Page 1

Instruction Manual for the Airspeed MicroSensor V3

Document Version 1.1

Thank you for your purchase! This instruction manual will guide you through the installation and operation of your Airspeed MicroSensor

V3 (the MicroSensor). Please read the entire manual carefully before proceeding. If, after you read the manual, you have further

questions or problems, see the Support page on http://www.eagletreesystems.com for additional information, or email us at

support@eagletreesystems.com. Please visit our support web page for the full color, electronic version of this manual which may be

updated if changes were made after printing, or if you want to view the manual on your computer.

What the MicroSensor Does

The MicroSensor is a precision instrument that uses a Prandtl style pitot-static tube to measure airspeed, just as full sized planes do.

Advanced temperature compensation and calibration ensure the best possible accuracy. When used standalone, the MicroSensor displays

your maximum speed on the built-in 7 segment LED display. Additionally, the MicroSensor can be connected to your eLogger (any

version) to provide airspeed data for your entire flight. When connected to the eLogger, airspeed can be displayed and graphed using the

eLogger’s Windows software.

IMPORTANT: It is extremely unlikely that the installation of the MicroSensor will affect your model’s radio range or control. But, as

always after making an electronics change to your model, it is very important that you range and function test your model once the

MicroSensor is installed to ensure that there is no impact on your system.

Packing List

Your package should include the following: The MicroSensor, a machined brass and aluminum Prandtl style pitot-static tube, the Standalone

Cable, two lengths of approximately 3 foot (1 meter) small diameter silicon hose, and a printed version of this manual. NOTE: Additional

Pitot Tube kits are available for purchase on our website, for use with multiple models.

