EarthWise CVP41810 Operator's Manual

OPERATOR’S MANUAL

ELECTRIC CONVERTIBLE 4 IN 1 COMBO

CHAIN SAW/ POLE SAW/ HEDGE TRIMMER/ POLE HEDGE TRIMMER

This product is covered by U.S. patents and other international patents

Copyright. All Rights Reserved.

This product has been engineered and manufactured to our high standard for dependability, ease of operation, and

operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before

using this product.

Thank you for your purchase.

DO NOT RETURN THIS PRODUCT TO THE STORE. OPERATING, ASSEMBLY, PARTS, SERVICE QUESTIONS?

CALL 1-800-313-5111 BETWEEN 8:00 AM—5:00 PM EST FOR ASSISTANCE.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Model CVP41810

GENERAL POWER TOOL SAFETY WARNINGS

IMPORTANT SAFETY WARNINGS

2

WARNING: Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term ―power tool‖ in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the risk

of electric shock.

Personal safety

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

Power tool use and care

Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

3

When servicing a power tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance

instructions may create a risk of shock or injury.

CHAIN SAW SAFETY WARNINGS

Keep all parts of the body away from the saw chain

when the chain saw is operating. Before you start the

chain saw, make sure the saw chain is not contacting

anything. A moment of inattention while operating chain

saws may cause entanglement of your clothing or body

with the saw chain.

Always hold the chain saw with your right hand on the

rear handle and your left hand on the front handle.

Holding the chain saw with a reversed hand configuration

increases the risk of personal injury and should never be

done.

Hold the power tool by insulated gripping surfaces

only, because the saw chain may contact hidden

wiring . Saw chains contacting a live wire may make

exposed metal parts of the power tool live and could give

the operator an electric shock.

Wear safety glasses and hearing protection. Further

protective equipment for head, hands, legs and feet is

recommended. Adequate protective clothing will reduce

personal injury by flying debris or accidental contact with

the saw chain.

Do not operate a chain saw in a tree. Operation of a

chain saw while up in a tree may result in personal injury.

Always keep proper footing and operate the chain saw

only when standing on fixed, secure and level surface.

Slippery or unstable surfaces such as ladders may cause a

loss of balance or control of the chain saw.

When cutting a limb that is under tension be alert for

spring back. When the tension in the wood fibres is

released the spring loaded limb may strike the operator

and/or throw the chain saw out of control.

Use extreme caution when cutting brush and saplings.

The slender material may catch the saw chain and be

whipped toward you or pull you off balance.

Carry the chain saw by the front handle with the chain

saw switched off and away from your body. When

transporting or storing the chain saw always fit the

guide bar cover. Proper handling of the chain saw will

reduce the likelihood of accidental contact with the moving

saw chain.

Follow instructions for lubricating, chain tensioning

and changing accessories. Improperly tensioned or

lubricated chain may either break or increase the chance

for kickback.

GENERAL POWER TOOL SAFETY WARNINGS

Service

Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery causing loss of control.

Cut wood only. Do not use chain saw for purposes

not intended. For example: do not use chain saw for

cutting plastic, masonry or non-wood building

materials. Use of the chain saw for operations different

than intended could result in a hazardous situation.

Causes and operator prevention of kickback:

Kickback may occur when the nose or tip of the guide bar

touches an object, or when the wood closes in and pinches

the saw chain in the cut.

Tip contact in some cases may cause a sudden reverse

reaction, kicking the guide bar up and back towards the

operator.

Pinching the saw chain along the top of the guide bar may

push the guide bar rapidly back towards the operator.

Either of these reactions may cause you to lose control of the

saw which could result in serious personal injury. Do not rely

exclusively upon the safety devices built into your saw. As a

chain saw user, you should take several steps to keep your

cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

Maintain a firm grip, with thumbs and fingers

encircling the chain saw handles, with both hands on

the saw and position your body and arm to allow you

to resist kickback forces. Kickback forces can be

controlled by the operator, if proper precautions are

taken. Do not let go of the chain saw.

Do not overreach and do not cut above shoulder

height. This helps prevent unintended tip contact and

enables better control of the chain saw in unexpected

situations.

Only use replacement bars and chains specified by

the manufacturer. Incorrect replacement bars and

chains may cause chain breakage and/or kickback.

Follow the manufacturer’s sharpening and

maintenance instructions for the saw chain.

Decreasing the depth gauge height can lead to increased

kickback.

4

HEDGE TRIMMER SAFETY WARNINGS

DANGER – Keep hands away from blade. Contact with

blade will result in serious personal injury.

Use both hands when operating the hedge trimmer.

Using one hand could cause loss of control and

result in serious personal injury.

Keep all parts of the body away from the cutter blade.

Do not remove cut material or hold material to be cut

when blades are moving. Make sure the switch is off

when clearing jammed material. Blades coast after turn

off. A moment of inattention while operating the hedge

trimmer may result in serious personal injury.

Carry the hedge trimmer by the handle with the cutter

blade stopped. Proper handling of the hedge trimmer will

reduce possible personal injury from the cutter blades.

Hold the power tool by insulated gripping surfaces

only, because the cutter blade may contact hidden

wiring or its own cord. Cutter blades contacting a ―live‖

wire may make exposed metal parts of the power tool

―live‖ and could give the operator an electric shock.

Keep cable away from cutting area. During operation

the cable may be hidden in shrubs and can be

accidentally cut by the blade.

WARNING – Only use with handle and guard properly

assembled to hedge trimmer. The use of the hedge trimmer

without the proper guard or handle provided may result in

serious personal injury.

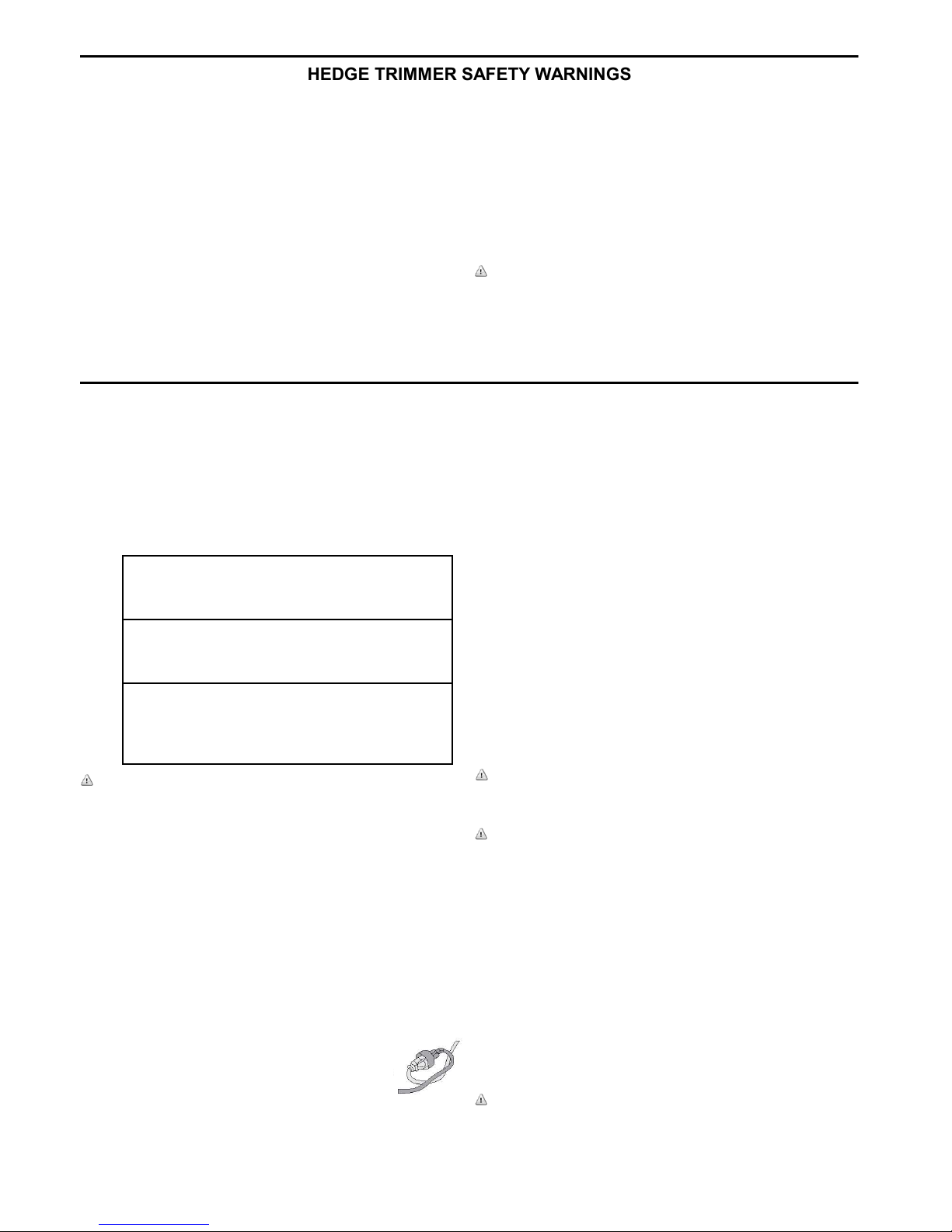

EXTENSION CORD. Make sure your extension cord is in

good condition. When using an extension cord, be sure it is

heavy enough to carry the current your product will draw. An

undersized extension cord will cause a drop in line voltage

resulting in loss of power and overheating. The following

table shows the correct size to use depending on cord length

and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier the

cord.

WARNING: Use out door extension cords marked SW-A,

SOW-A, STW-A, SJW-A, or SJTW-A. These cords are rated

for outdoor use and reduce the risk of electric shock.

DOUBLE INSULATION—Double Insulation is a concept in

safety in electric power tools, which eliminates the need for

the usual three-wire grounded power cord. All exposed metal

parts are isolated from the internal metal motor components

with protecting insulation. Double insulated tools do not need

to be grounded.

NOTE: The double insulated system is intended to protect

the user from shock resulting from a break in the tool’s

internal insulation. Observe all normal safety precautions to

avoid electrical shock.

