Page 1

ASSEMBLY INSTRUCTIONS &

PARTS EXPLOSIONS

LOG SPLITTERS

W2265V 6.5 HP VIPER

W2260B 6 HP BRIGGS

RW2255H 5.5 HP HONDA

W2813V 13 HP VIPER ELECTRIC

RW2808H 8 HP HONDA

ARDISAM

.com

OMLS06

Rev. 8/23/07

© Copyright 2007 Ardisam, Inc.

All Rights Reserved. Printed in USA.

Page 2

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

Thank You . . .

for purchasing an Earthquake® Log Splitter from Ardisam, Inc.

We guarantee that this log splitter conforms to applicable North

American safety standards, and have worked to ensure that it meets

high standards for usability and durability. With proper care, it will

provide you with many years of service. Please take the time to read

this booklet carefully to learn how to correctly assemble and operate

your log splitter. Congratulations on your investment in quality.

CONTENTS

Safety Instructions ....................................................................... 2-3

Safety Decals ...................................................................................4

Set-up Instructions ....................................................................... 5-7

Parts Explosions ........................................................................ 8-18

Registration/Warranty ....................................................................19

SAFETY INSTRUCTIONS:

• Before operating this log splitter, carefully read this manual and

follow all instructions.

• Do not allow anyone to operate your log splitter who has not read

this manual.

• Never operate your log splitter for any other purpose than splitting wood.

• Donotoperatethelogsplitterundertheinuenceofalcohol,

drugs or medication.

• Never allow children to operate the log splitter. Keep small children away from the work area.

• If a second person is assisting in loading logs, never activate the

log splitter until the helper is clear of the work area.

PREPARATION:

• Dress appropriately when operating the log splitter. Always wear

safety footwear. Never wear sandals, sneakers, or open shoes,

and never operate the log splitter with bare feet. Do not wear

loose clothing or jewelry that might get caught in moving parts.

• Always wear safety glasses while operating your log splitter.

Wear proper head gear to keep hair away from moving parts.

• Always wear a protective hearing device.

• Ifyouweargloves,besuretheyaretightttingwithoutloose

cuffs or draw strings.

• Both ends of each log should be cut as square as possible to

help prevent the log from sliding out of the splitter during operation.

• Handle fuel with care; it is highly flammable.

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot engine.

c. Fill fuel tank outdoors with extreme care. Never fill fuel tank

indoors.

d. Replace gasoline cap securely and clean up spilled fuel before

restarting.

• Never attempt to make any adjustments to the log

splitter while the engine is running.

OPERATION:

• Never operate the log splitter without guards in place.

• Only operate the log splitter from the operator zone.

• Know how to stop the unit and disengage the controls.

• Never place hands and/or feet between log and splitting wedge

or between log and ram during forward or reverse stroke.

• Do not step over or straddle the log splitter when the engine is

running. Never reach or bend over the log splitter to pick up a

log.

• Never try to split more than one log at the same time.

• Never allow one person to operate the valve while another is

positioning the log.

• Never attempt to load your log splitter when the wedge is in motion.

• Only use your hand to operate the control lever. Never use your

foot or a rope or any other extension device.

• Always keep fingers away from any cracks that open in the log

during splitting operation.

• Never move the log splitter while the engine is running.

• Never leave your log splitter unattended with the engine running.

Shut off the engine if you are leaving your splitter--even for a

short period of time.

• Do not run the engine in an enclosed area. Exhaust gases

contain carbon monoxide. This odorless gas can be deadly when

inhaled.

• Do not operate your log splitter on slippery, wet, muddy, or icy

surfaces.

• Only operate your log splitter on level ground and not on a hillside.

• Never attempt to move the log splitter over hilly or uneven terrain

without a tow vehicle or adequate help.

• Always block wheels to prevent movement of log splitter while in

operation.

• Keep work area clear of tools, logs and any other debris.

• Always use your log splitter in daylight.

800-345-6007

Earthquake, Division of Ardisam, Inc.Page 2

Page 3

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

REPAIR AND MAINTENANCE SAFETY:

• Do not operate your log splitter in poor mechanical condition or

when in need of repair.

• Periodically check that all nuts, bolts, and screws are tightened.

• Always perform recommended maintenance procedures before

using your log splitter.

• Do not alter your log splitter in any manner such as attaching a

rope or extension to the control lever or adding to the width or

height of the wedge.

• Replace all damaged or worn parts immediately.

• Never tamper with the engine in order to operate at excessive

speeds. The maximum engine speed is preset by the manufacturer.

• Do not service or repair your log splitter without removing the

spark plug wire.

• All replacement parts must meet manufacturer’s specifications.

TOWING SAFETY:

• Obey all federal, state and local regulations when towing on

public roads and highways.

• Before towing, be certain that your log splitter is correctly and

securely attached to the towing vehicle and that a safety chain is

in place.

• Never carry any cargo or wood on your log splitter. Do not allow

anyone to sit or ride on your log splitter.

• Before using your log splitter, disconnect it from the towing

vehicle.

• When turning, parking, crossing an intersection, and driving in all

situations allow for added length of your log splitter.

• Be careful when backing up.

• Adjust towing speed for terrain and conditions.

• Never operate your log splitter under the influence of alcohol,

drugs or medication. A clear mind is essential for safety.

• Maximum speed of 45 mph is recommended when towing log

splitter.

FIRE PREVENTION:

• Never operate your log splitter near a flame or spark. Hydraulic

oil and gasoline are flammable and can explode.

• Do not fill the gas tank while the engine is hot or running. Allow

the engine to cool before refueling.

• Never smoke while operating or refueling your log splitter. Gas

fumes can easily explode.

• Only refuel your log splitter outdoors in a clear area. Always use

an approved fuel container. Always replace the gas cap securely.

• If gas is spilled, move machine away from the area of the spill

and avoid creating any source of ignition until the spilled gas has

evaporated or been cleaned up.

• Keep a Class B fire extinguisher nearby when operating your log

splitter in dry areas as a precautionary measure against possible

flying sparks.

• Completely drain the fuel tank prior to storage. Do not siphon by

mouth.

• Always store gasoline in an approved, tightly sealed container.

Store the container in a cool, dry place. Do not store indoors or

near a heating appliance.

