Page 1

Page 2

©2009-2013 Dynojet Research, Inc. All Rights Reserved.

Linx Installation for Model 424 Automotive Dynamometers

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, and the software described in it, is furnished

under license and may only be used or copied in accordance with the terms of such

license. This manual is furnished for informational use only, is subject to change without

notice, and should not be construed as a commitment by Dynojet. Dynojet assumes no

responsibility or liability for any error or inaccuracies that may appear in this manual.

Except as permitted by such license, no part of this manual may be reproduced, stored in

a retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98200021 Version 06 (05/2013)

Page 3

T

ABLE OF

C

ONTENTS

424 Linx Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Drill and Drill Bit Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Linx Belt Drive Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Linx Belt Drive Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking the Linx Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dynojet Logo Panels and Pit Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removing the Dynojet Logo Panels—Above Ground . . . . . . . . . . . . . . . . . . 7

Removing the Pit Covers—In Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Inner Mounting Plate Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the Inner Mounting Plate—Moveable Dyno . . . . . . . . . . . . . . . . 10

Installing the Inner Mounting Plate—Stationary Dyno . . . . . . . . . . . . . . . . 12

Flange Bearing, Outer Shaft, and Splined Shaft Installation . . . . . . . . . . . 13

Drive Pulley Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Idler Pulley Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Belt and Tensioner Pulley Assembly Installation . . . . . . . . . . . . . . . . . . . . . 18

Pulley Mounting Plates and Outer Bearings Installation . . . . . . . . . . . . . . 20

Installing the Idler Pulley Outer Bearing, Bearing Mounting Plate,

and Lower Pulley Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installing the Moveable Dyno Pulley Outer Bearing, Bearing

Mounting Plate, and Lower Pulley Mount . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing the Upper Moveable Dyno and Idler Pulley Mounts . . . . . . . . . . 23

Installing the Stationary Dyno Pulley Outer Bearing, Bearing

Mounting Plate, and Lower Pulley Mount . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installing the Upper Stationary Dyno Pulley Mount . . . . . . . . . . . . . . . . . . 27

Brake Signal Relay Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tension the Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Above Ground Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

In Ground Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Disconnect the Belt Drive from the Dyno Drums . . . . . . . . . . . . . . . . . . . . 41

Reconnecting the Belt Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Linx Installation for Model 424 Automotive Dynamometers

i

Page 4

TABLE OF CONTENTS

Appendix A Red Head Anchor Installation

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Appendix B Disconnect the Belt Drive from the

Dyno Drums—Early Version Shafts

Disconnect the Belt Drive from the Dyno Drums . . . . . . . . . . . . . . . . . . .B-2

Appendix C Shaft Safety Wire Installation

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

ii

Linx Installation for Model 424 Automotive Dynamometers

Page 5

424 L

INX INSTALLATION

Thank you for your interest in Dynojet’s Automotive Dynamometers. Dynojet’s

software and dynamometers will give you the power to get the maximum

performance out of vehicles you evaluate. Whether you are new to the benefits of a

chassis dynamometer or an experienced performance leader, the repeatability and

diagnostic tools of WinPEP 7 software and a Dynojet dynamometer (dyno) will give

you the professional results you are looking for.

The Linx belt drive system synchronizes the speed of the front and rear drums for

testing sensitive all-wheel drive and two-wheel drive vehicles with traction control.

This document is designed to help you install the Linx system on your model 424

automotive dyno. To ensure safety and accuracy in the procedures, perform the

procedures as they are described.

Note: The Linx system is for 88-130-inch wheel base dynos only and cannot be

used with the extension kit.

Document Part Number: 98200021

Versio n 6

Last Updated: 05-30-13

This chapter is divided into the following categories:

•Introduction, page 2

• Linx Belt Drive Specifications, page 3

• Unpacking the Linx Parts, page 4

• Dynojet Logo Panels and Pit Covers, page 7

• Inner Mounting Plate Installation, page 10

• Flange Bearing, Outer Shaft, and Splined Shaft Installation, page 13

• Drive Pulley Installation, page 15

• Idler Pulley Assembly Installation, page 17

• Belt and Tensioner Pulley Assembly Installation, page 18

• Pulley Mounting Plates and Outer Bearings Installation, page 20

• Brake Signal Relay Installation, page 29

• Tension the Belt, page 31

• Above Ground Covers, page 33

• In Ground Covers, page 37

• Disconnect the Belt Drive from the Dyno Drums, page 41

Linx Installation for Model 424 Automotive Dynamometers

1

Page 6

424 LINX INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

INTRODUCTION

Thank you for your interest Dynojet’s Automotive Dynamometers. Before installing

the Linx system, please take a moment to read this guide for proper installation

procedures.

Note: The Linx system is for 88-130-inch wheel base dynos only and cannot be

used with the extension kit.

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

DRILL AND DRILL BIT REQUIREMENTS

You will need to provide a drill and drill bit capable of drilling holes in concrete. Refer

to Appendix A for more information on installing Red Head Anchors.

• drill bit size: 1/2-inch

• minimum hole depth: 1 5/8-inch (41.2 mm)

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, e-mail

Dynojet at dynosales@dynojet.com, or write to Dynojet at 2191 Mendenhall Drive,

North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, 3D visualizations, and press releases

about our latest product lines.

2

Linx Installation for Model 424 Automotive Dynamometers

Page 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

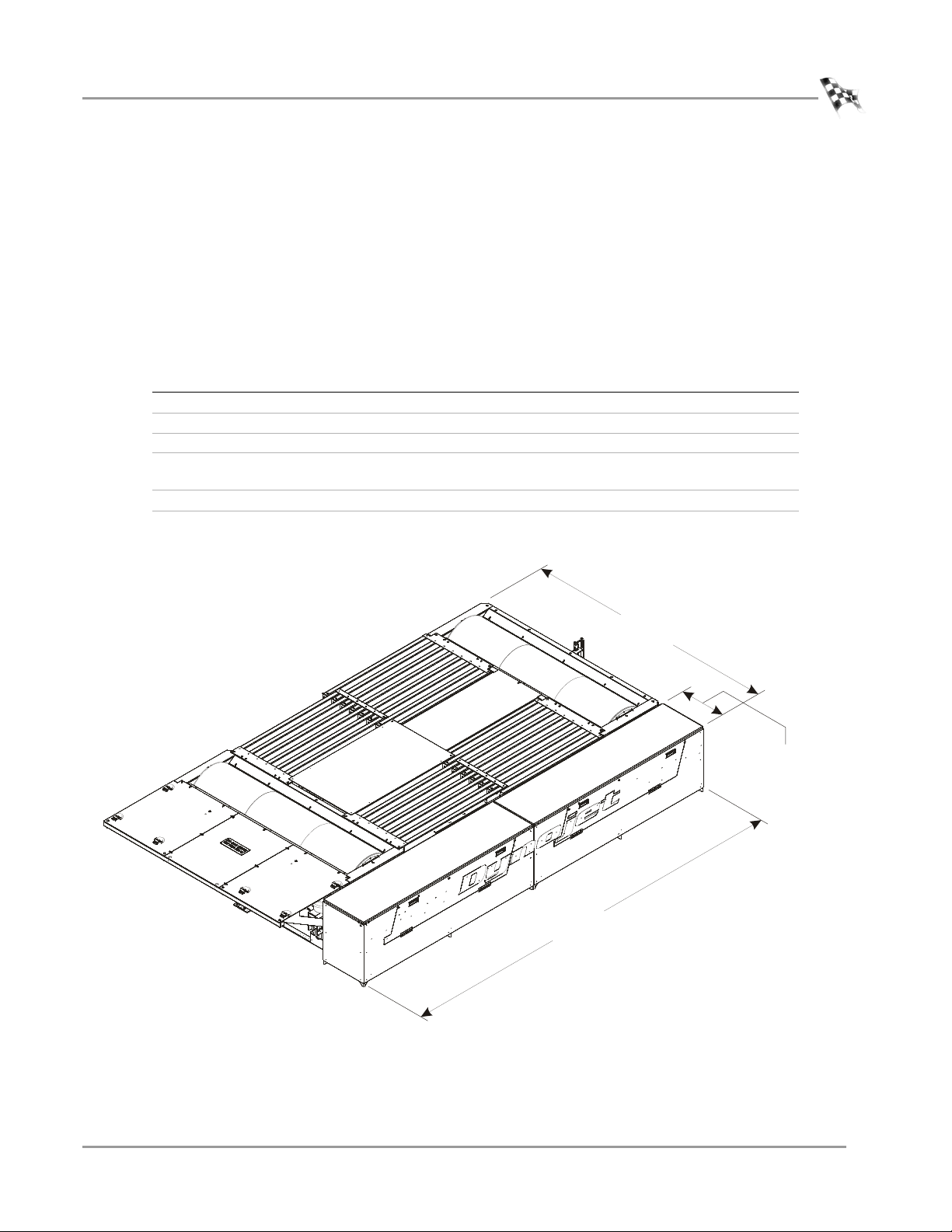

LINX BELT DRIVE SPECIFICATIONS

XD085

372.03 cm (146.46 in.)

frame, brake, and Linx option

441.96 cm (174.00 in.)

Linx option

50.80 cm (20.00 in.)

Linx option

The following specifications specific to the Linx belt drive dyno application will help

you set up your dyno area and verify you have met the requirements necessary to

operate your dyno safely.

For more detailed information about your dyno specifications, refer to the installation

guide included with your dyno.

LINX BELT DRIVE SPECIFICATIONS

description specifications

Length

of Linx option 441.96 cm (174.00 in.)

Width

of frame with eddy current brake and

Linx option

of Linx option 50.80 cm (20.00 in.)

Maximum Speed 290 kph (180 mph)

372.03 cm (146.46 in.)