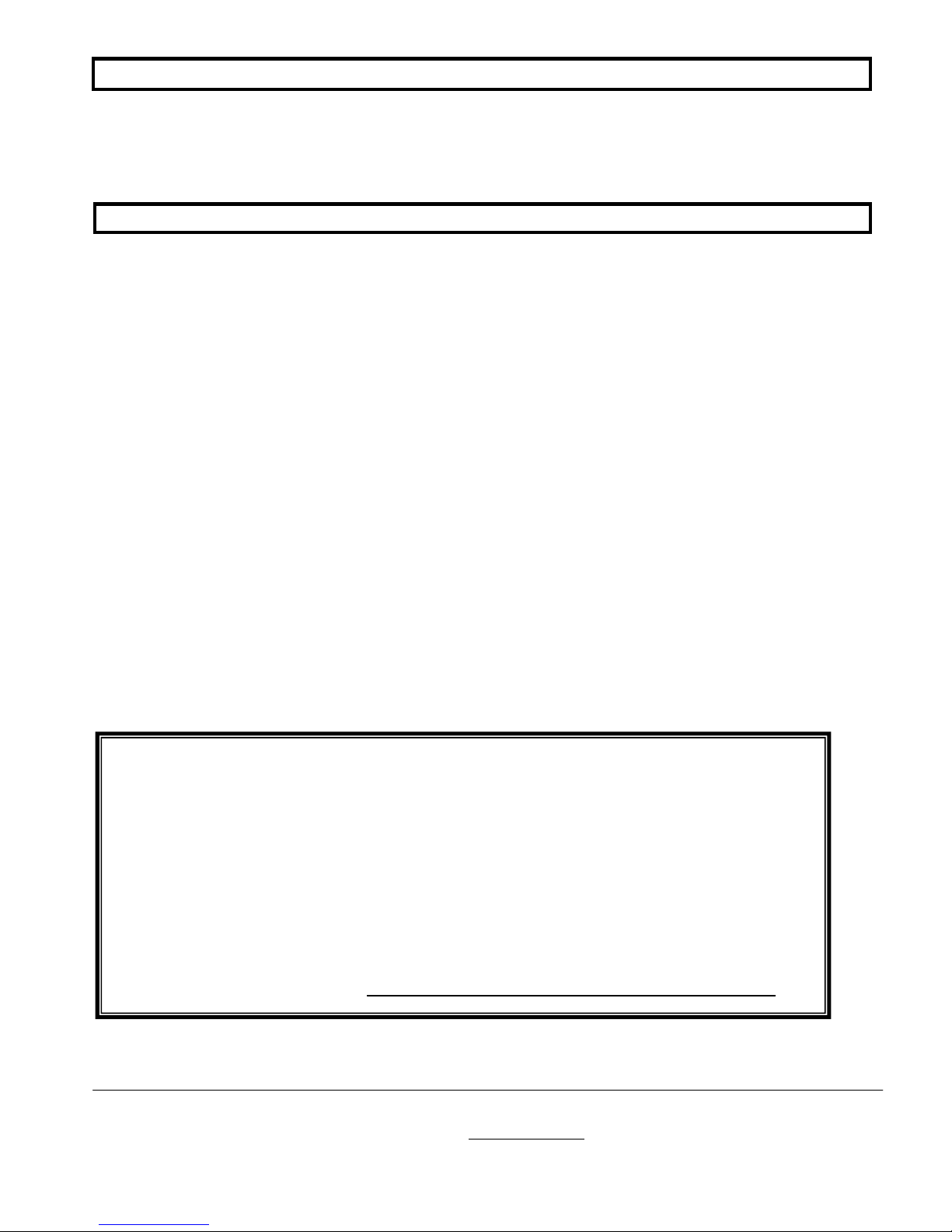

It is possible to tie the extension cord and power

cord in a knot to prevent them from becoming

disconnected during use. Make the knot as

shown, then connect the plug end of the power

cord into the receptacle end of the extension

cord. This method can also be used to tie two

extension cords together.

Minimum Gage for Cord Sets

Volts Total Length of cord in Feet

120V 0-25 26-50 51-100 101-150

Ampere Rating

More Not More American wire Gage

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

POLARIZED PLUGS—To reduce the risk of electric shock,

this equipment has a polarized plug (one blade is wider than

the other). This equipment must be used with a suitable

polarized 2 wire or 3 wire extension cord. Polarized

connections will fit together only one way. Make sure that the

receptacle end of the extension cord has large and small

blade slot widths. If the plug does not fit fully into the

extension cord, reverse the plug. If it still does not fit obtain a

suitable extension cord. If the extension cord does not fit fully

into the outlet, contact a qualified electrician to install the

proper outlet. Do not change the tool plug or extension cord in

any way.

CHECK DAMAGED PARTS – Before further use of the tools,

a guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting and any

other condition that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced.

Call our customer service help line at 1-800-313-5111 for

assistance.

WARNING: California Proposition 65: This product

contains chemicals known to the State of California to cause

cancer, birth defect or other reproductive harm.

WARNING: Some dust and debris created by the use of this

tool could contain chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm.

Some examples of these chemicals are:

Chemicals in fertilizers

Compounds in insecticides, herbicides and

pesticides

Arsenic and chromium from chemically treated

lumber

Your risk from exposure to these chemicals varies,

depending on how often you do this type of work. To reduce

your exposure, work in a well-ventilated area and with

approved safety equipment, such as dust masks that are

specially designed to filter out microscopic particles.

WARNING: DO NOT USE ON A LADDER OR UNSTABLE

SUPPORT. Stable footing on a solid surface enables better

control of the power tool in unexpected situations.

Steel Blade Support - Hardened Steel Blades - Telescopic Pole - Blade Guard - Bar Cover

PRODUCT SPECIFICATIONS

CVP41810

Pole/ Chain Saw Pole/ Hedge Trimmer

Input….………………………….….……..120V, 60Hz, 7A, AC Only ………………….….…………….…….120V, 60Hz, 4.5A, AC Only

Speed ………………………..……………...…………………...12m/s ……………………………………….……….3200 Strokes per Min.

Bar Length……………………………...…...……..10 in. Oregon Bar …………………………………………….……………………..18 in.

Extended Length…………...………………..………...…………. 8 ft. ……………………………………………….………….……….8.8 ft.

Max. Cut …………..………...………………..………...…………………..…………………………………………….………….……….0.7 in.

Weight ……………………………….……………………….10.27 Ibs. ………………………………………………………………..…9.7 lbs.

5

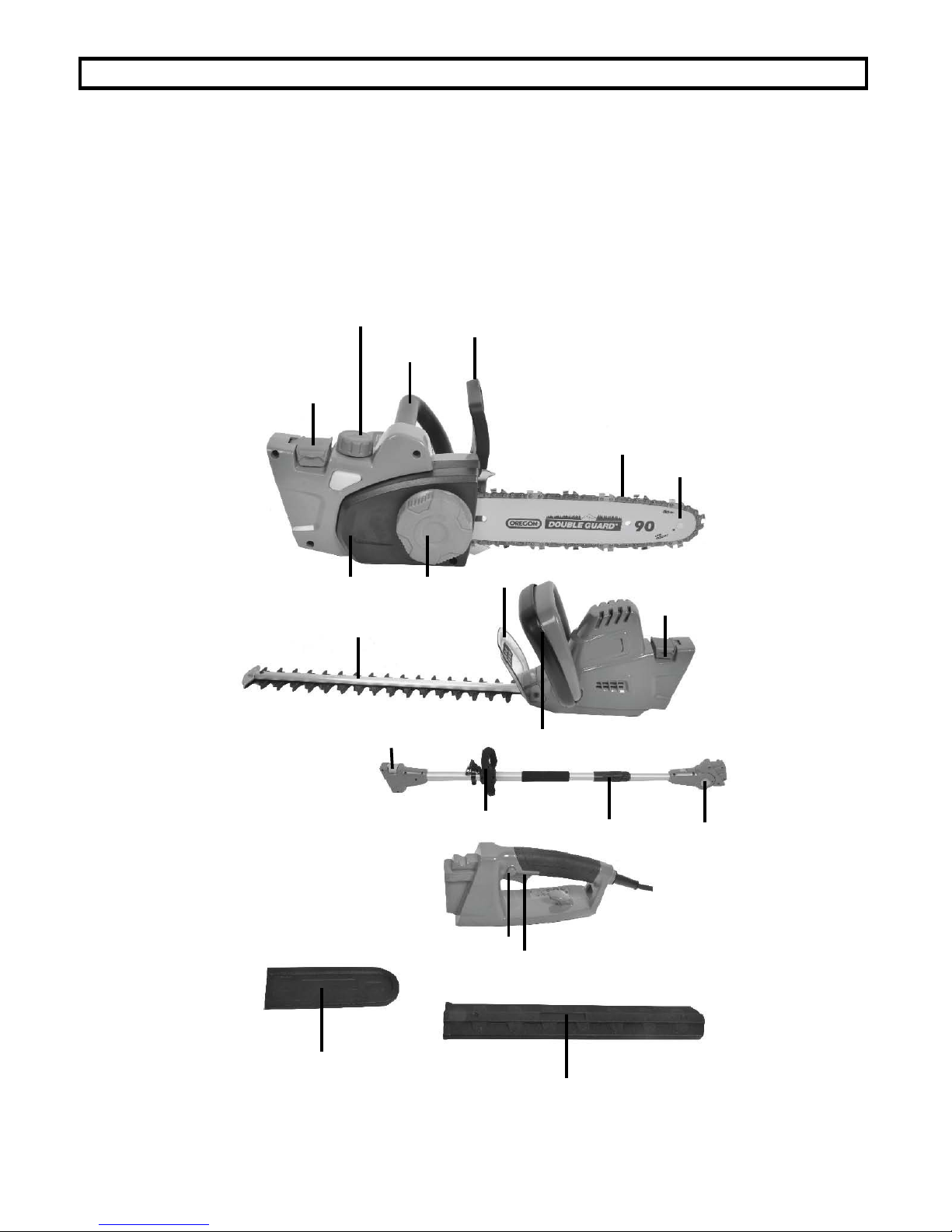

Chain

Guide Bar

Hand Guard/ Chain Brake

Front Handle

Oil Tank Cap

Quick Release Button

Tension Knob

Quick Release Button

Guard

Front Handle/Safety Switch

Cutter Blade

Shoulder Strap

Quick Release Button

Locking Collar Angle Adjustment Button

Safety Button

Trigger Switch

Bar Cover

Blade Cover

Chain Cover

PACKING LIST

Hedge Trimmer Cutting Head - Chain Saw Cutting Head

Blade Covers - Telescopic Pole w/Should Strap - Rear

Handle - Instruction Manual

WARNING: If any parts are damaged or missing do not operate this

product until the parts are replaced. Failure to heed this warning

could result in serious personal injury.

