Page 1

Operator’s Manual

GAS/OIL

RATIO

50:1

Original Operating Instructions

WP4310

43cc Water Pump

Get parts online at

www.getearthquake.com

P/N: OMWP4310

ECN: 10159

REV 2: 10/08/13

© 2014 Ardisam, Inc.

All Rights Reserved

Page 2

Operator’s Manual

WP4310 43cc Water Pump

2 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 3

Operator’s Manual

WP4310 43cc Water Pump

INTRODUCTION

Congratulations on your investment in quality. Thank you for purchasing a 1-Inch Pump from Earthquake®. We have worked to

ensure that the pump meets the highest standards for usability and durability. With proper care, your1-Inch Pump will provide many

years of service.

Please read this entire manual before installation and use. Earthquake reserves the right to change, alter or improve the

product and this document at any time without prior notice.

CONTENTS

Registration ........................................................................................................................................................................................................................................3

Safety ................................................................................................................................................................................................................................................ 4-6

Operation ........................................................................................................................................................................................................................................ 6-8

Maintenance and Storage .......................................................................................................................................................................................................9-10

Service, Troubleshooting and Repair ............................................................................................................................................................................... 11-12

Parts Breakdown ...................................................................................................................................................................................................................... 13-15

Notes ...................................................................................................................................................................................................................................................16

Warranty ..................................................................................................................................................................................................................................... 17-19

FEDERAL EMISSION INFORMATION

Earthquake warrants to the retail purchaser, that this small, o-road engine was designed, built and equipped to conform at the time

of initial sale to all applicable regulations of the U.S. Environmental Protection Agency (EPA).

REGISTRATION, SERVICE AND MAINTENANCE LOG

Record the model number and serial number in the space provided for easy reference. Warranty is valid only if the completed registration is received by Earthquake within 30 days of purchase. You can register your warranty online by visiting www.getearthquake.

com. If you do not have a computer, call our customer service department at (800) 345-6007 Mondays through Fridays from 8 a.m.

to 5 p.m. CST.

OWNERSHIP RECORDS

Owner’s Name:

Owner’s Address:

City: State/Province: Zip Code/Postal Code:

Model Number: Serial Number:

Date of Purchase:

Notes:

This manual may contain information for several models. Read and keep this book for future reference. This manual contains

important information on SAFETY, ASSEMBLY, OPERATION, AND MAINTENANCE. The owner must be certain that all the product

information is included with the unit. This information includes the MANUAL, the REPLACEMENT PARTS and the WARRANTIES.

This information must be included to make sure state laws and other laws are followed. All persons to whom rent/loan this unit

must have access to and understand this information. This manual should remain with the product even if it is resold.

3Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 4

SAFETY

Operator’s Manual

WP4310 43cc Water Pump

OWNER’S RESPONSIBILITY

It is the owner’s responsibility to accurately assemble

the pump for safe and eective use.

• Read and follow all safety instructions.

• Carefully follow all assembly instructions.

• Maintain the pump according to directions and

schedule included in this Earthquake operator's

manual.

• Ensure that anyone who uses the pump is familiar

with all controls and safety precautions.

SPECIAL MESSAGES

Your manual contains special messages to draw

attention to potential safety concerns, machine

damage as well as helpful operating and servicing

information. Please read all the information carefully

to avoid injury and machine damage.

CAUTION

AVOID INJURY! THIS SYMBOL AND TEXT HIGHLIGHT

POTENTIAL HAZARDS OR DEATH TO THE OPERATOR

OR BYSTANDERS THAT MAY OCCUR IF THE HAZARDS

OR PROCEDURES ARE IGNORED.

IMPORTANT SAFETY PRECAUTIONS

Please read this section carefully. Operate the

water pump according to the safety instructions

and recommendations outlined here and inserted

throughout the text. Anyone who uses this water

pump must read the instructions and be familiar with

the controls.

This symbol points out important safety

instructions which if not followed could

endanger your personal safety. Read and

follow all instructions in this manual before

attempting to operate this equipment.

• Always keep hands, feet, hair and loose clothing

away from any moving parts on engine or pump.

• Do not allow children to operate this pump. Do not

allow adults to operate the pump without proper

instruction.

• Do not operate any power equipment under the

inuence of alcohol or drugs.

• Keep all screws, nuts and bolts tight.

• Engine should be turned o and cool, spark plug

wire must be removed from spark plug before any

repairs are attempted.

• Temperature of muer and nearby areas may

AVOID DAMAGE! THIS TEXT IS USED TO TELL THE

OPERATOR OF ACTIONS OR CONDITIONS THAT

MIGHT RESULT IN DAMAGE TO THE MACHINE.

NOTE: General information is given throughout

the manual that may help the operator in the

operation or service of the machine.

4 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

exceed 150° F (65° C). Avoid these areas.

• Never run engine indoors or in an enclosed area.

Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

• Use only original equipment parts from Ardisam,

Inc., including all nuts and bolts.

• Never attempt to operate the pump without

priming water.

Page 5

Operator’s Manual

WP4310 43cc Water Pump

ENGINE SAFETY PRECAUTIONS

Warning Carbon Monoxide Poisoning

All engine exhaust contains carbon monoxide.

Carbon monoxide is a deadly, colorless, tasteless,

odorless gas which may be present even if you do

not smell or see engine exhaust. Levels of carbon

monoxide, which can be deadly, can be present for

days in an enclosed area that has poor ventilation.

Any level of carbon monoxide, if inhaled, can cause

headaches, drowsiness, nausea, dizziness, confusion

and eventually death. If you experience any of these

symptoms, seek fresh air and medical attention

immediately.

Preventing Carbon Monoxide Poisoning

• Never run engine indoors or in a conned area.

• Never try to ventilate engine exhaust indoors.

Carbon monoxide can reach dangerous levels very

quickly.

• Never run engine outdoors where exhaust fumes

may be pulled into a building.

• Never run engine outdoors in a poorly ventilated

area where the exhaust fumes may be trapped and

not easily removed. (Examples include large holes

or areas where hills surround your working area.

• Never run engine in an enclosed or partially

enclosed area. (Examples include: buildings that

are enclosed on one or more sides, under tents, car

ports or basements.

