Eagle Access Control Systems X9S, X9L Installation & Owner's Manual

X9S & X9L

ACCESS CONTROL SYSTEMS, INC.

BY

EAGL

E

AC

CESS CONT

RO

L SYST

E

MS, INC.

TM

X9L - Long Arm

X9S - Short Arm

X9S & X9L

Swing Gate Operators

Gate Capacity 16 ft - 800 lbs.

Gate Capacity 10 ft - 700 lbs.

Installation & Owners Manual

AVI Slide Rev - C

2

X9 Swing Rev - H

ou

essed

publishe

spec

subjec

TABLE OF CONTENTS

UL 325 Listings

UL 325 Model Classifications

Swing Gate Recommendations

Important Safety Informatio

General Safety Information

Sample Single Gate Installation Setups

Sample Dual Gates Installation Setups

Disassemble Operator

Mount Arm

Mount Control Box

Open INSIDE Mounting Dimensions

Open OUTSIDE Mounting Dimensions

Adjusting Physical Limits

120 VAC Input Power Connection

Photo Eye Installation

Open INSIDE - Single Operator & Photo Eye Wiring

Open OUTSIDE - Single Operator & Photo Eye Wiring

Open INSIDE - Dual Operators & Photo Eye Wiring

Open OUTSIDE - Dual Operators & Photo Eye Wiring

Wiring Accessories

Advanced Accessory Connection

Loop Detectors

DIP-Switch Descriptions

n

INSTALLATION

SAFETY

2

2

3

4

5

5

6

6

7

8

9

10

11

12

13

13

14

15

16

17

18

19

20

21

22-23

PROGRAMMING & ADJUSTMENTS

Program Travel Distance and Pause Time to Close Gate(s)

SINGLE Gate Programming

Bi-Parting Gates Programming

Modify Programmed Pause Time

LEARN Remote Button

Adjust Reverse Sensor

Power Fail Operation

Control Box Wiring Diagram

X9 SWING GATE OPERATOR SPECIFICATIONS

Control Box Power 115 VAC @ 60 Hz - 4 amps per Arm

Motor Power 24 VDC @ 180 Watts per Arm

Thrust 1900

Normal Gate Cycles Intensive

Traveling Distance (Drive Screw) X9S: 13 3/4” X9L: 19 5/8”

Max Gate Length X9S: 10 ft per Gate X9L: 16 ft Per Gate

Max Gate Weight X9S: 700 lbs per Gate X9L: 800 lbs per Gate

Opening Time 90° X9S: 20 sec X9L: 25 sec

Entrapment Protection:

Built-In ERD adjustable reversing sensor

Input for non-contact sensor

Input for contact sensor

24

24

24

25

26

26

27

27

28

Control Box

11”

BY EAGLE ACCESS CONTROL SYSTEMS, INC.

4 5/8” 8 3/4”

X9L - Long Arm

41”

5 1/2”

5”

X9S - Short Arm

35”

© 2018 Eagle Access Control Systems, Inc.

All rights reserved. No part of this manual may be reproduced in any means: graphics, electronics or mechanical. Including photocopying

t the expr

with

X9 Slide Rev - H

written permission of the

r. Materials components and

ifications are

t to change without notice.

1

SAFETY

UL 325 Listings

1. Install the gate operator only when:

a) The operator is appropriate for the construction of the gate and the usage class of the gate.

b) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 6 feet (1.83 m) above the

ground to prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the openings anywhere in the gate, and in that portion

of the adjacent fence that the gate covers in the open position.

c) All exposed pinch points are eliminated or guarded, and

d) Guarding is supplied for exposed rollers.

2. The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access opening. The

pedestrian access opening shall be designed to promote pedestrian usage. Locate the pedestrian gate such that persons will not come in

contact with the vehicular gate during the entire path of travel of the vehicular gate.

3. The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when opening and

closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

4. The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do not over-tighten the

operator clutch or pressure relief valve to compensate for a damaged gate.

5. For gate operators utilizing Type D protection:

a) The gate operator controls must be placed so that the user has full view of the gate area when the gate is not moving.

b) The placard provided marked in letters at least 1/4 in. (6.4-mm) high with the word “WARNING” and the following statement or the

equivalent: “Moving Gate Has the Potential of Inflicting Injury or Death – Do Not Start Gate Unless Path is Clear” shall be placed adjacent

to the controls,

c) An automatic closing device (such as a timer, loop sensor, or similar device) shall not be employed, and

d) No other activation device shall be connected.

6. Controls intended for user activation must be located at least six feet (6’) away from any moving part of the gate and where the user is

prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily accessible controls shall have a

security feature to prevent unauthorized use.

7. The Stop and /or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall not cause the operator to

start.

UL 325 Listings

8. A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

9. For gate operators utilizing a non-contact sensor in accordance with Usage Class:

a) See instructions on the placement of non-contact sensors for each type of application,

b) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the sensor while the gate is still moving,

and

c) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter reachable

by a moving gate or barrier.

