Page 1

Duo, Trio, Quattro,

Duo Tandem, Quattro Tandem

Installation and operating instructions

EN

0297

9000-610-45/30

1811V007

Page 2

Page 3

Contents

Important information

1 About this document � � � � � � � � � � � � � � � 3

1�1 Warnings and symbols � � � � � � � � � � 3

1�2 Copyright information � � � � � � � � � � � 3

2 Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2�1 Intended purpose � � � � � � � � � � � � � � 4

2�2 Intended use � � � � � � � � � � � � � � � � � � 4

2�3 Improper use � � � � � � � � � � � � � � � � � 4

2�4 General safety information � � � � � � � � 4

2�5 Qualified personnel � � � � � � � � � � � � � 4

2�6 Electrical safety � � � � � � � � � � � � � � � � 4

2�7 Only use original parts � � � � � � � � � � � 4

2�8 Transport � � � � � � � � � � � � � � � � � � � � 5

2�9 Disposal � � � � � � � � � � � � � � � � � � � � � 5

Product description

3 Overview� � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Scope of delivery � � � � � � � � � � � � � � 6

3�2 Optional accessories � � � � � � � � � � � � 6

3�3 Wear parts and replacement

parts � � � � � � � � � � � � � � � � � � � � � � � � 6

4 Technical data � � � � � � � � � � � � � � � � � � � � 7

4�1 Duo � � � � � � � � � � � � � � � � � � � � � � � � 7

4�2 Duo � � � � � � � � � � � � � � � � � � � � � � � � 9

4�3 Trio � � � � � � � � � � � � � � � � � � � � � � � � 11

4�4 Quattro � � � � � � � � � � � � � � � � � � � � � 13

4�5 Duo Tandem � � � � � � � � � � � � � � � � � 15

4�6 Quattro Tandem � � � � � � � � � � � � � � 17

4�7 Distance between rubber feet � � � � 19

4�8 Type plate � � � � � � � � � � � � � � � � � � � 19

5 Operation � � � � � � � � � � � � � � � � � � � � � � � 20

5�1 Duo with membrane drying unit � � � 20

Assembly

6 Requirements� � � � � � � � � � � � � � � � � � � � 21

6�1 Installation/setup room � � � � � � � � � 21

6�2 Setup � � � � � � � � � � � � � � � � � � � � � � 21

6�3 Information about electrical

connections � � � � � � � � � � � � � � � � � 22

7 Transport � � � � � � � � � � � � � � � � � � � � � � � 22

8 Quattro Tandem assembly and

installation � � � � � � � � � � � � � � � � � � � � � � 23

9 Installation � � � � � � � � � � � � � � � � � � � � � � 23

9�1 Remove the transport locks � � � � � 23

9�2 Establishing the compressed air

connection � � � � � � � � � � � � � � � � � � 23

9�3 Pressure reducer � � � � � � � � � � � � � 24

9�4 Place a collector tray underneath � 24

9�5 Electrical connections � � � � � � � � � � 24

10 Commissioning� � � � � � � � � � � � � � � � � � � 25

10�1 Check the motor protection

switch � � � � � � � � � � � � � � � � � � � � � � 25

10�2 Checking the switch-on/cut-off

pressure � � � � � � � � � � � � � � � � � � � � 25

10�3 Checking the safety valve � � � � � � � 26

10�4 Draining the condensation water � � 26

10�5 Adjusting the rate of flow at the

pressure reducer � � � � � � � � � � � � � � 27

11 Adjustment options � � � � � � � � � � � � � � � 27

11�1 Adjusting the pressure switch � � � � 27

11�2 Adjusting the motor protection

switch � � � � � � � � � � � � � � � � � � � � � � 28

12 Circuit diagrams� � � � � � � � � � � � � � � � � � 29

12�1 1/N/PE AC 110-127 V, 230 V

layout � � � � � � � � � � � � � � � � � � � � � � 29

12�2 3/N/PE AC 400 V layout � � � � � � � � 29

12�3 1/N/PE AC 230 V layout, Duo

Tandem � � � � � � � � � � � � � � � � � � � � 30

12�4 3/N/PE AC 230 V layout, Quattro

Tandem � � � � � � � � � � � � � � � � � � � � 31

EN

9000-610-45/30 1811V007 1

Page 4

Contents

Usage

13 Operation � � � � � � � � � � � � � � � � � � � � � � � 32

13�1 Switching the unit on/off � � � � � � � � 32

14 Maintenance� � � � � � � � � � � � � � � � � � � � � 33

14�1 Maintenance schedule � � � � � � � � � 33

14�2 Replacing the air intake filter � � � � � 34

14�3 Replacing the filter in the

condensate separator � � � � � � � � � � 34

EN

14�4 Replacing the filter of the

membrane drying unit � � � � � � � � � � 35

15 Taking out of use � � � � � � � � � � � � � � � � � 36

15�1 Taking the unit out of use � � � � � � � 36

15�2 Storage of the unit � � � � � � � � � � � � 37

Troubleshooting

16 Tips for operators and service

technicians � � � � � � � � � � � � � � � � � � � � � � 38

2 9000-610-45/30 1811V007

Page 5

Important information

1 About this document

These installation and operating instructions

represent part of the unit�

If the instructions and information in

these installation and operating instructions are not followed, Dürr Dental will

not be able to offer any warranty or assume any liability for the safe operation

and the safe functioning of the unit�

1.1 Warnings and symbols

Warnings

The warnings in this document are intended to

draw your attention to possible risks of personal

injury or material damage�

The following warning symbols are used:

General warning symbol

Warning – dangerous high voltage

Warning – hot surfaces

Warning - automatic start-up of the unit

The warnings are structured as follows:

SIGNAL WORD

Description of the type and source of

danger

Here you will find a description of the

possible consequences of ignoring the

warning�

i Follow these measures to avoid the

danger�

The signal word differentiates between four

levels of danger:

– DANGER

Immediate danger of severe injury or death

– WARNING

Possible danger of severe injury or death

– CAUTION

Risk of minor injuries

– ATTENTION

Risk of extensive material/property damage

Other symbols

These symbols are used in the document and

on or in the unit:

Note, e�g� specific instructions regarding

efficient and cost-effective use of the unit�

Observe the operating instructions�

Switch off and de-energise the unit

(e�g�unplug from mains)�

Air

Dispose of correctly in accordance with

EU Directive 2012/19/EU (WEEE)�

CE labelling with the number of the notified body

Order number

Serial number

Manufacturer

1.2 Copyright information

All circuits, processes, names, software programs and units mentioned in this document are

protected by copyright�

The Installation and Operating Instructions must

not be copied or reprinted, neither in full nor in

part, without written authorisation from Dürr

Dental�

EN

9000-610-45/30 1811V007 3

Page 6

Important information

2 Safety

Dürr Dental has designed and constructed this

unit so that when used properly and for the intended purpose it does not pose any danger to

people or property� Nevertheless, residual risks

can remain� You should therefore observe the

following notes�

2.1 Intended purpose

The compressor is designed to supply compressed air for dental applications�

EN

2.2 Intended use

The air supplied by the compressor is suitable

for driving dental tools�

The compressed air generated by the compressor is delivered to the pipeline system of the

surgery� The entire compressed air system must

be designed in such a way that the quality of the

compressed air generated by the compressor is

not impaired�

With this prerequisite, the air provided by the

compressor is also suitable for blow-drying

tooth preparations�

2.3 Improper use

Any other usage or usage beyond this scope is

deemed to be improper� The manufacturer accepts no liability for damages resulting from improper use� In these cases the user/operator will

bear the sole risk�

WARNING

Risk of explosion due to ignition of

combustible materials

i Do not operate the unit in any rooms

in which inflammable mixtures may be

present, e�g� in operating theatres�

i The unit is not suitable for providing an air

supply to respirators�

i This unit is not suitable for drawing up fluids

or for compressing aggressive gases or potentially explosive gases�

2.4 General safety information

i Always comply with the specifications of all

guidelines, laws, and other rules and regulations applicable at the site of operation for the

operation of this unit�

i Check the function and condition of the unit

prior to every use�

i Do not convert or modify the unit�

i Comply with the specifications of the Installa-

tion and Operating Instructions�

i The Installation and Operating Instructions

must be accessible to all operators of the unit

at all times�

2.5 Qualified personnel

Operation

Unit operating personnel must ensure safe and

correct handling based on their training and

knowledge�

i Instruct or have every user instructed in han-

dling the unit�

Installation and repairs

i Installation, readjustments, alterations, up-

grades and repairs must be carried out by

Dürr Dental or by qualified personnel specifi-

cally approved and authorized by Dürr Dental�

2.6 Electrical safety

i Observe and comply with all the relevant elec-

trical safety regulations when working on the

unit�

i Replace any damaged cables or plugs imme-

diately�

2.7 Only use original parts

i Only use Dürr Dental parts or accessories and

special accessories specifically approved by

Dürr Dental�

i Only use only original wear parts and replace-

ment parts�

Dürr Dental accepts no liability for damages or injury resulting from the use of

non-approved accessories or optional

accessories, or from the use of non-original wear parts or replacement parts�

The use of non-approved accessories,

optional accessories or non-genuine

wear parts / replacement parts (e�g�

mains cable) can have a negative effect

in terms of electrical safety and EMC�

4 9000-610-45/30 1811V007

Page 7

2.8 Transport

The original packaging provides optimum protection for the unit during transport�

If required, original packaging for the unit can be

ordered from Dürr Dental�

Dürr Dental will not accept any responsibility or liability for damage occurring during transport due to the use of incorrect

packaging, even where the unit is still under guarantee�

i Only transport the unit in its original packag-

ing�

i Keep the packing materials out of the reach of

children�

2.9 Disposal

Unit

The unit must be disposed of properly�

Within the European Union, the unit must

be disposed of in accordance with EU

Directive 2012/19/EU (WEEE)�

i If you have any questions about the correct

disposal of parts, please contact your dental

trade supplier�

Important information

EN

9000-610-45/30 1811V007 5

Page 8

Product description

3 Overview

3.1 Scope of delivery

The following items are included in the scope of

delivery (possible variations due to country-specific requirements and/or import regulations):

Duo 110V, 1~, with condensate separator � � � � � � � � � � � � � � � � � � � � � � 5250100004

Duo 110V, 1~, with membrane drying unit � � � � � � � � � � � � � � � � � � � � � 5252100001

EN

Duo 230V, 1~, with membrane drying unit � � � � � � � � � � � � � � � � � � � � � � � � 5252-01

Duo 230V, 1~, with membrane drying unit � � � � � � � � � � � � � � � � � � 5252-01/Service

Duo 400V, with membrane drying

unit � � � � � � � � � � � � � � � � � � � � � � � � � � � 5252-51

Trio 230V, 1~, with membrane drying

unit � � � � � � � � � � � � � � � � � � � � � � � � � � � 5352-01

Trio 230V, 1~, with membrane drying

unit � � � � � � � � � � � � � � � � � � � � � � � � 5352100001

Quattro 400V, with membrane drying

unit * � � � � � � � � � � � � � � � � � � � � � � � � � 5452-51

Quattro 400V, with membrane drying

unit * � � � � � � � � � � � � � � � � � � � � � � 5452100001

Duo Tandem 230V, 1~, with membrane drying unit � � � � � � � � � � � � � � � � 4252-01

Duo Tandem CAD/CAM 230V, 1~,

with membrane drying unit * � � � � 4252100004

Quattro Tandem 230V, 3~, with

membrane drying unit * � � � � � � � � � � � 4682-52

Quattro Tandem 400V, 3~, with

membrane drying unit * � � � � � � � � � � � 4682-53

– Fabric reinforced hose

– Hose nozzle

– Hose clamp

– Installation and operating instructions

– Appliance log book

– Collector tray

* with sterile filter

3.2 Optional accessories

The following items can optionally be used with

the unit; these items do not bear the CE mark:

Pressure reducer � � � � � � � � � � � � � � 6040-992-00

Sterile filter � � � � � � � � � � � � � � � � � � 1640-981-00

Wooden cabinet for for sound insula-

tion of Duo Compressors � � � � � � � 5150-500-00

Wooden cabinet for for sound insula-

tion of DuoTandem, Trio and Quattro

Compressors � � � � � � � � � � � � � � � � 4251-500-00

3.3 Wear parts and replacement parts

The following working parts must be replaced at

regular intervals (refer also to "Maintenance");

these articles do not bear the CE mark:

Air intake filter � � � � � � � � � � � � � � � � 0832-982-00

Fine filter � � � � � � � � � � � � � � � � � � � � 1610-121-00

Sterile filter � � � � � � � � � � � � � � � � � � 1640-981-00

Sintered filter � � � � � � � � � � � � � � � � � 1650-101-00

Fleece filter � � � � � � � � � � � � � � � � � �4280-982-00

Any repairs exceeding routine maintenance may only be carried out by qualified personnel or our service�

Information about replacement parts is

available from the portal for authorised

specialist dealers at:

www�duerrdental�net�

If the mains cable of this unit is damaged

it must only be replaced by an original

mains cable from the manufacturer�

6 9000-610-45/30 1811V007

Page 9

Product description

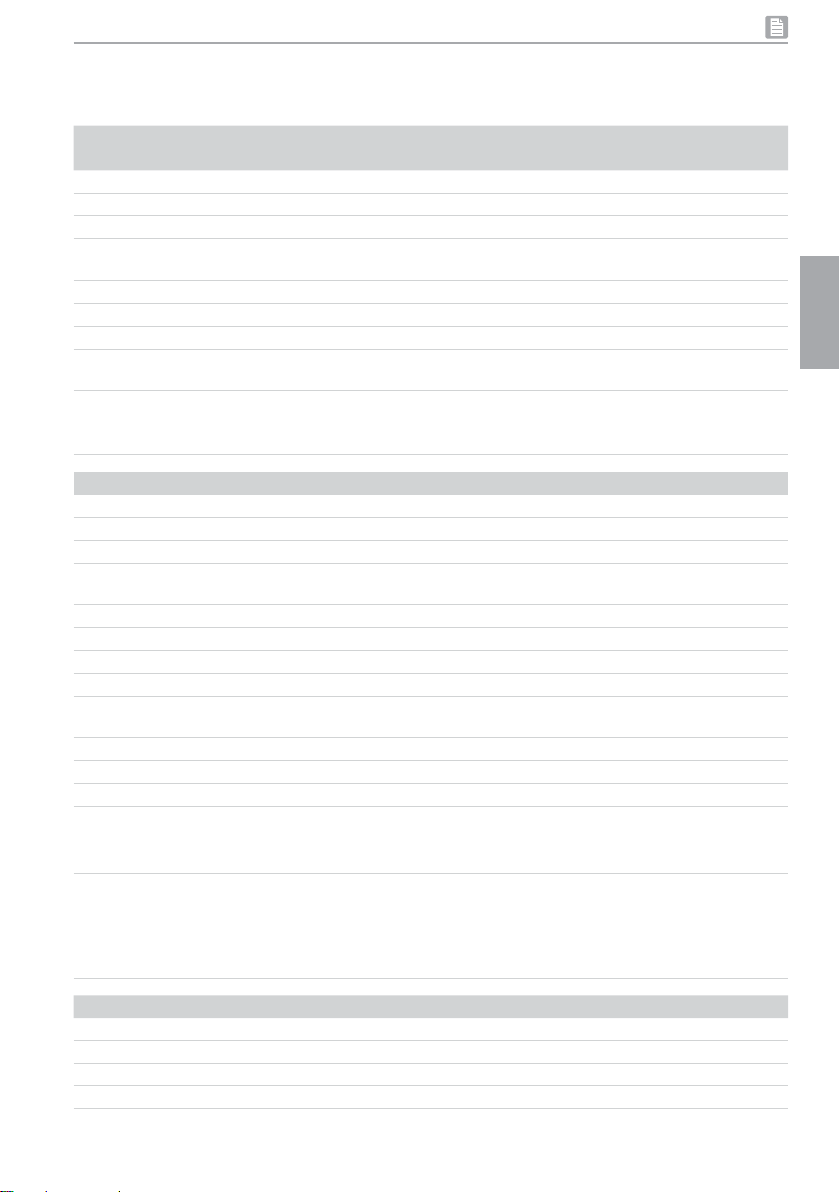

4 Technical data

4.1 Duo

Electrical data 5252-01

5252-01/Service

Rated voltage V 230 400

Mains frequency Hz 50 60 50 60

Nominal current at 8 bar (0�8 MPa) A 6�3 7�0 3�1 2�5

Motor protection switch, recommended

settings A 6�5 7�6 3�1 2�5

Speed rpm 1360 1600 1410 1690

Type of protection IP 24 IP 24

Mains fuses * A 10 10

Max� permissible mains impedance in ac-

cordance with EN61000-3-11 ** W ≤ 0�142 * Circuit breaker fuse characteristics B, C or D in acc� with EN60898-1

** Mains impedance at 6 switching cycles per hour� If the number of switching cycles per hour is

higher a lower mains impedance is required�

General technical data

Pressure tank volume l 20 20

Suction power, approx� l/min 210 255 210 255

Delivery at 5 bar (0�5 MPa) l/min 115 130 115 130

Pressure build-up phase 0 - 7�5 bar (0 -

0�75 MPa) approx� s 85 70 85 70

Duty cycle % 100 100

Start-up pressure bar (MPa) 6 (0�6) 6 (0�6)

Cut-off pressure bar (MPa) 7�8 (0�78) 7�8 (0�78)

Cut-off pressure, max� adjustable bar (MPa) 9�5 (0�95) 9�5 (0�95)

Safety valve, maximum permissible oper-

ating pressure bar (MPa) 10 (1) 10 (1)

Pressure dew point at 7bar (0�7MPa) * °C ≤+5 ≤+5

Dimensions (H x W x D) ** cm 69 x 49 x 46 69 x 49 x 46

Weight kg 47 47

Noise level ***

without sound insulation

with sound insulation

* Value determined at an ambient temperature of +40°C

** Values without accessories and add-on parts

*** Noise level in accordance with ENISO1680 "Airborne noise emissions"; measured in a room

with sound damping� The levels are average values with a tolerance of ± 1�5 dB(A)� Higher values may be obtained in rooms with reverberating sound characteristics�

dB(A)

dB(A)

66

55

69

61

5252-51

66

55

69

61

EN

Filter mesh size

Compressor air intake filter µm 3

Fine filter for membrane drying unit µm 3

Sterile filter for membrane drying unit µm 0�01

Sintered filter for membrane drying unit µm 35

9000-610-45/30 1811V007 7

Page 10

Product description

Ambient conditions during storage and transport

Temperature °C -10 to +55

Relative humidity % max� 95

Ambient conditions during operation

Temperature °C +10 to +40

Ideal temperature °C +10 to +25

Relative humidity % max� 95

Classification

Medical Devices Directive (93/42/EEC) Class IIa

EN

8 9000-610-45/30 1811V007

Page 11

Product description

4.2 Duo

Electrical data 5250100004 5252100001

Nominal voltage V 110-115 110-127 110-115 110-127

Electrical frequency Hz 50 60 50 60

Nominal current at 8 bar (0�8 MPa)

Motor protection switch, recommended

settings A 17 16 17 16

Speed

Type of protection IP 24 IP 24

Mains fusing * A 20 20

* Circuit breaker fuse characteristics B, C or D in acc� with EN60898-1

General technical data

Pressure tank volume l 20 20

Suction power, approx� l/min 210 255 210 255

Delivery at 5 bar (0�5 MPa) l/min 130 145 115 130

Pressure build-up phase 0 - 7�5 bar (0 -

0�75 MPa) approx� s 75 65 85 70

Duty cycle % 100 100

Start-up pressure bar (MPa) 6 (0�6) 6 (0�6)

Cut-off pressure bar (MPa) 7�8 (0�78) 7�8 (0�78)

Cut-off pressure, max� adjustable bar (MPa) 9�5 (0�95) 9�5 (0�95)

Safety valve, maximum permissible oper-

ating pressure bar (MPa) 10 (1) 10 (1)

Pressure dew point at 7bar (0�7MPa) * °C - ≤+5

Dimensions (H x W x D) ** cm 69 x 49 x 44 69 x 49 x 46

Weight kg 46 50

Noise level ***

without sound insulation

with sound insulation

* Value determined at an ambient temperature of +40°C

** Values without accessories and add-on parts

*** Noise level in accordance with ENISO1680 "Airborne noise emissions"; measured in a room

with sound damping� The levels are average values with a tolerance of ± 1�5 dB(A)� Higher values may be obtained in rooms with reverberating sound characteristics�

A

rpm

dB(A)

dB(A)

14�1-

14�6

1350-

1370

66

55

14�2-

13�3

1560-

1640

69

61

14�1-

14�6

1350-

1370

66

55

14�2-

13�3

1560-

1640

69

61

EN

Filter mesh size

Compressor air intake filter µm 3

Fine filter for membrane drying unit µm 3

Sterile filter for membrane drying unit µm 0�01

Sintered filter for membrane drying unit µm 35

Fleece filter for automatic condensate

drain µm 5

Ambient conditions during storage and transport

Temperature °C -10 to +55

Relative humidity % max� 95

9000-610-45/30 1811V007 9

Page 12

Product description

Ambient conditions during operation

Temperature °C +10 to +40

Ideal temperature °C +10 to +25

Relative humidity % max� 95

Classification

Medical Devices Directive (93/42/EEC) Class IIa

EN

10 9000-610-45/30 1811V007

Page 13

Product description

4.3 Trio

Electrical data 5352-01

5352100001

Rated voltage V 230

Mains frequency Hz 50

Nominal current at 8 bar (0�8 MPa) A 8�6

Motor protection switch, recommended

settings A 8�6

Speed rpm 1350

Type of protection IP 24

Mains fuses * A 10

Max� permissible mains impedance in ac-

cordance with EN61000-3-11 W ≤ 0�078

* Circuit breaker fuse characteristics B, C or D in acc� with EN60898-1

General technical data

Pressure tank volume l 50

Suction power, approx� l 315

Delivery at 5 bar (0�5 MPa) l/min 160

Pressure build-up phase 0 - 7�5 bar (0 -

0�75 MPa) c� s 140

Duty cycle % 100

Start-up pressure bar (MPa) 6 (0�6)

Cut-off pressure bar (MPa) 7�8 (0�78)

Cut-off pressure, max� adjustable bar (MPa) 9�5 (0�95)

Safety valve, maximum permissible oper-

ating pressure bar (MPa) 10 (1)

Pressure dew point at 7bar (0�7MPa) * °C ≤+5

Dimensions (H x W x D) ** cm 76 x 74 x 52

Weight kg 70

Noise level ***

without sound insulation

with sound insulation

* Value determined at an ambient temperature of +40°C

** Values without accessories and add-on parts

*** Noise level in accordance with ENISO1680 "Airborne noise emissions"; measured in a room

with sound damping� The levels are average values with a tolerance of ± 1�5 dB(A)� Higher values may be obtained in rooms with reverberating sound characteristics�

dB(A)

dB(A)

69

54

EN

Filter mesh size

Compressor air intake filter µm 3

Fine filter for membrane drying unit µm 3

Sterile filter for membrane drying unit µm 0�01

Sintered filter for membrane drying unit µm 35

Ambient conditions during storage and transport

Temperature °C -10 to +55

Relative humidity % max� 95

9000-610-45/30 1811V007 11

Page 14

Product description

Ambient conditions during operation

Temperature °C +10 to +40

Ideal temperature °C +10 to +25

Relative humidity % max� 95

Classification

Medical Devices Directive (93/42/EEC) Class IIa

EN

12 9000-610-45/30 1811V007

Page 15

Product description

4.4 Quattro

Electrical data 5452-51

5452100001

Rated voltage V 400

Mains frequency Hz 50 60

Nominal current at 8 bar (0�8 MPa) A 4�4 4�8

Motor protection switch, recommended

settings A 5�0 5�0

Speed rpm 1440 1700

Type of protection IP 24

Mains fuses * A 10

Max� permissible mains impedance in ac-

cordance with EN61000-3-11 ** W ≤ 0�24

* Circuit breaker fuse characteristics B, C or D in acc� with EN60898-1

** Mains impedance at 6 switching cycles per hour� If the number of switching cycles per hour is

higher a lower mains impedance is required�

General technical data

Pressure tank volume l 50

Suction power, approx� l/min 420 505

Delivery at 5 bar (0�5 MPa) l/min 215 240

Pressure build-up phase 0 - 7�5 bar (0 -

0�75 MPa) c� s 105 95

Duty cycle % 100

Start-up pressure bar (MPa) 6 (0�6)

Cut-off pressure bar (MPa) 7�8 (0�78)

Cut-off pressure, max� adjustable bar (MPa) 9�5 (0�95)

Safety valve, maximum permissible oper-

ating pressure bar (MPa) 10 (1)

Pressure dew point at 7bar (0�7MPa) * °C ≤+5

Dimensions (H x W x D) ** cm 76 x 74 x 52

Weight kg 82

Noise level ***

without sound insulation

with sound insulation

* Value determined at an ambient temperature of +40°C

** Values without accessories and add-on parts

*** Noise level in accordance with ENISO1680 "Airborne noise emissions"; measured in a room

with sound damping� The levels are average values with a tolerance of ± 1�5 dB(A)� Higher values may be obtained in rooms with reverberating sound characteristics�

dB(A)

dB(A)

70

54

75

55

EN

Filter mesh size

Compressor air intake filter µm 3

Fine filter for membrane drying unit µm 3

Sterile filter for membrane drying unit µm 0�01

Sintered filter for membrane drying unit µm 35

9000-610-45/30 1811V007 13

Page 16

Product description

Ambient conditions during storage and transport

Temperature °C -10 to +55

Relative humidity % max� 95

Ambient conditions during operation

Temperature °C +10 to +40

Ideal temperature °C +10 to +25

Relative humidity % max� 95

Classification

Medical Devices Directive (93/42/EEC) Class IIa

EN

14 9000-610-45/30 1811V007

Page 17

Product description

4.5 Duo Tandem

Electrical data 4252-01 4252100004

Rated voltage V 230 230

Mains frequency Hz 50 60 50 60

Nominal current at 8 bar (0�8 MPa) A 12�2 14�3 12�2 14�3

Motor protection switch, recommended

settings A 6�5 7�6 6�5 7�6

Speed rpm 1410 1690 1410 1690

Type of protection IP 24 IP 24

Mains fuses * A 20 20

* Circuit breaker fuse characteristics B, C or D in acc� with EN60898-1

General technical data

Pressure tank volume l 50 50

Suction power, approx� l/min 420 505 420 505

Delivery at 5 bar (0�5 MPa) l/min 230 260 230 260

Pressure build-up phase 0 - 7�5 bar (0 -

0�75 MPa) c� s 115 100 115 100

Duty cycle % 100 100

Start-up pressure bar (MPa) 6 (0�6) > 7 (0�7)

Cut-off pressure bar (MPa) 7�8 (0�78) 9 (0�9)

Cut-off pressure, max� adjustable bar (MPa) 9�5 (0�95) 9�5 (0�95)

Safety valve, maximum permissible oper-

ating pressure bar (MPa) 10 (1) 10 (1)

