Page 1

www.eaglesonar.com

r

Pub. 988-0143-96A

Fish-finding Sona

Installation and Operation Instructions

Page 2

A

Copyright © 2008 Navico

All rights reserved.

No part of this manual may be copied, reproduced, republished,

transmitted or distributed for any purpose, without prior written

consent of Eagle Electronics.

ny unauthorized commercial

distribution of this manual is strictly prohibited.

Eagle® and Cuda

®

300 are registered trademarks of Navico.

Eagle Electronics may find it necessary to change or end our policies,

regulations, and special offers at any time. We reserve the right to do so

without notice. All features and specifications subject to change without

notice. All screens in this manual are simulated.

For free owner's manuals and the most current information on

this product, its operation and accessories,

visit our web site:

www.eaglesonar.com

Eagle Electronics

P.O. Box 669

Catoosa, OK USA 74015

Printed in USA.

Page 3

Table of Contents

Specifications: Cuda™ 300 & Cuda™ 300 Portable ......................... iii

Preparations .........................................................................................1

Transducer Installation .......................................................................1

Selecting a Transducer Location .....................................................2

How low should you go? ...................................................................4

Transom Transducer Assembly And Mounting .............................4

Trolling Motor Bracket Installation (single-frequency only) ......10

Transducer Orientation and Fish Arches.....................................11

Power Connections (permanent mount only) ...................................13

Mounting the Sonar Unit: In-Dash, Bracket or Portable ............14

Bracket Installation .......................................................................15

Portable Sonar Installation ...............................................................17

Installing the Batteries..................................................................17

Mounting the Unit .............................................................................18

Portable Transducer Assembly .....................................................19

Operation..........................................................................................21

Keyboard Basics .................................................................................21

Memory ...............................................................................................21

Display ................................................................................................22

Full Chart ...........................................................................................22

Depth Range ....................................................................................... 23

Zoom ....................................................................................................24

Sensitivity...........................................................................................25

Grayline®.............................................................................................25

Chart Speed ........................................................................................26

Fish I.D.™ ........................................................................................... 27

FishTrack™ ........................................................................................28

Fish Alarm ..........................................................................................28

Depth Alarms .....................................................................................29

Shallow Alarm ....................................................................................29

Deep Alarm.........................................................................................30

Battery Alarm.....................................................................................31

i

Page 4

Noise Reject and ASP™ .....................................................................32

Depth Display.....................................................................................32

Voltage ................................................................................................33

Temperature Display .........................................................................33

Units....................................................................................................33

Backlight.............................................................................................34

Contrast ..............................................................................................34

Simulator ............................................................................................35

Set Language ......................................................................................35

Software Information.........................................................................35

Reset Options......................................................................................35

ii

Page 5

Specifications: Cuda™ 300 & Cuda™ 300 Portable

General

Case size: .........................5.8" H x 4.3" W x 2.5" D (14.7 cm H x 10.8 cm

W x 6.6 cm D) sealed, waterproof; suitable for

saltwater use.

Display: ............................High-contrast Film SuperTwist LCD. Diago-

nal viewing area: 3.5" (8.9 cm).

Resolution: ......................240 pixels (vert.) x 160 pixels (horiz.) resolu-

tion; 38,400 total pixels

Backlighting: ..................incandescent backlit screen

Input power: ...................10 to 17 volts DC.

Current drain:................170 ma lights off; 240 ma lights on.

Back-up memory:...........Built-in memory stores sonar settings when

unit is turned off.

Sonar

Frequency: ......................200 kHz.

Transducers:...................A Skimmer

your unit. Its 20° cone angle offers a wide

fish detection area of up to 60º with high sensitivity settings. Operates at boat speeds up

to 70 mph (61 kts).

Transmitter:....................800 watts peak-to-peak power (typical); 100

watts RMS power (typical).

Sonar sounding

depth capability:............600 feet (180 meters). Actual capability de-

pends on transducer configuration and installation, bottom composition and water conditions. All sonar units typically read deeper in

fresh water than in salt water.

Depth display: ................Continuous digital readout.

®

transducer comes packed with

iii

Page 6

Audible alarms:..............Deep/shallow/fish.

Automatic ranging: ....... Yes, with instant screen updates.

Auto bottom track: ........ Yes.

Zoom bottom track:....... Yes.

Split-screen zoom: ......... No.

Surface water temp: .....Yes, built into transducer. Optional external

temperature sensor or combo speed/temp

sensor available.

NOTICE!

The storage temperature for your unit is from -4 degrees to +167

degrees Fahrenheit (-20 degrees to +75 degrees Celsius). Extended

storage in temperatures higher or lower than specified will damage

the liquid crystal display in your unit. This type of damage is not

covered by the warranty. For more information, contact the factory's Customer Service Department; phone numbers are inside the

manual's back cover.

iv

Page 7

Transducer Installation

Preparations

You can install the sonar in some other order if you prefer, but we recommend this installation sequence:

Caution:

You should read over this entire installation section before drilling any holes in your vehicle or vessel!

1. Determine the approximate location for the sonar/GPS unit, so you

can plan how and where to route the cables for the transducer and

power. This will help you make sure you have enough cable length for

the desired configuration.

2. Determine the approximate location for the transducer and its cable

route.

3. Determine the location of your battery or other power connection,

along with the power cable route.

4. Install the transducer and route the transducer cable to the sonar/GPS unit.

6. Install the power cable and route it to the sonar/GPS unit.

7. Mount the sonar/GPS unit to the bracket.

Transducer Installation

®

These instructions will help you install your Skimmer

transom, on a trolling motor or inside a hull. These instructions cover

both single- and dual-frequency Skimmer transducers. Please read all

instructions before proceeding with any installation.

The smaller single-frequency Skimmers typically use a one-piece,

stainless steel mounting bracket. The larger dual-frequency Skimmers

typically use a two-piece, plastic mounting bracket. The trolling motor

mount uses a one-piece plastic bracket with an adjustable strap.

transducer on a

1

Page 8

These are all "kick-up" mounting brackets. They help prevent damage if the

transducer strikes an object while the boat is moving. If the transducer does

"kick-up," the bracket can easily be pushed back into place without tools.

Read these instructions carefully before attempting the installation.

Determine which of the mounting positions is right for your boat. Re-

member, the transducer installation is the most critical part of

a sonar installation.

NOTE:

The following installation types also call for these recommended

tools and required supplies that you must provide (supplies listed

here are not included):

Single-frequency transom installations

Tools include: two adjustable wrenches, drill, #29 (0.136") drill bit,

Phillips head screwdriver. Supplies: high quality, marine grade aboveor below-waterline sealant/adhesive compound.

Dual-frequency transom installations

Tools: two adjustable wrenches, drill, #20 (0.161") drill bit, Phillips head screwdriver. Supplies: four, 1" long, #12 stainless steel slotted wood screws, high

quality, marine grade above- or below-waterline sealant/adhesive compound.

Single-frequency trolling motor installations

Tools: two adjustable wrenches, Phillips head screwdriver. Supplies:

plastic cable ties.

Selecting a Transducer Location

1. The location must be in the water at all times, at all operating speeds.

2. The transducer must be placed in a location that has a smooth flow

of water at all times. If the transducer is not placed in a smooth flow of

water, interference caused by bubbles and turbulence will show on the

sonar's display in the form of random lines or dots whenever the boat is

moving.

2

Page 9

NOTE:

p

Some aluminum boats with strakes or ribs on the outside of the

hull create large amounts of turbulence at high speed. These boats

typically have large outboard motors capable of propelling the boat

at speeds faster than 35 mph. Typically, a good transom location on

aluminum boats is between the ribs closest to the engine.

3. The transducer should be installed with its face pointing straight

down, if possible.

4. If the transducer is mounted on the transom, make sure it doesn't

interfere with the trailer or hauling of the boat. Also, don't mount it

closer than approximately one foot from the engine's lower unit. This

will prevent cavitation (bubble) interference with propeller operation.

5. If possible, route the transducer cable away from other wiring on the

boat. Electrical noise from engine wiring, bilge pumps and aerators can

be displayed on the sonar's screen. Use caution when routing the transducer cable around these wires.

CAUTION: Clamp the transducer cable to transom near

the transducer. This will help

revent the transducer from

entering the boat if it is

knocked off at high speed.

