ROD & VALVE ROCKER 25

CYLINDER HEAD & CYLINDER HEAD COVER ASSEMBLY 26

CRANKCASE COVER ASSEMBLY 27

CRANKSHAFT, PISTON & TIE-ROD 28

CARBURETOR ASSEMBLY & AIR CLEANER ASSEMBLY 29

FLYWHEEL & RECOIL STARTER 30

IGNITION COIL 31

REGULATING CONTROL SYSTEM 31

LIMITED WARRANTY 32

PRODUCT REGISTRATION 35

2

Page 4

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

TECHNICAL SPECIFICATIONS AND DATA

TG32P12

Engine Type 4-stroke, Air-cooled, OHV

Displacement

Bore × Stroke

Engine Rated Power

5.15 KVA @ 3600 r/min

207 cc

12.63 cu in

70×54 mm

2.76×2.13 in

7 Hp @ 3600 r/min

Fuel Unleaded

Fuel Tank Capacity

15.14 L

4 Gal

Operation Hours 13Hrs @ 50% load

Engine Oil SAE 10W-30 or equivalent motor oil

0.6L (20.3 Ounces)

Engine Oil Capacity

1.Need to add oil to engine when “oil warning light “ is on.

2.Engine may stop and will damage if the oil is too low.

Engine Start Pattern Manual start

Generator Type Synchronous generator

Phase Single

Power Factor Cos θ = 1.0

AC Output Voltage 120V

AC Output Frequency 60Hz

AC Output Max Power 4000 ± 10% Watts

AC Output Rated Power 3250 ± 3% Watts

Noise Level 65 dB @ 7m

Product Weight

Product Dimensions

25.0 x 21.3 x 19.5 in

46.3 kg

102 lbs

63.5×54.0×49.5 cm

3

Page 5

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

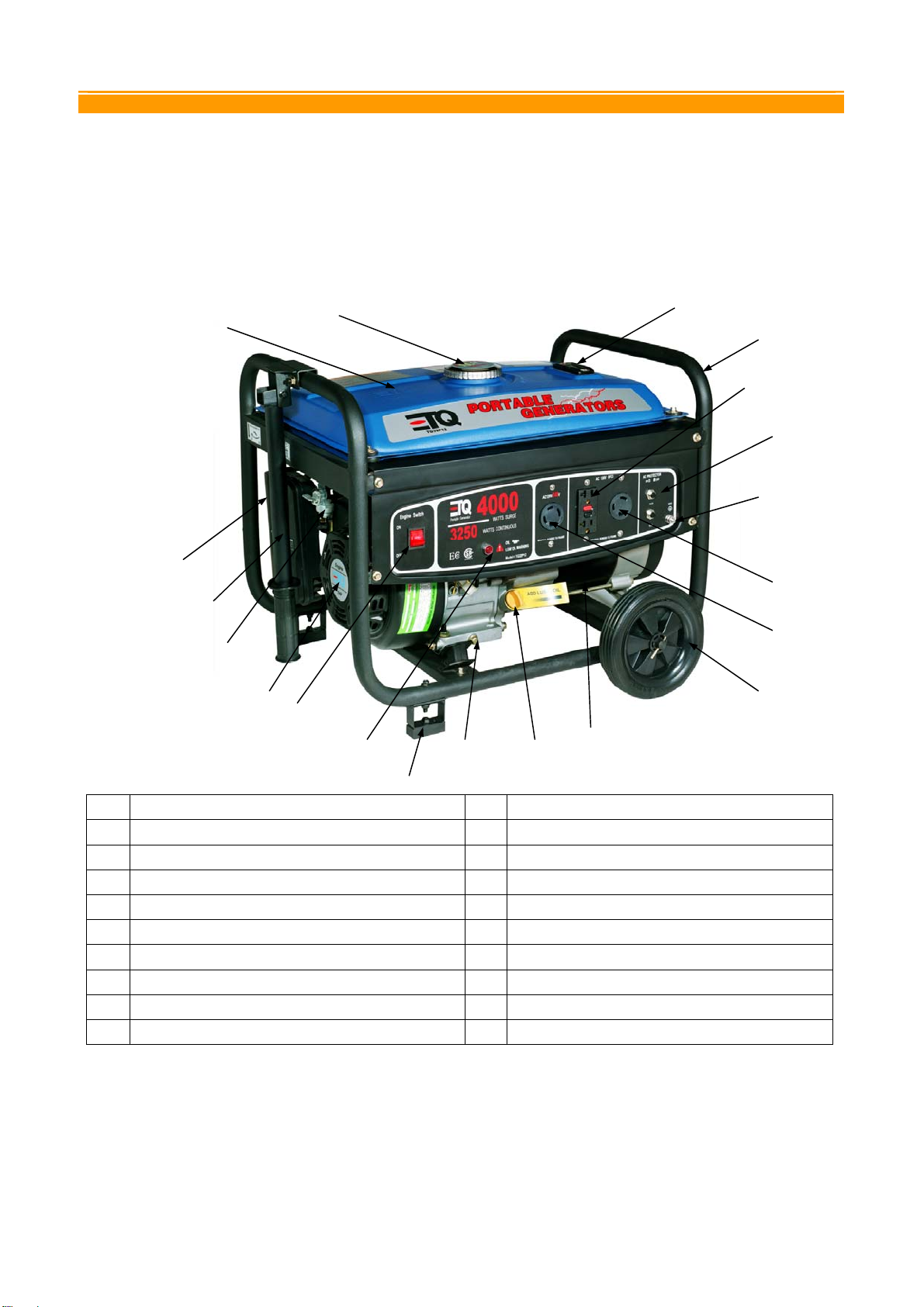

EQUIPMENT DESCRIPTION & KNOWING YOUR GENERATOR

Please read this manual and follow the procedures covered in this manual. Become familiar with the

generators functions, applications, and limitations.

Below is a diagram of the locations of the various controls and functions of the generator

ILLUSTRATION OF CONTROLS

16

15

14

13

12

11

10

17

18

19

20

1

2

1 ENGINE SWITCH 11 AC CIRCUIT BREAKER 13.5A

2 OIL INDICATOR LIGHT ASSY 12 120V GFCI RECEPTACLE 5-20R

3 GENERATOR FOOT 13 FRAME COMP

4 OIL DRAIN PLUG 14 FUEL GAUGE

5 OIL FILLER CAP 15 FUEL TANK CAP

6 ALTERNATOR 16 TANK COMP,FUEL

7 RUBBER WHEEL 7’ 17 AIR CLEANER

8

240/120V LOCKING RECEPTACLE L14-30R

9 120V LOCKING RECEPTACLE L5-30R 19 COCK ASSY.FUEL

10 GROUND TERMINAL 20 RECOIL STARTER

3

4 5

18 HANDLE

6

9

8

7

WARNING: DO NOT

continuously being changed and improved. Every effort has been made to ensure that information in

the manual is accurate and up to date. However, we reserve the right to change, alter or otherwise

improve the product and this manual at any time without prior notice.

exceed the generator’s wattage/amperage capacity. Our products are

4

Page 6

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

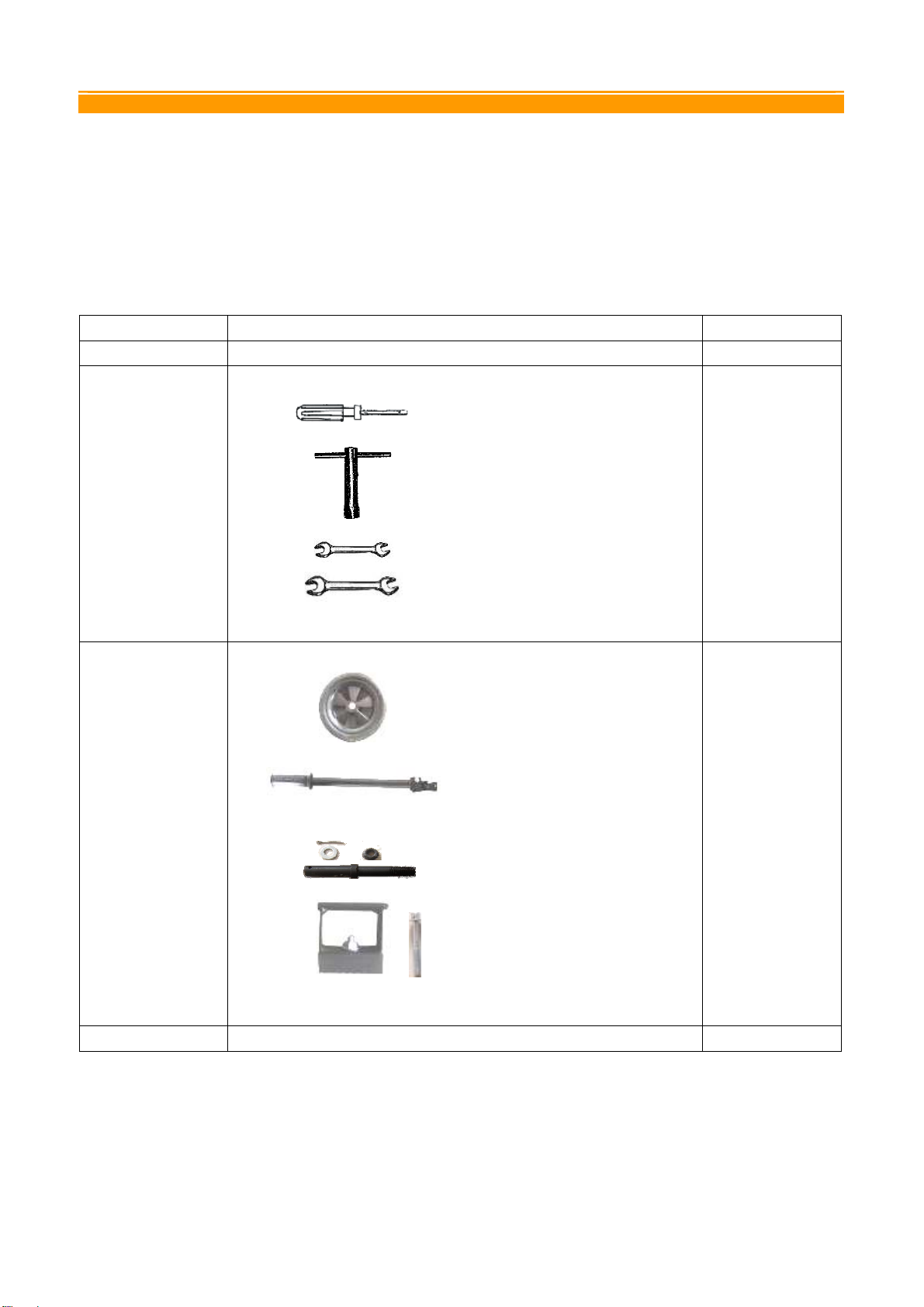

PACKAGE CONTENTS

Your generator comes with the items listed below. Please check to see that all of the following items

are included with your generator.

If you are missing components DO NOT RETURN TO STORE, please call (888)908-6200 for

customer service.

Order No. Name Qty

1 Air-cooled generator set 1

Tool Kit:

2

3

Assembly Kit:

Flat Head Screwdriver

Spark Plug Wrench

1

Wrench, 8×10 17×19

Wheel (2 pcs)

Handle

1

Wheel Kit Hardware (2 set)

Generator Foot (2 pcs)

4 Owner’s manual 1

5

Page 7

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

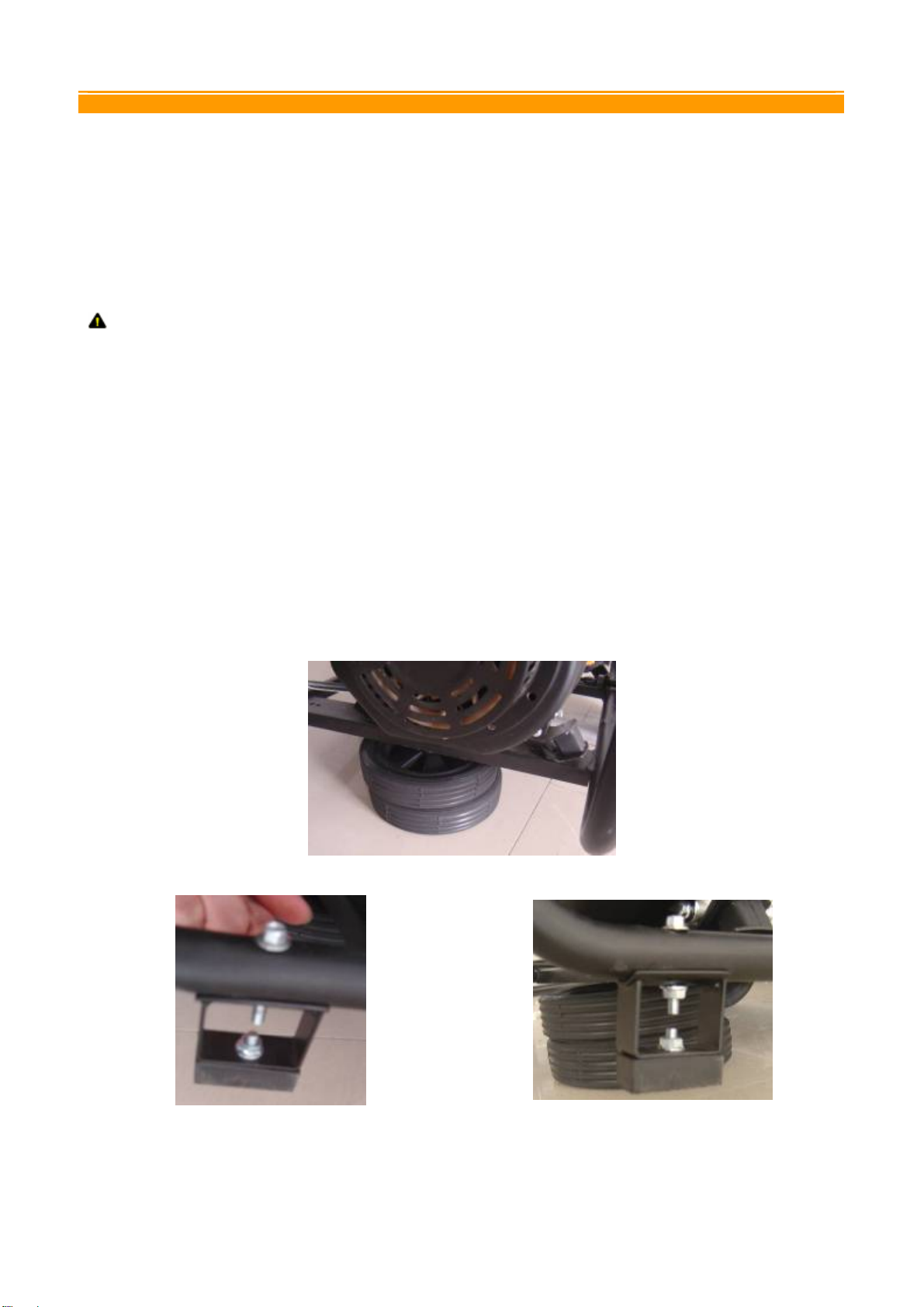

ASSEMBLY

In order to best protect the generator while in the package, this product comes with some components

disassembled. Please complete the following assembly steps before proceeding to use the generator.

For ease of assembly, we recommend attaching the components in the order listed in this manual.

If after reading this section, you are unsure about how to perform any of the steps,

please call (888)908-6200 for customer service.

WARNING: This generator is heavy. Some assembly procedures may require

two people.

