EXCEPT AS OTHERWISE NOTED

TOLERANCE: .XXX = ± .XX= ±

SURFACE FINISH

EXCEPT AS NOTED

BREAK EDGES TO DEBURR

RADIUS OR CHAMFER

THESE DIAS TO T.I.R.

FILLETS - MAX RAD.

ALL PART NUMBER LETTERSUFFIXES ARE TOBE INTERPRETED ASFOLLOWS:

I.E. - 107-0000-01 X

M - MACHINED ONLY (UNPLATED) G - MATERIAL HAS BEEN GRAINED

P - PLATED/PAINTED

H - HEAT TREATED E - ENVIRONMENTAL TEST

S - MATERIAL HAS BEEN SAWCUT

ALL DIMENSI0NS IN INCHES

CHATSWORTH, CA.

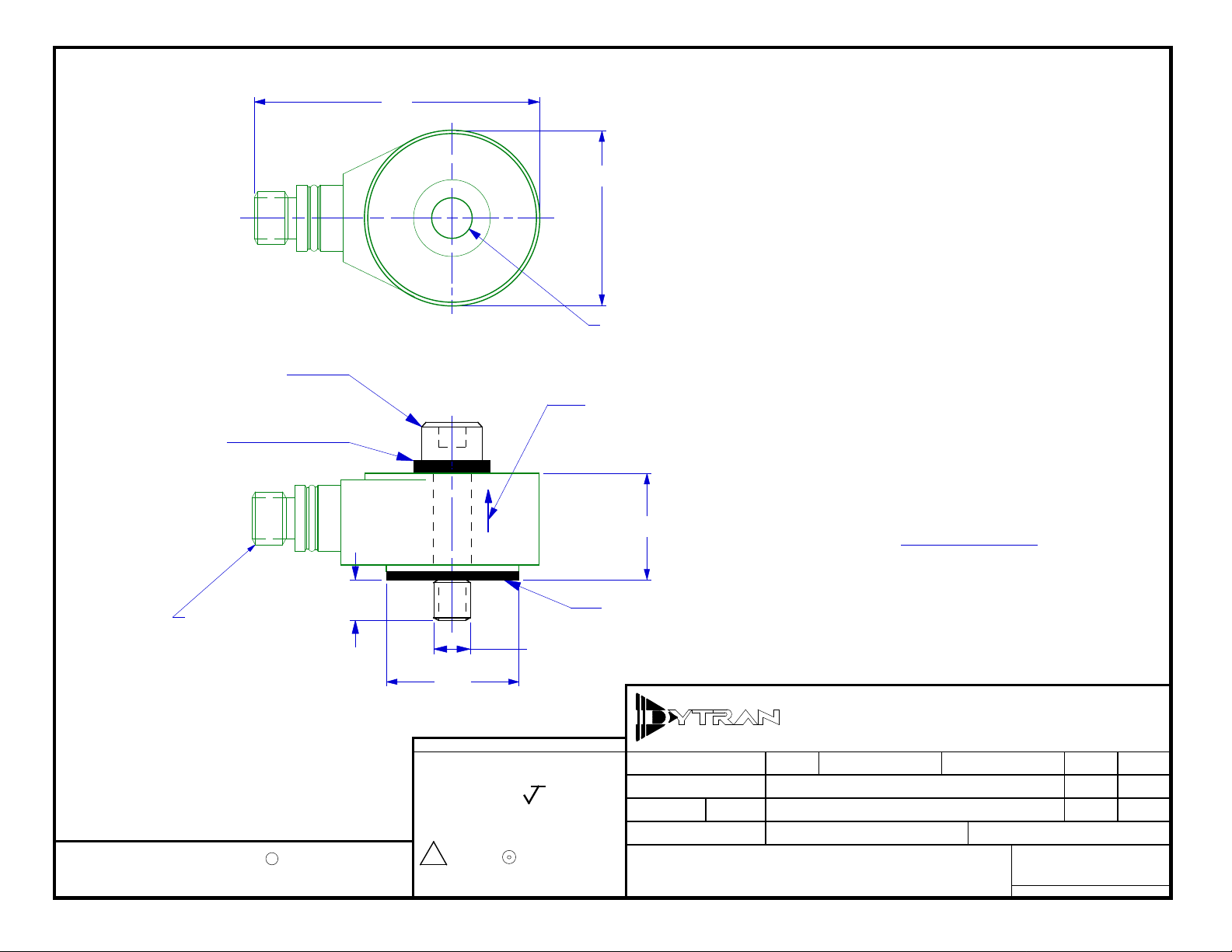

Ø .41

.670

4X

OUTLINE/INSTALLATION DRAWING

MODELS 3220B & 3220C

1

OF

MODEL 3220B & C

127-3220B

4/4/96

D.Z.N.C.

- -

.250

Ø .093 THRUHOLE

-

5-44 COAXIAL

CONNECTOR

MODEL 6165 MOUNTING SCREW

ASSY

(REMOVABLE)

NOT SHOWN IN TOP VIEW

+

.10 REF

2-56 THD (REF)