10. For gate operators utilizing a contact sensor in accordance with Usage Class:

a) One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading edge, trailing

edge, and post-mounted both inside and outside of a vehicular horizontal slide gate.

b) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

c) One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

d) A hardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor and the gate

operator is not subjected to mechanical damage.

e) A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for entrapment protection

functions shall be located where the transmission of the signals are not obstructed or impeded by building structures, natural

landscaping or similar obstruction. A wireless contact sensor shall function under the intended end-use conditions.

f) One or more contact sensors shall be located on the inside and outside leading edge of a swing gate.

Additionally, if the bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of travel, one

or more contact sensors shall be located on the bottom edge.

g) One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

2

X9 Swing Rev - H

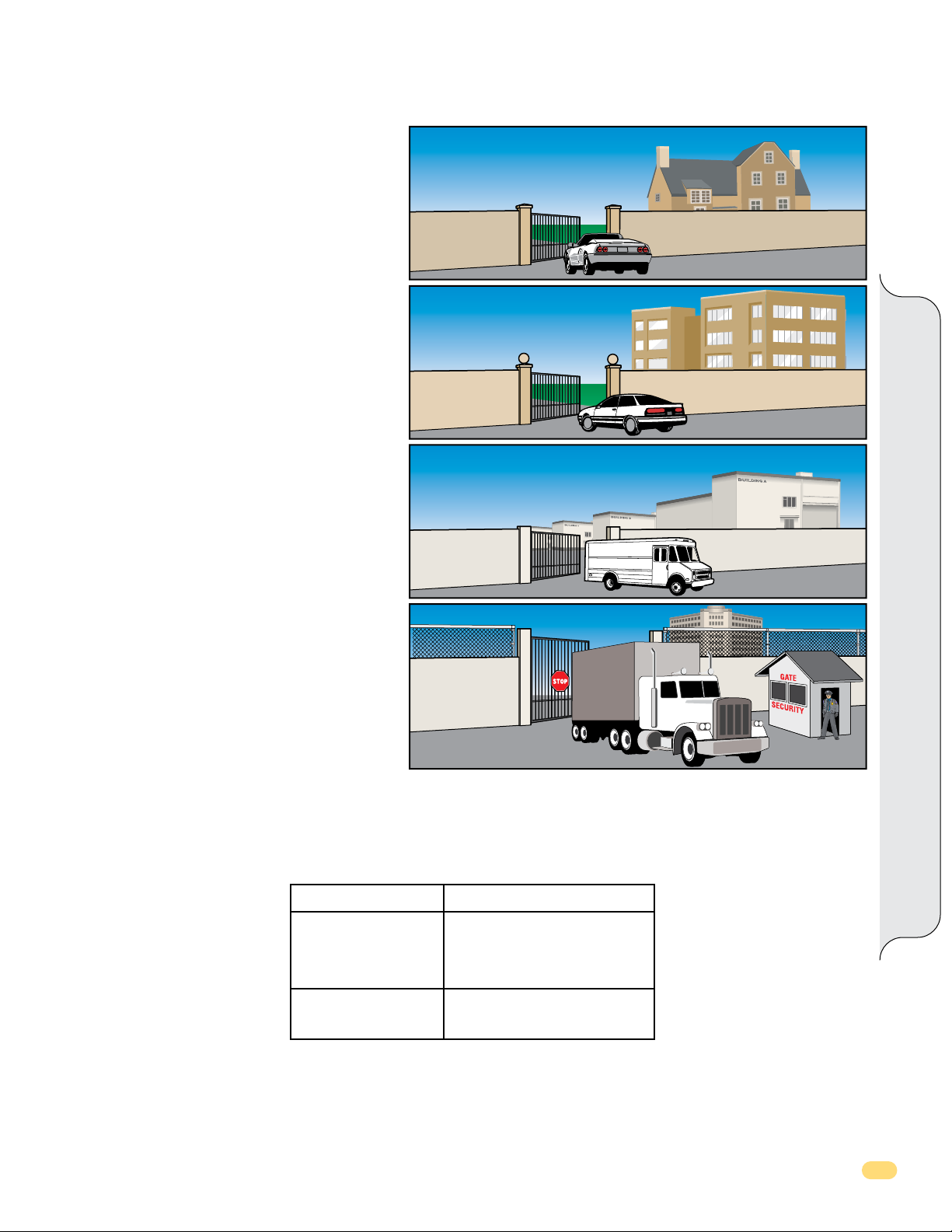

UL 325 Model Classifications

CLASS I

Residential Vehicular Gate Operator - A vehicular gate

operator (opener or system) intended for use in a home

of one to four single family dwellings, or a garage or

parking area associated therewith.

CLASS II

Commercial/General Access Vehicular Gate Operator - A

vehicular gate operator (opener or system) intended for

use in a commercial location or building such as a

multi-family housing unit (five or more single family

units) hotel, garages, retail store or other building

servicing the general public.

CLASS III

Industrial/Limited Access Vehicular Gate Operator - A

vehicular gate operator (opener or system) intended for

use in a industrial location, loading dock area or other

location not intended to service the general public.