• Always run the engine with the exhaust and muer

pointed away from the operator.

• Never point the exhaust muer towards anyone.

Bystanders should always be many feet away from

the operation of the engine.

Gasoline Fires and Handling Fuel Safely

Fuel and fuel vapors are highly ammable. Never use

fuel where a spark or ame may be present. Never use

fuel where a potential source of ignition could occur.

(Examples include: hot water or space heaters, clothes

dryer, electric motors, etc.) Keep ames and sparks

away from engine and fuel to prevent res. Fuel res

spread very quickly and are highly explosive.

Prevention of Gasoline Fires

• Always ll fuel tank outside in a well ventilated area

with the engine stopped.

• Never remove the fuel cap or add fuel with the

engine running. Stop engine and allow to cool

before lling.

• Never drain fuel from engine in an enclosed area.

• Always wipe up excess (spilled) fuel from engine

before starting. Clean up spilled fuel immediately.

• If fuel spillage occurs, wipe away carefully and allow

fuel to dry before starting the engine.

• Allow fuel fumes/vapors to escape from the area

before starting engine.

• Test the fuel cap for proper installation before

starting and using engine.

• Always run the engine with fuel cap properly

installed on the engine.

• Never smoke while relling engine fuel tank.

• Prevent re and explosion caused by static

electric discharge. Use only nonmetal, portable

fuel containers approved by the Underwriter’s

Laboratory (U.L.) or the American Society for

Testing & Materials (ASTM).

• Do not store engine with fuel in fuel tank indoors.

Fuel and fuel vapors are highly explosive.

• During storage, screw down gas cap vent screw

tightly.

• Never pour fuel from engine fuel tank.

• Never siphon fuel by mouth to drain fuel tank.

• Always have an adult ll the fuel tank.

• Never allow anyone under the inuence of drugs or

alcohol to ll engine.

• Never allow children to ll the fuel tank.

5Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 6

Operator’s Manual

GAS OIL R AT I O

1 ga llo n 2.5 ounces 50:1

2 ga llo ns 5 o unces 50:1

5 ga llo ns 13 ounces 50:1

WP4310 43cc Water Pump

BURNS AND FIRES

The muer, muer guard and other parts of the

engine become extremely hot during the operation

of the engine. These parts remain extremely hot after

the engine has stopped.

This engine is designed to operate using a catalytic

converter which contributes to the engine’s

compliance with the EPA.

Prevention of Burns and Fires

• Never remove the muer guard from the engine.

• Never touch the muer guard because it is

extremely hot and will cause severe burns.

• Never touch parts of the engine that become hot

during and after operation.

• Always keep materials and debris away from

muer guard and other hot parts of the engine to

avoid res.

CAUTION

AVOID INJURY! HOT GASES ARE A NORMAL

BYPRODUCT OF A FUNCTIONING CATALYTIC

CONVERTER. FOLLOW ALL SAFETY INSTRUCTIONS

TO PREVENT BURNS AND FIRES.

3. Securely place the disconnected spark plug wire

away from the spark plug and any metal parts. This

must always be done or arcing may occur between

spark plug wire and metal parts.

4. Replace or repair the part on the engine or pump.

5. Check all parts that were repaired, or removed

during repair, that they are secure and t correctly.

NOTE: All repair parts must come from the factory.

Never replace parts that are not specically

designed for the pump.

6. Replace spark plug wire

CAUTION

AVOID INJURY! ALWAYS WEAR HEARING

PROTECTION WHILE OPERATING ENGINE.

CAUTION

AVOID INJURY! PLEASE DO NOT START YOUR

WATER PUMP UNTIL YOU HAVE READ THE

PREVIOUS SECTION OF THIS MANUAL. ONCE

COMPLETED, FOLLOW THE STEPS BELOW TO

START YOUR PUMP.

OPERATION

STEPS FOR WORKING ON ENGINE OR

PUMP

CAUTION

DO NOT ALTER/MODIFY ENGINE OR PUMP:

AVOID INJURY! NEVER ALTER OR MODIFY

THE ENGINE FROM THE FACTORY. SERIOUS

INJURY OR DEATH MAY OCCUR IF ENGINE IS

MODIFIED OR ALTERED.

CAUTION

AVOID INJURY! WHEN WORKING ON OR

REPLACING PARTS FOR THE ENGINE OR PUMP

YOU MUST ALWAYS DISCONNECT SPARK PLUG

WIRE FROM THE SPARK PLUG AND KEEP IT

AWAY FROM THE SPARK PLUG.

1. Turn o engine switch.

2. Disconnect the spark plug wire from the spark plug.

PREPARING ENGINE FOR STARTING

GAS AND OIL

Quality

To operate the engine you must use a high quality

2-cycle oil to ensure that the engine operates

correctly for the life of the engine. Use unleaded

regular, unleaded premium or reformulated

automotive fuel only. It may contain up to 10%

ethanol, 10% gasohol, 15% MTBE, and 15% ETBE. DO

NOT use Methanol or leaded fuels.

Mixture

Run pump with a ratio of 50:1. DO NOT use marine

2-cycle oil. See chart below.

6 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 7

Operator’s Manual

WP4310 43cc Water Pump

MIXING FUEL AND FILLING FUEL TANK

CAUTION

AVOID INJURY! NEVER STORE ENGINE WITH

FUEL IN THE TANK INDOORS. FUEL AND FUEL

VAPORS ARE HIGHLY FLAMMABLE.

CAUTION

AVOID INJURY! NEVER MIX FUEL AND OIL

DIRECTLY IN ENGINE FUEL TANK. USE ONLY

NONMETAL, PORTABLE FUEL CONTAINERS

APPROVED BY THE UNDERWRITER’S

LABORATORY U.L. OR THE AMERICAN SOCIETY

FOR TESTING & MATERIALS ASTM.

CAUTION

AVOID INJURY! AN ADULT MUST ALWAYS

HANDLE AND FILL THE ENGINE WITH FUEL.

Mixing Fuel

1. Fuel must be mixed in a container outside in a

well-ventilated area.

2. Fill certied fuel container 1/4 full of

recommended fuel.

Filling Fuel Tank

1. Shut-o engine and allow engine to completely

cool before lling the fuel tank.

2. Move to a well ventilated area or outdoors away

from ames and spark.