Installing the Pitot Tube and MicroSensor in your Model

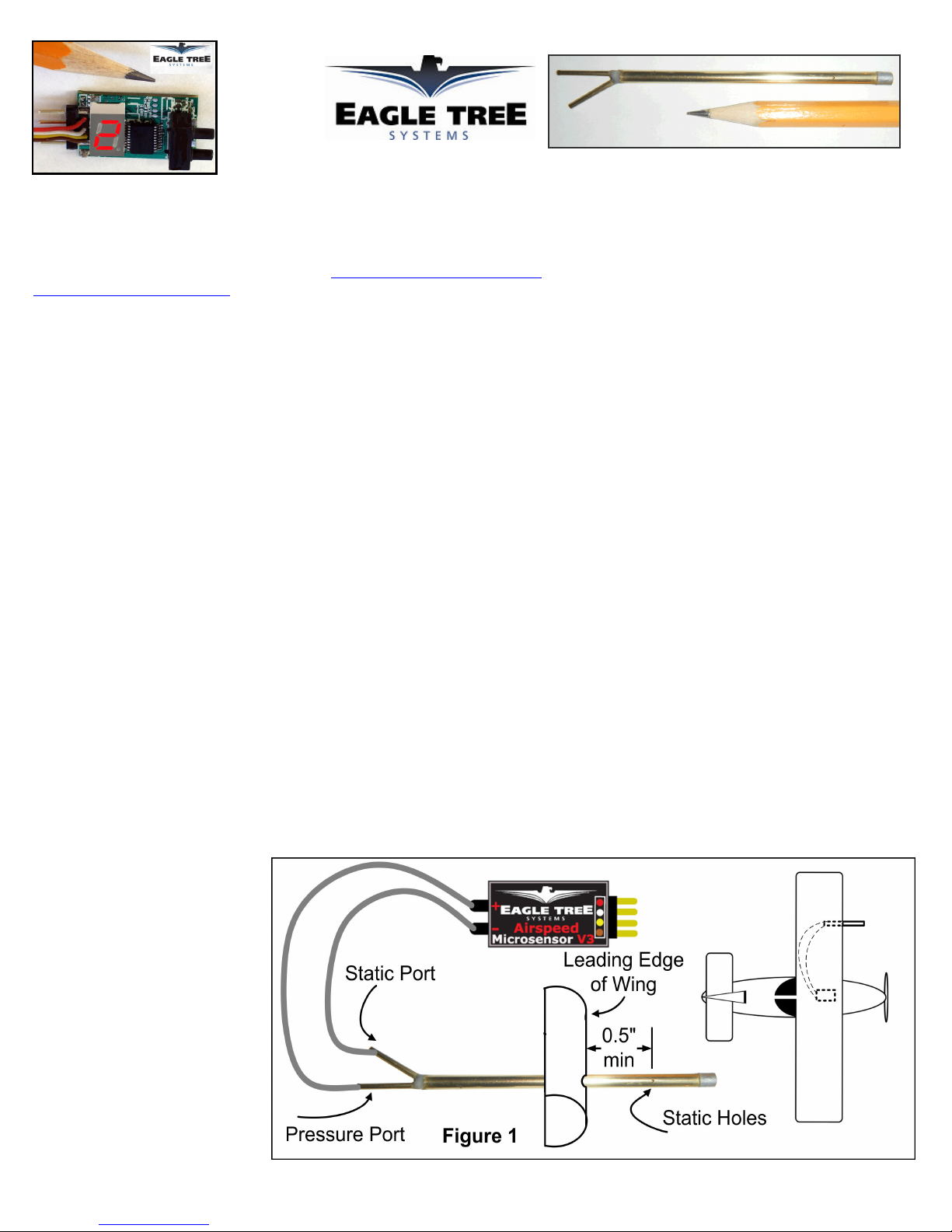

Using two lengths of the included small diameter silicon tube, the pressure and static connections of the pitot tube connect to the “+” and “-”

ports of the MicroSensor, respectively, as shown in Figure 1. It is best to mount the pitot tube in your model first, then determine where

you will mount the MicroSensor, and then cut the two lengths of silicon tube so they reach between the two.

Follow these guidelines when mounting the pitot tube:

1. The pickup end of the pitot tube (the silver colored tip) should be pointing toward the direction of the model’s travel. While best results

will be obtained if the pitot tube is perfectly aligned with the direction of travel in both axes, the “Prandtl” design of the tube will

compensate somewhat for higher angles of attack.

2. The static holes on the pitot

tube (shown on Figure 1)

should extend at least 1/2”

(13mm) past the wing’s

leading edge, or past any other

obstructions - the farther out,

the better. This is to ensure

that the static holes and pitot

pickup are in undisturbed air.

3. For prop planes, it’s important

that the tube be placed so that

it is not directly in the plane’s

prop-wash, which will result in

erroneous readings. The best

place to install the tube is on

the leading edge of the wing

Copyright © 2008 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Page 2

Page

2

several inches out from the fuselage, as shown in Figure 1.

4. For jets, gliders, or “pusher” prop planes, the nose cone often provides a perfect mounting location.

After Pitot Tube installation, it is recommended that you glue or otherwise attach the silicon hose to the airframe, to reduce the chance that

hose vibration or movement could cause erroneous readings.

The MicroSensor circuit board can be mounted anywhere in the model. If you wish to read the LED without removing the wing, a small

rectangular hole can be cut at the mounting location of the circuit board, and the board mounted with tape or Velcro, so that the LED is

visible at all times.

