Page 1

Dynamic Transducers and Systems

21592 Marilla St. • Chatsworth, CA 91311 • Phone 81 8-700-7818

www.dytran.com • e-mail: info@dytran.com

OG3055D.docx

Rev A ECN 10060 06/21/13

Rev B ECN 11394 11/04/14

Rev C ECN 12135 07/27/15

OPERATING GUIDE

SERIES 3055D

IEPE ACCELEROMETERS, 10, 20, 50, 100, 200 & 500 mV/g

HERMETICALLY SEALED AND BASE ISOLATED

NOTE:

Series 3055D features hermetically sealed construction and

electrically isolated base for "off-ground" performance.

Hermeticity is obtained by all-welded construction and

glass-to-metal sealed connector. Case material is titanium.

Base ground isolation is by an electrically isolated threaded

insert located in the base of the instrument. Signal ground

return is electrically isolated from the mounting surface.

This guide contains:

1) Operating instructions, Series 3055D.

2) Outline/installation drawing, Series 3055D

3) Specifications, Series 3055D

NOTE: IEPE is an acronym for Integrated Electronics Piezoelectric types of low impedance voltage mode sen so rs with

built-in amplifiers operating from constant current sources over two wires. IEPE instruments are compatible with other

comparable systems labeled LIVM™

1

Page 2

OPERATING INSTRUCTIONS MODEL SERIES 3055D

IEPE ACCELEROMETERS

INTRODUCTION

The Dytran Model Series 3055D consists of

six accelerometers, differing only in sensitivity and

range. Model 3055D1 is 10 mV/g, Model 3035D2 is

100 mV/g, Model 3055D3 is 500 mV/g, Model 3055D4

is 50 mV/g, Model 3055D5 is 20mV/g, and Model

3055D6 is 200mV/g

These accelerometers features Integrated

Electronics Piezoelectric (IEPE) operation. The selfgenerating seismic element, utilizing piezoceramic

crystals in planar shear mode, convert acceleration to

an analogous electrostatic charge mode signal. This

very high impedance signal is fed to the input of a

miniature on-board IC JFET charge amplifier that

drops the output impedance level ten orders of

magnitude, allowing this instrument to drive long

cables without an appreciable effect on sensitivity and

frequency response.

Simple constant current type power units

supply power to operate the integral charge amplifier

and separate the signal from the DC bias at the output

of the internal amplifier. Coaxial cables or even twisted

pair wire may be used to connect accelerometer to

power units. Power and signal are conducted over the

same two-wire cable.

Model series 3055D also features signal

ground isolation from the mounting surface to avoid

annoying ground loops and hermetic sealing for

normal operation in moist and dirty environments.