3. Clean debris from area around the fuel cap.

4. Loosen fuel cap slowly. Place the cap on a clean,

dry surface.

5. Carefully add fuel without spilling.

6. Do not ll gas tank completely full allowing space

for fuel to expand.

7. Immediately replace fuel cap and tighten. Wipe o

spilled fuel and allow to dry before starting engine.

CAUTION

AVOID INJURY! DO NOT START ENGINE IF FUEL

IS SPILLED. WIPE OFF EXCESS FUEL AND ALLOW

TO DRY. REMOVE ENGINE FROM AREA TO AVOID

SPARKS.

ASSEMBLY

1. Connect the suction hose to water pump inlet and

the discharge hose to pump outlet using provided

hose clamps.

3. Add recommended amount of 2-cycle oil. DO

NOT use 2-cycle marine oil.

4. Screw on container cap straight and tight.

5. Shake the container to mix fuel and oil.

6. Unscrew cap slowly to vent. Add the remainder of

fuel requirements.

7. Wipe away any spilled fuel or oil and allow to

evaporate before moving or transporting.

CAUTION

AVOID INJURY! ALWAYS HANDLE GAS IN A WELL

VENTILATED AREA, OUTDOORS, AWAY FROM

FLAMES OR SPARKS.

THIS ENGINE USES A GAS/OIL MIXTURE. DO NOT

RUN ON STRAIGHT GAS ONLY, ENGINE DAMAGE

WILL RESULT.

2. Attach suction screen to inlet hose.

NOTE: 1” suction hose is required.

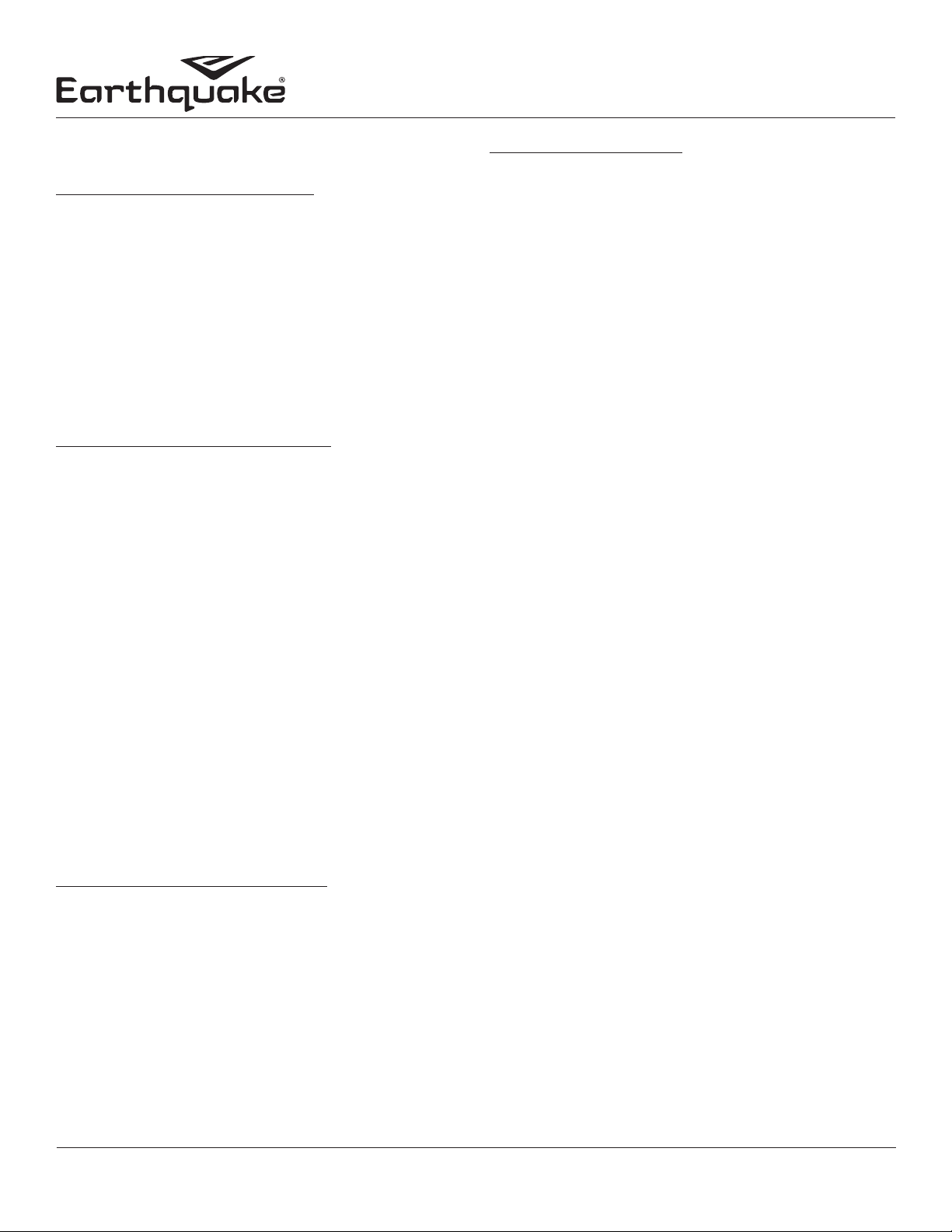

NORMAL OPERATION

1. Always prime water pump fully with water before

starting engine. Loosen the ller cap and ll the pump

with priming water.

Outlet

Fill Port

Inlet

Drain Port

7Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 8

OPERATION

Operator’s Manual

WP4310 43cc Water Pump

STARTING AND STOPPING ENGINE

1. Move engine to a well ventilated area or outdoor

to prevent carbon monoxide poisoning.

2. Move to an area away from ames or sparks to

avoid ignition of vapors if present.

3. Remove all debris from air cleaner holes and fuel

cap to ensure proper air ow.

4. Turn switch to the ON position.

5. PRIMING:

• When using the primer bulb, allow the bulb to return

completely to its original position between pushes.

• Choke must be in the OFF or RUN position when

pushing or using the priming bulb.

First Start: Starting new engine for the rst time or

after running out of gas, prime three times.

