Page 1

Quick Start Guide

DynoWare RT - 224 Dynos

CABLE ROUTING

Connect the pendant cable to the DynoWare RT module.

Connect the atmospheric cable to the DynoWare RT module.

Connect the four-pin communication cable from the Air Fuel Ratio module to the

DynoWare RT module.

Connect the four-pin communication cable from the front of the Eddy Current Brake driver

module to the DynoWare RT module.

Connect a primary RPM pick up cable or a secondary pick up cable to the DynoWare RT module.

Connect the six-pin speed/brake cable to position 1 on the DynoWare RT module.

Note: For 4WD dynos, connect the speed/brake cable from the stationary dyno to

position 1 and connect the speed/brake cable from the moveable dyno to position 2.

Connect the ethernet cable from the ethernet port on the DynoWare RT module to your

Local Area Network or directly to the network port on your computer. Refer to your dyno

installation guide for more information.

Connect the three-pin temperature sensor cable to the three-pin port on the Eddy Current Brake

driver module.

Note: Make these connections for both Eddy Current Brake driver modules for 4WD dynos.

DWRT ECB AFR

B

B

B

C

C

B

DynoWare RT Main Module

(DWRT)

Eddy Current Brake

Driver Module (ECB)

98200047.01

Connect the five-pin load cell cable to the five-pin port on the Eddy Current Brake driver module.

Note: Make these connections for both Eddy Current Brake driver modules for 4WD dynos.

Set the ID switch on the Eddy Current Brake driver module to 0 for 2WD dynos.

For 4WD dynos, set the Eddy Current Brake driver module ID switch on the

stationary dyno to 0 and set the ID switch on the moveable dyno to 2.

1. Insert the Dynojet Power Core CD in your CD-ROM drive. The launch program will run automatically.

If auto-run is disabled on your computer, click Start on the Windows task bar, and click Run.

Type D:\setup.exe, where D corresponds to your CD-ROM drive.

2. Follow the on-screen instructions to install the Power Core software.

3. Double-click the Power Core program icon installed on your desktop or on your start menu. This will

run the Dynojet Application Launcher.

