Page 1

Connecting Your Kompressor (S-10 & S-12)

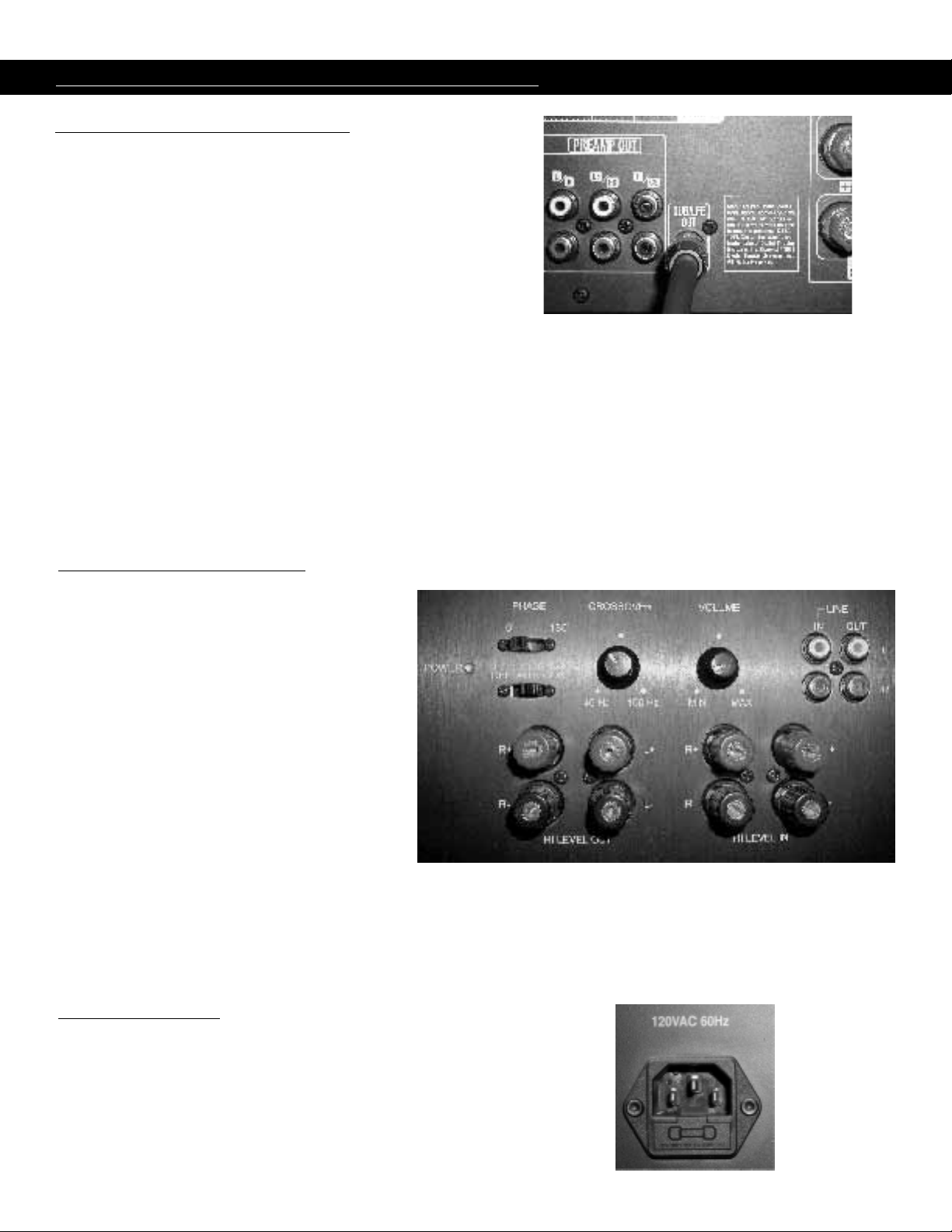

Low level -RCA- audio input connection:

This is the best way to drive an audio signal into the

Kompressor subwoofer. Today, all signal processors(5.1/6.1 and more

advanced ones) come equipped with built-in pre-amplifier outputs

(RCA) that include a subwoofer output.

Generally, the SUB/OUT is in mono format. As shown in the

photos across, connect the SUB/OUT from the processor to the

Kompressor using a "Y" connector to feed both RCA inputs of the

subwoofer.

We strongly recommend that you use the best available RCA

connectors and cables. High quality cables are normally triple shielded,

and the connectors are gold plated with forceful grasping (refer to

Earthquake line of accessories- SI superior Interconnect - at

www.earthquakesound.com).

RCA connection from Processor to

a Kompressor using a "Y" connector.