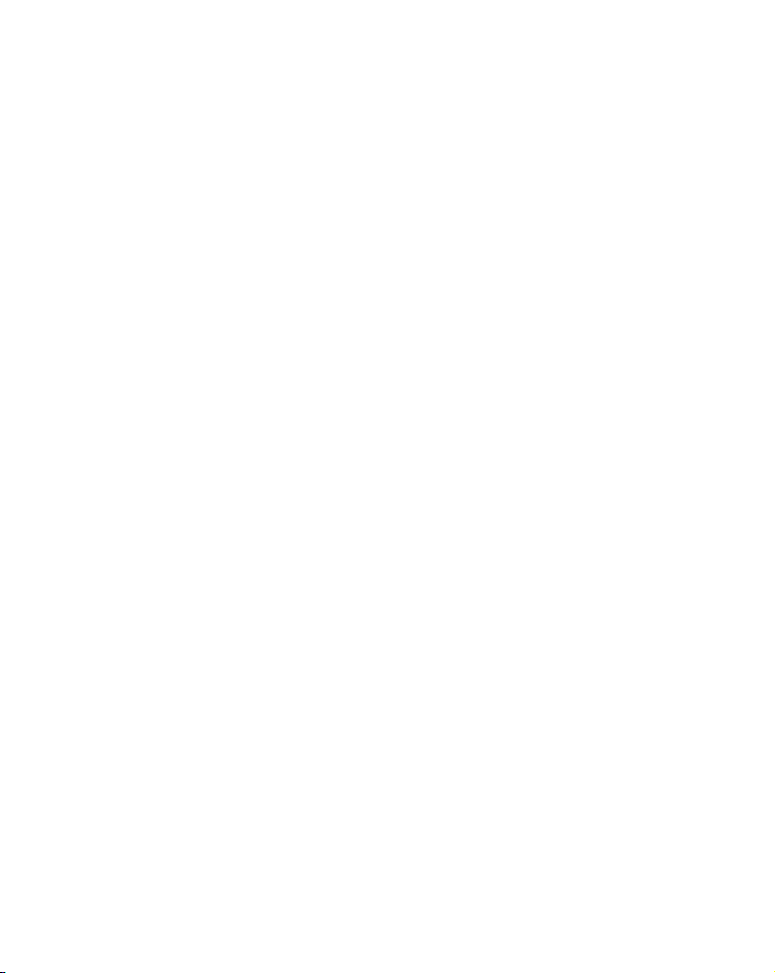

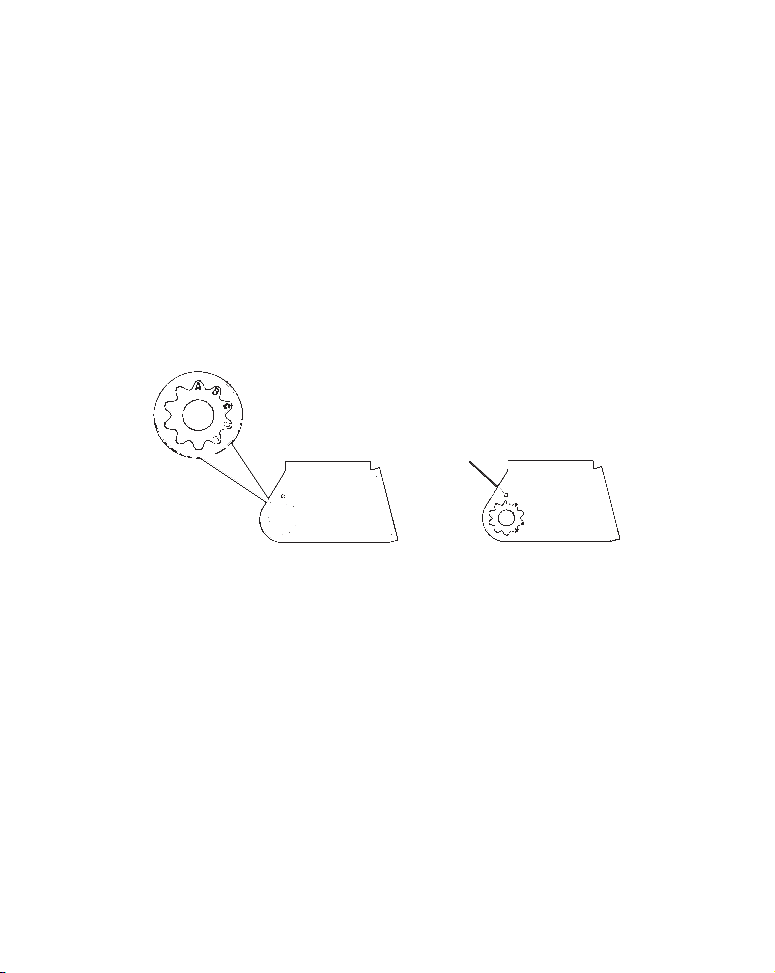

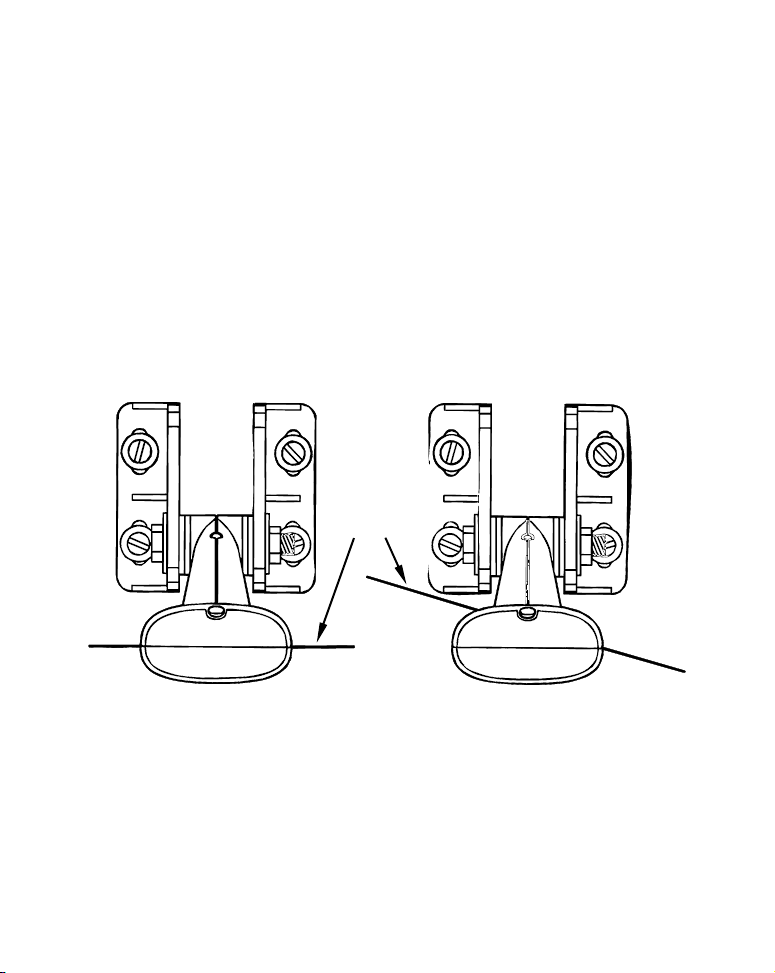

Good location

Good

location

Poor angle

Good and poor transducer locations.

Poor location

Good location

3

Page 10

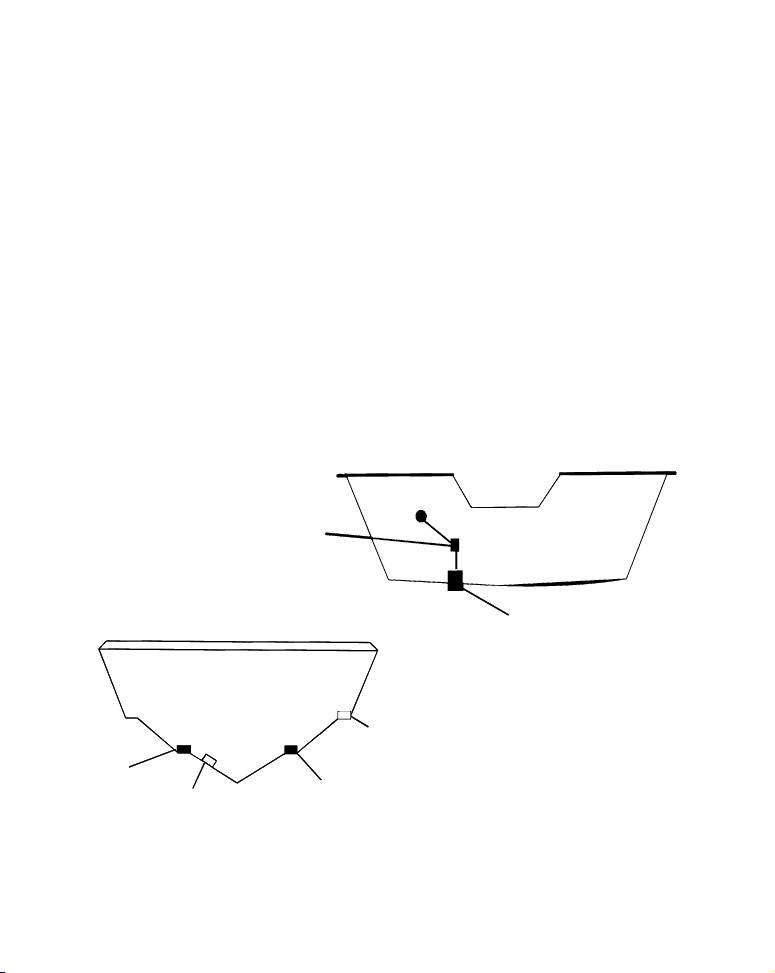

How low should you go?

For most situations, you should install your Skimmer transducer so

that its centerline is level with the bottom of the boat hull.

This will usually give you the best combination of smooth water flow

and protection from bangs and bumps.

Transducer

centerline

Align transducer centerline with hull bottom.

Transom

Hull bottom

However, there are times when you may need to adjust the transducer

slightly higher or lower. (The slots in the mounting brackets allow you

to loosen the screws and slide the transducer up or down.) If you frequently lose bottom signal lock while running at high speed, the transducer may be coming out of the water as you cross waves or wakes.

Move the transducer a little lower to help prevent this.

If you cruise or fish around lots of structure and cover, your transducer

may be frequently kicking up from object strikes. If you wish, you may

move the transducer a little higher for more protection.

There are two extremes you should avoid. Never let the edge of the

mounting bracket extend below the bottom of the hull. Never let the

bottom – the face – of the transducer rise above the bottom of the hull.

Transom Transducer Assembly And Mounting

The best way to install these transducers is to loosely assemble all of the

parts first, place the transducer's bracket against the transom and see if

you can move the transducer so that it's parallel with the ground.

4

Page 11

The following instructions sometimes vary depending on the mounting

bracket that came with your transducer. Single-frequency Skimmers come

with a one-piece stainless steel bracket, while dual-frequency Skimmers

come with a two-piece plastic mounting bracket. Use the set of instructions that fits your model.

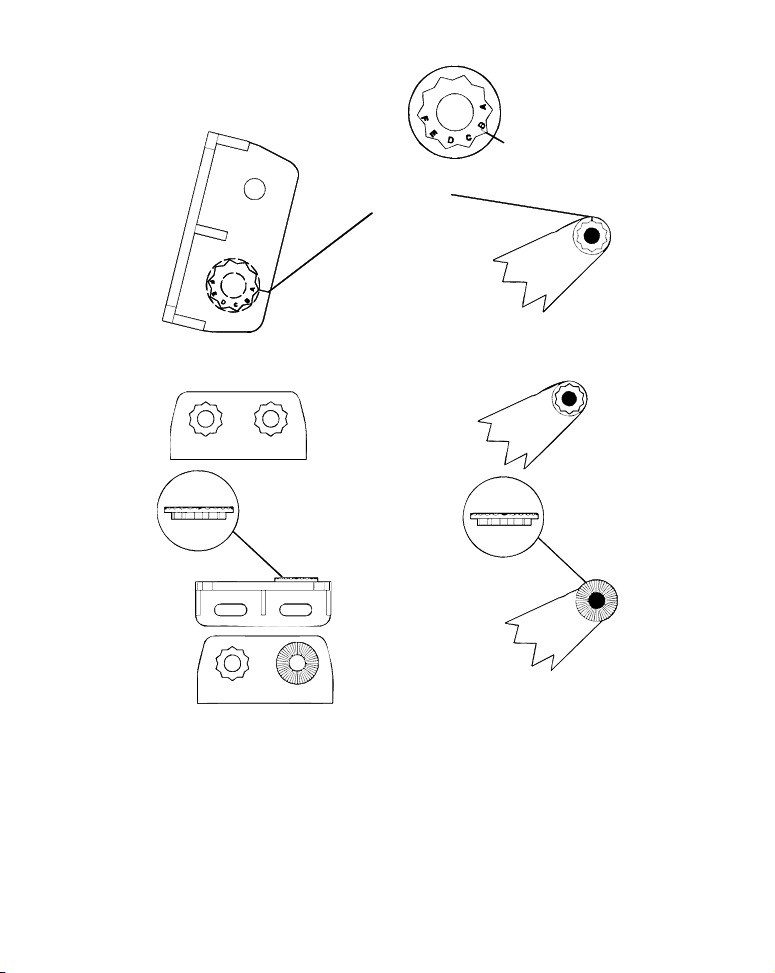

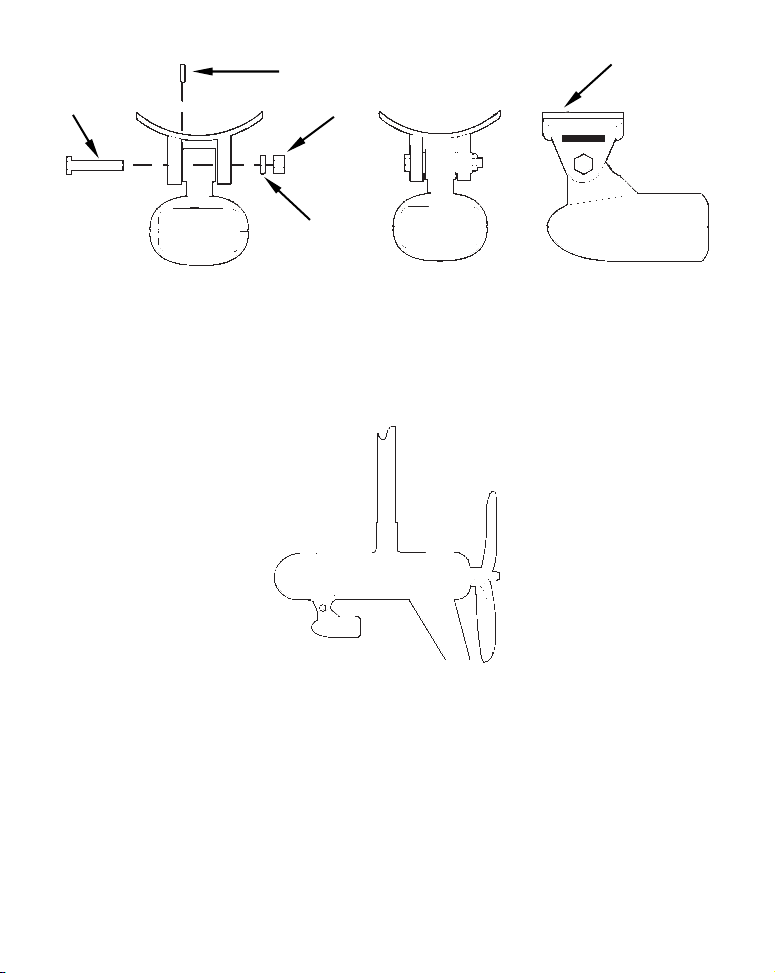

1. Assembling the bracket.

A. One-piece bracket: Press the two small plastic ratchets into the

sides of the metal bracket as shown in the following illustration. Notice

there are letters molded into each ratchet. Place each ratchet into the

bracket with the letter "A" aligned with the dot stamped into the metal

bracket. This position sets the transducer's coarse angle adjustment for a

14° transom. Most outboard and stern-drive transoms have a 14° angle.

Dot

Align plastic ratchets in bracket.

B. Two-piece bracket: Locate the four plastic ratchets in the trans-

ducer's hardware package. Press two ratchets into the sides of the plastic bracket and two on either side of the transducer as shown in the following illustrations. Notice there are letters molded into each ratchet.

Place the ratchets into the bracket with the letter "A" aligned with the

alignment mark molded into the bracket. Place the ratchets onto the

transducer with the letter "A" aligned with the 12 o'clock position on

the transducer stem. These positions set the transducer's coarse angle

adjustment for a 14° transom. Most outboard and stern-drive transoms

have a 14° angle.

5

Page 12

Alig

Alignment

r

positions

Transduce

nment letters

Transducer bracket

Transducer

bracket

Insert and align ratchets.