Using the MicroSensor in Standalone Mode

Powering the MicroSensor in Standalone Mode

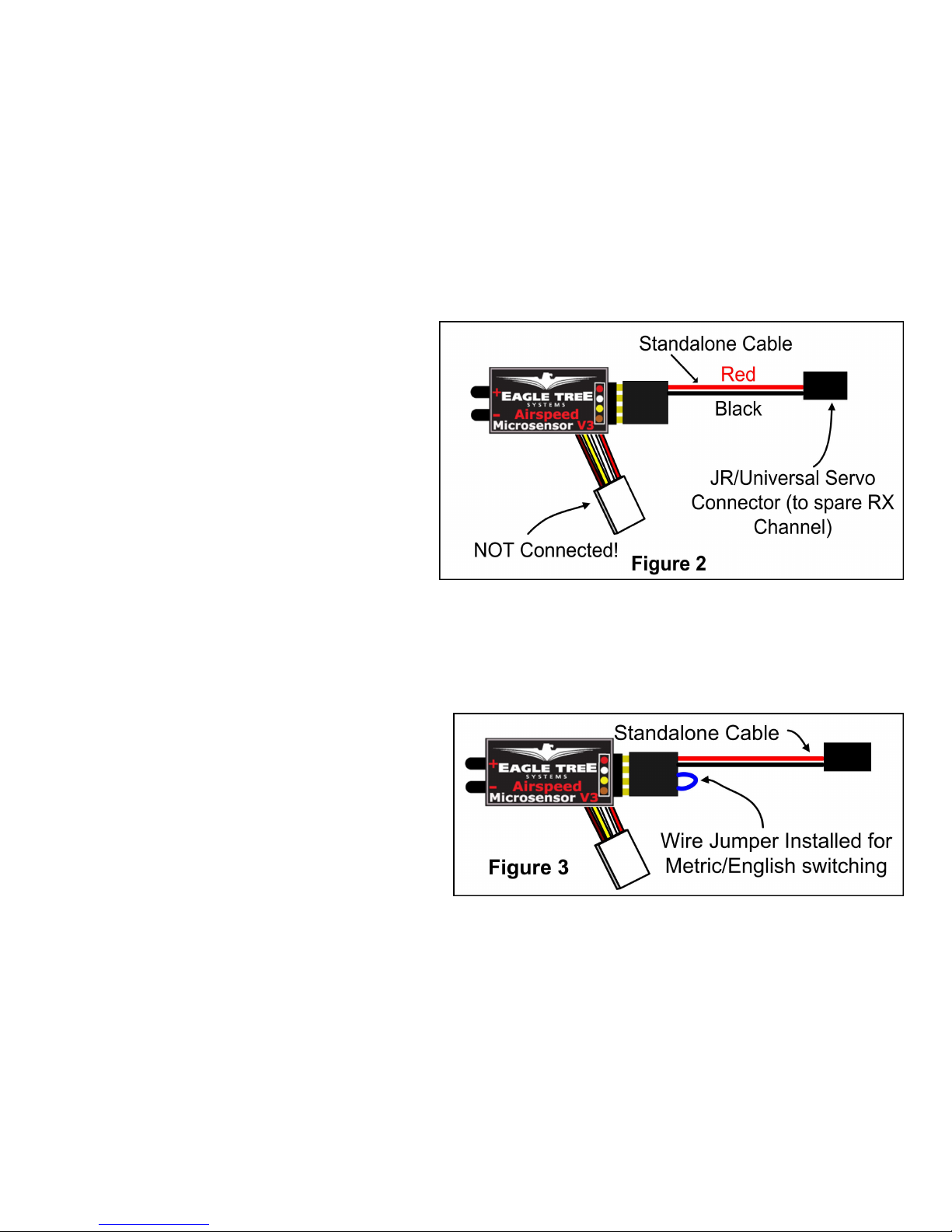

For standalone mode (not connected to an eLogger), connect

the Standalone Cable to the gold pins of the MicroSensor, as

shown in Figure 2. Note that the RED wire of the standalone

cable corresponds with the red dot on the label.

The JR/Universal servo end of the Standalone Cable connects

to a spare Receiver channel or small battery. Note that the

voltage must be between 3V and 16V. Do not exceed 16V!

IMPORTANT: Ensure that you connect the Standalone

Cable with the correct polarity, or the MicroSensor could

be damaged, voiding the warranty!

Note that in Standalone Mode, the 4 wire cable built into

the MicroSensor must NOT be connected to anything!

