Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

1999/12

DÜRR AMALGAM SEPARATOR AZ 50

25

Page 2

26

Page 3

CONTENTCONTENT

CONTENT

CONTENTCONTENT

Important information

1. Note......................................................... 26

1.1 CE-marking ...................................... 26

1.2 General Information .........................26

1.3 Electromagnetic Compatibility ........ 26

1.4 General Safety Information .............. 26

1.5 Electric Safety Instructions ..............26

1.6 Warning Information and Symbols .. 27

2. Product information .............................. 27

2.1 Use for the Intended Purpose ......... 27

2.2 Use other than that for the Intended

Purpose ........................................... 27

2.3 Product Description.........................27

3. Overview of models .............................. 28

4. Scope of delivery................................... 28

4.1 Special Accessories ........................28

5. Technical Data ....................................... 29

6. Overview of functions ........................... 30

7. Functional description .......................... 31

7.1 Method of Functioning..................... 31

7.2 Amalgam separation Separation..... 31

7.3 Filling Level Measurement .............. 31

7.4 Equipment Failure ........................... 32

7.5 Service Button ................................. 32

Assembly

8. Installation hints ....................................33

8.1 Installation Room ............................. 33

8.2 Installation Site ................................ 33

8.3 Combination Facilities ..................... 34

8.4 Planning a Pressure Equalising Pipe or

Air Demixer ......................................34

8.5 Hose Material .................................. 34

8.6 Hose Laying .................................... 34

8.7 Odour Trap ......................................35

9. Installation of AZ 50 .............................. 35

9.1 Fixing the AZ 50 in Place ................ 35

9.2 Fixing the Pressure Equalising Pipe in

10. Electrical connection............................. 36

11. Putting into operation ........................... 37

12. Tips for tracing faults............................ 38

Place ................................................35

10.1 Mains Connection via Earthing-

Contact Type Socket ....................... 36

10.2 Fixed Mains Connection ..................36

10.3 Electrical Connection in AZ 50 ........36

10.4 Display Module................................37

11.1 Functional Check ............................. 37

11.2 Visual Check ................................... 37

11.3 Service Button .................................37

11.4 Emergency Program ....................... 37

13. Service-Programm ................................ 40

Functional sequence ........................... 41

13.1 Start .................................................41

13.2 Indicator Test .................................. 41

13.3 Safety Switch ..................................41

13.4 Motor Running and Braking Action 41

13.5 Sediment Scanning ........................41

13.6 Output Signals ................................41

13.7 Stop .................................................41

14. Transport of the AZ 50 ........................ 42

Use

15. Operation................................................43

15.1 Ready for Operation State ...............43

15.2 Amalgam Collecting Vessel

95% full ............................................43

15.3 Amalgam Collecting Vessel

100% full ..........................................43

15.4 Fault ................................................. 44

16. Cleaning and disinfection..................... 44

17. Replacing the amalgam

collecting vessel.................................... 44

17.1 BEFORE replacing the amalgam

collecting vessel, please observe the

following:.......................................... 44

17.2 Replacement of Amalgam Collecting

Vessel .............................................. 44

17.3 Disposal of Amalgam Collecting

Vessel .............................................. 44

18. Maintenance........................................... 45

18.1 Annual Testing of Indicators on

Display Module ................................ 45

18.2 Testing for Proper Working Order -

Every 5 Years...................................46

18.3 Inspection of the Centrifugal Pump -

Every 2 Years...................................46

19. Disposal of the machine .......................46

Spare parts

AZ 50 ....................................................... 48-49

27

Page 4

IMPORTANT INFORMATION

1. NOTE

1.1 CE-marking

•CE-marking in accordance with the

Machinery Directives.

•The product bears the CE-marking

in accordance with the directive governing

Machinery Directives 89/392/EWG and

conforms to the basic requirements of that

Directive.

1.2 General Information

• The Installation and Operating Instructions

form an integral part of the machine. They

must be kept close to the machine and in

readiness whenever required. Precise

observance of these instructions is a prior

condition for use of the machine for the

intended purpose and for its correct

operation.

• Safety for the operator as well as troublefree operation of the machine are only

ensured if use is made of original equipment

parts. Moreover, use may only be made of

those accessories that are specified in the

technical documentation or that have been

expressly approved and released by Dürr

Dental for the intended purpose.

If and where use is made of accessories or

consumer supplies from outside sources,

Dürr Dental are unable to assume any

guarantee for safe operation or safe

functioning.

• No warranty claims are accepted in respect

of damage arising from the use of

accessories or consumer supplies from

outside sources.

• Dürr Dental only regard themselves as

being responsible for the machines

regarding safety, reliability and proper

functioning if assembly, resettings, changes

or modifications, extensions and repairs

have been carried out by Dürr Dental or an

agency authorised by Dürr Dental and if the

machine is used in conformity with the

Installation and Operating Instructions.

• The Installation and Operating Instructions

conform to the relevant version of the

machine and the underlying safety

standards valid at the time of going to press.

All proprietary rights are reserved in respect

of the specified circuitry, methods, names,

software programs and equipment.

• Any reprinting of the technical

documentation, in whole or in part, is

subject to written prior approval of Dürr

Dental.

1.3 Electromagnetic Compatibility

EN 60601-1-2 and IEC 1000-4-3 EN Standards governing Electromagnetic

Compatibility - Medico-electrical Equipment

are fully complied with.