HYDRAULIC SAFETY:

• The hydraulic system and mechanical parts of your log splitter require careful inspection. Be sure to replace any damaged

hydraulic component.

• Fluid escaping from a very small hole can be very difficult to see.

Do not check for leaks with your hand. Escaping fluid under pressure can have sufficient force to penetrate skin, causing serious

personal injury or even death. Leaks can be located by passing

a piece of cardboard or wood over the suspected leak. Look for

discoloration.

• If injured by escaping fluid, see a doctor at once. Serious infection or reaction can develop if proper medical treatment is not

administered immediately.

• Should it become necessary to loosen or remove any hydraulic

fitting or line, be sure to relieve all pressure by shutting off the

engine and moving the control handle back and forth several

times.

• The pressure relief valve on your log splitter is preset at the factory. Do not adjust the valve. Only a qualified service technician

should perform this adjustment.

Earthquake, Division of Ardisam, Inc. Page 3

800-345-6007

Page 4

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

USE EXTREME CARE WHEN TILTING THE

BEAM. DUE TO THE HEAVY WEIGHT OF

THE BEAM, SOME ASSISTANCE MAY BE

NEEDED TO INSURE SAFETY AND

PREVENT INJURY.

CAUTION

!

LBL4185

WARNING

!

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

READ AND UNDERSTAND OPERATOR'S MANUAL THOROUGHLY

BEFORE OPERATION. FAILURE TO DO SO MAY RESULT IN

SERIOUS INJURY.

KEEP ALL SHIELDS IN PLACE.

KEEP HANDS, FEET AND CLOTHING AWAY FROM POWER-

DRIVEN PARTS.

ALWAYS WEAR SAFETY GLASSES AND SAFETY SHOES

DURING OPERATION.

ALWAYS OPERATE OUT-OF-DOORS WITH GOOD VENTILATION.

ALWAYS STOP ENGINE AND REMOVE SPARK PLUG WIRE

BEFORE PERFORMING MAINTENANCE OPERATIONS.

ALWAYS SHUT OFF ENGINE WHEN LEAVING LOG SPLITTER

UNATTENDED, EVEN FOR A SHORT PERIOD OF TIME.

ONLY ONE PERSON SHOULD LOAD AND OPERATE THE LOG

SPLITTER. KEEP ALL OTHERS CLEAR DURING OPEATION.

NEVER ALLOW ONE PERSON TO OPERATE VALVE WHILE

ANOTHER IS POSITIONING THE LOG.

ALWAYS POSITION LOG WITH HANDS ON THE SIDES OF LOG.

KEEP HANDS CLEAR OF ENDS.

KEEP ALL CHILDREN AWAY FROM THE LOG SPLITTER.

DO NOT STEP OVER THE LOG SPLITTER.

ONLY USE HANDS TO OPERATE THE CONTROL VALVE.

DO NOT OPERATE THE LOG SPLITTER WHILE UNDER THE

INFLUENCE OF ALCOHOL, DRUGS OR MEDICATION.

ALWAYS OPERATE THE LOG SPLITTER ON LEVEL, DRY, NON-

SLIPPERY SURFACES. KEEP OFF SLOPES.

KEEP WORK AREA CLEAR OF SPLIT WOOD, DEBRIS OR OTHER

OBSTACLES.

ALWAYS STAY IN THE OPERATOR ZONE WHEN USING THE LOG

SPLITTER.

ALWAYS SPLIT WOOD IN THE DIRECTION OF THE GRAIN ONLY.

DO NOT ADD GASOLINE WHILE THE ENGINE IS HOT OR

RUNNING. ALLOW ALL SPILLED GAS TO EVAPORATE BEFORE

USING LOG SPLITTER.

