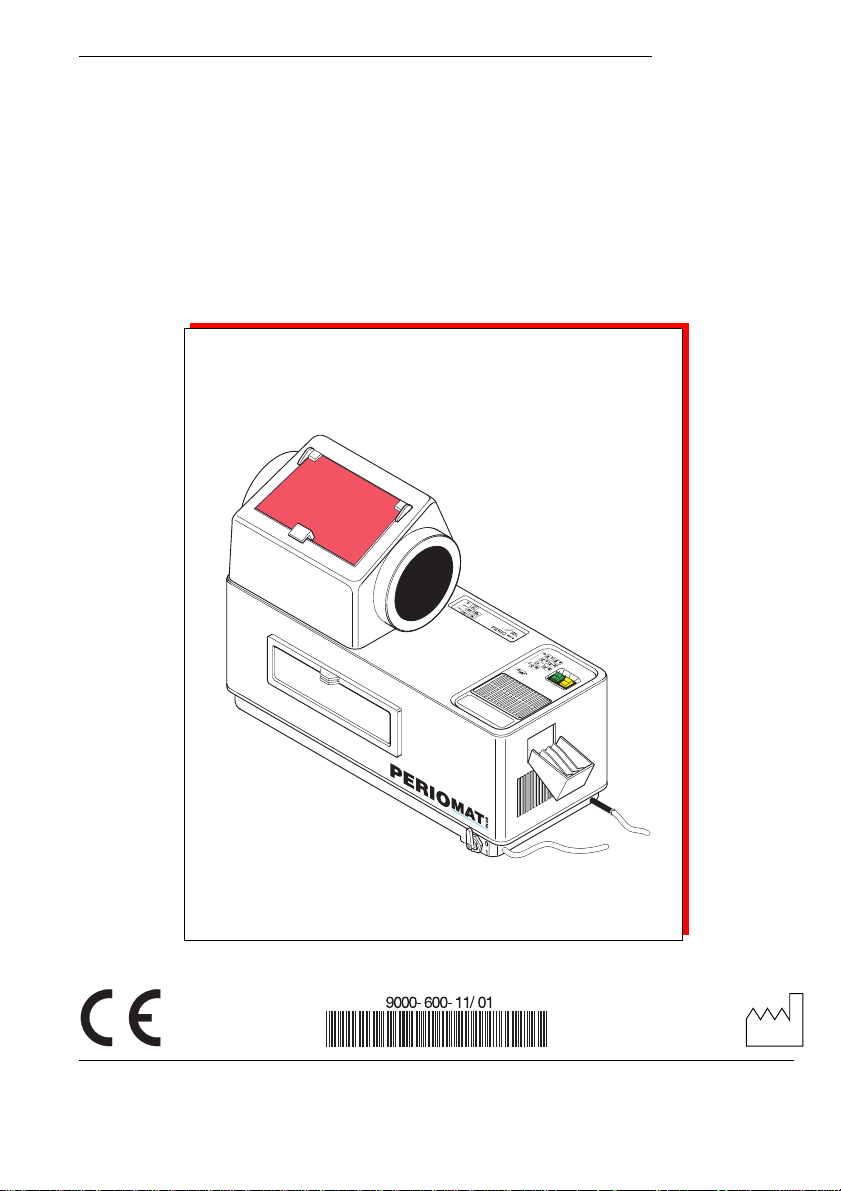

Page 1

OPERATING INSTRUCTIONS

2000/04

DÜRR PERIOMAT PLUS 1307 / 1308

Page 2

Page 3

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

Important information

1. Advice..................................................... 28

1.1 Safety advice ...................................28

1.2 Electrical safety checks .................. 28

1.3 Safety advice and symbols .............28

2. Product information .............................. 29

2.1 Correct usage .................................. 29

2.2 Incorrect usage ............................... 29

3. Model overview...................................... 29

4. Delivery contents ..................................31

4.1 Accessories ..................................... 31

4.2 Special accessories ........................31

5. Technical Data ....................................... 31

5.1 Recommended film sizes and

adapters .......................................... 32

6. Operating functions .............................. 33

6.1 Indicators ......................................... 33

Mounting

7. Installation ............................................. 34

7.1 Installation - room ............................34

7.2 Installation ....................................... 34

8. Commissioning ..................................... 35

9. Circuit diagram ...................................... 37

9.1 Description ...................................... 38

9.2 Cable coloring .................................38

Use

10.10.

Filling ChemicalsFilling Chemicals

10.

Filling Chemicals ..................................... 39

10.10.

Filling ChemicalsFilling Chemicals

11. Operation ............................................... 40

11.1 Film insertion WITHOUT adapter .... 40

11.2 Film insertion WITH adapter ............ 42

11.3 Miscellaneous ..................................45

12. Maintenance........................................... 46

12.1 Changing the water ......................... 46

12.2 Changing chemicals ....................... 48

12.3 Chemical cleaning ..........................49

Spare parts list

Base ............................................................... 50

Cover ............................................................. 52

Film transport ................................................. 54

Heater ............................................................ 55

27

Page 4

IMPORTANT INFORMATION

1. ADVICE

1.1 Safety advice

Work on electrical equipment may only be

carried out by qualified electricians (per

VBG 4) or by our service personnel!