1.4 General Safety Information

• Dispose of the packaging material in the

proper manner, and make sure that it is kept

out of the reach of children.

• The product is classified as medicotechnical equipment and may only be used

by such persons as can guarantee that they

will handle it properly on account of their

training and/or technical knowledge.

• Each time prior to using the machine the

user must check to ensure that it is

functionally safe and in proper condition.

• The user must be familiar with how to

operate the machine.

• The product is not intended for use in areas

of rooms employed for medical purposes

that are exposed to risk of explosion.

Explosion hazards may result from the use

of inflammable anaesthetics, skin cleansing

agents, oxygen and skin disinfectants.

Moreover the machine is only suitable to a

limited extent for operation in a combustionstimulating atmosphere.

1.5 Electric Safety Instructions

• The AZ 50 must be connected up to a

properly installed earthing-contact type

socket. For fixed connections please

observe points 9 and 10 of these

instructions.

• Prior to connecting up the machine a check

must be carried out to see whether the

mains voltage and mains frequency

specified on the machine conform to the

data applicable to the supply mains.

• No extension cables or leads must be used

for power supply purposes.

28

Page 5

• Prior to being put into operation, the

machine and the lines

for damage. Damaged lines, socket outlets

and plugs must be replaced immediately.

• Never touch the patient and non-protected

socket outlets or plugs of the machine at the

same time!

need to be inspected

for damage resulting therefrom. All risk is

borne solely by the user.

Use for the intended purpose includes

observance of the Installation and Operating

Instructions as well as the installation,

operating and maintenance conditions.

The machine must not be used in

operating rooms.

1.6 Warning Information and Symbols

In the Installation and Operating Instructions

use is made of the following terms or symbols

to denote data or information of special

importance:

Angaben bzw. Ge- und Verbote zur

Information and/or mandatory

regulations or prohibitions for the

prevention of personal injury or

substantial property damage.

Warning of dangerous electrical

voltage.

Special information regarding the

economical use of the machine and

other information

Floating Application Part Type BF

CE Marking without Notified Body

Number

Observe Instructions for Use

To protect operating personnel

working on the AZ 50, protective

gloves must be worn.

2. PRODUCT INFORMATION

2.1 Use for the Intended Purpose

The function of the Dürr Amalgam Separator is

to separate and intercept heavy metals and

amalgam dust drawn off by dental suction

equipment in the form of fillings that have

been drilled open.

The amalgam separator is intended for

installation of a maximum number of two

treatment units in dental surgeries or dental

clinics.

Any other use or use beyond what is

specified is deemed to be not for the intended

purpose. The manufacturer accepts no liability

2.2 Use other than that for the

Intended Purpose

Any other use or use beyond what is

specified is deemed to be not for the intended

purpose. The manufacturer accepts no liability

for damage resulting therefrom. All risk is

borne solely by the user.

2.3 Product Description

Among other substances, heavy metals and

amalgam dust accumulate, drawn off by

dental suction equipment in the form of fillings

that have been drilled out. Biodegradation of

amalgam that has found its way into the

waste-water system is a difficult undertaking.

To reduce contamination in waste water

caused by heavy metal stemming from dental

treatment equipment, it is essential - in

compliance with the General Sewage Administration Regulations (Annex 50, Dental

Treatment) in force in Germany - to install

amalgam separators ahead of the dental

waste-water drain furnished with a seal of

approval issued by the German Institute of

Structural Engineering in Berlin.

The AZ 50 Amalgam Separator has been

designed by Dürr Dental to produce the

required separation efficiency factor of over 95%

proceeding based on a rate of flow of 8 ltr./min.

Amalgam slurry is intercepted in an amalgam

collecting vessel underneath the centrifuge

drum. Depending on the volume accumulating,

the amalgam collecting vessel needs replacing

once or twice a year.

The AZ 50

used in conjunction with a Dürr Suction Unit

VS 300.

The AZ 50

employed in connection with water ring pumps.