LBL4178

Log Splitter Models

SAFETY DECALS

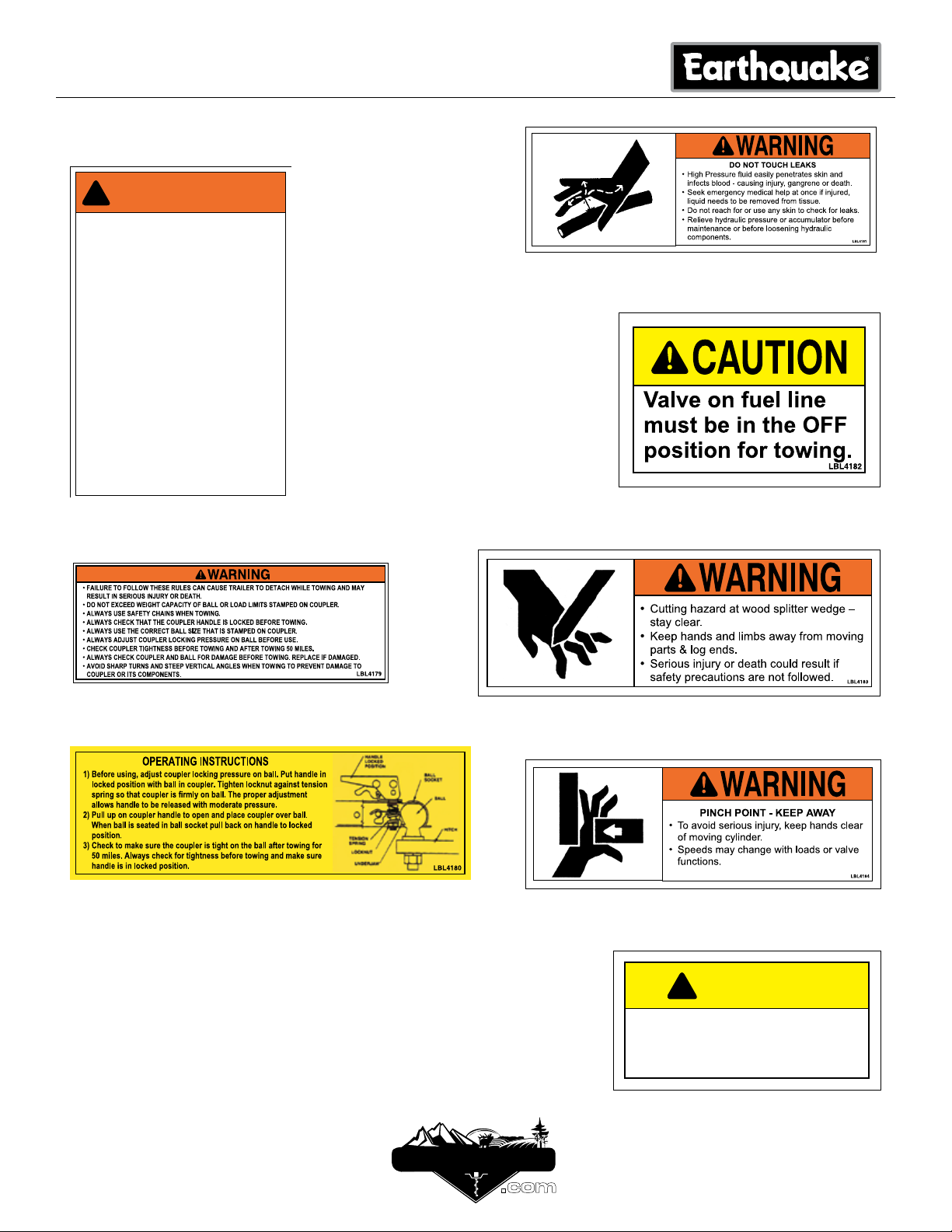

Part Number: LBL4178Description: All General Warnings Decal

Location: Back of Hydraulic Reservoir

Part Number: LBL4179

Description: Towing Warning Decal

Location: Tongue Near Trailer Hitch Coupler

Description: Do Not Touch Leaks Warning Decal

Part Number: LBL4181

Location: Hydraulic Cylinder

Part Number: LBL4182

Description: Fuel Line Caution Decal

Location: Rear Side of Reservoir, Left of Engine

Part Number: LBL4183

Description: Wedge Cutting Hazard Decal

Location: Beam

Part Number: LBL4180

Description: Coupler Operating Instructions Decal

Location: Tongue Near Trailer Hitch Coupler

800-345-6007

Description: Pinch Point Warning Decal

Part Number: LBL4184

Location: Beam

Part Number: LBL4185

Description: Tilting Beam Decal

Location: Beam

Earthquake, Division of Ardisam, Inc.Page 4

Page 5

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

SET-UP INSTRUCTIONS:

Tools needed - (2) 9/16” wrenches, (2) 1/2” wrenches, (2) 3/4” wrenches, (1)

atscrewdriver,(1)pairofpliers,(1)10”adjustablewrench,(1)pipewrench

and (1) rubber mallet.

NOTE: EACH LOG SPLITTER WAS PARTIALLY ASSEMBLED AT THE

FACTORY. REFER TO THE PARTS EXPLOSIONS FOR DETAILED ASSEMBLY.

IMPORTANT ASSEMBLY TIP: ALL THREADED HOSE CONNECTIONS

NEED TO BE WRAPPED WITH TEFLON TAPE SUPPLIED IN THE PARTS

BAG BEFORE CONNECTING HOSES.

1. Remove all components from the crate. Inspect each piece for shipping

damage. If any part is damaged, contact your dealer.

2. Attach the wheels to each side of the hydraulic cage by sliding the end of

the spindle into the tubes at the bottom of the cage. Make sure that the

holes line up as you insert the spindle. Secure in place with two 5/16-18

x 2-1/4” bolts and two 5/16-18 bi-way locknuts. Avoid damage to bearing

protectors while tapping in place with a rubber mallet.

NOTE: The rest of the assembly is easier done with at least two

people.

3. Next,attachkickstandtotongueusingone3/8-16x3”bolt,two3/8”at

washers, one 3/8-16 bi-way locknut, one 3/8” x 2-3/4” pin and one hair

clip. Attach the kickstand to the tongue so that it will support the weight

of the log splitter as you assemble the rest of the pieces. DO NOT OVER

TIGHTEN - MUST SWING FREELY.

4. Next, attach the tongue to the hydraulic cage using two 3/8-16 x 3” bolts

and two 3/8-16 bi-way locknuts. Attach travel lock assembly to the tongue

using two 3/8-16 x 3” bolts and two 3/8-16 bi-way locknuts. Position of pin

should be toward operator’s side.

