Page 1

DK7

DrumKit™

User’s Guide

Page 2

Congratulations on your purchase of the Earthworks DK7 DrumKit™ High Denition Multi-microphone Drum System. You will be thrilled with the results you will

obtain when using the included microphones. You will hear more detail in the attack

in addition to hearing subtle low level details that are not audible using conventional

microphones. You will now walk into a whole new world of pristine drum sound us-

ing Earthworks High Denition Drum Microphones™. After reading this manual, if

you have any unanswered questions, please email or phone us using the contact

information on the back page of this manual.

Happy Drumming!

Please verify that you have received everything listed below.

Included with the DK7 DrumKit™ Drum Microphone System:

2 – SR25 Cardioid Microphones (overheads)

4 – DM20 DrumMic™ (tom & snare)

1 – SR20LS (kickdrum)

4 – RM1 RimMount™ (for DM20s)

3 – SRW3 Foam Windscreens (for SR25s & SR20LS)

4 – PW1 Windscreens (for DM20s)

1 – High Impact Carrying Case

with custom foam insert

1 – User’s Manual

Version 4, January 30, 2018

1

Page 3

IMPORTANT NOTICE - Please Read This:

Drums and Microphone Output Level

The SR25, DM20 & SR20LS have been designed for drum applications, and in

most cases will not require the use of a pad to prevent overloading outboard

microphone preamps, preamps in mixers or consoles and computer audio interfaces. The majority of preamps will accommodate high input levels at the

microphone preamp input without distortion. However, some preamps will not

handle high input levels at the preamp input and will require using a pad to pre-

vent distorting. We encourage you to check the specications of your preamps

to verify that they will accommodate high microphone output levels of approxi-

mately +20dBV.

Different Types of Preamp Input Pads

Some outboard microphone preamps, preamps in mixers or consoles and computer audio interfaces may have a built-in pad that can be switched in or out.

However, on some units these pads are not attenuators that precede the preamplier input, but instead just reduce the gain of the preamplier. Unless these

preamplier inputs will handle a high input level (i.e. +20dBV) these so-called

pads will typically provide no preamp input overload protection from high level

microphone signals (see Fig. 1-A). In contrast, other outboard preamps, mixers,

consoles or computer audio interfaces have actual attenuators (pads) that precede the preamplier input. These types of pads will provide the input overload

protection that is needed (see Fig. 1-B). Such pads will typically provide 10dB or

20dB attenuation. If an external XLR type microphone pad is needed, Earthworks

offers a LevelPad™ that provides 20dB of attenuation and is simply plugged into

the microphone cable. The DM20 and SR20LS have been designed with a lower

output level than the SR25 and should not require an external pad even when

close-miking toms, snares or kickdrums. Likewise, in most cases the SR25 overhead mics should require no external mic pad. In case you do need an external

mic pad, please read further.

A B

Figure 1-A and 1-B Types of Preamp Input Pads

2

Page 4

If it becomes necessary to lower the microphone output level to avoid over-

loading the preamp, then the use of an XLR-type outboard pad is suggested.

The Earthworks® LevelPad™ XLR-type outboard mic pad provides 20dB of

attenuation and can be simply plugged into the microphone cable. The LevelPad™can be inserted into the microphone cable in one of the three ways

indicated below:

Figure 2-A LevelPad™ inserted at the microphone

Figure 2-B LevelPad™ inserted in the microphone cable

CAUTION: Plugging the LevelPad™ into the mic in-

put of a mixer can cause damage to the mixer input

connector if the LevelPad™ receives a hard push

to the side. However, if you are careful, placing the

LevelPad™ at the mixer mic input can provide greater

accessibility in installing or removing the LevelPad™.

Figure 2-C LevelPad™ inserted into mixer mic input

3

Page 5

Earthworks Drum Mics

The Earthworks DrumKit™ High Denition Three-Microphone Systems™ have

had great success because they pick up drum sounds with far more detail and

accuracy than conventional microphones. This improved sound quality is due to

proprietary technologies utilized in Earthworks High Denition Microphones™.

