Page 1

CLUTCH KIT

INSTALLATION GUIDE

2020 Canam X3 RR models

PARTS LIST

6 CLUTCH ARMS

1 PRIMARY SPRING GOLD

1 SECONDARY SPRING LIGHT GREEN

PLEASE READ ALL DIRECTIONS BEFORE STARTING INSTALLATION

THIS KIT REQUIRES SPECIAL TOOLS FOR INSTALLATION.

FOR BEST RESULTS, DYNOJET RECOMMENDS

INSTALLATION BY A QUALIFIED TECHNICIAN.

2191 MENDENHALL DRIVE, NORTH LAS VEGAS, NV 89081

800-992-4993 WWW.DYNOJET.COM

25-DCK3

24 MAGNETS (3/8”)

12 WASHERS

Page 2

CLUTCH KIT ADJUSTMENT

SETTINGS

INTENDED USE ELEVATION MAGNETS TOTAL WEIGHT PRIMARY SPRING SECONDARY SPRING HELIX POS

Trail Std Tire

Paddle Tire / Heavy load

0-4000 ft 2 52 gr GOLD LIGHT GREEN 1

0-4000 ft 1 50 gr GOLD LIGHT GREEN 1

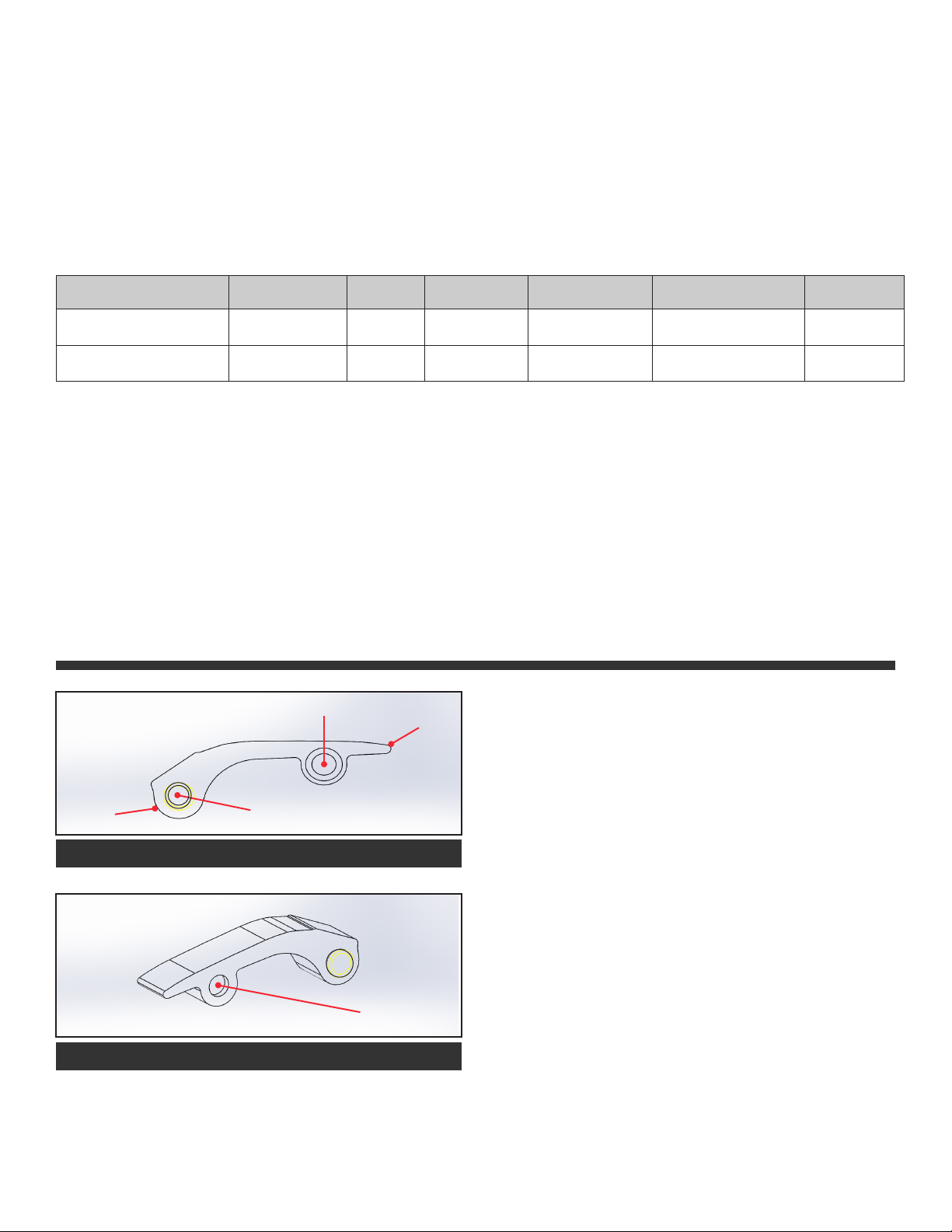

CLUTCH ARM ADJUSTMENT

MAGNET POS

TOE

HEEL

LOAD MAGNETS STARTING AT HEEL - POS #1

PIVOT

LOAD MAGNETS PER THE TABLE ABOVE. MAKE SURE EACH

CLUTCH ARM IS LOADED WITH THE SAME AMOUNT OF

WEIGHT.