Transducer

Ratchet

Ratchet

Add ratchets to bracket and transducer.

2. Aligning the transducer on the transom.

To align the transducer to the transom, side the transducer between

the ratchets. Look at the transducer from the side and adjust it so that

its face is parallel to the ground. The alignment letters on either side of

the bracket need be the same.

6

Page 13

If the transducer's face isn't parallel with the ground, remove the

transducer and ratchets from the bracket. Place the ratchets into the

holes in the bracket with the letter "B" aligned with the dot stamped in

the bracket.

Reassemble the transducer and bracket and place them against the

transom. Again, check to see if you can move the transducer so it's parallel with the ground. If you can, then go to step 3A.

3. Assembling the transducer.

A. One-piece bracket: Once you determine the correct position for

the ratchets, assemble the transducer as shown in the following figure. Don't tighten the lock nut at this time.

Position transducer mount on transom and mark mounting holes. Side

view shown, left, and seen from above at right.

7

Page 14

Metal

r

r

Nut

Rubber

washers

washer

Metal washer

Bolt

Assemble transducer and bracket.

B. Two-piece bracket: Once you determine the correct position for

the ratchets, assemble the transducer as shown in the figure in step

2B. Don't tighten the lock nut at this time.

Bolt

Flat washer

Lock washe

Nut

Flat washe

Assemble transducer and bracket.

4. Drilling mounting holes.

Hold the transducer and bracket assembly against the transom. The

transducer should be roughly parallel to the ground. The transducer's centerline should be in line with the bottom of the hull. Don't

let the bracket extend below the hull!

8

Page 15

Mark the center of each slot for the mounting screw pilot holes. You

will drill one hole in the center of each slot.

Drill the holes. For the one-piece bracket, use the #29 bit (for the #10

screws). For the two-piece bracket, use the #20 bit (for the #12 screws).

5. Attaching transducer to transom.

Both bracket types: Attach the transducer to the transom. Slide the

transducer up or down until it's aligned properly with the bottom of

the hull as shown in the preceding and following figures. Tighten the

bracket's mounting screws, sealing them with the sealant.

Adjust the transducer so that it's parallel to the ground even if you

have a Deep-"vee" hull. Tighten the nut until it touches the outer

washer, then add 1/4 turn. Don't over tighten the lock nut! If you do,

the transducer won't "kick-up" if it strikes an object in the water.

Bottom

of

hull

Flat-bottom hull Deep-"vee" hull

Align transducer centerline with hull bottom and attach transducer to

transom. Rear view of dual-frequency Skimmer shown.

6. Route the transducer cable through or over the transom to the sonar

unit. Make sure to leave some slack in the cable at the transducer.

9

Page 16

If possible, route the transducer cable away from other wiring on the

boat. Use caution when routing the transducer cable around these

wires.

WARNING:

Clamp the transducer cable to the transom close to the

transducer. This can prevent the transducer from entering the boat if it is knocked off at high speed.

Caution:

If you need to drill a hole in the transom to pass the connector

through, the required hole size be 1". If you drill the hole, make

sure it is located above the waterline. After installation, be sure

to seal the hole with the same marine grade above- or belowwaterline sealant used for the mounting screws.

7. Make a test run to determine the results. If the bottom is lost at

high speed, or if noise appears on the display, try sliding the transducer bracket down. This puts the transducer deeper into the water,

hopefully below the turbulence causing the noise. Don't allow the

transducer bracket to go below the bottom of the hull!

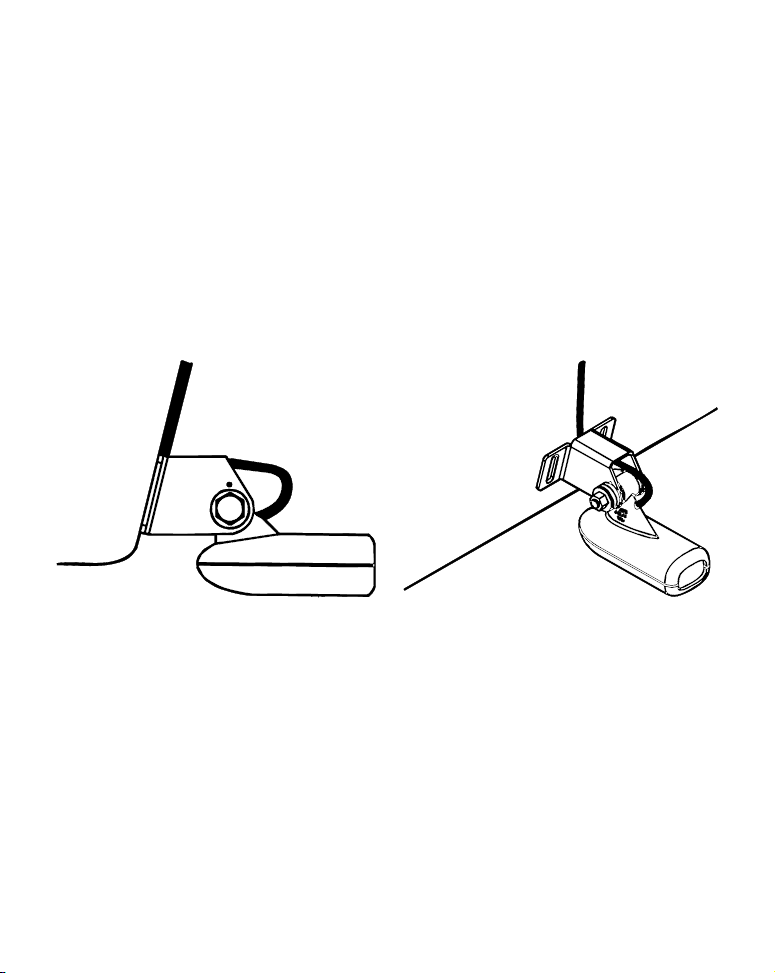

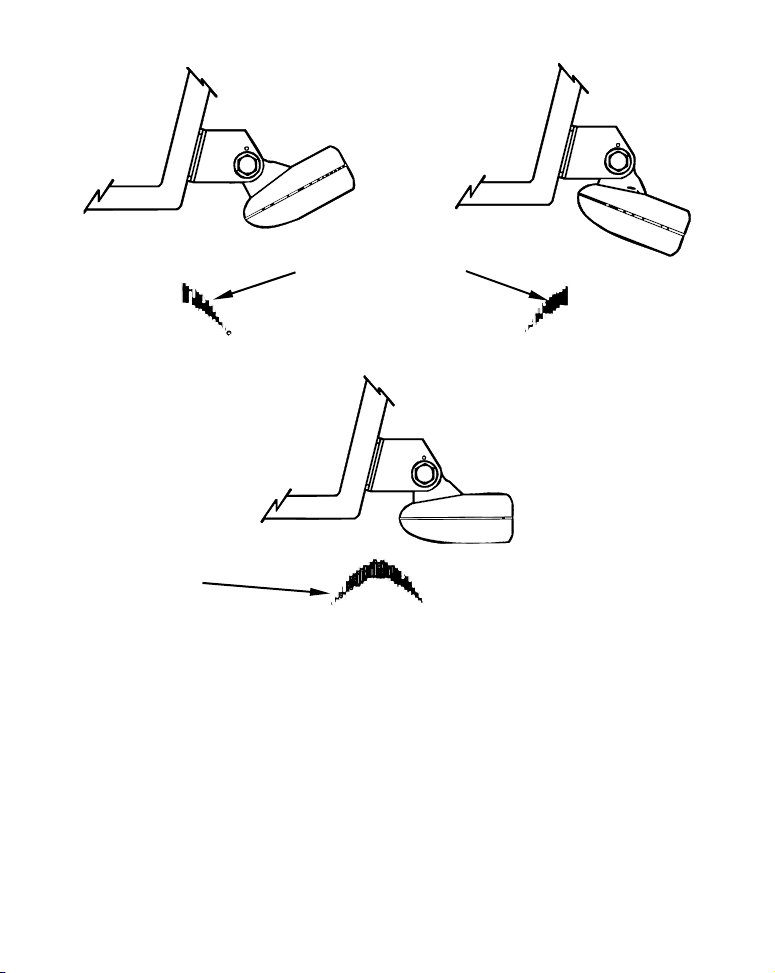

Trolling Motor Bracket Installation

(single-frequency only)

1. Attach the optional TMB-S bracket to the transducer as shown in the

following figure, using the hardware supplied with the transducer.

(Note: The internal tooth washer is supplied with the TMB-S.)

2. Slide the adjustable strap supplied with the TMB-S through the slot

in the transducer bracket and wrap it around the trolling motor. Position the transducer to aim straight down when the motor is in the

water. Tighten the strap securely.

10

Page 17

r

TMB-S bracket

Bolt

Internal tooth washer

Nut

Flat washe

Attach motor mounting bracket to transducer.

3. Route the transducer cable alongside the trolling motor shaft. Use

plastic ties (not included) to attach the transducer cable to the trolling motor shaft. Make sure there is enough slack in the cable for the

motor to turn freely. Route the cable to the sonar unit and the transducer is ready for use.

Transducer mounted on trolling motor, side view.

Transducer Orientation and Fish Arches

If you do not get good fish arches on your display, it could be because

the transducer is not parallel with the ground when the boat is at rest

in the water or at slow trolling speeds.

11

Page 18

Partial fish arches

Transducer aimed

too far back

Full fish arch

Proper transducer angle

Transducer angles and their effects on fish arches.

Transducer aimed

too far forward

If the arch slopes up – but not back down – then the front of the transducer is too high and needs to be lowered. If only the back half of the

arch is printed, then the nose of the transducer is angled too far down

and needs to be raised.

NOTE:

Periodically wash the transducer's face with soap and water to remove

any oil film. Oil and dirt on the face will reduce the sensitivity or may

even prevent operation.

12

Page 19

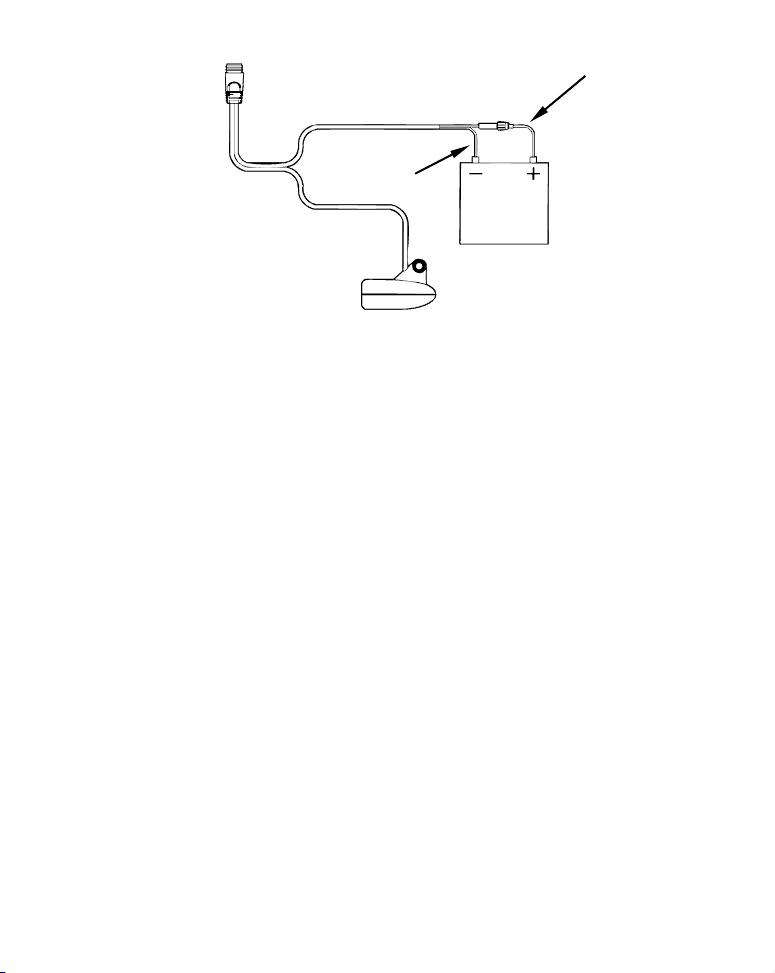

Power Connections (permanent mount only)

The unit works from a 12-volt battery system. You can attach the

power cable to your boat's accessory or power buss (or directly to the

battery). If you use an accessory buss but have problems with electrical

interference, attach the power cable directly to the battery. If the cable

is not long enough, splice #18 gauge wire onto it.