Only use original spare parts for repairs,

otherwise the guarantee will be invalidated.

When combining pieces of equipment, or

during repairs to electrical parts, the

relevant safety and testing regulations

must be observed:

• IEC 364-.-.., prEN 50110-1, IEC 64 (Sec)

629,VDE 0702 Part 1

• Accident protection regulations UVV VBG 1,

4, 121.

• Regulations concerning X-rays DIN 6868,

T5 / T51

1.2 Electrical safety checks

As per VDE 0701 after installation and

commissioning, service, maintenance and

repair of an electrical device an electrical

safety check is mandatory.

28

1.3 Safety advice and symbols

The operating instructions employ certain

terms and symbols for especially important

applications:

Instructions relating to efficient use of

the appliance and other instructions

Instructions and regulations relating

to the avoidance of injury and / or

serious damage

Unplug the appliance.

Page 5

2. PRODUCT INFORMATION

2.1 Correct usage

The Periomat Plus must only be used to

develop intra-oral X-ray films in dental

surgeries and dental clinics.

The size of film to be developed must lie in the

range 2 x 3 to 5.7 x 7.6 cm.

Film of the size 3 x 4 cm can be placed

directly into the film feed, for films of other

sizes the appropriate adapter must be used.

Perfect archive-ready results can best be

achieved by using the specially developed

DÜRR Periomat Intra Chemicals at 25°C.

In the FRG, as well as in a number of

other countries, used X-ray chemicals

are classified as Special Waste and

must be separated and disposed of

appropriately.

2.2 Incorrect usage

The Periomat Plus cannot be used for OPG or

panorama views.

3. MODEL OVERVIEW

Periomat Plus with Daylight Attachment,

Heater and Front Flap

1307-01 (230V, 50Hz)

Periomat Plus without Daylight

Attachment, Heater and Front Flap

1308-01 (230V, 50Hz)