CLASS I

CLASS II

UL 325 Classifi cations

CLASS III

CLASS IV

Restricted Access Vehicular Gate Operator - A vehicular

gate operator (opener or system) intended for use in a

guarded industrial location or buildings such as airport

security area or other restricted access locations not

servicing the general public, in which unauthorized

access is prevented via supervision by security

personnel.

CLASS IV

UL 325 Entrapment Protection

Entrapment Protection Requirements for Each Type of Operator.

Proper installation must satisfy the entrapment protection chart as shown.

Gate Type

Horizontal Slide

Vertical Lift

Vertical Pivot Gate

Swing Gate or

Vertical Barrier (arm)

A - Inherent (built into the gate operator) entrapment protection.

B1 - Non-contact sensor such as photo-eye or equivalent.

B2 - Contact sensor such as edge sensor or equivalent.

Entrapment Protection

A, B1*, B2* or D

A, B1*, B2* C or D

C - Inherent adjustable clutch or pressure relief device.

D - Actuating device requiring continuous pressure to

maintain gate motion.

* UL 325 requires that B1 and B2 means of entrapment protection must be MONITORED.

X9 Slide Rev - H

3

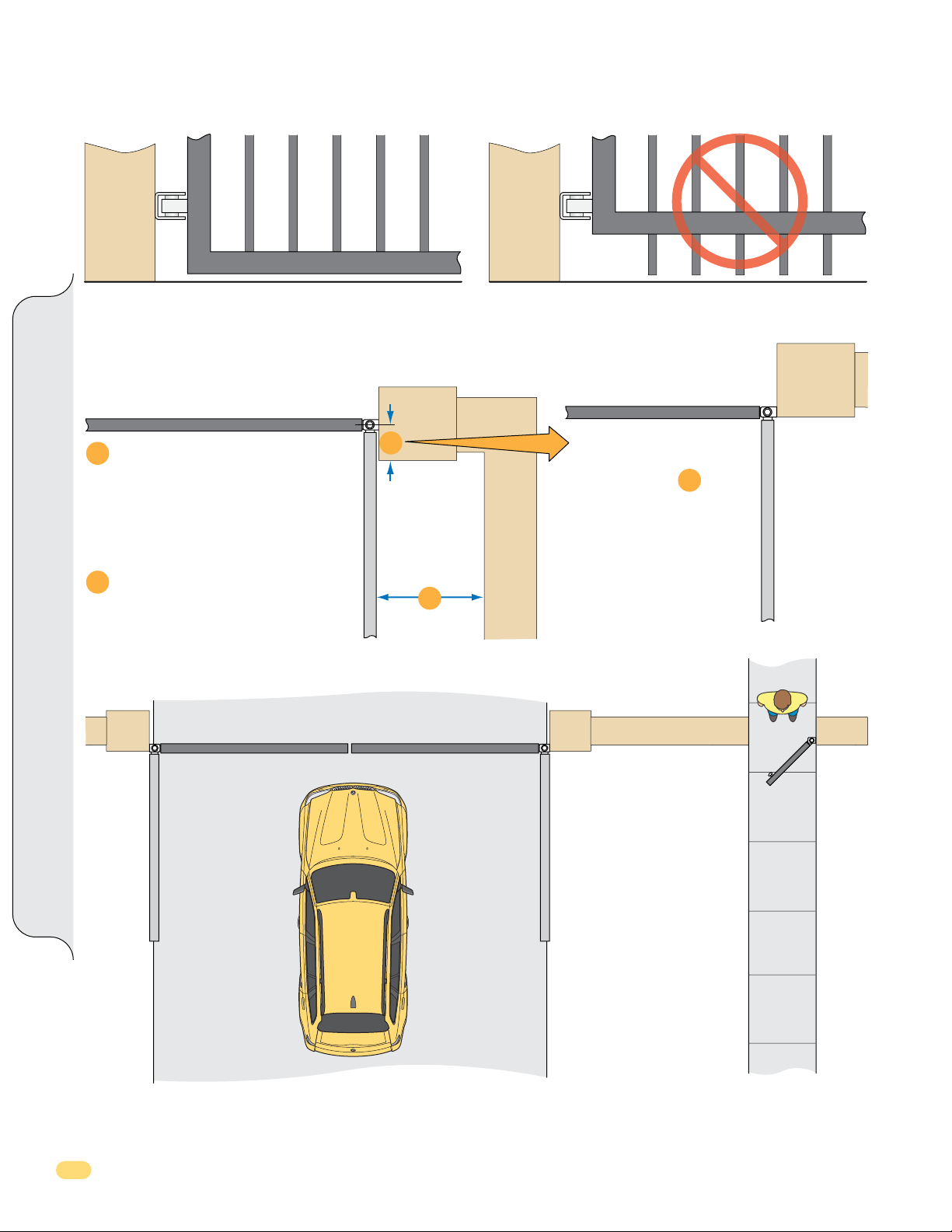

Swing Gate Recommendations

Gates should have smooth bottom edges, with vertical bottom edged protrusions not exceeding 0.50 inches.

Gate Closed

If distance is greater than 4 inches,

1

entrapment protection for this area

is recommended.

If distance is less than 16 inches,

2

entrapment protection in this area

is recommended.