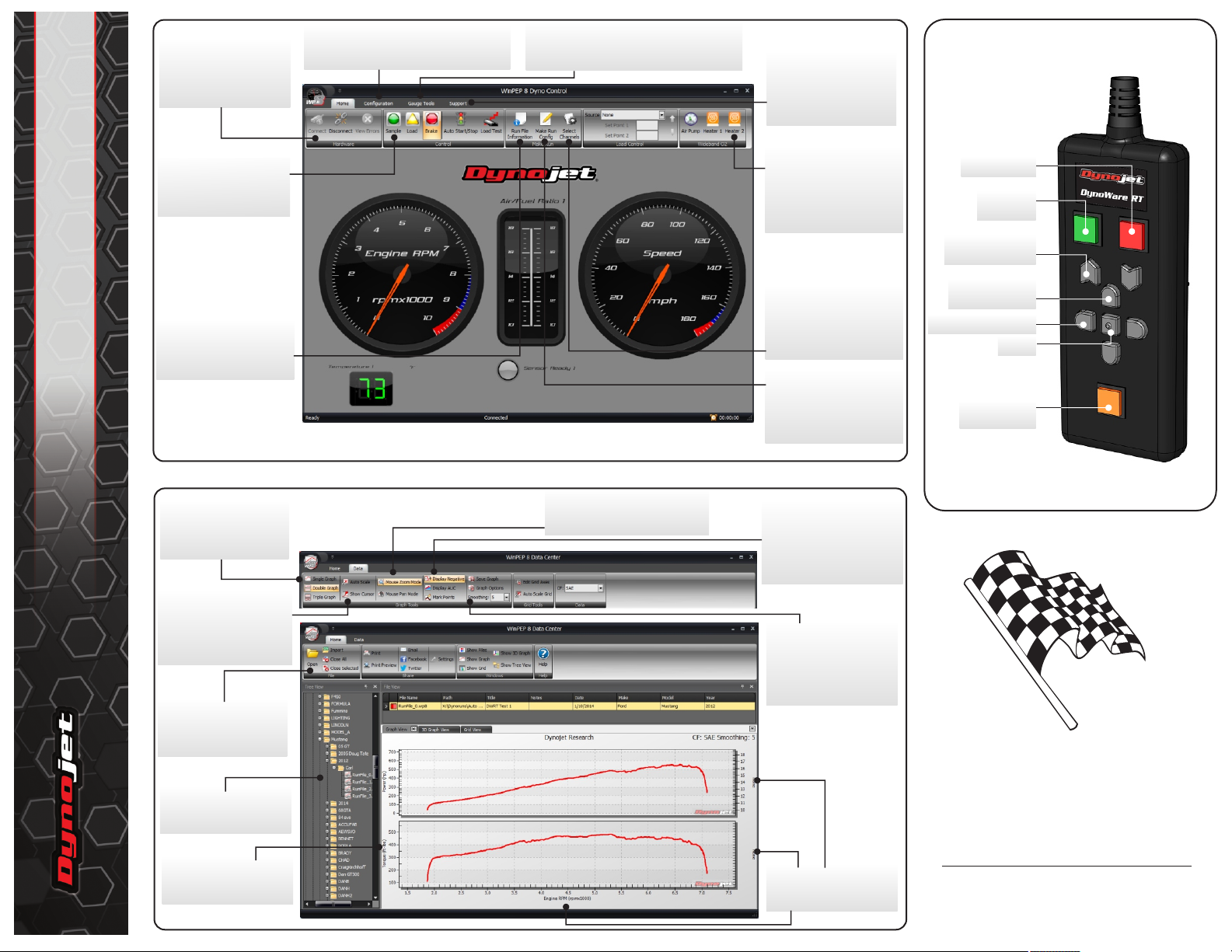

4. Click WinPEP 8 Dyno Control from the Application Launcher.

5. Connect to DynoWare RT Control. See page 2 for more information.

6. Turn on the DynoWare RT main module. Allow several minutes for your computer to

connect to the main module.

Dynojet Research 2191 Mendenhall Drive North Las Vegas, NV 89081

1-800-992-4993 www.dynojet.com

I.D.

Air Fuel Ratio Module

(AFR)

INSTALL YOUR SOFTWARE

Page 2

Get Connected

Check the Connect

Automatically box, choose

DynoWare RT, and Click

Connect.

Configuration Options

Calibrate the load cells, select the RPM

source, and configure your analog sensors.

Manage your Gauges

Choose a template or design your own! Add

a new gauge and configure existing gauges.

PENDANT OVERVIEW

Get Help

Update your device, get

device support, and find

answers to your questions

using the Help.

DynoWare RT - 224 Dynos

98200047.01

Ready to Sample

Click Sample or the green

button on the pendant to

start a run.

Save Run File Info

Enter vehicle data, notes,

and important run file

information.

WINPEP 8 DYNO CONTROL

Want to see more

graphs?

Switch views between

one, two, or three graphs.

View cursor and all data

When zoomed or panned,

click Auto Scale to show all

data. Click Show Cursor to

show or hide the cursor.

Manage your runs

Use the File functions to

browse for, open, import

and close your runs.

Tree View

Browse to your run files.

Double-click to view a file.

Choose your channels

Click any axis to view a list

of channel options.

WINPEP 8 DATA CENTER

Home and Data Ribbons

Zoom and pan

When highlighted, click and drag

on the graph to zoom or pan.

Have a Wideband O2?

Activate the AFR Pump and

O2 sensor heaters. When

the sensor is in an exhaust

bung, the pump can be left

off.

Log Data Channels

Choose which data

channels will be logged.

Any channel assigned to a

gauge will be logged.

Dyno Run Options

Set your dyno run options in

Make Run Config.

Show the information

you need

Click Display AUC to view

the area under the curve.

Click Mark Points to view the

data points on the graph.

More Graph Options

Save your graph as an

image file, change the axis

scaling and add labels to

your graph, and control

the smoothing level.

Choose your channels

Click any axis to view a list

of channel options.

Brake on/off

Sample

start/stop

Load control set

point up/down

Brings dyno

control to front

Left/Right in dialog

Okay

Load Control

on/off

The Next Step

Congratulations!

You are now ready to use your new

Dynoware RT integrated platform.

Access more detailed Dynoware RT

installation and user instructions in the

Dynojet Power Core Software Help.

For more information on Dynoware RT,

visit us online at www.dynojet.com

or call 800-992-4993.

Loading...

Loading...