Page 1

PART # 339333

Heated Drawers

OPERATING MANUAL AND INSTRUCTIONS

CAUTION

INSPECT CONTENTS IMMEDIATELY AND FILE CLAIM

WITH DELIVERING CARRIER FOR ANY DAMAGE.

SAVE YOUR BOX AND ALL PACKING MATERIALS.

YOU ARE RESPONSIBLE FOR DAMAGE TO YOUR

UNIT IF RETURNED IMPROPERLY PACKED.

Retain this manual for future reference.

Contact this factory, the factory representative or

Eagle’s authorized service center in your area to

perform maintenance and repairs.

This unit has been manufactured in accordance with

Underwriters Laboratories and National Sanitation

Foundation standards, consult local electrical and

sanitation codes for compliance. Please reference

the electrical specifications in this manual to insure

that proper amperage and voltage is used for your

application. Built-in units must be installed in

compliance with the NEC.

UNPACKING INSTRUCTIONS

To unpack the heated drawer, first remove

the four 3⁄8˝ bolts, using a wrench, that

secure the unit to the crate located on the

underside of the crating (freestanding units

only). Carefully remove the crating from

the unit so as to not cause damage.

Remove all plastic wrap from the exterior of

the unit. Remove any tape or adhesive that

may be holding the drawers closed. Please

remove any warranty or instruction infor-

mation from the drawers prior to use and

store in safe location for future reference.

Remember to properly sanitize and clean

the unit before use.

Page 2

INSTALLATION INSTRUCTIONS

Freestanding Unit

1

2

3

Place unit on a flat, even surface and check that the unit is level both left to right and

front to back. Adjust feet as needed for a level installation.

Legs

Install the legs into the bottom of the unit by threading them into the nut inserts and

tightening securely.

Outlet

Locate the unit in a desired area within reach of an appropriately sized electrical outlet.

Consult electrical chart.

Level

CAUTION

LEGS MUST BE INSTALLED PRIOR TO THE OPERA-

TION OF THE UNIT. TO AVOID DAMAGE, DO NOT

LAY UNIT ON IT’S FRONT OR BACK SIDE.

Built-in Unit

1

Tape

Remove any tape that may be holding the conduit to the unit before installing.

2

Location

Please read the information below before determining installation site.

Locate the unit in an area that is convenient for use. The location should be

a

level to prevent the unit or it’s contents from accidentally falling, and strong

enough to support the weight of the unit and it’s contents.

For safe and proper operation, the unit must be located a reasonable distance

b

from combustible walls and materials. If safe distances are not maintained

discoloration or combustion could occur.

3

Level

Determine cutout sizes for your unit using the chart located below.