424 LINX INSTALLATION

Linx Belt Drive Specifications

Version 6 Linx Installation for Model 424 Automotive Dynamometers

Figure 1: Above Ground Model 424xLC2 Dyno with Linx Belt Drive Dimensions

3

Page 8

424 LINX INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking the Linx Parts

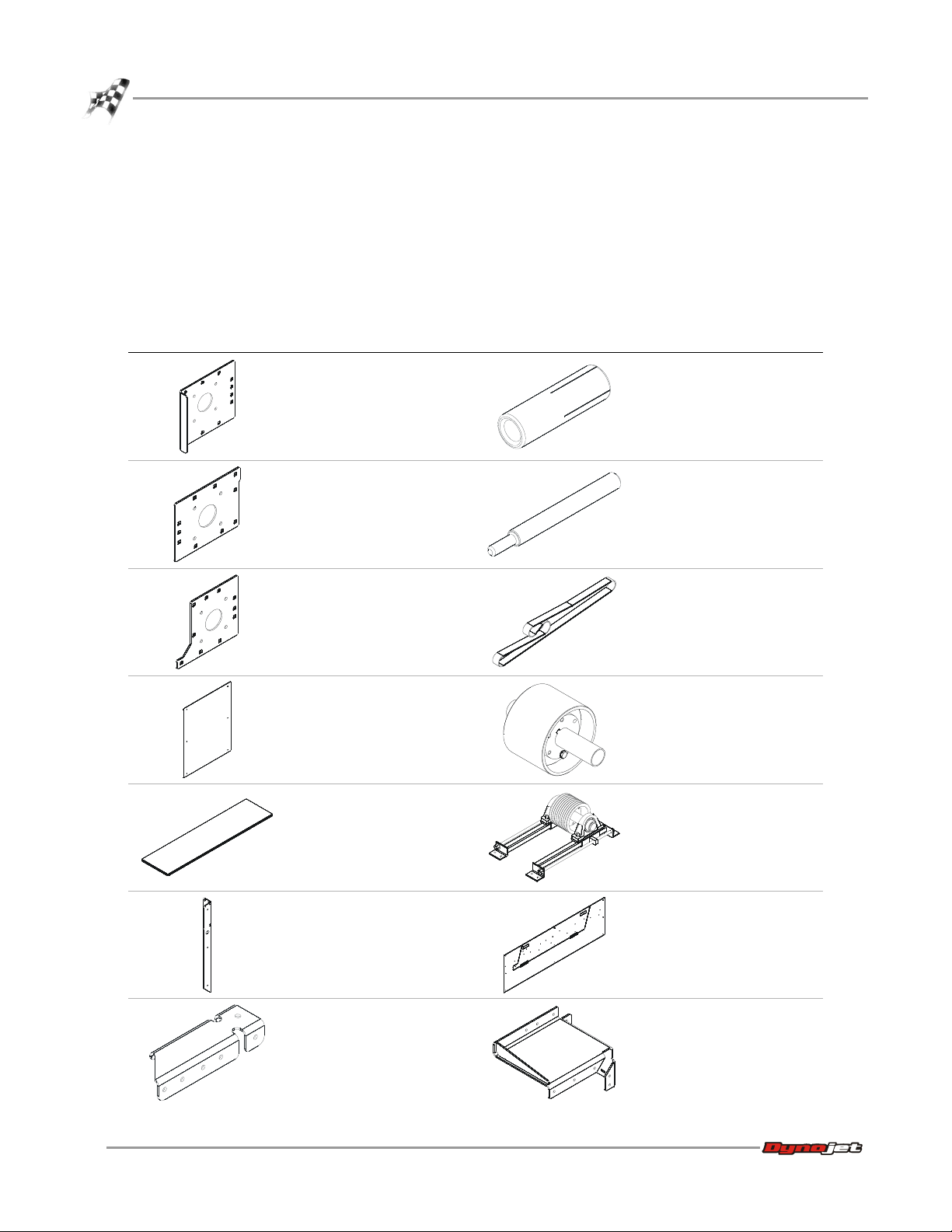

UNPACKING THE LINX PARTS

Use the following steps to unload your Linx system parts.

1 Using a pry bar, or a large flat screwdriver, and a hammer, carefully remove the

top and sides of the crate. At this point, you will want to inspect the exterior of

the dyno for any indications of damage. Report any damage immediately.

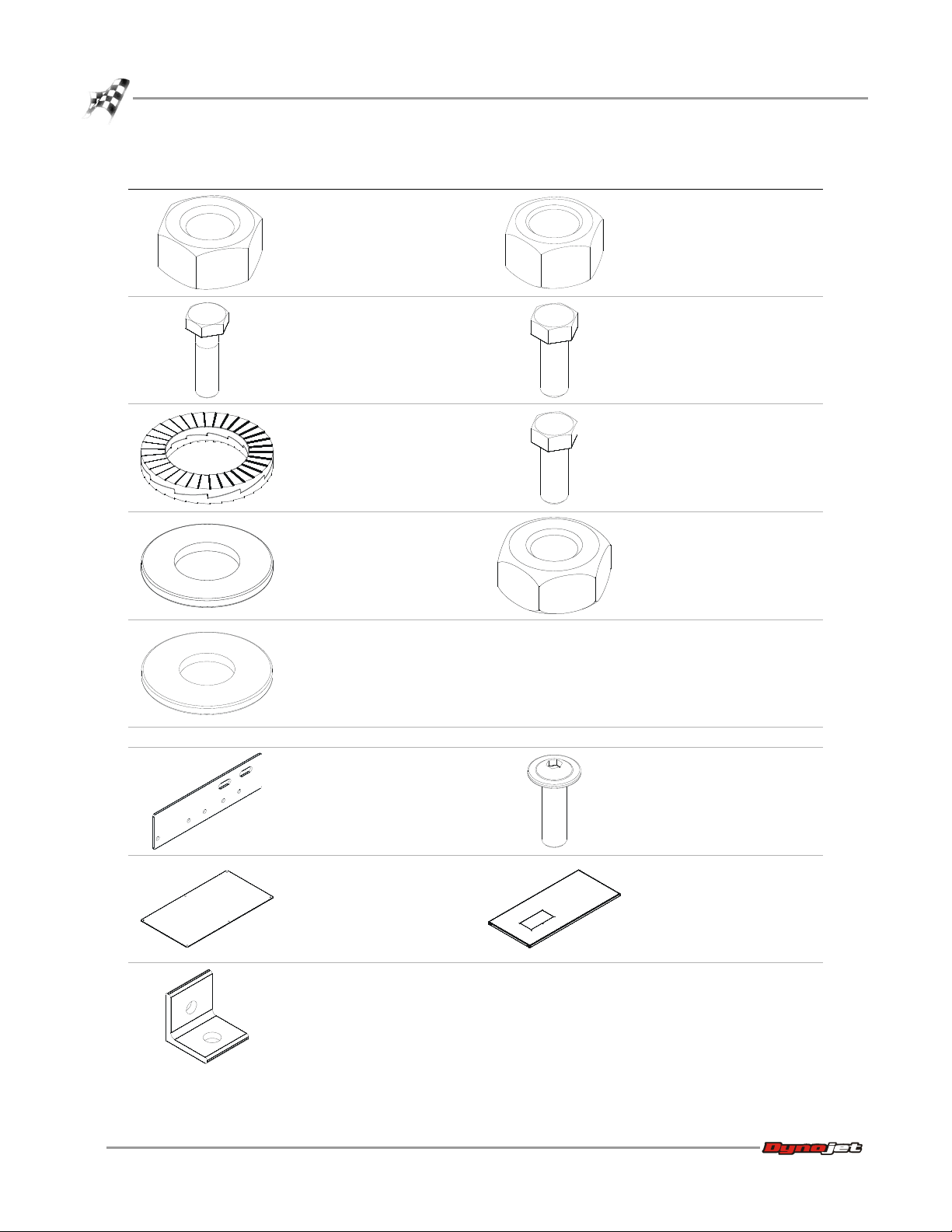

2 Remove the following parts from the crate and set aside.

part description part description

stationary pulley mounting

plate

P/N 21200083

anchor, red head, 3/8" (10

above ground, 6 additional

for in ground, plus 2 extra)

P/N 37513200

moveable pulley mounting

plate

P/N 21200090

idler pulley mounting plate

P/N 21200091

belt cover, end panel (2)

P/N 21200095

belt cover, top (2)

P/N 21200097

belt cover, leg (8)

P/N 21400006

installation tool, red head

anchor

P/N 37518200

v-belt 10/5V3800

P/N 46200007

idler pulley assembly

61100007

tensioner assembly

P/N 61100008

belt cover, front panel

assembly (2)

P/N 61100013

belt cover, center support

P/N 21600026

4

Linx Installation for Model 424 Automotive Dynamometers

upper stationary pulley

mount

P/N 61300022

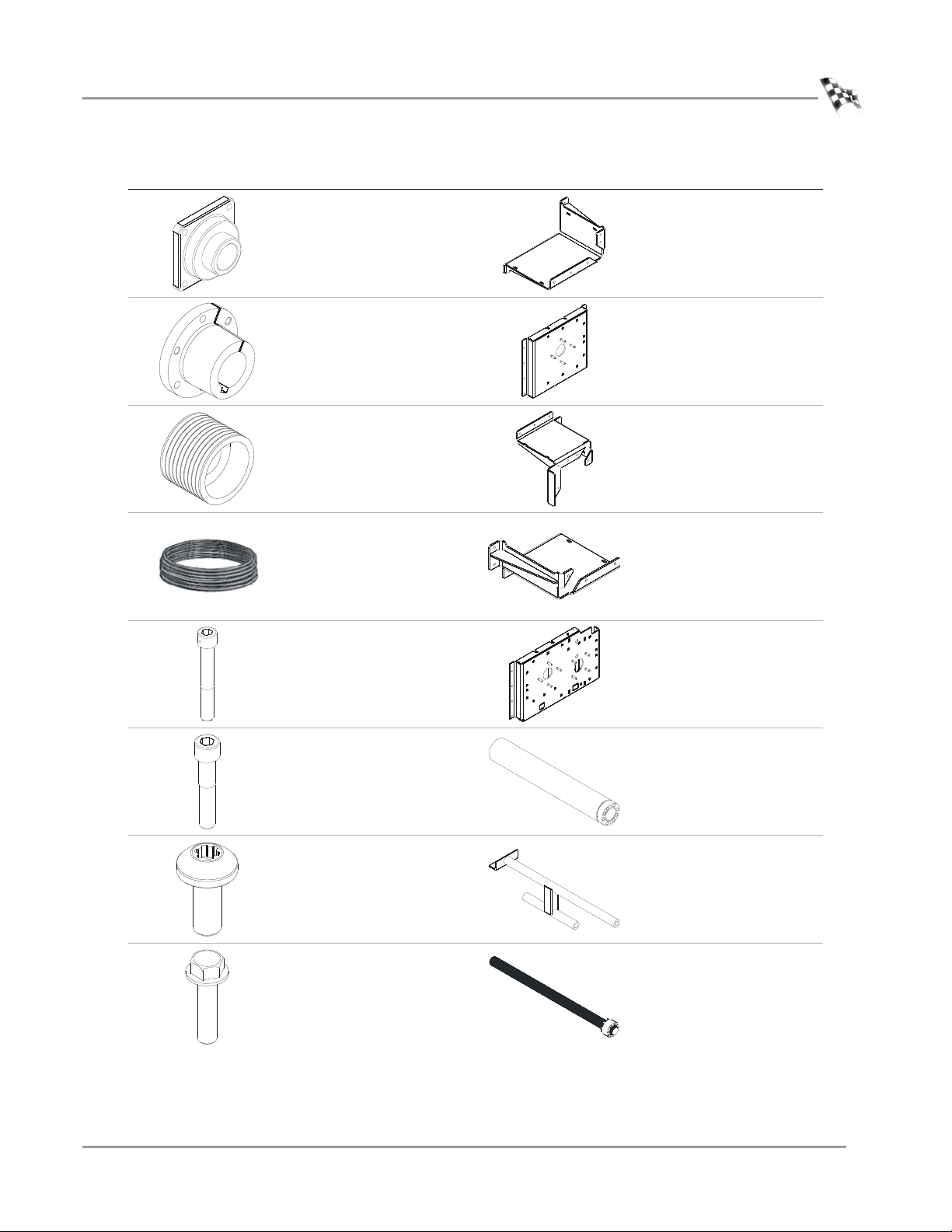

Page 9

424 LINX INSTALLATION

Unpacking the Linx Parts

part description part description

flange bearing with lock

collar (6)

P/N 32300001

lower stationary pulley

mount (3)