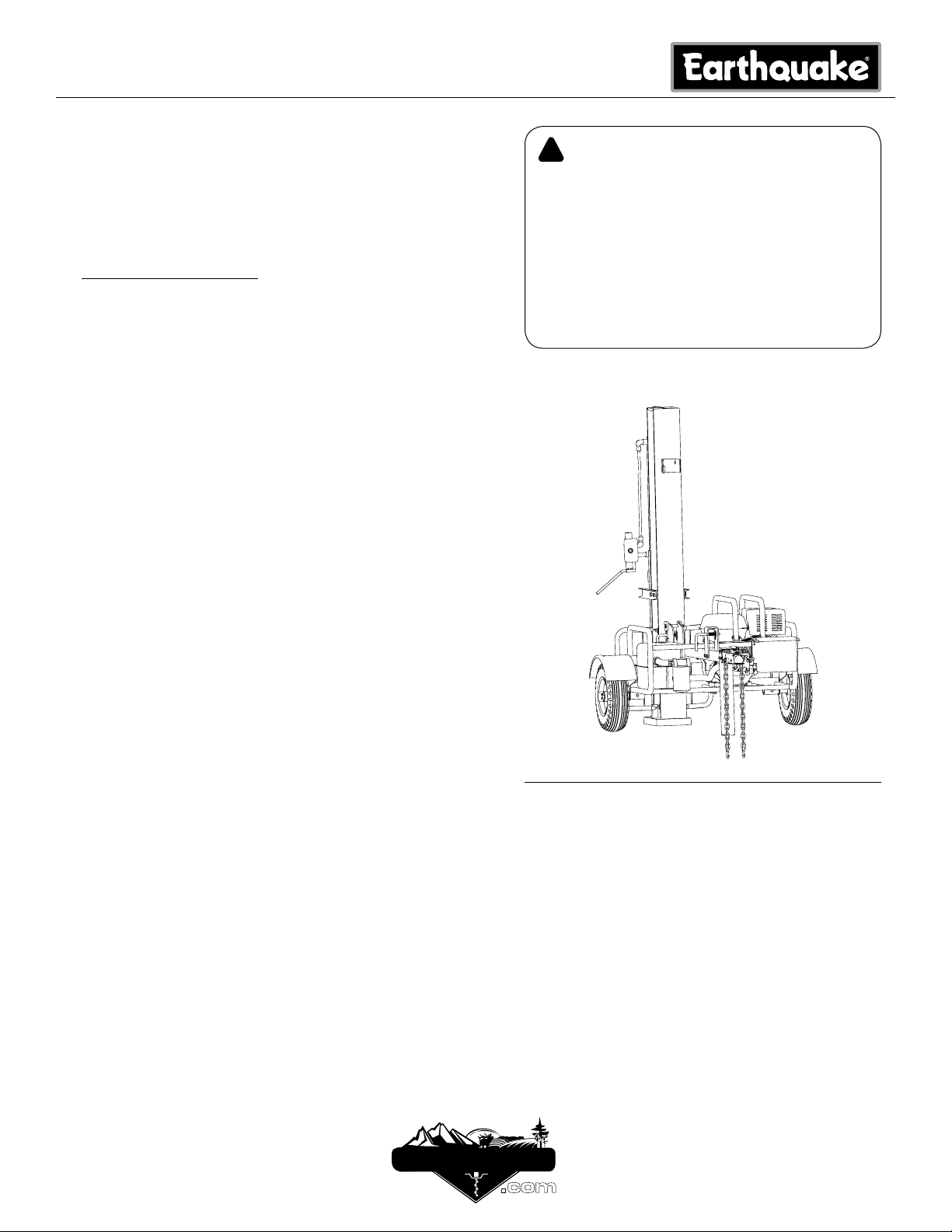

NOTE: At least two people are required to lift and assemble the

beam to the hydraulic cage. To avoid injury, always lift with your

legs and not your back.

5. Remove the beam and stand it upright on the foot as it would be in use.

Roll the hydraulic power pack into position and rotate the hydraulic power

pack with the tongue until the holes line up to insert the 5/8” x 4” pivot

pin. Insert a cotter pin into hole in pin and bend with pliers to secure. SEE

PARTS EXPLOSION ON PAGES 8 & 14 FOR MORE DETAIL.

6. Rotate the beam until it is horizontal. Install the stripper bars facing upward using four 1/2-13 x 1” bolts and four 1/2-13 bi-way locknuts. Install

the engine guard using two 1/4” x 2-1/4” safety snap pins and two 1/4-20

x 1-3/4” bolts with two 1/4-20 nyloc nuts.

!

WARNING

READ AND UNDERSTAND ALL ASSEMBLY,

SAFETY, & MAINTENANCE INSTRUCTIONS PROVIDED BEFORE EACH USE.

BECOME FAMILIAR WITH YOUR LOG SPLITTER

FOR YOUR OWN SAFETY. FAILURE TO DO SO

MAY CAUSE SERIOUS INJURY AND/OR DEATH.

DO NOT ALLOW ANYONE TO OPERATE YOUR

LOG SPLITTER WHO HAS NOT READ THIS MANUAL. READ EACH STEP COMPLETELY BEFORE

PROCEEDING.

LOG SPLITTER IN VERTICAL POSITION

Earthquake, Division of Ardisam, Inc. Page 5

800-345-6007

Page 6

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

7. Connect hose from bottom of valve control to pump and connect hose

fromltertotopofvalvecontrol.WraptightlyusingTeontapetoavoid

leaks.

8. Move control valve handle to operation position. Remove 1/4” pin and

1/16” cotter pin from parts bag and insert pin through hole in control

valve handle and secure with cotter pin.

9. Filling hydraulic reservoir. The capacity of the hydraulic tank is approxi-

mately 3.75 gallons. However, more oil may be required as oil ows

throughthevalve,pump,lter,andhoses.

a. Fill the reservoir with hydraulic oil 2 inches from the top.

b. Fill engine with crankcase oil and fuel as required.

c. Start the engine and operate the log splitter running the

wedge to the end of the beam and back. Repeat step a.

d. Start engine and operate the log splitter wedge to the end of the

beam and back until it runs smoothly. Check hydraulic oil level

to be sure it is 2 inches from top of tank when the wedge is in

the returned position.

STARTING:

IMPORTANT: THE ENGINE AND HYDRAULIC RESERVOIR ARE

SHIPPED WITHOUT OIL. SEE THE ENGINE OPERATOR’S MANUAL

PACKED WITH YOUR LOG SPLITTER FOR THE TYPE OF CRANKCASE

OIL, FUEL, ETC. THE ENGINE MANUFACTURER RECOMMENDS LEADFREE GASOLINE ONLY.

1. ThehydraulicreservoirshouldbelledwithanSAE30hydraulicoil(if

temperature will be above 50º Fahrenheit when operating unit) and SAE

20 hydraulic oil (if temperature will be between 32º Fahrenheit and 50º

Fahrenheit).Ifhydraulicoilisdifculttoobtain,automatictransmission

uidcanbesubstitutedandshouldbeusedinsteadofhydraulicoilwhen

temperatures are below 32º Fahrenheit. Use only clean oil and take care

to prevent dirt from entering the hydraulic reservoir.