29

Page 6

1

11

12

3

2

4

5

8

7

6

10

16

13

15

14

17

30

9

1

19

2

18

3

Page 7

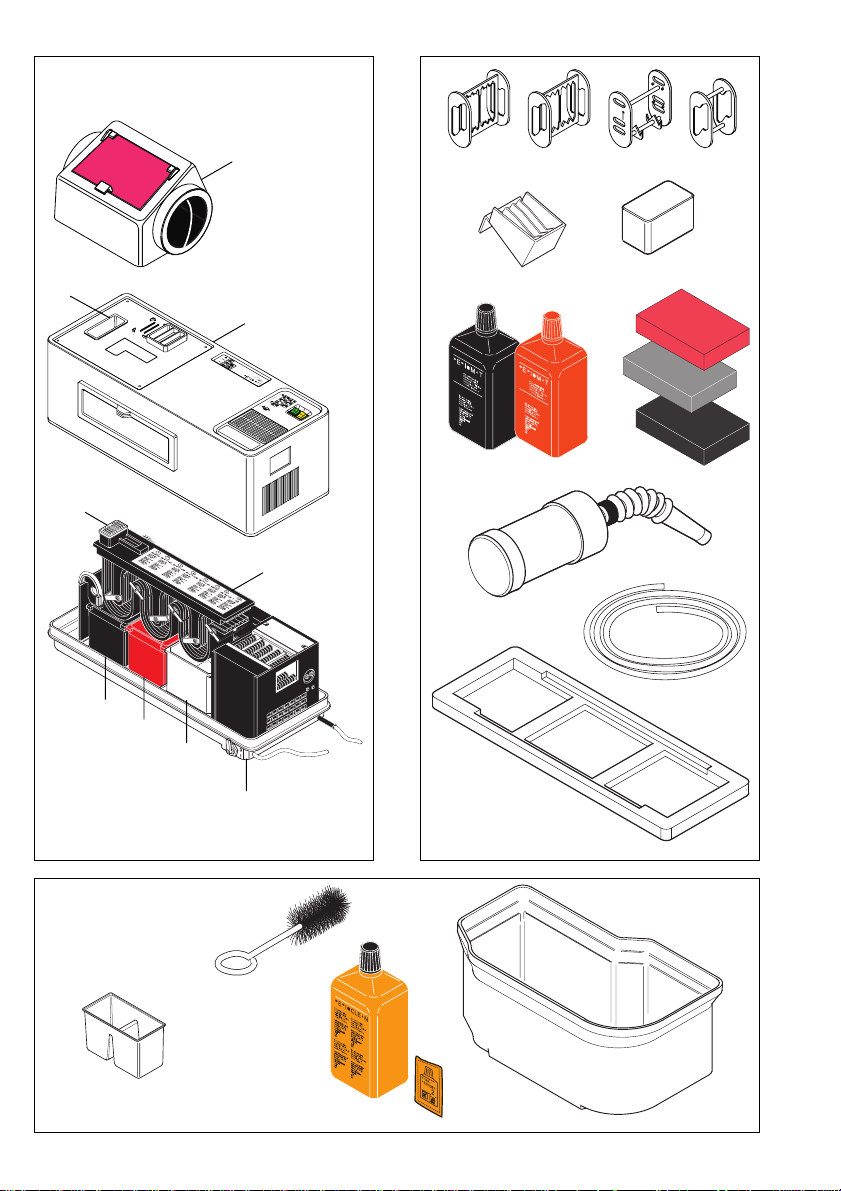

4. DELIVERY CONTENTS

5. TECHNICAL DATA

Fig. 1

(1) Daylight attachment

Model 1307-01, -02, -03 ..... 1307-700-00

(2) Lid ........................................ 1307-981-00

(3) Waste receptacle ................ 1303-000-06

(4) Film feed frame ................... 1303-000-05

(5) Film transport ...................... 1307-300-00

(6) Water bath ........................... 1307-007-00

(7) Fixer bath ............................ 1303-000-09

(8) Developer bath ................... 1303-000-08

(9) Base

Operating instructions D/GB ..9000-600-11/01

4.1 Accessories

Fig. 2

(10) 1 Set of chemicals

Periomat Intra ......................1307-080-00

(11) Adapters for films

3 Pcs. 2x3.5 cm .................. 1303-000-01

2 Pcs. 4x5 and 2.7x5.4 cm .1303-000-02

3 Pcs. 2.4x4 cm .................. 1303-000-18

1 Pcs. 5.7x7.6 cm ............... 1303-000-22

(12) 1 Film collector ....................1303-001-00

(13) 1 Draining rack .................... 1303-000-13

(14) Sponges

2 Pcs. grey .......................... 1330-000-06

1 Pcs. red ............................ 1330-000-05

(15) 1 Lightproof cap

for film entry ....................... 1303-000-14

(16) 1 Water bottle ...................... 1307-001-00

(17) 1 Drain hose ........................ 1307-000-07

4.2 Special accessories

Fig. 3

(18) Cleaning Set

“Perio-Clean” ....................... 1304-070-00

(19) Bath, dual-walled ................ 1303-000-16

Model 1308- 1307-

Voltage (V) 230 230

Frequency(Hz) 50 50

Current (A) 1,8 1,8

Output (W) 400 400

Duty

cycle (%ED) 100

Film run

through

time (min)

50 Hz 5

Developing

temperature (°C) 25

Heating up

time (min/°C) ~7

Heating (V) 24

Fuse (A) T 2,5

Container (l)

Developer 1

Fixer 1

Water 1,25

Weight (kg) 10,2 11,2

Size (HxBxT)