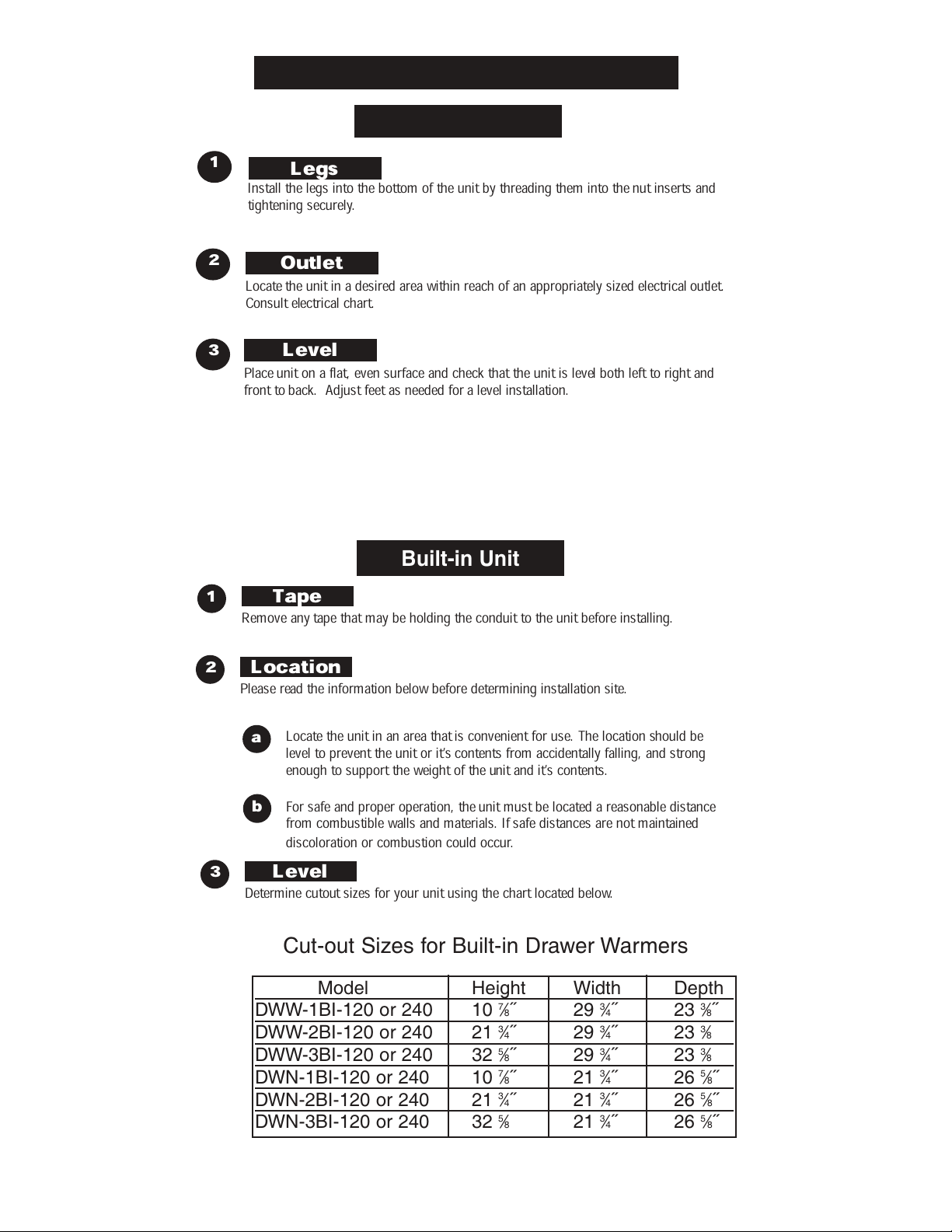

Cut-out Sizes for Built-in Drawer Warmers

Model Height Width Depth

DWW-1BI-120 or 240 10 7⁄8˝ 293⁄4˝ 233⁄8˝

DWW-2BI-120 or 240 21 3⁄4˝ 293⁄4˝ 233⁄8

DWW-3BI-120 or 240 32 5⁄8˝ 293⁄4˝ 233⁄8

DWN-1BI-120 or 240 10 7⁄8˝ 213⁄4˝ 265⁄8˝

DWN-2BI-120 or 240 21 3⁄4˝ 213⁄4˝ 265⁄8˝

DWN-3BI-120 or 240 32 5⁄8 213⁄4˝ 265⁄8˝

Page 3

4

Locking Strip

When the proper cutout has been made, a locking strip (not supplied by Eagle) must be

permanently fixed to the lower front side of the cabinet opening.

Note:

Maintain a minimum clearance of 1˝ from the bottom of the cutout to floor.

5

Installing

Once the unit is installed into the opening, apply a bead of NSF approved sealant around

the drawer cabinet flanges and the location.

6

Connections

Final connections must be made in accordance with a NEC listed junction box.