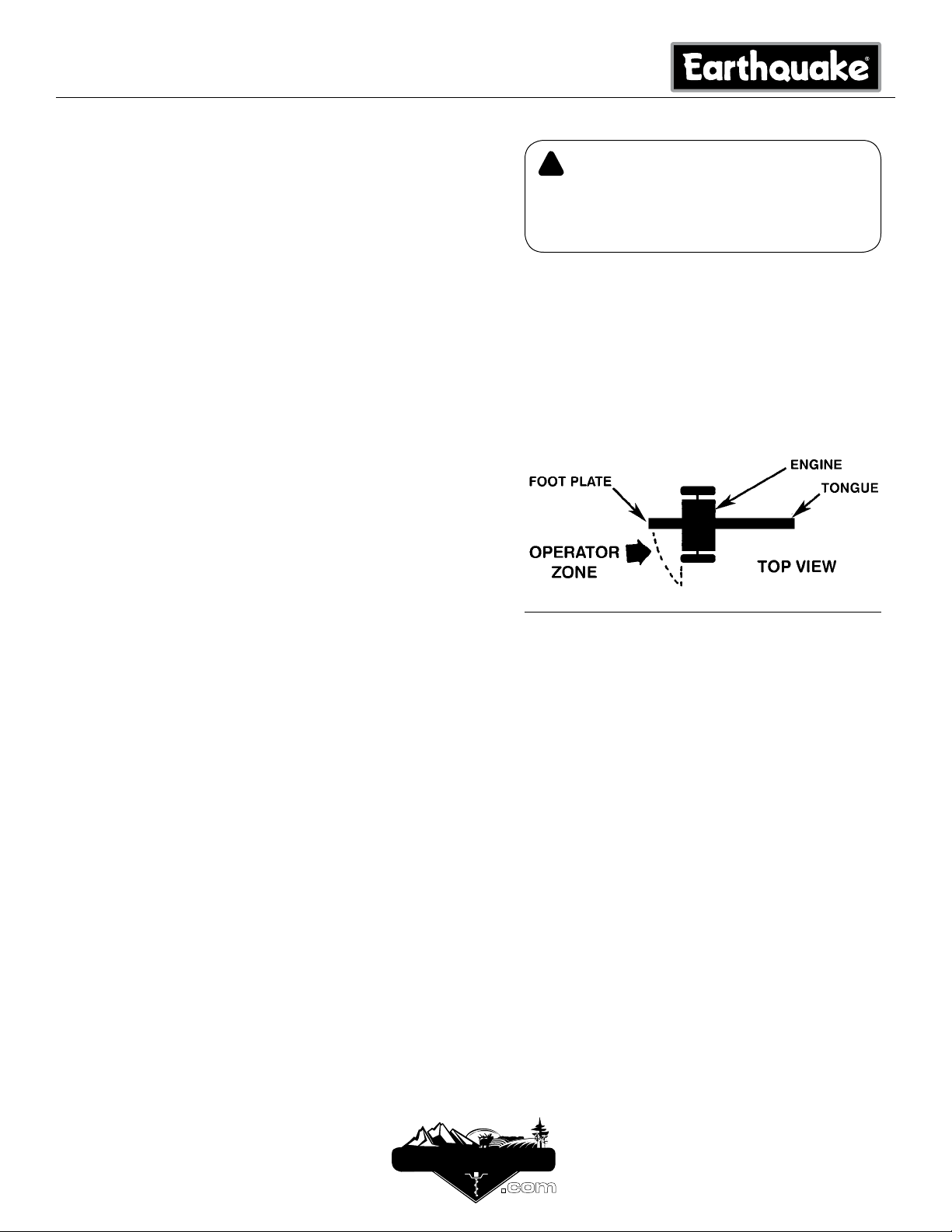

!

CAUTION

DO NOT START OR RUN THE ENGINE WITHOUT

OIL IN THE HYDRAULIC RESERVOIR AND ENGINE.

LOG SPLITTER OPERATOR ZONE

ENGINE OIL RECOMMENDATIONS:

1. Refer to Engine Operator’s Manual for further information.

STARTING INSTRUCTIONS:

1. Move the throttle lever to “FAST”. Always operate the engine with throttle

lever in the “FAST” position.

2. Move choke control lever to “CHOKE” position.

3. Grasp rope handle and pull slowly until resistance is felt. Then pull rapidly

to start engine and avoid engine kickback.

4. Allow the engine to warm up. If operating in warm weather, move the

choke control lever toward “RUN” in small increments over several

seconds. For cold weather operation do this procedure over several

minutes. Operate with choke lever in the “RUN” position.

5. To stop engine, move the throttle lever to the “STOP” position.

NOTE: The maximum governed speed on the engine is preset

at the factory to 3600 RPM no load speed. When splitting wood,

the throttle should be set at the maximum setting to develop the

horsepower required for the pump.

800-345-6007

Earthquake, Division of Ardisam, Inc.Page 6

Page 7

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

TOWING:

1. The log splitter is equipped with a safety chain and a coupler that requires

a 2 inch diameter ball. Before towing, the safety chain must be secured

to the hitch or bumper of the vehicle and the kickstand rotated to the road

position. Local regulations should be checked regarding licensing, lights,

towing, etc. See also Towing Safety in the Safety information section of

this manual.

OPERATION:

1. Set up the log splitter on a clear, level area and block the wheels. Make

sure that the suction port on the reservoir is always on the lower side of

the log splitter.

2. Place a log on the beam against the foot plate. Make sure that the log is

placed securely on the foot plate and up against the beam.

3. Depress the control valve handle so that the cylinder will drive the wedge

into the log. Extend the cylinder until the log splits or travels to the end of

its stroke. If the log has not completely split after the cylinder has reached

the end of its extension, retract the cylinder.

IMPORTANT: LEAVING THE VALVE IN THE “ACTUATE” POSITION AT

THE END OF THE STROKE MAY DAMAGE THE PUMP. ALWAYS USE

EXTRA CARE WHEN SPLITTING LOGS WITH ENDS NOT SQUARE.

NOTE: For operation in wooded areas, obtain a spark arrestor for

the exhaust system from the manufacturer of your engine. See also

Fire Prevention in the Safety information section of this manual.

IMPORTANT: TO EXTEND THE LIFE OF THE HYDRAULIC CYLINDER,

AVOID “BOTTOMING OUT” WEDGE PLATE TO THE FOOT PIECE. TO

CONFORM WITH INDUSTRY SAFETY RECOMMENDATIONS, THE

WEDGE STOPS TWO INCHES FROM THE END OF THE STROKE.

!

WARNING

ALWAYS WEAR SAFETY GLASSES DURING OPERATION.

KEEP HANDS AND FEET CLEAR OF RAM, STRIPPER CHANNELS AND FOOT PLATE AT ALL

TIMES.

DO NOT OPERATE LOG SPLITTER IF THE OIL

LEVEL IS MORE THAN TWO INCHES FROM TOP

OF TANK WHEN THE WEDGE IS IN THE RETURNED POSITION.

MAINTENANCE:

1. Consult the operating and maintenance instructions of the Engine

Operator’s Manual for engine care and maintenance.