High level audio input connection:

This is the least desired way to drive an

audio signal into the subwoofer. Older stereo

systems are not equipped with pre-amplifier audio

outputs, normally they come with stereo speaker

outputs (left & right).

Using "banana" plugs, connect the speaker

outputs to the corresponding Subwoofer high level

inputs (marked "FROM RECEIVER). In this

configuration, the front stereo speakers (towers)

can be powered up by connecting them to the

subwoofer speaker outputs (marked "TO

SPEAKERS"). The amount of power (watts) driven

into the stereo speakers (towers) is identical to the

amount of power (watts) fed into the SuperNova

from the stereo system (ratio 1:1).

AC power connection:

The Kompressor subwoofer is designed to run in 110V

and 220V/240V. The power socket if fused to protect the

amplifier from surges. Do not over-fuse, replace the fuse with

identical value.

Page 2

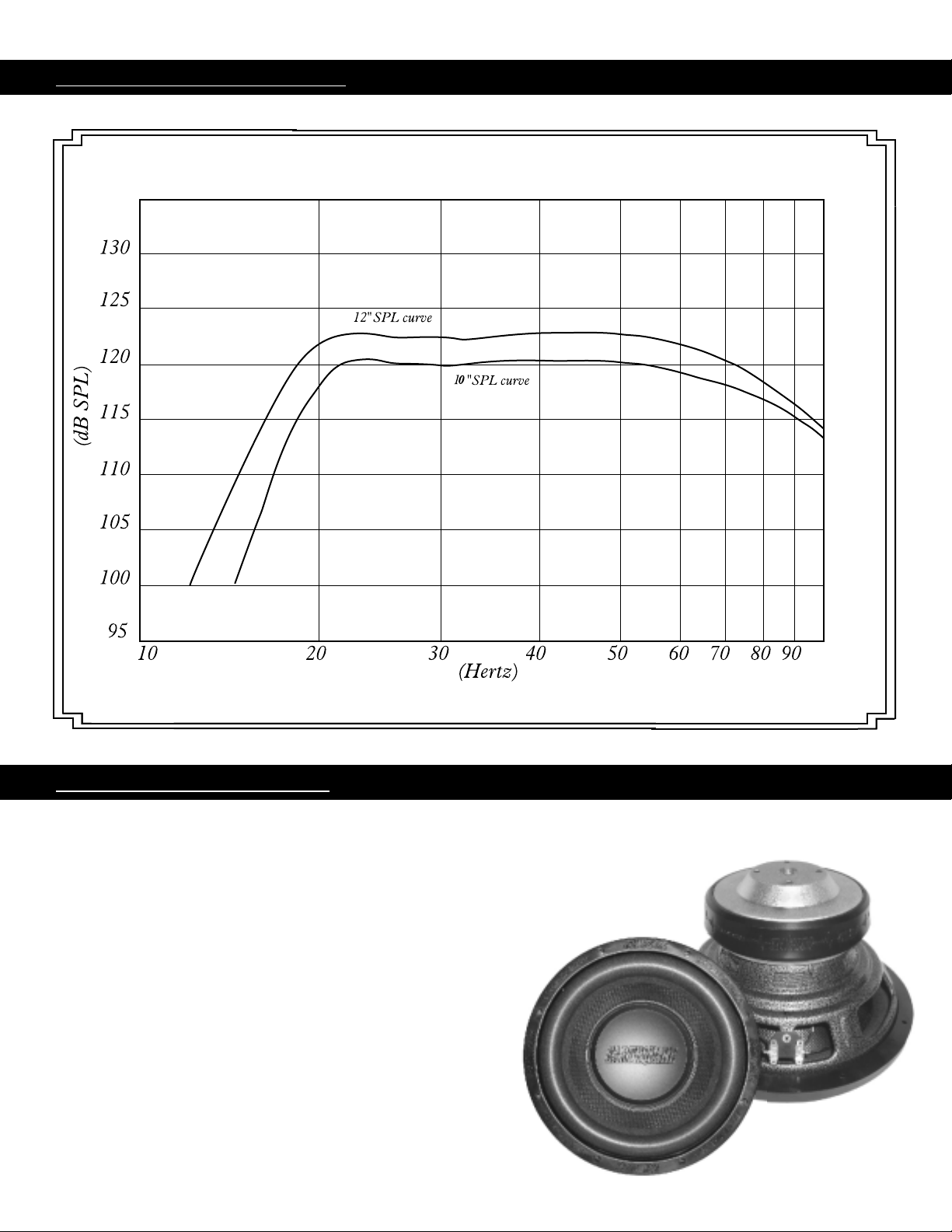

Kompressor Performance.