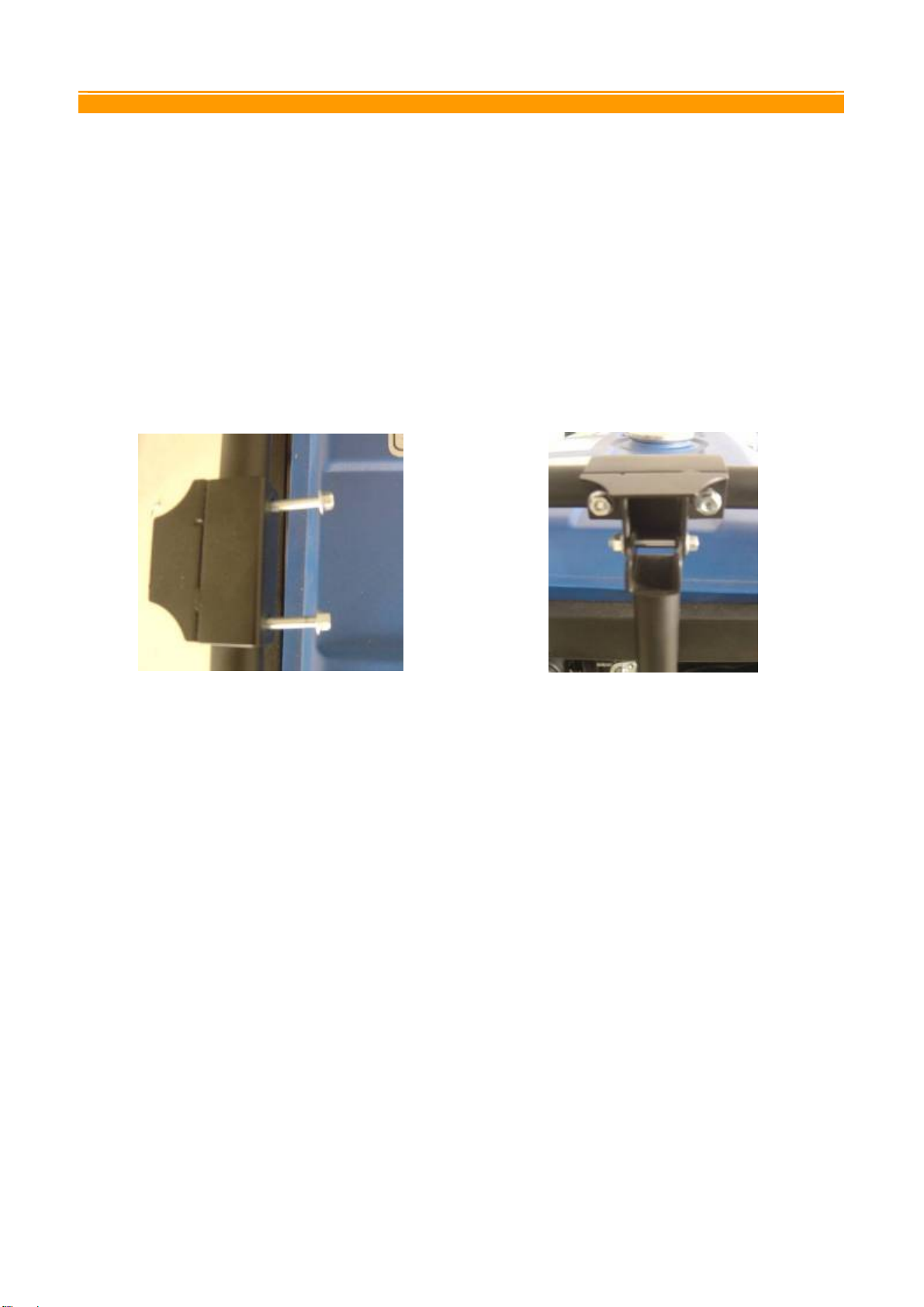

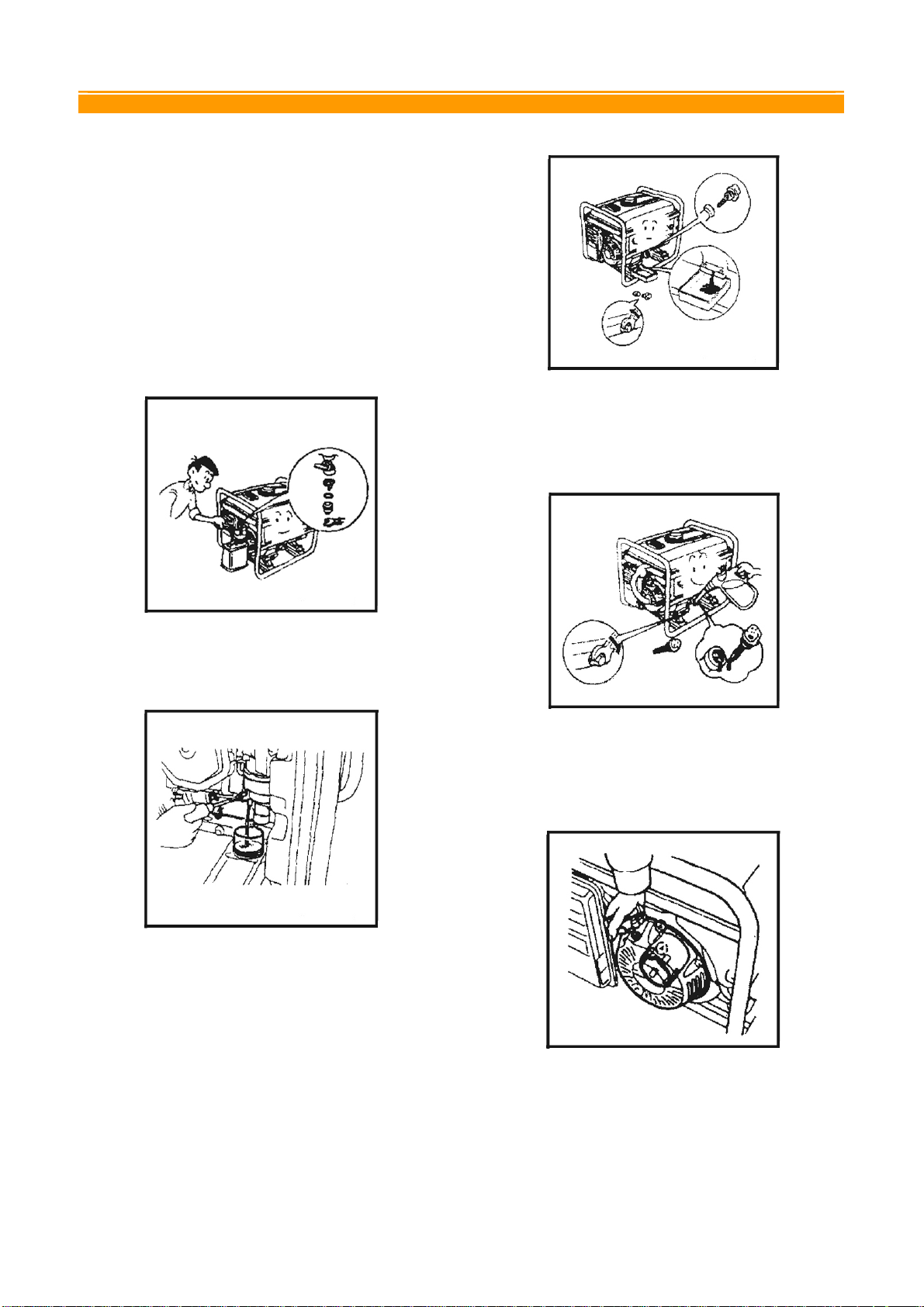

Attach Feet

To attach the feet to the generator, perform the following steps:

1. Stack the two generator wheels on top of each other. Lift the end of the generator that has the

recoil starter onto the stack of wheels (see figure 1). Be careful not to obstruct any holes on the

generator.

2. Place one foot onto the frame as shown in figure 2. Line up the holes on the generator frame with

the holes on the bracket portion of the foot. Tighten the M6x40 bolts and M6 nuts, using the

included wrench.

3. Repeat step 2 for the other generator foot.

A

Figure 1 - Stacking the wheels

Figure 2- Foot assembly

6

B

Page 8

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

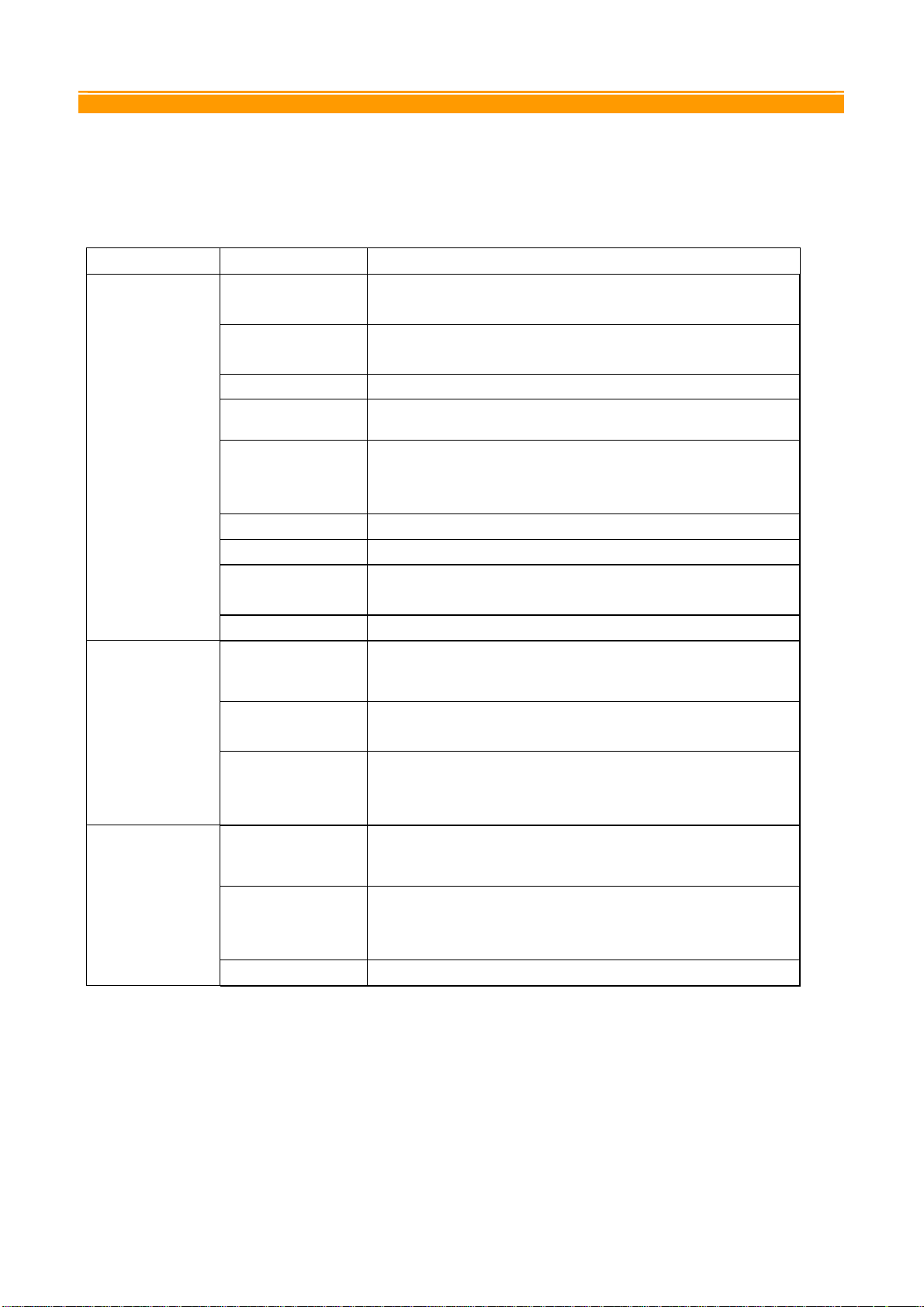

Attach Wheels

To attach the wheels to the generator, perform the following steps:

1. Take one wheel shaft and one M12 nut as shown. Slide the wheel shaft, with the threaded part

facing inward, through the frame holes. Secure using an M12 nut and the included wrench as

shown in figure 4.

2. Lift up slightly the generator frame and put shaft into the holes of wheel and tighten it on the frame

and Slide the wheel onto the axle and secure in place using a large cotter pin as shown in figure 5.

3. Place one washer on the shaft and do not obstruct the hole of the shaft. Spread the pin legs apart

slightly to help secure the pin in place.

4. Repeat steps 2 and 3 for the other wheel.

Figure 3 - Placing the shaft

Figure 5 - Wheel installation

Figure 4 - Shaft assembly

7

Page 9

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Attach Handles

The handles attach to the same end of the generator as the feet. To attach the handles to the

generator, perform the following steps:

1. The handle assembly consists of the handle, two bolts, and two nuts as shown in figure 6.

2. Line up the holes on the handle bracket, with bolts attached, the holes on the generator frame.

Fasten it tightly with wrench.

3. Secure the handle to the frame using the bolt and nut. Make this attachment so that the nut is on

the inside of the frame.

4. Fasten the bolt of the movable part.

5. Repeat steps 1-4 for the other handle.

Figure 6 - Handle assembly

8

Page 10

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

SAFETY PRECAUTIONS

In order to ensure safety for the consumer,

please carefully follow instructions on being

careful with the generators.

Operate the generator ONLY outdoors. Never

run the generator indoors as the engine gives

off poisonous carbon monoxide, an odorless

and colorless gas. Inhaling carbon monoxide

will cause nausea, fainting or death. Also, keep

the generator at least 3 feet away from

flammable matter for adequate ventilation.

ELECTRIC SHOCK AND SHORT CIRCUIT

Be sure to notify the utility company when using

the generator for backup power. Use approved

transfer equipment to isolate the generator from

electric utility. In highly conductive area such as

metal decking or steel work, use a ground

circuit fault interrupter. Never touch the

generator if the generator is wet. Also, never

touch the generator if your hand is wet. Never

operate your generator if the weather

conditions call for any type of precipitation such

as rain, snow, or fog.

DANGER

Always properly ground the generator. Failing

to do so can result in electrocution, particularly

if the generator is equipped with a wheel kit.

PREVENTION FROM ACCIDENTAL BURNS

Never touch the muffler and its cover when the

engine is running. Never touch the muffler and

cover after the engine has been used, as the

muffler remains hot for a good period of time.

REFUELING PRECAUTIONS

Gasoline and its vapors are extremely

flammable. Do not smoke near gasoline and

keep gasoline away from generator while the

generator is running. When adding fuel, turn the

generator off and let it cool at least 2 minutes

before removing the gas cap. Loosen gas cap

slowly to relieve the pressure in the tank.

Fill fuel tank outdoors and never overfill the

tank.

9

Page 11

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

devices are in the "OFF" position before

disconnecting.

Operate the generator on level surfaces only.

Inclined surfaces reduce the effective

lubrication of the engine.

When storing gasoline or equipment with fuel in

tank.

Store away from appliances or equipment that

have a pilot light or other ignition sources

because it can ignite gasoline vapors.

ENGINE SAFETY PRECAUTIONS

Do not touch hot surfaces. Allow equipment to

fully cool down before touching.

Do not expose the generator to excessive

moisture, dust, dirt, or corrosive vapors.

PREPARATION BEFORE

OPERATION

Before starting the generator, verify the

following conditions.