CAUTION:

When using

ommend that you shut off the power supply to the power cable

when the unit is not in use. When the unit is turned off but still

connected to a power supply, electrolysis can occur in the power cable plug. This may result in corrosion of the plug body along with

the electrical contacts in the cable and the unit's power socket.

In saltwater environments we recommend you connect the power

cable to the auxiliary power switch included in most boat designs.

If that results in electrical interference, or if such a switch is not

available, we recommend connecting direct to the battery and installing an inline switch. This will let you shut off power to the

power cable when the unit is not in use. When you are not using

the unit, you should always shut off power to the power cable, especially when the power cable is disconnected from the unit.

If possible, keep the power cable away from other boat wiring, especially the engine's wires. This will provide the best isolation from electrical noise. The power cable has two wires, red and black. Red is the

positive lead, black is negative or ground. Make sure to attach the inline fuse holder to the red lead as close to the power source as possible.

the unit in a saltwater environment, we strongly rec-

13

Page 20

To unit

Black wire

12 volt

battery

Red wire with

3 amp fuse

Power connections for the Cuda 300 sonar unit

(direct battery connection shown).

For example, if you have to extend the power cable to the battery or

power buss, attach one end of the fuse holder directly to the battery or

power buss. This will protect both the unit and the power cable in the

event of a short. It uses a 3-amp fuse.

Caution:

Do not use this product without a 3-amp fuse wired into the

power cable! Failure to use a 3-amp fuse will void your warranty.

This unit has reverse polarity protection. No damage will occur if the

power wires are reversed. However, the unit will not work until the

wires are attached correctly.

Mounting the Sonar Unit: In-Dash, Bracket or Portable

You can install the sonar unit on the top of a dash with the supplied

bracket. This unit can be installed in a dash with the optional FM-6 indash adapter kit. The FM-6 kit includes an instruction sheet, part 9880147-631, which contains a template for cutting out the mounting hole.

This document can be downloaded free from the www.eaglesonar.com

web site.

14

Page 21

Bracket Installation

Recommended tools for this job include: drill, 1" (25.4 mm) drill bit,

screwdriver. Required supplies for this job include: high quality, ma-

rine grade above- or below-waterline caulking compound, three #10

stainless steel screws. Screw length and type should be suitable for the

material on which you intend to mount the bracket.

Mount the unit in any convenient location, provided there is clearance

when it’s tilted for the best viewing angle. You should also make sure

there is enough room behind the unit to attach the power/transducer

cable. (See the following drawings, which show the dimensions of a

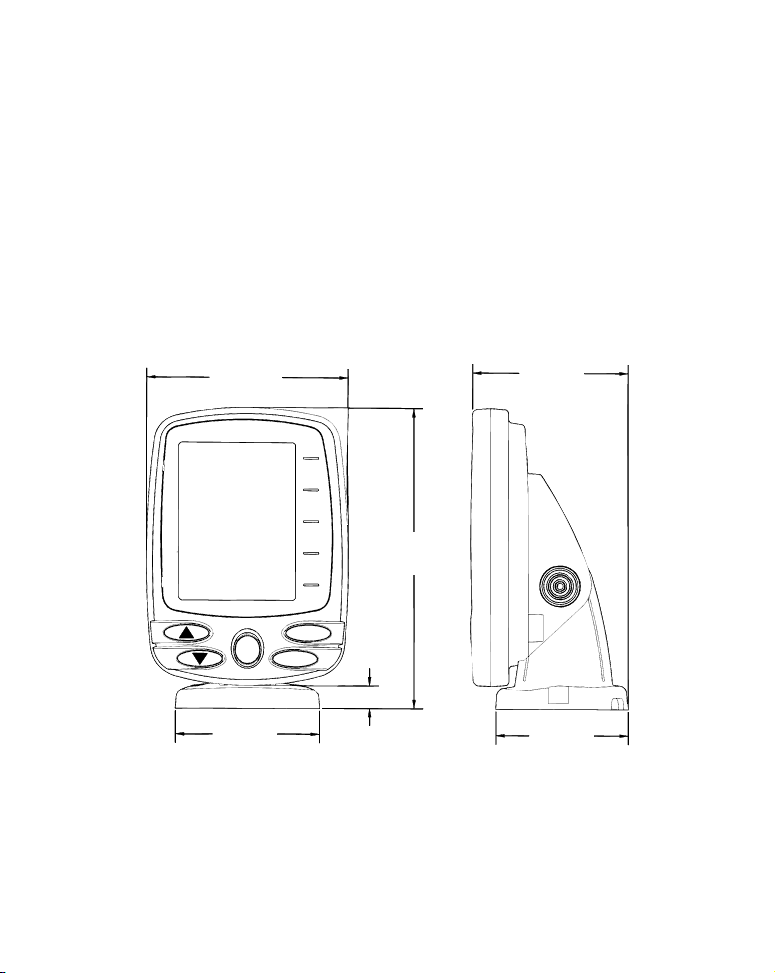

gimbal-mounted Cuda 300 sonar unit.)

107.5

[4.23]

156

[6.26]

82.7

[3.26]

12.09 [0.48]

76.9

[3.03]

Front view (left) and side view (right) showing dimensions

of the Cuda 300 when mounted on quick release bracket.

Millimeter

[Inch]

70.3

[2.77]

15

Page 22

Holes in the bracket’s base allow wood screw or through-bolt mounting.

You may need to place a piece of plywood on the back side of thin panels to reinforce the panel and secure the mounting hardware.

Drill a 1" (25.4 mm) hole in the dash for the power/transducer and accessory cables. The best location for this hole is immediately under the

gimbal bracket location. This way, the bracket can be installed so that

it covers the hole, holds the cables in position and results in a neat installation. Some customers, however, prefer to mount the bracket to the

side of the cable hole — it's a matter of personal preference.

After drilling the hole, pass the connectors up through the hole from

under the dash. If you wish, you can fill in the hole around the cable with

a good marine caulking compound. (Some marine dealers stock cable hole

covers to conceal the opening.)

Using the Quick Release Mounting Bracket

These units use a quick release mounting bracket. When you run the

cables through the bracket's cable slots, make sure you allow enough

slack for tilting the unit and attaching the connector. (The snug fit of

the push-on waterproof connector requires some force to attach.)

Ratchet

Screw hole

Power/transducer

cable

Cuda 300 quick release mounting bracket (left). Adjusting the viewing

angle of a display unit (right).

Rear

view

Cable slot

Depress

ratchets to

release

16

Page 23

Attach the unit to the bracket by first connecting the power/transducer

and accessory cables. Then, hold the sonar unit vertically and slide it

onto the bracket from above. (The back of the unit should be touching

the front of the bracket as you lower it into position.) As you push

down, the unit will lock into place with a distinct click.

To adjust the viewing angle, pinch the ratchets with one hand, then tilt

the unit with your other hand. Release the ratchets and the unit locks

into the new position. To dismount the unit for storage, press the ratchets and lift the unit off the bracket.

Portable Sonar Installation

Like many Eagle products, the Cuda 300 sonar is capable of portable

operation. It uses the optional PPP-12 portable power pack.

The PPP-12 package includes the power pack, battery adapter and a portable transducer. The transducer can be stored inside the power pack. The

PPP-12 requires eight AA alkaline batteries. Batteries are not included.

To use a portable power pack, you install the batteries and then attach

the sonar unit to the power pack's bracket. Plug in the

power/transducer cable and you're ready to fish.

The PPP-12 has a quick-release mounting bracket built into the case.

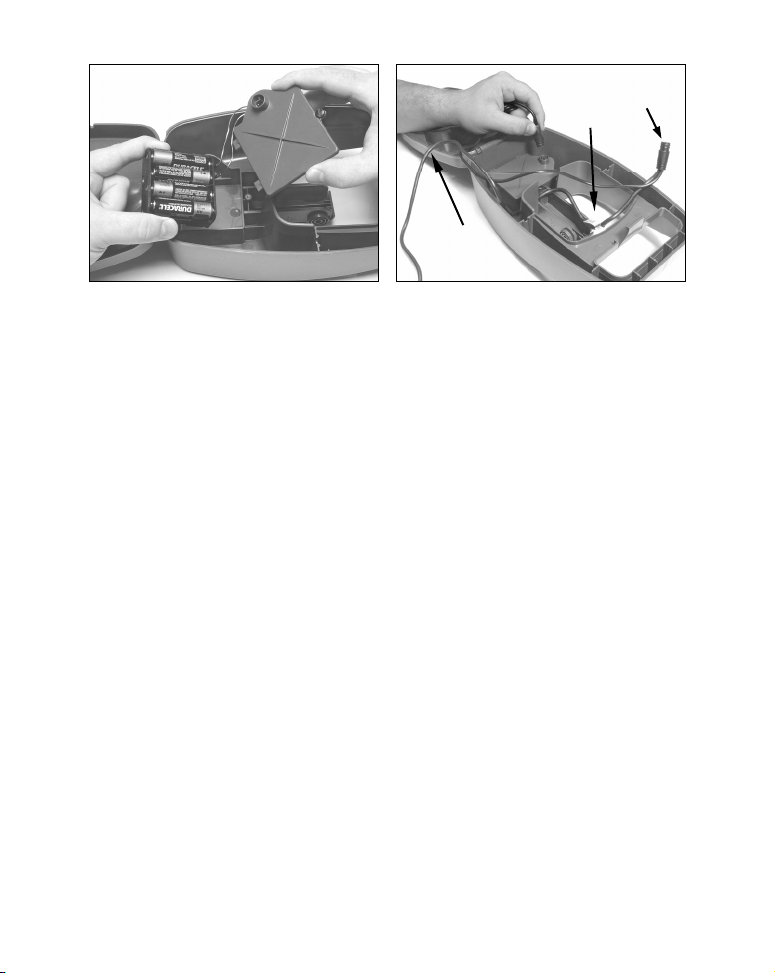

Installing the Batteries

Open the case and lay it flat. (The latch is located below the handle.)

Insert eight "AA" size batteries into the battery adapter and place it in

the battery compartment. Slip the battery cover tabs into the slots in

the case wall, then close the battery cover with the thumb screw.

Plug the cable's power (dog bone-shaped) connector into the socket on

the battery compartment cover. Route the cable's unit connector and

about 6 inches (15.2 cm) of cable through the opening under the sonar

mount. Close the case bottom, using the slot in the case wall to avoid

pinching the cable. Turn the unit over to mount the sonar.

17

Page 24

Route this

p

g

cable through

enin

o

Cable slot

in case wall

Install batteries in battery compartment (left).

Attach power cable, and route wires as shown (right).

CAUTION:

When using the sonar in a saltwater environment, we strongly

recommend that you unplug the power connector from the battery socket when the unit is not in use. When the unit is turned

off but still connected to a power supply, electrolysis can occur in

the power cable plug. This may result in corrosion of the plug

body along with the electrical contacts in the cable and the

unit's power socket.

Mounting the Unit

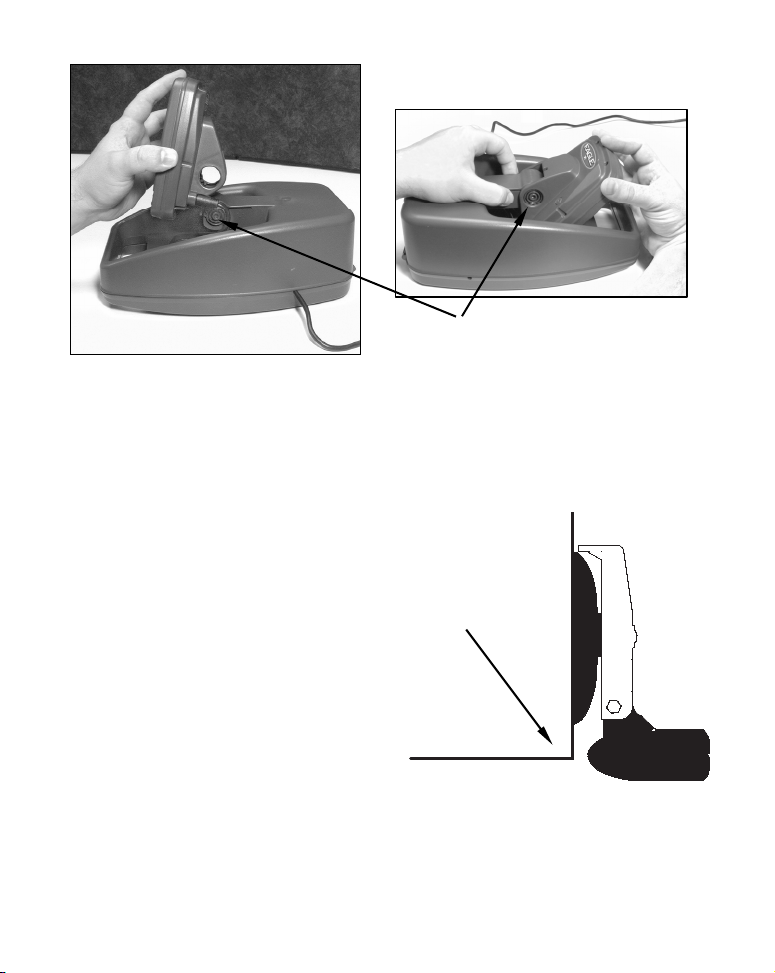

A quick-release mount is built into the top of the portable power pack. To

attach the unit, first plug in the cable connector. Then, hold the sonar unit

vertically and slide it onto the bracket from above. (The back of the unit

should be touching the front of the bracket as you lower it into position.)