Gates Closed

1

2

Gate Opened

Swing Gate Requirements

Gate Closed

With the hinge mounted on

the corner of the pilaster, the

entrapment area is

eliminated and protection is

NOT needed for this area.

1

Separate

Pedestrian

Access

Opening

Gate Opened

The operator is intended for installation ONLY on gates used for vehicles. Pedestrians should be supplied with a separate

access opening. The pedestrian access opening should be designed to promote pedestrian usage. Locate the gate such that

persons will not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

4

X9 Swing Rev - H

Important Safety Information

WARNING

To reduce the risk of injury or death read and follow the instructions

1. Never let children operate or play with gate controls. Keep the remote control away from children.

2. Always keep people and objects away from gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

3. Test the operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object activates the non-contact

sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and retest the gate operator properly can

increase the risk of injury or death.

4. Use the emergency release ONLY when the gate is not moving and verify that operator power has been turned OFF.

5. KEEP GATES PROPERLY MAINTAINED. Read the owner's manual. Have a qualified service person make repairs to gate hardware.

6. The entrance is for vehicles only. Pedestrians must use separate entrance.

7. SAVE THESE INSTRUCTIONS.

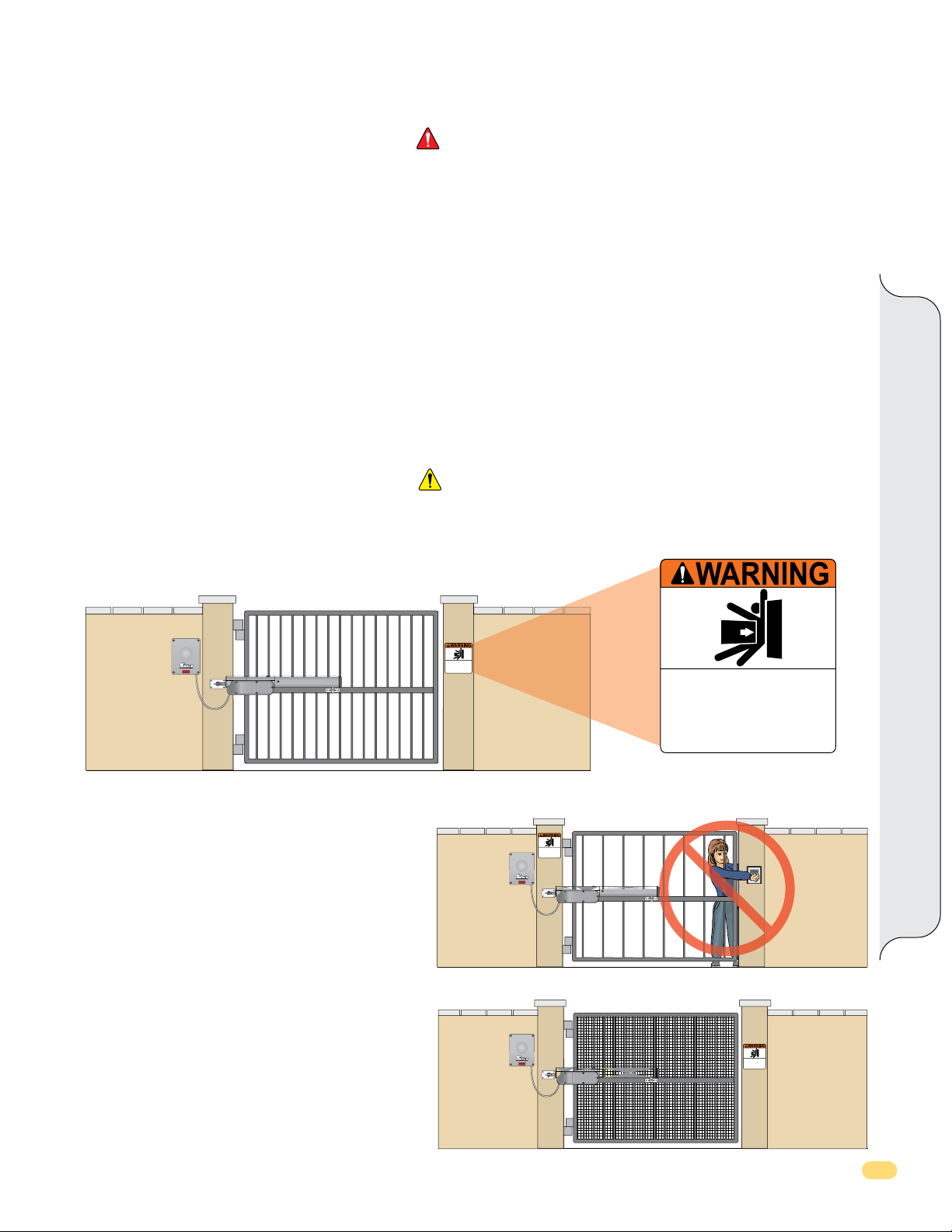

General Safety Information

CAUTION

Be sure to read and follow all the Eagle Access Control Systems, Inc. and UL instructions before installing and

operating any Eagle Access Control System, Inc. products. Eagle Access Control Systems, Inc. is not responsible

for any improper installation procedures caused by failure to comply with local building codes.