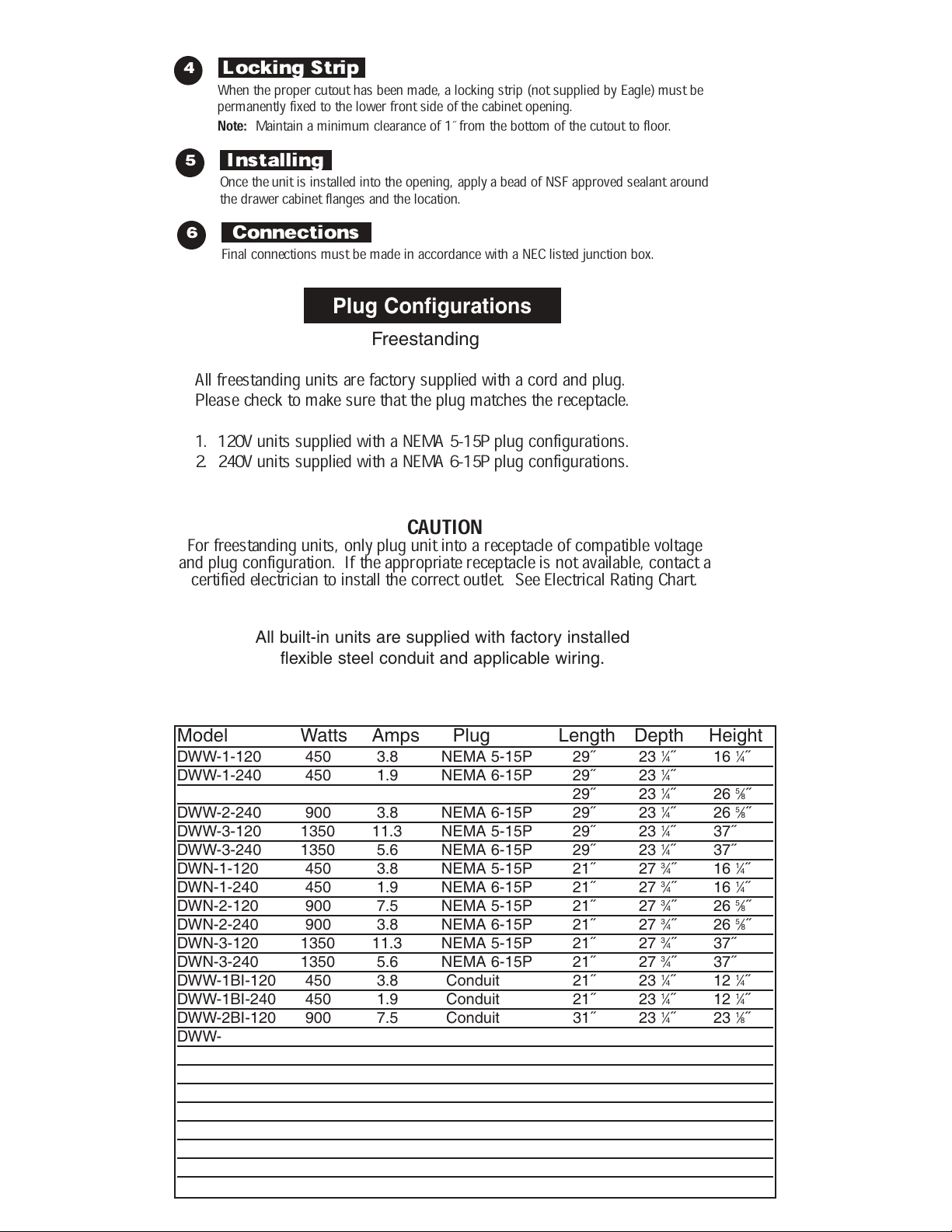

Plug Configurations

Freestanding

All freestanding units are factory supplied with a cord and plug.

Please check to make sure that the plug matches the receptacle.

1. 120V units supplied with a NEMA 5-15P plug configurations.

2. 240V units supplied with a NEMA 6-15P plug configurations.

CAUTION

For freestanding units, only plug unit into a receptacle of compatible voltage

and plug configuration. If the appropriate receptacle is not available, contact a

certified electrician to install the correct outlet. See Electrical Rating Chart.

All built-in units are supplied with factory installed

flexible steel conduit and applicable wiring.

