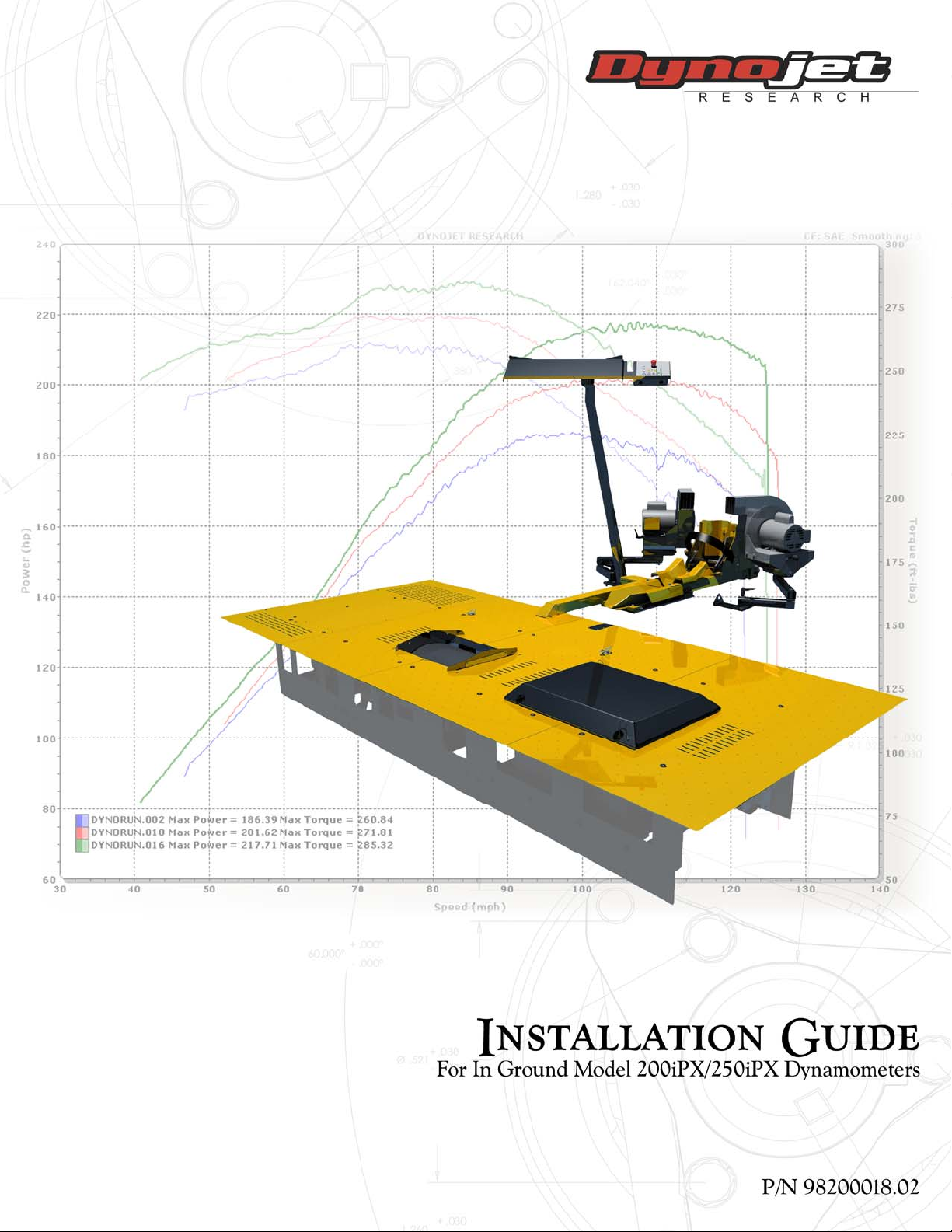

Page 1

Page 2

©2008-2009 Dynojet Research, Inc. All Rights Reserved.