01 01

22x63x25

40x63x25

31

Page 8

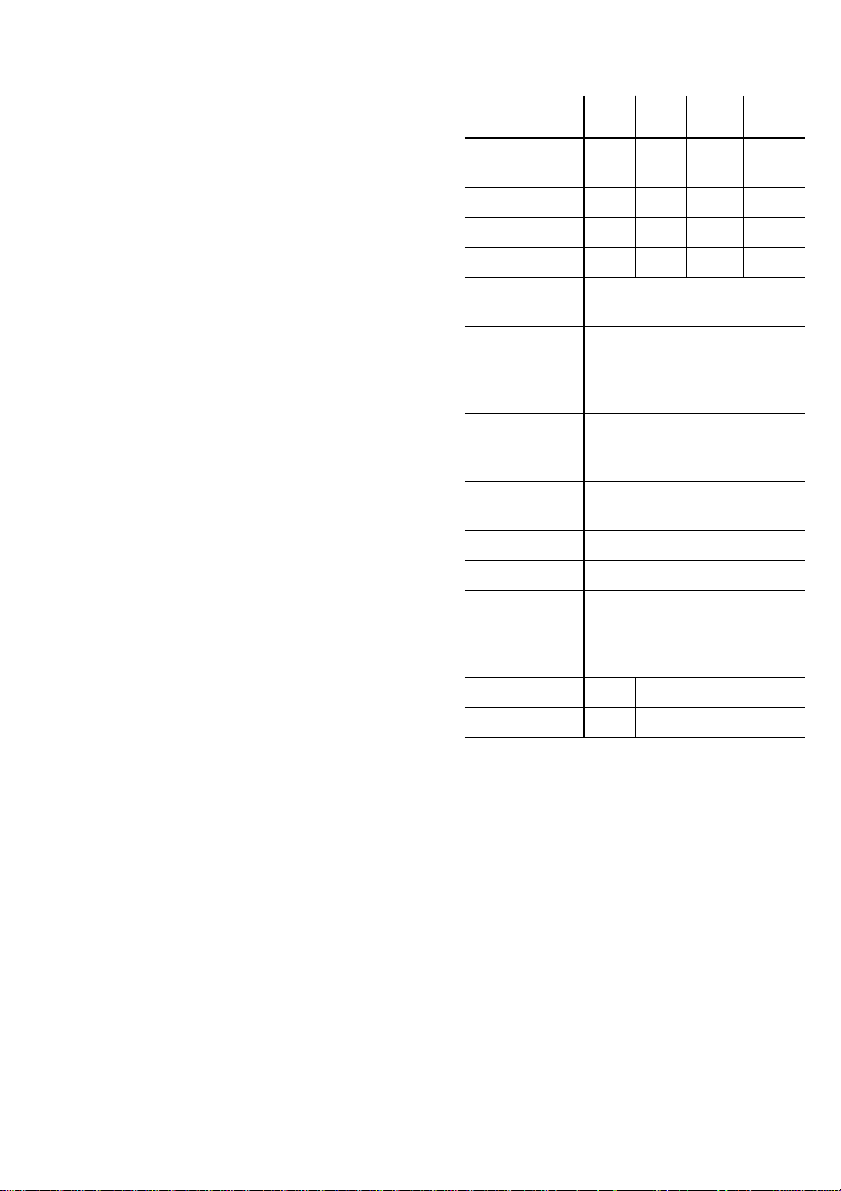

5.1 Recommended film sizes and

adapters

1303-000-22

5,7 x 7,6 cm

1303-000-02

2,7 x 5,4 cm

4 x 5 cm

1303-000-01

WITHOUT Adapter:

• 3 x 4 cm (max. 8 films)

WITH Adapter:

• 5.7 x 7.6 cm (max. 1 film)

• 2.7 x 5.4 cm (max. 2 films)

• 4 x 5 cm (max. 1 film)

• 2 x 3.5 cm (max. 6 films)

• 2.4 x 4 cm (max. 6 films)

The film applications together with the

relevant order numbers can be seen in Fig. 4.

32

2 x 3,5 cm

1303-000-18

2,4 x 4 cm

4

Page 9

6. OPERATING FUNCTIONS

6.1 Indicators

Yellow Indicator: Mains Supply Switch (20)

Pos. O: Periomat + Heating OFF

Pos. l: lit, Periomat + Heating ON

Green Switch: Film-transport Switch (21)

Pos. O: Film transport OFF

Pos. l: Film transport ON, developing starts

20

Green Control Lamp: Heating (30)

Blinks during the warm-up phase from bath

21

temperature of 22° C

5

Lights permanently when chemicals are at

developing temperature

The Periomat is ready for operation when both

mains supply and transport switch indicator

lights are on.

Transport interruption when opening front

panel or cover

For safety reasons, if the front panel is opened

during film development, the transport motor

30

is automatically switched off and the films will

not be transported. The same is true for the

cover (2). This switch-off is controlled by a

31

Reed-switch (30) mounted on the temperature

sensor holder, which is activated by a magnet

(31) mounted on the front panel.

2

6

Disconnect the appliance from the

mains supply before removing the lid.

33

Page 10

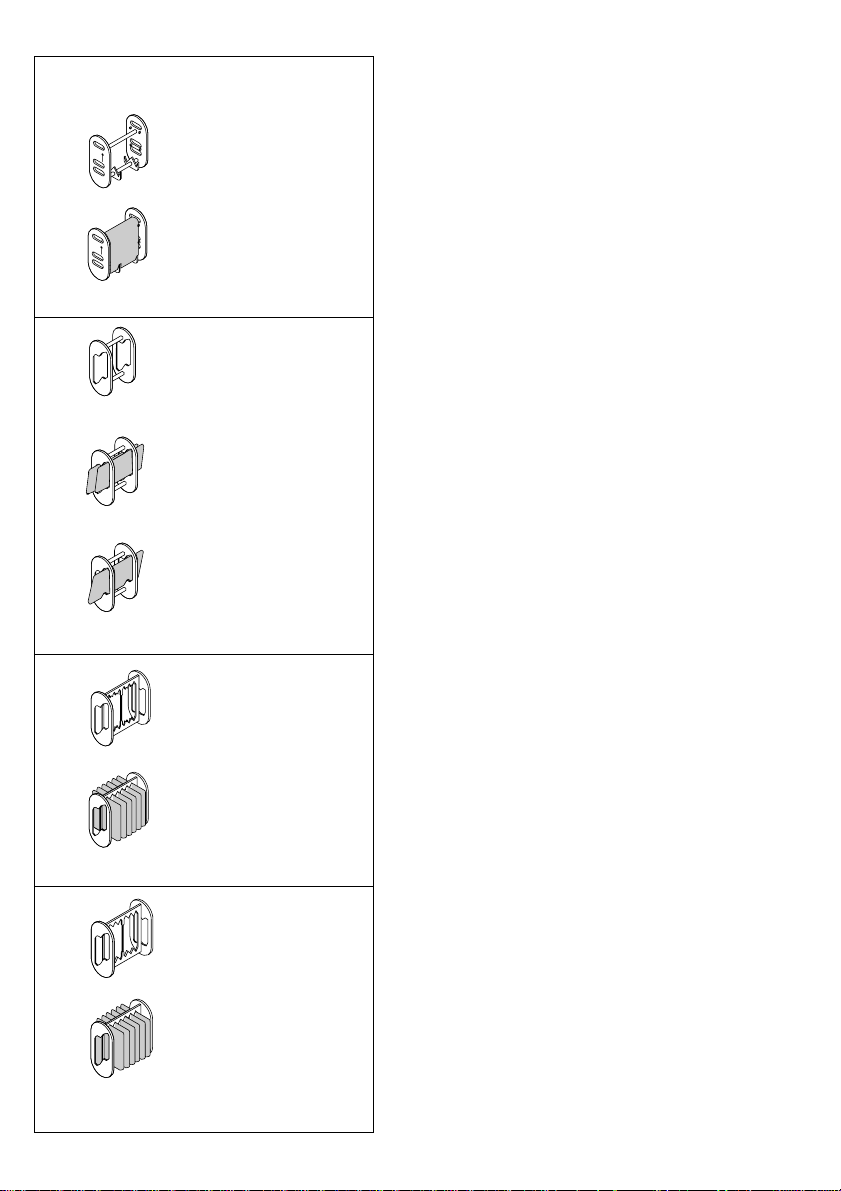

MOUNTING

7. INSTALLATION

7.1 Installation - room

• Install the Periomat in a dry, well-ventilated

room.