Cold Start: Starting engine after it has been sitting or

stored briey with fuel in the tank, prime one time above

55° Fahrenheit or two times below 55° Fahrenheit.

Warm Start: Do not use primer or full choke if engine

did not run out of gas or has not cooled completely.

Flooding will occur.

6. CHOKE:

• Full choke position is dened by moving the

choke lever as far to the ON or CHOKE position as

possible. Half choke is dened when the choke

lever is between ON or CHOKE and OFF or RUN.

First Start & Cold Start: After priming, move choke

lever to full choke.

Warm Start: No choke or half choke is needed.

9. After engine starts running, move choke lever to

HALF CHOKE.

10. Move choke lever to OFF or RUN position and

move throttle to desired speed.

CAUTION

AVOID INJURY! IF ENGINE FAILS TO START AFTER

THE ABOVE OPERATIONS, PLEASE CONTACT

ARDISAM, INC. AT 8003456007.

DO NOT attempt to start engine in the following

ways:

• DO NOT use starting uid.

• DO NOT spray ammable liquids or vapors into

air cleaner, carburetor or spark plug chamber.

• DO NOT remove spark plug and pull on starter

rope. Flammable fuel can spray out and ignite

from a spark caused by the spark plug.

CAUTION

AVOID INJURY! NEVER LEAVE ENGINE RUNNING

WHILE UNATTENDED. TURN OFF AFTER EVERY

USE.

CAUTION

AVOID INJURY! STARTER ROPE CAN CAUSE AN

UNANTICIPATED JERK TOWARDS ENGINE. PLEASE

FOLLOW INSTRUCTIONS TO AVOID INJURY.

7. Grasp starter handle and pull out slowly, until

tension increases. Without letting handle retract, pull

rope with a rapid full arm stroke. Let rope return to its

original position very slowly. Repeat this step every

time the starter rope is pulled.

8. Pull recoil until engine res or runs.

NOTE: If engine fails to start after 5-6 pulls, push

primer one time and pull starter rope again.

8 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 9

MAINTENANCE AND STORAGE

CAUTION

TO PREVENT ACCIDENTAL STARTING:

AVOID INJURY! ENGINE MUST BE TURNED

OFF AND COOL, AND SPARK PLUG WIRE MUST

BE REMOVED FROM SPARK PLUG BEFORE

CHECKING AND ADJUSTING ENGINE OR

EQUIPMENT.

CAUTION

AVOID INJURY! TEMPERATURE OF MUFFLER

AND NEARBY AREAS MAY EXCEED 150° F 65°

C. AVOID THESE AREAS.

CAUTION

AVOID INJURY! CHECK PUMP OFTEN FOR

LOOSE NUTS AND BOLTS. KEEP THESE ITEMS

TIGHTENED.

PUMP MAINTENANCE

1. Keep all screws, nuts, and bolts tight.

2. For cold weather operation, store the unit in a cool

environment. Transferring the unit from a warm to a

cold area can cause build up of harmful condensation.

Operator’s Manual

WP4310 43cc Water Pump

ENGINE MAINTENANCE

Please read the maintenance schedule and observe

these recommendations to extend the life of your

engine.

Good maintenance is essential for safe, economical,

and trouble-free operation. It will also help reduce air

pollution. To help you properly care for your engine,

the following pages include a maintenance schedule,

routine inspection procedures, and simple maintenance procedures using basic hand tools. Other

service tasks that are more difficult, or require special

tools, are best handled by professionals and are

normally performed by a technician or other qualified

mechanic.

Maintenance, replacement or repair of the emissions

control devices and systems may be performed by

any non-road engine repair establishment or individuals. However, items must be serviced by an authorized

dealer to obtain "no charge" emissions control service.

The maintenance schedule applies to normal operating conditions. If you operate your engine under

unusual conditions, such as sustained high-load or

high-temperature operation, or use in unusually wet

or dusty conditions, consult your servicing dealer for

recommendations applicable to your individual needs

and use.

MAINTENANCE SCHEDULE

CAUTION

AVOID INJURY! NEVER STORE ENGINE WITH FUEL

IN THE TANK INSIDE A BUILDING. POTENTIAL

SPARKS MAY BE PRESENT FOR IGNITION OF FUEL

AND FUEL VAPORS.

CAUTION

AVOID INJURY! AN ADULT MUST ALWAYS DO

MAINTENANCE AND REPAIR ON ENGINE AND

ATTACHMENTS.

CAUTION

AVOID INJURY! ENGINE MUST BE SHUTOFF,

COOL, AND SPARK PLUG WIRE REMOVED

BEFORE ANY REPAIR OR MAINTENANCE CAN

BE DONE.

Every 8

hours

MAINTENANCE ITEM

Clean Engine and

Check Bolts & Nut

Air Filter Check X

(See Air Filter section)

Spark Plug

(Gap .028”)

(See Spark Plug section)

* Service more frequently under dusty conditions

Clean * X

Replace X X

Check/

Adjust

Replace X

(daily)

X

Every 20

hours or

seasonally

X

Each

Year

9Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 10

Operator’s Manual

WP4310 43cc Water Pump

Cooling Fins

• Cooling ns, air inlets and linkages must be free

from any debris before each use.

Air Filters

• Never run engine without air cleaner properly

installed. Added wear and engine failure may occur if

air cleaner is not installed on engine.

• Service air cleaner every 3 months or after 20 hours

of operation. Clean more frequently if engine is

operated in extremely dusty conditions.

Steps for Cleaning Air Filters

NEVER TWIST AIR FILTERS WHEN CLEANING.

ALWAYS PRESS.

1. Wash in warm water with mild soap until dirt and debris

are removed. Press lter when washing, do not twist.

2. Rinse in warm water until soap and dirt are

removed.

3. Dry lter by wrapping in a clean cloth and pressing

lter until dry.

4. Apply oil to the entire lter.

5. Remove excess oil.

6. Attach the lter and lter cover to the engine.

Spark Plug

• Check spark plug every 50 operating hours.

1. Remove dirt and debris around the spark plug

before removing.

2. Remove spark plug and replace if any of the following

have occurred: pitted electrodes, burned electrodes,

cracked porcelain or deposits around the electrodes.

3. Check spark plug for proper gap (.025” to .030”).

4. After analysis of the spark plug, install original or a

new spark plug and tighten securely.