Ø .31

ANODIZED ALUMINUM

WASHERS (2) FOR GROUND

ISOLATION

ARROW INDICATES SENSE AND

DIRECTION OF ACCELERATION FOR

POSITIVE GOING OUTPUT SIGNAL FOR

MODEL 3220B. 3220C HAS OPPOSITE

POLARITY SIGNAL

1) WEIGHT: 4 GRAMS

2) MATERIAL: 316L STAINLESS STEEL

MOUNTING SURFACE

(ANODIZED ALUMINUM)

INSTRUMENTS, INC.

SCALE

DATE

DRAWN

APPROVED

TITLE

1) PREPARE (OR SELECT) A FLAT MOUNTING

SURFACE OVER A MINIMUM .32 DIAMETER. SURFACE

SHOULD BE FLAT TO .001 TIR FOR BEST HIGH

FREQUENCY RESPONSE.

2) AT THE CENTER, DRILL #50 (Ø .070) X .20 DEEP.

3) TAP #2-56 UNC-2B X .125 MIN DEPTH.

4) CLEAN THE AREA CAREFULLY AFTER MACHINING

TO REMOVE ALL CHIPS AND CUTTING OILS.

DATEREV

PART NO.

CHECKED

MAT'L

PORT PREPARATION

ECN

USED ONNEXT ASSEMBLY

DWG NO.