If any parts are damaged or missing, please call 1-800-313-5111 for

assistance.

UNPACKING

This product requires assembly.

Carefully remove the product and any accessories from the box.

Make sure that all items listed in the packing list are included.

Inspect the product carefully to make sure no breakage or damage

occurred during shipping.

Do not discard the packing material until you have carefully inspected

and satisfactorily operated the product.

ASSEMBLY

6

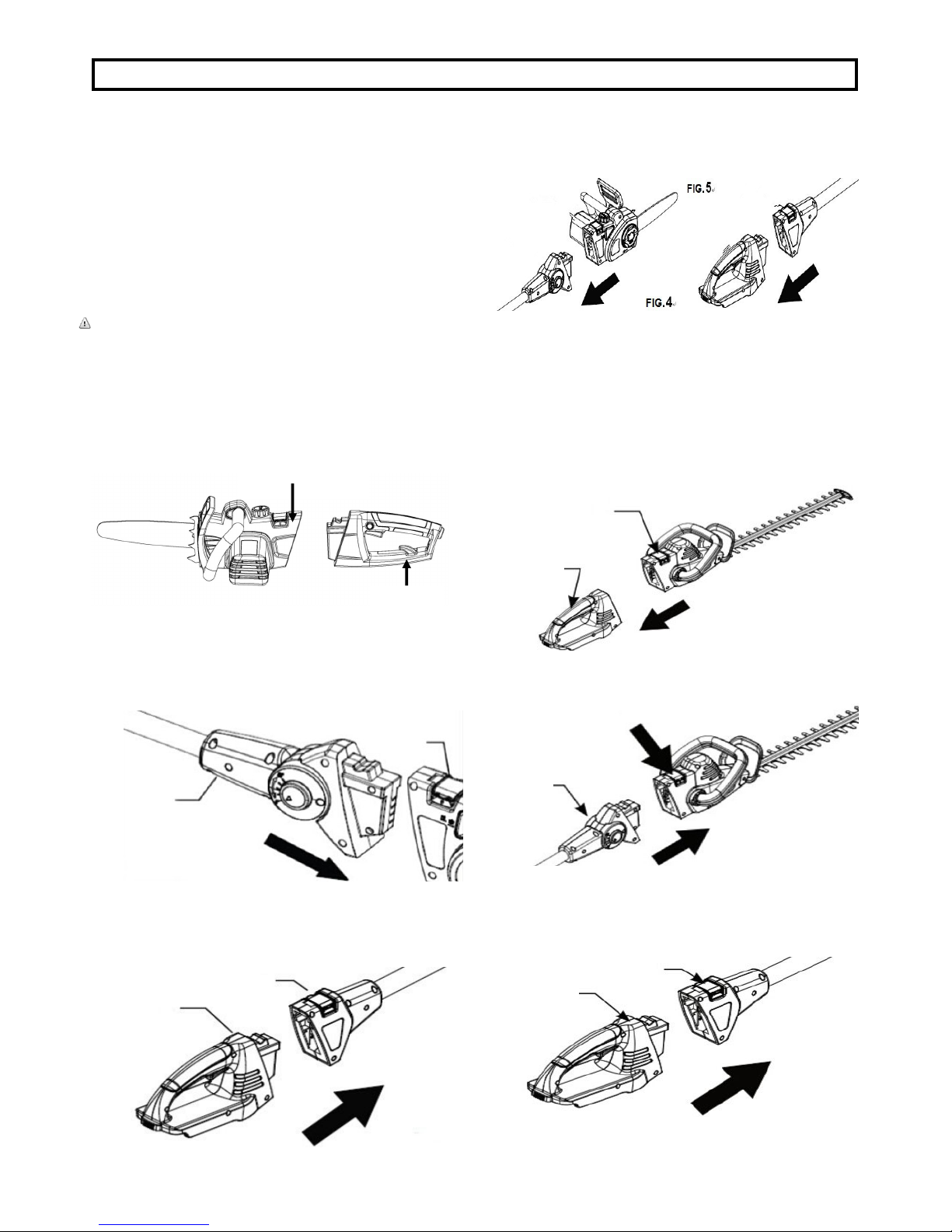

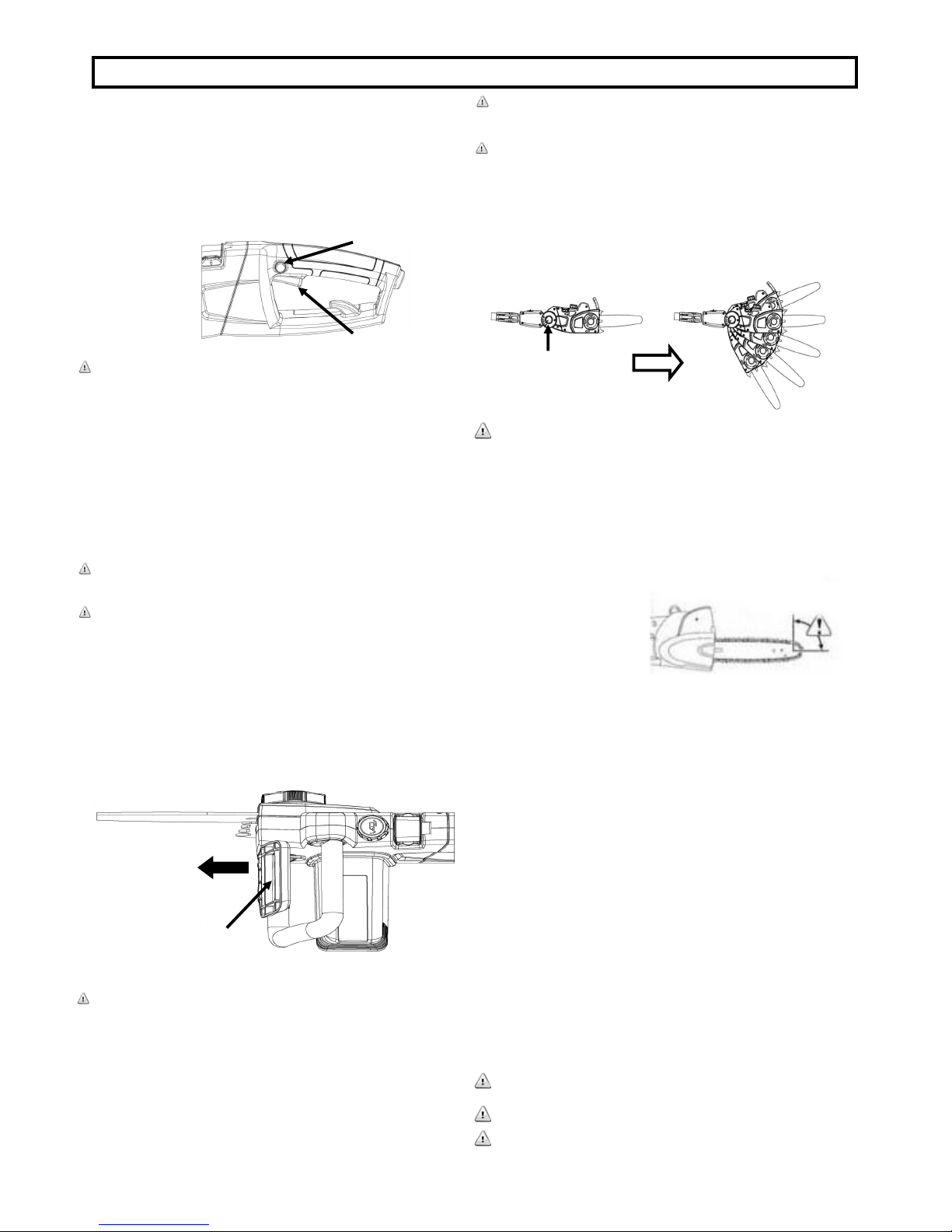

CONVERTING FROM CHAIN SAW TO POLE SAW

1. Lift the quick release button. Pull to remove the handle from the

cutting head. (Fig. 1)

2. Insert the telescopic pole into the chain saw cutting head. Press

down the quick release button. Make sure the release button

snaps firmly to lock the parts securely. (Fig. 2)

3. Insert the rear handle into the end of the telescopic pole. (Fig. 3)

Press down the quick release button. Ensure the release button

snaps firmly into position to lock the handle securely.

CONVERTING FROM POLE SAW TO CHAIN SAW

1. Disconnect rear handle and cutting head from ends of tele-

scopic pole by lifting the quick release button and pulling straight

out. (Fig. 4-5)

2. Insert the rear handle directly into the chainsaw cutting head .

When fully inserted, press down the quick release button.

Make sure the button snaps in firmly and securely, locking the

parts together.

CONVERTING FROM HEDGE TRIMMER TO POLE HEDGE

TRIMMER

1. Lift the quick release button. Pull to remove the handle from the

cutting head. (Fig. 6)

2. Insert the telescopic pole into the hedge trimmer cutting head.

(Fig. 7) Press the quick release button into a locked position.

3. Insert the rear handle into the end of telescopic handle. (Fig. 8)

Press down the quick release button. Ensure the release button

snaps firmly into position to lock the handle securely.