Many drummers such as Jeff Campitelli, Steve Gadd, Keith Carlock, Ronnie

Vannucci, Anton Fig and Anthony King, in addition to many FOH engineers

touring with major artists who are using Earthworks High Denition Drum Microphones™ for overheads, toms, snare and kickdrum with exceptional results.

The SR25 has been a popular drum microphone for many years and will handle up to 145dB SPL. The DM20 is a new generation of Earthworks tom and

snare microphones. It features a stable gooseneck for easy positioning that

will stay in place even when the drums are played very hard. It also can handle

high acoustic sound levels up to 150dB SPL. The Earthworks proprietary

polar technology provides a stunning 32dB of rear rejection (nearly double

that of conventional microphones) and a consistent frequency response out

to 80 degrees off-axis. This vastly reduces phase cancellations, minimizes

pickup of unwanted sounds at the rear of the microphone and provides a substantial reduction in unwanted acoustic feedback for live sound applications.

Earthworks High Definition Microphones

™

the New Science in Microphones

David Blackmer, the brilliant engineer who invented the innovative technol-

ogies of dbx, is also the inventor and founder of Earthworks. In the last few

years of his life, David developed a number of revolutionary technologies that

dramatically improve the sound quality and performance of microphones. In

short, Earthworks High Definition Microphones™ pick up sounds more accurately and with more detail than conventional microphones. These dramatic

improvements are in the areas of impulse response, diaphragm settling time

and advanced polar technologies. Those who have heard Earthworks High

Definition Microphones™ say they have more rear rejection and more gain

before feedback in addition to hearing more detail of the attack, more subtle

detail in low level signals thereby providing a more pristine sound quality than

with any conventional microphones can provide, regardless of price.

Miking Drums

There are many ways to mic drums and it seems that most every recording or live

sound engineer has their own way of doing this. Our objective is not to indicate

which drum miking approach is better, but to make suggestions and look at ad-

4

Page 6

vantages and disadvantages of each. Every engineer or producer uses their own

methods to obtain the results they desire, and that’s what matters.

Multi-microphone Method

The objective in multi-microphone drum miking is to place a separate micro-

phone on most or all the elements of a drum set. Typically, separate mics are

used on snare, toms, hi-hat and kickdrum, along with one or two overhead

microphones. The overhead mics pick up the overall sound of the drum set

including cymbals (which are typically not miked separately). By this method,

the mixing engineer can control the level, and signal processing (limiting, EQ,

etc.) for each element of the drum set (toms, snare, hi-hat, etc.). This provides

a great deal of control over the sound of the entire drum set and allows bring-

ing out certain patterns on hi-hat, snare, etc. Multi-miked drums are desirable

for live sound, providing more control and increased gain before feedback,

and when recording in a large room with high ambient sound this reduces the

amount of unwanted room sound and provide greater control of the drum mix.