• The mains supply socket must be so chosen

that the mains supply plug is visible, safe

and easily accessible.

Max. ambient temperature is 25°C.

Do not position the Periomat in

direct sunlight!

Otherwise the films will be exposed

8

5

9

22

8

7

despite the daylight attachment.

7.2 Installation

Please keep the original packing for

possible return of product. DÜRR

DENTAL accepts no liability for

damage caused during transport,

resulting from faulty or inadequate

packing!

• Lift the Periomat out of its box. Remove the

water bottle and flexible hose from the right

hand packaging. Remove the plastic

packing material.

• Stand the appliance on a stable and level

surface near a mains supply socket.

• Remove lid.

• Remove cardboard box with adapters.

• Remove transport packaging (blue foam

rubber and material in dryer area)!

• Remove sponges from baths.

• Remove the film transport (5) and the three

baths, black “E” (8), red “F” (7) and white

“W” (6), and clean them of any packing

material and dust.

Before removing the “E”-bath,

swing the temperature regulater (22)

to the rear.

34

10

• Fit drainage hose (17).

17

6

Page 11

11

8. COMMISSIONING

4

5

Check that the voltage as given on the

appliance model label corresponds

with the voltage as supplied at the

mains!

If using the appliance for the first time

during winter allow the appliance to

warm to room temperature first,

otherwise there is the risk that

condensation builds up on the

electronic control board causing a

short circuit!

After filling the chemicals do not

move the Periomat as there is the

risk of chemicals mixing!

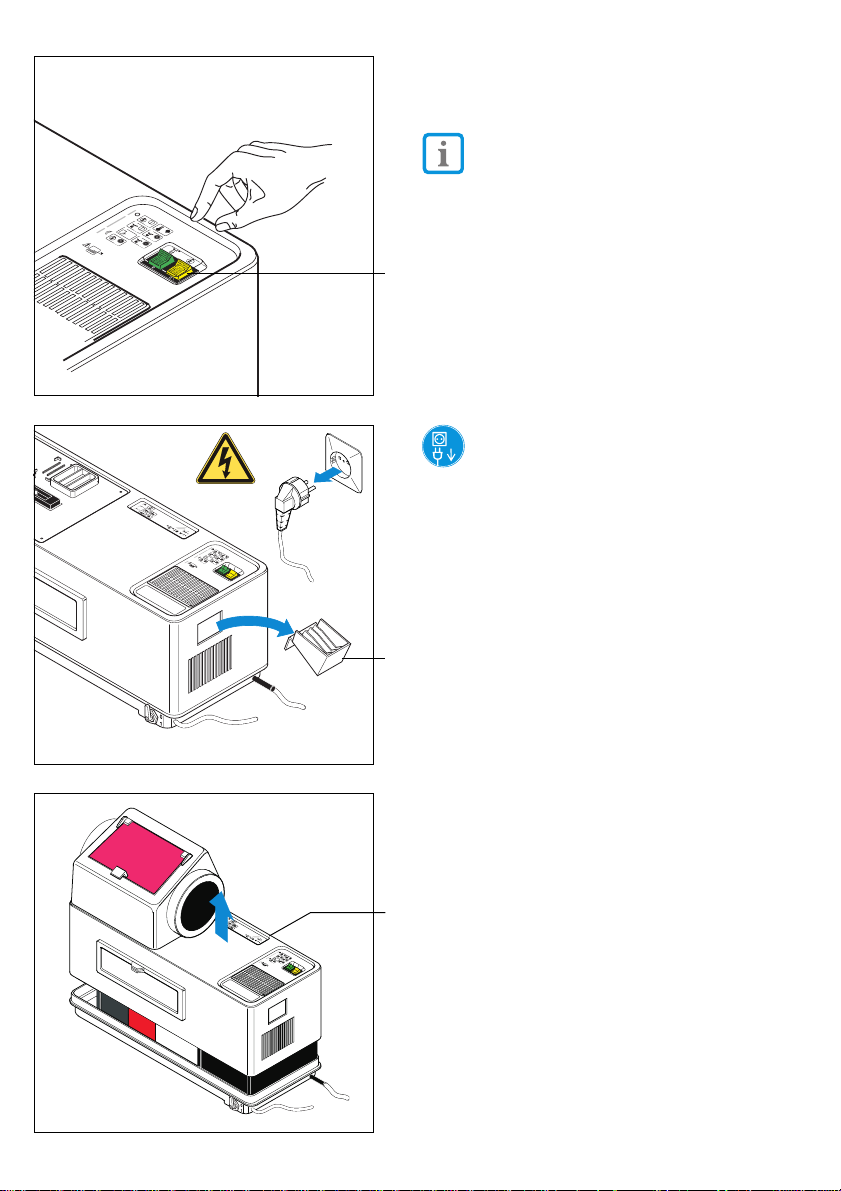

• Carefully insert the film transport (5).