As you push down, the unit will lock into place with a distinct click.

To adjust the viewing angle, pinch the quick-release mount's ratchets

with one hand, then tilt the unit with your other hand. Release the

ratchets and the unit locks into the new position. To remove the unit

from the PPP-12, press the ratchets and lift the unit off the bracket.

18

Page 25

Ratchet

To mount the sonar, slide the unit onto the bracket from above (left).

To adjust the view, press and release spring-loaded ratchets while tilt-

ing the unit (right).

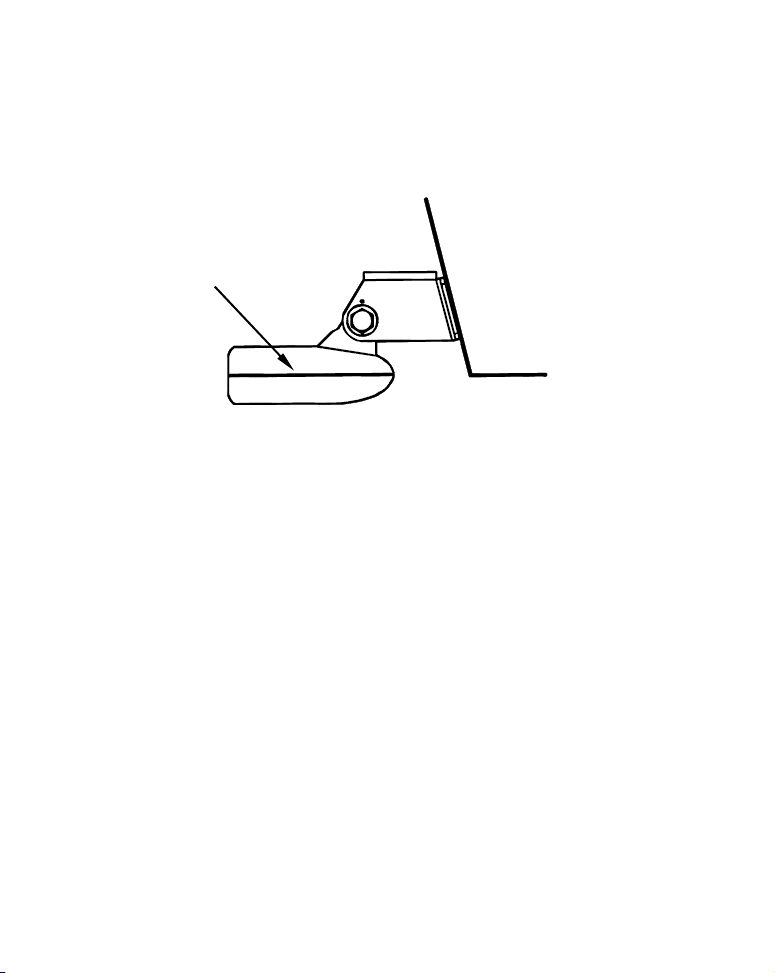

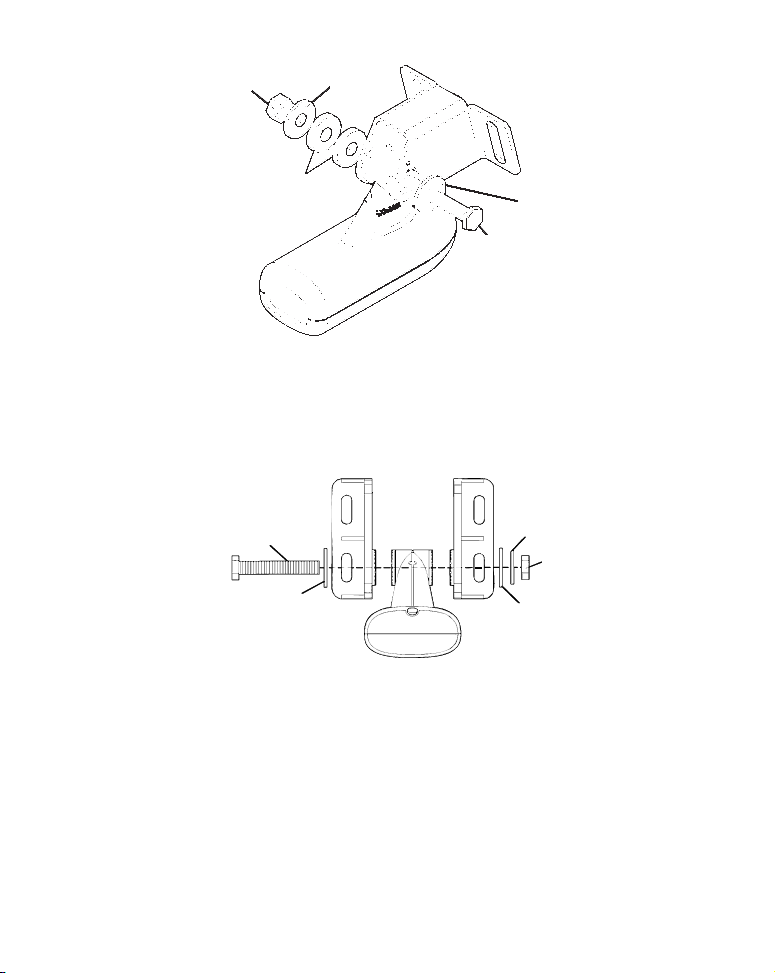

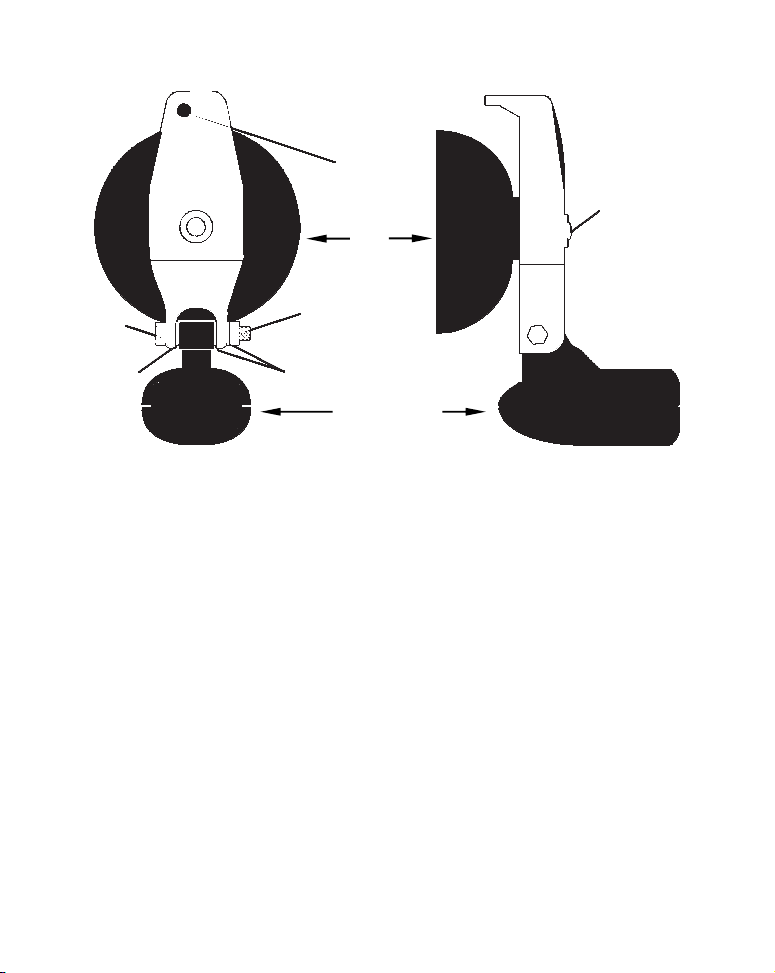

Portable Transducer Assembly

Make sure there is one washer on each side of the transducer, inside the

bracket. Slide the other washer over the end of the bolt and screw on the nut.

Screw the suction cup onto the bracket

using the supplied screw and flat

washer. Tie the nylon cord through the

hole in the top of the bracket. When

using the transducer, tie the other end

Hull

of the nylon cord to the boat. This will

help prevent losing the transducer if it

comes off. Clean the chosen area of

the hull before attaching the suction cup. Locate the transducer on

the hull as shown in the following

figure. Don't let the bracket extend

below the hull, because water pres-

Portable transducer installed on

boat transom.

sure against it can cause the suction

cup to come off at speed.

19

Page 26

Tie

nylon

cord

here

Screw

Bolt

Washer

Suction

cup

Nut

Washer

Transducer

Portable transducer assembly: rear view (left) and side view (right).

NOTE:

For optimum operation, the portable transducer should be adjusted

so that it is parallel to the ground. For more information on this,

see the segment in the unit's operation manual on Transducer Ori-

entation and Fish Arches.

Moisten the suction cup, then press it onto the hull as firmly as possible. Tie the nylon cord to the boat and set the power pack and sonar unit in

a location for easy viewing. Your portable sonar is now ready for use.

20

Page 27

Operation

Keyboard Basics

The Cuda 300 has five buttons including, Power/Clear, Menu Up, Menu

Down and two arrow keys.

1

3

Eagle Cuda 300 keyboard.

PWR/CLEAR

Press the

menu selections from the screen.

MENU UP & MENU DOWN

The MENU UP key cycles forward through the menus. The MENU DOWN

key moves backward through the menus. To scroll through the unit's

menus, repeatedly press a

UP & DOWN ARROWS (↑ ↓)

The

PWR key to turn the unit on and off. It also clears menus and

MENU key.

UP and DOWN ARROW keys are used to adjust features and functions.

2

Memory

This unit has an internal backup battery that saves the following user

settings when power is turned off: Units of Measure, Temp Size, Depth

21

Page 28

Size, Fish I.D. mode, Noise Reject mode, Range mode, Zoom, Sensitivity,

p

r

Grayline, Chart Speed, Battery Alarm, Display Contrast, Backlight, Language, Fish Alarm, Battery Alarm and Shallow and Deep alarms.

Display

When the unit is turned, the backlight menu will appear. Use the

ARROW keys to turn the backlight on or off. Press PWR to clear the

menu from the screen.

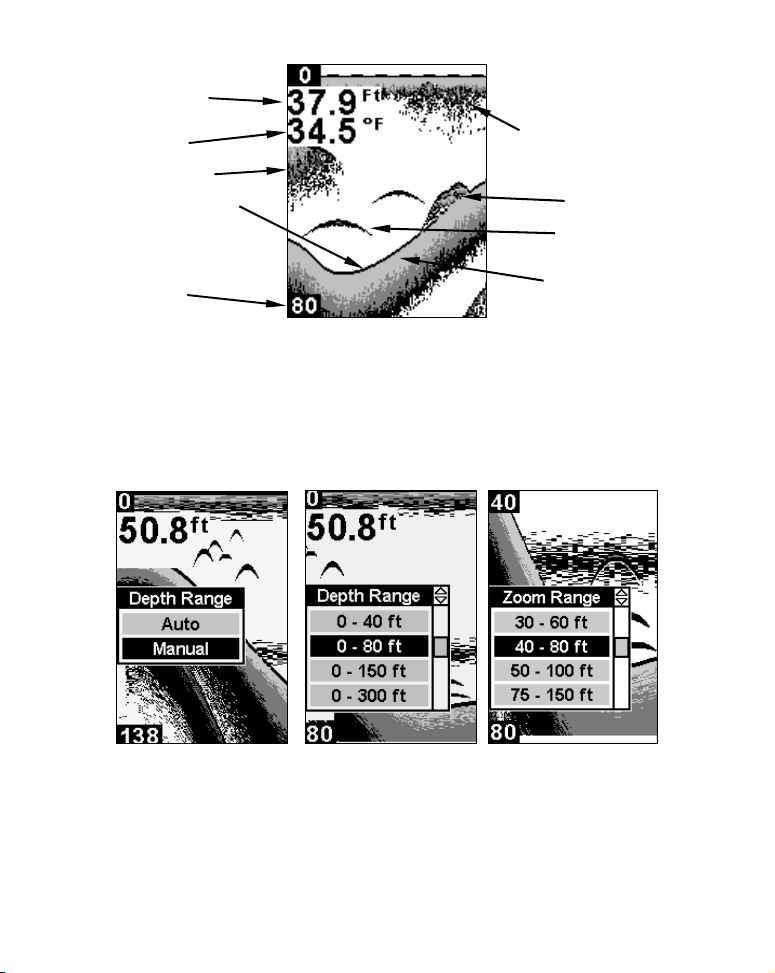

Depth range will be displayed on the left side of the screen. In the following figure, the screen shows a depth range from 0 to 80 feet and the

bottom depth is 36.9 feet, shown by the digital sonar. The water temperature is 34.5° F.