ENGINE OIL

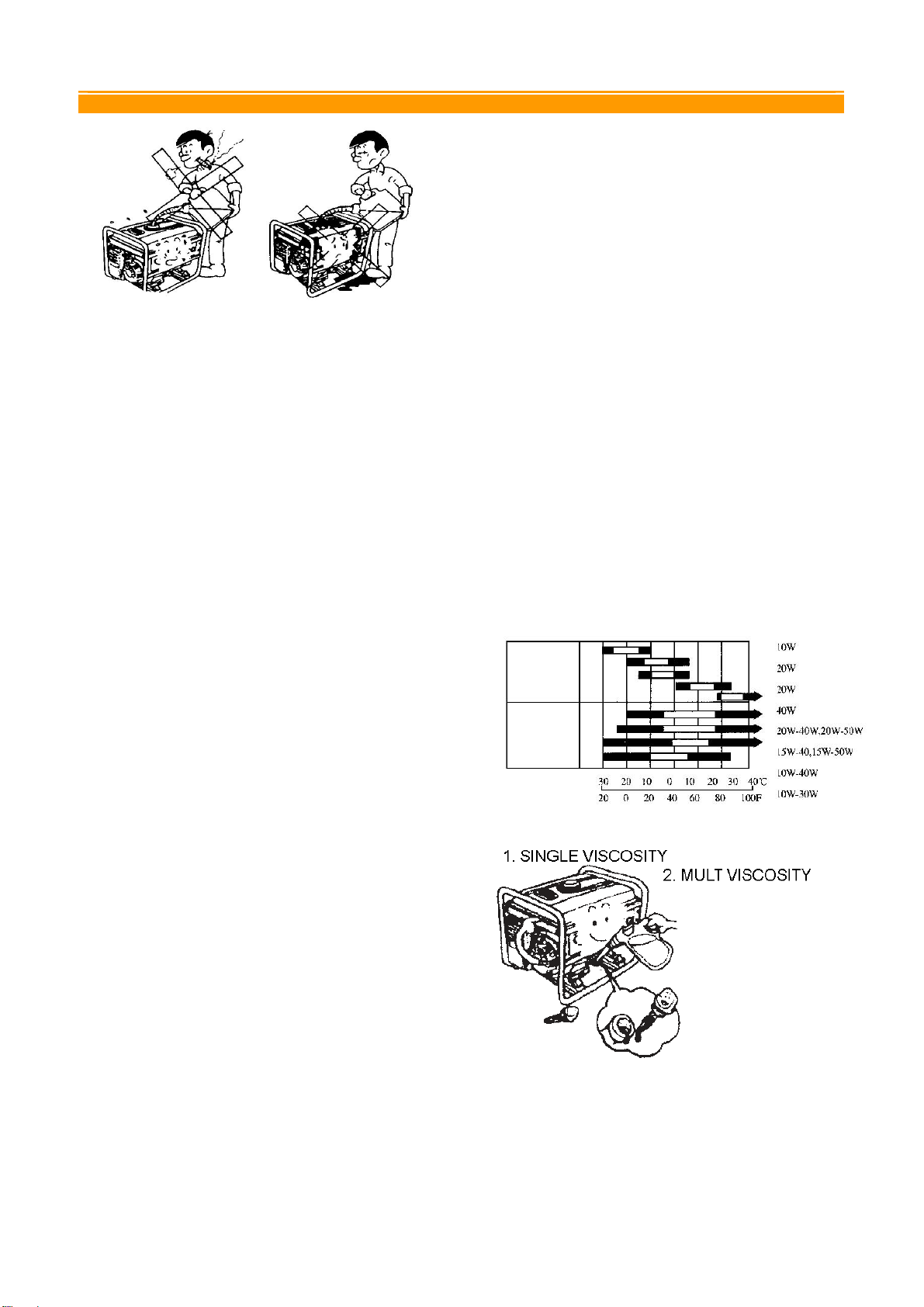

• Fill the engine with SAE 10W-30 engine oil

for generator use or follow the table below.

After the generator has been run, the engine

produces heat. The temperature of the muffler

and nearby areas can reach or exceed 1600 F.

Severe burns will occur on contact with skin. Do

not modify the generator in any way. The

generator supplies the rated voltage and rated

frequency at its governed speed.

GENERATOR SAFETY

Never overload your generator as this can

damage your generator or the electrical devices

connected to it

Do not start generator with electrical devices

connected to it. Start the generator first and

after the speed of the generator stabilizes,

electrical loads can be applied to it.

When connecting electrical loads, make sure

the devices are "OFF" first before connecting

them. Keep the same concept when

disconnecting electrical devices; make sure all

• Make sure the generator is on a level

surface and make sure the oil dipstick is on

tight.

10

Page 12

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

GASOLINE

• Add unleaded gasoline and never fill the

fuel tank indoors. Also, be sure to install the

fuel tank cap on tight after filling.

• If the air filter is dirty, remove and clean the

element.

o Wash in solvent

o Squeeze

o Soak oil

o Squeeze dry

• DO NOT overfill the fuel tank. Always allow

room for fuel expansion. Never fill the fuel

tank when the engine is running or hot.

Allow the unit to cool for two minutes before

refueling. DO NOT use light a cigarette or

smoke when filling the fuel tank.

AIR CLEANER

• Unscrew the bolt from the air cleaner cover,

and remove the air cleaner cover.

• Check the air cleaner element to be sure

they are clean and in good condition.

• Reinstall the air cleaner element and

secure the cover by setting the cover

spring.

11

Page 13

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

GROUNDING THE GENERATOR

The National Electric Code requires that the

frame of generator and the external electrically

conductive parts of the generator be connected

to an approved earth ground. Local codes may

differ and require other grounding specifications.

For this purpose, please use the ground wire

that attaches from the frame to the generator

OPERATING THE GENERATOR

STARTING THE ENGINE

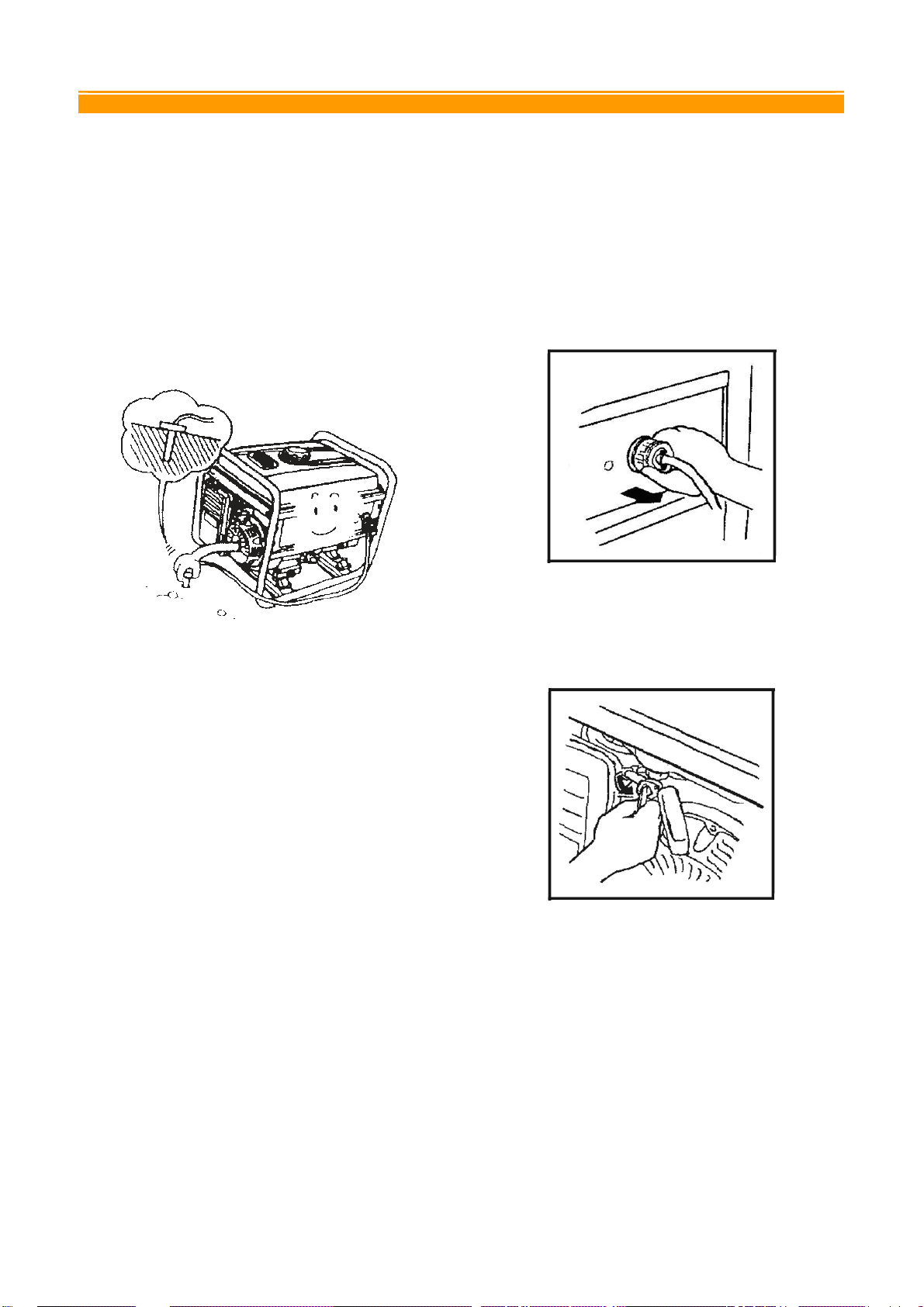

Before starting the engine, verify that the

engine oil is full, gasoline is full, and air Filter is

in place. Also, disconnect any load from the AC

receptacle (Figure 1) .

Figure 1. Disconnecting electrical devices

unit.

Using a No. 12 AWG (American Wire Gauge)

stranded copper wire to the frame and to an

earth-driven copper or brass grounding rod

provides sufficient safety against shock.

However, local codes may differ. Contact a

local electrician to find out specifications for

grounding your generator.

Note: Grounding your generator is highly

recommended. It helps prevent electrical shock

if a ground fault condition exists in the

generator or in faulty connected electrical

devices. Also, because the generator is rotating

at high speeds, static electricity tends to buildup

within the unit. Grounding helps dissipate the

static electricity buildup often buildup in

underground devices.

• Turn the fuel valve to the "On" position

(Figure 2).

Figure 2. Fuel Valve

• Turn the engine switch to the "ON" position

(Figure 3).

12

Page 14

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Figure 3. Engine switch on position

Make sure all electrical devices are 60 Hz

devices.

Do not connect 50 Hz devices to the generator.

Do not connect 3-phase loads to the generator.

Do not overload the generator.

Before beginning your work, you must verify

that the rated (running) and surge (starting)

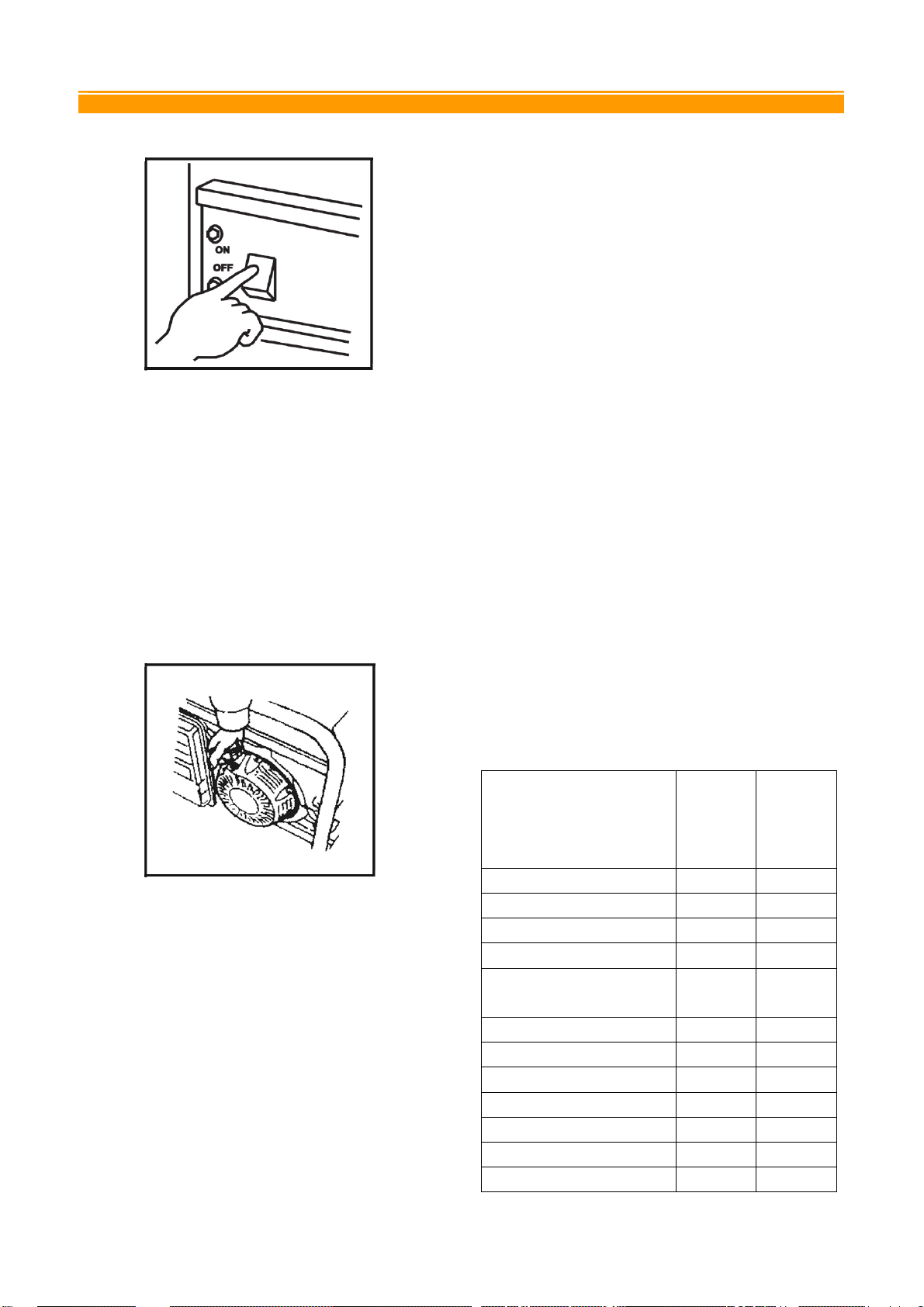

• Pull the recoil starter grip lightly until

resistance is felt, then pull hard.

• Warning: Do not allow the starter grip to

snap back against the engine. Return it

gently.

• When start the generator, please push the

choke rod to the “close” position. If can not

start with the correct step, please adjust the

position of the choke rod.

Figure 4. Recoil starting rope

watts for the items you will power at the same

time are within the generators operating

capacity. Please refer to the following Table 1

for wattage / amperage ratings. Also, to prolong

the life of your generator, prolong the life of your

generator, sequentially add loads and permit

the generator to stabilize before adding another

load. Never exceed the capacity of the

generator.

Estimate how many surge (starting) watts you

will need. Surge wattage is the short burst of

power needed to start electric motor-driven

tools or appliances such as a circular saw or

refrigerator.

Table 1. Wattage reference chart

Additional

Surge

(Starting)

Watts

• Push the choke rod to the "OPEN" position

a short distance at a time over several

seconds as the engine warms up.

CONNECTING ELECTRICAL LOADS AND

ELECTRICAL CAPACITY

After starting the generator, let the engine warm

up after connecting electrical loads to it. Do not

have any electrical loads connected before

starting the generator.

Rated

Tool or Appliance

Essentials

Light Bulb – 75 watt 75 Freezer 500 500

Sump Pump 800 1200

Refrigerator / Freezer – 18

Cu. Ft.

1/3 HP Water Well Pump 1000 2000

Heating/Cooling

Air condition – 10000 BTU 1200 1800

Window Fan 300 600

½ HP Furnace Fan Blower 800 1300

Kitchen

1000 Watt Microwave Oven 1000 -

(Running)

Watts

800 1600

13

Page 15

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Coffee Maker 1500 -

Single element electric stove 1500 Hot plate 2500 -

Family Room

DVD / CD Player 100 VCR 100 Stereo Receiver 450 -

27 “ Color Television 500 Personal Computer w/17”

monitor

Other

Security system 180 AM / FM clock radio 300 ½ HP Garage door opener 480 520

40 Gallon electric water

heater

DIY / Job Site

Halogen work light 1000 -

1/3 HP Airless sprayer 600 1200

Reciprocating Saw 960 960

½ HP Electric Drill 1000 1000

7 ¼ “ Circular saw 1500 1500

10” Miter saw 1800 1800

6” Table Planer 1800 1800

10” Table saw / Radial arm

saw

1 ½ HP air compressor 2500 2500

Note: wattages listed are only approximates. Check

your electrical device for actual wattage.

STOPPING THE ENGINE

• Unplug all the electrical loads from the

800 -

4000 -

2000 2000

• Let the engine run at no-load for several

minutes to stabilize the internal

temperatures of engine and generator.

• Turn the engine switch to the "OFF"

position (Figure 2).

• Turn the fuel valve to the "OFF" position

(Figure 3).

generator panel (Figure 1).

Figure 1.

Figure 2.

Figure 3.