Installation Guide For In Ground Model 200iPX and 250iPX Motorcycle Dynamometers.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual is furnished under license and may only be used

or copied in accordance with the terms of such license. This manual is furnished for

informational use only, is subject to change without notice, and should not be construed

as a commitment by Dynojet. Dynojet assumes no responsibility or liability for any error

or inaccuracies that may appear in this manual. Except as permitted by such license, no

part of this manual may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, recording, or otherwise, without the prior

written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98200018 Version 2 (01/2009)

RECORD

Dynamometer Number: ____________________________________________________

iPX Dynamometer Number: _________________________________________________

Eddy Current Brake

(Retarder) Number:______________________________________________________

#

Page 3

T

ABLE OF

C

ONTENTS

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Chapter 1 Specifications and Operating Requirements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Confirmation of Compliance Testing and Certification . . . . . . . . . . . . . . . . 1-3

Your Dyno Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Dynamometer Specifications and Requirements . . . . . . . . . . . . . . . . . . . .1-5

Battery Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Chassis Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Compressed Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Computer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Drill and Drill Bit Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Forklift Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Ground Hook Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Phone and Internet Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Tie-Down Straps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Dyno Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Verify the Pit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

i

Page 4

TABLE OF CONTENTS

Chapter 2 Installation

Dyno Drum Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpacking the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Removing the Dyno from the Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Placing the Dyno in the Pit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Eddy Current Brake Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Unpacking the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Installing the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

iPX Drum Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Removing the Items from Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Installing the iPX Drum Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Lining up and Securing the Module Uprights . . . . . . . . . . . . . . . . . . . . . .2-16

Secure the Drum and Brake Module to the Pit Floor . . . . . . . . . . . . . . . . 2-17

Pickup Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Left Side Blower and Monitor Arm Installation . . . . . . . . . . . . . . . . . . . . .2-19

Installing the Left Blower Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Installing the Monitor Support and the Junction Box . . . . . . . . . . . . . . . .2-21

Installing the Left Blower Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Installing the Monitor Arms and Monitor Tray . . . . . . . . . . . . . . . . . . . . .2-23

Trike Carriage Adapter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

Installing the Trike Carriage Adapter Plate . . . . . . . . . . . . . . . . . . . . . . . .2-24

Installing the Right Blower Mount and Blower Assembly . . . . . . . . . . . . .2-25

Installing the Cable Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Routing Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

Battery Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Installing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Accessing the CPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Routing the Control Panel, Pendant Cables, and RPM Cable . . . . . . . . . .2-33

Routing the High Pressure Blower Cables . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Routing the Power Carriage and Wheel Clamp Cables . . . . . . . . . . . . . . . 2-38

Routing the Eddy Current Brake, Battery, and Dyno Power Cables . . . . . .2-39

Routing the Pickup Card and Dyno Electronics Cables . . . . . . . . . . . . . . . 2-41

Routing the Air Pump Power, Air Fuel Sensor, and Dyno Electronics

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

Wiring the Breakout Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

Carriage Assembly and Power Carriage Installation . . . . . . . . . . . . . . . . .2-45

Installing the Carriage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

Installing the Power Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

Installing the Tire Stop and Cable Track Adapter Bracket . . . . . . . . . . . . .2-47

Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

Turning On the Dyno Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

High Pressure Blower Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Power Carriage Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . .2-49

Trike Adapter Assembly Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Wheel Clamp Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . .2-49

Pit Covers Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Junction Box Cover, Cable Cover, and End Cap . . . . . . . . . . . . . . . . . . .2-58

Zip Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

Ground Hook Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-60

ii

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 5

Chapter 3 Accessories

Main Dyno Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Air Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Routing the Air Brake Cable and Air Hose . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installing the Emergency Stop Sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Air Brake Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Changing the Brake Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Adjusting the Brake Pad Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Compressed Air Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Wheel Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Installing the Wheel Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Wheel Clamp Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . .3-19

Chapter 4 Control Panel Interface Operation

Basic CPI Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Using the Air Fuel Ratio Air Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Using the Emergency Stop/Dyno Shutdown . . . . . . . . . . . . . . . . . . . . . . .4-4