• Place the numbered film frame (4) onto the

film entry (slot 8 to the front).

• Remove the drainage hose from its holder

and set in collector (min. 5 l) (to collect

water from the water bath). Place this

collector on the floor.

12

13

• Place lid (2) onto appliance (flap to the

front).

• Open and close the front flap until you hear

it click firmly into place.

2

35

Page 12

14

15

• Place the film collector (12) into position.

• Plug appliance into mains socket.

12

• Yellow main switch is set (20) ON (lit).

Both baths “E” and “F” are mounted

on a temperature-regulated heating

plate. If the temperature is below 25°C

during filling, when the yellow main

switch (20) is activated the chemicals

are automatically heated and

maintained at the required

temperature.

Example: Start-up temperature 18°C, warm-

20

up time approx 7 min per °C, ie waiting time is

c. 45 min. until the correct developing

temperature is reached.

21

• The green display (21) begins to blink at a

temperature of 22°C and is fully lit when the

correct developing temperature has been

reached (after ca. 45 min).

Do not develop films until the

control lamp (30) stops blinking!

36

Page 13

9. CIRCUIT DIAGRAM

37

Page 14

9.1 Description

1 Main switch orange

2 Transport switch green

3 Relay

4 Reed contact

5 Transformer

6 Electronics

7 Temperature -Sensor

8 Bath Heating

9 Main plug (earthed)

10 Film dryer ventilator

11 Transport motor

12 Film dryer heating

13 Thermal fuse

14 Power input fuse

15 Controller fuse

16 Distributor 1

17 Distributor 2