Pressure dew point at 7bar (0�7MPa) * °C ≤+5 ≤+5 **

Dimensions (H x W x D) *** cm 76 x 79 x 52 76 x 79 x 52

Weight kg 90 90

Noise level ****

without sound insulation

with sound insulation

* Value determined at an ambient temperature of +40°C

** With ORANGE rinsing nozzle

*** Values without accessories and add-on parts

**** Noise level in accordance with ENISO1680 "Airborne noise emissions"; measured in a room

with sound damping� The levels are average values with a tolerance of ± 1�5 dB(A)� Higher values may be obtained in rooms with reverberating sound characteristics�

dB(A)

dB(A)

69

55

74

56

69

55

EN

74

56

Filter mesh size

Compressor air intake filter µm 3

Sterile filter for membrane drying unit µm 0�01

Sintered filter for membrane drying unit µm 35

Ambient conditions during storage and transport

Temperature °C -10 to +55

Relative humidity % max� 95

9000-610-45/30 1811V007 15

Page 18

Product description

Ambient conditions during operation

Temperature °C +10 to +40

Ideal temperature °C +10 to +25

Relative humidity % max� 95

Classification

Medical Devices Directive (93/42/EEC) Class IIa

EN

16 9000-610-45/30 1811V007

Page 19

Product description

4.6 Quattro Tandem

Electrical data 4682-52 4682-53

Rated voltage V 230 / 3~ 400 / 3~

Mains frequency Hz 50 60 50 60

Nominal current at 8 bar (0�8 MPa) A 15�2 16�6 8�8 9�6

Motor protection switch, recommended

settings A 9 9 5 5

Speed rpm 1440 1700 1440 1700

Type of protection IP 24 IP 24

Mains fuses * A 20 20

Max� permissible mains impedance in ac-

cordance with EN61000-3-11 ** W ≤0�445 ≤0�18

* Circuit breaker fuse characteristics B, C or D in acc� with EN60898-1

** Mains impedance at 6 switching cycles per hour� If the number of switching cycles per hour is

higher a lower mains impedance is required�

General technical data

Pressure tank volume l 90 90

Suction power, approx� l/min 845 1010 845 1010

Delivery at 5 bar (0�5 MPa) l/min 430 480 430 480

Pressure build-up phase 0 - 7�5 bar (0 -

0�75 MPa) c� s 90 80 90 80

Duty cycle % 100 100

Start-up pressure bar (MPa) 6�5 (0�65) 6�5 (0�65)

Cut-off pressure bar (MPa) 8�5 (0�85) 8�5 (0�85)

Cut-off pressure, max� adjustable bar (MPa) 9�5 (0�95) 9�5 (0�95)

Safety valve, maximum permissible oper-

ating pressure bar (MPa) 10 (1) 10 (1)

Pressure dew point at 7bar (0�7MPa) * °C ≤+5 ≤+5

Dimensions (H x W x D) ** cm 76 x 102 x 62 76 x 102 x 62

Weight kg 143 143

Noise level *** dB(A) 69 74 69 74

* Value determined at an ambient temperature of +40°C

** Values without accessories and add-on parts

*** Noise level in accordance with ENISO1680 "Airborne noise emissions"; measured in a room

with sound damping� The levels are average values with a tolerance of ± 1�5 dB(A)� Higher values may be obtained in rooms with reverberating sound characteristics�

EN

Filter mesh size

Compressor air intake filter µm 3

Fine filter for membrane drying unit µm 3

Sterile filter for membrane drying unit µm 0�01

Sintered filter for membrane drying unit µm 35

Ambient conditions during storage and transport

Temperature °C -10 to +55

Relative humidity % max� 95

9000-610-45/30 1811V007 17

Page 20

Product description

Ambient conditions during operation

Temperature °C +10 to +40

Ideal temperature °C +10 to +25

Relative humidity % max� 95

Classification

Medical Devices Directive (93/42/EEC) Class IIa

EN

18 9000-610-45/30 1811V007

Page 21

Product description

1

1

b

a

1

4.7 Distance between rubber feet

Distances between the rubber feet for different

pressure vessel volumes:

a (cm) b (cm)

20 l 23 27

50 l 32�5 45

90 l 32�5 59

4.8 Type plate

Complete system

The type plate of the overall system is located

on the mounting plate for the compressor unit�

Compressor unit

The type plate of the compressor unit is located

on the crankcase below the cylinder�

EN

1 Compressor unit type plate

Membrane drying unit

The type plate of the membrane drying unit is

located on the side of the membrane drying

unit�

1 Membrane drying unit type plate

1 Type plate for the complete system

9000-610-45/30 1811V007 19

Page 22

Product description

1

2

34

14

15

16

17

18

19

5 Operation

5.1 Duo with membrane drying unit

13

6

EN

7

5

1 Compressor unit

2 Air intake filter

3 Pressure tank

4 Condensate drain valve

5 Non-return valve

6 Pressure switch

7 Safety valve

8 Pressure gauge/display

9 Pressure relief valve

10 Cooler with ventilating fan

11 Membrane drying unit

12 Pressure limiting valve

13 Humidity display

14 Fine or sterile filter

15 Rinsing nozzle

16 Membrane fibre

17 Sinter filter

18 Water collection chamber

19 Water outlet valve

The compressor unit draws in atmospheric air and compresses it without oil� It then transports the oilfree compressed air to the membrane drying unit� The cooler and the membrane dryer extract moisture from the compressed air� The oil-free, hygienic and dry air is stored in the pressure tank ready for

use in connected devices�

20 9000-610-45/30 1811V007

9

8

10 11

12

Page 23

Assembly

6 Requirements

The unit must not be set up or operated

within the vicinity of the patients (within a

radius of 1�5m)�

The unit can be installed either at the same level

as the surgery room or on a floor below (e�g�cellar)�

Due of the amount of noise generated, we recommend that the unit is installed in an adjoining

room�

The pipes provided on-site must at least meet

the country-specific requirements for drinking

water�

Further information can be found in our

separate planning information leaflet for

compressed air�

6.1 Installation/setup room

The room chosen for set up must fulfil the following requirements:

– Closed, dry, well-ventilated room

– Should not be a room made for another pur-

pose (e�g� boiler room or wet cell)

– If the unit is installed in a machine room, e�g�in

an adjoining room or cellar, the requirements

set out in ISO-TS22595 must be complied

with�

NOTICE

Risk of overheating due to insufficient ventilation

The units generates heat� Possibility of

heat damage and/or reduced service life

of the unit�

i Do not cover the unit�

i Install a fan for auxiliary ventilation in

rooms where ambient temperatures

exceed ≥40 °C while the unit is in operation�

≥ 40 °C

EN

6.2 Setup

The following conditions must be taken into account for installation:

The air is filtered when it is sucked in�

This does not alter the composition of

the air� For this reason it is important to

keep the sucked-in air free of harmful

substances (e�g�do not suck in exhaust

gases or contaminated exhaust air)�

– Clean, level and sufficiently stable subsurface

(note the weight of the unit)�

– Type plate easy to read�

– Unit easy to access for operation and main-

tenance�

– Easy-to-access power outlet to which the unit

is connected�

– Maintain sufficient distance to the wall (at least

20cm)�

– The compressed air pipe should be routed as

closely as possible to the place of installation

(note the length of the hose supplied)�

9000-610-45/30 1811V007 21

Page 24

Assembly

6.3 Information about electrical connections

i Ensure that electrical connections to the

mains power supply are carried out in accordance with current valid national and local regulations and standards governing the installation of low voltage units in medical facilities�

i Install an all-pole disconnect switch with a

contact opening width of at least 3mm in the

electrical connection to the mains power supply�

i Observe the current consumption of the de-

vices that are to be connected�

EN

7 Transport

WARNING

Risk of explosion of the pressure

tank and pressure hoses

i The pressure tank and the pressure

hoses must be vented before they are

stored or transported�

i Protect the unit against moisture, dirt and ex-

treme temperatures during transport ("4 Technical data")�

i Always make sure that the condensate collec-

tor chamber is empty before transporting the

unit ("15 Taking out of use")�

i Always transport the unit in an upright posi-

tion�

i Only transport the unit using the transport

handles provided�

i Check the unit for transport damage�

22 9000-610-45/30 1811V007

Page 25

Assembly

1 21

8 Quattro Tandem assembly

and installation

For weight reasons the unit is not supplied fully

assembled� Instead, the compressor units are

installed at the site of use�

i Set up the tank at the planned installation site�

i Screw the vibration reducers into the motor

mounting�

i Place the compressor units on the vibration

reducers�

i Attach the compressor units with the lock

washers and nuts�

9 Installation

9.1 Remove the transport locks

For safe transport, the unit is secured with foam

padding blocks and a transport strap�

i Cut and remove the transport strap�

i Remove the foam padding blocks�

9.2 Establishing the compressed air connection

The supplied flexible pressure hose between the pipe system and the compressor prevents vibrations from being transmitted and thus reduces noise� This ensures safe and reliable operation�

i Connect the pre-assembled connecting

sleeve of the pressure hose to the quick release coupling�

i Measure the required length of the pressure

hose and shorten if necessary�

i Press a fitting hose connector (not included in

the scope of delivery) onto the pressure hose

(internal diameter 10mm) and secure it with a

hose clip�

i Connect the connecting sleeve of the pres-

sure hose to the compressed air tube�

EN

i Insert the compressed air connections from

the compressor unit into the cooler�

i Plug in the electrical connections of the com-

pressor units at the control box� Connect the

left-hand unit to the left-hand plug connector

and the right-hand unit to the right-hand plug

connector�

1 Compressed air connections

2 Electrical connections

9000-610-45/30 1811V007 23

Page 26

Assembly

i Place a collector tray under the condensate

separator or the membrane drying unit (depending on type)�

EN

Figure 1: Duo with condensate separator

9.3 Pressure reducer

i Insert the pressure reducer into the quick re-

lease coupling�

i Insert the pressure hose into the quick release

coupling on the pressure reducer�

9.4 Place a collector tray underneath

During operation, condensation water on the

unit is continuously separated and automatically

drained� In order to prevent water damage due

to drained condensation, it is collected in the

collector tray�

As an option, the condensation can also

be drained through a hose into the waste

water system� Always comply with applicable national regulations for waste water

systems�

9.5 Electrical connections

Safety when making electrical connections

The unit has no main power switch� For

this reason it is important that the unit is

be set up in such a way that the plug can

be easily accessed and unplugged if required�

i The unit must only be connected to a correct-

ly installed power outlet�

i Make sure that none of the electrical cables

leading to the unit are under any mechanical

tension�

i Before initial start-up check that the mains

supply voltage and the voltage stated on the

type plate match (see also "4� Technical

data")�

Establishing the electrical connections

DANGER

Risk of electric shock due to defective mains cable

i Mains cables must not be allowed to

come into contact with any hot surfaces on the unit�

i Connect the mains plug to an earthed power

outlet�

24 9000-610-45/30 1811V007

Page 27

Assembly

1

2

10 Commissioning

In many countries technical medical

products and electrical devices are subject to regular checks at set intervals� The

owner must be instructed accordingly�

i Turn on the unit power switch or the main sur-

gery switch�

i Carry out an electrical safety check in accord-

ance with applicable local regulations (e�g� the

German Ordinance on the Installation, Operation and Use of Medical Devices / Medizinprodukte-Betreiberverordnung) and record the results as appropriate, e�g� in the technical log

book�

10.1 Check the motor protection switch

After installation of the compressor the motor

protection switch needs to be checked and adjusted if it is not set up correctly� It was set to

the recommended setting in the factory (see "4

Technical data")�

i Switch on the unit at the pressure switch by

rotating the switch to the "I" position�

10.2 Checking the switch-on/cut-off pressure

The switch-on/cut-off pressure is preset at the

factory� Check the setting during first start-up�

i Switch on the unit at the pressure switch by

rotating it to the position "I AUTO"�

i Read off the cut-off pressure from the pres-

sure gauge�

i Drain the air from the pressure tank (e�g� via

the condensate drain valve) until the unit starts

and then close it again�

i Read off the pressure when the unit switches

on�

If the readings deviate from the values preset

at the factory, adjust the pressure switch to

the factory settings�

EN

1 On/off switch

2 Pressure gauge

i Measure the maximum current consumption

(this is the value just before the cut-off pressure is reached)�

If the reading deviates from the recommended setting then the motor protection switch

needs to be adjusted (see "11�2 Adjusting

the motor protection switch")�

9000-610-45/30 1811V007 25

Page 28

Assembly

10.3 Checking the safety valve

Correct operation of the safety valve must be

checked when the unit is started up for the first

time and again subsequently at regular intervals�

At the factory, the safety valve is set to

10 bar (1 hPa), checked and stamped�

DANGER

Risk of explosion of the pressure

tank and pressure hoses

i Do not change the safety valve set-

EN

tings�

i Switch on the unit at the pressure switch and

fill the pressure tank to the cut-off pressure�

WARNING

Risk of damage to the safety valve

Risk of explosion of the pressure tank

and pressure hoses due to a defective

safety valve

i Do not use the safety valve to vent the

pressure tank�

i To open, rotate the screw of the safety valve

anti-clockwise until the valve begins to blow

off� Only allow the safety valve to blow for a

short period�

i Then turn the screw clockwise as far as it will

go to close the valve� The valve must now be

closed again�

10.4 Draining the condensation water

Temperature changes during transport may

cause condensation water to accumulate in the

pressure tank� The condensation water can only

be drained from the pressurised pressure tank�

i Switch on the unit at the pressure switch and

wait until the cut-off pressure is reached�

Pressure tank

i At maximum tank pressure, open the conden-

sate drain valve�

i Close the condensate drain valve as soon as

all of the accumulated condensation water

has been blown out�

Condensate separator

i At maximum tank pressure, unscrew the bot-

tom screw fitting on the condensate separator�

26 9000-610-45/30 1811V007

Page 29

Assembly

+

1.

i Close the screw connection as soon as all of

the condensate has been blown out�

Figure 2: Duo with condensate separator

10.5 Adjusting the rate of flow at the pressure reducer

The pressure reducer regulates the rate of flow

in the system and adjusts it to the required operating pressure� In order to adjust the rate of

flow air needs to be extracted via a consumer�

i Activate the air consumer unit�

i Lift the rotary knob at the pressure reducer�

i Adjust the rate of flow via the rotary knob�

Turn the knob in the "+" direction to increase

the rate of flow�

Turn the knob in the "-" direction to reduce the

rate of flow�

i Press in the rotary knob until it engages and

cannot be adjusted�

2.

