Page 1

C3600P AND C7200P

OPERATION INSTALLATION AND SERVICE MANUAL

PRECISION TON CONTAINER SCALES

EAGLE MICROSYSTEMS, INC.

366 Circle of Progress, Pottstown, PA 19464

610-323-2250 Phone - 610-323-0114 Fax

e-mail: infomicrosys@verizon.net

FILE NAME C3600 & C7200P MANUAL

1

Page 2

TABLE OF CONTENTS

CONTENTS PAGE

SECTION 1.0 DESCRIPTION..................................................................... 1

SECTION 2.0 PREPARATION FOR USE 3

2.1 RECEIVING INSPECTION 3

2.2 SHIPMENT 3

2.3 SITE SELECTION 3

2.4 INSTALLING 3

2.5 LEVELING 3

2.6 HOOK-UP CABLE 3

SECTION 3.0 OPERATION

SECTION 4.0 TROUBLE SHOOTING

SECTION 5.0 SERVICING

5.1 CHECKING THE CONNECTIONS

5.2 SERVICING THE LOAD CELL

5.3 CHECKING THE LOAD CELL

5.4 REPLACING THE LOAD CELL

SECTION 6.0 SPECIFICATIONS

SECTION 7.0 SPARE PARTS LIST

LIST OF ILLUSTRATIONS

FIGURE 1 C3600P AND C7200P DIMENSIONS

FIGURE 2 HOOK-UP CABLE TABLE

FIGURE 3 SUMMING BOARD CONNECTIONS

FIGURE 4 RESISTANCE TABLE

2

Page 3

SECTION 1.0 DESCRIPTION

The Eagle Microsystems C3600P and C7200P Precision Ton Container Scales are designed specifically

for the water and wastewater industry. They incorporate 4 stainless steel shear beam load cells with

integral overload stops. The C3600P and C7200P are supplied with the required amount of rollers for

easy rotation of ton containers. Each scale is supplied with 15' of cable. Additional lengths are available

upon request.

The mechanical overload stop and the shock isolation pad prevents damage to the load cell when placing

ton containers on the scale.

C7200P WT3600

SECTION 2.0 PREPARATIO N FOR USE

2.1 RECEIVING INSPECTION

1. Upon receiving the scale, carefully inspect the condition of the crate including the banding

and any protective covering used for shipping. Report any damage to the shipper and to

Eagle Microsystems.

2. Remove the scale from crating and inspect for damage. Report any damage to the shipper

and to Eagle Microsystems.

2.2 SHIPMENT

Should re-shipment of your scale become necessary.

1. Use a strong, well built crate. The crate must be larger than the outer dimensions of the

scale to protect it in shipping.

2. Make sure the hook-up cable is protected and secured in crate.

3

Page 4

3. Use strong banding to secure scale in shipment.

2.3 SITE SELECTION

1. Extreme temperature variations may cause the scale to drift slightly off zero. Your precision

ton container scale has temperature compensated load cells to minimize such effects.

However, whenever possible, avoid placing your scale near air ducts, heating or cooling

elements, doors opening to the outside, ect. to minimize temperature effects.

2. Line power devices causing large inductive currents should not run off the same circuit as

the scale. Fluctuations in line voltage caused by such devices may result in display instability.

3. The hook-up cable to the read-out should not run close to other unshielded cables. Display

instability may result.

4. For best accuracy, a flat, level, and rigid surface is recommended to support the scale and ton

containers.