Electrical Rating Chart

Model Watts Amps Plug Length Depth Height

DWW-1-120 450 3.8 NEMA 5-15P 29˝ 23 1⁄4

DWW-1-240 450 1.9 NEMA 6-15P 29˝ 23 1⁄4˝ 161⁄4˝

DWW-2-120 900 7.5 NEMA 5-15P 29˝ 23 1⁄4˝ 265⁄8˝

DWW-2-240 900 3.8 NEMA 6-15P 29˝ 23 1⁄4˝ 265⁄8˝

DWW-3-120 1350 11.3 NEMA 5-15P 29˝ 23 1⁄4˝ 37˝

DWW-3-240 1350 5.6 NEMA 6-15P 29˝ 23 1⁄4˝ 37˝

DWN-1-120 450 3.8 NEMA 5-15P 21˝ 27 3⁄4˝ 161⁄4˝

DWN-1-240 450 1.9 NEMA 6-15P 21˝ 27 3⁄4˝ 161⁄4˝

DWN-2-120 900 7.5 NEMA 5-15P 21˝ 27 3⁄4˝ 265⁄8˝

DWN-2-240 900 3.8 NEMA 6-15P 21˝ 27 3⁄4˝ 265⁄8˝

DWN-3-120 1350 11.3 NEMA 5-15P 21˝ 27 3⁄4˝ 37˝

DWN-3-240 1350 5.6 NEMA 6-15P 21˝ 27 3⁄4˝ 37˝

DWW-1BI-120 450 3.8 Conduit 21˝ 23 1⁄4˝ 121⁄4˝

DWW-1BI-240 450 1.9 Conduit 21˝ 23 1⁄4˝ 121⁄4˝

DWW-2BI-120 900 7.5 Conduit 31˝ 23 1⁄4˝ 231⁄8˝

DWW-2BI-240 900 3.8 Conduit 31˝ 23 1⁄4˝ 231⁄8˝

DWW-3BI-120 1350 11.3 Conduit 31˝ 23 1⁄4˝ 34˝

DWW-3BI-240 1350 5.6 Conduit 31˝ 23 1⁄4˝ 34˝

DWN-1BI-120 450 3.8 Conduit 23˝ 26 3⁄4˝ 121⁄4˝

DWN-1BI-240 450 1.9 Conduit 23˝ 26 3⁄4˝ 121⁄4˝

DWN-2BI-120 900 7.5 Conduit 23˝ 26 3⁄4˝ 231⁄8˝

DWN-2BI-240 900 3.8 Conduit 23˝ 26 3⁄4˝ 231⁄8˝

DWN-3BI-120 1350 11.3 Conduit 23˝ 26 3⁄4˝ 34˝

DWN-3BI-240 1350 5.6 Conduit 23˝ 26 3⁄4˝ 34˝

˝ 16

1

⁄4

˝

Page 4

Page 5

1

Plug

On freestanding models, plug unit into an electrical outlet of the correct voltage,

size and plug configuration

.

2

3

Power

To turn the power on, turn the thermostat control to the desired temperature.

See chart below for Recommended Settings under food holding guide.

Pre-heat

Allow the unit 15-20 minutes to reach operating temperature. Moist applications

may require additional pre-heat time.

4

Vents

Adjust the drawer vents for desired humidity by loosening front drawer knob to

unlock the vent and slide the vent to desired location. Opening the vent all the way

allows maximum moisture to escape.

Food Holding Guide

Product Rec. Storage Temp. Heat Type Vent Control Capacity

Rolls, Hard 160-185˚F (71-85˚C) Dry closed 6-8 dz

Rolls, Soft 150-175˚F (66-79˚C) Moist open-half 6-8 dz

Vegetables 175-185˚F (66-85˚C) Moist open-half 3-3

Meat, Poultry 165-185˚F (74-85˚C) Dry closed 25-30 lbs. ribs

Fish 165-185˚F (74-85˚C Moist open

Casseroles 150-175˚F (66-79˚C) Dry closed

Pies, Desserts 160-185˚F (71-85˚C Dry closed

1

⁄2 dz potatoes

Care and Maintenance

To avoid injury, turn the power off and allow unit to cool before

cleaning or performing maintenance. On freestanding units,

unplug the electrical cord and/or turn off circuit breaker.

To preserve the finish of the drawer warmer, it is recommend-

ed that the surface be wiped daily with a damp cloth. Food

pans should be removed and washed. Stubborn stains may be

removed with a non-abrasive cleaner. Hard to reach areas

should be cleaned with a small brush and mild soap.

CAUTION

Abrasive cleaners could scratch the finish

of the drawer warmer.

Page 6

Care and Maintenance Continued

Removing Lime and Mineral Deposits

Note: If the water used has an excessive amount of lime or

mineral content, use the following instructions for periodic

cleaning and de-liming of the water pan.

1. Turn off the power. On freestanding units, unplug the

cord from the power source.

2. After the unit has cooled down, remove the water pan.

3. Fill the water pan with a mixture of water and delimer.

Allow the pan to stand with the mixture for the

recommended period of time. The time required will

depend on the solution used and the amount of deposits

in the pan. Check delimer manufacturer for specific

directions.

4. After the deliming period, drain the solution from the pan.

5. Continue to fill and rinse the pan with water only, until the

pan becomes clean.

6. Install the pan into the unit. On freestanding units, plug the

power cord into the receptacle and fill the pan as usual.

Wiring Diagram

Page 7

Parts List

Loading...

Loading...