NOTE: DO NOT OVERTIGHTEN!

NOTE: CROSS REFERENCE SPARK PLUG IS A

CHAMPION CJ8.

Carburetor

• Never tamper with factory setting of the

carburetor.

TRANSPORTING YOUR WATER PUMP

1. Never transport engine inside an enclosed space

or vehicle. Fuel or fuel vapors may ignite causing

serious injury or death.

2. If fuel is present in the fuel tank, transport in an

open vehicle in an upright position

3. If an enclosed vehicle must be used, remove gas

into an approved red gasoline container. DO NOT

SIPHON BY MOUTH.

4. Run engine to expand fuel in the carburetor and

fuel tank. Always run engine in a well ventilated area.

5. Wipe away any spilled fuel from engine and pump.

Allow to dry.

LONG TERM STORAGE

• If your pump will not be used for more than one

month, prepare it for long-term storage.

Steps for Long Term Storage

1. Add fuel stabilizer before storing for long periods

of time.

2. Run engine for 10-15 minutes to ensure that the

stabilizer reaches the carburetor.

3. Remove the remaining fuel from the gas tank into

an approved fuel container.

4. Drain water from pump if storing in temperatures

below freezing.

CAUTION

AVOID INJURY! TO AVOID INJURY OR DEATH,

NEVER SIPHON FUEL BY MOUTH.

CAUTION

AVOID INJURY! NEVER STORE WATER PUMP WITH

FUEL IN THE FUEL TANK INSIDE AN ENCLOSED

AREA OR BUILDING.

5. Store in an upright position.

6. Remove all debris from engine and water pump.

10 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 11

SERVICE, TROUBLESHOOTING AND REPAIR

Operator’s Manual

WP4310 43cc Water Pump

SERVICE INFORMATION

IN CASE OF A SERVICE PROBLEM, DO NOT SEND

UNIT BACK TO RETAILER. CONTAC T ARDISAM, INC.

AT 800-345-6007. WE WELCOME YOUR CALL.

At Ardisam, we build quality and durability into

the design of our products. No amount of careful

design by us, and careful maintenance by you, can

guarantee a repair-free life for your water pump. Most

repairs will be minor and easily xed by following

the suggestions in the troubleshooting guide in this

section. This guide will help you pinpoint the causes

of common problems and identify solutions.

For more complicated repairs, you may want to rely

on your retailer, an authorized mechanic or Ardisam,

Inc. Contact your retailer for a list of authorized

mechanics in your area. A parts catalog is included in

this section.

ORDERING REPAIR PARTS

Parts can be obtained from the store where your water

pump was purchased or direct from the factory. To order

from the factory, call or write to:

Ardisam, Inc.

1160 Eighth Avenue; P.O. Box 666

Cumberland, Wisconsin 54829

800-345-6007 · Fax (715) 822-2223

Email: info@ardisam.com

www.ardisam.com

www.getearthquake.com

Please include the following information with your order:

1. Part numbers

2. Part description

3. Quantity

4. Model number and serial number

We will always be glad to answer any questions you

have or help you nd suitable assistance. To order

parts or inquire about warranty, call or write us at the

address found in the next column under the section

"Order Repair Parts."

11Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 12

SERVICE, TROUBLESHOOTING AND REPAIR

CAUTION

PRACTICE SAFETY AT ALL TIMES. ENGINE MUST

BE TURNED OFF AND ALLOWED TO COOL, AND

SPARK PLUG WIRE MUST BE DISCONNECTED

BEFORE ATTEMPTING ANY MAINTENANCE OR

REPAIR.

TROUBLESHOOTING

Operator’s Manual

WP4310 43cc Water Pump

Problem Possible cause

Engine will not start

Engine runs rough, oods during

operation

Engine is hard to start

Engine misses or lacks power

Engine runs, but has no power

Engine revs too high

1. Power switch o

2. Spark plug wire disconnected

3. Spark plug has no spark

1. Dirty air cleaner

2. Choke partially engaged

3. Carburetor out of adjustment

1. Stale fuel

2. Spark plug wire loose

3. Dirty carburetor

1. Clogged fuel tank

2. Clogged air cleaner

3. Improper carburetor adjustment

4. Spark plug dirty, improper gap, or

wrong type

1. Choke on

2. Carburetor out of adjustment

3. Worn engine lower seal

1. Low fuel in tank

Remedy/Action

1. Flip switch to on position

2. Connect spark plug wire to spark plug

3. Clean or replace spark plug

1. Clean or replace air cleaner

2. Turn o choke

3. Call factory

1. Drain old fuel and replace with fresh.

Use gas stabilizer at end of season

2. Make sure spark wire is securely

attached to spark plug

3. Clean carburetor, use gas stabilizer,

new gas can

1. Remove and clean

2. Clean or replace

3. Call factory

4. Replace spark plug and adjust gap

1. Turn o choke after engine is running

2. Call factory

3. Call factory

1. Add fuel to tank

Engine runs, but doesn’t pump water

1. Pump not primed

2. Suction hose elevated too high

3. Strainer clogged

4. Hose(s) damaged

1. Prime water pump as directed in

manual

2. Lower suction hose

3. Unclog foreign objects from strainer

4. Replace hoses

12 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 13

WP4310 WATER PUMP ENGINE BREAKDOWN

Operator’s Manual

WP4310 43cc Water Pump

13Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 14

WP4310 WATER PUMP BREAKDOWN

10

25

24

Operator’s Manual

WP4310 43cc Water Pump

23

10

37

43

26

25

24

23

15

36

27

16

28

29

17

20

19

22

21

33

32

31

30

16

28

29

31

34

6

4

3

2

14

12

11

10

39

8

40

14 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

41

9

7

6

42

9

5

4

3

4

3

2

35

3

2

1

2

Page 15

WP4310 WATER PUMP PARTS LIST

MINIMUM ORDER ...........................................................................................................$10.00

Operator’s Manual

WP4310 43cc Water Pump

ENGINE PARTS

Part # Description Qty.