Using the High Pressure Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Understanding Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Using the Power Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Using the Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Using the Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Using the Wheel Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Power Distribution Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Main Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

High Pressure Blower Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Maintaining and Troubleshooting the Wheel Clamp . . . . . . . . . . . . . . . . . 4-9

Replacing the Theta Controller Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Troubleshooting CPI Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

TAB LE OF CON T ENTS

Chapter 5 Basic Dyno Operation

Loading the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Connecting the RPM Pickup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

RPM Pickup Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Connecting the Secondary Inductive Pickup . . . . . . . . . . . . . . . . . . . . . . .5-5

Connecting The Primary Inductive Pickup . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Pre-Run Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Before Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Engine Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

After Engine Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Making a Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

iii

Page 6

TABLE OF CONTENTS

Appendix A Red Head Anchor Installation

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Contact Information for ITW Ramset/Red Head . . . . . . . . . . . . . . . . . . . . .A-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Appendix B Power Requirements and Installation

Locations Using 60 Hz Power (North America and Japan) . . . . . . . . . . . .B-2

Installing the Wall Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Testing for Correct Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Replacing the Power Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Hard Wiring to the Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Connecting the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

Locations Using 50 Hz Power (Locations other than North America

and Japan)

Installing the Wall Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Testing for Correct Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-9

Replacing the Power Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-10

Hard Wiring to the Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-10

Connecting the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Appendix C EEC Finger Guard and

Door Safety Switch Installation

EEC Finger Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Installing the EEC Finger Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Adjusting the EEC Finger Guards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Door Safety Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Installing the Door Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Appendix D Theta Controller

Power Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Accessing the Dip Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Appendix E Dyno Preparation for Upgrade Installation

Dyno Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Removing the Cable Cover, End Cap, and Junction Box Cover . . . . . . . . . . E-2

Removing the Monitor Tray and Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Disconnecting the Cable Track and Moving the Cables. . . . . . . . . . . . . . . . E-5

Removing the Monitor Support and Junction Box. . . . . . . . . . . . . . . . . . . . E-6

Removing the Carriage and Carriage Plate . . . . . . . . . . . . . . . . . . . . . . . . . E-7

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-i

iv

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 7

W

ARNINGS

Disclaimers

Dynojet Research, Inc. (Dynojet) makes no representation or warranties with respect to the contents

hereof and specifically disclaims any implied warranties of merchantability for any particular purpose.

Dynojet reserves the right to revise this publication and to make changes from time to time in the

content hereof without obligation of Dynojet to notify any person of such revision or changes.

Dynojet is not responsible for false operation due to unexpected dynamometer operation such as may

be caused by static, software bugs, hardware failure, etc.

Dynojet is not responsible for damage resulting from improper installation of the dynamometer or

from improper service rendered to the dynamometer. Dynojet is not responsible for damage incurred

due to alteration of the dynamometer or components, use of unapproved parts, or abuse to the

dynamometer.

Do not connect or disconnect cables or components on the dynamometer with the power on.

Always wear protective clothing, ear protection, and eye protection (goggles, safety glasses) when

using and servicing the dynamometer.

Equipment Power Requirements

The dynamometer has specific power requirements. Connecting the dynamometer to the incorrect

voltage will void the dynamometer warranty. Installation may require a licensed electrician.

Potentially Lethal Voltages

Components attached to and within the dynamometer operate with potentially lethal voltages. To

provide the greatest assurance of safety, the AC power cord(s) must be disconnected from the power

source before servicing electrical components or wiring. Disconnect all power cords before servicing

electrical components for the greatest assurance of safety.