Pole

FIG. 2

Quick Release

Button

FIG. 3

Pole

Rear

Handle

FIG. 6

Quick Release

Button

Rear

handle

Quick Release

Button

Pole

FIG. 7

FIG.8

Rear

Handle

Quick Release

Button

FIG. 1

Quick release button

Rear handle

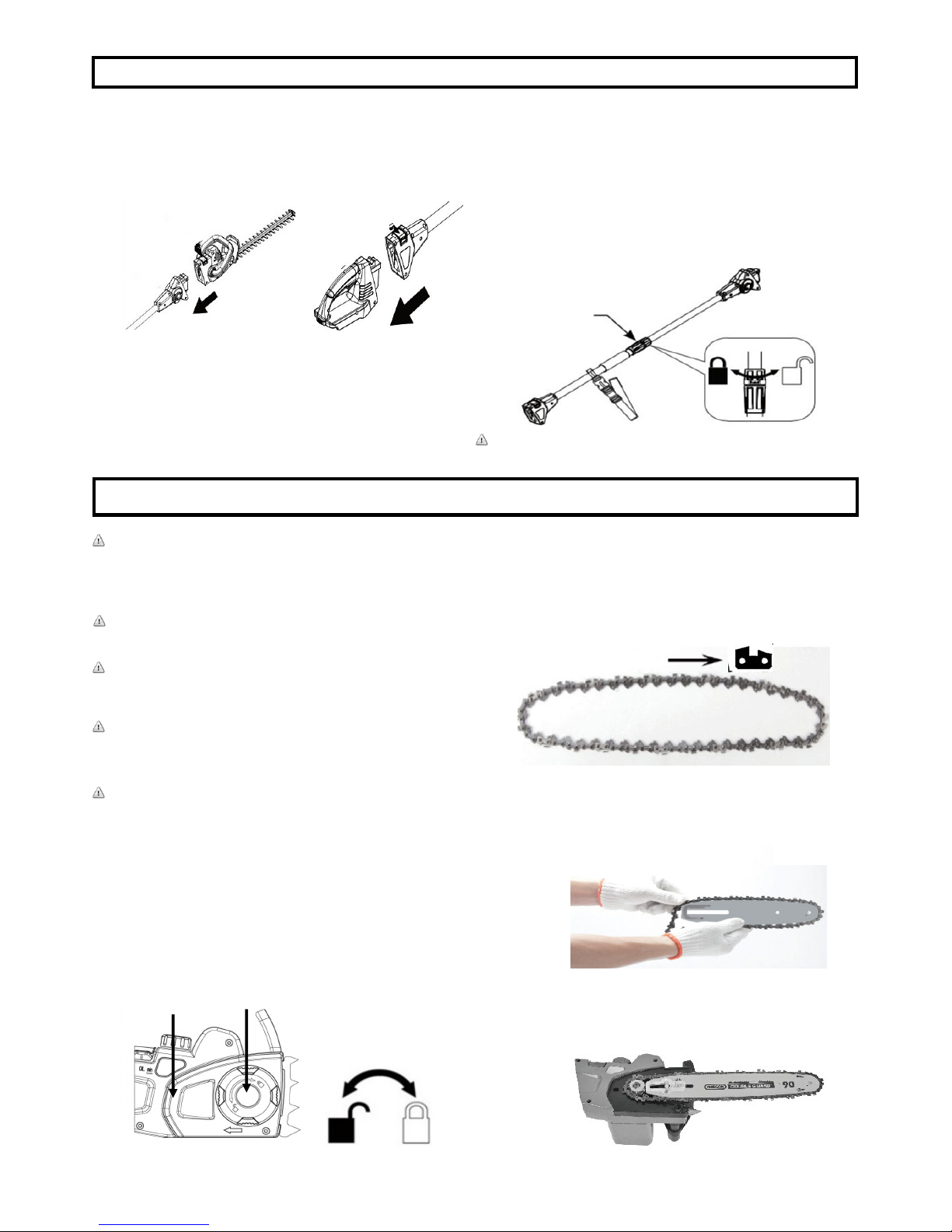

CONVERTING FROM POLE HEDGE TRIMMER TO HEDGE

TRIMMER

1. Disconnect rear handle and cutting head from ends of

telescopic pole by lifting the quick release button and pulling

straight out. (Fig. 9-10)

2. Insert the rear handle directly into the chainsaw cutting head .

When fully inserted, press down the quick release button.

Make sure the button snaps in firmly and securely, locking the

parts together.

ASSEMBLY

7

ADJUSTING THE LENGTH OF THE TELESCOPIC POLE (FIG.11)

1. To adjust the telescopic pole, disconnect the product from

the power supply. Rotate the collar counterclockwise to

loosen.Extend the pole to the desired length.

NOTE: Only extend the pole to minimum length required to

reach the limb or shrub to be cut.

2. Lock the pole in position by turning the collar clockwise

firmly to secure.

WARNING: Failure to lock the telescopic pole collars as directed

could result in personal injury.

FIG.9 FIG.10

INSTALLING/REPLACING THE GUIDE BAR AND CHAIN

DANGER: Never start the motor before installing the guide bar,

chain, chain cover and tension knob. Without all these parts in

place, the clutch can fly off or explode, exposing the user to

possible serious injury.

WARNING: To avoid serious personal injury, read and

understand all the safety instructions provided.

WARNING: Before performing any maintenance, make sure

the tool is unplugged from the power supply. Failure to heed

this warning could result in serious personal injury.

CATUION: Always wear gloves when handling the bar and

chain; these components are sharp and may contain burrs,

which can cause serious injury.

WARNING: Never touch or adjust the chain while the motor

is running. The saw chain is very sharp. Always wear

protective gloves when performing maintenance to the chain

to avoid possible serious lacerations.

NOTE: When replacing the guide bar and chain, use only

identical replacement parts.

1. Disconnect the saw from power supply.

2. Loosen the tension knob by turning counterclockwise.

3. Remove the chain cover.(Fig. 12)

4. Remove the bar and chain from the mounting surface.

5. Remove the old chain from the bar.

6. Lay out the new chain in a loop, and straighten any kinks.

The cutters should face in the direction of the chain

rotation. If they face backwards,turn the loop over.(Fig. 13)

7. Place the chain drive links into the bar groove.

NOTE: Make certain of the direction of chain.

8. Position the chain so there is a loop at the back of the bar.

(Fig. 14)

9. Hold the chain in position on the bar and place the loop

around the sprocket.(Fig. 15)

FIG. 12

FIG. 14

FIG. 15

FIG.11

Locking

Collar

FIG. 13

Cutter Direction

Chain cover

Tension knob

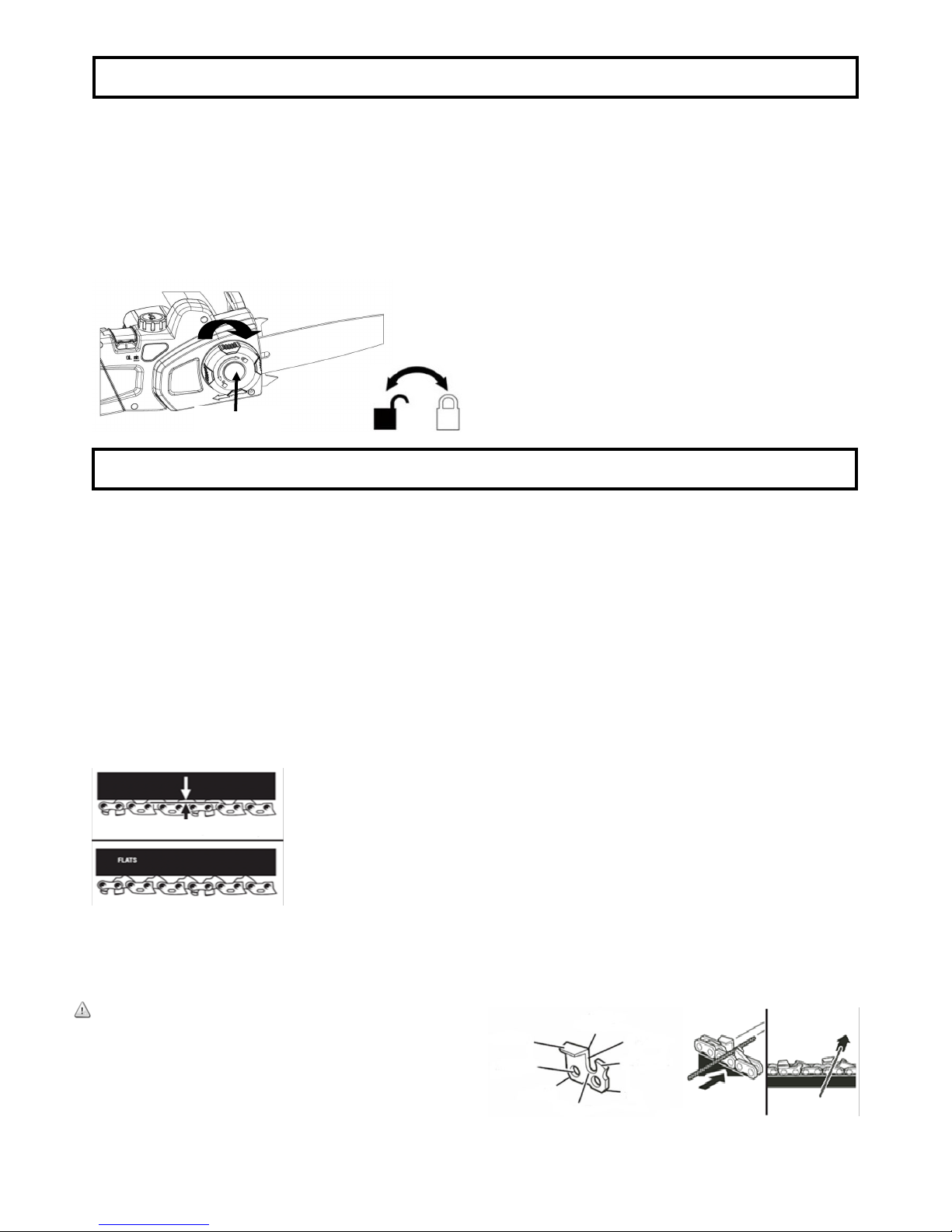

10. Fit the bar flush against the mounting surface so that the bar

stud is in the slot of the bar.

NOTE: When placing the bar on the bar stud, ensure that the

adjusting pin is in the chain tension pin hole.

11. Replace the chain cover.

12. Tighten the tension knob. Remove all slack from the chain by

turning the knob clockwise until the chain seats snugly against

the bar with the drive links in the bar groove. (Fig. 16)

INSTALLING/REPLACING THE GUIDE BAR AND CHAIN

8

13. When the tension knob is fully tightened, the chain is the

tightest. To minor adjust the chain tension, loosen the tension

knob and turn it counter-clockwise slightly until the chain is

correctly tensioned.

NOTE: The chain is correctly tensioned when there is no sag on the

underside of the guide bar, then chain is snug, but it can be turned by

hand without binding.

NOTE: A new chain tends to stretch, check chain tension

frequently and tension as required.

14. After a period of usage, the chain may get loose. To tighten the

chain, loosen the tension knob by turning counter-clockwise,

repeat 12 and 13 to correctly adjust the chain tension.

CHAIN TENSION AND MAINTENANCE

CHAIN TENSION

Stop the motor before setting the chain tension. Make sure the

tension knob is loosened to finger tight, turn the tension knob clockwise to tension the chain. A cold chain will be correctly tensioned

when there is no slack on the underside of the guide bar, the chain is

snug, but it can be turned by hand without binding.

Chain must be re-tensioned whenever the flats on the drive links hang

out of the bar groove.