P/N 61300023

bushing (2)

includes three bolts and

washers per bushing

P/N 32300002

grooved pulley (2)

P/N 32300003

safety wire

P/N 35300002

screw, 1/4-20 x 1.75",

shcs, drilled (4)

P/N 36500016

screw, 1/4-20 x 1.25",

shcs, drilled (4)

P/N 36500017

inner stationary dyno

mounting plate

P/N 61300024

upper moveable pulley

mount

P/N 61300025

lower moveable pulley

mount

P/N 61300026

inner moveable dyno

mounting plate

P/N 61300027

outer shaft, drive pulley (2)

P/N 61300030

screw, 1/4-20 x 5/8", panhead, torx, black (64 above

ground, 16 in ground)

P/N 36561045

bolt, 3/8-16 x 1.5", flangehex (2)

P/N 36582471

Version 6 Linx Installation for Model 424 Automotive Dynamometers

tension arm assembly

P/N 62100003

splined shaft (2)

P/N 62200006

5

Page 10

424 LINX INSTALLATION

Unpacking the Linx Parts

part description part description

nut, 9/16-12, hex (24)

P/N 36711100

nut, 3/8-16, hex (2)

P/N DM150-011-004

bolt, 9/16-12 x 2", hex (12)

P/N 36811640

washer, 1/4", lock (4)

P/N 36900001

washer, 3/8", hardened, flat

(86 above ground)

P/N 36923100

6 additional for in ground as

P/N DM150-011-002

washer, 9/16", flat (24)

P/N 36943101

The following parts are included in the In Ground Installation P/N 78100007:

pit cover mount

P/N 21200098

bolt, 3/8-16 x 1.25", hex (4)

included as extras

P/N DM150-011-006

bolt, 3/8-16 x 1", hex (85

above ground, 1 to de

couple the drums, 6

additional for in ground)

P/N DM150-019-012

nut, crush, 1/4-20 (8 above

ground, 4 in ground)

P/N DM150-020-005

bolt, 3/8-16 x 1/2", buttonhead flange allen, (8)

P/N 36580434

calibration access cover (2)

P/N 21217513

feet (6)

P/N 21919101

6

Linx Installation for Model 424 Automotive Dynamometers

pit cover assembly (2)

P/N 61329400

Page 11

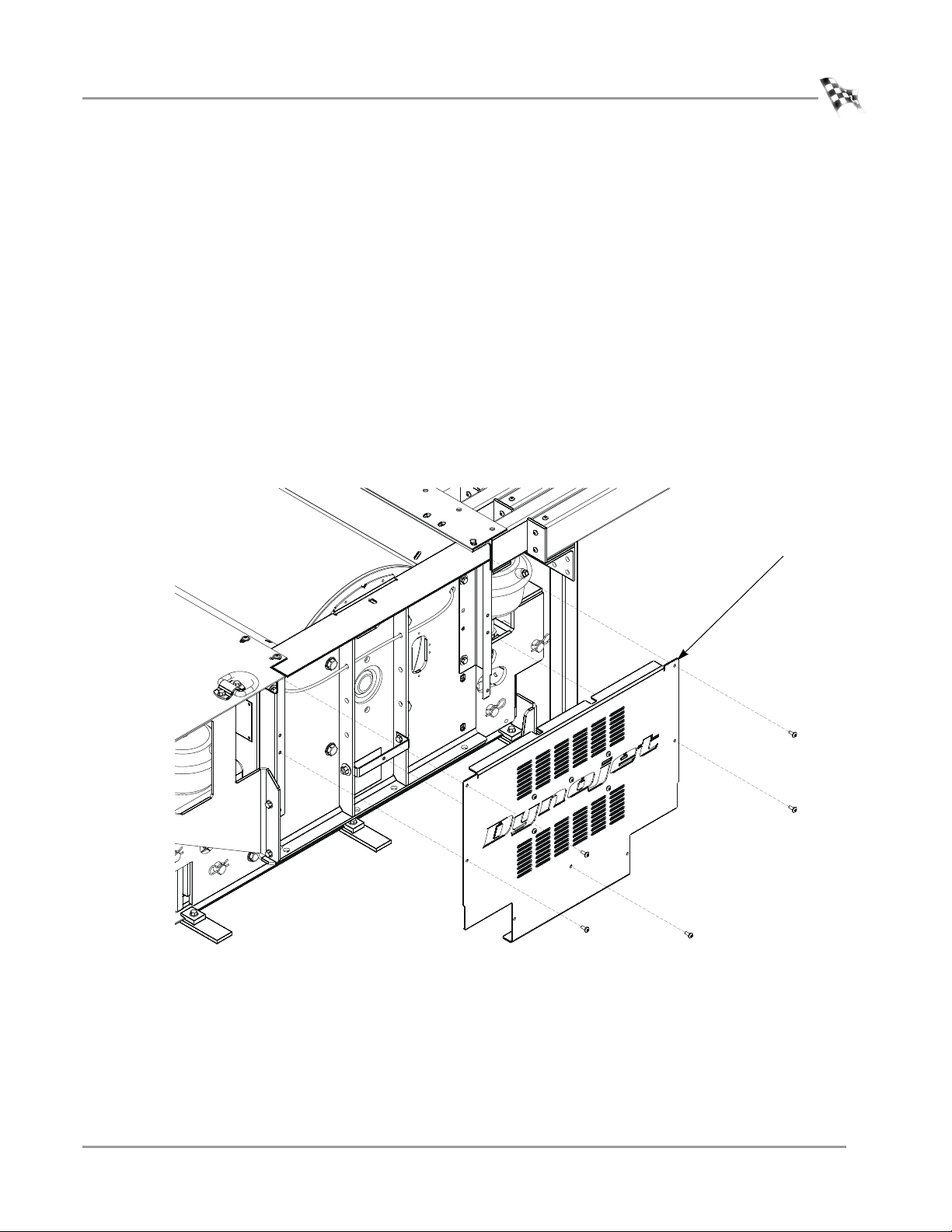

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DYNOJET LOGO PANELS AND PIT COVERS

XD001

logo panel

The Linx option can only be installed on one side of the dyno, refer to Figure 1. When

the Linx option is being installed on an existing above ground dyno, the Dynojet logo

panels must be removed. When the Linx option is being installed on an existing in

ground dyno, the pit covers must be removed.

If your Dynojet logo panels or pit covers are already removed, continue with “Inner

Mounting Plate Installation” on page 10.

424 LINX INSTALLATION

Dynojet Logo Panels and Pit Covers

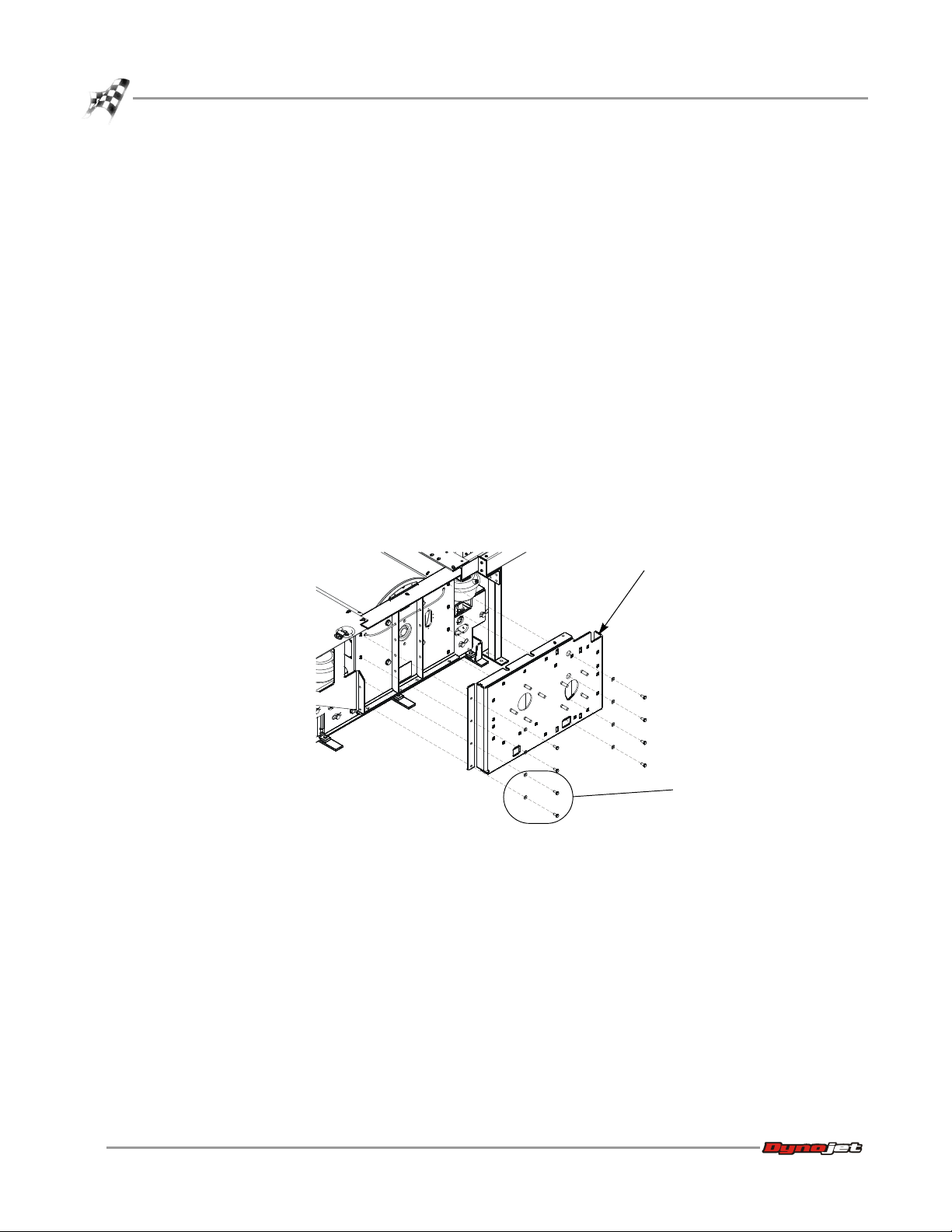

REMOVING THE DYNOJET LOGO PANELS—ABOVE GROUND

Repeat the following steps for each logo panel.

1 Remove the five 1/4-20 x 5/8-inch pan-head torx screws securing the logo panel to

the mounting brackets. Set these screws aside.