18 Distributor power supply

9.2 Cable coloring

gn/ge = green/yellow

rt/sw = red/black

ws/or = white/orange

sw = black

rt = red

br = brown

bl = blue

or = orange

gn = green

38

Page 15

17

18

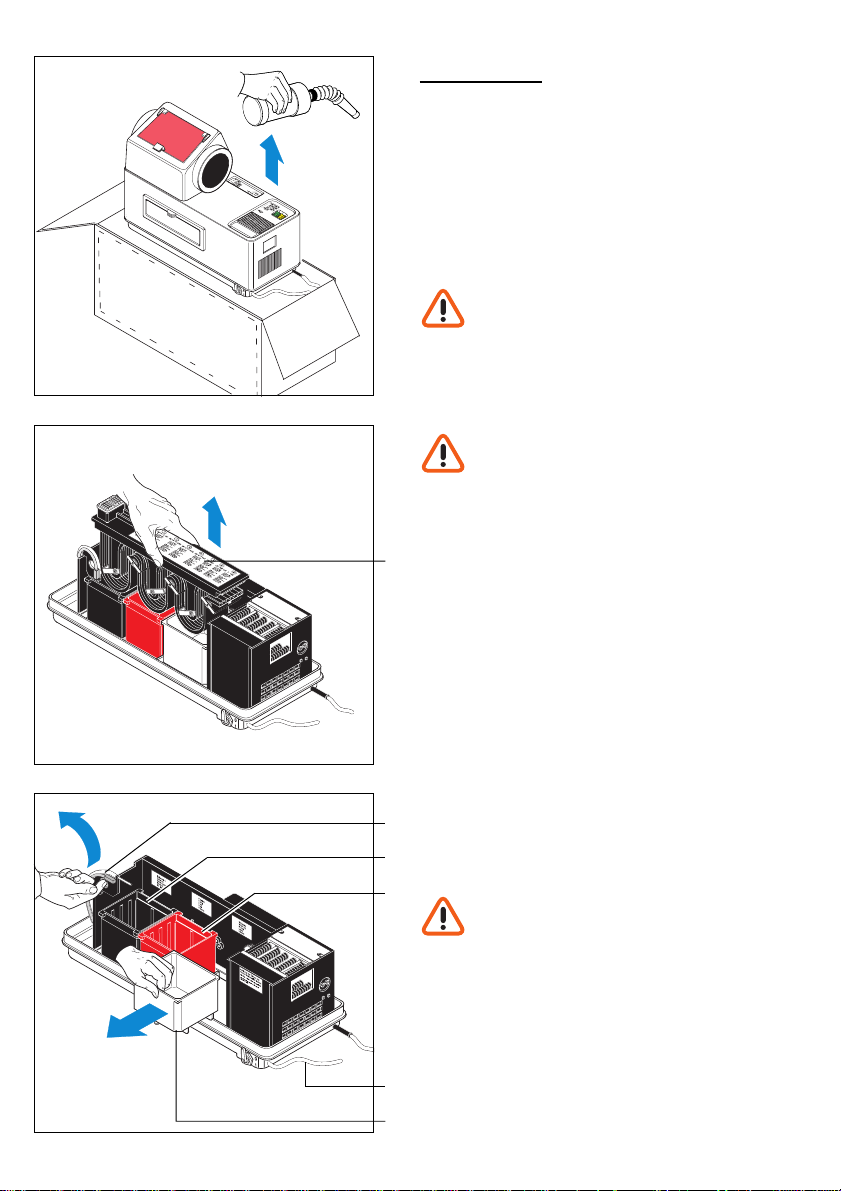

USE

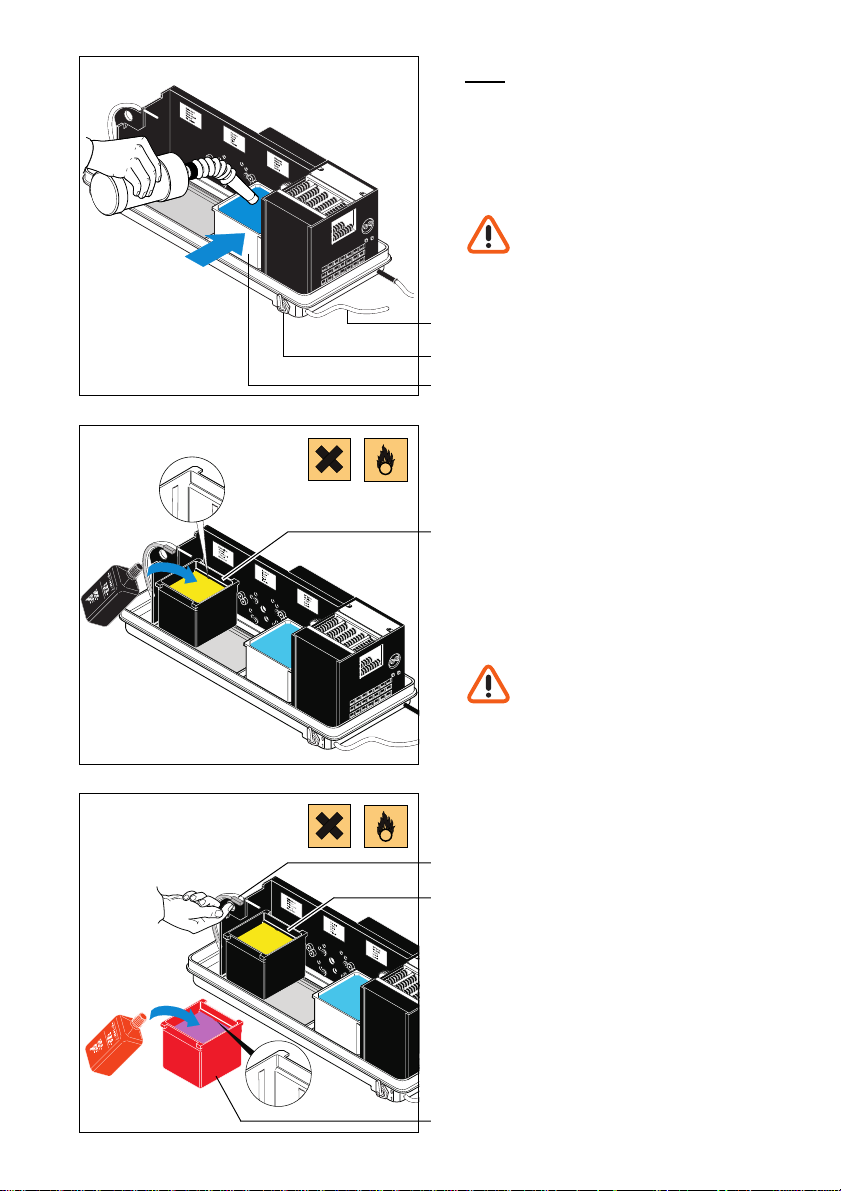

10. FILLING CHEMICALS

In order to produce perfect film results, we

strongly recommend using the specially

developed DÜRR Periomat Intra Chemicals.

Before removing the lid, turn the

yellow power switch OFF and

unplug the appliance.

• Close the water outlet (30).

• Fill the water bottle to the marking (1.25 l)

17

with max. 25°C warm water. Attach hose to

30

bottle.

6

• Pour the complete contents of the water

bottle into the water bath “W” (6).

• Place the black developer bath “E” (8) into

position.

• Pour developer (black bottle) into the black

bath “E” (8).

• Swing the temperature regulater (22)

8

downwards.

• Pour fixer (red bottle) into the red bath “F”

(7) and place bath into position.

• Both baths “F” (7) and “E” (8) should now

be filled with max. 25°C warm water to the

lower marking.

The developer and fixer should be

well stirred, otherwise the results of

developing could vary greatly due

to temperature fluctuations.

19

22

8

7

39

Page 16

20

11. OPERATION

Before inserting films see 5.1

“Recommended film sizes and adapters”.

11.1 Film insertion WITHOUT adapter

• Switch the green transport button (21) ON.

21

• Insert 3 x 4 cm film directly into the

numbered cover (4) of the 8-slot film feeding

frame.

Only 1 film per slot!