SHEET

OF

Dynamic Transducers and Systems

21592 Marilla St. • Chatsworth, CA 91311 • Phone 818-700-7818

www.dytran.com • e-mail: info@dytran.com

SPECIFICATIONS MODEL 3220C MINIATURE CHARGE MODE ACCELEROMETER

SPECIFICATION VALUE UNITS

RANGE F.S. 500 G

SENSITIVITY, +/- 20 % [1] 1.5 pC/G

CAPACITANCE, NOM 835 pF

NATURAL FREQUENCY, MOUNTED, NOM. 35 kHz

FREQUENCY RESPONSE, +/- 5% (+/- 15%) 2 to 5,000 (1 to 10,000) Hz

LINEARITY 2 %FS

TRANSVERSE SENSITIVITY, MAX 5 %

OPERATING TEMPERATURE RANGE -60 to +500 DEG F

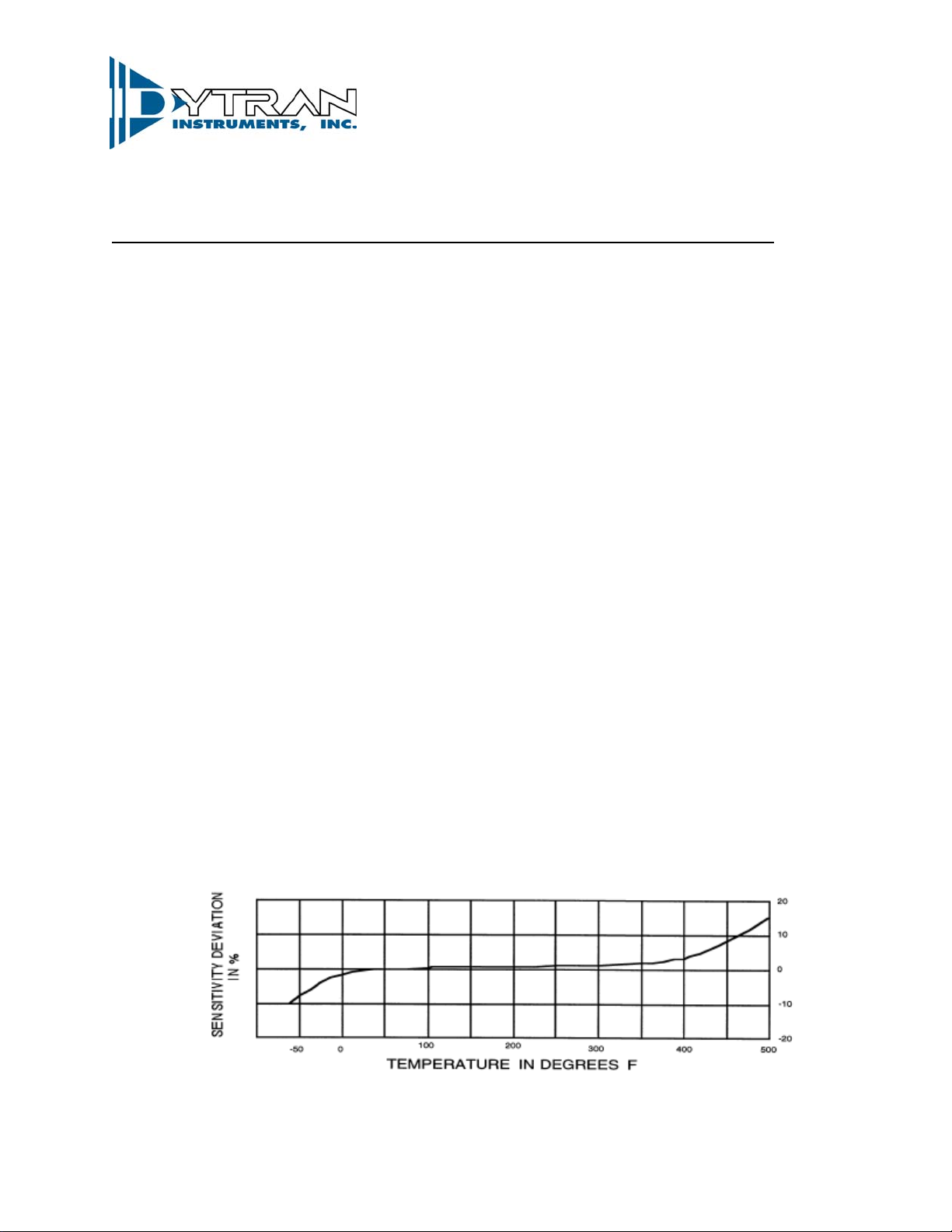

THERMAL COEFFICIENT OF SENSITIVITY SEE GRAPH BELOW

MAXIMUM VIBRATION +/- 1000 G

MAXIMUM SHOCK 2000 G, PEAK

SIZE, DIA X HEIGHT (SEE DWG 127-3220) .375 X .245 IN

WEIGHT 4.0 GRAMS

CONNECTOR, RADIALLY MOUNTED 5-44 COAXIAL

MOUNTING SCREW, INSULATED (SUPPLIED) 2-56 X .437 LONG SS

CASE MATERIAL 300 SERIES STAINLESS STEEL

SEAL HERMETIC, WELDED/GLASS TO METAL

SENSITIVITY VS. TEMPERATURE:

ACCESSORIES PROVIDED: (1) MODEL 6165 MOUNTING SCREW ASSEMBLY.

Rev D ECN 7025 09/02/10

2

Loading...

Loading...