14

Page 16

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

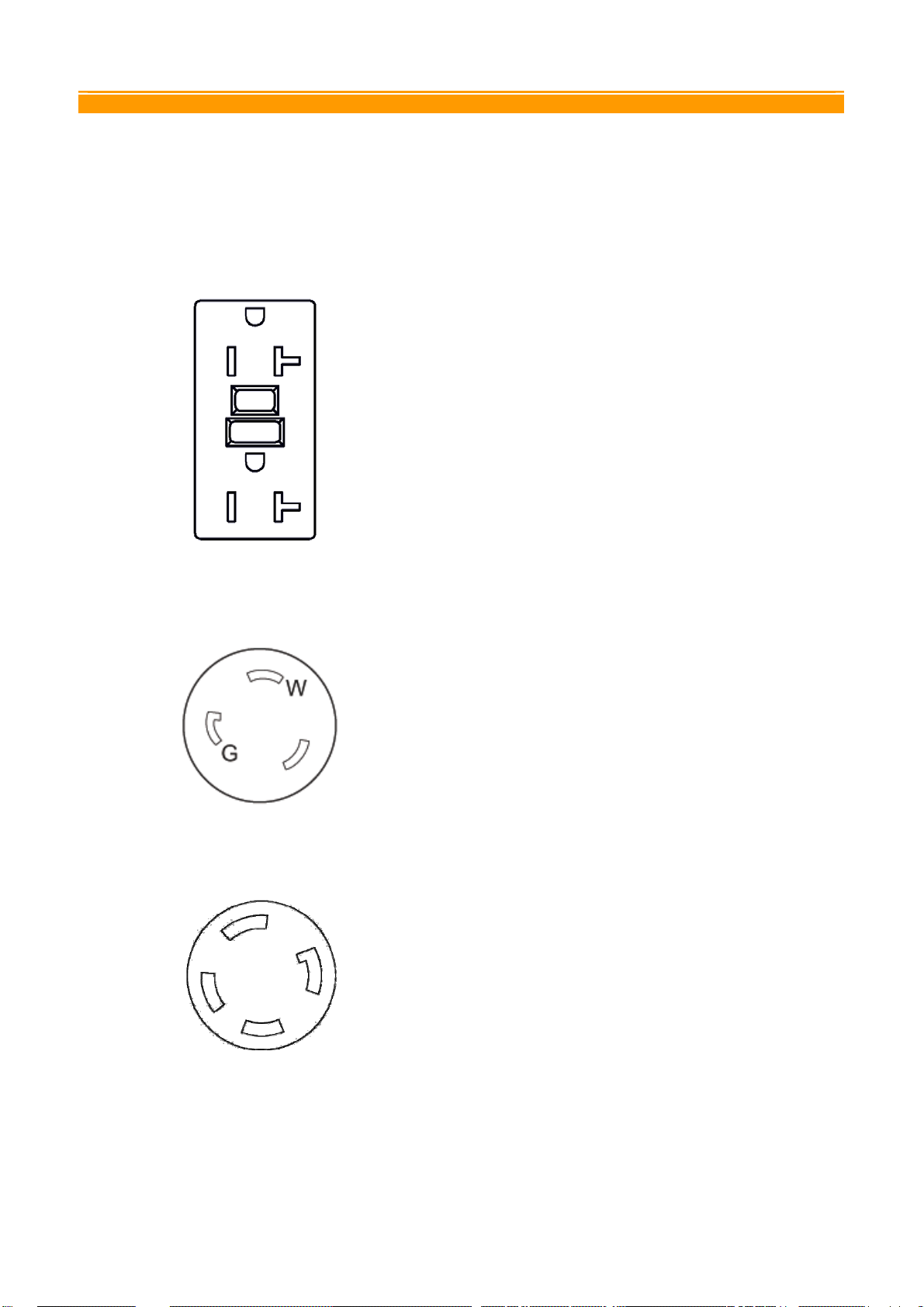

RECEPTACLES

This generator is equipped with the following

Receptacles

Figure 1. NEMA 5-20R: 125 Volt, 20 Amp

GFCI Duplex Receptacle

Figure 2. L5-30R: 120Volt, 30Amp Twist

Lock Receptacle

Figure 3. NEMA L14-30R: 240/120Volt,

30Amp Twist Lock Receptacle

X

G

W

Y

Note: Please be sure to use electrical cords that

support the amount of wattage being used.

The electrical cords should be able to handle

13.5 Amps of current at 125/250 Volts.

15

Page 17

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

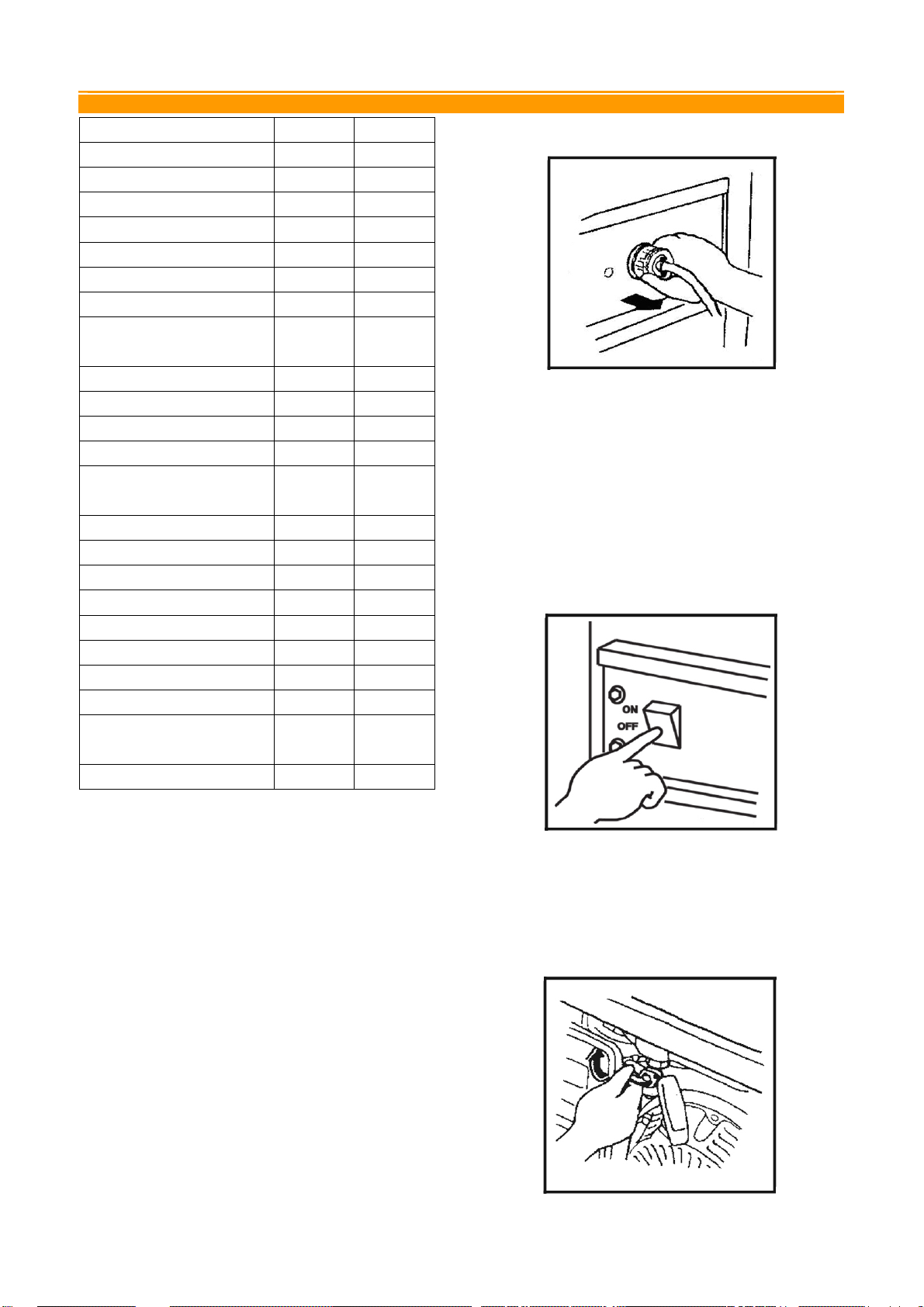

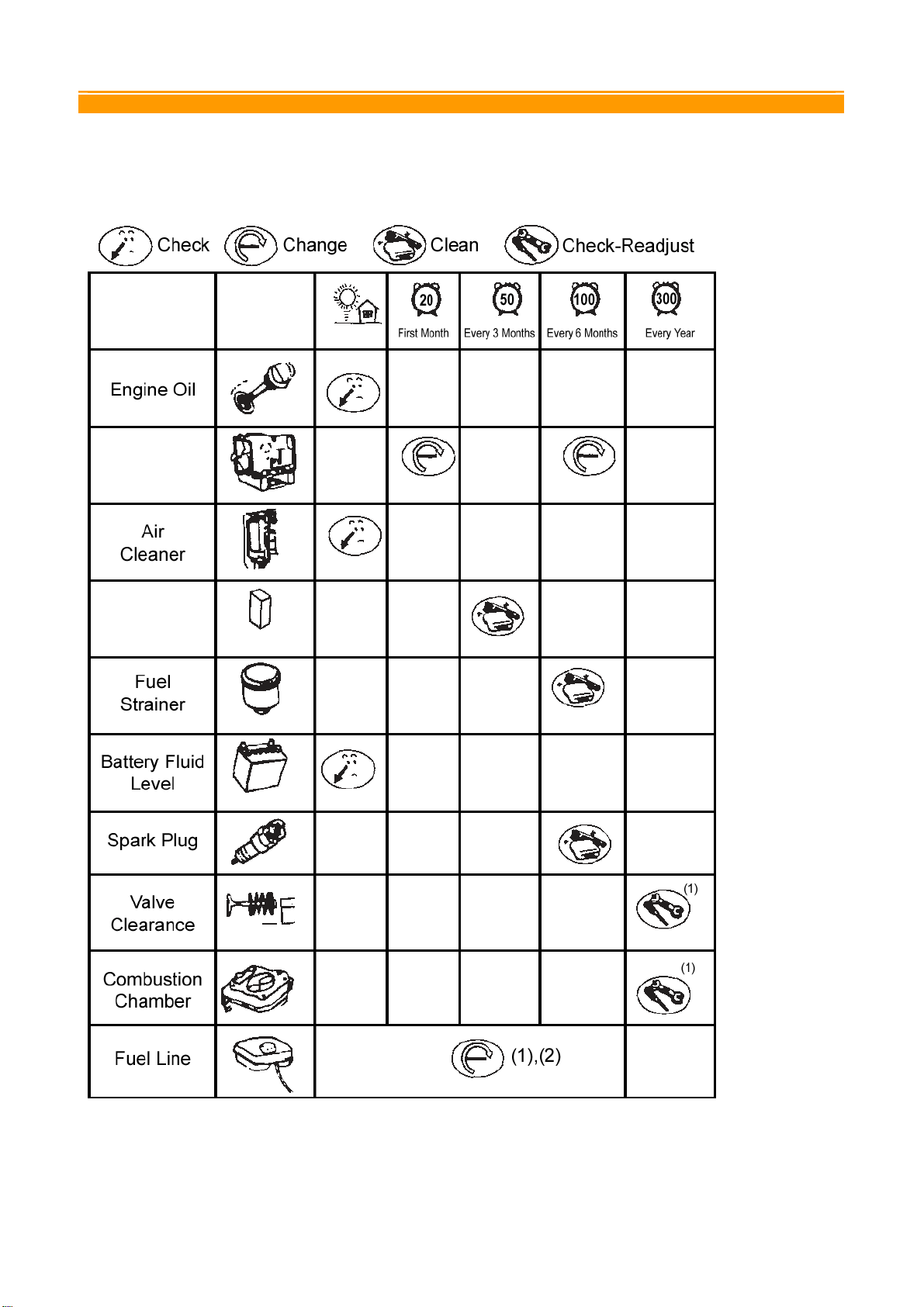

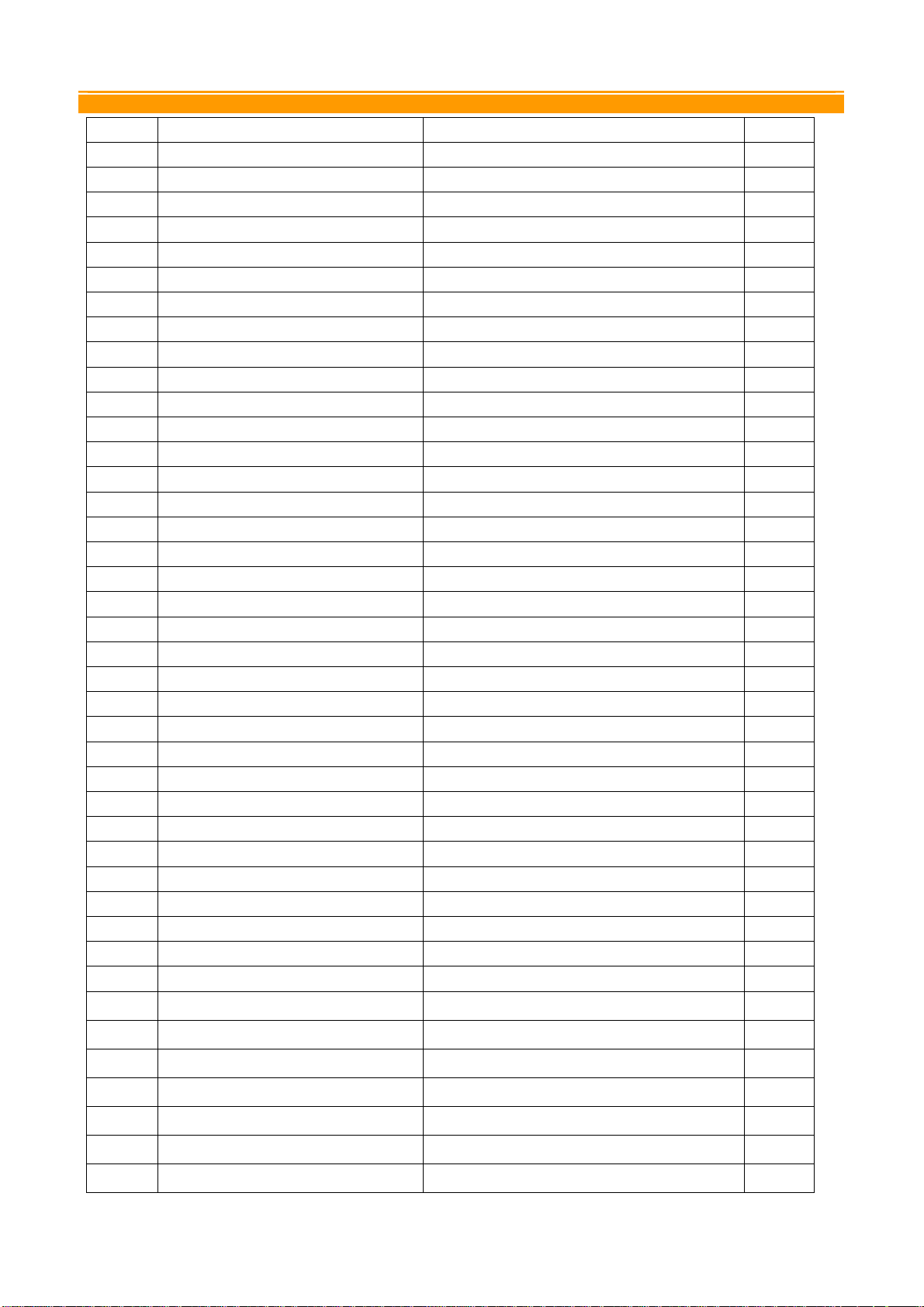

MAINTENANCE

Below is a routine maintenance schedule.

(1): These items should be serviced by a dealer.

(2): Every 3 years.

16

Page 18

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

CLEANING THE GENERATOR

Generator maintenance consists of keeping the

unit clean and dry. Be sure to store the unit in a

clean and dry environment, where it will not be

exposed to excessive dust, dirt, moisture or any

corrosive vapors. Cooling slots should always

be clean and free from clogs.

Note: Do not use a garden hose to clean the

generator. Water can enter the fuel and intake

system and cause problems. In addition, if water

and dirt buildup on the generators internal

windings, the resistance of these windings will

decrease.