withoutwithout

without Pump (Model 7112-01) is

withoutwithout

withwith

with Pump (Model 7112-02) is

withwith

29

Page 6

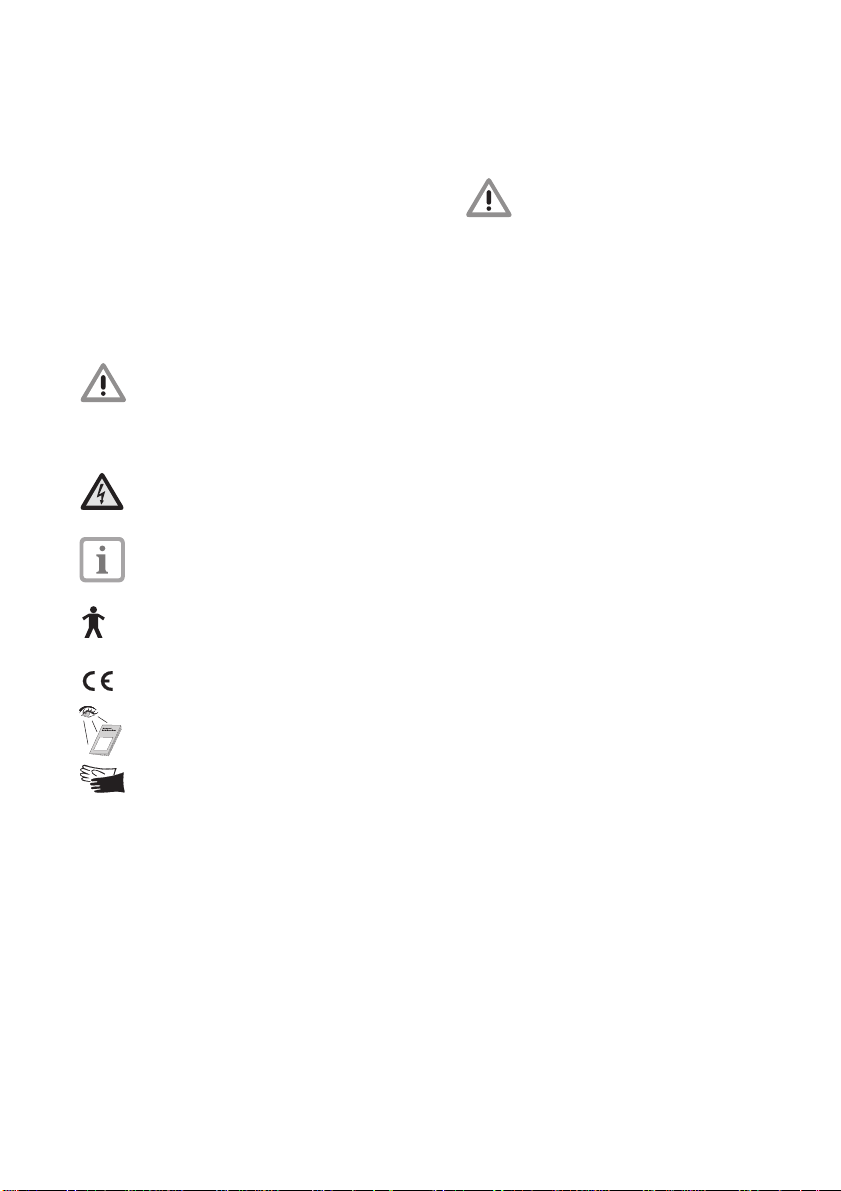

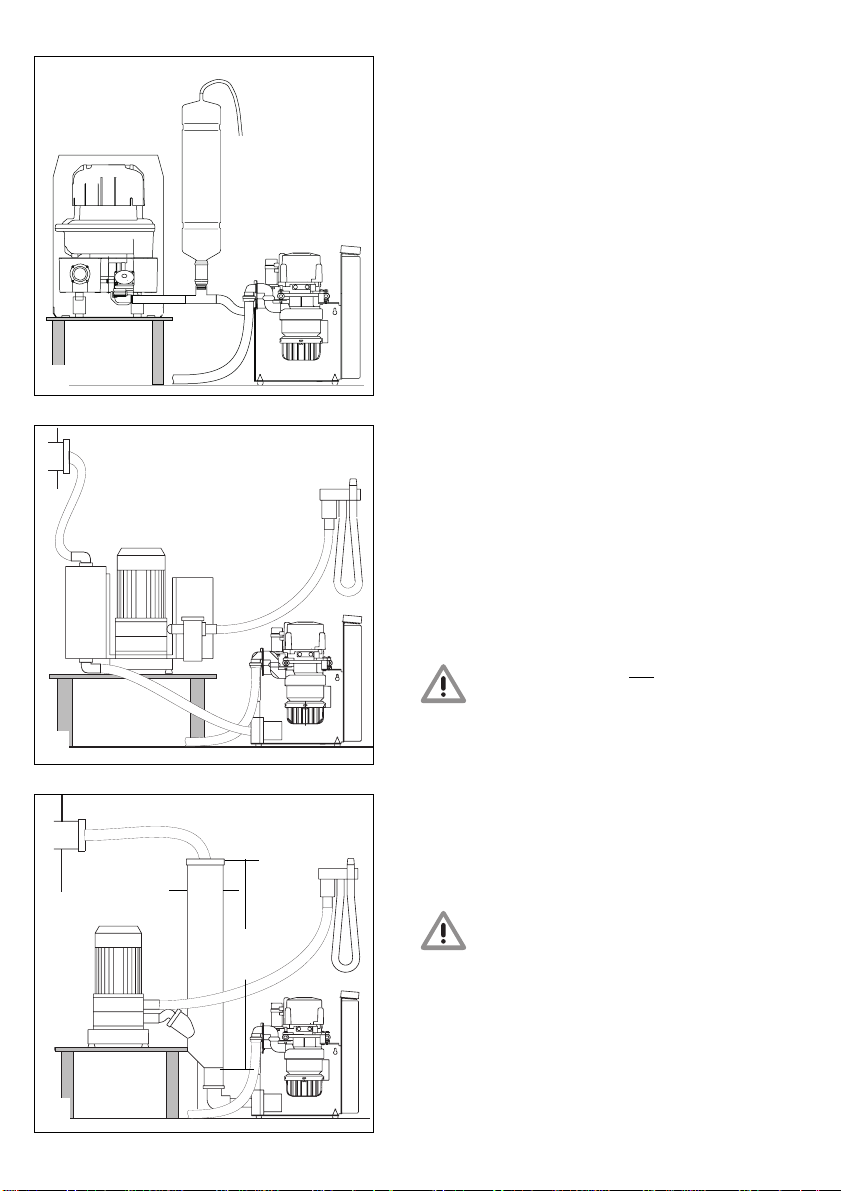

3. OVERVIEW OF MODELS

4. SCOPE OF DELIVERY

Amalgam Separator

AZ 50 without Pump.......................... 7112-01

Amalgam Separator

AZ 50 with Pump ............................... 7112-02

Amalgam Separator AZ 50

without Pump..................................... 7112-01

Amalgam Separator .................... 7112-100-50

Pressure Equalising Pipe ............ 7112-101-00

Accessories, complete ............... 7112-001-00

Installation and Operating

Instructions AZ 50 .................. 9000-605-95/01

Instructions for Use - Disinfection

and Cleaning of Suction Systems 9000-605-10

Amalgam Separator AZ 50

with Pump ..........................................7112-02

Amalgam Separator .................... 7112-100-51

Accessories, complete ............... 7112-001-00

Installation and Operating

Instructions AZ 50 .................. 9000-605-95/01

Instructions for Use - Disinfection

and Cleaning of Suction Systems 9000-605-10

4.1 Special Accessories

The parts listed below are

scope of delivery.

Please order as required.

Base for PAL 14 .......................... 7112-992-00

Base for PAL 50 .......................... 7112-993-00

Hood ............................................ 7112-200-00

Remote Indicator ......................... 7110-994-00

Test Set, complete ...................... 7110-064-00

notnot

not included in the

notnot

30

Page 7

7112-01

7112-02

5. TECHNICAL DATA

Model 7112-01 without Pump

Model 7112-02 with Pump

Electrical Rating

Voltage (V) 230

Frequency (Hz) 50

Max. Current Consumption (A) 1,7

Centrifuge Motor

Voltage (V) 230

Frequency (Hz) 50

Max. Current Consumption (A) 0,95

Rated Speed (1/min) 2780

Rated output (W) 90

Elektronic System

Protective Low Voltage (V) AC/DC24

Current Delivery (A) max.0,7

Rate of Flow

Volume of Secretion (l/min) max. 8

Amalgam Collecting Vessel

Usable Volume (ccm) ca.150

Replacement Interval (Monate) ca. 6-9

A Vakuum-Anschluß, Schlauch D=25mm

B Abwasser-Anschluß,Schlauch D=25mm

Dimensions

7112-01: D = 14cm, L = 32,8cm, H = 36cm

7112-02: D = 14cm, L = 38cm, H = 36cm

Temperature Range

Machine in operation ....... +10 to +40 °C

Storage and transport .......... -25 bis +70 °C

Atmospheric Humidity

Machine in operation ...................... max. 80%

Storage and transport ..................... max. 95%

Weight

7112-01 ................................ approx. 7.5 kg

Inspection label

• CE-label

• Institut für Bautechnik, Berlin:

General Structural Supervisory Approval