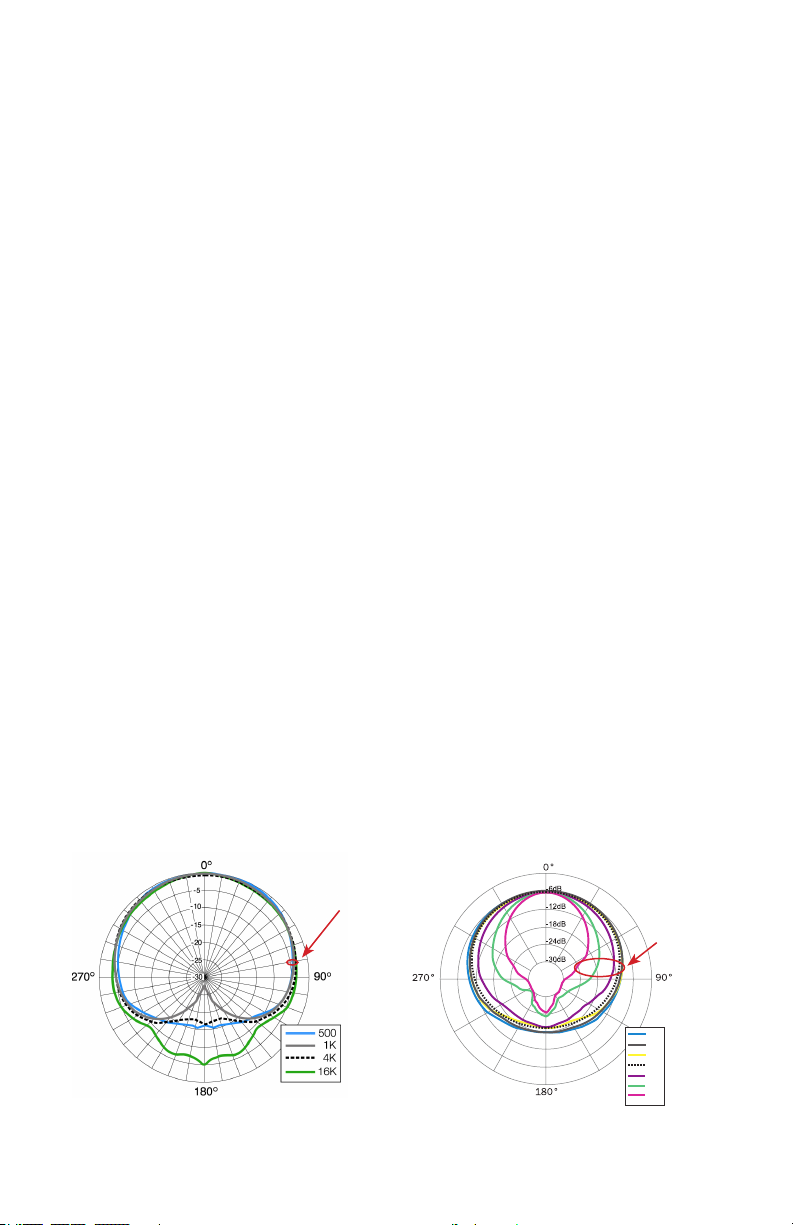

Earthworks Near-Perfect Polar Response

One of Earthwork’s proprietary technologies is near-perfect polar response

i.e. very uniform response over the front 160 degrees of the microphone. Con-

ventional microphones (even expensive ones) have a loss of high frequencies

at the sides of the microphone. Have you ever tried to put three singers on a

single directional microphone? The singer at the front of the mic sounds great,

but the two on the sides of the microphone sound muffled due to the lack of

high frequency pickup at the sides of the microphone. In contrast, the Earthworks proprietary polar technology provides virtually the same frequency response on the sides of the microphone as at the front. This uniform frequency

response at the front and sides of the microphone dramatically reduces phasing

issues. Refer to Figure 3-A & 3-B to see the uniform Earthworks microphone

(A) polar response, in comparison to the conventional microphone (B).

A

Within 3dB

500Hz to

16kHz

DM20 Polar

B

Conventional Polar

Figure 3-A & 3-B Earthworks vs. Conventional Polar Response

Within 12dB

500Hz to

15kHz &

Within18dB

to 20kHz

500

1K

2K

5K

10K

15K

20K

5

Page 7

Nearly Twice the Amount of Rear Rejection

One of the typical disadvantages in the multi-microphone approach is picking

up the unwanted sound of other elements of the drum set from the rear of

each microphone. Conventional microphones provide only 18dB of rear rejec-

tion, while Earthworks microphones with 32dB of rear rejection provide nearly

twice the amount of rejection of conventional microphones. The Earthworks

drum mics will nearly eliminate any leakage present at the rear of the microphone. Figure 4 shows conventional drum microphones with 18dB of rear

rejection and Figure 5 shows the Earthworks drum microphones with 32dB of

rear rejection.