2. Always check the oil level of the hydraulic reservoir before operation. Oil

must be no more than two inches from top of tank when the wedge is in

the returned position. Operating the log splitter without an adequate oil

supply will cause severe damage to the hydraulic pump.

3. Changetheoillteraftertherst25hoursofoperation.Thereafter,change

theoillterevery100hoursorseasonally,whichevercomesrst.

4. If the wedge becomes dull or nicked, it can be removed and sharpened.

While the log splitter is in the horizontal position, remove the 1/2” x 3-1/2”

bolt that connects the wedge to the hydraulic cylinder. Carefully rotate the

hydraulic cylinder, take special care not to damage the control valve. The

wedge can now be removed and sharpened.

6. Allreplacementpartsmustmeetmanufacturer’sspecications.

7. Check air pressure of tires before each use. Maintain pressure between

20 psi and 30 psi.

8. Grease wheel bearings annually.

Earthquake, Division of Ardisam, Inc. Page 7

800-345-6007

Page 8

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2265V, W2260B, RW2255H PARTS EXPLOSION

PARTS EXPLOSION & PARTS LIST FOR THE FOLLOWING

LOG SPLITTER MODELS:

6.5 HP VIPER (W2265V)

6 HP BRIGGS (W2260B)

5.5 HP HONDA (RW2255H)

800-345-6007

Earthquake, Division of Ardisam, Inc.Page 8

Page 9

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2265V, W2260B, RW2255H PARTS LIST

W2265V

REF. NO. PART NO. DESCRIPTION

1 4359 BOLT 3/8-16 X 3 HHCS 4 4 4

2 1662 NUT, NYLOC 3/16-16 7 7 7

3 4099 WHEEL, HIGH SPEED 2 2 2

4 4100 VALVE, 4-WAY CONTROL 1 1 1

5 4101 NIPPLE, PIPE 1/2” X 3” 1 1 1

6 4113 REDUCER 3/4” TO 1/2” BLK 2 2 2

7 4117 NUT, LOCK 1/2” BI-WAY 5 5 5

8 4121 COUPLER 90º SWIVEL 1/2” PIPE THREAD 2 2 2

9 4125 CYLINDER 4” X 24” X 1-3/4” 22-TON 1 1 1

10 4127 PIN, CLEVIS 1 1 1

11 4133 BOLT 5/16-18 X 3-1/2” HH GR5 ZN 1 1 1

12 4146 CHAIN, ASSEMBLED 2 2 2

13 4155 PIN, COTTER 5/32” X 1-1/2” SUPPLIED W/4099 5 5 5

14 4157 NUT, CASTLE 3/4” RETAINER 2 2 2

15 4159 WASHER 3/4” SPINDLE SAE 2 2 2

17 4210 HYDRAULIC HOSE 60” 2 2 2

18 4304 SQUARE TONGUE TUBE 1 1 1

19 4305 HORIZONTAL BEAM SUPPORT 1 1 1

20 4306 TONGUE STAND, FORMED 1 1 1

21 4314 STRIPPER BAR CHANNEL 2 2 2

22 43281 CAST WEDGE, MACHINED 1 1 1

23 4330 CHAIN SPACER 2 2 2

24 4331 FITTING 1/2” NPT TO 1/2” JIC 90º 2 2 2

25 4333 SPRING 1-3/4” 2 2 2

26 4334 PIN, JACK STAND 3/8” X 2.75” 1 1 1

27 4336 PIN, SPRING 1/2” 2 2 2

28 4337 PIN, PIVOT 5/8” X 4” 1 1 1

29 4339 SPINDLE, DRILLED 2 2 2

30 4343 LINE, HYDRAULIC CYLINDER STEEL ZN 1 1 1

31 4360 BOLT 3/8-16 X 4-1/2” HHCS 1 1 1

32 4362 BOLT 1/2-13 X 3-1/2” HHCS 1 1 1

33 4363 BOLT 1/2-13 X 1” HHCS 4 4 4

34 4386 COUPLER 2” BALL LATCH 1 1 1

35 26124 BOLT 5/16-18 X 1” HHCS GR5 ZN 8 8 8

QTY.

W2260B

QTY.

RW2255H

QTY.

Earthquake, Division of Ardisam, Inc. Page 9

800-345-6007

Page 10

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2265V, W2260B, RW2255H PARTS LIST

W2265V

REF. NO. PART NO. DESCRIPTION

36 48300 BOLT 5/16-18 X 2-1/4” HHCS GR5 ZN 2 2 2

37 300818 BEAM 1 1 1

38 300831 LOG CRADLE 0 0 2

39 300833 HYDRAULIC PACK, 6.5 HP VIPER & 5.5

HP HONDA (SEE PAGE 11 FOR PARTS

EXPLOSION)

39 300808 HYDRAULIC PACK, BRIGGS (SEE PAGE 12

FOR PARTS EXPLOSION)

40 60G5NY NUT, NYLOC 5/16-18 5 5 13

41 HAIR5 PIN, HAIR OVAL 5/16” 1 1 1

42 WF12 WASHER, FLAT 1/2” STANDARD ZN 3 3 3

43 WF38 WASHER, FLAT 3/8” STANDARD ZN 8 8 8

44 43591 BOLT 3/8-16 X 3-1/2” HHCS 2 2 2

300845 WHEEL FENDER 0 0 2

QTY.

1 0 1

0 1 0

W2260B

QTY.

RW2255H

QTY.