11 Adjustment options

11.1 Adjusting the pressure switch

WARNING

Risk of explosion of the pressure

vessel

The pressure vessels used in the compressors are designed to withstand

continuous pressure changes of 2bar

and can be used continuously under

these pressure changes�

i For load changes > 2bar (max� per-

missible: 3bar), comply with the maximum load change cycles specified in

the operating instructions of the pressure vessel�

DANGER

Exposed live parts

Risk of electric shock due to live parts

i Disconnect all power from the device�

i Use insulated tools�

i Do not touch live parts�

The cut-off pressure must be at least 0�5

bar (0�05 hPa) below the maximum pressure of 10 bar (1 hPa) of the safety valve�

Otherwise the safety valve can open too

early, which will prevent the compressor

unit from attaining the cut-off pressure,

as a result of which it will run continuously� The maximum permitted pressure is

marked by a red line on the attached

pressure gauge�

If the read-off values differ from the factory settings or if other settings are required, the cut-off

pressure of the compressor can be adjusted at

the adjusting screw on the pressure switch� The

start-up pressure can then be adjusted using

the pressure difference Δp�

i Take off the pressure switch cover�

i Adjust the cut-off pressure P at the adjust-

ment screw�

The cut-off pressure increases in the "+"

arrow direction and decreases in the "-" arrow

direction� The pressure difference ∆p is also

influenced by this adjustment�

EN

-

3.

9000-610-45/30 1811V007 27

Page 30

Assembly

i Adjust the start-up pressure via the pressure

difference ∆p at the adjustment screw�

The pressure difference increases in the "+"

arrow direction and decreases in the "-" arrow

direction�

The maximum permissible pressure difference

must not be set to more than 3bar�

EN

11.2 Adjusting the motor protection switch

Pressure switch

i Take off the pressure switch cover�

i Adjust the motor protection switch with the

adjustment screw to the measured value (observe the range between the MIN permissible

setting and the MAX permissible setting of the

motor protection switch, see "4 Technical

data")�

Controller

i Remove the cover from the controller�

i Adjust the motor protection switch with the

adjustment screw to the measured value (observe the range between the MIN permissible

setting and the MAX permissible setting of the

motor protection switch, see "4 Technical

data")�

28 9000-610-45/30 1811V007

Page 31

12 Circuit diagrams

X1 M1

1~

LP

X1 M1

1~

12.1 1/N/PE AC 110-127 V, 230 V layout

135

P>

I >

I >I >

Q1

246

EN

X1 Mains connection L/N/PE AC 230V

Q1 Pressure switch

M1 Compressor unit

M2 Fan motor, membrane drying unit

M3 Fan motor, noise insulation (if required)

12.2 3/N/PE AC 400 V layout

Z2/U1U2Z1

M

1~

Assembly

PE

EN

PE

1~

M2 M3

X1 Mains connection 3/N/PE AC 400V

Q1 Pressure switch

M1 Compressor unit

M2 Fan motor, membrane drying unit

M3 Fan motor, noise insulation (if required)

9000-610-45/30 1811V007 29

L1 L2 L3 PEN

135

P>

I >

I >I >

Q1

246

3~

PE

N

1~

M2 M3

Page 32

Assembly

Q1

M1

M2 M5

12.3 1/N/PE AC 230 V layout, Duo Tandem

A1

246

135

P>

333 222 111 777

X1 X4

PE PE PE

PE

2211

EN

L1/PE/N

X5

X5 Mains connection L/N/PE AC 230V

Q1 Pressure switch

A1 Controller

X1 Distributor rail

X2 Plug connection of compressor unit

X3 Plug connection of compressor unit

X4 Distributor rail

Q1�2 Motor protection switch

Q1�3 Motor protection switch

M1 Compressor unit

M2 Compressor unit

M5 Fan motor, membrane drying unit

13

21

Q1.2 Q1.3

246

14 22

I>

I>

I>

135

X2

64

31

PE

3~ 1~

X3

246

I>

135

13

21

14 22

I>

I>

31

64

PE

1~

30 9000-610-45/30 1811V007

Page 33

12.4 3/N/PE AC 230 V layout, Quattro Tandem

Q1

M1X1 M2 M3 M4

A1

246

135

P>

444555

X5 X4

PE

Assembly

PE

2211

EN

Q2

I> I>

X2

L1/L2/L3/N/PE

X1 Mains connection 3/N/PE AC 230V

Q1 Pressure switch

A1 Control box

X2 Plug connection of compressor unit

X3 Plug connection of compressor unit

X4 Distributor rail

X5 Distributor rail

Q2 Motor protection switch

Q3 Motor protection switch

K1 Time-lag relay

M1 Compressor unit

M2 Compressor unit

M3 Fan motor, membrane drying unit

M4 Fan motor, membrane drying unit

246

135

321

3~

14 22

13 21

I>

PE

64

135

A1

K1

A2

246

Q3

X3

I> I>

246

135

321

3~

14 22

13 21

I>

PE

64

1~

1~

9000-610-45/30 1811V007 31

Page 34

Usage

13 Operation

Prior to working on the device or in case

of danger, disconnect it from the mains

(e�g� pull the mains plug)�

13.1 Switching the unit on/off

i Switch on the unit at the pressure switch by

rotating it to the position "I AUTO"�

The compressor unit will start up automati-

EN

cally and fill the pressure tank� When the

cut-off pressure is reached the compressor

unit switches itself off automatically�

i The unit can be switched off when required by

turning the pressure switch to the "0 OFF"

setting�

32 9000-610-45/30 1811V007

Page 35

14 Maintenance

Prior to working on the device or in case of danger, disconnect it from the mains (e�g� pull the

mains plug)�

CAUTION

Risk of infection due to burst filters

Particles enter the compressed air network and can therefore enter the mouth of the patient�

i Replace filters in accordance with the maintenance schedule�

14.1 Maintenance schedule

Usage

NOTICE

Risk of damage to the unit due to blocked filters

Continuous running due to reduced delivery� Damage to the unit due to burst filters�

i Replace filters in accordance with the maintenance schedule�

Unit with condensate separator

Maintenance

interval

At regular intervals i Empty the collector tray under the condensate separator (the interval may

Annually i Replace the air intake filter in the compressor unit – every six months if the

Every 4 years i Replace the vibration dampers�

In accordance

with national law

Unit with membrane-drying unit

Maintenance

interval

At regular intervals i Empty the collector tray under the membrane drying unit (the interval may