General Safety

Install Warning Signs

BY EAGLE ACCESS CONTROL SYSTEMS, INC.

Install warning signs on BOTH sides of the gate.

Installing Opening Devices

Be sure to mount ALL gate operating devices at least six

feet (6’) away from any moving part of the gate. They must

NOT be able to be operated reaching through the gate.

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

BY EAGLE ACCESS CONTROL SYSTEMS, INC.

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

Ornamental Grill Styled Gates

Injuries may be avoided if a mesh screen is installed on

the gate. Injuries resulting from hands and feet becoming

stuck in the gate or children riding on the gate while gate

is moving can be greatly reduced if this “screen” or

“mesh” is applied to the gate as a safety precaution.

X9 Slide Rev - H

BY EAGLE ACCESS CONTROL SYSTEMS, INC.

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

5

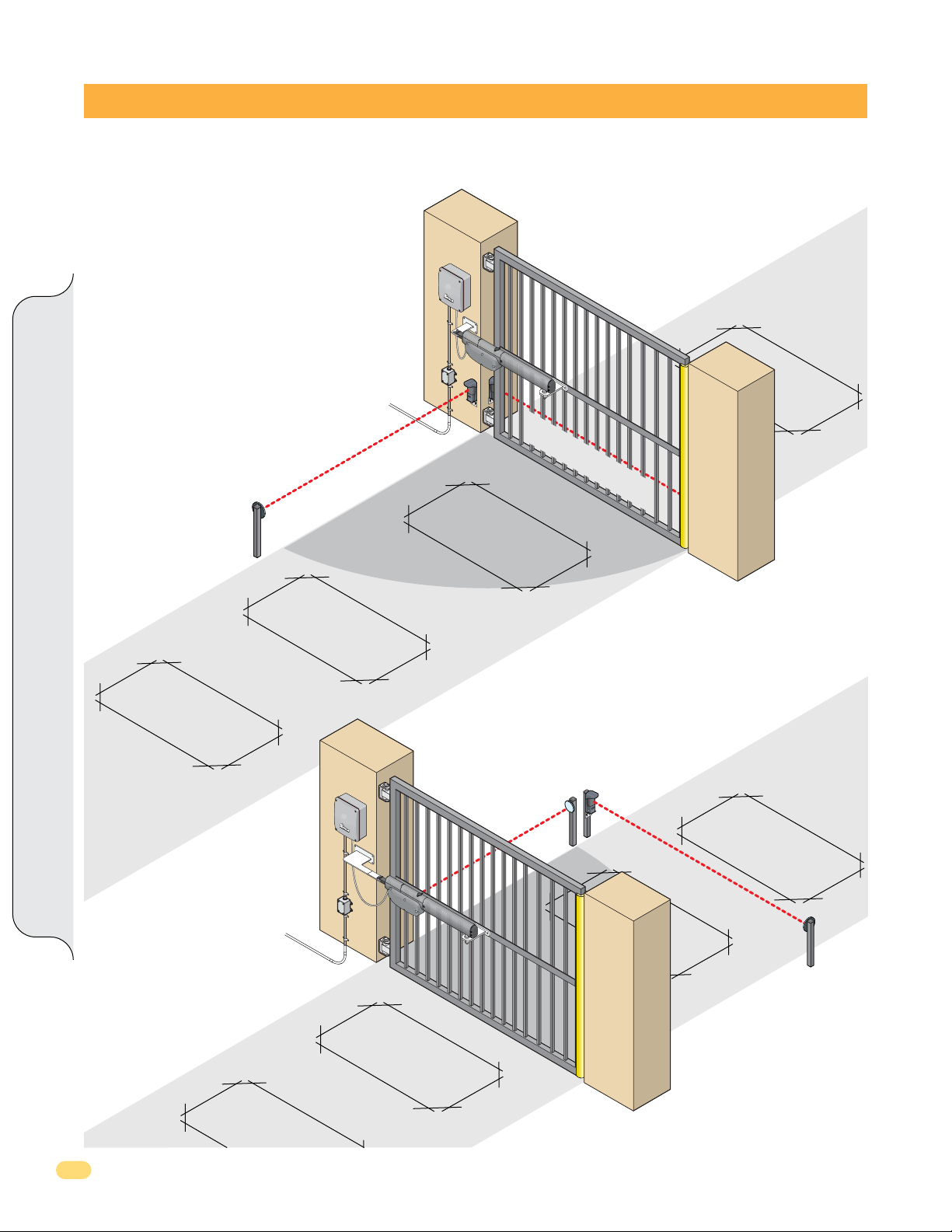

SAMPLE SINGLE GATE INSTALLATION SETUPS

An experienced installer should perform the installation. Improper installation may result in property damage, severe injury or death.

Read the entire manual before proceeding with the installation.

Eagle Access Control Systems, Inc. is not responsible for researching and complying with local building codes. Be sure to check all local

building codes before installation.