2 Remove the logo panel and set aside.

Figure 2: Remove the Dynojet Logo Panel

Version 6 Linx Installation for Model 424 Automotive Dynamometers

7

Page 12

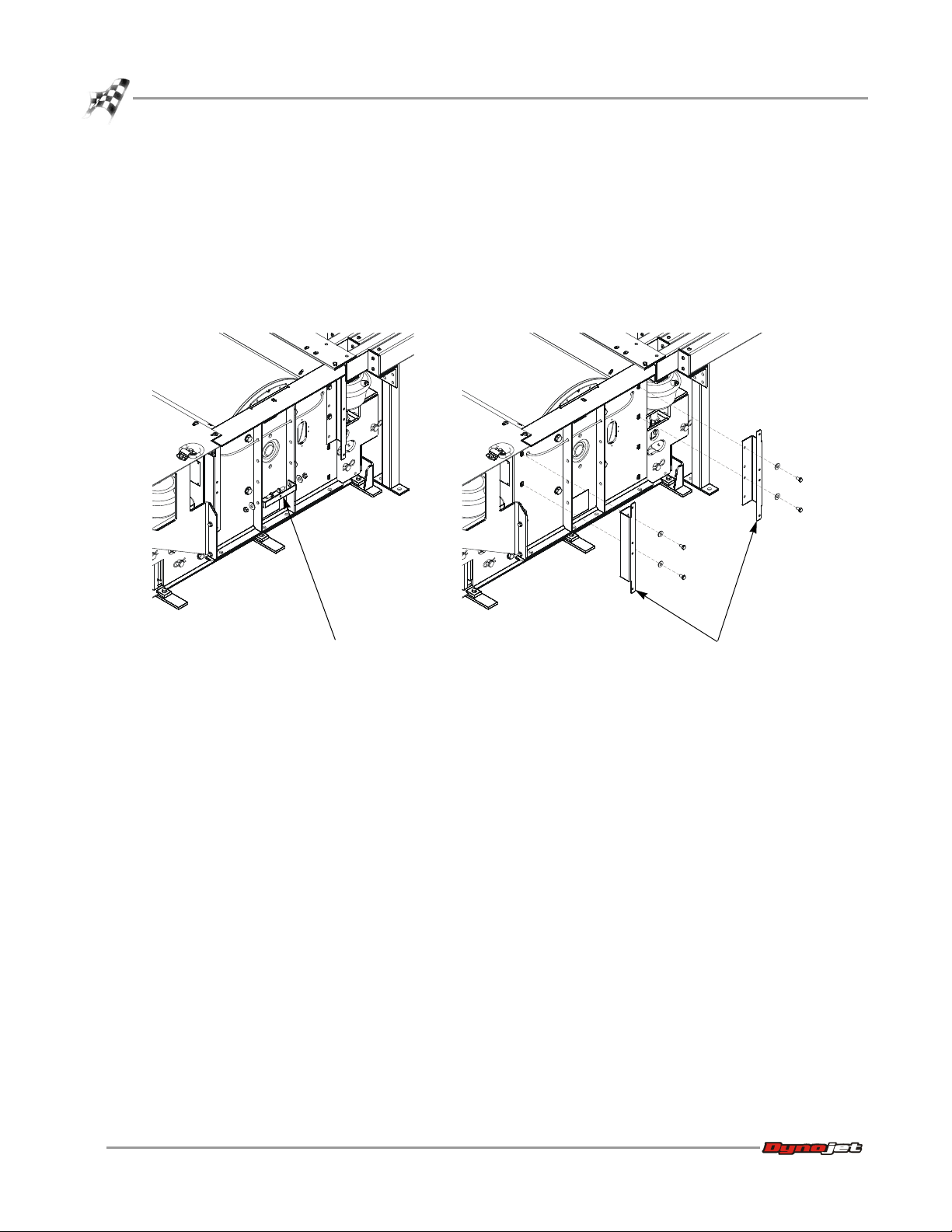

424 LINX INSTALLATION

XD002

XD003

mounting bracket

lower mounting bracket

Dynojet Logo Panels and Pit Covers

3 Remove the two 7/16-14 x 1-inch hex bolts, two 7/16-inch flat washers, and two

7/16-14 nuts securing the lower mounting bracket to the dyno. Set the hardware

aside.

4 Remove the lower mounting bracket and set aside.

5 Remove the two 3/8-16 x 3/4-inch hex bolts and two 3/8-inch flat washers securing

each mounting bracket to the dyno. Set the hardware aside.

6 Remove each mounting bracket and set aside.

Figure 3: Remove the Logo Panel Mounting Brackets

8

Linx Installation for Model 424 Automotive Dynamometers

Page 13

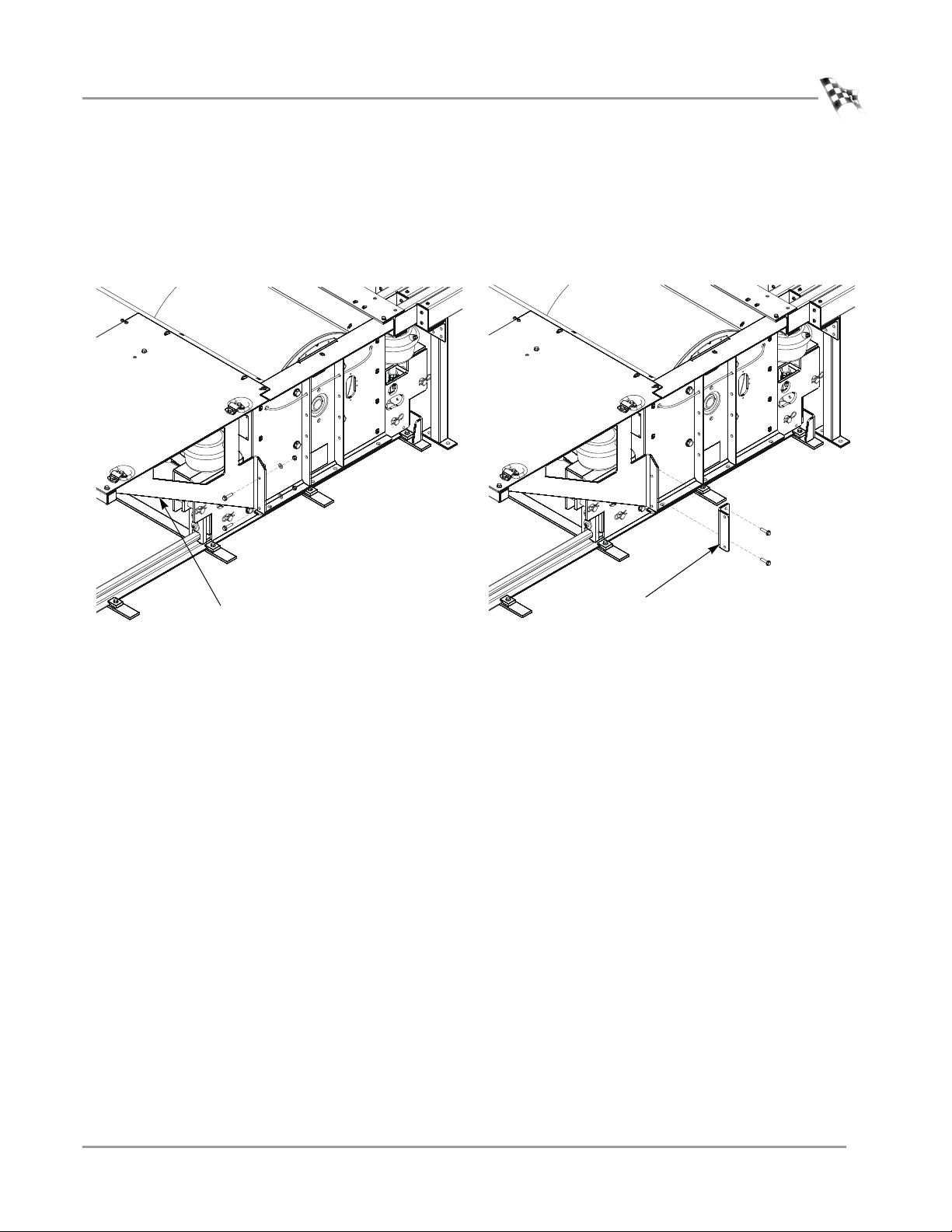

424 LINX INSTALLATION

XD004

XD005

rear deck brace

mounting bracket

rear deck brace

Dynojet Logo Panels and Pit Covers

7 Remove the two 3/8-16 x 1.5-inch flange hex bolts, washers, and nuts securing the

rear deck brace to the mounting bracket. Set the hardware aside.

8 Remove two 3/8-16 x 1.5-inch flange hex bolts securing the rear deck brace

mounting bracket to the dyno. Set the hardware aside.

9 Remove the rear deck brace mounting bracket and set aside.

Figure 4: Remove the Rear Deck Brace Mounting Bracket

REMOVING THE PIT COVERS—IN GROUND

If present, remove any pit covers on this side of the dyno.

Version 6 Linx Installation for Model 424 Automotive Dynamometers

9

Page 14

424 LINX INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XD006

for in ground

installations only

inner mounting plate

Inner Mounting Plate Installation

INNER MOUNTING PLATE INSTALLATION

Use the following instructions to install the moveable dyno and stationary dyno inner

mounting plates.

You will need the following parts:

• 36582471 Bolt, 3/8-16 x 1.5", Flange-Hex (2)

• 36923100 Washer, 3/8", Flat (18)

• 61300024 Inner Mounting Plate, Stationary Dyno

• 61300027 Inner Mounting Plate, Moveable Dyno

• DM150-011-004 Nut, 3/8-16, Hex (2)

• DM150-019-012 Bolt, 3/8-16 x 1", Hex (16)

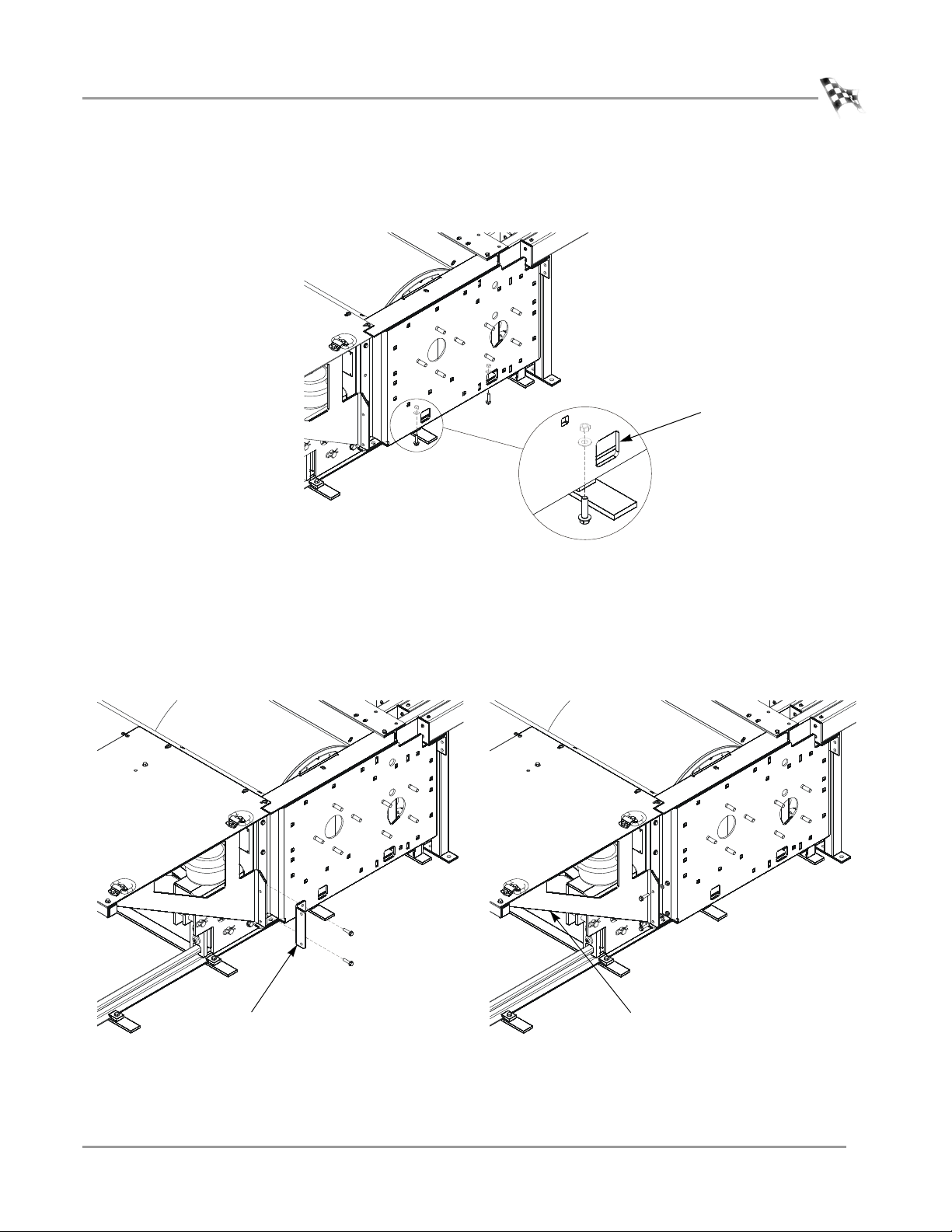

INSTALLING THE INNER MOUNTING PLATE—MOVEABLE DYNO

1 Secure the inner mounting plate to the moveable dyno using eight 3/8 x 1-inch

bolts and eight 3/8-inch flat washers.