with Inspection label: Z-64.1-13

• Electromagnetic Compatibility Test in

accordance with IEC 1000-4-3 EN V 50 140

regarding high-frequency irradiation 3 V/M

corresponds to EN 60 601-1-2.

31

Page 8

6. OVERVIEW OF FUNCTIONS

32

16 15

14

13

17

Page 9

7. FUNCTIONAL DESCRIPTION

1 Centrifuge Drum

2 Light Barrier

3 Solenoid Coil

4 Probe

5 Level Pump

6 Amalgam Particles

7 Collecting Vessel

8 Motor

9 Speed Monitoring Unit

10 Motor Fan

11 Safety Switch

12 Centrifugal Pump

13 Yellow LED Indicator

14 Pushbutton

15 Orange LED Indicator

16 Green LED Indicator

17 Display Module

7.1 Method of Functioning

The function of the AZ 50 Amalgam Separator

is to provide continuous amalgam separation

in all waste water stemming from the treatment

units.

During the process of suction removal, the

secretion that is drawn off is separated from

the suction air in the upstream suction unit.

The secretion that accumulates continuously

enters the centrifuge drum (1) in which the

particles of amalgam are retained by

centrifugal forces.

Mounted below the centrifuge drum (1) is a

replaceable collecting vessel (7) into which

the separated particles of amalgam (6) are

flushed after the motor (8) has been switched

off. A probe (4) serves to check the filling level

inside the collecting vessel (7) and indicates

on the display module (17) when the vessel

needs changing. A secure turn-lock fastener

serves to facilitate replacement and closure of

the collecting vessel (7).

The compact dimensions of the AZ 50 makes

it possible to install the separator close to the

treatment units, thus resulting in short

secretion-flow channels. Sturdy features of

design on the amalgam separator serve to

warrant reliable functioning. After the

centrifuge drum has been switched off, a

braking cycle provides a self-cleaning effect.

This caters for extremely quiet running

combined with a reliable separation efficiency

factor exceeding 95% even when subjected to

maximum loading.

7.2 Amalgam separation Separation

Microswitches located in the hose manifold or

in the spittoon serve to activate the motor (8)

(see wiring diagram). The amalgamcontaminated secretion arriving from the

suction unit is retained by centrifugal forces in

the centrifuge drum (1) of the AZ 50.

Hooking the suction hoses into the hose

manifold serves to switch off the motor (8).

The motor (8) receives a switch-off signal and

immediate braking takes place of the

centrifuge drum (1) which is brought to an

immediate standstill so that inertia produced

by the rotating water ring flushes the separated

particles out of the centrifuge drum (1)

downwards into the collecting vessel (7).