Conventional

Microphones

Approx 18dB

Rear Rejection

Figure 4

18dB of

Rear

Rejection

Using

Conventional

Drum mics

Figure 5

32dB of

Rear

Rejection

Using

Earthworks

Drum mics

6

Earthworks

Microphones

Approx 32dB

Rear Rejection

Page 8

Close Miking Toms and Snares with the

DM20 DrumMic™ Microphones

Inserting the DM20 Microphone into the RM1 RimMount

The RM1 is designed specifically for the DM20 allowing you to mount the microphone on the side of a tom or snare. The RM1 can also be used on the top

or bottom of a tom or snare.

It is suggested that you insert the DM20 microphone into the RM1 RimMount™

prior to attaching the RimMount™ to the drum.

To insert the DM20 microphone into the RM1 just insert the mic head and the

gooseneck into the rubber holder from the bottom of the RimMount™. Push on

the body of the microphone from the bottom (XLR connector end) to move the

microphone up inside the rubber holder. The fit will be firm, so you will need to

apply a little pressure to move the microphone body up into the rubber holder.

The suggested procedure is shown in Figure 6.

1 2 3 4

Figure 6 Inserting the DM20 DrumMic™ into the RimMount™

Mounting the RM1 RimMount™ to the Drum

The RM1 RimMount™ is designed for metal drum rims, and will not work on

wooden drum rims. Attaching the RimMount to the drum rim is quite easy.

While reading this section, please refer to Figure 7-A, which shows the various elements of the RimMount™. First, loosen the thumbscrew so there is

more than enough space for the Delrin® cushioned rim-guide to clear the

bottom of the drum rim. Then determine where on the drum rim you want to

position the microphone and place the “hook portion” of the RimMount bracket

over the desired place on the drum rim.

7

Page 9

Hook Portion

of Bracket

Soft Polyolen® Coated

Metal Bracket

Rubber

Holder

Delrin®

Cushioned Rim-guide

Thumbscrew

Figure 7-A. Elements of the RM1 RimMount™

Referring to Figure 7-B, notice that on the Delrin® cushioned rim-guide there

are two sets of grooves. One groove is in the “center” of the rim-guide (1),

while the other groove (2 & 3) is “off center” (or closer to the edge of the rimguide). These two sets of grooves provide you with “three” mounting options:

(A) using the “off center” rim-guide groove will place it closest to the drum

shell, (B) or rotating the “off center” groove 180 degrees will place the rimguide furthest away from the drum shell, and (C) the “center” groove will allow

placement in-between the positions (A) and (B).

1

Centered

Groove

2

Offset Groove

Positioned

on Left

3

Offset Groove

Positioned

on Right

Figure 7-B Positioning the Cushioned Rim-guide

Various types of metal drum rims have the bottom flange of the rim either

closer or further from the drum shell. One of the three positions (A, B or C

previously mentioned) will allow the RimMount™ bracket to be mounted parallel to the drum shell. Position the rim-guide so the bottom edge “flange” of

the drum rim fits comfortably into one of the RM-1 rim-guide grooves. This will

ensure that the cushioned rim-guide remains securely in place as you tighten

the thumbscrew to firmly secure the RM-1 to the drum rim. The soft protective

Polyolefin® coating on the RimMount™ bracket will prevent the possibility of

scratching the drum shell finish.

8

Page 10

Adjusting the Microphone Height

Once the RimMount™ is mounted securely on the drum rim with the DM20

microphone housed in the rubber holder, the microphone body can be moved

either up or down in the rubber holder to provide the desired height. Then

the gooseneck will provide a good amount of latitude in positioning the mi-

crophone head from any microphone body height. Adjusting the height of the

DM20 microphone body is indicated in Figure 8-A and 8-B.