Digital depth

Water Temp

Bottom signal

Depth range

at bottom of

th scale

de

Surface signal

Fish symbols

Structure

or cove

Grayline

®

Full Chart page. Fish I.D. (fish symbols) is on by default.

Full Chart

On the Full Chart page, the bottom signal scrolls across the screen

from right to left. The line at the top of the screen represents the surface. The bottom depth is shown in the upper left-hand corner.

If the transducer with a built-in temperature sensor is connected, the

water temperature also will be shown.

22

Page 29

y

Digital depth

p

r

Water Temp

Bait fish

Bottom signal

Depth range

at bottom of

th scale

de

Surface clutter

Structure

or cove

Fish arches

line

®

Gra

Full Chart page with Fish I.D. turned off.

Depth Range

Depth Range has two modes: Automatic and Manual. In auto range

mode, the unit always keeps the bottom displayed in the lower portion

of the screen. If you want to manually select a depth range, you can

override automatic depth range control.

Depth Range menu with Manual setting selected (left). Range Size

menu with 0-80 ft highlighted (center). Zoom Range menu with the 40-

80 foot zoom selected.

23

Page 30

To turn off Auto Depth Range:

1. Repeatedly press MENU until the DEPTH RANGE menu appears. Press ↓

to select MANUAL, then press MENU UP to display the RANGE SIZE menu.

2. Use the arrow keys to select a desired depth range. Press

PWR to

clear the menu from the display.

Zoom

The zoom feature enlarges all images on the screen by doubling the size

of the echoes (a 2X zoom).

To turn on the Zoom feature:

1. Press the MENU key until the ZOOM menu appears. Press ↑ to select

ON, then press PWR to clear the menu.

You can tell when the display is in Zoom mode because the top depth

scale on the left of the screen will no longer show zero. If the current

range is 0 to 80 feet, turning on the zoom feature will magnify the water

column between 40 feet to 80 feet.

To turn off the zoom feature:

1. Press the MENU key until the ZOOM menu appears. Press ↓ to select

OFF, then press PWR to clear the menu. The top of the depth range scale

returns to zero.

NOTE:

You can select from these zoom size ranges: 0-10, 5-15, 10-20, 15-

30, 20-40, 30-60, 40-80, 50-100, 75-150, 100-200, 150-300, 200-400,

300-600, 400-800, 500-1000, 750-1500 and 1000-2000.

To select a zoom range:

1. Make sure Depth Range is set to manual mode. Press MENU until

ZOOM menu appears. Press ↑ to select ON, then press MENU UP to

the

display the

2. Use the arrow keys to select a desired zoom size. Press

the menu from the display.

ZOOM RANGE menu.

PWR to clear

24

Page 31

Sensitivity

Sensitivity adjusts the way echoes will be displayed on the screen. If

you want to see more detail, try increase sensitivity. If your unit is

picking up a lot of clutter, decrease the sensitivity to reduce the

amount of clutter displayed on the screen.

Sensitivity set to manual mode (left). Sensitivity control bar (right).

To adjust sensitivity in Auto Mode:

1. Press MENU until the SENSITIVITY control bar appears. Press ↑ to increase

the sensitivity,

2. Press

sensitivity level, a tone will sound.

To turn on Manual mode:

1. Repeatedly press Menu to display the Sensitivity menu. Highlight

MANUAL and press PWR to clear the menu.

↓ to decrease it.

PWR to clear the menu. If you reach the maximum or minimum

Grayline®

Grayline® helps you tell the difference between a hard and a soft bottom by coloring weaker sonar returns (soft, muddy or weedy bottom)

with a narrow gray line or no gray line at all. A strong sonar return

(hard bottom) will be displayed as a wide gray line.

25

Page 32

y

Bait

school

Fish

arches

Sensitivity at 71 percent (left). Sensitivity at 100 percent (right).

To change the Grayline level:

1. Press MENU until the GRAYLINE control bar appears.

2. Press

↑ to increase the level of Grayline or press ↓ to decrease it. If

you reach the maximum or minimum level, a tone will sound. Press

PWR to clear the menu.

Thin or no Grayline

®

A small amount of Grayline indicates a soft bottom (left), probably

sand or mud. More Grayline indicates a harder, rocky bottom (right).

Chart Speed

The rate that echoes scroll across the screen is called the chart scroll

speed. The default for this unit is the maximum, 100 percent.

26

Wider

Gra

line

®

Page 33

Chart Speed control bar.

NOTE:

When you are stationary or traveling slowly and using a higher

chart speed, a fish swimming through the sonar signal will be dis-

played as a long line instead of a fish arch. You can counteract this

by decreasing the chart speed to match the speed of your boat,

which will shorten the line, making it look more like a fish arch.

To adjust Chart Speed:

1. Press MENU until the CHART SPEED control bar appears. Press ↑ to increase the speed of the chart. Press ↓ to decrease it.

2. Press

PWR to clear the menu.

Fish I.D.™

The Fish I.D. feature displays fish symbols on the screen in place of the

actual fish echoes. There are three symbol sizes: small, medium and

large. These show the relative size between targets.

To see what's under your boat in maximum detail

turn off Fish I.D. and begin learning to interpret fish arches.

To turn Fish I.D. on/off:

1. Press MENU until the FISH ID menu appears. Press ↓ to select ON/OFF.

2. Press

PWR to clear the menu from the display.

27

, we recommend you

Page 34

Fish

arches

Fish I.D.

symbols

Underwater scene in normal fish arch mode (left). Fish I.D. menu with

the feature turned on (right).

FishTrack™

The FishTrack™ feature shows the depth of a fish symbol when it appears on the display.

To turn on/off FishTrack:

1. Press MENU until the FISH ID menu appears. Press ↑ ↓ to select TRACK

OFF.

or

2. Press

I.D. on, press

PWR. (If you want to turn off FishTrack depths but leave Fish

↓ to select ON, then press PWR.) Remember, Fish I.D.

must be on in order to use the FishTrack feature.

Fish Alarm

The Fish Alarm sounds a tone when a fish symbol appears on the

screen. The Fish I.D. feature must be turned on for fish alarms to work.

To turn on/off the fish alarm:

1. Press MENU until the FISH ALARM menu appears. Press ↑ to select

ON/OFF.

2. Press

PWR to clear the menu from the screen

28

Page 35

Fish ID menu and symbol with FishTrack on (left). Fish Alarm menu

(right).

Depth Alarms

The depth alarms consist of a shallow and a deep alarm. The shallow

alarm sounds an alarm tone when the bottom is shallower than the

alarm's setting. The deep alarm sounds a tone when the bottom is

deeper than the alarm's setting.

Shallow Alarm

To set the shallow alarm:

1. Press MENU repeatedly until SHALLOW ALARM appears.

2. Press

box, then press

↓ to SET VALUE. Use ↑ ↓ to enter the first number in the dialog

DOWN MENU to move to the next digit. Repeat those

steps until the desired depth has been entered in the dialog box. To

move the cursor back to any of the previously entered numbers, press

UP MENU.

3. Press

which will turn on the alarm, then press

PWR to return to the Shallow Alarm menu. Use ↑ to select ON,

PWR to clear the menu. When

the alarm goes off a message will appear and a tone will sound. Press

PWR to silence the alarm.

29

Page 36

To turn off the alarm:

1. Repeatedly press MENU until the SHALLOW ALARM menu appears. Press

↓ to OFF.

2. Press

PWR to clear the menu.

Shallow Alarm Value Dialog box (left). Shallow Alarm menu (right).

Deep Alarm

To set the deep alarm:

1. Press MENU repeatedly until DEEP ALARM appears.

2. Press

Use

MENU

depth has been entered in the dialog box. To move the cursor back to

any of the previously entered numbers, press

3. Press

Press

than the alarm’s setting, an alarm will sound and a message will appear on the screen.

To turn off the alarm:

1. Repeatedly press MENU until the DEEP ALARM menu appears. Press ↓

to OFF. Press PWR to clear the menu.

↓ to SET VALUE. The Deep Alarm Value dialog box will appear.

↓ to enter the first number in the dialog box, then press DOWN

to move to the next digit. Repeat those steps until the desired

UP MENU.

PWR to return to the Deep Alarm menu. Use ↑ to select ON.

PWR to clear the menu. When the bottom depth becomes deeper

30

Page 37

Battery Alarm

To set the Battery alarm:

1. Press MENU repeatedly until BATTERY ALARM appears.

2. Press the

will appear. Input a voltage value between 7 and 18 volts. Use the

keys to enter the first number in the dialog box, then press DOWN

MENU

to move to the next digit. Repeat those steps until the desired

value has been entered in the dialog box. To move the cursor back to

any of the previously entered numbers, press

Low Battery Alarm Value (left). Battery Alarm menu (right).

3. Press PWR to return to the Battery Alarm menu. Use ↑ to select ON,

which will turn on the alarm, then press

voltage value falls below the alarm’s setting, the alarm will sound and

a message will appear on the screen.

To turn off the alarm:

1. Repeatedly press MENU until the BATTERY ALARM menu appears. Press

↓ to OFF.

2. Press

↓ to SET VALUE. The Low Battery Alarm Value dialog box

↑ ↓

UP MENU.

PWR to clear the menu. If the

PWR to clear the menu.

31

Page 38

Noise Reject and ASP™

The ASP™ (Advanced Signal Processing) feature is a noise rejection

system that constantly evaluates the effects of boat speed, water conditions and electrical interference and automatically gives you the best

display possible under most conditions. The ASP feature has three settings — Off, Low and High.

To change the ASP setting:

1. Press MENU until the NOISE REJECTION menu appears. Use ↑ ↓ to select

the desired setting.

2. Press

PWR to clear the menu.

Depth Display

Depth may be displayed in a small, medium or large size, or can be

turned off completely.

To display Depth:

1. Repeatedly press MENU until the DEPTH menu appears. Use ↑ ↓ to select the size of the depth display.

2. Press

PWR to clear the menu.

Depth display set to large (left). Voltage display set to small (right).

32

Page 39

Voltage

The Voltage menu allows you to display battery voltage in a small or

medium size, or can be turned off completely.

To display battery voltage:

1. Repeatedly press MENU until the VOLTAGE menu appears. Use ↑ ↓ to

select the size of the voltage display.

2. Press

PWR to clear the menu.

Temperature Display

Temperature may be displayed in a small or medium size, or can be

turned off completely.

To display Temperature:

1. Repeatedly press MENU until the TEMPERATURE menu appears. Use ↑ ↓

to select the size of the temperature display.

2. Press

PWR to clear the menu.

Units

This unit can show the depth in feet or meters and temperature in Celsius or Fahrenheit.

The Backlight menu with backlight turned on.

33

Page 40

To change units of measure:

1. Press MENU until the UNITS menu appears. Use the arrow keys to select the desired unit of measure.

2. Press the

PWR key to clear the menu.

Backlight

Turning on your unit's backlight will allow you to use it at night.

To turn the backlight on/off:

1. Press MENU repeatedly until the BACKLIGHT menu appears. Press ↑ to

turn the light on or

2. Press

PWR to clear the menu.

↓ to turn it off.

Contrast

The unit’s display contrast is adjustable to suit different lighting conditions. It will help you see the screen from different angles or at various

times of the day.

To adjust the contrast:

1. Press MENU until the CONTRAST control bar appears. To decrease

screen contrast, press ↓. Press ↑ to increase screen contrast.

2. Press the

PWR key to clear the menu.

Contrast control bar (center). Simulator menu (center). Languages

menu with English selected (right).

34

Page 41

Simulator

This unit has a simulator that displays a simulated bottom signal with

fish signals.

To turn on/off the simulator:

1. Repeatedly press MENU until the SIMULATOR menu appears. Press ↑ ↓

to turn it on or off.

2. Press

PWR to clear the menu.