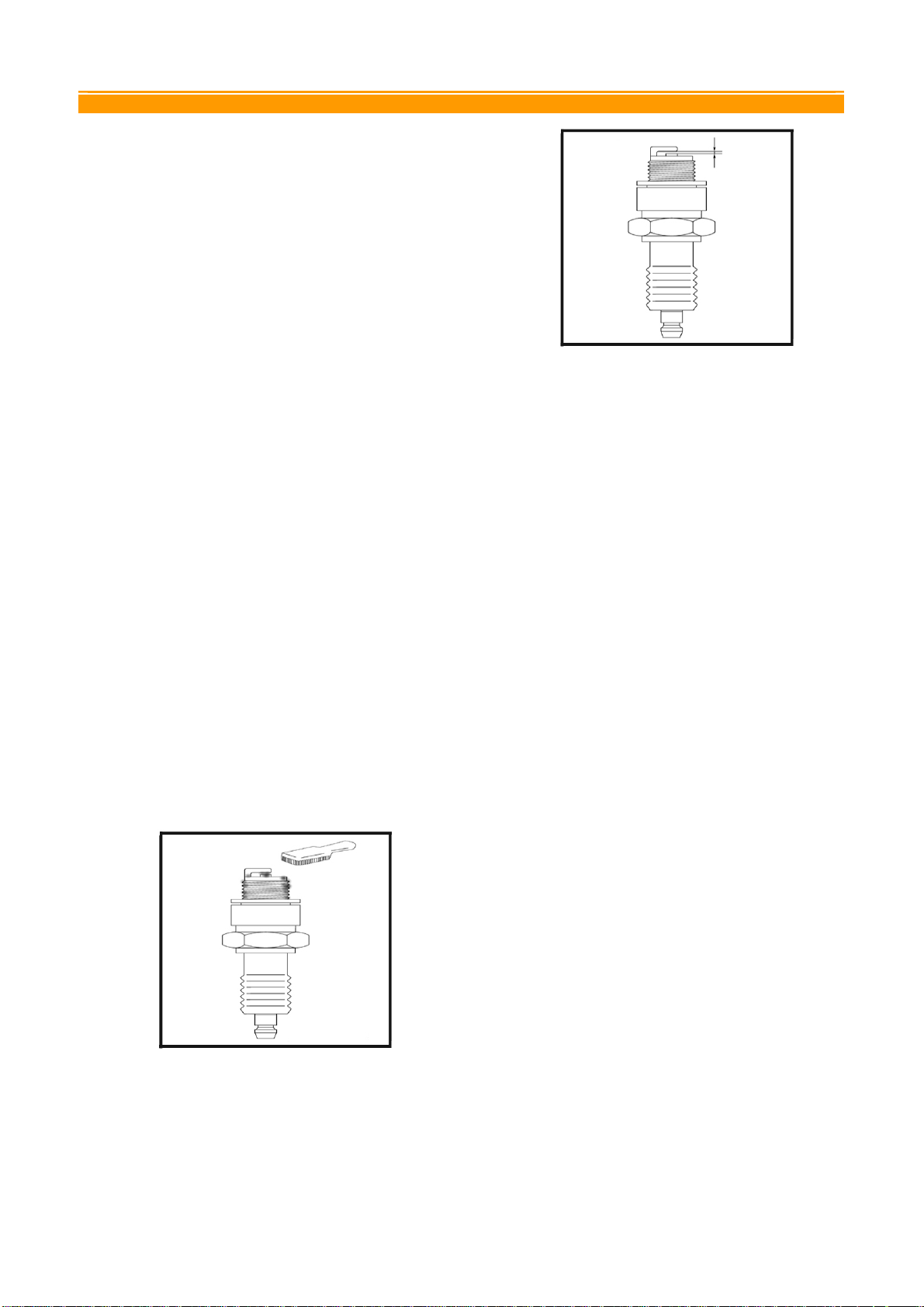

Gap measurements

0.7~0.8 mm (.028~.031 inches)

NOTE: If spark plug needs to be replaced, use

NGK(or LG) Brand: BPR4ES or F6(R)TC

• To clean the generator, use a damp cloth to

wipe the exterior surfaces.

• Use a soft bristle brush to loosen caked on

dirt of oil.

• Use a vacuum cleaner to pick up loose dirt

and debris.

• Compressed air (not to exceed 25 psi) may

be used to blow away dirt.

SPARK PLUG

• Remove the spark plug

• Remove the carbon deposits

• Check for discoloration. Standard is tan in

color.

• Check spark plug gap

17

Page 19

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

STORAGE

Figure 3.

The generator should be started at least once

every week. If this cannot be done and you must

store the unit more than 30 days, please follow

the following guidelines.

Close the fuel valve: drain the fuel from the fuel

tank (Figure 1).

Figure 1.

• Tighten the oil drain plug and fill the engine

with new oil to the filter neck (Figure 4).

Figure 4.

• Drain the fuel from the carburetor (Figure 2).

Figure 2.

• Remove the oil filter cap and drain plug to

drain the oil (Figure 3).

• Pull the starter grip carefully until resistance

is felt (Figure 5).

Figure 5.

• Store the generator in a clean area.

18

Page 20

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

TROUBLESHOOTING

IMPORTANT: If trouble persists please call our customer help line at (888) 908-6200 M-F

8-5 Central Time.

Problem Cause Solution

Engine will not

start

Engine switch is set

to "off".

Fuel valve is turned

to "closed".

Choke is open. Close the choke

Engine is out of gas. Add gas.

Engine is filled with

contaminated or old

gas

Spark plug is dirty. Clean spark plug.

Spark plug is broken. Replace spark plug.

Generator is not on

level surface.

Oil is low Add or replace oil.

Set engine switch to "on" position.

Turn fuel valve to "open" position.

Change the gas in the engine.

Move generator to a level surface to prevent low oil shutdown

from triggering.

Engine runs but

there is no

electrical output

Generator runs,

but does not

support all

electrical devices

connected to it.

Circuit reset button is

off.

Bad connecting

wires/cables.

Wait for 2 minutes and push the circuit reset button to the "on"

position.

If you are using an extension cord, try a different one.

Bad electrical device

connected to

Try connecting a different device.

generator.

Generator is

overloaded

Try connecting fewer electrical loads to the generator.

There is a short in

one of the connected

Try disconnecting any faulty or short-circuited electrical loads.

devices.

Air cleaner is dirty. Clean or replace air cleaner.