A level pump (5) connected to the centrifuge

drum (1) maintains the liquid inside the

collecting vessel (7) at a constant level. This

prevents any escape of liquid when changing

the collecting vessel (7).

7.3 Filling Level Measurement

The filling level in the collecting vessel (7) is

checked by a probe (4) each time the main

switch is switched on. The filling level is also

scanned every 12 hours when the AZ 50 is

switched on.

The solenoid coil (3) triggers the scanning

process, whereupon the probe (4) attracted

by gravity sinks under its own weight. The

filling level is measured via a light barrier (2)

and indicated on the display module (17)

when reaching 95%.

As soon as the collecting vessel (7) has filled

up with amalgam slurry to a level of 95 %, the

green LED (16) will be accompanied by a

permanent yellow LED (13) appearing on the

display module (17). In addition a hooter will

sound which can be silenced by briefly

pressing pushbutton (14). Afterwards the

amalgam separator will be “READY FOR

OPERATION” once more.

The yellow LED (13) lights up as a reminder to

change the vessel.

Each time the main switch is switched on

these warnings will continue to be displayed

until the vessel has been replaced.

As soon as the filling level has attained 100 %

the green LED (16) will go out and the yellow

LED (13) will light up permanently, the orange

LED (15) will start flashing and the hooter will

sound. In this case, the hooter

silenced by pushbutton control. The amalgam

separator will then be placed out of service

cannotcannot

cannot be

cannotcannot

33

Page 10

new collecting vesselnew collecting vessel

until a

new collecting vessel (7) has been

new collecting vesselnew collecting vessel

fitted. After the vessel has been replaced the

AZ 50 can be put into normal operation once

again.

16

7.4 Equipment Failure

15

If failure occurs on the amalgam separator

due to a technical defect, a fault alarm will be

14

indicated on the orange LED (15). In addition,

13

a hooter will sound which can be silenced by

pressing pushbutton (14).

The “FAULT” indicator is triggered for

example by a motor (8) defect via a speed

monitoring unit (9), defect on the motor fan

(10) or by absence of collecting vessel (7)

unleashed by a safety switch (11).

7.5 Service Button

If pushbutton (14) is pressed for longer than 2

seconds, the motor (8) will start up. If the

suction unit is activated during this process by

lifting up the suction hoses, the hoses can be

cleaned and disinfected in this way along with

the amalgam separator. To do this, switch on

the rinsing basin or place the hoses onto the

Orocup filled with disinfectant.

If the orange LED (15) lights up, the amalgam

separator can be started up manually by

pressing pushbutton (14) for at least 2 sec.

If, in response to pressing pushbutton (14)

several times, a fault alarm is registered each

time or if the amalgam separator fails to start

up after pressing pushbutton (14), this is a

sign of a technical defect having occurred.

34

Page 11

ASSEMBLY

8. INSTALLATION HINTS

8.1 Installation Room

• The room temperature must not be allowed

to fall below + 10 °C in winter or rise above

+ 40 °C in summer.

• Installation in purpose-built rooms, e.g.

heating plant room must be clarified

beforehand as regards building legislation.

• Installation in wet rooms is not permissible.

8.2 Installation Site

• The Amalgam Separator AZ 50 must be

placed directly next to or at a distance not

exceeding 30 cm away from the suction

unit.

If the spacing distance between the

AZ 50 and the suction unit is too

great combined with failure to

ensure correct hose laying, there is

a risk of the secretion not being

conveyed as it should.

• If installing the amalgam separator in

conjunction with a Dürr Suction Unit VS 300

space needs to be provided for the pressure

equalising pipe.

• The amalgam separator can be mounted as

follows:

Directly on the wall.

Use Mounting Set, Part no. 7801-003-00

(included in accessories).

35

Page 12

8.3 Combination Facilities

The Amalgam Separator AZ 50 can be

combined with the following suction machines:

VS 300

• AZ 50 combined with the Dürr Suction Unit.

VS 300

• AZ 50 combined with water ring pumps.

8.4 Planning a Pressure Equalising

Pipe or Air Demixer

To cater for proper pressure equalisation in

the suction system between the amalgam

separator and the suction unit, a pressure

6

PAL

equalising pipe or air demixer needs to be

mounted in conjunction with the following

combinations:

7112-017112-01

•

7112-01 - Pressure equalising pipe from

7112-017112-01

Dürr Dental - to be mounted in conjunction

with the Dürr Suction Unit VS 300!

7112-02 7112-02

•

7112-02 - Air demixers,

7112-02 7112-02

Dental must be mounted with a water ring

pump, e.g. Dental EZ!

notnot

not supplied by Dürr

notnot

8.5 Hose Material

In conjunction with the amalgam separator

use may only be made of flexible PVC spiral

hoses with integral spiral or equivalent hoses.

The following must not be used:

Hoses not resistant to dental

disinfectants and chemicals as well

as rubber hoses or solid PVC hoses

7

that are insufficiently flexible.

36

8

Dental EZ

10cm

100cm

8.6 Hose Laying

Hose laying

i.e. between the suction unit or water ring

pump and the AZ 50 must proceed observing

a slope. The hose length must not be allowed

to exceed 30 mm.

Hoses positioned

5050

50 must observe a slope.