5. The area should be accessible for periodic cleaning.

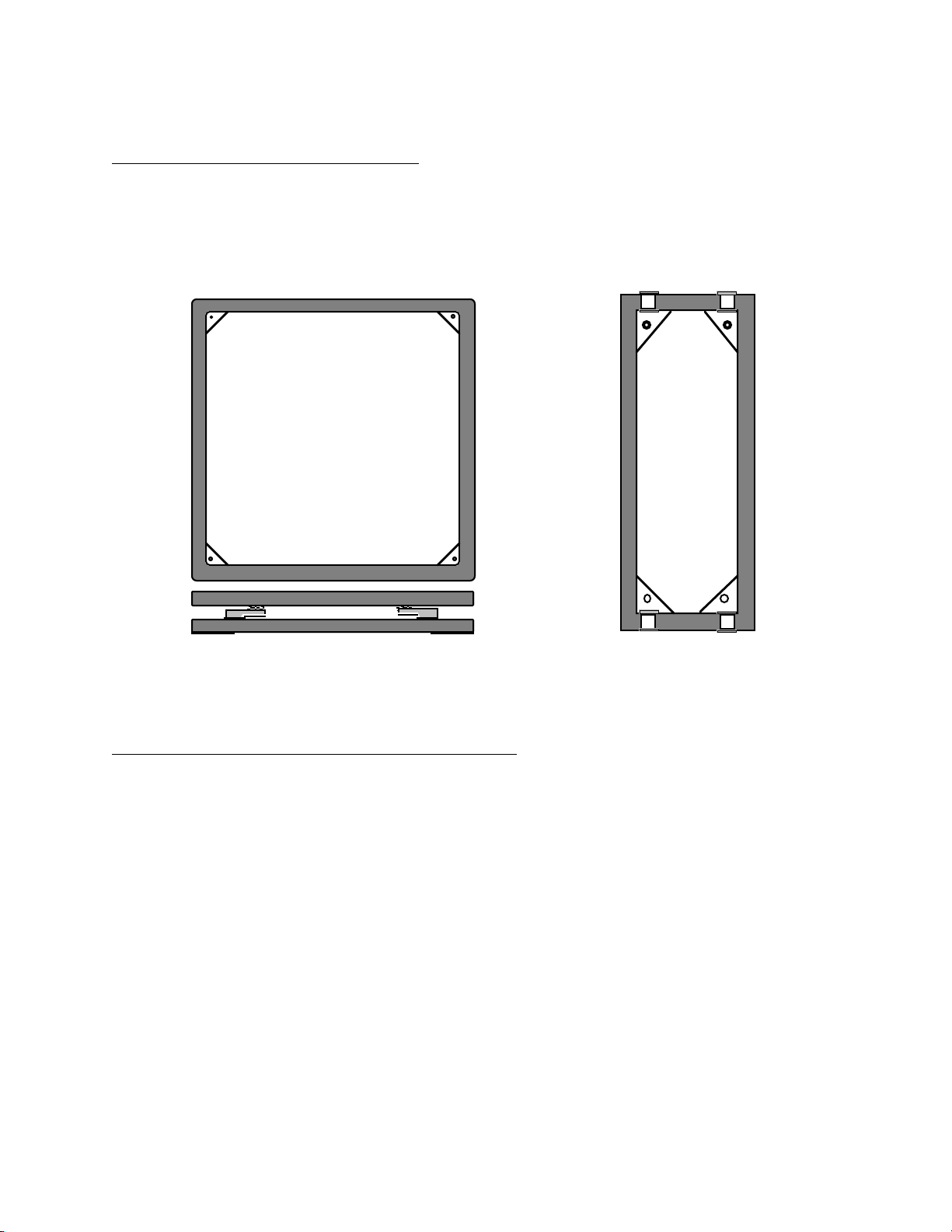

2.4 INSTALLING

1. Clean the site area of dirt and debris.

2. Locate and mark all four corners. See Figure 1 for bolt/stud locations.

3A 1/2" to 5/8" diameter bolt/stud is suggested. The bolt/stud should protrude 2" above ground.

4. Set scale into place.

52"

52"

FIG. 1

2.5 LEVELING

1. For best scale performance scale should be level within 1/2 degree.

2. Check all corners for wobble and shim if required.

4

Page 5

3. Using wrench to tighten all corners

2.6 HOOK-UP CABLE

Figure 2 shows the wiring connections necessary to attach the platform to the read-out instrument. The

color code and function are as noted. Consult read-out manual for the required information for its hookup.

(Most scales are shipped with mating connector for easy hook-up to the instrument supplied)

COLOR CODE FUNCTION

BLACK – EXCITATION

WHITE – SIGNAL

RED + EXCITATION

GREEN + SIGNAL

YELLOW SHIELD

FIG. 2

SECTION 3.0 OPERATION

Follow the instrument's manual for correct power-up instructions.

The C3600P and C7200P Ton Container Scales are relatively simple devices. Once the operation of the

instrument is understood, the ton containers are simply placed on the rollers that are provided. Listed are

a few helpful points to follow when using Eagle Microsystems scales.

1. Always place the ton container in the approximate center of the scale

2. Place the ton containers on the scale. Do not drop them. Although the scale is designed to

withstand impact loads, care should be taken to avoid accidents.

SECTION 4.0 TROUBLE SHOOTING

The following is a list of potential problems and likely cures.

1. Inaccurate but repeatable weight readings:

a. Adjust span on read-out (see instrument manual)

2. Blank or drifting display:

a. Consult the instrument manual.

b. Look for loose connection in hook-up cable at the instrument or in the Summing Box.

See Section 5.1

d. Look for moisture in the Summing Box

c. Test for bad load cell (see section 5.2)

SECTION 5.0 SERVICING

5.1 Checking the connections to the Summing Box.

1. Locate the Summing Box on the bottom frame and remove the cover. (4 screws)

2. View and compare all connections to Figure 3.

5

Page 6

3. Check all connections by lightly pulling on each lead. Tighten terminal connections as

needed.

4. If problem persists, press lightly on the circuit board itself and check meter response.

Replace board if required.