19

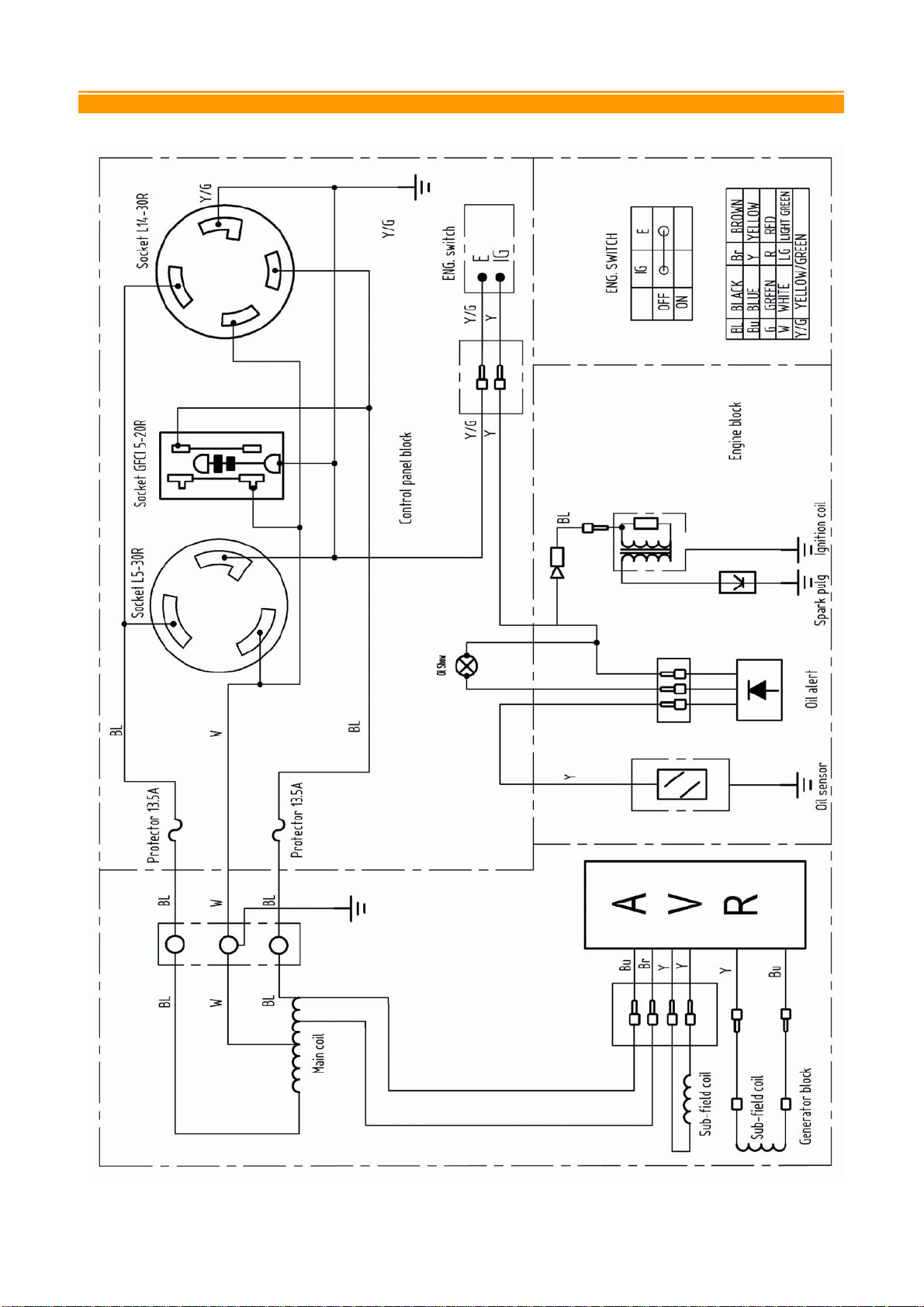

Page 21

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

WIRING DIAGRAM

20

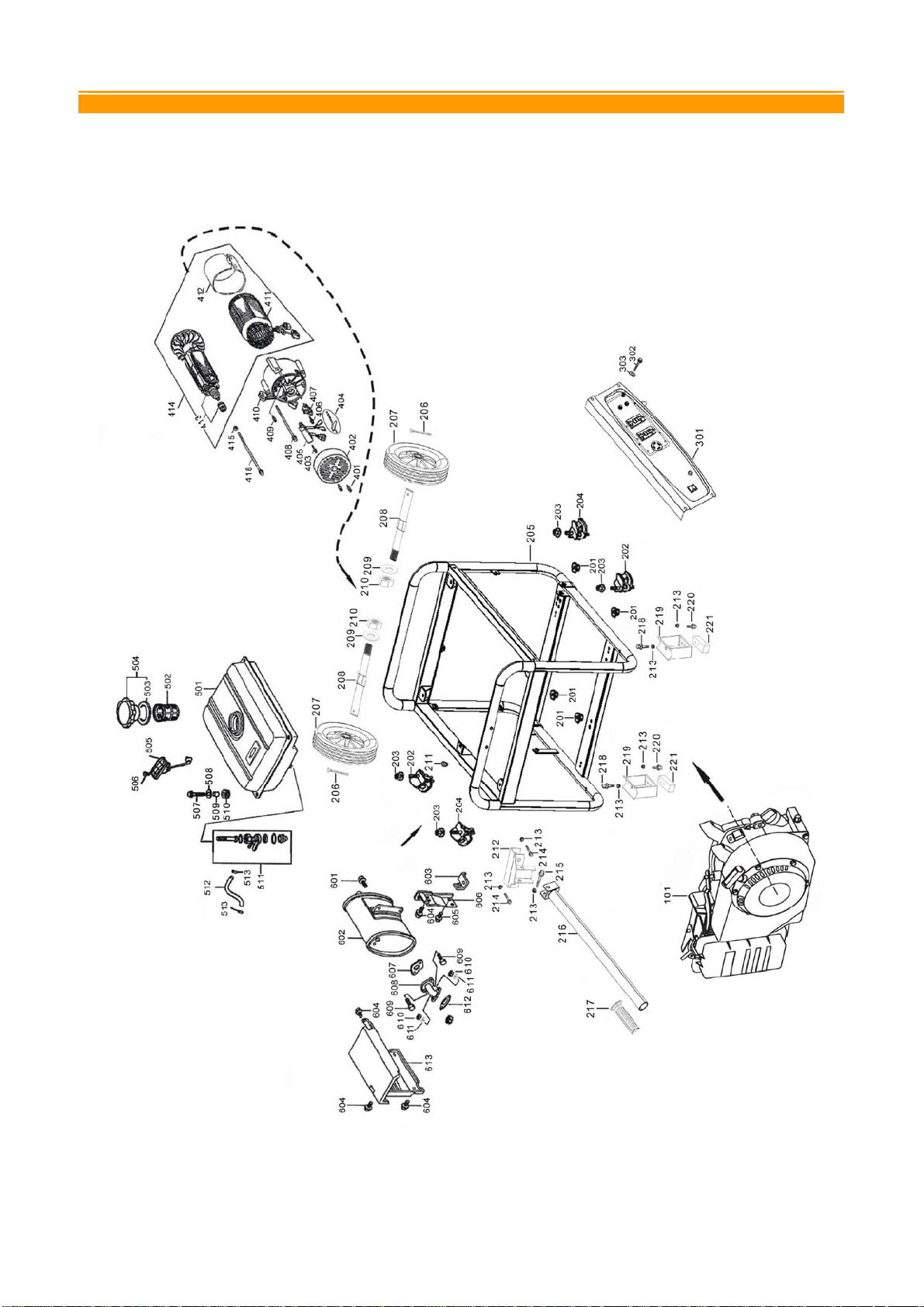

Page 22

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

PART LISTINGS

EXPLODED GENERATOR VIEW

21

Page 23

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

NO. PARTS NO. PARTS NAME QTY

101 E0001-170-00 ENGINE ASSY 1

201 94050-08000-00 NUT FLANGE M8 4

202 77320-168-00 BOTTOM RUBBER A 2

203 94050-08000-00 NUT FLANGE M8 4

204 77330-168-00 BOTTOM RUBBER B 2

205 50310-170-00 FRAME COMP 1

206 94201-03028-00 PIN,SPLIT 3×28 2

207 42710-168-00 LATEX WHEEL 2

208 44300-168-00 AXLE’WHEEL 2

209 90486-14000-00 WASHER PLAIN 14MM 2

210 94045-12000-00 NUT M12×1.75 2

211 50325-168-00 RUBBER(FRAME) 1

212 50620-168-00 IMMOBILITY PIECE BOTTOM 1

213 94050-06000-00 NUT,FLANGE M6 7

214 95701-06040-00 BOLT,FLANGE M6×40 2

215 95701-06040-00 BOLT,FLANGE M6×40 1

216 50610-168-00 HANDLE BRACKET 1

217 53135-168-00 RUBBER SHEATH,HANDLE 1

218 95701-06040-00 BOLT,FLANGE M6×40 2

219 50630-168-00 IMMOBILITY CIRCLE BELOW 2

220 95701-06016-00 BOLT,FLANGE M6×16 2

221 60407-168-00 RUBBER SHEATH 2

301 33100-T32-00 CONTROL PANEL ASSY 1

302 95701-06012-00 BOLT,FLANGE,6X12 6

303 94101-06000-00 WASHER PAPER 6MM 6

401 95701-05012-00 BOLT,FLANGE,5X12 2

402 31203-168-00 BRACKET,RR.,MOTOR(BLACK) 1

403 95701-05016-00 BOLT,FLANGE,5X16 4

404 19620-168-00 CONNECTION FLAT 1

405 30300-T40-00 VOLTAGE REGULATOR(AVR) 1

406 95701-05016-00 BOLT,FLANGE,5X16 2

407 31160-168-00 BRUSH ASSY 1

408 95701-06165-00 BOLT FLANGE 6×165 4

409 95701-05016-00 BOLT,FLANGE,5X16 1

410 31170-168-00 GENERATOR STAY 1

411 31120-032-00 STATOR COMP 1

412 31150-170-00 STATOR COVER 1

413 31130-D32-01 ROTOR,COMP 1

414 31200-032-01 MOTOR ASSY.,STARTING 1

415 94102-08000-00 WASHER,PLAIN(ROTOR) 8MM 1

416 95701-08220-00 BOLT FLANGE(ROTOR)8×220 1

22

Page 24

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

NO. PARTS NO. PARTS NAME QTY

501 17510-T40-01 TANK COMP,FUEL(BLUE) 1

502 17670-168-00 FILTER,FUEL 1

503 17631-168-00 PACKING,FUEL FILLER CAP 1

504 17620-168-01 CAP COMP,FUEL FILLER 1

505 17640-168-00 FUEL SENSOR ASSY 1

506 93800-05010-00 SCREW 5×10 2

507 95701-06025-00 BOLT,FLANGE M6X25 4

508 90486-06000-00

509 91551-168-00

510 90851-168-00

WASHER, TANK CUSHION 6×22×2

COLLAR, TANK CUSHION

RUBBER, FUEL CUSHION

4

4

4

511 16950-168-00 COCK ASSY.FUEL 1

512 95001-168-00-CARB TUBE,FUEL(CARB) 1

513 95003-168-00 CLIP,TUBE (B8) 2

601 95701-08016-00 BOLT,FLANGE,8X16 2

602 18310-170-00 MUFFLER COMP 1

603 18383-168-00 SUPPORTING PLSTE 1

604 95701-08016-00 BOLT,FLANGE,8X16 6

605 95701-06012-00 BOLT,FLANGE,6X12 1

606 18382-168-00 MUFFLER STAY 1

607 18381-170-00 GASKET,MUFFLER 1

608 18330-168-00 PIPE,EXH 1

609 95701-06020-00 BOLT,FLANGE,6X20 2

610 94050-08000-00 NUT 8MM 2

611 94111-08000-00 WASHER,SPRING 8.5MM 2

612 18381-170-00 GASKET,MUFFLER 1

613 18320-168-00 PROTR,OUT MUFFLER 1

23

Page 25

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

CRANKCASE

NUMBER PART NUMBER DESCRIPTION QTY

1 12000-170-00 CRANKCASE 1

2 16541-168-00 SHAFT,GOVERNOR ARM 1

3 94251-08000-00 PIN,LOCK,8MM 1

4 94101-168-00 WASHER,PLAIN 1

5 16506-170-00 GOVERNOR ASSY 1

6 94101-168-00 WASHER,PLAIN 1

7 95701-06016-00 BOLT,FLANGE,6X16 2

8 15510-168-00 SWITCH ASSY,OIL LEVEL 1

9 94050-10000 -00 NUT, FLANGE, 10MM 1

10 96100-168-00 BEARING BALL RADIAL 6205 1

11 90601-10200-00 WASHER,PLUG DRAIN 10.2MM 2

12 95701-10015-00 BOLT,PLUG,DRAIN 10×15 2

13 91201-168-00 OIL SEAL 25X41.25X6 1

24

Page 26

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

PUSH ROD & VALVE ROCKER

NUMBER PART NUMBER DESCRIPTION QTY

1 12209-168-00 SEAL,VALVE STEM 1

2 14100-168-00 CAM SHAFT ASSY 1

3 14410-168-00 ROD,PUSH 2

4 14431-168-00 ARM,VALVE ROCKER 2

5 14441-168-00 LIFTER VALVE 8×35 1

6 14451-168-00 PIVOT,ROCKER ARM 2

7 14568-168-00 SPG,WEIGHT RETURN 1

8 14711-168-00 VALVE,INLET 1

9 14721-168-00 VALVE,EXHAUST 1

10 14751-168-00 SPRING,VALVE 2

11 14771-168-00 RETAINER,IN.VALVE SPRING 1

12 14773-168-00 RETAINER,EXH VALVE SPRING 1

13 14781-168-00 ROTATOR,VALVE 1

14 50142-168-00 LIMIT POSITION PANEL 1

15 90012-168-00 BOLT PIVOT 2

16 90206-168-00 NUT,PIVOT ADJUSTING 2

25

Page 27

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

CYLINDER HEAD & CYLINDER HEAD COVER ASSEMBLY

NUMBER PART NUMBER DESCRIPTION QTY

1 12204-168-00 GUIDE.IN,VALVE 1

2 12205-168-00 GUIDE ,EXH VALVE 1

3 12210-168-00 HEAD ASSY., CYLINDER 1

4 12216-168-00 CLIP, VALVE GUIDE 1

5 12251-170-00 GASKET,CYLINDER HEAD 1

6 12310-168-00 COVER COMP,HEAD(BLACK) 1

7 12391-168-00 PKG,HEAD COVER 1

8 94301-10016-00 DOWEL,PIN,10X16 2

9 15721-168-00 TUBE,BREATHER(ARC) 1

10 95701-06012-00 BOLT,FLANGE,6X12 4

11 90043-06090-00 BOLT, STUD. 6X90 2

12 90047-08035-00 BOLT,STUD 8X35 2

13 98097-168-00 SPARK PLUG F6TC 1

14 95701-08060-00 BOLT,FLANGE 8X60 4

26

Page 28

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

CRANKCASE COVER ASSEMBLY

NUMBER PART NUMBER DESCRIPTION QTY

1 15600-168-00 CAP ASSY,OIL FILLER 1

2 11300-168-00 COVER ASSY.,CRANK CASE 1

3 95701-08032-00 BOLT,FLANGE 8X32 6

4 96100-168-00 BEARING BALL RADIAL 6205 1

5 91201-168-00 OIL SEAL 25X41.25X6 1

6 94301-08014-00 DOWEL,PIN,8X14 2

7 11381-170-00 PKG,CASE COVER 1

8 15625-168-00 PKG,OIL FILLER CAP 1

27

Page 29

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

CRANKSHAFT, PISTON & TIE-ROD

NUMBER PART NUMBER DESCRIPTION QTY

1 13011-170-00 PISTON RING (A) 1

2 13012-170-00 PISTON RING (B) 1

3 13014-170-00 SIDE RING 2

4 13013-170-00 WAVE RING 1

5 13010-170-00 RING SET,PISTON (STD) 1

6 90551-168-00 CLIP PISTON PIN 2

7 13101-170-00 PISTON 1

8 13111-168-00 PIN,PISTON 1

9 13200-168-00 CONN ROD ASSY 1

10 90001-07032-00 BOLT,CONN.ROD 7×32 2

11 13202-168-00 TIE-ROD COVER 1

12 13201-168-00 TIE-ROD 1

13 90741-168-00 WOODRUFF KEY 5×5×33 1

14 23460-168-00 DRIVE GEAR 1

15 23470-168-00 TIMING DRIVING GEAR 1

16 13310-168-00 CRANK SHAFT COMP 1

28

Page 30

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

CARBURETOR ASSEMBLY & AIR CLEANER ASSEMBLY

NUMBER PART NUMBER DESCRIPTION QTY

1 17250-168-00 AIR/C 1

2 16269-170-01 PKG,AIR/C 1

3 16100-170-00 CARBURETOR ASSY 1

4 16221-170-01 PKG,CARB 1

5 16211-168-00 INSULATOR,CARB COMP 1

6 16212-170-01 GASKET,INLET 1

7 95701-06012-00 BOLT,FLANGE 6X12 1

8 17239-168-00 STAY,AIR/C 1

29

Page 31

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

FLYWHEEL & RECOIL STARTER

NUMBER PART NUMBER DESCRIPTION QTY

1 28400-170-00 STARTER ASSY,RECOIL 1

2 19610-168-01 COVER COMP.,FAN 1

3 95701-06012-00 BOLT,FLANGE 6X12 8

4 19630-168-00 LEAD WIND COVER 1

5 90201-14000-00 NUT, SPECIAL, 14M X1.5M 1

6 28451-168-00 STARTING CUP 1

7 19511-168-00 FAN,COOLING 1

8 31110-168-00 FLYWHEEL COMP 1

9 19611-168-00 PLATE,COMP,SIDE 1

10 95701-06020-00 BOLT,FLANGE 6X20 1

11 19613-168-00 CLAMP, CORD 1

12 15520-168-01 ALERT UNIT,OIL 1

30

Page 32

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

IGNITION COIL

NUMBER PART NUMBER DESCRIPTION QTY

1 90121-06025-00 BOLT,FLANGE 6X25 2

2 30515-168-00 IG COIL ASSY 1

3 36101-168-00 CORD, STOP SWITCH 1

4 30700-168-00 CAP ASSY,NOISE SUPPRESSOR 1

REGULATING CONTROL SYSTEM

NUMBER PART NUMBER DESCRIPTION QTY

1 16551-168-00 ARM,GOVERNOR 1

2 16555-168-00 ROD,GOVERNOR 1

3 16584-168-00 SPRING,CONTL ADJ 1

4 16562-168-00 SPRING THROTTLE RETURN 1

5 72880-06021-00 BOLT,GOV.ARM(T) 6×21 1

6 94050-06000-00 NUT,FLANGE 6MM 1

7 16580-168-00 BASE COMP,CONTROL 1

8 95701-06012-00 BOLT,FLANGE,6X12 2

9 93500-05035-00 SCREW,PAN 5×35 1

10 16561-168-00 SPRING GOVERNOR 1

31

Page 33

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

LIMITED W A RRANTY

Eastern Tools & Equipment, Inc. will repair or replace, free of charge, any part or parts of the generator that are defective

in material or workmanship or both. Transportation charges on parts submitted for repair or replacement under this

Warranty must be borne by purchaser. This warranty is effective for the time period and subject to the conditions provided

for in this policy. For warranty service, find the nearest Authorized Service Dealer by contacting the place of purchase or

Eastern Tools & Equipment, Inc. THERE IS NO OTHER EXPRESSED WARRANTY. IMPLIED WARRANTIES,

INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE

YEAR FROM PURCHASE, OR TO THE EXTENT PERMITED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER ANY AND ALL WARRANTIES ARE EXCLUDED

TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some states do not allow limitations on how long an implied

warranty lasts, and some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you may also have

other rights, which vary from state to state.

Eastern Tools & Equipment, Inc.

WARRANTY PERIOD***

ENGINES

GASOLINE

GENERATOR

*The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues

for the period of time stated in the table above. “Consumer use” means personal residential household use by a retail

consumer. “Commercial use” means all other uses, including the commercial, income producing or rental purpose. Once

the engine has experienced commercial use, it shall thereafter be considered as a commercial use engine for purpose of

this warranty. Engines use in competitive racing or commercial or rental tracks are not warranted.

***A two-year warranty applies to the emission control system on engines certified by EPA and CARB.

IMPORTANT

“WARRANTY REGISTRATIONS IS NECESSARY

EQUIPMENT, INC., ENGINES. THE WARRANTY REGISTRATION CARD MUST BE RETURNED WITHIN 15 DAYS

OF PURCHASE FOR LIMITED WARRANTY TO BE VALID”

About Your Product Warranty

Eastern Tools & Equipment, Inc. welcomes warranty repair and apologizes to you for being inconvenienced. Any

Authorized Service Dealer may perform warranty repairs. Most warranty repairs are handled routinely, but sometimes

warranty service may be inappropriate. For example, warranty would not apply if an engine is damaged because of

misuse, lack of routine maintenance, shipping, handling, warehousing and improper installation. Similarly, warranty is void

if the serial number on the engine has been removed or if the engine has been altered or modified. If a customer differs

with the decision of the Service Dealer, an investigation will be made to determine whether the warranty applies. Ask the

Service Dealer to submit all supporting facts to his Distributor or the factory for review. If the distributor or the factory

decides that the claim is justified, the customer will be fully reimbursed for those items that are defective. To avoid

misunderstanding, which might occur between the customer and the dealer, listed below are some of the causes of engine

failure that the warranty does not cover.

WITHIN U.S.A AND CANADA OUTSIDE U.S.A. AND CANADA

CONSUMER

USE

1 year

Or 600 hours

COMMERCIAL

USE

1 year

Or 600 hours

TO OBTAIN LIMITED WARRANTY ON EASTERN TOOLS &

CONSUMER

USE

1 year

Or 600 hours

COMMERCIAL

USE

1 year

Or 600 hours

32

Page 34

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

Normal wear:

Engines and generators, like all mechanical devices, need periodic parts service and replacement to perform well.

Warranty will not cover repair when normal use has exhausted the life of a part of an engine.

Improper maintenance:

The life of an engine or your equipment depends upon the conditions under which it operates, and the care it receives.

Some applications, such as tillers, pumps, and rotary movers, are very often used in dusty or dirty conditions, which can

cause what appears to be premature, wear. Such wear, when caused by dirt, dust, spark pug cleaning grit, or other

abrasive material that has entered the engine because of improper maintenance is not covered by warranty.

This warranty cover engine related defective material and/or workmanship only, and not replacement or refund of

the equipment to which the engine may be mounted. Nor des the warranty extend to repairs required because of:

1. Problems caused by parts that are not original eastern tools & equipment, inc., parts.

2. Equipment controls or installations that prevent starting, cause unsatisfactory engine performance, or shorten

engine life. (Contact equipment manufacturer.)

3. Leaking carburetor, clogged fuel pipes, sticking valves, or other damage, caused by using contaminated or stale

fuel. (Use clean, fresh, lead-free gasoline.)

4. Parts which are scored or broken because an engine was operated with insufficient or contaminated lubricating

oil, or and incorrect grad of lubricating oil (check oil level daily or after every 8 hours of operation. Refill when

necessary and change at recommended intervals.) Engine damage may occur if oil level is not properly

maintained. Read Operating & Maintenance Instructions.

5. Repair or adjustment of associated parts or assemblies such as clutches, transmissions, remote controls, etc.,

which are not manufactured by Eastern Tools & Equipment, Inc.

6. Damage or wear to parts caused by dirt, which entered the engine because of improper air filter maintenance,

re-assembly, or use of a non-original air filter element or cartridge. Read Operating & Maintenance Instructions.

7. Parts damaged by over-speeding, or overheating caused by grass, debris, or dirt, which plugs or clogs the

cooling fins, or flywheel are, or damaged caused by operating the engine in a confined area without sufficient

ventilation.

8. Engine or equipment parts broken by excessive vibration caused by a loosen cutter blades unbalanced blades or

loose unbalanced impellers, improper attachment of equipment to engine crankshaft, over speeding or other

abuse in operation.

9. A bent or broken crankshaft, caused by striking a solid object with the cutter blade of a rotary lawn mower, or

excessive v-belt tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e., combustion chamber, valves, valve seats, valve guides, or burned

starter motor winding, caused by the alternated fuels such as, liquefied petroleum, natural gas, altered gasoline’s

etc.

Warranty is available only through service dealers, which have been authorized by Eastern Tools & Equipment,

Inc., please contact the place of purchase or Eastern Tools & Equipment, Inc. for a Service Dealer near you.

CALIFORNIA & US EPA EMISSION CONTROL WARRANTY STATEMENT

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board (CARB) and Eastern Tools &

Equipment, Inc. are pleased to explain the Federal and California Emission Control System Warranty on your small

nonroad engine. In California, new small nonroad engines must be designed, built and equipped to meet the State’s

33

Page 35

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

stringent and anti-smog standards. Eastern Tools & Equipment, Inc. must warrant the emission control system on your

small nonroad engine for the periods of time listed above listed above provided there has been no abuse, neglect or

improper maintenance of your small nonroad engine.

Your emission control system may include parts such as the carburetor, or fuel-injection system, the ignition system and

catalytic converter. Also included may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, Eastern Tools & Equipment, Inc. will repair your small nonroad engine at no cost to

you including diagnosis, parts and labor.

OWNER’S WARRANTY RESPONSIBILITIES

As the small nonroad engine owner, you are responsible for the performance of the required maintenance listed in your

Owner’s Manual. Eastern Tools & Equipment, Inc. recommends that you retain all receipts covering maintenance on your

small nonroad engine, but Eastern Tools & Equipment, Inc. cannot deny warranty solely for the lack of receipts or for your

failure to ensure the performance of all scheduled maintenance.