Annually i Replace the air intake filter in the compressor unit – every six months if the

Every 4 years i Replace the vibration dampers�

In accordance

with national law

Maintenance work

vary depending on the ambient conditions and method of working; empty it

daily if the humidity is high)�

concentration of dust is high�

i Replace the fleece filter in the condensate separator�

i Check the safety valve�

i Carry out recurring safety inspections (e�g� pressure tank inspections, electri-

cal safety inspections) in accordance with applicable national laws�

Maintenance work

vary depending on the ambient conditions and method of working; empty it

daily if the humidity is high)�

concentration of dust is high�

i Replace the fine or sterile filter�

i Replace the sintered filter�

i Check the safety valve�

i Carry out recurring safety inspections (e�g� pressure tank inspections, electri-

cal safety inspections) in accordance with applicable national laws�

EN

9000-610-45/30 1811V007 33

Page 36

Usage

14.2 Replacing the air intake filter

i Switch off the compressor at the pressure

switch�

i Pull off the noise reducer from the air intake fil-

ter�

i Remove the air intake filter�

i Insert a new air intake filter�

i Push on the noise reducer onto the air intake

filter�

1

EN

1 Noise reducer

2 Air intake filter

2

14.3 Replacing the filter in the condensate separator

i Switch off the compressor at the pressure

switch�

i Unplug the mains plug�

i Release the pressure from the pressure tank�

To do this, unscrew the bottom screw fitting

on the condensate separator�

i Push the slider of the housing locking mecha-

nism downwards�

i Open the housing by rotating and pulling

downwards�

i Rotate the black filter mount (approx� 45°)�

i Remove the filter mount upwards from the

water accumulation chamber�

45°

i Unscrew the rejected part downwards�

i Remove the filter element�

34 9000-610-45/30 1811V007

Page 37

Usage

i Replace the filter element�

i Re-assemble the condensate separator�

During assembly pay attention to detents and markings�

14.4 Replacing the filter of the membrane drying unit

Fine/sterile filter

i Switch off the unit�

i Disconnect all power from the device�

i Unscrew and remove the filter cover�

i Remove the fine/sterile filter�

i Insert the new fine/sterile filter�

i Replace the filter cover and close�

Sintered filter

i Unscrew and remove the filter housing�

i Remove the sintered filter�

i Insert a new sintered filter�

i Replace the filter housing and close�

EN

9000-610-45/30 1811V007 35

Page 38

Usage

15 Taking out of use

15.1 Taking the unit out of use

If the unit is not to be used for a prolonged period of time, we recommend that it is properly

shut down and taken out of use�

To do this, the accumulated condensation water

from the unit must be drained�

i Switch on the unit and wait until the cut-off

pressure is reached�

Condensate separator

i Open the condensate drain valve on the con-

EN

densate separator�

Once the start-up pressure has been

reached the compressor will switch on�

i With the compressor switched on and the

condensate drain valve open, wait until no

more condensation water emerges�

i Switch off the unit�

i Close the condensate drain valve when no

more air emerges�

i Disconnect the mains plug�

i Disconnect the compressed air connection on

the quick release coupling�

Membrane drying unit

i While the compressor unit is running, open

the condensate drain valve on the membrane

drying unit� When no more condensation water emerges, close the condensate drain

valve�

i Switch off the device�

Pressure tank

i Open the condensate drain valve�

Once the start-up pressure has been

reached the compressor will switch on�

i With the compressor switched on and the

condensate drain valve open, wait until no

more condensation water emerges�

i Switch off the unit�

i Close the condensate drain valve when no

more air escapes�

i Disconnect all power from the device�

Figure 3: Duo with condensate separator

36 9000-610-45/30 1811V007

Page 39

i Disconnect the compressed air connection on

the quick release coupling�

15.2 Storage of the unit

WARNING

Risk of explosion of the pressure

tank and pressure hoses

i The pressure tank and the pressure

hoses must be vented before they are

stored or transported�

i Protect the unit against moisture, dirt and ex-

treme temperatures during transport (refer to

the section on "Ambient conditions")�

i Only store the unit when it has been com-

pletely emptied�

Usage

EN

9000-610-45/30 1811V007 37

Page 40

Troubleshooting

16 Tips for operators and service technicians

Any repairs exceeding routine maintenance may only be carried out by qualified personnel or

our service�

Prior to working on the device or in case of danger, disconnect it from the mains (e�g� pull the

mains plug)�

Fault Probable cause Solution

Compressor will not start No mains voltage� On three-

EN

phase units: one phase is missing

or not connected (generation of a

humming sound)

i Check the mains fuse; if neces-

sary, switch the circuit breaker

back on� If the fuse is defective,

replace it� Check the mains

supply voltage�

Humming noise from

motor

Compressor does not

switch off

Compressor switches on

from time to time even

though no air is being taken for a consumer unit

Undervoltage or overvoltage i Measure the supply voltage; call

Relief valve defective, unit starts

against pressure

Mechanical sluggishness of a unit

(piston is stuck); motor protection

has tripped

Motor capacitor is defective i Replace the capacitor�

Wrong size of compressor, air intake too high

Leak in the compressed air system

Defective membrane drying unit i Check whether there is an

Leak in the compressed air system

an electrician if necessary�

i Check that the relief valve

discharges after switching off

the unit� Free up the movement

of the relief valve operable or

replace it�

i Switch the unit off and discon-

nect it from the power supply,

remove the fan hood from the

blocked compressor and turn

the fan wheel� If this is not

possible, replace the piston and

cylinder or the complete unit�

i Calculate the air requirement

(this can be up to 50 l/min per

treatment unit), if necessary

install a larger compressor�

i Locate and seal the leak�

i Inform a service technician�

increased flow of air at the filter

housing of the membrane drying

unit (bottom), if necessary replace the membrane drying unit�

i Locate and seal the leak�

i Inform a service technician�

38 9000-610-45/30 1811V007

Page 41

Fault Probable cause Solution

Knocking or loud noises

on the compressor

Reduced delivery. Compressor needs longer to

charge the pressure tank,

see charging times in "4

Technical data"

Water dripping from air

consumers

Compressor unit defective i Disconnect all power from the

Air intake filter dirty i Replace the air intake filter at

Defective membrane drying unit i Replace the membrane drying

Maintenance work not carried out

regularly (without membrane drying unit)

Defective membrane drying unit i Inform a service technician�

device and inform a service

technician�

least 1x per year� The air intake

filter must never be cleaned�

unit�

i Inform a Service Technician�

i Regularly drain the condensation

water from the pressure tank,

see "10�4 Draining the condensation water"

Troubleshooting

EN

9000-610-45/30 1811V007 39

Page 42

Page 43

Page 44

Hersteller/Manufacturer:

DÜRR DENTAL SE

Höpfigheimer Str. 17

74321 Bietigheim-Bissingen

Germany

Fon: +49 7142 705-0

www.duerrdental.com

info@duerrdental.com

Loading...

Loading...