21

22

4

15

23

Place root-treatment films in slot 8.

After 2 min. 30 sec. the film should be

removed from slot 8 using tweezers

via the front flap. This film cannot be

used for archival purposes due to

omission of water stage!

• Position lightproof cap (15) in place.

• Push the start lever (23) to the right.

A new film can only be inserted, when

the start lever (23) has returned to its

starting position (after c. 50 seconds).

40

Page 17

23

• After development the 3 x 4 cm films are

deposited in the film collector (12) between

the film separators (24) *.

12

24

• After all films have been deposited in the

film collector, turn the green transport

switch (21) to OFF.

• When the surgery is closed or during longer

breaks (e.g. lunch break) turn the yellow

power switch (20) to OFF.

24

21

41

Page 18

11.2 Film insertion WITH adapter

• Remove the film separators (24) from the

film collector (12).

26

24

12

4

In cases where there is frequent

developing

adapter, we recommend that you

order a second film collector (12).

(Order Nr. 1303-001-00)

• Remove film feed numbered frame (4).

WITH

and WITHOUT an

42

27

• Place film(s) in appropriate adapter:

Occlusal-Film (5.7 x 7.6 cm)

25

• Carefully bend the Occlusal-Film in the

middle.

• Place in the correct adapter (25).

The film must sit firmly in the holder

(26).

26

28

Page 19

29

• Place the adapter (25) in the film feed.

The arrow on the adapter (25) must

point downwards.

25

2 x 3.5 and 2.4 x 4 cm Films

• Place the adapter (27) laterally into the

holder (28) next to the film entry.

27

• Each film (max. 6 films) must be pressed

cross-wise into the slots in the adapter (27)

until they touch the holder.

The films must lie parallel to each other and

must not touch.

28

30

31

• Place the adapter (27) vertically into the film

feed.

27

43

Page 20

32

4 x 5 and 2.7 x 5.4 cm Films

• Each film (max. 2 films) must be placed into

the slots in the adapter (29).

29

• Place the adapter (29) vertically into the film

feed. The edges of the film must not touch

the sides of the film feed shaft.

29

44

33

• Set lightproof cap (15) into place.

• Slide the start lever (23) to the right.

15

23

34

Page 21

35

• After developing, the adapter complete with

film will fall into the film collector (12).

12

• After developing switch the green transport

button (21) to OFF.

• When the surgery is closed or during longer

breaks (e.g. lunch break) turn the yellow

power switch (20) to OFF.

36

37

20

21

11.3 Miscellaneous

• The waste receptacle (3) is provided for the

film packaging, and can be removed for

emptying.

3

45

Page 22

38

12. MAINTENANCE

12.1 Changing the water

Weekly 2 x

and

check level of chemicals!

The drainage hose must be

connected to a water collector (min.

5 l) (to receive water from the water

bath). Place the container on the

floor. On disposal of the waste

water observe all relevant

regulations!

• Turn the yellow mains switch (20) to OFF.

Unplug the appliance.

46

39

40

20

• Open the water outlet (30) and wait until the

container is empty.

30

Page 23

41

42

• Close the water outlet (30).

30

• Fill the water bottle with max. 25°C warm

water to the marking. Replace hose on

bottle.

When changing the water we

recommend the use of an anti-alga

solution.

• Open front flap.

• Pour the contents of the water bottle into

bath “W”.

• Check the levels of developer “E”- and fixer

baths “F” and, if necessary, fill to the

marking (see inside of flap) with max. 25°C

warm water.

The temperature for developer and

fixer is set at 25°C and must not be

exceeded, or the films will appear too

dark.

• Close front flap.

43

• Plug in appliance.

• Switch yellow power switch (20) to ON.

20

47

Page 24

44

12.2 Changing chemicals

Every 3 weeks

After c. 3 weeks, or after developing c.

350 films of 3 x 4 cm format, the

developer and fixer

must be replenished.

• Turn the yellow mains switch (20) to OFF.

20

Unplug the appliance.

• Remove film collector (12).

are used up and

48

12

45

• Remove lid (2).

2

46

Page 25

47

• Slightly raise the film transport (5), allow the

chemicals to drain off.

• Place the film transport on to the draining

rack.

• Swing temperature regulater (22) to the rear

5

• Rinse the film transport (5) under luke-warm

running water (the film feed must remain

dry).

• Remove any deposits with a brush (included

in the cleaning set “Perio-Clean”).

• Empty of water and chemicals.

In Germany X-ray chemicals are

22

classified as Special Waste and

must be separated and disposed of

separately. Observe all relevant

regulations!

• All 3 baths (6, 7, 8) should be cleaned,

using the appropriate colour-coded sponge,

with warm water and any dirt thoroughly

removed.

• The area around the film feed should be

cleaned using a fluff-free cloth.

• Change the chemicals according to the

instructions in section 9.

48

49

12.3 Chemical cleaning

Every 6 months

• Every 6 months clean the film transport with

8

“chemical cleaner”.

We strongly recommend the use of our

7

chemical cleaning set “Perio-Clean”,

Order.Nr.: 1304-070-00.

Detailed instructions are included in each

cleaning set.

6

49

Loading...

Loading...