As the small nonroad engine owner, you should, however, be aware that Eastern Tools & Equipment, Inc. may deny you

warranty coverage if your; small nonroad or part thereof has failed due to abuse, neglect, improper maintenance or

unapproved modifications.

You are responsible for presenting your small nonroad engine to Eastern Tools & Equipment, Inc. distribution center as

soon as a problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30

days.

If you have any questions regarding your warranty rights and responsibilities or request warranty service you should

contact either the place of purchase or Eastern Tools & Equipment, Inc., c/o Service Manager, Engine and Equipment

Service Division.

IMPORTANT NOTE:

This warranty statement explains your rights and obligations under Emission Control system Warranty (ECS Warranty),

which is provided to our by Eastern Tools & Equipment, Inc. pursuant to California law, Eastern Tools & Equipment, Inc.

also provides to original purchasers of new Eastern Tools & Equipment, Inc. engines. Eastern Tools & Equipment, Inc.

Limited Warranties for New engines & other Equipment associated with the engine (Eastern Tools & Equipment, Inc.

Products Warranty), which is enclosed with all New Eastern Tools & Equipment, Inc. engines and products on a separate

sheet. The ECS Warranty applies only to the emission control system of your new engine. To the extent that there is any

conflict in terms between the ECS Warranty and the Eastern Tools & Equipment, Inc., Warranty, the ECS Warranty shall

apply except in any circumstances in which the Eastern Tools & Equipment, Inc. Product Warranty may provide a longer

warranty period. Both the ECS Warranty and the Eastern Tools & Equipment, Inc. product Warranty describe important

right and obligations with respect to your new engine.

Eastern Tools & Equipment, Inc. at its location in Ontario, California can perform warranty service or any authorized

service dealer near you. At the time of requesting warranty service, evidence must be presented of the date of sale to the

original purchaser. The purchaser shall pay any charges for transporting the product to and from the place when the

inspection and/or warranty preformed. The purchaser shall be responsible for any damage or loss incurred in connection

with the transportation of any engine or any part(s) thereof submitted for inspection and/or warranty work.

If you have any questions regarding your warranty rights and responsibilities, you should contact Eastern Tools &

Equipment, Inc.

34

Page 36

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

PRODUCT REGISTRATION

For more efficient customer service, please fill out the information below and mail to Eastern Tools &

Equipment, Inc. Product Warranty and Registration Division.

Model No._________________ Engine Serial No.____________ Purchase Date ____/____/_____

Purchased from:

[ ] Retail Location [ ] Private Consumer [ ] Other_________________________________________

Name_________________________________________________________________________________

Address_______________________________________________________________________________

Telephone (____)____-________ Purchase Price____________

Purchased: [ ] New [ ] Used

Consumer Information:

Name___________________________________________________ Telephone (____) ____ - _________

Street Address__________________________________________________ Suite or Apt No.___________

City______________________________________________ State_______ Zip Code_________________

Province or County______________________________________________________________________

Are you a: [ ] Business [ ] Residence

Product Usage Information:

How often will you use this product?

[ ] Everyday [ ] Periodically [ ] Emergency Use Only [ ] Other

What type of application will you use this product in?

[ ] Heavy Commercial [ ] Moderate Commercial [ ] Light Commercial [ ] Tradeshows

[ ] Heavy Residential [ ] Moderate Residential [ ] Light Residential [ ] Camping/Backpacking

[ ] Other________________________________________________________________________

Important information:

It is critical to your warranty that the original point of sales receipt the retained by current consumer, and in

order to comply with Eastern Tools &Equipment Product Warranty statement you must return the registration

card within 15 days of original purchase Product warranty is valid from original date of purchase.

Please mail the above card to: Eastern Tools & Equipment, Inc.

111 Bluegrass Dr.

Norwalk, OH 44857

35

Page 37

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

EASTERN TOOLS & EQUIPMENT, INC.

TEL:1-909-390-8989

FAX:1-909-390-6068

For sales, call toll free 1-888-696-2345

WEB SITE.http://easterntools.com

36

Page 38

ETQ

EASTERN TOOLS & EQUIPMENT INC Tele: (888)908-6200 Web Site: easterntools.com

Guide du propriétaire – Modèle TG32P12

37

Page 39

ETQ

EASTERN TOOLS & EQUIPMENT, INC. TÉL. : (888)908-6200 SITE WEB : easterntools.com

PRÉFACE

Merci d'avoir acheté des produits chez EASTERN TOOLS & EQUIPMENT, INC. Nous

apprécions faire affaire avec vous. Le présent guide a uniquement pour but de vous

assister et n'est pas un manuel complet ou exhaustif touchant tous les aspects de

l'entretien et de la réparation de votre génératrice. L'équipement que vous avez acheté est

une pièce d'équipement complexe. Nous vous recommandons de consulter un

concessionnaire si vous avez des hésitations ou des préoccupations concernant votre

expérience à pouvoir faire l'entretien ou la réparation de votre équipement. Vous

épargnerez du temps et l'inconvénient d'avoir à retourner au magasin si vous choisissez de

nous appeler ou de nous écrire concernant pièces manquantes, questions de service,

conseils à propos de l'exploitation et/ou questions sur les assemblages. Nos groupes

électrogènes à essence comprennent certaines des caractéristiques ci-après :

.Construction légère

.Refroidi à l'air

.Moteur quatre-temps à combustion interne d'essence

.Lanceur à rappel

.Grand réservoir à essence

.Régulateur de tension automatique

.Protection de circuit par disjoncteur

.Sorties CA

.Capteur de bas niveau d'huile

Les groupes électrogènes à essence ETQ refroidis par air sont largement utilisés lorsque

l'alimentation électrique se fait rare. Nos génératrices offrent une solution mobile portable

pour la fourniture d'alimentation électrique au cours des opérations sur le terrain durant les

projets de construction.

Le présent guide explique comment utiliser et faire l'entretien de votre groupe électrogène.

Pour toute question ou suggestion à propos du présent guide, veuillez contacter votre

concessionnaire local ou communiquer directement avec nous. Les consommateurs

prendront note que le présent guide peut différer légèrement du produit réel étant

donné que nous apportons constamment des améliorations à nos produits.

Certaines des images incluses dans ce guide peuvent également différer

légèrement du produit réel. Eastern Tools and Equipment, Inc. se réserve le droit de

faire des modifications en tout temps sans préavis ni obligation quelle qu'elle soit.

1

Page 40

ETQ

EASTERN TOOLS & EQUIPMENT, INC. TÉL. : (888)908-6200 SITE WEB : easterntools.com

TABLE DES MATIÈRES

Page

CARACTÉRISTIQUES ET DONNÉES TECHNIQUES

DESCRIPTION ET CONNAISSANCE DE VOTRE GÉNÉRATRICE

CONTENU DE L'EMBALLAGE

ASSEMBLAGE

CONSIGNES DE SÉCURITÉ

Danger

Chocs électriques et courts-circuits

Prévention contre les brûlures accidentelles

Précautions au remplissage

Consignes de sécurité concernant les moteurs

La sécurité avec les génératrices

PRÉPARATION AVANT L'UTILISATION

Huile moteur

ESSENCE

Filtre à air

MISE À LA TERRE DE LA GÉNÉRATRICE

EXPLOITATION DE LA GÉNÉRATRICE

Démarrage moteur

Branchement de la charge électrique et capacité électrique

Arrêt du moteur

PRISES DE COURANT

ENTRETIEN

Nettoyage de la génératrice

Bougie

Entreposage

DÉPANNAGE

SCHÉMA DE CÂBLAGE

LISTE DES PIÈCES

VUE ÉCLATÉE DE LA GÉNÉRATRICE

CARTER

TIGE-POUSSOIR ET CULBUTEUR DE SOUPAPE

CULASSE ET ENSEMBLE DE COUVRE-CULASSE

ENSEMBLE DE COUVERCLE DE CARTER

VILEBREQUIN, PISTON ET BIELLE

ENSEMBLE DE CARBURATEUR ET ENSEMBLE DE FILTRE À AIR

VOLANT MOTEUR ET LANCEUR À RAPPEL

BOBINE D'ALLUMAGE

SYSTÈME DE CONTRÔLE DE RÉGLAGE

GARANTIE RESTREINTE

ENREGISTREMENT DU PRODUIT

3

4

5

6

9

9

9

9

9

10

10

10

10

11

11

12

12

12

13

14

15

16

17

17

18

19

20

21

21

24

25

26

27

28

29

30

31

31

32

35

2

Page 41

ETQ

EASTERN TOOLS & EQUIPMENT, INC. TÉL. : (888)908-6200 SITE WEB : easterntools.com

CARACTÉRISTIQUES ET DONNÉES TECHNIQUES

TG32P12

Type de moteur Quatre-temps, refroidi par air, soupapes en tête

Cylindrée

Alésage × Course

Puissance moteur nominale

5,15 KVA @ 3600 tr/min

7 HP @ 3600 tr/min

207 cc

12,63 pi cu

70 × 54 mm

2,76 × 2,13 po

Carburant Sans plomb

Contenance du réservoir de

carburant

Durée de fonctionnement en

heures

13 hres @ 50 % de charge

15,14 L

4 Gal

Huile moteur SAE 10W-30 ou huile moteur équivalente

0,6 L (20,3 oz)

1. Il est nécessaire d'ajouter de l'huile moteur lorsque le témoin

Capacité d'huile moteur

d'alerte d'huile est allumé.

2. Le moteur pourrait s'arrêter et s'endommager si le niveau

d'huile est trop bas.

Schéma de démarrage moteur Démarrage manuel

Type de génératrice Alternateur

Phase Monophasé

Facteur de puissance Cos θ = 1,0

Tension de sortie c.a. 120 V

Fréquence de sortie c.a. 60 Hz

Puissance de sortie c.a.

maximale

Puissance nominale de sortie

c.a.

4000 ± 10 % watts

3250 ± 5 % watts

Niveau de bruit 65 dB @ 7 m

Poids du produit

Dimensions du produit

25,0 x 21,3 x 19, 5 po

46,3 kg

102 lb

63.5×54.0×49.5 cm

3

Page 42

ETQ

EASTERN TOOLS & EQUIPMENT, INC. TÉL. : (888)908-6200 SITE WEB : easterntools.com

DESCRIPTION ET CONNAISSANCE DE VOTRE GÉNÉRATRICE

Veuillez lire le présent guide et suivre les procédures qu'il renferme. Familiarisez-vous avec les fonctions,

les applications et les limitations de cette génératrice.

Voici un schéma des emplacements de différentes commandes et fonctions de la génératrice.

(16)

(15)

(14)

(13)

(12)

(11)

(17)

(18)

(19)

(20)

(1) INTERRUPTEUR MOTEUR (11) DISJONCTEUR CC 13,5 A

(2) ENS. TÉMOIN LUMINEUX NIV. D'HUILE (12) PRISE DOUBLE 120 V 5-20R

(3) PATTE DU GENERATEUR (13) COMPOSANT CADRE

(4) BOUCHON DE VIDANGE (14) JAUGE À ESSENCE

(5) BOUCHON DE REMPLISSAGE D'HUILE (15) BOUCHON DE RÉSERVOIR À ESSENCE

(6) ALTERNATEUR (16) COMP. RÉSERVOIR À CARBURANT

(7) ROUES (17) FILTRE À AIR

(1)

(2)

(3)

(4)

(5)

(7)

(6)

(10)

(9)

(8)

(8) PRISE DE COURANT L14-30R (18) POIGNEE

(9) PRISE VERROUILLABLE 120 V L5-30R (19) ENS. ROBINET D'ESSENCE

(10) BORNE DE MISE À LA TERRE (20) LANCEUR À RAPPEL

AVERTISSEMENT : NE PAS dépasser la capacité de puissance/intensité de la génératrice. Nos

produits sont constamment modifiés et améliorés. Tous les efforts ont été faits pour faire en sorte que

l'information de ce guide soit exacte et à jour. Toutefois, nous nous réservons le droit de modifier, altérer

ou autrement améliorer le produit et le présent guide en tout temps sans avis préalable.

4

Page 43

ETQ

EASTERN TOOLS & EQUIPMENT, INC. TÉL. : (888)908-6200 SITE WEB : easterntools.com

CONTENU DE L'EMBALLAGE

Le générateur est livré avec les articles indiqués ci-dessous. Il faut vérifier que tous les articles

suivants sont inclus avec le générateur.

Si des articles sont absents, NE PAS RAMENER LE GÉNÉRATEUR AU MAGASIN, contacter le

service clientèle à (888)908-6200.

Numéro de

référence

1 Générateur à refroidissement à air 1

2 Trousse à outils

Nom Quant.

3 Nécessaire d'assemblage

Tournevis à lame plate

Clé à bougie

Clé plate, 8 × 10,17×19

2 roues

Poignée

Quincaillerie de nécessaire de

roue (2 jeux)

1

1

Patte de générateur (2)

4 Manuel d'utilisation 1

5

Page 44

ETQ

EASTERN TOOLS & EQUIPMENT, INC. TÉL. : (888)908-6200 SITE WEB : easterntools.com

ASSEMBLAGE

De manière à protéger au mieux le générateur dans son emballage, ce produit est livré avec certains

éléments pas assemblés. Il faut faire l'assemblage suivant avant d'utiliser le générateur. Pour faciliter

l'assemblage, nous recommandons de monter les éléments dans l'ordre indiqué dans ce manuel.

Si, après avoir lu cette section, vous n'êtes pas certain de l'exécution d'une étape

de la procédure, appelez (888)908-6200 pour consulter le service clientèle.

MISE EN GARDE – Ce générateur est lourd. Certaines étapes de l'assemblage

peuvent nécessiter deux personnes.

Montage des pattes

Il faut suivre la procédure suivante pour monter les pattes sur le générateur.

4. Mettre les deux roues du générateur l'une sur l'autre. Soulever l'extrémité du générateur avec le

lanceur et la mettre sur les deux roues empilées (figure 1). Prendre soin de ne pas obstruer des

trous du générateur.

5. Mettre une patte sur le bâti, comme montré à la figure 2. Aligner les trous du bâti du générateur sur

les trous du support de la patte. Serrer les boulons M6x40 et écrous M6, à l'aide de la clé incluse.

6. Répéter l'étape 2 pour l'autre patte du générateur.

A

Figure 1 – Empilage des roues

Figure 2 – Montage des pattes

6

B

Page 45

ETQ

EASTERN TOOLS & EQUIPMENT, INC. TÉL. : (888)908-6200 SITE WEB : easterntools.com

Montage des roues

Il faut suivre la procédure suivante pour monter les roues sur le générateur.

5. Prendre un axe de roue et un écrou M12, comme montré. Glisser l'axe de roue dans les trous du

bâti, la portion filetée vers l'intérieur. Maintenir en place avec l'écrou M12 et serrer avec la clé

incluse, comme montré à la figure 4.

6. Soulever légèrement le bâti du générateur et mettre l’axe dans les trous pour la roue et serrer sur

le bâti. Glisser la roue sur l'axe et la maintenir en place au moyen d'une grande goupille, comme

montré à la figure 5.

7. Mettre une rondelle sur l'axe et ne pas bloquer le trou de l'axe. Écarter légèrement les branches de

la goupille pour maintenir la goupille en place.

8. Répéter les étapes 2 et 3 pour l'autre roue.

Figure 3 – Mise en place de l'axe

Figure 5 – Installation d'une roue

Figure 4 – Axe

7

Page 46

ETQ

EASTERN TOOLS & EQUIPMENT, INC. TÉL. : (888)908-6200 SITE WEB : easterntools.com

Montage de la poignée

La poignée est montée sur la même extrémité du générateur que les pattes. Il faut suivre la procédure

suivante pour monter la poignée sur le générateur.

6. La poignée comprend la poignée proprement dite, deux boulons et deux écrous, comme montré à

la figure 6.

7. Aligner les trous sur le support de la poignée, avec les boulons en place, et les trous sur le bâti du

générateur. Serrer fermement avec la clé.

8. Monter la poignée sur le bâti en utilisant le boulon et l'écrou. Faire le montage de manière à avoir

l'écrou à l'intérieur du bâti.

9. Serrer le boulon de la pièce mobile.

Figure 6 – Poignée

8

Page 47

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

CONSIGNES DE SÉCURITÉ

Afin d'assurer la sécurité du consommateur,

veuillez suivre attentivement les instructions à

propos des précautions à rendre avec les

génératrices.