1 MAGNET CHANGE ON EACH ARM WILL ALTER

•

RPM APPROXIMATELY 150RPM

WHERE THE SPRING IS INDICATED ON THE

•

HELIX ALSO AFFECTS TARGET RPM

OUR SETTINGS ARE A GENERAL BASELINE. MANY THINGS

CAN EFFECT CLUTCH SETUP:

USE A SMALL

ALLEN KEY OR

SIMILAR TO PUSH

THE MAGNETS

OUT FROM THIS

SIDE

TO REMOVE MAGNETS

25-DCK3 CLUTCH KIT 2020 CANAM X3 RR

TIRE BRAND & SIZE

•

STATE OF CLUTCH WEAR

•

DRIVEBELT CONDITION

•

ENGINE POWER OUTPUT

•

ENVIRONMENT CONDITIONS

•

Page 3

INSTALLATION INSTRUCTIONS

IT IS RECOMMENED TO HAVE AN AUTHORIZED CANAM

TECHNICIAN INSTALL THE CLUTCH KIT AS SPECIAL TOOLS

ARE NEEDED TO COMPLETE THE INSTALLATION.

Remove all the 8mm head bolts for the plastic, clutch

housing. Remove clutch housing. Mark the direction of the

drivebelt. Remove the drivebelt. Although there are arrows

on the sheaves it is a good idea to make a mark that you

can easily see to ensure proper alignment when reinstalling. Using the Canam clutch puller part #529 035 746 remove the primary clutch. It is recommended to grease the

threads of the clutch puller before usage.

To disasemble the primary clutch use special tool 529 036

350.

Remove the 6 bolts

for the spring cover to access the

primary spring.

Replace the primary spr ing with the supplied Dynojet

GOLD spring. Reverse order of disassembly. Make sure

to clean the taper of the assembly and the face of the

sheaves properly. When installing the primary assembly

back on the crankshaft make sure that your original marks

are aligned before tightening. Replace the drive pulley

screw and torque to 89lb/ft.

Remove the secondary

clutch assembly from the

vehicle. To disasseble the

secondary clutch use special tool part #529 036 012.

Take notice of the arrow

marks on each sheave. It is

best to make marks on the

edge of each sheave with a

marker for ease of reassembly.

Once the sheaves have been separated you can remove the

special tool. Slide the governor cup out of the guides. If the

slider shoes fall out make sure you inspect the slider and

O’ring.

Remove the stock clutch arms using a T25 torx and 8mm

wrench. Replace with the Dynojet arms using the required number of magnets per chart on page 2. Make sure

to reinstall the stock thrust washers on each side of the

arms. There are replacement washers included in the kit if

needed.

Place special tool part # 529 036 012 in a secure vice. Slide

primary assembly over the tool and tighten down the tool

over the spring cover. Remove the 6 bolts holding the sping

cover in place. Remove the special tool.

#1

#6

#5

#2

#3

#4

While the secondary is compressed remove the 3 torx

cam retaining screws.

With the secondary clutch

disassembled inspect the

cam.

The #1 location in this pic

is the location where the

STOCK alignment arrow is.

INSTALLATION GUIDE

Page 4

Slide the secondary sheave onto the special tool. Put the stock plastic cup and Dynojet Light Green spring into the sheave

making sure the tab on the spring is inserted into the hole in the sheave correctly. Install the cam over the spring engaging

the hole location per the chart on page 2. Rotate the sheave per the pictures below so the roller engages the next finger.

CAM POSITION #1

Rotate cam 130°

Roller

Roller

STOCK CAM POSITION CAM POSITION #3

Rotate cam 90°

Align the marks on each sheave. Fully compress the sheaves and

reinstall the 3 torx screws to 45 lb/ft. Clean the sheaves thoroughly

and the transmission shaft. Reinstall the secondary clutch assembly onto the transmission shaft. Replace the bolt and torque to 52

lb/ft.

Rotate cam 50°

Roller

FINGER AND ROLLER ENGAGMENT

TUNING NOTES

For best performance your RPM when checked at 55 mph should be 7850-8000rpm. This should be checked on a surface

that offers good traction and tested with normal load in the vehicle. Adjustments to overall weight of each clutch arm and/

or secondary springs may be necessary to achieve this RPM target.

If you were to test on the street and then ride in the sand or mud it is not uncommon to see a loss of 300-400rpm if using

paddle tires.

Our settings are based on using a PowerVision tune in the ECM for optimal performance.

TOOLS NEEDED FOR INSTALLATION

DYNOJET CLUTCH SERVICE KIT 16300002

•

8MM SOCKET

•

T27 TORX

•

T30 TORX

•

22MM SOCKET

•

17MM SOCKET

•

25-DCK3 CLUTCH KIT 2020 CANAM X3 RR

Page 5

PUSH THE LIMIT.

WWW.DYNOJET.COM

© 2018 DYNOJET RESEARCH ALL RIGHTS RESERVED

INSTALLATION GUIDE

Loading...

Loading...