5050

upstream or ahead of the AZ 50upstream or ahead of the AZ 50

upstream or ahead of the AZ 50,

upstream or ahead of the AZ 50upstream or ahead of the AZ 50

On the VS 300 the entrance to the

amalgam separator must not be

higher than the exit of the suction

machine, otherwise there will be a

risk of liquid and sediment flowing

back into the suction machine.

downstream or after the AZdownstream or after the AZ

downstream or after the AZ

downstream or after the AZdownstream or after the AZ

Page 13

8.7 Odour Trap

The drain on the AZ 50 must be connected via

an odour trap by the user.

9. INSTALLATION OF AZ 50

Integration of the Amalgam AZ 50 into

existing or new suction drawoff systems:

9.1 Fixing the AZ 50 in Place

• If mains connection proceeds via an

earthing-contact type socketearthing-contact type socket

earthing-contact type socket (wired to the

earthing-contact type socketearthing-contact type socket

equipment or surgery main switch) the

50 need not be fixed in position50 need not be fixed in position

50 need not be fixed in position.

50 need not be fixed in position50 need not be fixed in position

• Where

• Fix the amalgam separator in a suitable

fixed mains connectionfixed mains connection

fixed mains connection of the AZ 50

fixed mains connectionfixed mains connection

takes place on terminal strips via the

equipment or surgery main switch the

must be fixed in positionmust be fixed in position

must be fixed in position.

must be fixed in positionmust be fixed in position

Refer to point 10 “Electrical Connection” for

this.

directly next to or at a distance notdirectly next to or at a distance not

place

directly next to or at a distance not

directly next to or at a distance notdirectly next to or at a distance not

exceeding 30 cmexceeding 30 cm

exceeding 30 cm from the suction unit or

exceeding 30 cmexceeding 30 cm

water ring pump with a dowel and screw

connection made to a shelf, wall or angle

frame.

If the spacing distance between the

AZ 50 and the suction unit is too

great combined with failure to

ensure correct hose laying, there is

a risk of the secretion not being

conveyed as it should.

AZAZ

AZ

AZAZ

AZ 50AZ 50

AZ 50

AZ 50AZ 50

9.2 Fixing the Pressure Equalising

Pipe in Place

The pressure equalising pipe as supplied

needs to be mounted in the connecting hose

between the Dürr Suction Unit VS 300 and the

Amalgam Separator AZ 50.

37

Page 14

10. ELECTRICAL CONNECTION

Electrical connection must proceed via the

main switch of the treatment unit or the

surgery main switch.

The leads or cables to the machine

must be laid without any stress or

strain (strain relief clamps).

10.1 Mains Connection via EarthingContact Type Socket

Where the mains connection, 230V, proceeds

earthing-contact type socketearthing-contact type socket

via an

earthing-contact type socket, this must

earthing-contact type socketearthing-contact type socket

be wired to the equipment or surgery main

switch.

10.2 Fixed Mains Connection

In the case of fixed mains connection, 230V

connection proceeds on suitable terminals

behind the main switch of the treatment unit

via the equipment or surgery main switch.

Line cross section: 0.75 mm

2

10.3 Electrical Connection in AZ 50

Connection of the control contact on the

suction unit or water ring pump takes place on

the marked terminals inside the terminal box

of the AZ 50.

Connection of the contact in the hose

manifold, dental mouth-rinsing basin valve,

position selection valve and flushing system

(built into the treatment unit) proceeds via the

control cable.

1, 2 and 3 in terminal box of AZ 50.

,,

,

,,

38

Page 15

10.4 Display Module

The display module should be visible and

audible at all times. For that reason, it needs

to be mounted in a place where it can be

easily observed.

A display module is mounted to the AZ 50. If

the machine is located in a clearly visible

place in the surgery, no further display module

will be required.

If the separator is not located in the dental

surgery, an

mounted. Again, this should be located in a

place where it can be easily observed, e.g.

mounted to the treatment unit. Connection to

the AZ 50 proceeds via a 6-core cable and

distribution box.

additionaladditional

additional display module can be

additionaladditional

11. PUTTING INTO OPERATION

• Switch on equipment or surgery main

switch. As soon as the green LED lights up,

the AZ 50 will be ready for operation.

• Carry out functional check and also check

the connections for tightness.

11.1 Functional Check

• To perform this check, switch on the

equipment or surgery main switch. The

sensor will be heard to fall as it proceeds to

measure the filling level.

11.2 Visual Check

Check connections, hoses and AZ 50 for

tightness, sealing if necessary. For this

purpose, proceed to lift up the suction hose

and switch on the basin flushing system. This

starts up the AZ 50 and the liquid is transported

to the centrifuge drum from where it flows into

the drain.

11.3 Service Button

Press the service button (14, page 8) for at

least 2 sec. This serves to start up the

centrifuge motor which will be braked to a

standstill after approx. 30 sec.

11.4 Emergency Program

In the event of failure occurring on the AZ 50

for technical reasons, short-time operation of

the suction unit will be possible despite this

failure. In that case, the secretion drawn off by

suction from the patient’s mouth will continue

to be pumped into the AZ 50. The AZ 50 will

then act as a sediment separator but will need

to be repaired as quickly as possible.

39

Page 16

12. TIPS FOR TRACING FAULTS

Faults Possible Cause

1. No indication on display module,

separator not “READY FOR

OPERATION”

2. Yellow LED appears on display

module,

centrifuge motor fails to start up Fault

• Main switch on treatment unit or surgery main switch

not switched on.

• Cable fault or display module defective.