During normal saw operation, the temperature of the chain will

increase. The drive links of a correctly tensioned warm chain will hang

approximately .050 in. (1.25mm) out of the bar groove. (Fig. 17) Be

aware that chain tensioned while warm, may be too tight upon cooling. Check the ―cold tension‖ before next use.

NOTE: A new chain tends to stretch, check chain tension frequently

and tension as required.

Approx. .050 (1.25mm)

CHAIN MAINTENANCE

CAUTION: Disconnect the saw from the power supply and make sure

the chain has stopped before you do any work on the saw.

For smooth and fast cutting, chain needs to be maintained properly.

The chain requires sharpening when the wood chips are small and

powdery, the chain must be forced through the wood during cutting,

or the chain cuts to one side. During maintenance of your chain

remember:

- Improper filing angle of the side plate can increase the risk

of severe kickback.

- Raker (depth gauge) clearance.

Too low increases the potential for kickback.

Not low enough decreases cutting ability.

- If cutter teeth have hit hard objects such as nails and stones, or

have been abraded by mud or sand on the wood, have service

dealer sharpen chain.

NOTE: Inspect the drive sprocket for wear or damage when

replacing the chain. If signs of wear or damage are present in the

areas indicated, have the drive sprocket replaced by a qualified

individual.

HOW TO SHARPEN THE CUTTERS

Be careful to file all cutters to the specified angles and to the same

length, as fast cutting can be obtained only when all cutters are

uniform.

Wear gloves for protection. Properly tension the chain prior to

sharpening. Refer to ―Chain Tension Section‖ earlier in this manual.

Do all of your filing at the midpoint of the bar.

Use a 5/32 in. diameter round file and holder.

Keep the file level with the top plate of the tooth. Do not let the file dip

or rock. Using light but firm pressure, stroke towards the front corner

of the tooth. (Fig. 18)

FIG.17

FIG.18

Cutting

Corner

Top Plate

Rivet Hole

Heel

Gullet

Toe

Depth Gauge

Side Plate

FIG.16

Tension knob

CHAIN TENSION AND MAINTENANCE

9

Lift file away from the steel on each return stroke.

Put a few firm strokes on every tooth. File all left hand cutters in one

direction. Then move to the other side and file the right hand cutters

in the opposite direction. Occasionally remove filing from the file with

a wire brush. (Fig. 19)

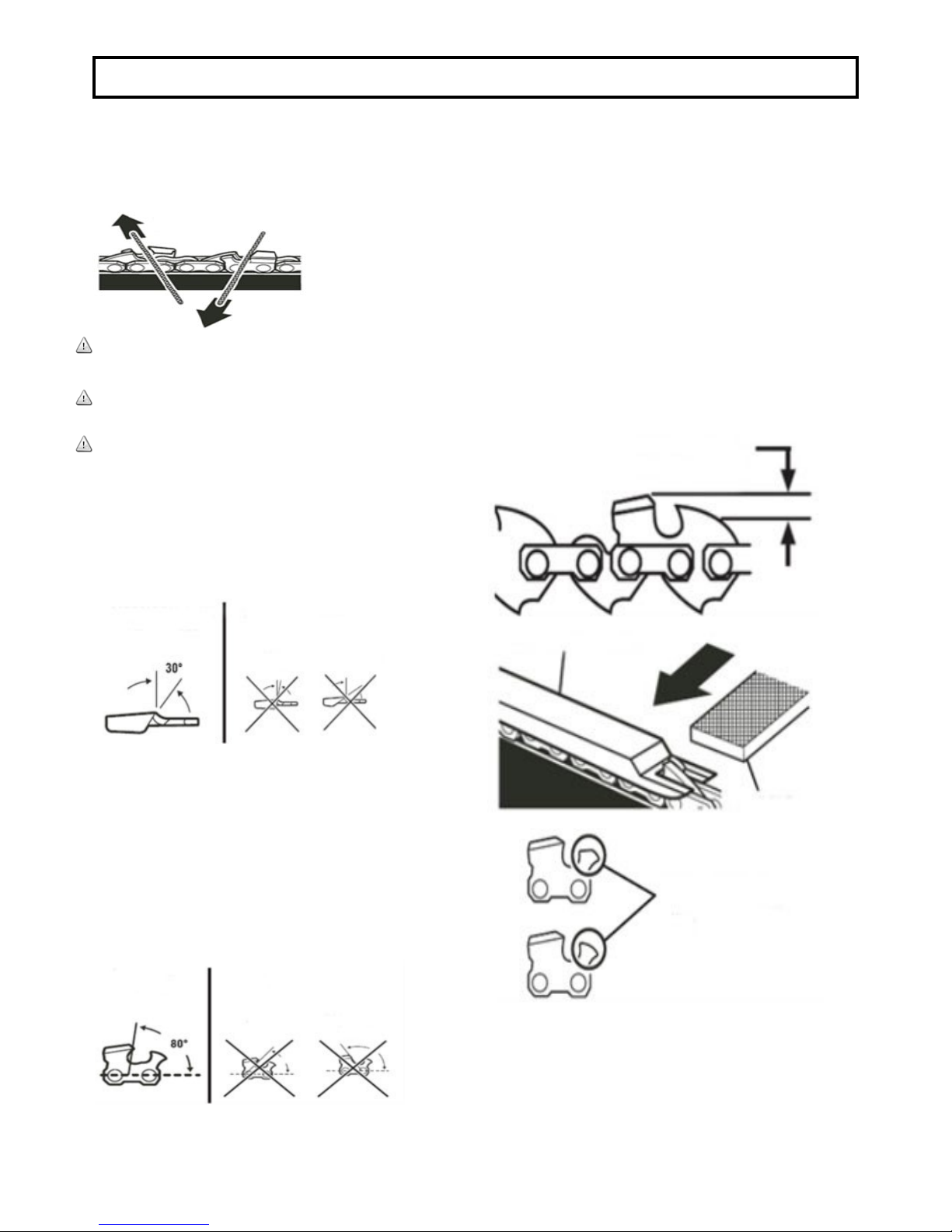

DEPTH GAUGE CLEARANCE (Fig. 22)

The depth gauge should be maintained at a clearance of .025 in.

(0.6 mm). Use a depth gauge tool for checking the depth gauge

clearances.

Every time the chain is filed, check the depth gauge clearance.

Use a flat file and a depth gauge jointer to lower all gauges uniformly.

Depth gauge jointers are available in .020 in. to .035 in. (0.5 mm to

0.9 mm). Use a .025 in. (0.6 mm) depth gauge jointer. After lowering

each depth gauge, restore original shape by rounding the front. Be

careful not to damage adjoining drive links with the edge of the file.

Depth gauges must be adjusted with the flat file in the same direction

the adjoining cutter was filed with the round file. Use care not to

contact cutter face with flat file when adjusting depth gauges.

WARNING: Improper chain sharpening increases the potential of

kickback.

WARNING: Failure to replace or repair damaged chain can cause

serious injury.

WARNING: The saw chain is very sharp, always wear protective

gloves when performing maintenance to the chain.

TOP PLATE FILING ANGLE (Fig. 20)

Correct 30 degrees – File holders are marked with guide marks to

align file properly to produce top plate angle.

Less than 30 degrees – for cross cutting.

More than 30 degrees – feathered edge dulls quickly.

SIDE PLATE ANGLE (Fig. 21)

Correct – 80 degrees produced automatically if correct diameter file is

used in file holder.

Hook – ―Grabs‖ and dulls quickly. Increases potential of kickback.

Results from using a file with a diameter too small, or file held too

low.

Backward Slope – Needs too much feed pressure, causes

excessive wear to bar and chain. Results from using a file with a

diameter too large, or file held too high.

FIG.19

FIG.20

FIG.21

FIG.22

Left Hand Cutters

Right Hand Cutters

CORRECT TOP PLATE

FILING ANGLE

INCORRECT TOP PLATE FILING

ANGL

LESS THAN

30°

MORE THAN

30°

CORRECT SIDE

PLATE FILING

ANGLE

INCORRECT SIDE PLATE

FILING ANGL

HOOK BACKWARD

SLOPE

RAKER CLEARANCE

.025 in. (0.6mm)

DEPTH GAUGE JOINTER

FLAT FILE

RESTORE ORIGIINAL

SHAPE BY ROUNDING

THE FRONT

ADJUSTING THE ANGLE OF POLE SAW HEAD (Fig. 25)

1. To adjust the sawing angle, pressing the angle adjustment button.

2. Turn the saw to the desired angle.

3. The angle can be kept between -20 and 60 degrees.

Before you start the unit, make sure the pole/chain saw is not

contacting any object.

STARTING THE POLE/CHAIN SAW

Push the safety button in with your thumb and then squeeze the

switch trigger with your fingers. Once the tool is running, you can

release the safety button. To turn the tool OFF, release the switch

trigger. (Fig. 23)

WARNING: To guard against injury, observe the following:

Read instruction manual before using.

Save instruction manual.

Keep hands away from blades.

Keep hands on handles. Don’t overreach.

A good, firm grip on the pole/ chain saw with both hands will help you

maintain control. Grip the rear handle with your right hand whether

you are right or left handed. Wrap the fingers of your left hand over

and around the front handle when using the chainsaw, or around the

pole shaft when using the pole saw. A firm grip together with positioning handle against your body will help you maintain control of the saw.

Don’t let go.

WARNING: Do not operate pole saw in a tree, on a ladder, or on a

scaffold; this is extremely dangerous.

CAUTION: Chain coasts after pole saw is turned off. Do not use under wet conditions.

Use extreme caution when cutting small size brush, saplings or limbs

under tension, because slender and tense material may catch the saw

and be whipped toward you, pull you off balance or spring back.

CHAIN BRAKE

When using the chainsaw, in case an emergency stop is necessary,

use the back of your hand to push hard the hand guard forward.

Chain will stop immediately. (Fig. 24)

CAUTION: Failure to lubricate the chain will cause damage to the bar

and chain. Use only a good quality bar and chain oil or, if not available, unused SAE 30 weight motor oil may be substituted. One minute

of use will consume approx. 0.15 fl. oz. (5ml) of oil.

NOTE: It is normal for oil to seep from the chainsaw cutting head

when not in use. To prevent seepage, empty the oil tank after each

use. When storing the unit for a long period of time (3 months or

longer) be sure the chain is lightly lubricated; this will prevent rust on

the chain and bar sprocket.