Figure 8-A and 8-B

Adjusting the DM20

Microphone Height

A

B

Positioning the Microphone Head

Once the DM20 microphone height has been set, you can position the microphone head. It is suggested that the microphone head be positioned between 1.5

inches and 3 inches above the drumhead. The flexible gooseneck will allow you

to move the microphone head either up or down above the drumhead as well

as in and out from the drum rim. You can also change the angle of the micro-

phone head as shown in Figure 9-A. Figure 9-B shows how the microphone

head can be aimed more toward the center of the drum head by changing the

position of the gooseneck. Keep in mind that the microphone head should

never be placed “parallel” to the drumhead, but should always be at “an angle”

to the drumhead. This will prevent the microphone diaphragm being forced to

its backplate which could cause an unwanted pop or thump in the live sound

or recording system.

Figure 9-A & 9-B

Positioning the

Microphone Head

A

B

9

Page 11

The High Acoustic Sound Levels of Close Miked Drums

In close miking drums, one should keep in mind that the acoustic sound level

at the microphone head is extremely high. Microphones used for close miking

drums should be able to handle at least 140dB SPL in order to prevent audible

distortion. The DM20 DrumMic™ handles up to 150dB SPL. With these high

sound pressure levels, the DM20 microphone output level may be as much as

+15dBV which can overload some types of microphone preamplifier inputs. In-

serting the Earthworks XLR type LP20 LevelPad™ into the microphone cable

will provide 20dB of attenuation to help prevent any distortion or overload. For

full information refer to pages 1 and 2 of this manual.

Close Miking Snare Drums with the DM20

The DM20 has been optimized for miking toms and snare. With its frequency

response of 50Hz to 20kHz, it will provide a full and fat sound from your toms

and a nice crisp sound from your snare. If you feel that there is still too much low

frequency response when miking a snare, use either a high-pass lter set somewhere between 60Hz and 100Hz or a low frequency equalizer (EQ) to attenuate

(i.e. cut) a few dB in the area of 60Hz to 100Hz for the desired results. The DM20

can be used on either the top drumhead, bottom drumhead or both. Figure 10-A

shows the DM20 placed over the top drumhead of a snare, while Figure 10-B

shows a snare drum with both the top and bottom heads miked.

A

Figure 10-A and 10-B Miking the Top or Top & Bottom of a Snare

B

Close Miking Toms with the DM20

The extended low frequency response of the DM20 DrumMic™ will provide a rich

and full tom sound. You can mike either the top or bottom head of a tom with the

DM20 as indicated in Figure 11A or B, or you can mike both the bottom and top

drum heads in a similar fashion as shown on a snare in Figure 10-B.

10

Page 12

You will notice in Figure 11-A the microphone head is placed closer to the drum

rim, while in Figure 11-B the microphone head is aimed toward the center of the

drumhead by changing the position of the gooseneck. Experiment with the mi-

crophone head placement as the sound or tone can change with various placements.

Earthworks High Denition Microphones™ are widely used successfully by drummers with major artists in both recording sessions and for live performance. The

DM20 is designed to withstand the rigors of the road and will provide you with

many years of exceptional and reliable results. We know that when you use the

Earthworks DM20 DrumMics™ for your recording and live performances you will

be thrilled with the results.

A

Figure 11-A and 11-B Miking the Top Head of a Tom

B

Drum Overhead Microphone Placement

For overhead drum miking use the SR25s. The low frequency response of the

SR25 will pick up less of the kickdrum and the lower frequencies from the toms.

This will be a help during mixing and provide more control in the mix from the

individual tom and kickdrum mics, rather than having too much low frequency in-

formation in the overhead mics.

X/Y Stereo Overhead Miking

There are two basic ways to position overhead drum mics, either by putting the

mics in an X/Y position or by separating the microphones by some pre-determined

distance. The X/Y position will provide less of a stereo image than the separated

microphone method.

11

Page 13

A

B

Figure 12-A Figure 12-B

Horizontal X/Y Positioning Vertical X/Y Positioning

Figures 12-A and 12-B show two variations of X/Y microphone placement. For

microphone “height” we suggest that you start with the microphone approxi-

mately 2 feet above the drummer’s head. Moving them down will provide more

detail, while moving them higher will capture a wider overall image along with

more room sound. Both the horizontal and vertical X/Y positioning will provide

excellent results in a drum booth or an acoustically treated small room as well

as a large room. If you are using a drum booth or a room with a low ceiling, the

horizontal X/Y version shown in Figure 12-A may be more ideal, as it requires

less height.