These drawings are typical and is supplied as working model

from which to choose the electronic components making up

the single gate installation. Dual gates setup is on the next

page. These drawings do not lay down any requirements

regarding the installation of the gate operator. Please see the

previous pages for safety and general gate recommendations.

Any external safety devices get wired to the control box in

conduit when possible.

B

Y

E

A

GL

E

A

C

C

E

S

S

C

O

NT

R

O

L

S

Y

S

T

E

M

S

,

I

N

C

.

Sensing Edge

Safety Loop

Closing-Direction Photocell

(Outside of Property

Opening-Direction Photocell

(Inside Property)

Phantom Loop

(Shadow)

OPEN INSIDE

Safety Loop

Exit

L

oop

Opening-Direction Photocell

B

Y

E

A

G

LE

A

C

C

E

S

S

C

O

N

T

R

O

L

S

Y

S

T

E

M

S

,

I

N

C

.

(Outside Property)

Single Gate Installation Setup

Sensing Edge

)

Closing-Direction Photocel

(Outside of Property

Phantom

Loop

(Sha

dow)

Safety Loop

l

)

Safety Loop

OPEN OUTSIDE

Exit

Loop

6

X9 Swing Rev - H

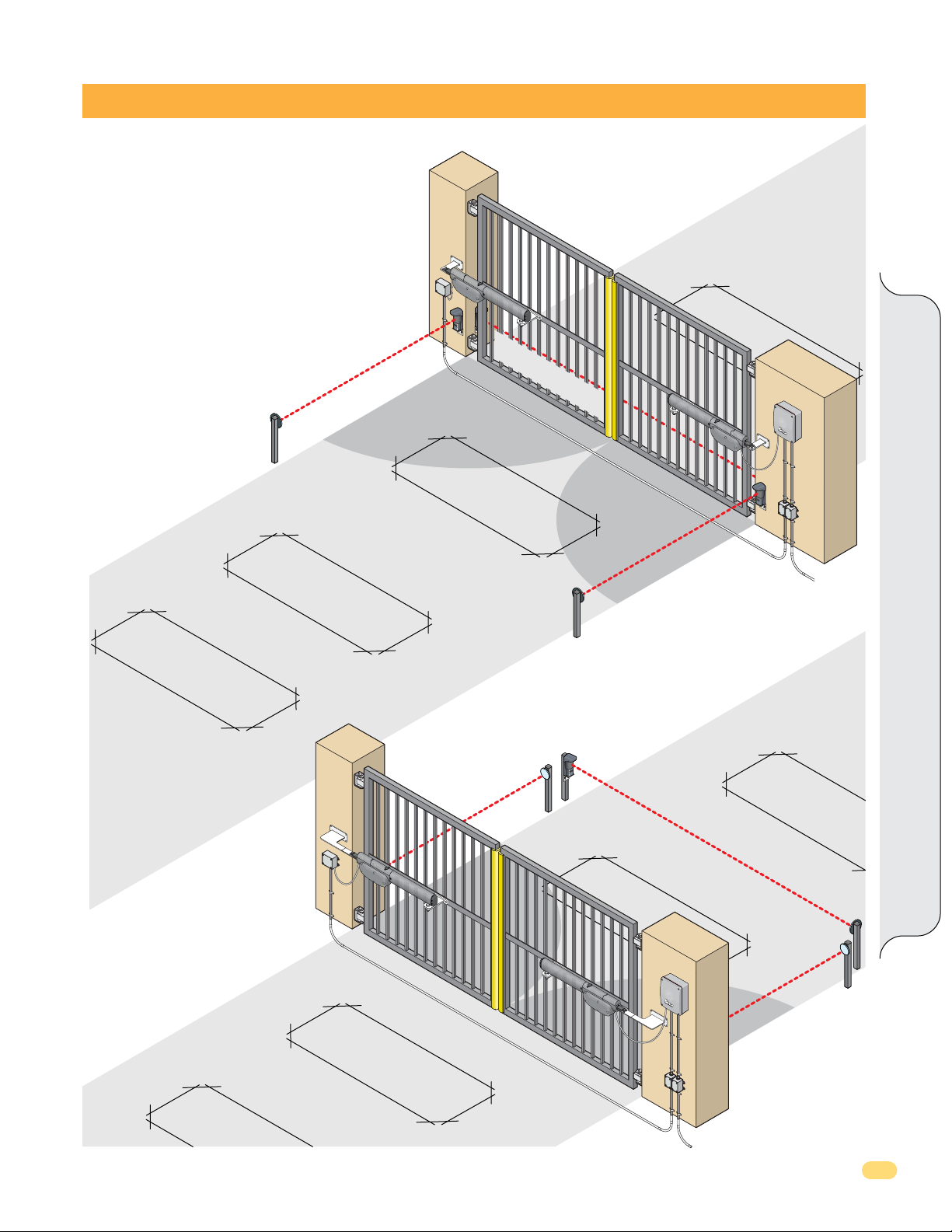

SAMPLE DUAL GATES INSTALLATION SETUPS

These drawings are typical and is supplied as working model from

which to choose the electronic components making up the dual

gates installation. These drawings do not lay down any requirements

regarding the installation of the gate operators. Please see the pages

2-5 for safety and general gate recommendations.