Note: For above ground installations, use only six 3/8 x 1-inch bolts and

six 3/8-inch flat washers.

Figure 5: Secure the Inner Mounting Plate to the Moveable Dyno

10

Linx Installation for Model 424 Automotive Dynamometers

Page 15

424 LINX INSTALLATION

XD007

access hole

XD008

XD009

rear deck brace

mounting bracket

rear deck brace

Inner Mounting Plate Installation

2 Using the access holes, secure the bottom of the inner mounting plate to the

moveable dyno using two 3/8-16 x 1.5-inch flange bolts, two 3/8-inch flat washers,

and two 3/8-inch nuts.

Figure 6: Secure the Bottom of the Inner Mounting Plate to the Moveable Dyno

The following steps are for the above ground dyno only.

3 Secure the rear deck brace mounting bracket to the inner mounting plate and

dyno using the two 3/8-16 x 1.5-inch flange-hex bolts removed earlier.

4 Secure the rear deck brace to the mounting bracket using the two

3/8-16 x 1.5-inch flange-hex bolts, washers, and nuts removed earlier.

Figure 7: Secure the Rear Deck Brace and Mounting Bracket

Version 6 Linx Installation for Model 424 Automotive Dynamometers

11

Page 16

424 LINX INSTALLATION

XD010

inner mounting plate

Inner Mounting Plate Installation

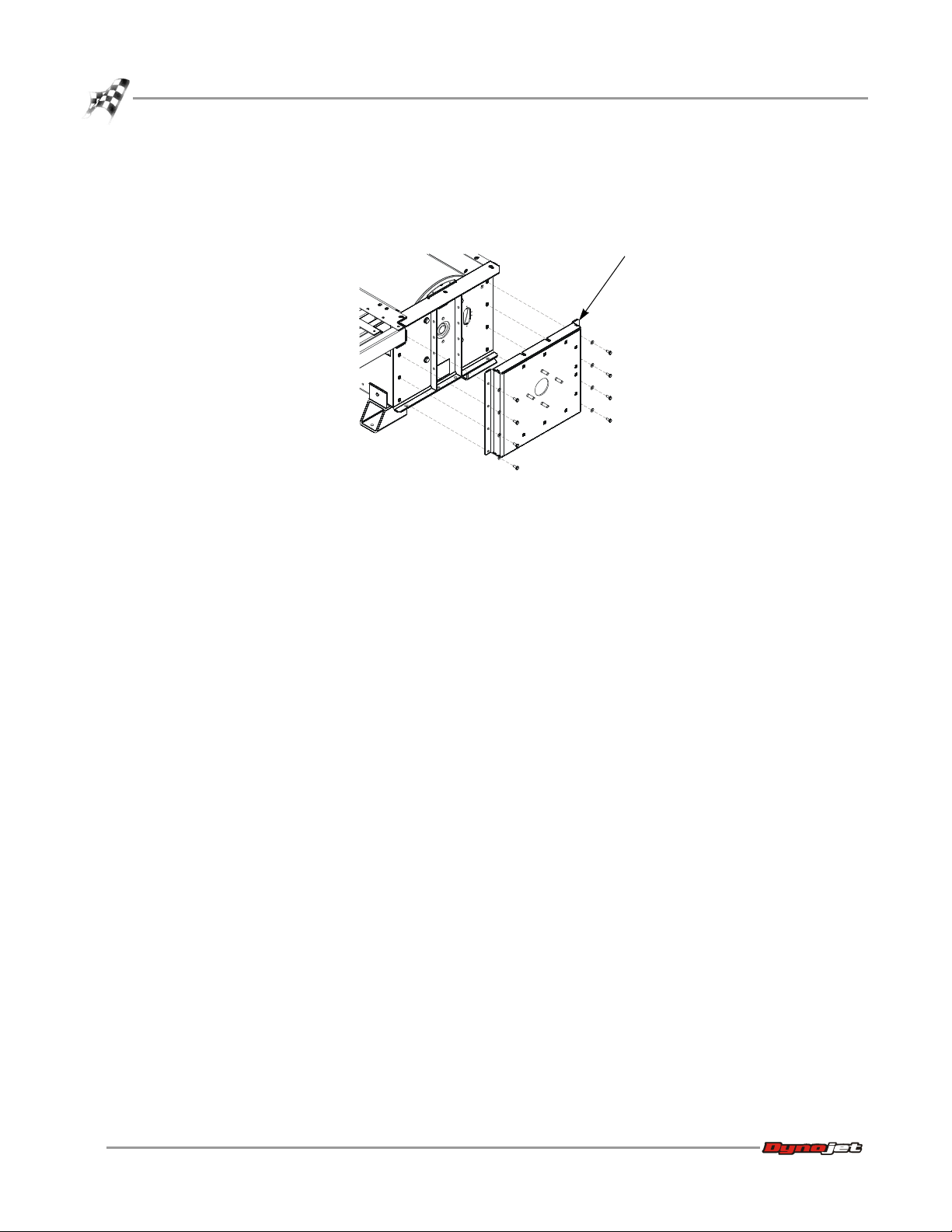

INSTALLING THE INNER MOUNTING PLATE—STATIONARY DYNO

Secure the inner mounting plate to the stationary dyno using eight 3/8 x 1-inch bolts

and eight 3/8-inch flat washers.

Figure 8: Secure the Inner Mounting Plate to the Stationary Dyno

12

Linx Installation for Model 424 Automotive Dynamometers

Page 17

424 LINX INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XD049

flange bearing

outer shaft

Flange Bearing, Outer Shaft, and Splined Shaft Installation

FLANGE BEARING, OUTER SHAFT, AND SPLINED SHAFT INSTALLATION

Use the following instructions to install the flange bearing, splined shaft, and outer

shaft on both the moveable and stationary dynos.

You will need the following parts:

• 32300001 Flange Bearing with Lock Collar (2)

• 36500016 Screw, 1/4-20 x 1.75", SHCS, Drilled (4)

• 36711100 Nut, 9/16-12, Hex (8)

• 36943101 Washer, 9/16", Flat (8)

• 61300030 Drive Pulley Shaft (Outer Shaft) (2)

• 62200006 Splined Shaft (2)

1 Place the flange bearing on the threaded studs on the inner plate.

2 Loosely secure the flange bearing to the inner plate using four 9/16-inch washers

and four 9/16-inch nuts.

3 Slide the outer shaft into the bearing.

Figure 9: Install the Flange Bearing and Outer Shaft

Version 6 Linx Installation for Model 424 Automotive Dynamometers

13

Page 18

424 LINX INSTALLATION

XD086

lock collar

threaded holes

splined shaft

unthreaded holes

outer shaft

splined shaft

flange

gap

16 1/8-inches

Flange Bearing, Outer Shaft, and Splined Shaft Installation

4 The distance from the face of the bearing mounting plate to the end of the outer

shaft should be approximately 16.125-inches.

5 Apply a small amount of grease to the first two inches of the splined shaft.

6 Slide the splined shaft through the outer shaft and into the splines in the dyno

drum.

7 Align the two unthreaded holes in the splined shaft flange with the two threaded

holes in the outer shaft.

8 Insert two 1/4-20 x 1.75-inch cap screws and tighten them just enough so the

tapered pins are engaged with the tapered holes.

Note: A gap will remain between the splined shaft flange and outer shaft.

9 While applying just enough upward pressure to support the shaft, tighten the

four 9/16-inch nuts.

10 Remove the two 1/4-20 x 1.75-inch cap screws.

11 Once the four 9/16-inch nuts are tight, it should be very easy to slide the splined

shaft in and out of the dyno splines.

12 Replace the 1/4-20 x 1.75-inch cap screws.

13 Confirm the outer shaft is 16 1/8-inches from the mounting plate.

14 Using the installation instructions included with the bearing, secure the lock

collar.

14

Linx Installation for Model 424 Automotive Dynamometers

Figure 10: Measure the Outer Shaft and Test Install the Splined Shaft

Page 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRIVE PULLEY INSTALLATION

grooved pulley

bushing

section view of bushing

and grooved pulley to

show correct alignment

with the tapered hole

XD051

bushing

grooved pulley

Use the following instructions to install the drive pulleys for both the moveable and

stationary dynos.

You will need the following parts:

• 32300002 Bushing (2)

includes three bolts and lock washers each

• 32300003 Grooved Pulley (2)

1 Place the bushing into the grooved pulley.

Figure 11: Align the Bushing in the Grooved Pulley

424 LINX INSTALLATION

Drive Pulley Installation

2 Loosely secure the bushing in the pulley using the three included bolts and lock

washers.

3 Slide the pulley assembly onto the outer shaft.

Figure 12: Install the Moveable Dyno Pulley Assembly

Version 6 Linx Installation for Model 424 Automotive Dynamometers

15

Page 20

424 LINX INSTALLATION

XD052

10-13/16 in. before tightening bolts

11.00 in. after tightening bolts

Drive Pulley Installation

4 The outer face of the pulley should be approximately 10-13/16 inches from the

face of the inner plate. Slowly tighten the bolts until the hub starts to pull into the

pulley, checking that it is approximately 10-13/16 inches from the inner plate

before the pulley is locked on the shaft.

5 Tighten the bolts by working around the bushing until none of the bolts will turn

at a torque wrench setting of 75 ft.-lb. The pulley should have moved out to

approximately 11 inches from the face of the inner plate.

Note: The measurement of 11 inches is not critical; however, this measurement

should be the same on both the moveable and stationary dynos.