800-345-6007

Earthquake, Division of Ardisam, Inc.Page 10

Page 11

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2265V, RW2255H HYDRAULIC PACK

PARTS EXPLOSION

Earthquake, Division of Ardisam, Inc. Page 11

800-345-6007

Page 12

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2260B HYDRAULIC PACK

PARTS EXPLOSION

800-345-6007

Earthquake, Division of Ardisam, Inc.Page 12

Page 13

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2265V, W2260B, RW2255H HYDRAULIC PACK

PARTS LIST

REF. NO. PART NO. DESCRIPTION

1 503 BOLT 5/16-18 X 1-1/2” HH 4 4 4

2 504 LOCKWASHER, SPRING 5/16” 4 4 4

3 813 BOLT 5/16-24 X 1-1/4” HH 4 4 4

4 4105 COUPLER, LOV-JOY 1/2” ID 1 1 1

5 4106 FILTER KIT, HYDRAULIC 1 1 1

6 4122 PIPE FITTING 3/4” 90º STREET ELBOW 1 1 1

7 4137 COUPLER, SPIDER 1 1 1

8 4142 COUPLER, LOV-JOY 3/4” ID 1 1 1

9 4160 COUPLER, BARBED 1” 3 3 3

10 4169 CLAMP, HOSE 1-3/4” 4 4 4

11 4193 KEY, HALF-MOON #304 1 1 1

12 4321 PUMP ADAPTER PLATE 2 2 2

13 4344 HYDRAULIC PUMP 11 GPM 1” INLET 1/2” NPT 1 1 1

14 4352 KEY 3/16” X 3/4” 1 1 1

15 4364 BOLT 5/16-18 X 5-1/2” HHCS 2 2 2

16 4379 BOLT 5/16-18 X 5” HHCS ZN 4 4 4

17 63281 LOCK PIN, SAFETY 1/4” X 1-3/4” 2 2 2

18 48250 BOLT 1/4-20 X 1-3/4” HHCS GR5 ZN 2 2 2

19 48270 BOLT 1/4-20 X 2-1/2” HHCS GR5 ZN 2 2 2

20 53606 NUT, NYLOC 10-24 HH ZN 3 3 3

21 60365 ENGINE, 6.5 HP VIPER HORZ 1 0 0

21 60501 ENGINE, 6 HP BRIGGS INTEK HORZ SHAFT 0 1 0

21 35055 ENGINE, 5.5 HP HONDA 0 0 1

22 67538 NUT, NYLOC 1/4-20 HH ZN 2 2 2

23 300804 SCREW 10-24 X 6” RHM 3 3 3

24 300806 HYDRAULIC TANK 1 1 1

25 300807 FRAME WELDMENT 1 1 1

26 300809 SPACER, PUMP MOUNT 1 1 1

27 300810 SPACER, HYDRAULIC TANK 3 3 3

28 300819 TAPE, FOAM CLOSED CELL 2 2 2

29 300820 SUCTION HOSE 6-1/4” 1 1 1

30 300821 SUCTION HOSE 11” 1 1 1

31 4322 PUMP SPACER, EXTRUDED ALUMINUM 1 - -

300823 PUMP SPACER, EXTRUDED ALUMINUM - 1 1

32 300841 SPACER, FILTER 2 2 2

33 300850 ENGINE GUARD 2 2 2

34 60G5NY NUT, NYLOC 5/16-18 10 10 10

35 WF516 WASHER, FLAT 5/16” STANDARD ZN 8 8 8

36 6388 HYDRAULIC CAP W/PACKING RING 1 1 1

W2265V

QTY.

W2260B

QTY.

RW2255H

QTY.

Earthquake, Division of Ardisam, Inc. Page 13

800-345-6007

Page 14

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

21

8

31

9

6

10

5

29

23

23

7

4

38

35

39

20

32

40

16

8

27

13

42

26

44

24

13

1

2

3

28

36

42

3

14

15

13

3

12

2

45

22

33

130

19

25

1

43

2

17

42

18

26

48

44

13

42

24

11

37

41

34

46

47

45

Log Splitter Models

W2813V, RW2808H PARTS EXPLOSION

PARTS EXPLOSION & PARTS LIST FOR THE FOLLOWING

LOG SPLITTER MODELS:

13 HP VIPER (W2813V)

8 HP HONDA (RW2808H)

800-345-6007

Earthquake, Division of Ardisam, Inc.Page 14

Page 15

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2813V, RW2808H PARTS LIST

W2813V

REF. NO. PART NO. DESCRIPTION

1 4359 BOLT 3/8-16 X 3 HHCS 4 4

2 1662 NUT, NYLOC 3/16-16 7 7

3 4099 WHEEL, HIGH SPEED 2 2

4 4100 VALVE, 4-WAY CONTROL 1 1

5 4101 NIPPLE, PIPE 1/2” X 3” 1 1

6 4005 CYLINDER 4.5” X 24” X 1-3/4” 27-TON 1 1

7 4113 REDUCER 3/4” TO 1/2” BLK 2 2

8 4117 NUT, LOCK 1/2” BI-WAY 5 5

9 4121 COUPLER 90º SWIVEL 1/2” PIPE THREAD 2 2

10 4127 PIN, CLEVIS 1 1

11 4133 BOLT 5/16-18 X 3-1/2” HH GR5 ZN 1 1

12 4146 CHAIN, ASSEMBLED 2 2

13 4155 PIN, COTTER 5/32” X 1-1/2” SUPPLIED W/4099 5 5

14 4157 NUT, CASTLE 3/4” RETAINER 2 2

15 4159 WASHER 3/4” SPINDLE SAE 2 2

16 4210 HYDRAULIC HOSE 60” 2 2

17 4304 SQUARE TONGUE TUBE 1 1

18 4305 HORIZONTAL BEAM SUPPORT 1 1

19 4306 TONGUE STAND, FORMED 1 1

20 4314 STRIPPER BAR CHANNEL 2 2

21 43281 CAST WEDGE, MACHINED 1 1

22 4330 CHAIN SPACER 2 2

23 4331 FITTING 1/2” NPT TO 1/2” JIC 90° 2 2

24 4333 SPRING 1-3/4” 2 2

25 4334 PIN, JACK STAND 3/8” X 2.75” 1 1

26 4336 PIN, SPRING 1/2” 2 2

27 4337 PIN, PIVOT 5/8” X 4” 1 1

28 4339 SPINDLE, DRILLED 2 2

29 4343 LINE, HYDRAULIC CYLINDER STEEL ZN 1 1

30 4360 BOLT 3/8-16 X 4-1/2” HHCS 1 1

31 4362 BOLT 1/2-13 X 3-1/2” HHCS 1 1

32 4363 BOLT 1/2-13 X 1” HHCS 4 4

33 4386 COUPLER 2” BALL LATCH 1 1

34 8930 BOLT 1/4-20 X 3/4” HH GR5 ZN 4 4

35 26124 BOLT 5/16-18 X 1” HHCS GR5 ZN 8 8

QTY.