OPERATING

10

WARNING: Kickback may occur when the moving chain contacts an

object at the upper portion of the tip of the guide bar or when the

wood closes in and pinches the chain saw in the cut. Contact at the

upper portion of the tip of the guide bar can cause the chain to dig

into the object and stop the chain for an instant. The result is a

lightening fast, reverse reaction which kicks the guide bar up and

back toward the operator. If the chain saw is pinched along the top of

the guide bar, the guide bar can be driven rapidly back toward the

operator. Either of these reactions can cause loss of saw control

which can result in serious

injury. Do not rely exclusively

upon the safety devices built

into the saw. As a chain saw

user, you should take several

steps to keep your cutting

jobs free from accident or

injury.

The following precautions should be followed to minimize

kickback:

1. Always grip the pole and/or handles firmly with both hands when

unit is running. When using the chainsaw, place your right hand

on the rear handle and your left hand on the front handle with

your thumbs and fingers encircling the chainsaw handles. When

using as a pole saw, place one hand on the pole and your other

hand on the rear handle with your thumbs and fingers encircling

the pole and handle. A firm grip together with positioning handle

against your body will help you maintain control of the saw if

kickback occurs.

2. Make sure that the area in which you are cutting is free from

obstructions. Do not let the nose of the guide bar contact a log,

branch, fence or any other obstruction that could be hit while you

are operating the saw.

3. Always cut with the unit running at full speed. Fully squeeze the

throttle trigger and maintain a steady cutting speed.

4. Wear non-slip gloves for maximum grip protection.

Cut lower branches first to allow the top branches more room to fall.

Work slowly, keeping both hands on the saw with a firm grip.

Maintain secure footing and balance.

WARNING: To protect yourself from electrocution, maintain a min. of

50 ft. (15m) from over head electrical lines.

WARNING:Keep bystanders at least 50 ft. away.

WARNING: Do not cut trees near electrical wires or buildings.

WARNING: Do Not use the pole saw with any type of accessory or

attachment. Such usage might be hazardous.

WARNING: Beware of the cord while operating the saw. Keep the

cord away from the chain. Be careful not to trip over the

extension cord.

FIG.23

KICKBACK

DANGER ZONE

Safety Button

Switch Trigger

FIG.25

Angle Adjustment

Button

-20°

20°

40°

60°

Hand Guard

FIG.24

OPERATING AND INSTRUCTIONS

11

PROPER CUTTING STANCE

Weight should be balanced with both feet on solid ground.

Keep left arm with elbow locked in a ―straight arm‖ position to

withstand any kickback force when using pole saw. Your right hand

should be gripping the handle and positioned firmly against body for

added support.

Your body should always be to the left of the chain line.

BASIC CUTTING PROCEDURE

Do not use the pole saw to fell saplings. Use the chain saw without

the pole attachment.

Small trees up to 6-7 inches in diameter are usually cut in a single

cut. Large tree limbs require notch cuts. Notch cuts determine the

direction the tree will fall.

WARNING: If the tree limb starts to fall in the wrong direction, or if

the saw gets caught or hung up during the fall, leave the saw and

save yourself.

WARNING: Periodically glance at the top of the tree during the

back-cut to assure the tree limb is going to fall in the desired direction.

Practice cutting a few small limbs using the following technique to

get the ―feel‖of using the saw before you begin a major sawing

operation.

Take the proper stance in front of the wood with the saw in the

―off‖position.

Squeeze the trigger and let the chain accelerate to full speed before

entering the cut.

Always hold the saw firmly with both hands.

Keep the unit running the entire time you are cutting, maintain a

steady speed.

Allow the chain to cut for you; exert only light downward pressure. If

you force the cut, damage to the bar, chain, or unit can result in

serious injury.

Do not put pressure on the saw at the end of the cut.

When felling the top of a small tree,keep everyone a safe distance

from the cutting area.During felling operations, the safe distance

should be at lease twice the height of the largest trees in the felling

area.If the tree makes contact with any utility line, the utility company

should be notified immediately.

Always cut with both feet on solid ground to prevent being pulled or

knocked off balance.

Do not extend arms above shoulder level when operating the pole saws.

Do not cut above chest height when using the chain saw.

FELLING A TREE

When bucking and felling operations are being performed by two or

more persons, at the same time, the felling operation should be

separated from the bucking operation by a distance of at least twice

the height of the tree being felled. Trees should not be felled in a

manner that would endanger any person, strike any utility line or

cause any property damage. If the tree does make contact with any

utility line, the utility company should be notified immediately.

Before felling is started, consider the force and direction of the wind, the

lean and balance of the tree, and the location of large limbs. These

things influence the direction in which the tree will fall. Do not try to fell a

tree along the line different from its natural line of fall.

The saw operator should keep on the uphill side of the terrain as the

tree is likely to roll or slide downhill after it is felled.

Remove dirt, stones, loose bark, nails, staples, and wire from the tree

where felling cuts are to be made.

NOTCHED UNDERCUT– Cut a notch about 1/3 diameter of the tree,

perpendicular to the direction of the fall. Make the cuts of the notch so

they intersect at a right angle to the line of fall. This notch should be

cleaned out to leave a straight line. To keep the weight of the wood off

the saw, always make the lower cut of the notch before the upper cut.

WARNING: Do not fell trees during periods of high wind or heavy

precipitation. Wait to do your cutting until the hazard has ended.

WARNING: Do not cut down trees having an extreme lean or large

trees that have rotten limbs, loose bark, or hollow trunks. Have these

trees pushed or dragged down with heavy equipment , then cut them

up.

FELLING BACK-CUT

The back-cut is always made level and horizontal, and at a minimum of

2 inches (5cm) above the horizontal cut of the notch.

Never cut through to the notch. Always leave a band of wood between

the notch and back-cut (approximately 2 inches (5cm) or 1/10 the

diameter of the tree). This is called ― hinge‖ or ―hinge wood‖. It controls

the fall of the tree and prevents slipping or twisting or shoot-back of the

tree off the stump.

This saw is not designed to fell large diameter tree tops, or tree trunks.

PLANNED

LINE OF FALL

SAFE

RETREAT

ZONE

SAFE

RETREAT

ZONE

PLANNED LINE OF FALL

SAFE

RETREAT

ZONE

PLANNED PATH OF SAFE RETREAT

135° FROM PLANNED LINE OF FALL

FIG. 26

WARNING: Check the tree for damaged or dead branches that could fall

and hit you during felling.

Before any cuts are started, pick your escape route (or routes in case

the intended route is blocked); clear the immediate area around the tree

and make sure there are no obstructions in your planned path of retreat.

A clear path of safe retreat is approximately 135 degrees from planned

line of fall. The retreat path should extend back and diagonally to the

rear of the expected line of fall.(Fig. 26)

OPERATING

12

CUTTING INSTRUCTIONS

As the tree limbs starts to fall, stop the saw and immediately retreat

along the cleared path. Watch the action in case something falls your

way. Be alert for overhead limbs or branches that may fall and watch

your footing.

WARNING: Never cut through to the notch when making a back-cut.

The hinge controls the fall of the tree, this is a section of wood between the notch and back-cut.(Fig. 27)

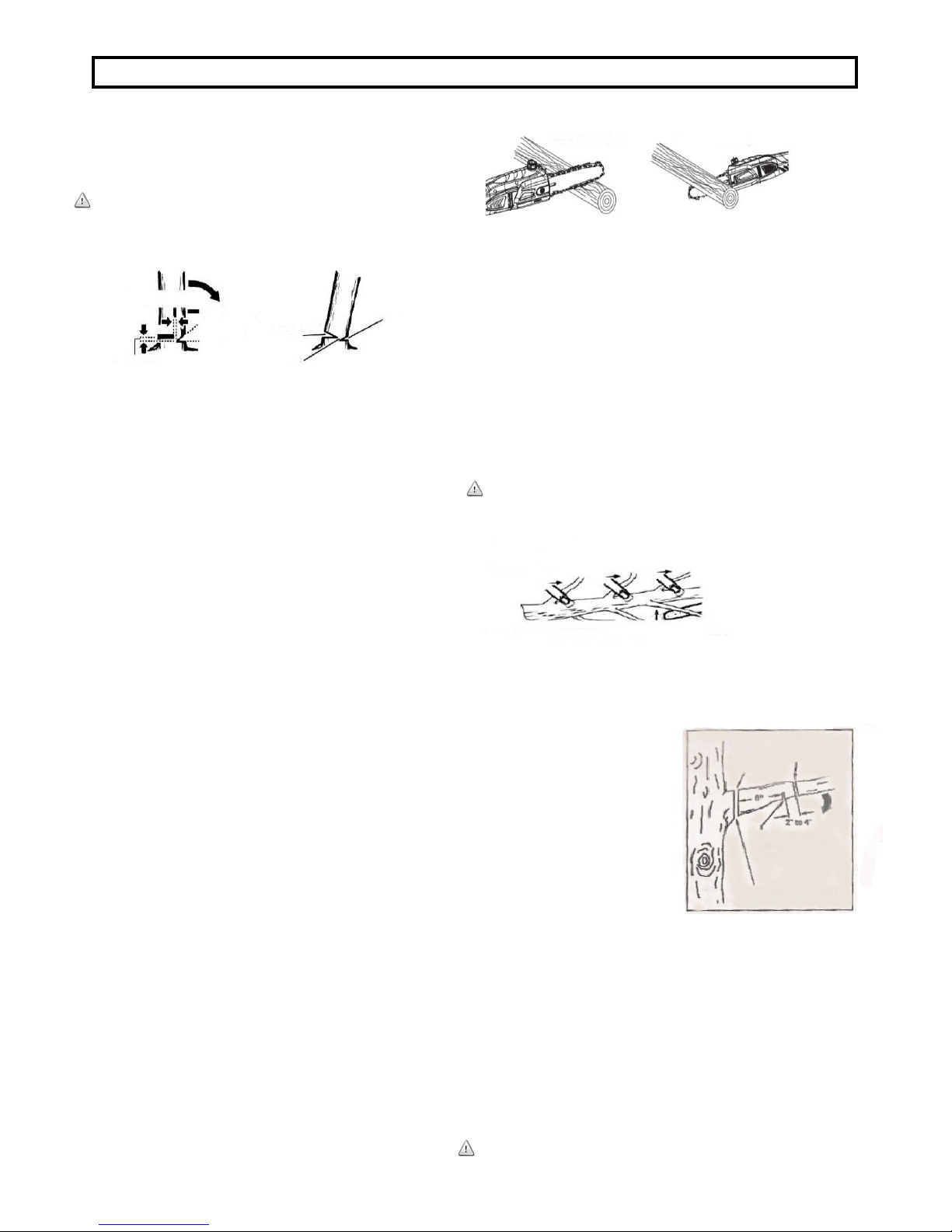

BUCKING

Bucking is the term used for cutting a fallen tree to the desired log

length.