Any external safety devices get wired to the control box in conduit

when possible.

Opening-Direction Photocell

(Inside Property)

OPEN INSIDE

Closing-Direction Photocell

(Outside of Property)

Master / Slave Connection

Phantom Loop

(Shadow)

Sensing Edges

Safety Loop

l

Dual Gate Installation Setup

BY

E

A

G

L

E

A

C

C

E

S

S

C

O

N

T

R

O

L

S

Y

S

TE

M

S

,

I

NC

.

Exit Loop

Safety

Loop

Opening-Direction Photocell

(Outside Property)

Sensing Edge

Master / Slave Connection

rection Photocel

-Di

g

in

Open

Closing-Direction Photocell

Safety Loop

(Outside of Property)

s

Phantom Loop

(Shadow)

n

o

g-Directi

B

Y

E

AG

L

E

A

CCES

S

C

O

NT

R

O

L

S

Y

S

T

E

M

S

,

I

N

C

.

Openi

n

Photocell

X9 Slide Rev - H

OPEN OUTSIDE

Exit Loop

Safety Loop

7

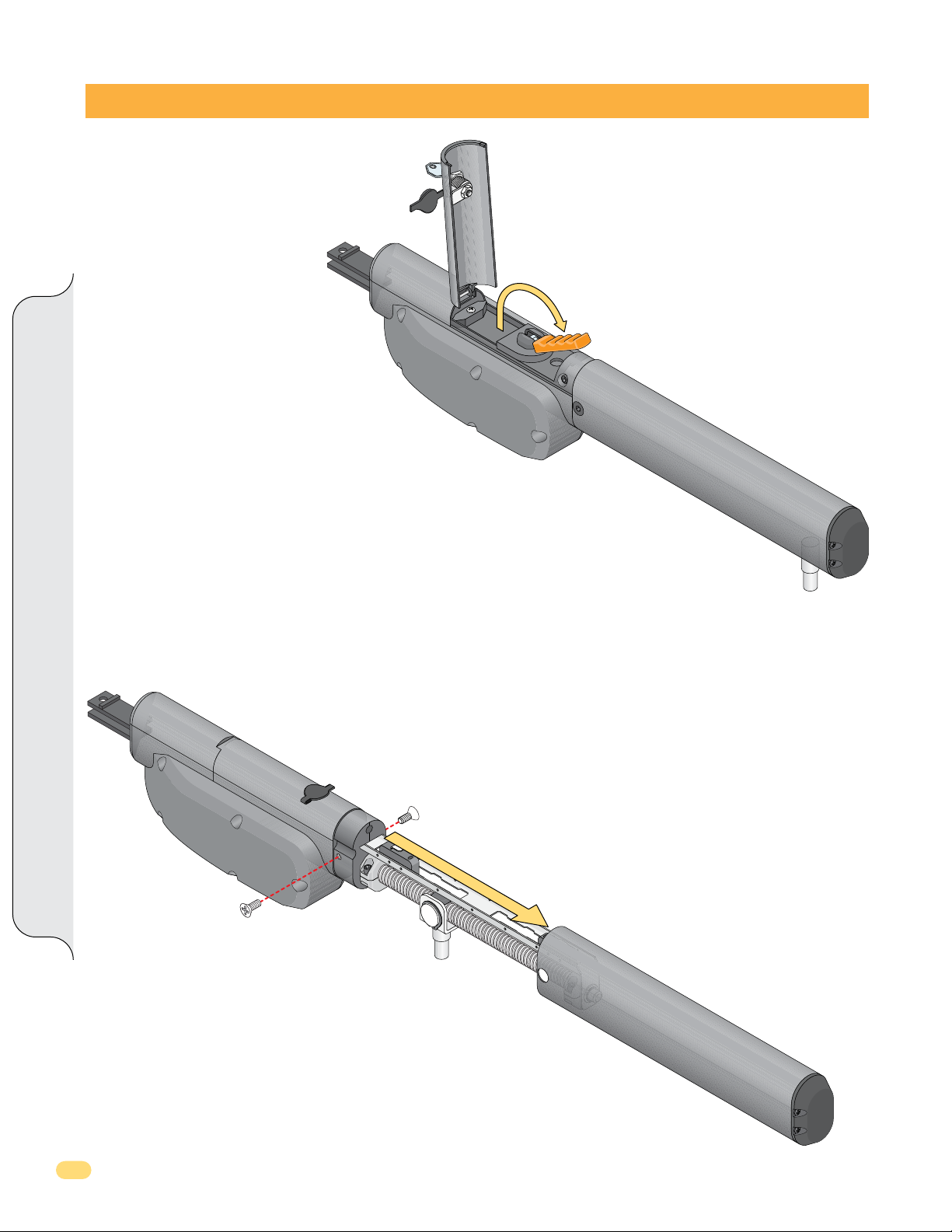

DISASSEMBLE OPERATOR

Step 1 - Release Stroke Pin

The stroke pin must be released before

installation.

1. Unlock with Key and open door.

2. Flip orange handle forward.

3. Stroke pin can now be moved.

NOTE: The stroke pin can REMAIN

UNLOCKED by simply removing

the orange handle in the released

position.