RW2808H

QTY.

Earthquake, Division of Ardisam, Inc. Page 15

800-345-6007

Page 16

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2813V

REF. NO. PART NO. DESCRIPTION

36 48300 BOLT 5/16-18 X 2-1/4” HHCS GR5 ZN 2 2

37 67538 NUT, NYLOC 1/4-20 HH ZN 4 4

38 300818 BEAM 1 1

39 300831 LOG CRADLE 2 2

40 300835 HYDRAULIC PACK 13 HP VIPER & 8

HP HONDA (SEE PAGE 17 FOR PARTS

EXPLOSION)

41 300845 WHEEL FENDER 2 2

42 60G5NY NUT, NYLOC 5/16-18 13 13

43 HAIR5 PIN, HAIR OVAL 5/16” 1 1

44 WF12 WASHER, FLAT 1/2” STANDARD ZN 3 3

45 WF38 WASHER, FLAT 3/8” STANDARD ZN 8 8

46 300857 BOX, BATTERY 1 -

47 300856 BATTERY 17 AMP HOUR 1 -

48 43591 BOLT 3/8-16 X 3-1/2” HHCS 2 2

QTY.

1 1

RW2808H

QTY.

800-345-6007

Earthquake, Division of Ardisam, Inc.Page 16

Page 17

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2813V, RW2808H HYDRAULIC PACK

PARTS EXPLOSION

Earthquake, Division of Ardisam, Inc. Page 17

800-345-6007

Page 18

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

W2813V, RW2808H HYDRAULIC PACK PARTS LIST

REF. NO. PART NO. DESCRIPTION

1 504 LOCKWASHER, SPRING 5/16” 4 4

2 1662 NUT, NYLOC 3/8-16 4 4

3 2001 BOLT 3/8-16 X 1-3/4” HH GR5 ZN 2 2

4 4105 COUPLER, LOV-JOY 1/2” ID 1 1

5 4106 FILTER KIT, HYDRAULIC 1 1

6 4122 PIPE FITTING 3/4” 90º STREET ELBOW 1 1

7 4137 COUPLER, SPIDER 1 1

8 4160 COUPLER, BARBED 1” 3 3

9 4169 CLAMP, HOSE 1-3/4” 4 4

10 4180 COUPLER, LOV-JOY 25MM ID 1 1

11 4193 KEY, HALF-MOON #304 1 1

12 4321 PUMP ADAPTER PLATE 1 1

13 4323 HYDRAULIC PUMP 16 GPM 1” INLET 1/2” NPT 1 1

14 4364 BOLT 5/16-18 X 5-1/2” HHCS 2 2

15 4365 KEY 3/16” X 3/4” 1 1

16 63281 LOCK PIN, SAFETY 1/4” X 1-3/4” 2 2

17 48250 BOLT 1/4-20 X 1-3/4” HHCS GR5 ZN 2 2

18 48270 BOLT 1/4-20 X 2-1/2” HHCS GR5 ZN 2 2

19 53606 NUT, NYLOC 10-24 HH ZN 3 3

20 60313 ENGINE, 13 HP VIPER HORZ 1 0

20 5018H ENGINE, 8 HP HONDA 0 1

21 67538 NUT, NYLOC 1/4-20 HH ZN 2 2

22 300804 SCREW 10-24 X 6” RHM 3 3

23 300806 HYDRAULIC TANK 1 1

24 300807 FRAME WELDMENT 1 1

25 300810 SPACER, HYDRAULIC TANK 3 3

26 300819 TAPE, FOAM CLOSED CELL 2 2

27 300820 SUCTION HOSE 6-1/4” 1 1

28 300841 SPACER, FILTER 2 2

29 300842 HYDRAULIC HOSE 1” X 16” 1 1

30 300848 PUMP SPACER, EXTRUDED ALUMINUM 1 1

31 300849 BOLT 8MM X 130MM HH 4 4

32 300850 ENGINE GUARD 2 2

33 300851 BOLT 3/8-16 X 2-1/2” HH GR5 ZN 2 2

34 60G5NY NUT, NYLOC 5/16-18 2 2

35 6388 HYDRAULIC CAP W/PACKING RING 1 1

W2813V

QTY.

RW2808H

QTY.

800-345-6007

Earthquake, Division of Ardisam, Inc.Page 18

Page 19

ARDISAM

.com

ASSEMBLY INSTRUCTIONS AND PARTS EXPLOSIONS

Log Splitter Models

REGISTRATION

Record your model number and serial number in the space provided

for easy reference. Fill out and mail the registration card located in

your parts packet. Warranty is valid only if your completed registration

card is received by Ardisam, Inc., at time of purchase.

Model Number

Serial Number

Date of Purchase

Place of Purchase

WARRANTY

Earthquake offers a one year limited warranty to be free from defects

in materials and workmanship for the service life of the product not

to exceed twelve consecutive months from the date of purchase.

The engine is covered under a separate warranty provided by the

manufacturer. This warranty applies to the original owner with a

proof of purchase and is not transferable. This warranty applies only

to products which have not been subjected to negligent use, misuse,

alteration, accident or if repairs have been made by anyone outside

our factory. This warranty supersedes all other warranties either expressed or implied and all other obligations or liabilities on our part.

Ardisam, Inc., does not assume, and does not authorize any other

person to assume for us, any liability in connection with the sale of our

products. Warranty work must be sent directly to Ardisam, Inc. or one

of our authorized service centers and performed by them. To obtain

warranty service and replacement instructions, contact our customer

service department at 800-345-6007 or by writing to: Ardisam, Inc.,

1690 Elm Street, Cumberland, WI 54829. All items must be shipped

prepaid. Ardisam, Inc. will at no charge, repair or replace, at their

discretion, any defective part which falls under the conditions stated

above.Ardisamretainstherighttochangemodels,specicationsand

price without notice.

Earthquake, Division of Ardisam, Inc. Page 19

800-345-6007

Page 20

ARDISAM

.com

Earthquake, Division of Ardisam, Inc.

1690 Elm Street

Cumberland, Wisconsin 54829

800-345-6007 · Fax (715) 822-2223

E-mail: info@ardisam.com

Loading...

Loading...