Set Language

This unit's menus are available in 11 languages: English, French, German, Spanish, Italian, Danish, Swedish, Russian, Czech, Dutch and

Finnish.

To select a language:

1. Repeatedly press MENU until the Languages menu appears.

2. Use ↑ ↓ to select the desired language. All menus now appear in the

language you selected. Press

PWR to clear the menu.

Software Information

The Software Information screen shows what version of software your

unit is using.

To show the software information:

1. Press MENU until the SOFTWARE INFORMATION menu appears.

2. Press

PWR to clear the screen.

Reset Options

This command is used to reset all features, options and settings to their

original factory defaults.

To Reset Options:

1. Turn the unit off. Press and hold ↓ and the MENU DOWN key at the

same time while pressing the

2. Release the keys as the unit powers up. The unit will turn on with

factory settings restored.

PWR key.

35

Page 42

Notes

36

Page 43

Table des Matières

Informations Techniques: Cuda™ 300 & Cuda™ 300 Portable............1

Préparations ..............................................................................................3

Outils et Matériel Recommandés ........................................................4

Installation à Travers Coque et Installation sur le Tableau ................7

Assemblage et Montage du Transducteur Sur le Tableau

Arrière....................................................................................................8

Installation Sur Un Moteur A La Traine (Trolling Motor).................15

Orientation du Transducteur et Repérage du Poisson ...................15

Branchements (pour les montages permanents uniquement) .......17

Installation du sondeur : Dans le Tableau de Bord, sur Support

ou Portable...........................................................................................19

Installation sur Support.....................................................................19

Installation Portative .........................................................................22

Installation des Piles ..........................................................................23

Installer l’Appareil..................................................................................24

Assemblage du transducteur portatif ...............................................25

Fonctionnement ................................................................................. 29

Clavier......................................................................................................29

Mémoire ...................................................................................................30

Menus.......................................................................................................30

Affichage ..................................................................................................31

Graphique Entier................................................................................32

Portée en Profondeur ..............................................................................33

Zoom .........................................................................................................34

Sensibilité ................................................................................................35

Grayline®.................................................................................................37

Fish I.D.™................................................................................................40

Fishtrack™ ..............................................................................................42

Alarmes....................................................................................................42

Alarme de Poisson ..............................................................................43

Alarmes de Profondeur.......................................................................43

Alarme de Hauts-Fonds .....................................................................44

i

Page 44

Alarme de Profondeur ............................................................................45

Alarme de l’Alimentation .......................................................................46

Rejet du Bruit et ASP™..........................................................................47

Affichage de la Profondeur.....................................................................47

Affichage de la Température .................................................................48

Tension.....................................................................................................48

Unités.......................................................................................................49

Rétro-éclairage ........................................................................................49

Contraste .................................................................................................49

Simulateur...............................................................................................50

Choisir la Langue....................................................................................51

Informations Système ............................................................................51

Ré-initialisation des Options .................................................................51

ii

Page 45

Informations Techniques: Cuda™ 300 & Cuda™ 300 Portable

Générales

Dimensions

du Boîtier:......................... 5.8" H x 4.3" L x 2.5" P (14.7 cm H x 10.8 cm L

x 6.6 cm P) hermétique, étanche; uti

Affichage:..........................

Film SuperTwist LCD Haute Dé

finition. 3.5"

(8.9 cm) en Diagonale.

Résolution: ....................... 240 pixels (vert.) x 160 pixels (horiz.); 38,400

pixels au total.

Rétro-éclairage: .............. écran rétro-éclairé à incandescence.

Alimentation:................... de 10 à 17 volts DC.

Puissance

Consommée:..................... 170 ma éclairage éteint; 240 ma éclairage al-

lumé.

Mémoire

de Sauvegarde:................ Mémoire intégrée sauvegardant les réglages

du sonar lorsque l’appareil est mis hors tension.

Sonar

Fréquence:........................ 200 kHz.

Transducteur:...................Un transducteur Skimmer

®

accompagne votre

sondeur. Son angle de 20° offre une large détection des poissons allant jusqu'à 60º avec les

réglages de haute sensibilité.

Emetteur:.......................... 800 watts crête à crête; 100 watts RMS.

Capacité de Sondage

en Profondeur:................ 600 pieds (180 mètres). La profondeur sondée

dépend de l'installation et de la configuration

du transducteur, de la composition du fond et

de la nature de l'eau.

1

Page 46

Affichage de la

profondeur: ...................... Affichage continu.

Alarmes audibles:........... Profondeur/hauts-fonds/poisson.

Portée Automatique: ..... Oui, avec des mises à jour instantannées à

l'écran.

Détection Automatique

du Fond: ............................ Oui.

Zoom suivant le Fond:... Oui.

Zoom en Ecran Divisé:.. Oui.

Température

de Surface:........................ Oui, intégrée au transducteur. Capteur de

température ou capteur combo vitesse/temp

externes en option disponibles.

Ce manuel concerne le Cuda™ 300 et le Cuda™ 300 Portable. Ces deux

appareils fonctionnent

de la même manière. La

seule différence entre les

deux est que l’appareil portable comprend un transducteur spécial ainsi

que d’autres accessoires permettant une utilisation portative.

AVERTISSEMENT!

Entreposez votre appareil à une température comprise entre -20°C et

+75°C. Un entreposage ou un fonctionnement prolongés à des températures supérieures ou inférieures à celles indiquées ci-dessus peuvent endommager l’écran de visualisation à cristaux liquides. Ce type

de dégât n’est pas couvert par la garantie. Pour plus d’informations,

veuillez contacter le Service Clientèle de l’entreprise; vous trouverez

les numéros de téléphone correspondants à la fin du manuel.

2

Page 47

Installation du Transducteur

Préparations

Voici la séquence des étapes recommandées pour l’installation de votre

transducteur :

Avertissement:

Nous vous recommandons de lire l'intégralité de cette section

avant de percer des trous dans votre bateau!

1. Déterminez l'emplacement approximatif du sondeur, de façon à pouvoir prévoir comment et où passeront les câbles du transducteur et de

l'alimentation. Cela vous permettra de vous assurez que vous disposez de

suffisamment de longueur de câble pour la configuration désirée.

2. Déterminez l'emplacement approximatif du transducteur et le parcours de son câble.

3. Déterminez l'emplacement de votre batterie ou de toute autre source

d'alimentation, ainsi que le parcours du câble d'alimentation.

4. Installez le transducteur et acheminez son câble vers le sondeur.

5. Acheminez le câble d’alimentation depuis le sondeur vers une source

d’alimentation appropriée et branchez-le.

6. Branchez le câble d’alimentation/transducteur au sondeur et installez

ce dernier sur son support.

Installation

Ces instructions vous permettront de mettre en place votre transducteur

Skimmer

motor - moteur de traîne - ou à l’intérieur d’une coque. Nous vous conseillons de lire attentivement ces instructions avant de procéder à

l’installation de votre matériel. Votre transducteur Skimmer est généralement accompagné d’un support de montage en acier inoxydable une

pièce pour un montage sur le tableau de votre bateau. Le montage pour

un trolling motor consiste en un support plastique en une seule pièce,

accompagné d'une courroie ajustable.

®

sur un travers (sonde pour tableau arrière), sur un trolling

3

Page 48

Ces supports de montage aident à éviter l'endommagement du transducteur dans le cas où ce dernier heurterait un objet pendant la marche du

bateau. Si le transducteur est effectivement touché, le support peut ainsi

facilement être repositionné sans outils.

En fonction des connecteurs de votre sondeur, il est possible que le câble

de votre transducteur soit également rattaché au câble d’alimentation. Si

c’est le cas, assurez-vous de bien installer le transducteur en premier,

avant de brancher le câble d’alimentation à une source d’alimentation.

Reportez-vous aux intructions de branchement du câble d’alimentation

plus loin dans ce manuel.

Lisez soigneusement ces instructions avant de procéder à l’installation

du transducteur. Déterminez quelle méthode d'installation convient le

mieux à votre embarcation. Soyez très prudent si vous installez le

transducteur à l'intérieur de la coque, car une fois en place avec

l'époxyde, le transducteur ne peut généralement pas être déplacé ou

retiré. Rappelez-vous que l’installation du transducteur consti-

tue la partie la plus critique de l’installation d’un sonar.

Outils et Matériel Recommandés

Si vous choisissez de faire passer le câble par le tableau arrière, vous aurez besoin d’une mèche de diamètre 25 mm. Un montage sur le tableau

nécessite l’utilisation d’un composé de calfatage de haute qualité marine

au-dessus et en-dessous de la ligne de flottaison.

REMARQUE:

Les types d’installations suivants nécessitent également les outils et

matériaux recommandés suivants (ces matériaux ne sont pas fournis):

Installation d’un transducteur à fréquence unique sur le tableau arrière

Outils recommandés: deux clefs universelles (à ouverture variable), perceuse, mèche #29 (3,5mm), tournevis à tête plate. Matériel: aucun.

Installation d’un transducteur à fréquence unique sur un trolling motor

Outils: Deux clefs universelles, tournevis à tête plate. Matériel: attaches

plastiques pour les câbles.

4

Page 49

Sélectionner l'emplacement du transducteur

1. L'emplacement choisi doit constamment se trouver dans l'eau, et cela à

n'importe quelle vitesse.

2. Le transducteur doit être installé à un endroit où le débit de l’eau sera

constamment le plus régulier possible. Si le transducteur n’est pas placé

au niveau d’une eau en mouvement uni et constant, les perturbations

causées par les bulles d’air et les turbulences se traduiront à l’écran du

sondeur par des interférences (apparition de lignes et de points) dès que

le bateau se mettra en mouvement.

REMARQUE:

Certains bateaux en aluminium, avec des virures ou des membrures

externes à la coque, créent de grandes quantités de turbulences lorsqu’ils sont lancés à grande vitesse. Ces bateaux sont généralement

équipés de puissants moteurs hors-bord capables de les propulser à

des vitesses supérieures à 35 mph (55km/h environ). Sur ce genre de

bateaux, le transducteur sera généralement le mieux installé entre

les membrures les plus proches du moteur.

3. Le transducteur doit si possible être orienté de façon à ce que son endroit pointe directement vers le bas. Pour les installations à l'intérieur de

la coque: Beaucoup de bateaux de pêche populaires possèdent une quille

plate qui constitue une bonne surface de montage. Sur les coques en V,

essayez de placer le transducteur à un endroit où l'inclinaison est égale

ou inférieure à 10°.

Inclinaison de moins de 10°

Quille plate

Coque en V à fond plat (gauche); Coque en V (droite). Un transducteur-

nacelle est illustré ici, mais le principe est le même pour les transduc-

teurs Skimmers installés dans la coque.

Lisses

5

Page 50

4. Si le transducteur est installé sur le tableau, assurez-vous qu’il

A

n’entravera pas le remorquage ou le halage du bateau. De plus, ne

l’installez pas à moins d’un pied (30 centimètres environ) du plus bas

élément du moteur. Cette précaution permettra de limiter les interférences causées par l’action des hélices (bulles d’air).

5. Si possible, évitez de faire passer le câble du transducteur à proximité

d’une autre installation électrique du bateau. Des bruits électriques parasites provenant du câblage du moteur, des pompes de drain et des aérateurs peuvent en effet être traduits à l’écran. Soyez prudent lorsque vous

faites passer le câble du transducteur à proximité de ces fils électriques.

VERTISSEMENT: Fixez le

câble du transducteur au

tableau à proximité du transducteur. Ceci empêchera le

transducteur d'entrer sur le

bateau s'il est arraché à

grande vitesse.

Mauvaise Position

Bonne

Position

Mauvais angle

Bonnes et mauvaises positions d’installation du transducteur

Bonne Position

Bonne Position

À quel niveau devez-vous installer le transducteur?

Dans la plupart des cas, nous vous conseillons d’installer votre transducteur Skimmer de façon à ce que sa ligne médiane soit au même niveau que le fond de la coque du bateau. Cela vous assurera généralement un débit régulier de l’eau et une protection contre les chocs.

6

Page 51

q

Ligne

médiane du

transducteur

Tableau

Alignez la ligne médiane du transducteur avec le fond de la coque.

Fond de la Co

ue

Néanmoins, il sera parfois nécessaire de réajuster la position du transducteur, vers le haut ou vers le bas. (Les fentes présentes sur les supports de

montage vous permettent de désserrer les vis et de faire glisser le transducteur). Si vous perdez fréquemment le signal de fond lorsque vous naviguez à grande vitesse, le transducteur sort probablement de l’eau au

contact de vagues ou lorsque vous traversez un sillage. Déplacez légèrement le transducteur vers le bas pour empêcher que cela se reproduise.