Figure 13: Verify the Pulley Distance

16

Linx Installation for Model 424 Automotive Dynamometers

Page 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

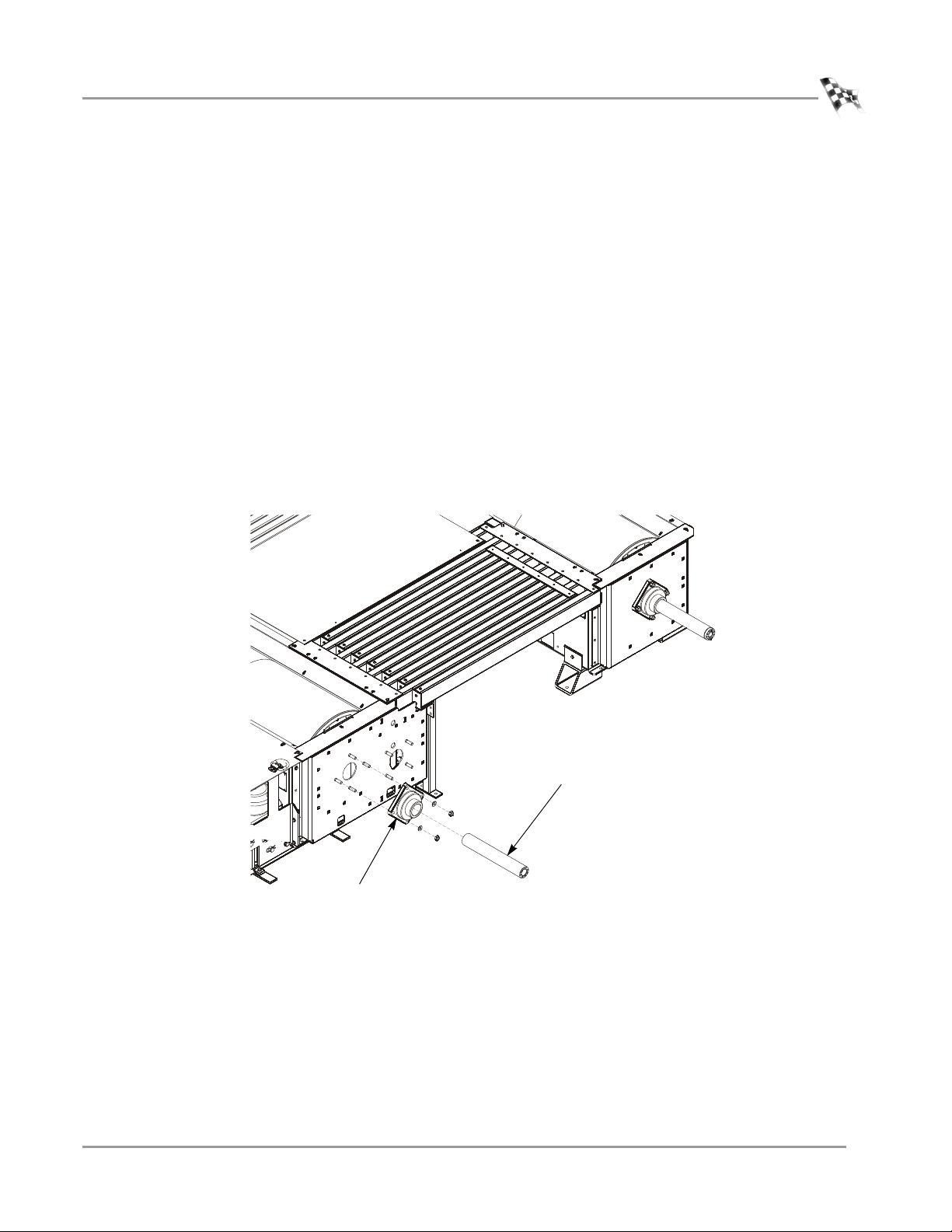

IDLER PULLEY ASSEMBLY INSTALLATION

XD053

flange bearing

idler pulley assembly

You will need the following parts:

• 32300001 Flange Bearing with Lock Collar

• 36711100 Nut, 9/16-12, Hex (4)

• 36943101 Washer, 9/16", Flat (4)

• 61100007 Idler Pulley Assembly

1 Place the flange bearing on the threaded studs on the inner plate.

2 Secure the flange bearing to the inner plate using four 9/16-inch flat washers and

four 9/16-inch nuts.

3 Holding the idler assembly horizontal, slide the assembly into the bearing until its

outer edge is approximately 11-1/8-inches from the face of the inner plate.

4 Using the installation instructions included with the bearing, secure the lock

collar.

Note: Refer to the installation instructions included with the bearing.

Carefully allow the idler pulley assembly to hang in the bearing.

424 LINX INSTALLATION

Idler Pulley Assembly Installation

Figure 14: Install the Idler Pulley Assembly

Version 6 Linx Installation for Model 424 Automotive Dynamometers

17

Page 22

424 LINX INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt and Tensioner Pulley Assembly Installation

BELT AND TENSIONER PULLEY ASSEMBLY INSTALLATION

You will need the following parts:

• 36923100 Washer, 3/8", Flat (8)

• 37513200 Anchor, Red Head, 3/8" (8)

• 37518200 Red Head Anchor Installation Tool

• 46200006 Belt

• 61100008 Tensioner Assembly

• DM150-019-012 Bolt, 3/8-16 x 1", Hex (8)

Use the following instructions along with Figure 15 on page 19.

1 Route the belt around the pulleys as shown in Figure 15 on page 19.

2 Place the belt around the tensioner pulley and place the tensioner assembly in the

position shown.

Note: Verify the welded on nuts on the tensioner assembly are towards the back

and the tensioner pulley is slid all the way to the end of the assembly towards the

stationary dyno.

3 Verify the bearings are the same distance from each mounting angle.

4 Slide the tensioner assembly on the floor as far back as possible, taking some slack

out of the belt.

Note: Do not tension the belt at this point.

5 Using a long straight edge, verify the tensioner pulley and the movable dyno

pulley are aligned.

6 With the tensioner assembly in this position, drill the eight holes needed to

secure the tensioner assembly to the floor.

7 Install eight Red Head anchors. Refer to Appendix A for installation instructions.

8 Secure the tensioner assembly to the floor using eight 3/8-16 x 1-inch bolts and

eight 3/8-inch flat washers.

Note: If a Red Head is drilled too deep, use one of the four 3/8 x 1.25-inch bolts

included. Two extra Red Heads are also included.

9 Apply some grease to the two ACME threads.

18

Linx Installation for Model 424 Automotive Dynamometers

Page 23

424 LINX INSTALLATION

XD054

tensioner pulley towards

stationary dyno

welded nuts towards back

apply grease to

ACME threads

Belt and Tensioner Pulley Assembly Installation

Figure 15: Install the Belt and Tensioner Pulley Assembly

Version 6 Linx Installation for Model 424 Automotive Dynamometers

19

Page 24

424 LINX INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulley Mounting Plates and Outer Bearings Installation

PULLEY MOUNTING PLATES AND OUTER BEARINGS INSTALLATION

Note: The inner pulley mounting plates and the pulley mounts are stamped with

numbers to help match the parts and guide you in the installation process.

You will need the following parts:

• 21200083 Stationary Dyno Pulley Bearing Mounting Plate

• 21200090 Moveable Dyno Pulley Bearing Mounting Plate

• 21200091 Idler Pulley Bearing Mounting Plate

• 32300001 Flange Bearing with Lock Collar (3)

• 36711100 Nut, 9/16-12, Hex (12)

• 36811640 Bolt, 9/16-12 x 2", Hex (12)

• 36900001 Washer, 1/4", Lock (4)

• 36923100 Washer, 3/8", Flat (60)

• 36943101 Washer, 9/16", Flat (12)

• 61300022 Pulley Mount, Upper, Stationary Dyno

• 61300023 Pulley Mount, Lower, Stationary Dyno (3)

used for stationary dyno pulley, lower

moveable dyno pulley, upper

idler pulley, lower

• 61300025 Pulley Mount, Upper, Idler Pulley

• 61300026 Pulley Mount, Lower, Moveable Dyno

• DM150-019-012 Bolt, 3/8-16 x 1", Hex (60)

20

Linx Installation for Model 424 Automotive Dynamometers

Page 25

424 LINX INSTALLATION

XD055

outer idler

bearing

idler bearing

plate

XD056

pulley mount

P/N 61300023

idler bearing plate

Pulley Mounting Plates and Outer Bearings Installation

INSTALLING THE IDLER PULLEY OUTER BEARING, BEARING MOUNTING PLATE, AND LOWER PULLEY MOUNT

1 Secure the outer idler bearing to the idler bearing mounting plate using four

9/16-12 x 2-inch bolts, four 9/16-inch flat washers, and four 9/16-inch nuts. Slide

this assembly onto the idler shaft.

Figure 16: Install the Outer Idler Pulley Bearing and Bearing Mounting Plate

2 Place a lower stationary dyno pulley mount (P/N 61300023) under the idler pulley

and loosely secure the mount to the inner plate using five 3/8-16 x 1-inch bolts

and five 3/8-inch flat washers (one of the holes in the pulley mount is not used).

3 Loosely secure the pulley mount to the idler bearing mounting plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers.

4 Before tightening these bolts, align the idler with the moveable dyno pulley.

With a straight edge on the idler pulley there should be a even gap of about

1/8-inch to the moveable dyno pulley.

5 Tighten all the bolts.

Figure 17: Secure the Pulley Mount Under the Idler Pulley

Version 6 Linx Installation for Model 424 Automotive Dynamometers

21

Page 26

424 LINX INSTALLATION

XD057

moveable dyno

puller bearing

moveable dyno pulley

bearing plate

moveable dyno

pulley

XD058

pulley mount

P/N 61300026

Pulley Mounting Plates and Outer Bearings Installation

INSTALLING THE MOVEABLE DYNO PULLEY OUTER BEARING, BEARING MOUNTING PLATE,

AND LOWER PULLEY MOUNT

1 Secure the outer moveable dyno pulley bearing to the moveable dyno pulley

bearing plate using four 9/16-12 x 2-inch bolts, four 9/16-inch flat washers, and

four 9/16-inch nuts. Slide this assembly onto the moveable dyno pulley outer

shaft.

Figure 18: Install the Outer Moveable Dyno Pulley Bearing and Bearing Plate

2 Place the lower moveable dyno pulley mount (P/N 61300026) under the

moveable dyno pulley and loosely secure the mount to the inner plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers.

3 Loosely secure the pulley mount to the moveable dyno pulley bearing plate using

three 3/8-16 x 1-inch bolts and three 3/8-inch flat washers.

Figure 19: Secure the Pulley Mount Under the Moveable Dyno Pulley

22

Linx Installation for Model 424 Automotive Dynamometers

Page 27

424 LINX INSTALLATION

XD059

pulley mount

P/N 61300023

Pulley Mounting Plates and Outer Bearings Installation

INSTALLING THE UPPER MOVEABLE DYNO AND IDLER PULLEY MOUNTS

1 Place a lower stationary dyno pulley mount (P/N 61300023) over the moveable

dyno pulley and loosely secure the mount to the inner plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers (one of the holes in the

pulley mount is not used).

2 Loosely secure the pulley mount to the moveable dyno pulley bearing plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers.