Separated Overhead Miking

Another overhead miking approach is called “Separated Overhead Miking.” In

this approach, the microphones are farther apart from each other and can be

positioned closer to the drum set if desired. Placing the overhead mics closer

to certain elements of the drum set can reduce the ambient room sound while

picking up more subtle details of the drums. When using Earthworks High De-

nition Microphones as overheads, you can bring the microphones down closer

to the drums without fear of hearing cymbal splash or splatter.

12

Page 14

A

Overhead miking

front view

B

Overhead miking

aiming positions

top view

Figure 13-A and 13-B Separated Overhead Miking

Miking the Hi-Hat

There are many various approaches to miking a hi-hat. We suggest that you use

an SR25 or DM20 and place it approximately two inches above the top hi-hat

cymbal (see Fig 14-A). You can also place the microphone under the hi-hat in

relatively the same position as shown in Figure 14-B. However, if the microphone

is placed close to where the two cymbals come together, bursts of air from the two

cymbals coming together may result in an undesirable thumping or popping sound

(see Fig 14-C).

A

B

C

Figure 14-A, B & C Miking a Hi-hat (front view)

We also suggest that you place the microphone approximately 2 to 3 inches from

the edge of the hi-hat cymbals (see Fig 15).

13

Page 15

Figure 15 Miking a Hi-hat (top view)

Using the SR20LS on Kickdrum with No Hole in the Front Head

The Earthworks SR20LS microphone is supplied for miking kickdrums and is a

precision condenser microphone which is sensitive to large bursts of air. Howev-

er, this microphone, when positioned properly, will produce an incredible kickdrum

sound. For optimum results it is crucial to place the SR20LS at a 45 degree angle

to the head (which reduces the air burst at the front of the microphone). Whether

your kickdrum has a front head or not, place the SR20LS at a 45 degree angle to the

front of the drum head as indicated in Figure 16-B and 16-C. Do not place the front

of the microphone parallel with the drum head as shown in Figure 16-A.

In our eld tests, we achieved the best results and the best sound by miking the

drum just off of the rim as shown in Figure 16-B, or you can mic the center of the

kickdrum as shown in gure 16-C. Whatever your approach, if you get any pop-

ping from the air bursts, place the enclosed windscreen on the kickdrum mic, and

place the mic at a 45 degree angle to the drum head.

DO NOT MIKE

LIKE THIS!

A B C

Figure 16-A, 16-B and 16-C Miking a Kickdrum

Miking a Kickdrum with a Hole in the Front Head

If there is a hole in the front head of the kickdrum, do not place the mic directly

in front, or slightly inside of the hole as there will be a large burst of air hitting

the microphone. The velocity of the air is dramatically reduced when placing the

microphone head inside the kickdrum (several inches inside). This will still allow

14

Page 16

you to get the nice fat bottom end in addition to hearing more of the snap of the

beater from the rear head. We suggest that you experiment with placement of the

SR20LS using the guidelines shown in Figures 17 A through E. Again, keep in

mind that the highest velocity of air from the hole is “slightly outside” the hole or

“slightly inside” the hole. So, placing the microphone where there is less air ve-

locity will yield the best results. Figure 17-A & B show our suggestions for placing

the SR20LS inside the hole of the front drum head where there is less air velocity.

With the microphone inside the drum (Figure 17-A) it should not matter whether

the microphone is parallel or at an angle to the beater head. If you do get some

pops, then place the enclosed foam windscreen on the SR20/SL kickdrum mic.

Figures 17-C, 17-B & 17-E show where not to place the kickdrum microphone.