1021 SWITCH, ROCKER ..................................................................1

300429 PLATE, RECOIL ........................................................................1

300430 RECOIL ASSEMBLY ............................................................... 1

300435 FILTER, AIR ............................................................................... 1

300438 BOLT W/WASHER, M5 X 25MM ........................................ 2

300439 BOLT W/WASHER, M5 X 18MM ..................................... 13

300454 BASE, INTAKE .......................................................................... 1

300455 PLATE, INTAKE COVER ADAPTER ....................................1

300456 BOLT, M5 X 50MM ................................................................. 2

300457 COVER, AIR FILTER ................................................................ 1

300463 GROMMET, ENGINE SHROUD .......................................... 1

300467 PIN, LOCATING ....................................................................... 2

300471 BOLT, M5 X 12MM ................................................................. 3

300472 COIL, IGNITION ......................................................................1

300475 GASKET, MUFFLER ............................................................... 1

300476 GASKET, INTAKE ....................................................................2

300477 HEAT DISK ................................................................................ 1

300478 WINDPIPE, INTAKE ...............................................................1

300479 GASKET, CARBURETOR ....................................................... 1

300480 SPACER, FUEL TANK THREADED .....................................2

300481 ORING ...................................................................................... 1

300482 SHROUD, ENGINE ................................................................. 1

300483 COVER, ENGINE SHROUD ..................................................1

300484 FLYWHEEL, MAGNETO........................................................1

300487 MOUNT RING AND SHROUD ...........................................1

300488 CHOKE NOT SHOWN ........................................................ 1

300491 RECOIL CLUTCH ....................................................................1

300492 NUT, M6 ....................................................................................2

300493 BOLT, STUD M6 X 62MM .................................................... 2

300494 GROMMET, FUEL TANK, 2HOLE .....................................1

300497 HOSE, PRIMER LINE 4” ......................................................... 1

300498 HOSE, PRIMER LINE 9” ......................................................... 1

3004103 FILTER, FUEL NOT SHOWN .............................................1

3004106 GUARD, FLYWHEEL NOT SHOWN ...............................1

3004109 PRIMER BULB NOT SHOWN ...........................................1

3004120 SCREW, CHOKE LEVER NOT SHOWN .........................1

3004122 FUEL TANK ............................................................................... 1

3004123 CAP, FUEL, MANUAL VENTING ........................................ 1

3004124 CARBURETOR ......................................................................... 1

3004126 THROTTLE LEVER ASSEMBLY NOT SHOWN ............1

3004127 ENGINE, 2CYCLE 43CC VIPER ..........................................1

3004128 LEVER, THROT TLE .................................................................1

3004129 WASHER WITH TAB, THROTTLE LEVER ......................... 1

3004130 WASHER, FLAT, THROTTLE LEVER .................................. 1

3004131 WASHER, NYLON, THROTTLE LEVER .............................1

3004132 SCREW, THROTTLE LEVER ................................................. 1

4812 COVER, MUFFLER, METAL .................................................1

4813 MUFFLER, CATALYTIC CONVERTER ...............................1

BM6A SPARK PLUG CHAMPION CJ8 ........................................1

CHASSIS PARTS

Key # Part # Description Qty.

1 42128 BOLT, ENGINE MOUNT...................................... 2

2 42131 BOLT, RUBBER FOOT ..........................................4

3 42132 WASHER, RUBBER FOOT .................................. 4

4 42127 FOOT, RUBBER ..................................................... 4

5 42129 BASE PLATE, PUMP ............................................ 1

6 42133 NUT, RUBBER FOOT ........................................... 4

7 42118 MOUNT, ENGINE ................................................. 1

8 42141 OUTPUT SHAFT, PUMP ..................................... 1

9 42121 BOLT, PUMP ADAPTER PLATE ........................ 4

10 42123 BOLT, PUMP COVER PLATE ............................. 7

11 42104 BOLT, HANDLE LONG ........................................ 1

12 42103 HANDLE W/ GRIP ................................................ 1

14 42101 MOUNT, ENGINE PUMP .................................... 1

15 42140 BACK COVER, PUMP .......................................... 1

16 42112 BOLT, PUMP HOUSING PLATE........................ 4

17 42126 SEAL, MECHANICAL .......................................... 1

19 42120 GASKET, RUBBER PUMP ................................... 1

20 42134 IMPELLER ............................................................... 1

21 42122 HOUSING, VOLUTE ............................................. 1

22 42142 SEAL, VOLUTE HOUSING ................................. 1

23 42105 NUT, WING HOSE ADAPTER ........................... 2

24 42106 NIPPLE BARBED, 1” ............................................. 2

25 42107 SEAL, 1” NIPPLE ................................................... 2

26 42108 BOLT, OUTLET ELBOW ...................................... 2

27 42139 OUTLET ELBOW .................................................. 1

28 42109 CAP, FILL ................................................................. 2

29 42110 SEAL, FILL CAP ..................................................... 2

30 42114 SEAL, OUTLET ELBOW ...................................... 1

31 42115 BOLT, PUMP HOUSING ..................................... 6

32 42125 GASKET/FLOW STOP, COVER PLATE ............ 1

33 42124 PLATE, PUMP COVER ......................................... 1

34 42111 HOUSING, PUMP ................................................. 1

35 42130 BOLT, ENGINE PUMP MOUNT ........................ 2

36 42135 CLAMP, HOSE ....................................................... 3

37 42137 SUCTION SCREEN, COMPLETE ...................... 1

39 42102 ADAPTER PLATE, PUMP ................................... 1

40 42116 MOUNT, ENGINE FUEL TANK .......................... 1

41 42117 GRIP, RUBBER FUEL TANK ................................ 1

42 42119 SPACER, ENGINE PUMP .................................... 4

43 48166 ADAPTER ASSEMBLY, 1" NPSH FEMALE

TO 3/4" GHT MALE ............................................. 2

42100 ENGINE ................................................................... 1

15Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 16

NOTES

Operator’s Manual

WP4310 43cc Water Pump

16 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 17

Operator’s Manual

WP4310 43cc Water Pump

WARRANTY TERMS AND CONDITIONS

PRODUCT WARRANTY: 1YEAR LIMITED WARRANTY

Ardisam, Inc. (Ardisam) warrants the product(s) under a one-year limited warranty to be free from defects in the material or

workmanship or both for a period not exceeding twelve consecutive months from the date of original purchase by the rst retail

consumer or rst commercial end user. “Consumer use“ means personal recreational use by a retail consumer. “Commercial use“

or “commercial application“ means all other uses, including use for commercial, income producing or rental purposes. Once

a product has experienced commercial use, it shall thereafter be considered as a commercial use product for the purpose of

this warranty. This warranty applies to the original owner that provides a proof of purchase. The warranty is not transferable.