Configuring Metric vs English Units in Standalone Mode

When powered on, the LED readout will briefly display “0” if the unit is configured for English (MPH), or will display a “1” if configured

for metric (KPH). The factory default configuration is MPH.

To switch between English and metric units, connect the

Standalone Cable as described above, but don’t power the

MicroSensor. Then, connect a small piece of wire between the

unconnected pins of the Standalone Cable’s 4 pin connector,

corresponding to the brown and yellow dots on the label, as

shown in Figure 3. This creates a jumper between the brown

and yellow labeled pins.

Then, power the MicroSensor via the Standalone Cable. A “0”

will then flash a few times to indicate that English units are

configured, or a “1” will flash if Metric units are configured. If

the wrong units are configured, just disconnect the power from the MicroSensor and reconnect it.

Once the desired units are configured, disconnect from power and remove the wire jumper. Then, when reconnected to power, the desired

units should be displayed briefly (“0” or “1”).

Reading Airspeed in Standalone Mode

When the MicroSensor is powered on, after the Units setting is displayed (“0” or “1”), the highest speed attained during your last flight is

repeatedly displayed, one digit at a time, on the LED. For example, if the highest speed attained was 120MPH, “1 – 2 – 0” will flash

repeatedly on the LED, with a pause (blank LED) after the speed is completely displayed, but before it is displayed again.

After landing from your next flight, the highest speed attained during that flight is displayed automatically, overwriting the highest speed

from your prior flight. Note that a speed of at least 9 MPH (15 KPH) must be attained before a new highest speed is displayed.

Copyright © 2008 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Page 3

Page

3

The highest speed of your last flight is automatically saved, so that when you turn the unit back on, that speed is displayed.

For example, if you fly and reach a max speed of 100 MPH, when you land “1 – 0 – 0” will be displayed. Then, when you turn power off

and on, “1 – 0 – 0” will again be displayed. If you then fly again and reach a speed of 50 MPH, “5 – 0” will be displayed when you land.

Using the MicroSensor with your eLogger

Windows Application and Firmware Update

To use the MicroSensor, you must update to Eagle Tree Windows Application version 6.77 or higher. To update, download the latest

application from the support page of our website, located at http://eagletreesystems.com/Support/apps.htm . After downloading and

installing the Application, the firmware of your MicroPower eLogger will need to be updated. To upgrade your firmware, just choose

“Tools, Firmware Control” and click the Update button.

Connecting the MicroSensor to the eLogger V3

The MicroSensor plugs into the “LCD/TX” port of your eLogger V3, as shown in Figure 4. If you have a PowerPanel or other

MicroSensors, those can “daisy chain” connect to the pins on the other side of your MicroSensor, with the polarity as indicated on the

MicroSensor label. NOTE: The Standalone Cable must not be used when connected to the eLogger!

Connecting the MicroSensor to the eLogger V1/V2

The MicroSensor plugs into the “Aux” or “LCD” port of your eLogger V1/V2, as shown in Figure 4. If you have a PowerPanel or other

MicroSensors, those can “daisy chain” connect to the pins on the other side of your MicroSensor, with the polarity as indicated on the

MicroSensor label. NOTE: The Standalone Cable must not be used when connected to the eLogger!

Configuring the MicroSensor with the Windows Application

If you have not already done so, set up the Recorder software as described in your instruction manual. Then, choose one or more of the

MicroSensor options below:

Logging Airspeed

To log airspeed, just click “Hardware, Choose Parameters to Log in the Recorder” and check the “Airspeed” box.

Displaying Airspeed in the Windows Application

To display the Airspeed Gauge and/or Numeric Airspeed Display, click “Software, Choose Instruments to Display on the PC Screen” and

check the “Airspeed Indicator Gauge,” and/or “Numeric Speed” boxes.

Graphing Airspeed

To graph airspeed, click “Chart, 2D Chart,” select either the Left Y Axis or Right Y Axis, and select “Speed” for graphing.