Correct Placement of SR20LS in Hole of Front Drum Head

A

Figure 17-A Mic tip approx 6”

inside kickdrum

Incorrect Placement of SR20LS in Hole of Front Drum Head

Figure 17-C, Mic tip too

close to Hole outside

Front Drum Head

E

Figure 17-D Mic tip too close to Hole

from outside Front Drum Head

B

Figure 17-B Mic tip approx half-

way inside kickdrum

C

D

Figure 17-E Mic tip too close to

Hole from inside Front Drum Head

15

Page 17

In Conclusion

We know that when you use the Earthworks DK7 DrumKit™ System for your

recording and live performances you will be thrilled with the results. We are

pleased to welcome you to the ever-growing family of artists and professionals

using Earthworks High Denition Microphones™. We hope the information and

suggestions in this manual have been benecial to you. You can be as creative

with your mic placement as you are with your music, don’t be afraid to experiment.

You are the judge of what sounds best.

If you have any questions, or require any additional information, feel free to con-

tact Earthworks using the contact information on the back cover of this manual.

NOTES:

EARTHWORKS WARRANTY

All Earthworks® products carry a limited warranty (parts and labor).

Please register your warranty at www.earthworksaudio.com/register

If you have any problems with your Earthworks products, please contact

our warranty/repair department by email at

returns@earthworksaudio.com or by telephone at (603) 654-2433, ext 119.

16

Page 18

SR25 Cardioid

for Overheads, High Hat

Frequency response

Polar Pattern

Sensitivity

Power requirements

Peak acoustic input

Signal-to-Noise Ratio

Output Impedance

Minimum output load

Dimensions L & D

50Hz to 25kHz +2dB @ 1’ (30cm)

Cardioid

10

mV/Pa (-40dBV/Pa)

24-48V Phantom @ 10mA

1

45dB SPL

74dB A-weighted

Output

XLR (PIN 2+)

65Ω bal. (between pins 2 &3 )

600Ω, balanced

between pins 2&3

20dB (A-weighted)

Noise

Length 6.5 inches (165mm)

Diameter .860 inches (22mm)

.35lb (

Weight

160

SR25

DM20 with RM1

SR20LS

g)

DM20 DrumMic

for Toms & Snare

Frequency response

Polar Pattern

Sensitivity

Power requirements

Peak acoustic input

Signal-to-Noise Ratio

Output

Output Impedance

Minimum output load

Noise

Dimensions L & D

Gooseneck L & D

Weight

SR25

Polar

Response

™

50Hz to 20kHz +2dB @ 6” (15cm)

Cardioid

8

mV/Pa (-42dBV/Pa)

24-48V Phantom @ 10mA

1

50dB SPL

74dB A-weighted

XLR (PIN 2+)

200Ω bal. (between pins 2 &3 )

1,000Ω, balanced

between pins 2&3

20dB (A-weighted)

11.12 inches (282.44mm)

.860 inches (22mm)

Length 4.75 inches (120.65mm)

Diameter .375 inches (9.53mm)

.25k

.55lb (

g)

DM20

Polar

Response

SR20LS Cardioid

for Kickdrum

Frequency response

Polar Pattern

Sensitivity

Power requirements

Peak acoustic input

Signal-to-Noise Ratio

Output

Output Impedance

Minimum output load

Noise

Dimensions L & D

Weight

50Hz to 20kHz +2dB @ 6” (15cm)

Cardioid

8

mV/Pa (-42dBV/Pa)

24-48V Phantom @ 10mA

1

50dB SPL

74dB A-weighted

XLR (PIN 2+)

200Ω bal. (between pins 2 &3 )

1,000Ω, balanced

between pins 2&3

20dB (A-weighted)

Length 7.57 inches (192.2mm)

Diameter .860 inches (21.8mm)

164

.36lb (

g)

SR20LS

Polar

Response

Made in U.S.A.

Earthworks, Inc.

37 Wilton Rd. Milford, NH 03055

603-654-2433

email: sales@earthworksaudio.com

www.earthworksaudio.com

Printed in U.S.A.

Loading...

Loading...