The warranty period begins on the date of purchase by the rst retail consumer or commercial end user, and continues for

the twelve month consecutive period thereafter. Any unit used in a commercial application is covered for a period of 90 days

after purchase by the rst commercial end user. For the warranty to be valid, the product must be registered online, or the

warranty card must be lled out and received by Ardisam, within 30 days of purchase. Ardisam shall not be obligated to ship

any repair or replacement product to any location outside of the United States of America or Canada.*

ENGINE WARRANTY: 2-YEAR LIMITED EMISSIONS CONTROL WARRANTY

(SEE EXPLANATION OF EMISSIONS CONTROL WARRANTY STATEMENT FOR DETAILS)

Ardisam warrants the Viper® engine(s) under a two-year limited emissions control warranty to be free from defects in the

materials or workmanship or both for the service life of the product not to exceed twenty-four consecutive months from the

date of purchase for consumer applications. As a Viper® small engine owner, you are responsible to perform periodic maintenance as specied in the product’s operator’s manual and/or engine manual. The warranty period begins on the date of

purchase by the rst retail consumer or commercial end user, and continues for the period of time stated above.*

For replacement parts, phone 800-345-6007.

*This warranty policy applies only to products which have not been subjected to negligent use, misuse, uses other than

those indicated in the product’s operator’s manual, alteration, accident, use of unauthorized parts, failure to perform periodic

maintenance as specied in product’s operator’s manual, normal wear and tear, use of unauthorized parts or repairs performed

at unauthorized service centers. There is no other expressed warranty. Implied warranties, including those of merchantability

and tness for a particular purpose, are limited to one year from purchase, or to the extent permitted by law. All other implied

warranties are excluded. Liability for incidental or consequential damages are excluded to the extent exclusion is permitted by

law. Ardisam does not assume, and does not authorize any other person to assume for Ardisam, any liability in connection with

the sale of Ardisam products. To be at “No Charge,” warranty work must be sent directly to and performed by Ardisam or

an Ardisam Authorized Warranty Service Facility. To obtain warranty service and/or replacement instructions, contact the

Ardisam Customer Service Department at 800-345-6007. If you choose to ship your product to Ardisam for warranty repair,

you must rst have prior approval from Ardisam by calling the Ardisam Customer Service Department for a return material

authorization number (RMA#). Under these circumstances, all items must be shipped prepaid. For Viper® engine warranty

repairs, Ardisam will cover the cost of shipping only for purchasers located more than 100 miles from an Ardisam Authorized

Warranty Service Facility if it is determined that warranted repair is indeed necessary. Ardisam will at no charge, repair or

replace, at the discretion of Ardisam, any defective part which satises all conditions stated above. Ardisam retains the right

to change models, specications and price without notice. Ardisam shall not be obligated to ship any repair or replacement

product to any location outside of the United States of America or Canada.

17645-REV1

17Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 18

FEDERAL EMISSIONS CONTROL WARRANTY STATEMENT

Operator’s Manual

WP4310 43cc Water Pump

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The United States Environmental Protection Agency (EPA), together

with Ardisam, Inc. (Ardisam), are pleased to explain the Emission

Control System Warranty on your small o-road engine (SORE). New

small o-road engines must be designed, built and equipped to meet

stringent anti-smog standards the federal government. Ardisam will

warrant the emission control system on your engine for the periods of

time listed below provided there has been no abuse, neglect, modication or improper maintenance of your engine.

The emission control system includes all components whose failure

would increase the emissions of any regulated pollutant. These

components are listed in the emission-related parts list located in a

subsequent section of this emissions warranty statement. Ardisam

will repair your engine at no cost to you for diagnosis, replacement

parts and labor, should a warrantable condition occur.

MANUFACTURER’S WARRANTY COVERAGE:

The emission control system is warranted for two years. If, during such

warranty period, any emission-related part on your engine is found to

be defective in materials or workmanship, repairs or replacement will

be performed by an Ardisam Authorized Warranty Service Facility.

PURCHASER’S/OWNER’S WARRANTY RESPONSIBILITIES:

As the SORE purchaser/owner, you are responsible for the completion of all required maintenance as listed in your factory supplied

Manual(s). For warranty purposes, Ardisam recommends that you

retain all receipts covering maintenance on your SORE. However,

Ardisam cannot deny warranty solely because of the lack of receipts

or for your failure to ensure the completion of all scheduled maintenance.

As the SORE purchaser/owner, you should, however, be aware that

Ardisam may deny any and/or all warranty coverage or responsibility

if your SORE or a part/component thereof, has failed due to abuse,

neglect, improper maintenance or modications, or the use of counterfeit and/or “grey market” parts not made, supplied or approved by

Ardisam.

You are responsible for presenting your SORE to an Ardisam Authorized Warranty Service Facility as soon as a problem occurs. The warranty repairs should be completed in a reasonable amount of time,

not to exceed 30 days.

Warranty service can be arranged by contacting either your selling

dealer or an Ardisam Authorized Warranty Service Facility. To locate

the Ardisam Authorized Warranty Service Facility nearest you, call our

free number:

800-345-6007

IMPORTANT NOTE: This warranty statement explains your rights and

obligations under the Emission Control System Warranty (ECS Warranty), which is provided to you by Ardisam pursuant to federal law.

See also the Ardisam “Product Warranty” (non-emission warranties),

which is enclosed herewith on a separate sheet or located in additional materials accompanying this product. The ECS Warranty applies

only to the emission control system of your new engine. If there is

any conict in terms between the ECS Warranty and the Ardisam

Warranty, the ECS Warranty shall apply except in circumstances where

the Ardisam Warranty may provide a longer warranty period. Both the

ECS Warranty and the Ardisam Warranty describe important rights

and obligations with respect to your new engine.