Displaying Airspeed on the PowerPanel

Select “Hardware, Configure PowerPanel Display”, and choose “Speed” for PowerPanel display.

Troubleshooting

Below is a list of problems that may be encountered, and steps to remedy them. If your particular issue is not addressed by the below, see

the Support page on http://eagletreesystems.com or email support@eagletreesystems.com. Include a full description of your problem, your

PC configuration, your Eagle Tree hardware and software versions, and any other relevant information.

Copyright © 2008 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Page 4

Page

4

Issue: Airspeed doesn’t vary in my recordings

Solutions:

• Ensure that the MicroSensor is connected correctly to the MicroPower

• Ensure that you are logging airspeed, under “Tools, Choose Parameters to Log in the Recorder”

• Ensure that the Pitot Tube is connected

Issue: My plane shows an airspeed variation during warm-up on the ground as I rev the throttle.

Solution: This problem can occur when the Pitot Tube’s opening is being hit by prop-wash. The solution is to move the tube farther away

from propeller airflow. Note that slight variations in speed is normal when stationary.

Specifications (Approx)

•

Measures airspeed from 2 MPH to 350 MPH (3KPH to 563KPH), with 1 MPH (1 KPH) Resolution

•

Power input (Standalone Mode) – 3V to 16V

•

Circuit Board: Weight 4 grams (0.15 oz), dimensions 28 mm x 16 mm x 10 mm (1.1” x 0.62” x 0.4”)

•

Pitot Tube: Weight 3 grams (0.1 oz), length 80mm (3.2”), diameter 4 mm (0.16”)

•

Precalibrated – no user calibration required

•

Advanced Temperature Compensation

•

Metric or English units

Limited Warranty

Eagle Tree Systems, LLC, warrants the MicroSensor to be free from defects in materials and workmanship for a period of one

(1) year from the date of original purchase. This warranty is nontransferable. If your unit requires warranty service during

this period, we will replace or repair it at our option. Shipping cost to us is your responsibility. To obtain warranty service,

email support@eagletreesystems.com for further instructions.

This limited warranty does not cover:

• The Software. See the Software license agreement for more information on Software restrictions.

• Problems that result from:

o

External causes such as accident, abuse, misuse, or problems with electrical power

o

Servicing not authorized by us

o

Usage that is not in accordance with product instructions

o

Failure to follow the product instructions

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH

VARY FROM STATE TO STATE (OR JURISDICTION TO JURISDICTION). OUR RESPONSIBILITY FOR

MALFUNCITONS AND DEFECTS IN HARDWARE IS LIMITED TO REPAIR AND REPLACEMENT AS SET FORTH IN

THIS WARRANTY STATEMENT. ALL EXPRESS AND IMPLIED WARRANTIES FOR THE PRODUCT, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES AND CONDITIONS OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED IN TIME TO THE TERM OF THE LIMITED WARRANTY PERIOD AS

DESCRIBED ABOVE. NO WARRANTIES, WHETHER EXPRESS OR IMPLIED, WILL APPLY AFTER THE LIMITED

WARRANTY PERIOD HAS EXPIRED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, SO THIS LIMITATION MAY NOT APPLY TO YOU.

WE DO NOT ACCEPT LIABILITY BEYOND THE REMEDIES PROVIDED FOR IN THIS LIMITED WARRANTY OR

FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT LIMITATION, ANY LIABILTY FOR

THIRD-PARTY CLAIMS AGAINST YOU FOR DAMAGES, FOR PRODUCTS NOT BEING AVAILABLE FOR USE, OR

FOR LOST DATA OR LOST SOFTWARE. OUR LIABILITY WILL BE NO MORE THAN THE AMOUNT YOU PAID

FOR THE PRODUCT THAT IS THE SUBJECT OF A CLAIM. THIS IS THE MAXIMUM AMOUNT FOR WHICH WE

ARE RESPONSIBLE. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Copyright © 2008 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Loading...

Loading...