DESCRIPTION

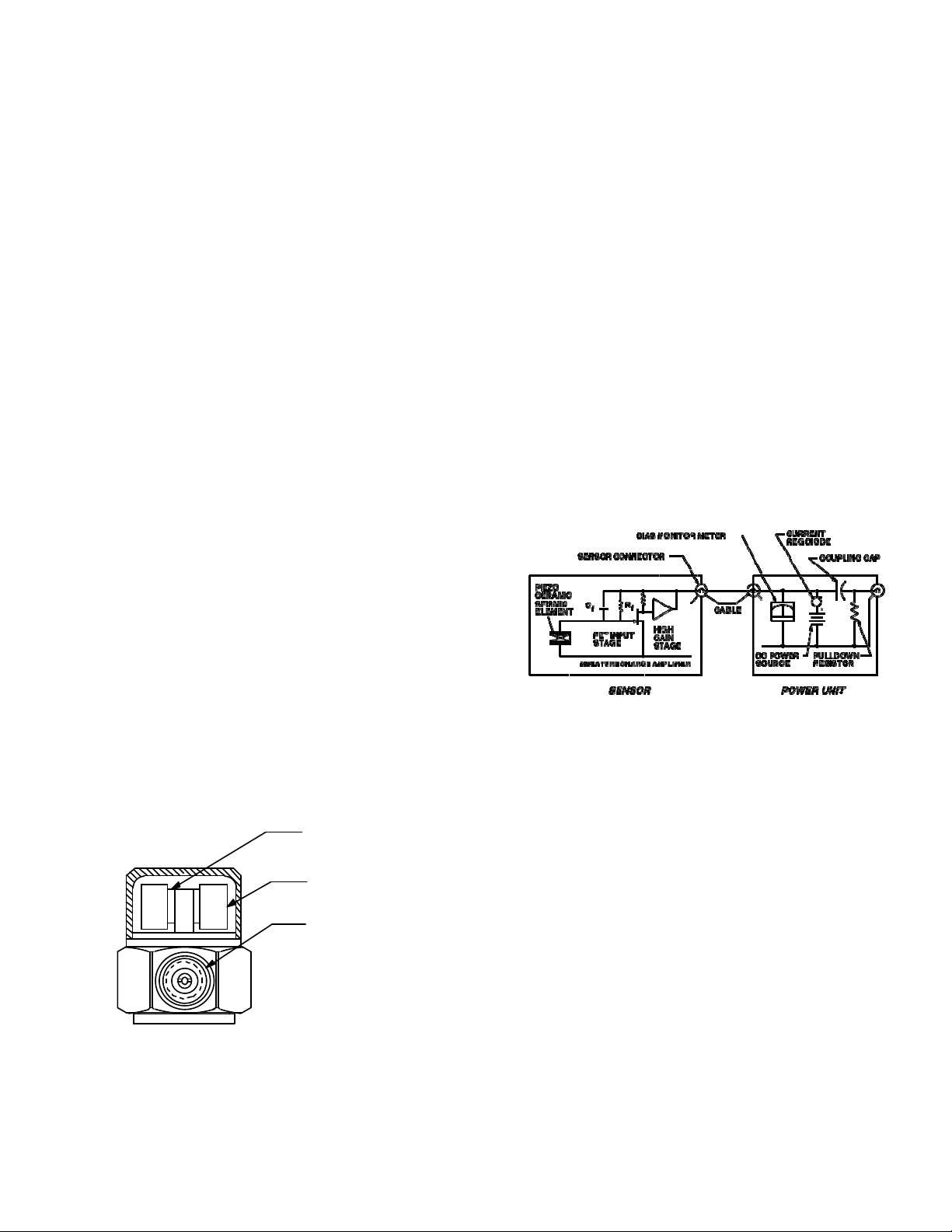

Figure 1, below, is a representative cross

section of series 3055D.

PIEZOCERAMIC CRYSTAL

SEISMIC MASS

10-32 CONNECTOR,

AMPLIFIER IS LOCATED IN

CAVITY BEHIND

CONNECTOR

Figure 1-Cross section, series 3055D

The seismic masses, made from a very dense

tungsten alloy, are tightly preloaded against the

ceramic crystals by means of a special preload screw,

under hundreds of pounds of force. This is so there is

absolutely no relative motion between mass, crystals

and base, thus keeping the non-linearity low and the

natural frequency high.

The force from acceleration (vibration or

shock) acting upon the mounting base is transferred to

the seismic masses through the crystals, stressing the

crystals in shear and producing an electrostatic charge

signal analogous to the input acceleration. This charge

is impressed across the input of the JFET IC charge

amplifier.

Because the IC is a 2-wire IEPE charge

amplifier, the dynamic output voltage signal is

impressed across the connector of the sensor which is

the same point into which the constant current from

the power unit is applied. (See Figure 2 below)

Figure 2-Electro-mechanical schematic,

accelerometer and power unit system.

When constant current from the IEPE power

unit is applied to the accelerometer amplifier input

terminal, the amplifier "turns on" at approx. +10 Volts

DC quiescent bias level. When the accelerometer

senses acceleration, the resultant signal is

superimposed upon this bias voltage.

In the power unit, in its simplest form, a

capacitor blocks the DC bias and allows the dynamic

signal voltage to be separated and brought out to an

"output" jack on the power unit. At this point the signal

may be connected directly to almost any type of

readout instrument such as DVM's, oscilloscopes, data

collectors, spectrum analyzers, etc. The approximate

100 Ohm output impedance of the signal allows the

driving of long cables without adverse effects on

sensitivity or frequency response.

2

Page 3

Referring to figure 2, the feedback resistor R

in conjunction with shunt capacitance C, forms a first

order high-pass filter which sets the low frequency

response of the accelerometer in accordance with the

following equation:

.16

f

= ------------------ (eq.1)

-3db

RC

where:

f

= lower -3db frequency (Hz)

-3db

R = resistance value R (Ohms)

C = total shunt capacitance C (Farads)

RC = discharge time constant TC (Seconds)

Equation 1 above, defines the frequency at

which the accelerometer sensitivity will be 3db down

when compared to the reference sensitivity measured

at 100 Hz.

The discharge time constant for all Models is

0.5 seconds, nom., yielding a lower -3db frequency of

0.3 Hz, from equation 1.

As rule of thumb, the lower -5% frequency is

three times the -3db frequency or 1 Hz.

INSTALLATION

(Refer to Outline/Installation drawing 1273055D) To install Model 3055D, is necessary to

prepare (or find) a flat mounting area of approximately

0.5 inch diameter. Ideally, the mounting surface should

be flat to .001 in. TIR. The flat mounting surface

ensures intimate contact between accelerometer base

and mounting surface for best high frequency

transmissibility, thus accuracy.

At the center of the mounting area, drill and

tap a 10-32 mounting hole in accordance with

instructions on drawing 127-3055D. Clean the area to

remove all traces of machining chips, burrs, etc.

Next, thread the Model 6200 mounting stud

into the base of the 3055D. The stud should enter

easily and thread in up to the raised collar of the stud

by hand. This collar prevents the stud from bottoming

inside the tapped hole in the 3055D where it could

possibly cause stresses in the base structure which

could, in turn, cause anomalous behavior of the

accelerometer at higher frequencies.