Warranty service can be performed only by an Ardisam Authorized

Warranty Service Facility. When requesting warranty service, evidence must be presented showing the date of the sale to the original

purchaser/owner. Ardisam will not be responsible for any and/or all

damages or losses incurred while the engine is being transported/

shipped for inspection or warranty repairs.

IF YOU HAVE ANY QUESTIONS REGARDING YOUR WARRANTY RIGHTS

AND RESPONSIBILITIES, YOU SHOULD CONTACT ARDISAM AT THE

FOLLOWING ADDRESS:

Ardisam, Inc.

1160 Eighth Avenue; P.O. Box 666

Cumberland, Wisconsin 54829

800-345-6007 · Fax (715) 822-4180

E-mail: info@ardisam.com

II. EMISSION CONTROL SYSTEM WARRANTY

Emission Control System Warranty (ECS Warranty) for equipment using small o-road engines:

(a) Applicability: This warranty shall apply to equipment that uses

small o-road engines. The ECS Warranty Period shall begin on the

date the new engine or equipment is purchased by/delivered to its

original, end-use purchaser/owner and shall continue for 24 consecutive months thereafter.

(b) General Emissions Warranty Coverage: Ardisam warrants to the

original, end-use purchaser/owner of the new engine or equipment

and to each subsequent purchaser/owner that each of its engines is...

(1) Designed, built and equipped so as to conform with all applicable regulations adopted by the EPA pursuant to their respective

authority, and

(2) Free from defects in materials and workmanship which, at

any time during the ECS Warranty Period, may cause a warranted

emissions-related part to fail to be identical in all material respects

to the part as described in the engine manufacturer’s application

for certication.

The ECS Warranty only pertains to emissions-related parts on your

engine, as follows:

(1) Any warranted, emissions-related parts that are not scheduled

for replacement as required maintenance in the Maintenance

Schedule (located in the section of the Manual(s) pertaining to

maintenance) shall be warranted for the ECS Warranty Period. If any

such part fails during the ECS Warranty Period, it shall be repaired

or replaced by Ardisam according to Subsection (4) below. Any

such part repaired or replaced under the ECS Warranty shall be

warranted for the remainder of the ECS Warranty Period.

(2) Any warranted, emissions-related part that is scheduled only

for regular inspection as specied in the Maintenance Schedule

(located in the section of the Manual(s) pertaining to maintenance)

18 Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 19

Operator’s Manual

WP4310 43cc Water Pump

shall be warranted for the ECS Warranty Period. A statement in such

written instructions to the eect of “repair or replace as necessary”

shall not reduce the ECS Warranty Period. Any such part repaired or

replaced under the ECS Warranty shall be warranted for the remainder of the ECS Warranty Period.

(3) Any warranted, emissions-related part that is scheduled for replacement as required maintenance in the Maintenance Schedule

(located in the section of the Manual(s) pertaining to maintenance)

shall be warranted for the period of time prior to the rst scheduled

replacement point for that part. If the part fails prior to the rst

scheduled replacement, the part shall be repaired or replaced by

Ardisam according to Subsection (4) below. Any such emissionsrelated part repaired or replaced under the ECS Warranty shall be

warranted for the remainder of the ECS Warranty Period prior to the

rst scheduled replacement point for such emissions-related part.

(4) Repair or replacement of any warranted, emissions-related part

under this ECS Warranty shall be performed at no charge to the

owner at an Ardisam Authorized Warranty Service Facility.

(5) When the engine is inspected by an Ardisam Authorized Warranty Service Facility, the owner shall not be held responsible for

diagnostic costs if the repair is deemed warrantable.

(6) Ardisam shall be liable for damages to other original engine

components or approved modications proximately caused by a

failure under warranty of any emission-related part covered by the

ECS Warranty.

(7) Throughout the ECS Warranty Period, Ardisam shall maintain a

supply of warranted emission-related parts sucient to meet the

expected demand for such emission-related parts.

(8) Any Ardisam authorized and approved emission-related

replacement part may be used in the performance of any ECS Warranty maintenance or repairs and will be provided without charge

to the purchaser/owner. Such use shall not reduce Ardisam’s ECS

Warranty obligations.

(9) Unapproved, add-on, modied, counterfeit and/or “grey market”

parts may not be used to modify or repair an Ardisam engine. Such

use voids this ECS Warranty and shall be sucient grounds for

disallowing an ECS Warranty claim. Ardisam shall not be held liable

hereunder for failures of any warranted parts of an Ardisam engine

caused by the use of such an unapproved, add-on, modied, counterfeit and/or “grey market” part.

(2) Air Induction System

(i) Controlled hot air intake system.

(ii) Intake manifold.

(iii) Air lter.

(3) Ignition System

(i) Spark Plugs.

(ii) Magneto or electronic ignition system.

(iii) Spark advance/retard system.

(4) Exhaust Gas Recirculation (EGR) System

(i) EGR valve body, and carburetor spacer if applicable.

(ii) EGR rate feedback and control system.

(5) Air Injection System

(i) Air pump or pulse valve.

(ii) Valves aecting distribution of ow.

(iii) Distribution manifold.

(6) Catalyst or Thermal Reactor System

(i) Catalytic converter.

(ii) Thermal reactor.

(iii) Exhaust manifold.

(7) Particulate Controls

(i) Traps, lters, precipitators, and any other device used to cap-

ture particulate emissions.

(8) Miscellaneous Items Used in Above Systems

(i) Electronic controls.

(ii) Vacuum, temperature, and time sensitive valves and switch-

es.

(iii) Hoses, belts, connectors, and assemblies.

EMISSION-RELATED PARTS INCLUDE THE FOLLOWING

(IF EQUIPPED):

(1) Fuel Metering System

(i) Carburetor and internal parts (and/or pressure regulator or

fuel injection system).

(ii) Air/fuel ratio feedback and control system.

(iii) Cold start enrichment system.

(iv) Fuel Tank.

19Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 20

Earthquake®, Division of Ardisam, Inc.

1160 8th Avenue, PO Box 666

Cumberland, WI 54829

800-345-6007 | Fax 715-822-2223

E-mail: info@getearthquake.com

All weights, specications and features are approximate and are subject to change without notice. Due to continuous product

improvements, product images may not be exact. Items used for props not included. Some assembly may be required.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Loading...

Loading...