• Orange LED lights up, safety switch (11, page 30)

activated or winding burned out.

• Mains fuse defective.

• Motor jammed.

40

Page 17

Solution

• Switch main switch of treatment unit or surgery main switch to “ON” position.

• Replace cable or display module.

• Collecting vessel incorrectly inserted or safety switch defective; if necessary replace switch or

AZ 50.

• Centrifuge motor defective, remove any particles that may be present in the pump area or

centrifuge drum. Replace fuse.

• Check to ensure that the centrifuge motor is running properly, remove any particles that may be

present in the pump area or centrifuge drum.

41

Page 18

13. SERVICE-PROGRAMM

42

Page 19

FUNCTIONAL SEQUENCE

In order to be able to check whether the AZ 50

is working properly, a service program can be

activated. The various program steps are as

follows:

• To effect STARTUP press start button on

display module while simultaneously

switching the main switch to ON.

• Indicator Test:

Green, orange and yellow LEDs light up.

• Safety limit switch

Switching-on signal for AZ 50.

• Motor run.

• Sediment filling-level measurement.

• Output signal AZ 50 for suction unit:

Yellow LED lights up.

• Stop

Pressing the service button

continue the sequence of program steps.

Pressing the service button

repeat a program step. Startup of the service

program is indicated by an audible signal tone

in addition to the 3 LEDs.

13.1 Start

To start the service program, keep the service

button pressed down on the display module

and switch on the voltage supply to the AZ 50.

As soon as the signal tone is heard, let go of

the service button.

13.2 Indicator Test

During the indicator test all three LEDs light

up in addition to a signal tone being heard.

13.3 Safety Switch

During this program step various input signals

undergo evaluation and are visible on the

display module. In addition to LED indication a

signal tone will sound.

In the normal state, the LEDs are switched off.

twicetwice

twice serves to

twicetwice

onceonce

once serves to

onceonce

13.4 Motor Running and Braking

Action

Starting up this program step automatically

activates the motor and causes the motor to

slow down after approx. 12 sec. This test step

can be repeated by pressing the service

button once only. In that case the motor

running action must be switched off by

pressing the service button once more.

During the program step Motor Running and

Braking Action the various speed ranges are

represented on the display module by

different LEDs.

The no-load speed is set to 2800 RPM.

13.5 Sediment Scanning

This program step serves to check the

sediment probe for proper functioning.

Each time the service button is pressed, the

sediment probe will descend. If use is made

test vesseltest vessel

of a

test vessel, the various filling levels can

test vesseltest vessel

be scanned and rendered visible on the

display module.

13.6 Output Signals

In the course of this program step, various

output signals are activated simultaneously

which can then be measured as a voltage on

different connectors.

The specified voltages are optimum values.

• Yellow LED on display module of AZ 50.

• Control signal for suction unit X 6 contact 1

& 2 has connected through (relay

responded).

13.7 Stop

Quit the service program (stop=display off) by

switching off the voltage supply on the

treatment unit.

Pressing the service button twice at the end of

the program will return you to the beginning of

the program again.

• Open collecting vessel, safety switch is

actuated => orange LED lights up.

• Remove suction hose for hose

manifold => green LED lights up.

43

Page 20

14. TRANSPORT OF THE AZ 50

Should it be necessary to move the Amalgam

Separator AZ 50 to a different place, the

following action needs to be taken prior to

transporting the unit:

• Clean and disinfect the suction system.

• Remove the contaminated collecting vessel

and replace by a new collecting vessel.

• Do not turn the AZ 50 upside down as

otherwise dirt will enter the centrifuge drum

and cause congestion.

44

Page 21

USE

16

15. OPERATION

15

15.1 Ready for Operation State

14

13

Green LED (16) lights up.

15.2 Amalgam Collecting Vessel

95% full

Green LED (16) lights up.

and

yellow LED (13) lights up.

and

hooter sounds.

• As soon as the 95% filling level

the hooter can be switched off by pressing

pushbutton (14). Afterwards the

green LED (16) - Amalgam Separator

“Ready for Operation” will light up.

1

2

• The yellow LED

of the necessity to replace the amalgam

collecting vessel.

The amalgam collecting vessel needs

to be replaced as soon as a filling

level of 95% is attained.

Refer to point 17 for this.

(13) lights up as a reminder

is attained,

15.3 Amalgam Collecting Vessel

100% full

Yellow LED (13) lights up.

and

orange LED (15) starts flashing.

and

hooter sounds.

• Once the 100% filling level

will no longer be possible to switch off the

hooter by pressing pushbutton (14).

• The AZ 50 will not be “Ready for Operati-

on” again until the amalgam collecting

vessel has been replaced.

is attained, it

45

Page 22

15.4 Fault

Orange LED (15) starts flashing

and

hooter sounds

• The hooter can be silenced by briefly

pressing pushbutton (14).

• If pushbutton (14 ) is held down for

than 2 seconds

be started up once more.

• Green LED (16) lights up denoting “Ready

for Operation”.

• If, in response to pressing pushbutton (14)

several times, a fault alarm is registered

each time, this is a sign of a technical defect

having occurred.

Call technician.

For hints to assist the dental

technician in locating the fault,

please refer to point 12.

the amalgam separator can

longer

16. CLEANING AND

DISINFECTION

A material-compatible, non-foaming

disinfectant for suction systems is prescribed

for cleaning and disinfecting the entire suction

system including the amalgam separator and

the water volume linked to the collecting

vessel.