4. To Lock Stroke Pin again: Flip orange

handle back to original position.

5. Close and lock door.

Key

Door

Released Position (Unlocked)

Step 2 - Remove Cover to Access Limit Assembly

1. Remove two 5mm allen screws

2. Slide cover off.

Disassemble Operator

Stroke Pin

Cover

8

X9 Swing Rev - H

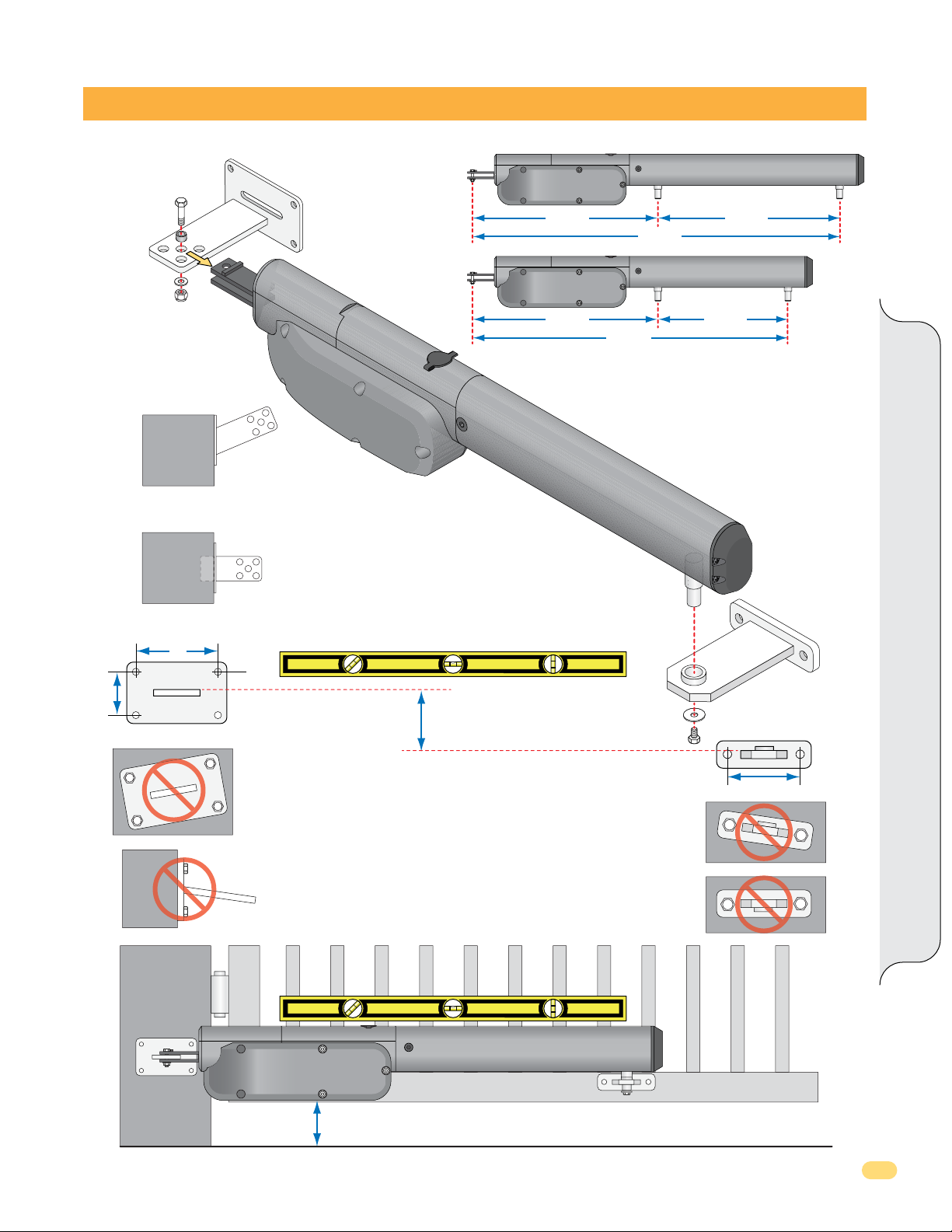

MOUNT ARM

Rear

Option

Weld Bracket at an Angle

Option

Cut Bracket to Fit

NOTE: Weld COMPLETELY around bracket.

X9L-Long Arm

18 3/4” 19 5/8”

X9S-Short Arm

18 3/4”

32 1/2”

Min Stroke

38 1/2”

Min Max

13 3/4”

NOTE: Release the stroke pin before installation,

see “Release Stroke Pin” on previous page.

Max Stroke

Stroke Pin

See pages 11 and 12 for

dimensional layouts.

Mount Arm

2”

4”

Rear Bracket

Not Level

Not Level

Arm MUST be Installed LEVEL!

2” Offset Between Brackets

COMMON MISTAKES

TO BE AWARE OF:

Front

Front Bracket

3 3/4”

Not Level

Upside Down

X9 Slide Rev - H

4” Minimum Above Ground

9

Loading...

Loading...