Note: Make sure when replacing the cover that the box is dry and the cover is tight.

SJB4-S

5.2 Checking the load cells.

1. Load Cell resistance test:

a. Disconnect the load cells from the Summing Box and measure the resistance as shown in

Figure 4.

b. Any electrical leakage between the leads and the load cell case is usually caused by moisture

leakage into the load cell or by moisture in a damaged load cell cable.

c. If a load cell does not pass the above resistance tests, replace it with a known good one.

2. Load Cell zero shift test:

a. Remove the top frame of the scale. (see section 5.3)

b. Connect a DC power supply of 10 or 15 volts to the Red (+) and Black (-) excitation load cell

leads.

c. The measured output between the Green (+) and White (-) signal leads should be less

than 5 millivolts.

d. An output signal greater than 5 millivolts indicates a zero shift caused by mechanical

overload.

e. If the output signal is between 5 and 15 millivolts, the load cells zero has shifted but will

probably still continue to work.

f. If the output signal is greater than 15 millivolts, the load cell should be replaced with a

known good one.

-E

+E

+E

-S

+S

SH

R1 R1

R1

R1R1

-

+

-SIG

-EXT

+SIG

-E

-S

+S

SH

+EXCT

EAGLE MICROSYSTEMS

SHLD

-E

-S

+S

+E

-E

+E

SH

-S

SH

+S

FIG. 3

NOTE: If the load cell's zero has shifted due to a mechanical overload, the reason for the

overload should be determined before a new load cell is installed.

5.3 REPLACING THE LOAD CELL

Call the factory to advise that the load cell is defective. Report model and serial numbers for both load cell

and scale.

1. Remove all ton containers from scale.

2. Remove plastic caps from top frame.

3. Use 3/4" deep socket to remove hex nuts inside top frame on all four load cells .

6

Page 7

TC-SC

4. Set top frame aside.

5. Remove the 4 screws from Summing Box lid. Disconnect the wires of defective load cell

being replaced. Gently pull cable out of the bottom frame.

6. Use hex wrenches to remove 2 socket head cap screws which secure load cell to frame.

7. Save the overload rod.

8. Install new load cell using 35 ft. lbs. torque to screws and fish wires back to the Summing Box.

9. Insert leads into terminal as before and tighten. Put lid on Summing Box and tighten.

10. Install overload rod with 1/8" gap to frame. Add shock pad.

11. Put top frame back onto load cells. Add flat washer, lock washer and hex nut.

12. With a screw driver, adjust overload rod to 0.018" gap with feeler gage. Tighten hex nut

SECTION 6.0 SPECIFICATIONS

PHYSICAL SIZE: Model C3600P: 24" X 60" X 10"

Model C7200P: 60" X 60" X 10"

WEIGHT: Model C3600P: 235#

Model C7200P: 340#

CONSTRUCTION: Welded steel box tubing frame.

FINISH: All parts are stainless steel, plastic, or painted with acrylic

urathane paint.

CAPACITY: Model C3600P: 4,000#

Model C7200P: 8,000#

SAFE OVERLOAD: 200% of Rated Capacity.

ULTIMATE OVERLOAD: 400% of Rated Capacity.

NOMINAL OUTPUT: Model C3600P: 1.0 mV/V at 4,000#

Model C7200P: 1.2 mV/V at 8,000#

7

Page 8

OPERATING ACCURACY: 0.1% of Capacity.

REPEATABILITY: 0.02% of Capacity.

LOAD CELLS: 4 stainless steel strain gage shear beams, 350 ohms.

SIGNAL CABLE: 15' of 6 conductor color coded shielded cable. PVC jacket.

SECTION 7.0 SPARE PARTS LIST

PART DESCRIPTION MODEL/CAPACITY INH P/N

S.S. Load Cell C3600P / 3,000# 500337

S.S. Load Cell C7200P / 5,000# 500088

S.S. Stop Rod C3600P / C7200P 400186

S.S. 1/2-20 Hex Nut C3600P / C7200P 615006

S.S. 1/2 Flat Washer C3600P / C7200P 615007

S.S. 1/2 Lock Washer C3600P / C7200P 615008

S.S. 1/2-20 X 1 3/4 S.H.C.S. Mounting bolt C3600P / C7200P 615003

Shock Pad (2" X 1.5" X .75") C3600P / C7200P 400014

Plastic Roller C3600P / C7200P 400132

S.S. Roller Axle C3600P / C7200P 400022

S.S. Retaining Ring C3600P / C7200P 670131

Plastic Plug C3600P / C7200P 650020

15' of 6 Conductor Cable C3600P / C7200P 500061

Summing Box SJB-4-S (complete) C3600P / C7200P 110143

Summing Board only SJB-4-S C3600P / C7200P 110048

8

Loading...

Loading...