Figure 20: Secure the Pulley Mount Over the Moveable Dyno Pulley

Version 6 Linx Installation for Model 424 Automotive Dynamometers

23

Page 28

424 LINX INSTALLATION

XD060

pulley mount

P/N 61300025

Pulley Mounting Plates and Outer Bearings Installation

3 Place the upper moveable dyno pulley mount (P/N 61300025) over the idler

pulley and loosely secure the mount to the inner plate using five 3/8-16 x 1-inch

bolts and five 3/8-inch flat washers.

4 Loosely secure the pulley mount to the idler pulley bearing plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers.

5 Loosely secure the pulley mount to the movable dyno pulley bearing plate using

two 3/8-16 x 1-inch bolts and two 3/8-inch flat washers.

6 While applying upward pressure to support the shaft and pulley, tighten all the

bolts.

Figure 21: Secure the Pulley Mount Over the Idler Pulley

24

Linx Installation for Model 424 Automotive Dynamometers

Page 29

424 LINX INSTALLATION

XD068

lock washer

serrated edges

facing outward

lock washer

cap screw

Pulley Mounting Plates and Outer Bearings Installation

7 Remove the 1/4-20 x 1.75-inch cap screws from the splined shaft.

8 Verify the splined shaft will slide in and out of the dyno splines easily once all the

bolts are tightened.

Note: The splined shaft must easily slide in and out of the dyno splines in order

to engage and disengage the Linx belt drive.

9 Using the installation instructions included with the bearing, secure the lock

collars of both bearings.

10 Using two 1/4-inch lock washers, replace the 1/4-20 x 1.75-inch cap screws.

11 Tighten the 1/4-20 x 1.75-inch cap screws to 7 ft.-lb. (9.5Nm).

Note: A gap will remain between the splined shaft flange and outer shaft.

Note: The lock washer is comprised of two individual pieces. Should the washer

separate, verify the pieces go back together with the serrated edges facing

outward as shown in Figure 22.

12 Secure the cap screws with the shaft safety wire. Refer to Appendix C for

installation instructions.

Failure to secure the cap screws with safety wire can result in damage to the

dyno and/or the vehicle.

Figure 22: Install the Cap Screws and Lock Washers

Version 6 Linx Installation for Model 424 Automotive Dynamometers

25

Page 30

424 LINX INSTALLATION

XD061

stationary dyno

pulley bearing

stationary dyno

pulley bearing plate

stationary dyno

pulley

XD062

pulley mount

P/N61300023

stationary dyno

pulley bearing plate

Pulley Mounting Plates and Outer Bearings Installation

INSTALLING THE STATIONARY DYNO PULLEY OUTER BEARING, BEARING MOUNTING PLATE,

AND LOWER PULLEY MOUNT

1 Secure the outer stationary dyno pulley bearing to the stationary dyno pulley

bearing plate using four 9/16-12 x 2-inch bolts, four 9/16-inch flat washers, and

four 9-16-inch nuts. Slide this assembly onto the stationary dyno pulley outer

shaft.

Figure 23: Install the Outer Stationary Dyno Pulley Bearing and Bearing Plate

2 Place a lower stationary dyno pulley mount (P/N 61300023) under the stationary

dyno pulley and loosely secure the mount to the inner plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers (one of the holes on the

pulley mount is not used).

3 Loosely secure the pulley mount to the stationary dyno pulley bearing plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers.

Figure 24: Secure the Pulley Mount Under the Stationary Dyno Pulley

26

Linx Installation for Model 424 Automotive Dynamometers

Page 31

Pulley Mounting Plates and Outer Bearings Installation

XD063

pulley mount

P/N 61300022

INSTALLING THE UPPER STATIONARY DYNO PULLEY MOUNT

1 Place the upper stationary dyno pulley mount (P/N 61300022) over the stationary

dyno pulley and loosely secure the mount to the inner plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers (one of the holes on the

pulley mount is not used).

2 Loosely secure the pulley mount to the stationary dyno pulley bearing plate using

five 3/8-16 x 1-inch bolts and five 3/8-inch flat washers.

3 While applying upward pressure to support the shaft and pulley, tighten all the

bolts.

424 LINX INSTALLATION

Figure 25: Secure the Pulley Mount Over the Stationary Dyno Pulley

Version 6 Linx Installation for Model 424 Automotive Dynamometers

27

Page 32

424 LINX INSTALLATION

XD069

lock washer

serrated edges

facing outward

lock washer

cap screw

Pulley Mounting Plates and Outer Bearings Installation

4 Remove the 1/4-20 x 1.75-inch cap screws from the splined shaft.

5 Verify the splined shaft will slide in and out of the dyno splines easily once all the

bolts are tightened.

Note: The splined shaft must easily slide in and out of the dyno splines in order

to engage and disengage the Linx belt drive.

6 Using the installation instructions included with the bearing, secure the lock

collars of the bearing.

7 Using two 1/4-inch lock washers, replace the 1/4-20 x 1.75-inch cap screws.

8 Tighten the 1/4-20 x 1.75-inch cap screws to 7 ft.-lb. (9.5Nm).

Note: A gap will remain between the splined shaft flange and outer shaft.

Note: The lock washer is comprised of two individual pieces. Should the washer

separate, verify the pieces go back together with the serrated edges facing

outward as shown in Figure 26.

9 Secure the cap screws with the shaft safety wire. Refer to Appendix C for

installation instructions.

Failure to secure the cap screws with safety wire can result in damage to the

dyno and/or the vehicle.

28

Linx Installation for Model 424 Automotive Dynamometers

Figure 26: Install the Cap Screws and Lock Washers

Page 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE SIGNAL RELAY INSTALLATION

Use the following instructions along with Figure 27 on page 30 if you are upgrading

an existing dyno. If you are installing a new dyno, skip these instructions and

continue with “Tension the Belt” on page 31.

1 Disconnect the 4WD power supply.

2 Turn off the power to the dyno electronics.

3 Remove the two brake signal wires from the terminal labeled BRK IN on the 4WD

board.

4 Cut off the ferrules and strip the wires.

5 Attach the butt connector from the relay 85 to the yellow brake signal wire.

6 Attach the butt connector from the relay 86 to the black brake signal wire.

7 Remove the black and white power wires from the terminal labeled GND and +12

on the 4WD board.

8 Cut off the ferrules and strip the wires.

9 Attach the butt connector from the white jumper wire to the white power wire.

10 Insert one of the ferrules from the white jumper wire to the BRK IN terminal and

secure.

11 Insert the other ferrule from the white jumper wire to the +12 terminal and

secure.

12 Attach the butt connector from the relay 30 to the black power wire.

13 Insert the ferrule from the relay 30 wire to the GND terminal and secure.

14 Attach the yellow wire from the relay 87a to the open BRK IN terminal.

15 Secure the relay to the 4WD board using an existing nut.

16 Reconnect the 4WD power supply.

17 Turn on the power to the dyno electronics.

18 Wheelbase adjustment may now be performed only with the dyno brakes

released.

424 LINX INSTALLATION

Brake Signal Relay Installation

Version 6 Linx Installation for Model 424 Automotive Dynamometers

29

Page 34

424 LINX INSTALLATION

drumbrakefromB.O.B.

powersupply

movementswitch

railbrakepressureswitch

BLK

WHT

BLK

WHT

RED

YEL

YEL

BLK

BLK

WHT

YEL

CB024

secure relay to 4WD

board using existing nut

Brake Signal Relay Installation

Figure 27: Install the Brake Signal Relay

30

Linx Installation for Model 424 Automotive Dynamometers

Page 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TENSION THE BELT

You will need the following part:

• 62100003 Tension Arm Assembly

Use the following instructions along with Figure 28 on page 32.

1 Verify the drum brakes are released.

424 LINX INSTALLATION

Tension the Belt

The dyno wheel base should only be adjusted with the brakes released or the

Linx belt drive system disengaged.

2 Set the dyno to a wheelbase adjustment of 101-inches.

3 Measure 50.5-inches from the center of one of the drums. Mark this point on the

bridge tube closest to the belt.

4 Loosen the ACME lock nuts on the tensioner.

Note: Before tensioning the belt, the brakes must be released and the drums free

to turn.

5 Turn the ACME screws on the tensioner to tension the belt. Alternate sides to

keep the pulley aligned with the belt.

6 Once the belt has some tension, place the tension arm centered on the mark.

Verify the angle is completely seated on the underside of the tube.

7 Place two weights on the tension arm with the outer weight flush with the end of

the arm. If the weights want to slip off of the bar, tension the belt more before

putting the weights on.

Note: Use the weights included in the Eddy Current Brake calibration set.

8 With the weights placed on the bar, tension the belt until the tension bar is

horizontal.

9 Place a straight edge on the side of the tensioner pulley so it runs parallel to the

belt. Verify the distance between the straight edge and the edge of the belt is even.

Adjust this distance by turning one of the ACME screws if necessary.

10 Tighten the lock nuts.

11 Remove the weights and the tension arm.

12 Recheck the belt tension after the first several dyno runs and occasionally after

that.

Version 6 Linx Installation for Model 424 Automotive Dynamometers

31

Page 36

424 LINX INSTALLATION

XD088

mark 50.50 in. from center of drum

angle on underside of bridge tube

lock nuts

tension arm

weights

ACME screws

Tension the Belt

Figure 28: Tension the Belt

32

Linx Installation for Model 424 Automotive Dynamometers

Page 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABOVE GROUND COVERS

XD090

end panel

You will need the following parts:

• 21200095 Belt Cover, End Panel (2)

• 21200097 Belt Cover, Top (2)

• 21400006 Belt Cover, Leg (8)

• 21600026 Belt Cover, Center Support

• 36561045 Screw, 1/4-20 x 5/8", Pan-Head, Torx (64)

• 61100013 Belt Cover, Front Panel Assembly (2)

• DM150-020-005 Nut-Crush, 1/4-20 (8)

1 Place the tops flange side up on the floor.

2 Secure two legs in the corners of each top as shown using four 1/4-20 x 5/8-inch

torx screws each.

3 Secure one leg in the middle of each top as shown using two 1/4-20 x 5/8-inch

torx screws each.

4 Secure one leg in the corner of each top as shown using two 1/4-20 x 5/8-inch torx

screws each.

5 Secure each end panel using six 1/4-20 x 5/8-inch torx screws.

424 LINX INSTALLATION

Above Ground Covers

Figure 29: Install the Legs and End Panels

Version 6 Linx Installation for Model 424 Automotive Dynamometers

33

Page 38

424 LINX INSTALLATION

XD091

center support

center support included with

wheelbase extension kit

Above Ground Covers

6 Secure the two tops together using two 1/4-20 x 5/8-inch torx screws and two

1/4-20 nuts each.

7 Secure the center support to the tops using four 1/4-20 x 5/8-inch torx screws and

four 1/4-20 nuts.

Note: When the dyno is equipped with the wheelbase extension kit

(P/N 61119183), use the center support (P/N 21200176) included in the kit.

Figure 30: Secure the Tops Together and Install the Center Support

34

Linx Installation for Model 424 Automotive Dynamometers

Page 39

424 LINX INSTALLATION

XD093

center support

Above Ground Covers

8 Remove the 1/4-20 x 5/8-inch torx screw from the outer most tube of the dyno

bridge.