High Performance Driver

Every component of the XLT driver is designed for accurate

reproduction of bass and sub-bass frequencies. With a massive

moving structure, the XLT operates with extremely low distortion

and impressive transient response. Its performance is attributed to a

non-conventional motor structure design, that integrates

components such as:

* Thick, high-gauss magnets, with a total height of 1.2 inches.

* Over 7 inch (D), epoxy coated super spider. Chill-plated for long

lasting linear performance.

* 2.5" diameter, high temperature voice coil, with 1,85" copper

winding (height).

* 1.5" thick, single layer, thermally pressed poly-ether foam

surround.

The XLT structure allows for extreme excursions (19 to 21mm)

without physical deformation or running out of Reactive

Electromagnetic Coupling.

Page 3

High Power Class A/B High Efficiency 200 watts rms Amplifier

110V 220V

* 200 watts class "AB" , high efficiency power amplifier.

* 24 dB / Octave variable filter from 40 Hz to 160 Hz.

* Automatic signal detection circuitry, When "ON", it automatically turn on the subwoofer when an audio

signal is detected. It also shuts the subwoofer off after 30 minutes if no signal is detected.

* High level (speaker) audio inputs.

* Low level (RCA) audio inputs.

* Full range speaker outputs that can be used to power up other full range speakers in the system.

Page 4

Setting Up Your Subwoofer

The Kompressor is a "true front firing subwoofer”, it must never be operated above the subharmonic / harmonic

frequency range. The Kompressor frequency response is limited by the built-in crossover (with an upper end of 160 Hz);

however, in most applications, the crossover should not be set above 80Hz to 95Hz. It is equipped with a fourth-order

Linkwitz-Riley filter which will block vocals from interfering with its performance.

When setting up the Kompressor as a part of a home audio system, users must understand that the subwoofer

requires different settings: one for music, and one for playing movie tracks. In order to set up the Kompressor for music, users

must recognize the frequency response of their existing speakers (tower & surround sound) and the limitations of these

speakers, i.e. the diameter (size) of the speakers and the SPL.

Crossover knob in 1 O'clock position - 85Hz @ -3dB.

CROSSOVER

FREQUENCY

24dB/Oct

40Hz 160Hz

0.0

10 20 30 40 50 60 70 80 90 100 200Hz

VOLUME

Crossover knob in 2 O'clock position - 90Hz @ -3dB.

CROSSOVER

FREQUENCY

24dB/Oct

40Hz 160Hz

0.0

10 20 30 40 50 60 70 80 90 100 200Hz

VOLUME

For music setting:

1- Position the Kompressor in the corner of the living room.

2- Turn the unit around to expose the controls .

3- Turn on your audio system, and switch your surround sound

processor to "MUSIC" mode, and equalize the rest of your audio system.

+9.0

+8.0

+7.0

+6.0

+5.0

+4.0

+3.0

+2.0

+1.0

-1.0

Level in dB.

-2.0

-3.0

-4.0

-5.0

-6.0

-7.0

-8.0

-9.0

+9.0

+8.0

+7.0

+6.0

+5.0

+4.0

+3.0

+2.0

+1.0

-1.0

Level in dB.

-2.0

-3.0

-4.0

-5.0

-6.0

-7.0

-8.0

-9.0

4- Connect the Kompressor to the processor, using high quality (triple shielded) RCA cables.

5- Set the crossover to 150Hz - maximum position, volume at minimum (0).

6- Gradually raise the main volume knob ( between the 10 O'clock to 2 O'clock) position, optimizing for the subwoofer

performance. That is when the Optical Compression Circuitry works best, allowing the amp maximum output with minimal

distortion.

7- With the crossover open to 160Hz, you will hear vocals coming out of the subwoofer. Gradually reduce the crossover point

until vocals are eliminated (typical crossing point of 80Hz).

T o control the volume level of the Kompressor, use the surround sound processor output controls; do not use the main

volume knob on the Kompressor (keep it between 10 & 2 O'Clock position). Once you set up the proper mix of low frequencies

and subharmonic response, that does not encroach on the rest of the speakers. Now you are ready to set up the Kompressor

for home theater use.

For movie viewing:

The Kompressor can be set up to your liking. There are no rules of thumb to how much bass is required. Often, users

like to feel the overwhelming bass, it brings the actions and events closer to real life. When viewing movies, a 10dB gain above

music setting is often pleasant, it brings movie viewing close to life.

If you desire to have a crossover setting for music, different than the setting for movie viewing. We suggest to cross the

Kompressor at higher frequency setting, and use the processor to control the desired lower crossing point.

Loading...

Loading...