After seating the stud, spread a light coating of

silicone grease, or other lubricant, on either of the

mating surfaces and thread the accelerometer/stud

combination into the tapped hole by hand, until the

accelerometer base seats against the mounting

surface. Check to see that the mating surfaces are

meeting properly, i.e., that they are meeting flush and

that there is not an angle formed between the two

surfaces indicating that they are not co-planar. If this

condition is observed, torquing the accelerometer

down will strain the base causing possible poor

frequency response and even erroneous reference

sensitivity. Inspect the perpendicularity of the tapped

hole.

If the hand tight meeting between the two

surfaces is satisfactory, torque the 3055D to the

mating surface with 15 to 20 lb-inches of torque,

preferably measuring the torque with a torque wrench

torquing on the hex surface only.

Proper torque will ensure the best high

frequency performance from the instrument as well as

repeatability of sensitivity when mounting and

remounting. Excessive torque could damage the

ground isolation base.

Connect the cable (typically Models 6010AXX

or 6011AXX) to the accelerometer snugging up the

threaded lock ring tightly by hand.

NOTE: Do not use a pliers or vise grips on the

knurled lock ring. This could damage the

connector of the 3055D and/or the cable

connector.

To avoid stressing the cables which could lead

to early failure, especially under larger excursions of

the test object, it is good practice to tie the cable down

to a fixed surface near the mounting area at a point

approximately one inch from the accelerometer.

If there is excessive motion between the

accelerometer and the nearest tie point, allow a strain

loop of cable to let relative motion occur without

stressing the cable.

Connect the other end of the cable to the

"Sensor" jack of the Dytran power unit (Models 4102,

4103, 4110, 4114, etc.) and switch the power on.

Observe the monitor voltmeter located at the

front panel of each of the power units. If the meter

reads in the mid-scale region, (labeled "Normal"), this

tells you that the cables, accelerometer and power unit

are functioning normally and you should be able to

proceed with the measurement.

3

Page 4

Check for shorts in the cables and connectors

if the meter reads in the "Short" region. Check for open

cables or connections if the meter reads in the "Open"

area. In this manner, the meter becomes a troubleshooting tool for the measurement system.

HIGH FREQUENCY RESPONSE

All piezoelectric accelerometers are basically

rigid spring mass systems, i.e., second order systems

with essentially zero damping. As a result, these

instruments will exhibit a rising characteristic as the

resonance is approached. A filter incorporated into

Model 3055D compensates for this rise.

The frequency at which the sensitivity may

increases or decrease by 5% is approximately 10,000

Hz, the frequency to which the 3055D series is

calibrated. The accelerometer is usable above this

frequency but to use it above 10,000 Hz, it must be

calibrated at the specific frequencies of intended use

because sensitivity deviations will increase drastically

as you greatly exceed this high frequency calibration

limit. Consult the factory for special calibrations

required above 10kHz.

CAUTIONS

1) Do not store or use the 3055D above 250

degrees F. To do so can damage the IC amplifier.

2) Do not allow cables to vibrate unrestrained.

This will eventually destroy the cable and could lead to

system inaccuracies.

3) Avoid dropping or striking the

accelerometer, especially against rigid materials such

as concrete and metals. While Model 3055D is

protected against shock induced overloads, the very

high overloads induced by dropping can do permanent

damage to the IC amplifier or to the mechanical

structure of the accelerometer. This type of damage is

not covered by the warranty.

MAINTENANCE AND REPAIR

The welded construction of the series 3055D

precludes field repair.

Should the mounting surface become

distorted, nicked and otherwise distressed, it can be

redressed by CAREFULLY wiping on a new sheet of

400 grit emery paper on top of a clean surface plate.

We stress "carefully" because if not done properly, this

procedure can do more harm than good. Press the

surface firmly against the paper and draw directly

toward you in several short precise strokes making

sure that the surface remains in full contact with the

paper and does not "rock". Rotate the accelerometer

90 degrees and repeat the procedure. When you

observe the bottom surface it should appear perfectly

flat with straight marks across it. If you cannot achieve

flatness with several attempts, return the instrument to

the factory for repair.

Should the electrical connector become

contaminated with moisture, oil, grease, etc., the entire

instrument may be immersed in degreasing solvents to

remove the contaminants. After degreasing, place the

instrument in a 200°F to 250°F oven for one hour to

remove all traces of the solvent.

Should a problem be encountered with the

operation of the instrument, contact the factory for

trouble shooting advice. Often our service engineers

may point out something which may have been

overlooked and which may save the expense and time

of returning the 3055D to the factory.

If the instrument must be returned, the service

department will issue you a Returned Materials

Authorization (RMA) number to aid in tracking the

repair through the system. Do not send the instrument

back without first obtaining an RMA number. At this

time you will be advised of the preferred shipping

method.

A short note describing the problem, included

with the returned instrument, will aid in trouble

shooting at the factory and will be appreciated.

We will not proceed with a non-warranty repair

without first calling to notify you of the expected

charges. There is no charge for evaluation of the unit.

4

Loading...

Loading...