Si vous vous déplacez ou que vous pêchez dans des zones riches en édifices rocheux, abris et/ou structures, votre transducteur peut fréquemment

remonter du fait d'à-coups ou de contacts avec ces obstacles. Si vous le

souhaitez, vous pouvez le remontez légèrement pour plus de protection.

Il existe deux extrêmes que nous vous conseillons d’éviter. La première est

de ne jamais laisser le bord du support de montage descendre plus bas que

le fond de votre coque. La deuxième est de ne jamais laisser le fond –

l’endroit – du transducteur s’élever plus haut que le fond de votre coque.

Installation à Travers Coque et Installation sur le Tableau

Dans le cas d'une installation dans la coque, le transducteur est collé à

l'intérieur de la coque par de la résine époxyde. Le signal "ping" du sonar

passe à travers la coque puis se propage dans l'eau. Cela diffère d'une

installation à travers coque classique où un trou est découpé dans la co

que et un transducteur spécialement conçu est monté à l'aide d'un passe

7

Page 52

coque et d'un écrou. Dans ce cas le transducteur est en contact direct avec

l'eau.

Généralement, l’installation du transducteur à l'intérieur de la coque

donne d’excellents résultats à grande vitesse, et une bonne, voir excellente, lecture en profondeur.

Il n’existe aucun risque de choc avec des objets flottants. Le transducteur

ne peut pas être heurté ou arraché lors de la mise à quai ou du chargement sur une remorque.

L’installation à l’intérieur de la coque présente cependant quelques inconvénients. Tout d’abord, il arrive qu’il y ait perte de sensibilité, même

au travers des meilleures coques. Ce phénomène varie d’une coque à une

autre, et même entre différentes installations sur une même coque. Ce

phénomène est du aux différentes structures et constructions de la coque.

De plus, l’angle du transducteur ne peut pas être ajusté pour un repérage

optimal des poissons (visibles à l’écran sous forme d’arcs). L'impossibilité

de réglage de l'angle peut particulièrement poser problème pour les coques dont l’avant se soulève à l’arrêt ou à vitesses lentes.

Troisièmement, un transducteur NE PEUT PAS émettre à travers des

coques en bois ou en métal. Ces coques recquièrent une installation sur

tableau arrière ou une installation à travers la coque classique.

Enfin, si votre transducteur Skimmer possède un capteur de température

intégré, il n'affichera que la température du fond de cale et non pas la

température de surface de l'eau.

Suivez les procédures d'essai listées dans la section concernant l'installation à l'intérieur de la coque pour déterminer si vous pouvez émettre à

travers votre coque de manière satisfaisante.

Assemblage et Montage du Transducteur Sur le Tableau Arrière

La meilleure façon d’installer ce type de transducteur est tout d’abord

d’assembler toutes les pièces qui le composent, puis de placer le support

du transducteur sur le tableau en vous assurant que vous puissiez dépla-

8

Page 53

cer le transducteur de façon à ce qu’il reste parallèle au sol.

1. Assemblage du support. Enfoncez les deux petits rochets en plastique sur les côtés du support en métal, comme le montre l’illustration suivante. Remarquez que des lettres sont gravées sur chaque rochet. Placez

chaque rochet avec la lettre "A" alignée sur la marque (point) présente

sur le support en métal.

Cette position ajuste l’angle du transducteur pour un tableau de 14°. La

plupart des tableaux de hors-bord et de bateaux propulsés par l'arrière

possèdent un angle de 14°.

Point

Placez les rochets en plastique sur le support.

2. Aligner le transducteur sur le tableau. Glissez le transducteur entre

les deux rochets. Glissez temporairement le boulon à travers l’assemblage

et maintenez le tout contre le tableau. En regardant le transducteur de côté,

vérifiez qu’il puisse être ajusté de façon à être parallèle au sol. Si c’est le cas,

alors la position "A" est la bonne pour votre coque.

Si le transducteur n’est pas parallèle au sol, retirez le transducteur et

les rochets du support. Placez les rochets avec la lettre "B" alignée avec

la marque présente sur le support.

Assemblez à nouveau le transducteur et le support et placez-les contre le

tableau. De nouveau, vérifiez que le transducteur puisse être déplacé

afin d’être parallèle au sol. Si c’est le cas, reportez-vous à l’étape 3. Sinon, répétez l’étape 2 en utilisant une lettre d’alignement différente jus-

9

Page 54

qu'à ce que le transducteur soit correctement placé contre le tableau.

Rochets

Insérez le boulon et vérifiez la position du transducteur contre le tableau.

3. Assemblage du transducteur. Une fois que vous aurez déterminé

la position correcte des rochets, assemblez le transducteur et le support

comme le montre l’image suivante. Ne resserrez pas encore l’écrou

autobloquant.

10

Page 55

Rondelle

Écrou

Rondelles en

caoutchouc

en métal

Rondelle en

métal

Boulon

Assemblez le transducteur et le support.

4. Perçage. Maintenez l’assemblage du support et du transducteur

contre le tableau. Le transducteur doit être approximativement parallèle au sol. La ligne médiane du transducteur doit être au même niveau

que le fond de la coque. Ne faites pas dépasser le support plus bas que

le fond de la coque!

Marquez sur le tableau l’emplacement du centre de chaque fente pour

le montage des vis. Vous percerez un trou à chacune de ces positions.

Percez les trous. Utilisez pour cela la mèche #29 (pour les vis #10).

11

Page 56

Tableau

arrière

Tableau

arrière

Positionnez le transducteur contre le tableau et marquez

l’emplacement des trous. Vue de côté, à gauche, et vue du dessus, à

droite.

5. Fixation du transducteur au tableau. Retirez le transducteur du

support et ré-assemblez le tout en faisant passer le câble dans le support

et par dessus le boulon, comme l’illustrent les figures ci-dessous.

Faites passer le câble par dessus le boulon puis dans le support. Vue de

côté (gauche), et vue du dessus (droite).

12

Page 57

Fixez le transducteur au tableau. Faites glisser le transducteur vers le

haut ou vers le bas jusqu’à ce qu’il soit correctement aligné avec le fond

de la coque, comme l'illustrent les figures suivantes et précédentes. Resserrez les vis du support et enduisez-les d’un produit de calfatage.

Ajustez la position du transducteur de façon à ce qu’il soit parallèle au sol

puis resserrez l’écrou jusqu’à ce qu’il entre en contact avec la bague se

trouvant le plus à l’extérieur. Resserrez alors encore d’un quart de tour.

Ne serrez pas trop l’écrou autobloquant! En effet, le transducteur ne

pourrait alors plus "rebondir" s'il heurtait un objet dans l’eau.

Fond de

la coque

Coque à fond plat Coque en V prononcé

Alignez la ligne médiane du transducteur avec le fond de la coque puis

fixez-le au tableau.

6. Faites passer le câble du transducteur à travers ou par dessus

le tableau arrière jusqu’à votre sondeur. Assurez-vous que le câble

du transducteur ne soit pas trop tendu, donnez-lui du mou. Si possible,

évitez de faire passer le câble du transducteur à proximité d’une autre

installation électrique sur le bateau. Des bruits électriques parasites provenant du câblage du moteur, des pompes de drain, de radio VHF (hyperfréquence) et des aérateurs peuvent en effet être traduits à l’écran. Soyez

prudent lorsque vous faites passer le câble du transducteur à proximité

de ces fils électriques.

13

Page 58

AVERTISSEMENT:

Fixez le câble du transducteur au tableau à proximité du

transducteur. Ceci empêchera le transducteur d'entrer

sur le bateau s'il est arraché à grande vitesse.

Si vous devez percer un trou dans le tableau pour y faire passer le raccord du câble, la taille du trou requise est de 16 mm (5/8"). (Si vous avez

l'intention d'acheminer un câble supplémentaire pour un capteur de vitesse ou de température à travers le même trou, vous aurez besoin d'une

mèche de 25,4mm de diamètre à la place.)

Attention:

Si vous percez un trou dans le tableau pour le passage du câble,

assurez-vous qu’il se situe bien au-dessus de la ligne de flottaison.

Une fois l’installation terminée, comblez convenablement le trou

avec le même produit d'étanchéité que celui utilisé pour les vis.

7. Procédez à un essai pour tester le matériel et visualiser les

résultats. Si vous perdez le signal du fond à grande vitesse, ou si des

interférences apparaissent à l’écran, essayez de faire glisser le support

du transducteur vers le bas. Le transducteur se retrouve ainsi positionné plus profondément dans l’eau, et avec un peu de chance, il se

trouvera au-dessous des turbulences à l’origine des interférences. Ne

faites jamais descendre le support plus bas que le fond de la coque!

Boulon

Rondelle dentée

Ecrou

Support TMB-S

Rondelle

plate

Fixez le support de montage du moteur au transducteur.

14

Page 59

Installation Sur Un Moteur A La Traine (Trolling Motor)

1. Fixez le support TMB-S au transducteur, comme l’illustre la figure

suivante, en utilisant le matériel fourni avec le transducteur (Remarque:

la rondelle dentée est fournie avec le TMB-S.)

2. Glissez la courroie de serrage fournie avec le TMB-S dans la fente du

support et enroulez-la autour du moteur. Positionnez le transducteur de

façon à ce que sa face se retrouve vers le bas quand le moteur sera à

l’eau. Resserrez bien la courroie.

3. Faites passer le câble du transducteur le long de l’axe du moteur. Utilisez des cordons en plastique (non fournis) pour attacher le câble du

transducteur à l’arbre du moteur. Assurez-vous que le câble soit suffisamment détendu pour que le moteur puisse tourner librement. Acheminez le câble jusqu’au sondeur, le transducteur est alors prêt à l’emploi.

Transducteur installé sur un moteur à la traîne, vue de côté.

Orientation du Transducteur et Repérage du Poisson

Si vous ne visualisez pas de bons repérages de poissons à l’écran (arcs), il

est possible que le transducteur ne soit pas parallèle au sol lorsque le

bateau est à l’arrêt ou marche à vitesse très lente.

Si seule la deuxième partie de l’arc de repérage est visible (inclinaison

vers le bas de gauche à droite), alors l’avant du transducteur est trop

haut et doit être descendu. Si seule la première partie de l’arc de

repérage est visible (arrière du signal, inclinaison vers le haut de gau-

15

Page 60

che à droite), alors l’avant du transducteur est trop bas et doit être relevé.

Repérages partiels

de poisson

Transducteur

orienté trop en

arrière

Arc de repérage

complet

Transducteur

orienté trop en

avant

Orientation appropriée

Orientations du transducteur et leurs conséquences sur les arcs de

poissons.

REMARQUE:

Nettoyez périodiquement la surface du transducteur avec de l’eau

et du savon pour retirer toute pellicule d’huile susceptible de se

16

Page 61

déposer. L’huile et la saleté qui peuvent se déposer à la surface du

transducteur réduiront sa sensibilité et peuvent également altérer

son fonctionnement.

Branchements

(pour les montages permanents uniquement)

L’appareil est alimenté par une batterie 12 Volts. Vous pouvez relier le

câble d'alimentation à la barre accessoire ou d’alimentation de votre bateau (ou directement à la batterie). Si vous utilisez une barre accessoire

et que vous rencontrez des problèmes d’interférences électriques, reliez

directement le câble d’alimentation à la batterie. Si le câble fourni n’est

pas assez long, raccordez-y un fil isolé de calibre #18.

ATTENTION:

Lorsque vous utilisez l’appareil en milieu salé, nous vous recommandons fortement de débrancher le câble de sa source

d’alimentation lorsque l’appareil est éteint. Lorsque l’appareil est

éteint mais qu’il reste connecté à une source d’alimentation, un phénomène d’électrolyse peut survenir au niveau de la fiche du câble

d’alimentation. Ceci peut entraîner une corrosion de la fiche ainsi

que des contacts électriques du câble et de la prise du sondeur.

En milieu salé, nous vous recommandons de brancher le câble à

l’interrupteur auxiliaire présent à bord de la plupart des bateaux.

Si vous rencontrez des problèmes d’interférences électriques, ou si

un tel interrupteur n’est pas disponible, nous vous recommandons

de brancher le câble directement à la batterie et d’installer un interrupteur en ligne. Cela vous permettra de couper le courant au

niveau du câble d’alimentation lorsque vous n’utiliserez pas

l’appareil. Lorsque vous n’utilisez pas l’appareil, vous devriez toujours couper le courant au niveau du câble d’alimentation, surtout

quand celui-ci n’est pas branché au sondeur.

17

Page 62

Vers le

sondeur

Fil noir

Batterie

12 volts

Fil rouge avec

fusible

Branchements du sondeur Cuda 300 (ici, branchement direct à la batte-