Utilisez la génératrice UNIQUEMENT à

l'extérieur. Ne jamais faire fonctionner la

génératrice à l'intérieur car le moteur dégage

du monoxyde de carbone toxique, un gaz

inodore et incolore. Inhaler du monoxyde de

carbone causera des nausées, des

évanouissements ou la mort. De plus, garder la

génératrice à 1 mètre / 3 pieds au minimum

d'une matière inflammable pour une ventilation

adéquate.

CHOCS ÉLECTRIQUES ET

COURT-CIRCUITS

Assurez-vous de notifier la compagnie de

service public lorsque vous utilisez la

génératrice comme source d'énergie de

secours. Utilisez de l'équipement de transfert

approuvé pour isoler la génératrice du service

public. Dans un endroit hautement conducteur

tel qu'un plancher-support métallique ou une

structure d'acier, utiliser un interrupteur de

circuit de défaut à la terre. Ne jamais toucher à

la génératrice si celle-ci est mouillée. En outre,

ne jamais toucher à la génératrice si vos mains

sont mouillées. Ne jamais utiliser votre

génératrice si les conditions météo annoncent

tout type de précipitation telle que pluie, neige

ou brouillard.

DANGER

Toujours mettre la génératrice à la terre. Ne pas

le faire peut entraîner une électrocution, en

particulier si la génératrice est équipée d'un jeu

de roues.

PRÉVENTION CONTRE LES BRÛLURES

ACCIDENTELLES

Ne jamais toucher au silencieux ni à son

couvercle lorsque le moteur est en marche. Ne

jamais toucher au silencieux ni au couvercle

après que le moteur a été utilisé, car le

silencieux reste chaud durant une longue

période de temps.

PRÉCAUTIONS AU REMPLISSAGE

L'essence et ses vapeurs sont extrêmement

inflammables. Ne pas fumer près de l'essence

et garder l'essence à distance de la génératrice

pendant que celle-ci fonctionne. Au moment

d'ajouter du carburant, éteindre la génératrice

et laisser celle-ci se refroidir durant au

minimum 2 minutes avant d'enlever le bouchon

d'essence. Desserrer le bouchon d'essence

lentement pour libérer la pression du réservoir.

Remplir le réservoir à l'extérieur et ne pas

remplir le réservoir exagérément.

9

Page 48

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

s'assurer que les appareils sont hors tension

(position "OFF") avant de les débrancher.

Utiliser la génératrice sur des surfaces de

niveau uniquement. Les surfaces inclinées

réduisent l'efficacité de la lubrification du

moteur.

Lorsque vous entreposez l'équipement avec de

l'essence dans le réservoir.

Rangez-les loin des appareils ou équipements

dotés d'une flamme pilote ou d'une autre source

d'inflammation car celle-ci peut enflammer les

vapeurs d'essence.

CONSIGNES DE SÉCURITÉ POUR LE

MOTEUR

Ne pas toucher aux surface chaudes. Laisser

l'équipement se refroidir entièrement avant d'y

toucher.

Ne pas exposer la génératrice à l'humidité, la

poussière, la saleté ou les vapeurs corrosives

excessives.

PRÉP ARATION A VANT

L'UTILISATION

Avant de démarrer la génératrice, vérifier les

conditions ci-après.

HUILE MOTEUR

• Remplir le moteur avec de l'huile moteur

SAE 10W-30 pour utilisation d'une

génératrice ou suivre le tableau ci-dessous.

Après que la génératrice a été utilisée, le

moteur produit de la chaleur. La température du

silencieux et les zones environnantes peuvent

atteindre ou dépasser 870 ºC / 1 600 ºF. Des

brûlures sérieuses se produiront au moment

d'un contact avec la peau. Ne pas modifier la

génératrice en quelque façon que ce soit. La

génératrice fournit la tension et la fréquence

nominales à sa vitesse régulée.

LA SÉCURITÉ AVEC LES GÉNÉRATRICES

Ne jamais surcharger votre génératrice car ceci

peut endommager votre génératrice ainsi que

les appareils électriques qui y sont branchés.

Ne pas démarrer la génératrice avec des

appareils branchés. Démarrer la génératrice en

premier, et une fois que la vitesse s'est

stabilisée, les charges électriques peuvent lui

être appliquées.

Au moment de brancher des charges

électriques, s'assurer que les appareils sont

hors tension (position "OFF") avant de les

• S'assurer que la génératrice est sur une

surface de niveau et s'assurer que la jauge

d'huile est bien vissée.

brancher. Garder le même concept au moment

de débrancher les appareils électriques ;

10

Page 49

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

ESSENCE

• Ajouter de l'essence sans plomb et ne

jamais remplir le réservoir à essence à

l'intérieur. En outre, s'assurer de revisser

correctement le bouchon de réservoir à

essence après le remplissage.

• Si le filtre à air est sale, enlever et nettoyer

l'élément.

o Laver dans un solvant

o Comprimer le filtre

o Tremper dans de l'huile

o Comprimer pour assécher

• NE PAS remplir le réservoir exagérément.

Laisser toujours de la place pour

l'expansion du carburant. Ne jamais remplir

le réservoir à essence lorsque le moteur est

en marche ou lorsqu'il est chaud. Laisser

l'unité se refroidir durant deux minutes avant

de faire le plein. N'allumez PAS de

cigarette et ne fumez PAS au moment de

remplir le réservoir.

FILTRE À AIR

• Dévissez le boulon de la couverture de filtre

à air, et enlevez la couverture de filtre à air.

• Vérifier l'élément du filtre à air pour vous

assurer qu'il est propre et en bon état.

• Réinstaller l'élément du filtre à air et fixer le

couvercle en replaçant les ressorts du

couvercle.

11

Page 50

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

MISE À LA TERRE DE

GÉNÉRATRICE

Le Code national de l'électricité exige que le

châssis de la génératrice et les pièces externes

conductrices de la génératrice soient

branchées à une mise à la terre approuvée.

Les codes locaux peuvent différer et exiger

d'autres spécifications de mise à la terre. À

cette fin, veuillez utiliser le câble de mise à la

terre qui relie le châssis à la génératrice.

EXPLOITATION DE LA

GÉNÉRATRICE

DÉMARRAGE MOTEUR

Avant de démarrer le moteur, vérifier si le

niveau d'huile moteur est normal, si le réservoir

d'essence est plein et si le filtre à air est en

place. En outre, débrancher toute charge de la

prise CA (Figure 1).

Figure 1. Comment débrancher les appareils

électriques

Utiliser un fil torsadé en cuivre nº 12 AWG

(American Wire Gauge) fixé au châssis et à

une tige de mise à la terre en cuivre ou en

laiton enfoncée dans le sol constitue une

sécurité adéquate contre les chocs. Toutefois,

les codes locaux peuvent différer. Contacter un

électricien local pour connaître les normes

concernant la mise à la terre de votre

génératrice.

Remarque : il est fortement recommandé de

mettre votre génératrice à la terre. Ceci aide à

éviter les chocs électriques s'il existe une

condition de mise à la masse défectueuse dans

la génératrice ou dans des appareils mal

branchés. En outre, étant donné que la

génératrice tourne à grande vitesse, l'électricité

statique a tendance à s'accumuler dans

l'appareil. Une mise à la terre aide à dissiper

l'accumulation d'électricité statique qui se

produit souvent dans les appareils sous terre.

• Tourner le robinet de carburant à la position

"On" (Figure 2).

Figure 2. Robinet de carburant

• Placer l'interrupteur moteur à la position

"ON" (Figure 3).

12

Page 51

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

Figure 3. Interrupteur moteur sous tension

Ne pas brancher d'appareils 50 Hz sur la

génératrice.

Ne pas brancher de charges triphasées sur la

génératrice.

Ne pas surcharger la génératrice.

Avant de commencer votre travail, vous devez

vérifier si la puissance nominale (en

fonctionnement) et la puissance de surtension

(au démarrage) pour les éléments que vous

allez utiliser en même temps sont à l'intérieur

de la capacité nominale de fonctionnement de

• Tirer légèrement sur le lanceur à rappel

jusqu'au moment de sentir une résistance,

puis, tirer fermement.

• Avertissement : ne pas laisser la poignée

du démarreur frapper violemment contre le

moteur. Retournez-la doucement en place.

• Au moment de démarrer la génératrice,

veuillez pousser la tige de l'étrangleur à la

position fermée (CLOSED)??? Si l'unité ne

démarre pas avec cette procédure normale,

veuillez régler la position de l'étrangleur.

Figure 4. Corde de lanceur à rappel

la génératrice. Veuillez vous référer au tableau

1 pour la puissance et l'intensité nominales. En

outre, afin de prolonger la durée utile de votre

génératrice, ajouter les charges de façon

séquentielle et allouer à la génératrice le temps

de se stabiliser avant d'ajouter une nouvelle

charge. Ne jamais dépasser la capacité de la

génératrice.

Estimer la quantité de puissance de surtension

(au démarrage) dont vous aurez besoin. La

puissance de surtension désigne cette courte

tension subite nécessaire pour démarrer les

outils ou les appareils mus par un moteur

électrique tels que scie circulaire ou

réfrigérateur.

Tableau 1. Schéma de référence des

puissances

Puissance

de

surtension

en watts (au

démarrage)

• Pousser la tige de l'étrangleur à la position

"OPEN" sur une courte distance à la fois

durant plusieurs secondes pendant que le

moteur se réchauffe.

BRANCHEMENT DE LA CHARGE

ÉLECTRIQUE ET CAPACITÉ ÉLECTRIQUE

Une fois la génératrice démarrée, laisser le

moteur se réchauffer après avoir branché les

charges électriques. Ne brancher aucune

charge électrique avant de démarrer la

génératrice.

S'assurer que tous les appareils électriques

sont des appareils 60 Hz.

Puissance

nominale en

Outil ou appareil

Dispositifs essentiels

Ampoule – 75 watts 75 Congélateur 500 500

Pompe de puisard 800 1200

Réfrigérateur /

congélateur – 18 pi cu

Pompe de puits 1/3 HP 1000 2000

Chauffage/réfrigérati

on

Climatiseur – 10 000

BTU

Ventilateur de fenêtre 300 600

Ventilateur refoulant de

fournaise ½ HP

Cuisine

Four à micro-ondes

1 000 watts

Cafetière électrique 1500 Poêle électrique à

élément unique

watts (en

fonctionnem

ent)

800 1600

1200 1800

800 1300

1000 -

1500 -

13

Page 52

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

Plaque chauffante 2500 Salle familiale

Lecteur DVD / CD 100 VCR 100 Ampli-syntoniseur

stéréo

Téléviseur couleur 27

po

Ordinateur personnel

avec écran 17 po

Autres

Système de sécurité 180 Radio-réveil AM/FM 300 Ouvre-porte de garage

½ HP

Chauffe-eau électrique

40 gallons

Atelier de bricolage /

aire de travail

Lampe de travail

halogène

Pulvérisateur haute

pression sans air 1/3

HP

Scie alternative à

lames multiples

Perceuse électrique ½

HP

Scie circulaire 7 ¼ po 1500 1500

Scie à onglets 10 po 1800 1800

Raboteuse 6 po 1800 1800

Banc de scie / scie

radiale 10 po

Compresseur d'air 1 ½

HP

Remarque : les puissances répertoriées ne sont

que des approximations Vérifiez votre dispositif

électrique pour connaître sa puissance nominale.

ARRÊT DU MOTEUR

450 -

500 -

800 -

480 520

4000 -

1000 -

600 1200

960 960

1000 1000

2000 2000

2500 2500

• Laisser le moteur tourner librement durant

plusieurs minutes pour stabiliser les

températures internes du moteur et de la

génératrice.

• Placer l'interrupteur moteur à la position

"OFF" (Figure 2).

• Tourner le robinet de carburant à la position

"OFF" (Figure 3).

• Débrancher toutes les charges électriques

Figure 1.

Figure 2.

Figure 3.

du panneau de la génératrice (figure 1).

14

Page 53

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

PRISES DE COURANT

Cette génératrice est dotée des prises de

courant suivantes :

Figure 1. Prise de courant double NEMA

5-20R : 125 volts, 20 A

Figure 2. Prise à verrouillage par rotation

L5-30R : 120 volts, 30 A

Figure 3. Prise à verrouillage par rotation

NEMA L14-30R : 240/120 volts, 30 A

X

W

G

y

Remarque : veuillez vous assurer d'utiliser des

cordons électriques pouvant accepter la

puissance utilisée.

Les cordons électriques devraient pouvoir

accepter une intensité de courant de 13.5 A à

125 volts.

15

Page 54

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

ENTRETIEN

Vous trouverez ci-dessous un échéancier d'entretien périodique.

(1): L'entretien de ces éléments devrait être effectué par un concessionnaire.

(2): Tous les 3 ans.

16

Page 55

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

NETTOYAGE DE LA GÉNÉRATRICE

L'entretien de la génératrice consiste à garder

• Vérifier s'il y a décoloration. La couleur

standard est une teinte havane (tan).

• Vérifier l'écartement des électrodes

l'appareil propre et sec. Assurez-vous

d'entreposer l'appareil dans un endroit propre

et sec où il ne sera exposé ni la poussière ni à

la saleté ni à l'humidité excessive ni à toute

vapeur corrosive. Les fentes de refroidissement

devraient être toujours propres et exemptes

d'obstructions.

Remarque : ne pas utiliser un tuyau d'arrosage

pour nettoyer la génératrice. L'eau pourrait

pénétrer dans le carburant et le système

d'admission et causer des problèmes. En outre,

si l'eau et la saleté s'accumulent sur les

bobinages internes, la résistance de ces

bobinages pourrait diminuer.

Mesures d'écartements

0,7~0,8 mm (.028~.031 pouces)

REMARQUE : si la bougie a besoin d'être

remplacée, utiliser la marque

Marque NGK (ou LG) : BPR4ES ou F6(R)TC

• Pour nettoyer la génératrice, utiliser un

linge humide pour essuyer les surfaces

extérieures.

• Utiliser une brosse à soies souples pour

détacher les saletés d'huile collées.

• Utiliser un aspirateur pour ramasser la

saleté et les débris libérés.

• On peut utiliser de l'air comprimé (sans

dépasser 25 psi) pour chasser la saleté.

BOUGIE

• Enlever la bougie

• Enlever les dépôts de carbone

17

Page 56

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

ENTREPOSAGE

Figure 3.

La génératrice devrait être démarrée au

minimum une fois par semaine. S'il est

impossible de le faire et que vous devez

entreposer l'unité durant plus de 30 jours,

veuillez suivre les directives ci-après.

Fermer le robinet de carburant : vidanger le

carburant du réservoir à essence (Figure 1).

Figure 1.

• Resserrer le bouchon de vidange et remplir

le moteur avec de la nouvelle huile jusqu'au

goulot du filtre (Figure 4).

Figure 4.

• Vidanger le carburant du carburateur

(Figure 2).

Figure 2.

• Enlever le couvercle du filtre à huile et le

bouchon de vidange pour vidanger l'huile

(Figure 3).

• Tirer doucement la poignée du démarreur

jusqu'à ce que vous sentiez de la

résistance (Figure 5).

Figure 5.

• Entreposer la génératrice dans un endroit

propre.

18

Page 57

ETQ

EASTERN TOOLS & EQUIPMENT, INC. Tél. : 1-888-908-6200 site Web : easterntools.com

DÉPANNAGE

IMPORTANT : Si le problème persiste, appeler notre service d'assistance téléphonique

au (888) 908-6200 de 8 h à 17 h, HNC.

Problème Cause Solution

Le moteur ne

démarre pas

Le moteur

fonctionne mais il

n'y a aucune

alimentation

électrique.

Interrupteur moteur réglé

à la position « Off ».

Le robinet de carburant

est à la position

« Closed » (fermé).

L'étrangleur est ouvert. Fermer l'étrangleur.

Le moteur est en panne

d'essence.

Le moteur est rempli

d'essence contaminée

ou de vieille essence.

La bougie est sale. Nettoyer la bougie.

La bougie est brisée. Remplacer la bougie.

La génératrice n'est pas

sur une surface de

niveau.

Le niveau d'huile est