Always make sure your footing is secure and your weight is

distributed evenly on both feet.

Cut only one log at a time, Support small logs on a saw horse or

another log while bucking.

Keep a clear cutting area. Make sure that no objects can contact the

guide bar nose and chain during cutting, this can cause kickback.

When bucking on a slope, always stand on the uphill side of the log.

When ―Cutting through‖, to maintain complete control of the pole saw,

release the cutting pressure near the end of the cut without relaxing

your grip on the pole saw handles. Do not let the chain contact the

ground After completing the cut, wait for the saw chain to stop before

you move the pole saw. Always stop the motor before moving from

tree to tree.

BUCKING LOGS UNDER STRESS

When the log is supported along its entire length, it should be cut from

the top or over-bucking.

When the log is supported on one end, cut 1/3 diameter from the

underside or under-bucking. Then make the finishing cut by

over-bucking to meet the first cut.

As the log is being cut, it will tend to bend The saw can become

pinched or hung in the log if you make the first cut deeper than 1/3 of

the diameter of the log.

Give special attention to logs under stress to prevent the bar and

chain from pinching.

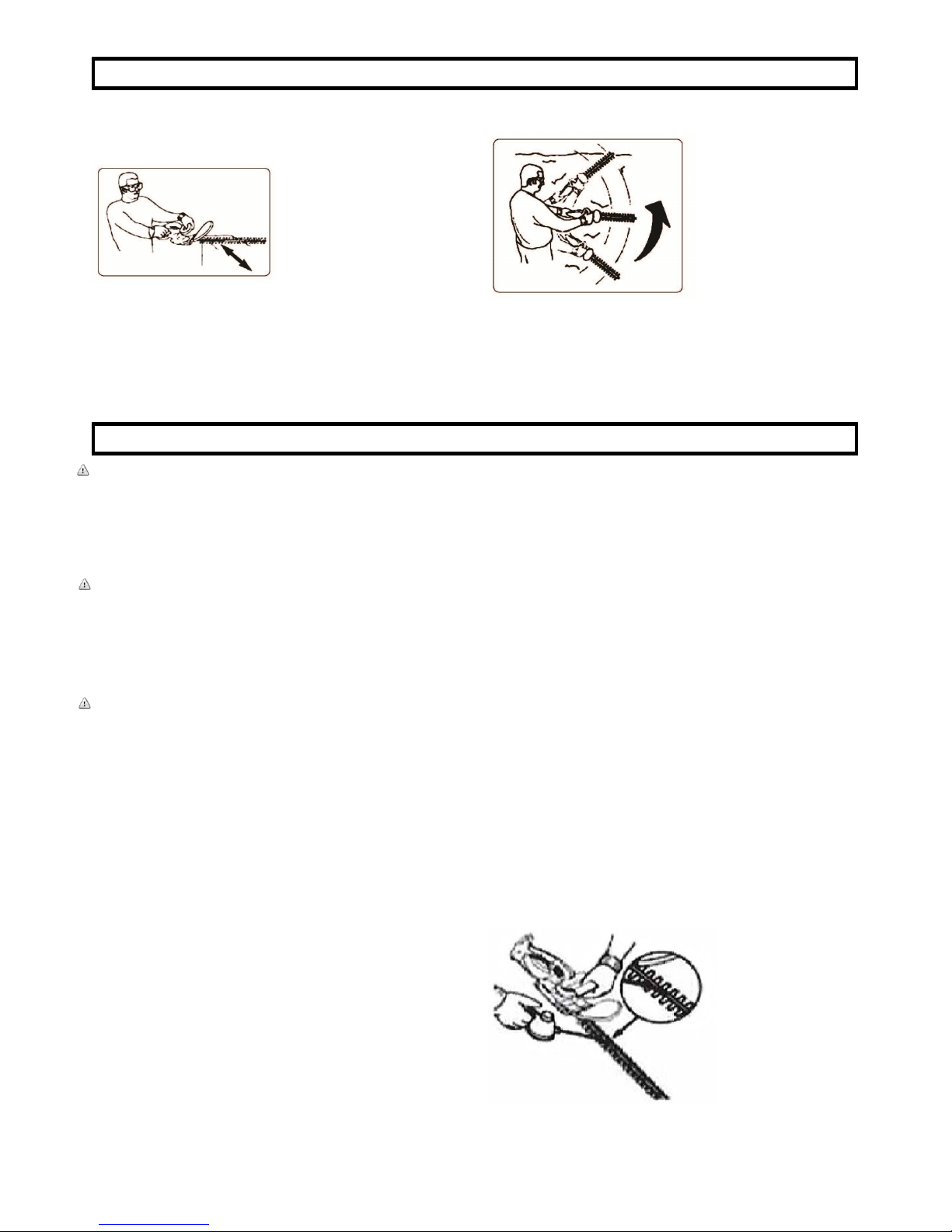

OVERBUCKING - Begin on the top side of the log with the button of

the saw against the log; exert light pressure downward. Note that the

saw will tend to pull away from you. (Fig. 28)

UNDER-BUCKING - Begin on the under side of the log with the top of

the saw against the log; exert light pressure upward. During

under-bucking, the saw will tend to push back at you. Be prepared for

this reaction and hold the saw firmly to maintain control. (Fig. 28)

LIMBING (Fig. 29)

Limbing is removing branches from a fallen tree.

Work slowly, keeping both hands on the pole saw with a firm grip.

Always make sure your footing is secure and your weight is distributed

evenly on both feet.

Leave the larger support limbs under the tree to keep the tree off the

ground while cutting.

Limbs should be cut one at a time. Remove the cut limbs from the work

area often to help keep the work area clean and safe.

Branches under tension should be cut from the bottom up to avoid binding the pole saw.

Keep the tree between you and the pole saw while limbing. Cut from the

side of the tree opposite the branch you are cutting.

WARNING: Never climb into a tree to limb or prune. Do not stand on

ladders, platforms, a log, or in any position which can cause you to lose

your balance or control of the saw.

PRUNING (Fig. 30)

Pruning is trimming limbs from a live tree.

Work slowly, keep both hands on

the pole saw with a firm grip and the

handle positioned firmly against your

body for added control and ease of

handling. Always make sure your

footing is secure and your weight is

distributed evenly on both feet.

When pruning trees it is important

not to make the finishing cut next to

the main limb or trunk until you have

cut off the limb further out to reduce

the weight. This prevents stripping

the bark from the main member.

Make first cut six inches from tree trunk as possible on underside of limb

stub. Use top of guide bar to make this cut. Cut 1/3 through diameter of

stub.

Move two to four inches farther out on limb. Make second cut from

above limb. Continue cut until you cut limb off.

Make third cut as close to tree trunk as possible on underside of limb

stub. Use top of guide bar to make this cut. Cut 1/3 through diameter of

stub.

Make fourth cut directly above third cut. Cut down to meet third cut. This

will remove limb stub.

SPRINGPOLES

A spring pole is branch, or sapling which is bent under tension by other

wood so that it springs back if the wood holding it is cut or removed.

WARNING: Watch out for spring poles, they are dangerous, They could

result in severe or fatal injury.

FIG.27

FIG.29

FIG.30

HINGE

2 IN. (5CM) OR 1/10 DIA

BACK CUT

2 IN. (5 CM)

NOTCH

APPROX. 1/3

DIAMETER

OF TRUNK

HINGE

BACK CUT

OVERBUCKING UNDER-BUCKING

LIMBING

CUT LIMBS ONE AT A TIME AND LEAVE SUPPORT

LIMBS UNDER TREE UNTIL LOG IS CUT

3rd Cut-Stub Undercut

(to avoid splintering)

2nd Cut-Pruning

Cut (to avoid

pinching)

1st Cut-Pruning

Undercut (to

avoid splintering)

4th Cut-Final

Stub Cut

PRUNING

Fig. 28

CAUTION: Blade coasts after turned off.

- Do not use under wet condition.

- Do not use with damaged extension cord.

- Do not unplug or store with switch locked on.

Before you start the unit, make sure the pole/ hedge trimmer is

not contacting any object.

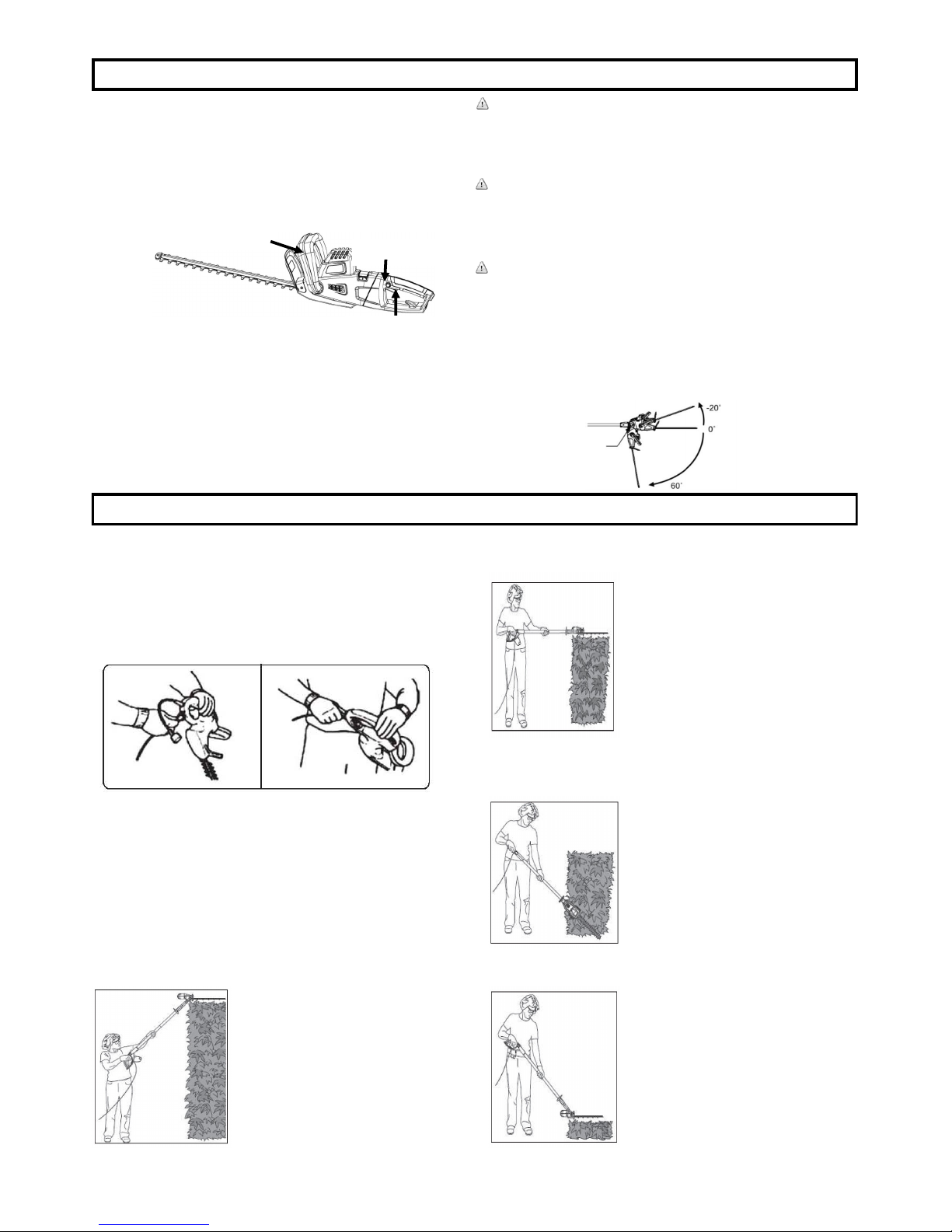

STARTING THE POLE HEDGE TRIMMER/ HEDGE TRIMMER (Fig.