We recommend cleaning and

disinfection of the suction system

twice a day.

Further information will be gathered

from the Instructions for Disinfecting

and Cleaning Suction Systems, Part

no. 9000-605-10.

17. REPLACING THE AMALGAM

COLLECTING VESSEL

17.1 BEFORE replacing the amalgam

collecting vessel, please observe

the following:

• Replace the amalgam collecting vessel in

the MORNING!

We recommend that the amalgam collecting

vessel always be replaced in the morning

prior to the commencement of work. This

serves to prevent liquid from dripping out of

the drum during replacement.

17.2 Replacement of Amalgam

Collecting Vessel

• Switch off the main switch of the treatment

unit.

If the collecting vessel is unscrewed

without the treatment unit having been

switched off, the orange LED will start

flashing and the hooter will sound.

• Remove the empty collecting vessel from

the carton and screw off the lid.

To reduce the risk of infection, we

recommend that liquid-proof gloves be

worn while replacing the collecting

vessel.

• Hold the collecting vessel attached to the

AZ 50 from underneath, turn in direction of

arrow and remove downwards.

• Cut the disinfectant bag open at one of the

corners and pour the contents into the full

collecting vessel.

The disinfectant causes acid burns.

If coming into contact with the eyes,

rinse thoroughly with water and

seek medical advice. If coming into

contact with the skin, wash off with

soap and water.

• Seal the lid on the full

paying careful attention to the markings on

the lid. If the lid is properly sealed, these

markings should face one another.

• Place the sealed collecting vessel in the

transport carton, seal and secure with

adhesive tape to prevent accidental

opening.

• Insert the empty collecting vessel in the AZ

50 from underneath and turn in the direction

of the arrow as far as it will go.

The AZ 50 is now “Ready for Operation”

once more.

collecting vessel,

17.3 Disposal of Amalgam Collecting

Vessel

Write the name and address of the recycling

enterprise on the transport carton and send to

authorised disposal company by post or by

other means.

Relevant national regulations must be

observed.

46

Page 23

18. MAINTENANCE

• Depending on the volume accumulating, the

amalgam collecting vessel will need

16

replacing once or twice a year.

15

14

13

To reduce the risk of infection, we

recommend that liquid-proof gloves be

worn while replacing the collecting

vessel.

18.1 Annual Testing of Indicators on

Display Module

This test must be carried out by suitably

trained personnel.

Accessories needed for testing

1 Test vessel

••

• Testing the green LED (16)

••

After the main switch is switched on, the

green LED should light up denoting that the

machine is “Ready for Operation”.

••

• Testing the orange LED (15) and

••

pushbutton (14)

- Remove collecting vessel. The orange LED

(15) should now light up and the hooter

should sound as well.

Pressing pushbutton (14) should silence

the hooter, while the orange LED will

continue to flash.

To reduce the risk of infection, we

recommend that liquid-proof gloves be

worn while replacing the collecting vessel.

• Testing the yellow LED (13)

- Position main switch to OFF

- Remove collecting vessel, insert test

vessel, close and set to 100% filling level.

- Position main switch to ON

After sediment querying has been carried

out, the yellow LED should now light up, the

orange LED will respond by flashing and

the hooter will sound.

- Position main switch to OFF

- Remove test vessel.

- Insert collecting vessel (7) and close.

Remember to record the results of the test

in operating log book!

47

Page 24

18.2 Testing for Proper Working

Order - Every 5 Years

This test should be carried out by an inspector

every 5 years observing national statutory

regulations (in accordance with the General

Sewage Handling Regulations, Annex 50,

Dental Treatment).

Required tools and equipment:

1 Phillips screwdriver

1 Test vessel

1 Measuring cup

• Remove collecting vessel. During this

process the orange LED on the display

module should respond by flashing and the

hooter should sound as well. The hooter can

be silenced by pressing pushbutton (14,

page 23) on the display module.

• Insert test vessel.

• Press pushbutton (14) on the display

module and the green LED denoting

“READY FOR OPERATION” should light up

once more.

• Turn on dental mouth-rinsing basin and

draw off at least 200 ml water via suction

hose. Hook suction hose back in place.

• After the AZ 50 has switched off, remove the

test vessel and pour the water contained in

the vessel into a measuring cup.

If contents exceed 70 ml this denotes that

the AZ 50 is in proper working order.

An operating log book must be kept

by the user covering all maintenance

work. See “OPERATING LOG BOOK

FOR DÜRR AMALGAM SEPARATOR”,

Part no. 9000-605-72

18.3 Inspection of the Centrifugal

Pump - Every 2 Years

Part no. 7112-991-00. Test and clean,

replacing if necessary.

19. DISPOSAL OF THE MACHINE

Substances including heavy metals and

amalgam dust in the form of fillings that have

been drilled open are drawn off via the suction

hoses. To reduce heavy metal contamination in

sewage stemming from dental treatment

equipment, the waste water accumulating must

be disposed of observing the valid general

sewage handling regulations in force in the

country of use.

Components contaminated with amalgam,

such as strainers, filters and hoses, etc. must

likewise be disposed of in accordance with the

respective national regulations.

The AZ 50 can be disposed of in the normal

way.

The built-in control unit, electronics board and

electronic components must be disposed of as

electronic scrap.

48

Loading...

Loading...