9 Turn the cover assembly over and move towards the dyno. Place the cover so the

center support is on the outer tube with the hole lined up as shown.

10 Secure the cover assembly to the dyno using the 1/4-20 x 5/8-inch torx screw

removed earlier.

Figure 31: Secure the Cover Assembly to the Dyno

Version 6 Linx Installation for Model 424 Automotive Dynamometers

35

Page 40

424 LINX INSTALLATION

XD094

Above Ground Covers

11 Secure each side panel to the cover assembly using seven 1/4-20 x 5/8-inch torx

screws.

Figure 32: Secure the Side Panels to the Cover Assembly

36

Linx Installation for Model 424 Automotive Dynamometers

Page 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IN GROUND COVERS

pit cover mount

center support

pit cover mount

center support

center support included with

wheelbase extension kit

You will need the following parts:

• 21200098 Pit Cover Mount

• 21217513 Calibration Access Cover (2)

• 21600026 Belt Cover, Center Support

• 21919101 Feet, Pit Cover (6)

• 36561045 Screw, 1/4-20 x 5/8", Pan-Head, Torx (16)

• 36580434 Bolt, 3/8-16 x 1/2" Button-Head Flange, Allen (8)

• 36923100 Washer, 3/8", Flat (6)

• 37513200 Anchor, Red Head, 3/8" (6)

• 37518200 Red Head Anchor Installation Tool

• 61329400 Pit Retarder Cover Assembly (2)

• DM150-019-012 Bolt, 3/8-16 x 1", Hex (6)

• DM150-020-005 Nut-Crush, 1/4-20 (4)

1 Secure the center support to the pit cover mount using four 1/4-20 x 5/8-inch torx

screws and four 1/4-20 nuts.

Note: When the dyno is equipped with the wheelbase extension kit

(P/N 61119183), use the center support (P/N 21200176) included in the kit.

424 LINX INSTALLATION

In Ground Covers

Figure 33: Secure the Center Support to the Pit Cover Mount

Version 6 Linx Installation for Model 424 Automotive Dynamometers

37

Page 42

424 LINX INSTALLATION

XD096

center support

assembly

In Ground Covers

2 Remove the 1/4-20 x 5/8-inch torx screw from the outer most tube of the dyno

bridge.

3 Secure the center support assembly to the outer bridge tube using the screw

removed earlier.

Figure 34: Secure the Center Support to the Dyno

38

Linx Installation for Model 424 Automotive Dynamometers

Page 43

424 LINX INSTALLATION

XD097

In Ground Covers

4 Place the pit cover assemblies on the floor in the position shown.

5 Secure the covers to the center support using two 3/8-16 x 1/2-inch button-head

flange bolts.

Figure 35: Secure the Pit Cover Assemblies to the Center Support

Version 6 Linx Installation for Model 424 Automotive Dynamometers

39

Page 44

424 LINX INSTALLATION

XD037

access cover

In Ground Covers

6 Secure the six angle feet to the pit cover assemblies in the positions shown using

one 3/8-16 x 1/2-inch button-head flange bolt each.

7 Using the feet as a template, drill each hole needed to secure the feet to the floor.

8 Install the six Red Head anchors. Refer to Appendix A for installation instructions.

9 Secure each foot to the floor using one 3/8-16 x 1-inch hex bolt and one 3/8-inch

washer.

10 Secure one access cover to each pit cover assembly using six 1/4-20 x 5/8-inch torx

screws each.

40

Figure 36: Install the Pit Cover Feet and Access Covers

Linx Installation for Model 424 Automotive Dynamometers

Page 45

424 LINX INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XD084

threaded holes

Disconnect the Belt Drive from the Dyno Drums

DISCONNECT THE BELT DRIVE FROM THE DYNO DRUMS

The Linx belt can be disengaged by pulling the splined shafts out of the dyno splines.

1 Loosen the three finger screws and lower the access panel.

For in ground dynos, remove the six 1/4-20 x 5/8-inch torx screws securing each

access cover and set aside. Remove each access cover and set aside.

2 Remove the two 1/4-20 x 1.75-inch cap screws and two 1/4-inch lock washers from

each shaft.

3 Thread the 1/4-20 x 1.25-inch cap screws into the threaded holes on the splined

shaft flange.

4 Tighten the cap screws until the tapered pins disengage from the tapered holes.

5 At each drum, pull the splined shaft out at least four inches.

Always disengage the belt drive at BOTH dynos.

Figure 37: Disconnect the Belt Drive from the Dyno Drums

Version 6 Linx Installation for Model 424 Automotive Dynamometers

41

Page 46

424 LINX INSTALLATION

Disconnect the Belt Drive from the Dyno Drums

RECONNECTING THE BELT DRIVE

1 Remove the 1/4-20 x 1.25-inch cap screws from the threaded holes in the splined

shaft.

2 Slide the shaft into the dyno drum aligning the two unthreaded holes in the

splined shaft flange with the two threaded holes in the outer shaft.

3 Install the 1/4-20 x 1.75-inch cap screws and 1/4-inch lock washers and torque to

7 ft.-lb. (9.5Nm).

4 Secure the cap screws with the shaft safety wire. Refer to Appendix C for

installation instructions.

Failure to secure the cap screws with safety wire can result in damage to the

dyno and/or the vehicle

42

Linx Installation for Model 424 Automotive Dynamometers

Page 47

R

ED

H

EAD

A PPENDIX

A

A

NCHOR INSTALLATION

This appendix contains instructions for installing the Red Head Multi-Set™II Anchors.

The anchors will be used to secure the dyno to concrete. To ensure safety and

accuracy in the procedures, perform the procedures as they are described. Be sure to

read and understand the warnings included in this appendix.

WARNINGS

Always wear safety glasses and other necessary protective devices or apparel

when installing or working with anchors.

ITW Ramset/Red Head Multi-Set II Anchors are designed to operate properly

only when installed with ITW Ramset/Red Head brand Setting Tools.

The use of a 24 to 40 ounce hammer is recommended for expanding Multi-Set II

anchors.

The use of carbide drill bits manufactured with ANSI B94. 12-77 drill bit diameter

requirements is recommended for installation of this anchor.

Not recommended for use in lightweight masonry material such as block or brick.

Use of core drills is not recommended to drill holes for use with this anchor.

Not recommended for use in new concrete which has not had sufficient time to cure.

Anchor spacing and edge distance requirements (anchor installation locations) are

the responsibility of the engineer of record.

CONTACT INFORMATION FOR ITW RAMSET/RED HEAD

Contact ITW Ramset/Red Head at 1-630-350-0370, or 1300 North Michael Drive,

Wood Dale, IL 60191.

Linx Installation for Model 424 Automotive Dynamometers

A-1

Page 48

APPENDIX A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

anchor

Installation

INSTALLATION

Use the table below to determine the catalog number, drill bit size, minimum hole

depth, and setting tool catalog number.

catalog number drill bit size minimum hole depth

Carbon Steel

RM-38/RL-38 (9.5 mm)

Use the following instructions to install the Red Head anchors.

1 Drill the hole in the concrete the same outside diameter as the anchor being used

to any depth exceeding minimum embedment.

setting tool

catalog number

1/2-inch 1 5/8-inch (41.2 mm) RT-138

Figure A-1: Red Head Anchor—Drill the Hole

2 Insert the anchor.

Figure A-2: Red Head Anchor—Insert the Anchor

A-2

Linx Installation for Model 424 Automotive Dynamometers

Page 49

RED HEAD ANCHOR INSTALLATION

setting tool

Installation

3 Using a hammer, drive the anchor flush with the surface of the concrete, or below

the surface if the hole depth exceeds minimum embedment.

Figure A-3: Red Head Anchor—Drive the Anchor Flush

4 Using a hammer, expand the anchor with the setting tool. The anchor is properly

expanded when the shoulder of the setting tool is flush with the top of the

anchor.

Note: Use only Ramset/Red Head setting tools to insure proper installtion.

Figure A-4: Red Head Anchor—Expand the Anchor

Version 6 Linx Installation for Model 424 Automotive Dynamometers

A-3

Page 50

Page 51

A PPENDIX

D

ISCONNECT THE

D

YNO

This appendix contains instructions for disconnecting the belt drive from the dyno

drums using early version shafts.

D

RUMS

B

—E

ELT

ARLY

D

RIVE FROM THE

V

ERSION

S

B

HAFTS

Linx Installation for Model 424 Automotive Dynamometers

B-1

Page 52

APPENDIX B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XD038

Disconnect the Belt Drive from the Dyno Drums

DISCONNECT THE BELT DRIVE FROM THE DYNO DRUMS

The Linx belt can be disengaged by pulling the splined shafts out of the dyno splines.

You will need the following part:

• 62100002 Shaft Puller Assembly

1 Remove the nine 1/4-20 x 5/8-inch torx screws securing each side panel and set

aside.

2 Remove the side panels and set aside.

For in ground dynos, remove the six 1/4-20 x 5/8-inch torx screws securing each

access cover and set aside. Remove each access cover and set aside.

3 Remove the cotter keys and clevis pins.

4 Insert a 3/8-inch bolt into the end of the splined shaft about three turns.

5 At each drum, pull the splined shaft out at least four inches.

Always disengage the belt drive at BOTH dynos.

B-2

Linx Installation for Model 424 Automotive Dynamometers

Figure B-1: Disconnect the Belt Drive from the Dyno Drums

Page 53

DISCONNECT THE BELT DRIVE FROM THE DYNO DRUMS—EARLY VERSION SHAFTS

XD039

shaft puller

Disconnect the Belt Drive from the Dyno Drums

6 If you are unable to pull the shaft out by hand, remove the top access cover and

use the shaft puller as shown.

Figure B-2: Using the Shaft Puller

Version 6 Linx Installation for Model 424 Automotive Dynamometers

B-3

Page 54

Page 55

S

HAFT

S

AFETY

W

A PPENDIX

C

IRE INSTALLATION

This appendix contains instructions for installing the shaft safety wire. To ensure

safety and accuracy in the procedures, perform the procedures as they are described.

Linx Installation for Model 424 Automotive Dynamometers

C-1

Page 56

APPENDIX C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

3

9,11

5

7

8

Installation

INSTALLATION

Use the following instructions to install the shaft safety wire.

Failure to secure the cap screws with safety wire can result in damage to the

dyno and/or the vehicle.

1 Torque the cap screws to 7 ft.-lb. (9.5Nm).

2 Bend the wire into a U shape with equal ends.

3 Insert the wire through the hole in the bolt.

4 Loop one end of the wire around the bolt clock-wise and match up the ends of

the wire.

5 Using safety wire pliers, clamp the ends of the wire together and twist the wires

together until you reach the second bolt.

6 Remove the safety wire pliers.

7 Insert the wire through the hole in the second bolt.

8 Loop one end of the wire around the bolt counter clock-wise and match up the

ends of the wire.

9 Using safety wire pliers, clamp the ends of the wire together and twist the wires

together.

10 Cut off the excess wire.

11 Tuck the remaining wire around the bolt.

Figure C-1: install the Shaft Safety Wire

C-2

Linx Installation for Model 424 Automotive Dynamometers

Loading...

Loading...