31)

When using the hedge trimmer, use your left hand to grip the front

handle with double switch, while the right hand press the safety

button and squeeze the trigger switch to start unit. Release the safety

button once the trimmer is started.

When using the pole hedge trimmer, grip the pole shaft with your left

hand, while use your right handle to press the safety button and

squeeze the trigger switch to start unit. Once the tool is running, you

can release the safety button.

Release either the trigger switch or front handle to stop the machine

when using the hedge trimmer. Release the trigger switch to stop the

machine when using the pole hedge trimmer.

WARNING: To guard against injury, observe the following:

- Read instruction manual before using.

- Save instruction manual.

- Keep hands away from blades.

- Keep hands on handles. Don’t overreach.

WARNING: Do not allow familiarity with this type of product to make

you careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

EXTENSION CORD - Always keep extension cord behind trimmer

and away from the trimming operation. Never drape it over a hedge

being trimmed. If you cut or damage the cord, unplug it at the

electrical outlet immediately, before inspection or repairing the cord.

You may also place the extension cord in the cord retainer. Form a

loop in extension cord and push the loop through the hole in the rear

handle. Position the loop over the cord retainer and pull back to secure. Connect power cord of unit to extension cord. (Fig. 33)

OPERATING

13

WORKING POSITION– Maintain proper footing and balance and do

not overreach. Wear safety goggles, non--skid footwear and rubber

gloves when trimming. Hold the tool firmly in both hands and turn the

tool ON. Always hold the trimmer with right hand on the switch handle

and left hand on the front handle or telescopic pole if using as a pole

trimmer. Never hold the tool by the blade guard.

TRIMMING INSTRUCTIONS

USING THE POLE HEDGE TRIMMER

To use the pole hedge trimmer for trimming tall, hard-to-reach

hedges or shrubs, hold the trimmer at the positions shown below.

(Fig. 34) Pivot the power head to several different positions to

shape or sculpt shrubs or hedges.

To use the pole trimmer for trimming smaller hedges or shrubs,

hold the pole hedge trimmer at the position as shown.(Fig. 35)

To use the pole hedge trimmer for trimming the bottoms and

sides of hedges and shrubs. Hold the pole hedge trimmer at

the positions as shown.(Fig. 36)

To use the pole hedge trimmer for trimming low-lying foliage or

ground cover, hold the pole hedge trimmer at the position as shown.

(Fig. 37)

FIG.33

FIG.34

FIG.35

FIG.36

FIG.37

ADJUSTING THE ANGLE OF POLE HEDGE TRIMMER HEAD (Fig.

32)

1. To adjust the sawing angle, pressing the angle adjustment button.

2. Turn the saw to the desired angle.

3. The angle can be kept between -20 and 60 degrees.

FIG.32

Angle Adjustment

Button

FIG.31

Front Handle with Double Switch

Safety Button

Trigger Switch

BEFORE USING: Fill oil well with new quality bar and chain oil.

Unused SAE30 weight motor oil may be substituted.

If you drop the product, carefully inspect it for damage. If the blade is

bent or cracked, handles broken or if you see any other condition that

may affect the product’s operation, it must be repaired before putting

it back into use. Call our customer service help line at 1-800-3135111 for assistance.

CAUTION: Do not at any time let brake fluids, gasoline, petroleum

based products, penetrating oils, etc., come in contact with plastic

parts. They contain chemicals that can damage, weaken or destroy

plastic.

Make sure the unit is detached from the power supply, then use only

mild soap and a damp cloth to clean the tool. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY,

repairs, maintenance and adjustment should be performed by a

qualified individual using identical replacement parts only.

Ensure that the plastic bar covers are in place when storing.

For smooth and fast cutting, chain needs to be maintained properly.

The chain requires sharpening when the wood chips are small and

powdery, the chain must be forced through the wood during cutting,

or the chain cuts to one side. Refer to instructions earlier in this manual for instructions on properly sharpening the chain.

LUBRICATION SYSTEM FOR POLE/CHAIN SAW

The chain is automatically lubricated.

Use only new bar and chain oil or unused SAE 30 weight motor oil

may be substituted. Never use wasted oil, low quality oil, or insufficient oil. This could damage the pump; the bar and the chain which

may result in serious personal injury.

Check oil level before each work session, refill if less than ¼ full.

If the lubrication system does not work properly, check if the oil filter

and all oil-ways are clean and free from obstructions. If it is still not

working, call our customer service help line at 1-800-313-5111 for

assistance.

GUIDE BAR MAINTENANCE

When the guide bar shows signs of wear, reverse it on the saw to

distribute the wear for maximum bar life. The bar should be cleaned

every day of use and checked for wear and damage.

The cutting blades are made from high quality, hardened steel and

with normal usage, they will not require re-sharpening. However, if

you accidentally hit a wire fence, stones, glass or other hard objects,

you may put a nick in the blade. There is no need to remove this nick

as long as it doesn’t interfere with the movement of the blade. If it

does interfere, make sure the unit is detached from the power supply

and use a fine toothed file or sharpening stone to remove the nick.

Fertilizers and other garden chemicals contain agents which greatly

accelerate the corrosion of metals Do not store the tool on or

adjacent to fertilizers or chemicals.

LUBRICATE BLADES - Stop the unit and disconnect the power cord.

Then remove any debris on blades. Apply a light machine oil along

the edge of the top and bottom blade supports. Make sure handles

remain clean and dry.

MAINTENANCE

SIDE-TRIMMING HEDGES—Begin at the bottom and sweep up.

(Fig. 39)

Do not force the trimmer through dense growth. A slight back and

forth sawing action may ease the cutting of larger, more dense

growth. If the trimmer begins to slow down, reduce the rate of speed

at which you are trying to cut. If the trimmer becomes jammed,

immediately turn trimmer off. Disconnect trimmer from the power

supply and remove the jammed debris from the cutting blades.

TRIMMING INSTRUCTIONS

14

LEVEL HEDGES - To obtain exceptionally level hedges, a piece of

string can be stretched along the length of the hedge as a guide. (Fig.

38)

CAUTION: Do not use the 18 inch trimmer for cutting stems greater

than .7‖. Use the trimmer only for cutting normal shrubbery found

around houses and buildings.

TRIMMING NEW GROWTH—A wide, sweeping motion, feeding the

blade teeth through the twigs is most effective. A slight downward tilt

of the blade in the direction of the motion gives the best cutting.

USING THE HEDGE TRIMMER

Feathering or burring of the bar rails is a normal process of bar wear.

Such faults should be smoothed with a file as soon as they occur.

A bar with any of the following faults should be replaced.

- Wear inside the bar rails which permits the chain to lay over

side ways.

- Bent guide bar

- Cracked or broken rails

- Spread rails

In addition, guide bars with a sprocket at their tip must be lubricated

frequently with a grease syringe to extend the guide bar life. Using a

grease syringe, lubricate weekly in the lubricating hole.

LUBRICATION SYSTEM FOR POLE HEDGE TRIMMER/HEDGE

TRIMMER (Fig. 40)

FIG.38

FIG.39

FIG.40

Call us first with questions about operating or maintaining your product

at 1.800.313.5111 between 8:00 a.m. – 5:00 p.m. Eastern Standard Time,

or send emails to earthwise@reelin.com.

CALL US FIRST !!

Problem Possible Cause Possible Solution

Unit does not run Extension cord not connected to

the plug

Check extension cord is fully connected to tool

Cord not connected to power

source

Check extension cord is fully connected to a live receptacle

Trigger switch not fully operated Check that safety lock of button is fully depressed prior to

moving trigger

Chain brake is engaged Pull hand guard back toward front handle

Slow running, noisy or hot blades Dry, corroded blades Lubricate blades

Blades or blade support bent Straighten blade or blade support

Bent or damaged teeth Straighten teeth

Loose blade bolts Tighten blade bolts

— Bar and chain running hot and

smoking

Check chain tension for

over-tight condition

Adjust chain tension

Chain oil tank empty Fill tank with chain oil

Chain installed in wrong

direction

Reverse chain so that cutters face the right direction

— Motor runs but chain is not rotating

Chain tension too tight Adjust chain tension

Check guide bar and chain for

damage

Replace damaged bar and chain with identical replacement

parts.

15

STORAGE

TROUBLE SHOOTING

Store the tool in a dry, clean area out of reach of children.

During extended periods of storage, ensure that the tool is

protected against corrosion and rust.

At the end of the season, or if the tool is not being used for

longer than a month, wipe over all metal surfaces with an oil

impregnated cloth to protect them from corrosion or spray with

a fine coat of oil.

SERVICE

Now that you have purchased your tool, should a need ever exist for repair parts or service, simply contact us

at 1-800-313-5111. Be sure to provide all pertinent facts when you call or visit.

REPAIR PARTS

Please record your serial number in the space provided below.

• NAME OF ITEM ELECTRIC CONVERTIBLE 4 IN 1 COMBO

• MODEL NUMBER CVP41810

• SERIAL NUMBER

Loading...

Loading...