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

v

Page 8

WARN IN GS

Electrostatic Discharge Precautions

Electrostatic Discharge

Electrostatic Discharge (ESD), or static shock, can damage electronic components within the

dynamometer. The damage may occur at the time of an ESD occurrence, or the shock may degrade

the component, resulting in a premature component failure later. To avoid ESD damage, always

practice good ESD control precautions when servicing the dynamometer. Dynojet designs its

dyn amo me ter s to be v er y to ler ant of sta tic sho ck s by the users, but the electronics are vulnerable when

the electronics are exposed. ESD occurs as a result of a difference of potential between two objects

when the two objects touch. Damage occurs as a result of the energy released when the discharge

(touch) occurs. The difference of potential can accumulate by as simple an action as a user moving

across carpet or a seat. If that person’s energy is discharged directly to the electronics, the electronics

can be damaged.

Precautions

To protect against ESD damage, you must eliminate the difference of potential before the electronics

are handled. Touch the chassis of the dynamometer before touching any of the electronics. By touching

the chassis, you discharge any static shocks to the chassis instead of to the electronics.

If you are holding a circuit board or dynamometer component in your hand when you approach the

machine, touch the chassis of the dynamometer with your hand before installing the circuit board or

component.

When handing a circuit board or component to someone, touch that person with your hand first, then

hand them the component.

Always carry circuit boards in anti-static bags when the boards are exposed (removed from the

dynamometer).

Battery Fire and Explosion Hazards

There is a danger of explosion if the battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the manufacturer. Discard used batteries according to the

manufacturer’s instructions.

Automotive Batteries

In operation, batteries generate and release flammable hydrogen gas. They must always be assumed

to contain this gas which, if ignited by burning cigarette, naked flame or spark, may cause battery

explosion with dispersion of casing fragments and corrosive liquid electrolyte. Carefully follow

manufacturer's instructions for installation and service. Keep away all sources of gas ignition and do

not allow metallic articles to simultaneously contact the negative and positive terminals of a battery.

Do not allow the positive and negative terminals to short-circuit. The dynamometer chassis is tied to

the negative side of the battery. Do not short between the positive battery terminal or the starter

connections to the chassis. In addition, make sure metal tools such as screw drivers, wrenches, and

torque wrenches do not come in contact with the negative and positive terminals of the battery. Short

circuiting the terminals of the battery can cause burn injuries, damage to the dynamometer, or trigger

explosions.

Charging

Batteries being charged will generate and release flammable hydrogen gas. Charging space should be

ventilated. Keep battery vent caps in position. Prohibit smoking and avoid creation of flames and sparks

nearby.

Wear protective clothing, eye and face protection, when charging or handling batteries.

vi

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 9

WAR NIN GS

Other Potential Hazards

The AC power outlet shall be installed near the equipment and it shall be easily accessible to allow for

disconnect before service.

The dynamometer should be located in a well ventilated area. There is a carbon monoxide hazard with

all internal combustion engines. Engine exhaust contains poisonous carbon monoxide gas. Breathing

it could cause death.

Any dyno room design must incorporate sufficient exhaust extraction.

Always wear proper ear and eye protection when operating the dynamometer.

Never operate the dynamometer with the covers removed.

Never stand behind the dynamometer when in operation.

Never operate the dynamometer when there is excessive vibration or noise. Resolve these problems

before proceeding.

Never fuel the vehicle on the dynamometer unless appropriate safety measures are taken.

Verify brake operation before beginning any dynamometer testing.

Verify the vehicle is properly secured to the dynamometer.

Never operate the blowers without the guards installed.

Exercise care with any dynamometer testing; portions of the dynamometer and vehicle may become

hot.

As with any equipment using electricity and having moving parts, there are potential hazards. To use

this dynamometer safely, the operator should become familiar with the instructions for operation of

the dynamometer and always exercise care when using it.

Do not repair or replace any part of the dynamometer or attempt any servicing unless specifically

recommended in published user-repair instructions that you understand and have the skills to carry

out.

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

vii

Page 10

Page 11

C HAPTER

S

PECIFICATIONS AND

Thank you for purchasing Dynojet’s In Ground Model 200iPX/250iPX Motorcycle

Dynamometer. Dynojet’s software and dynamometers will give you the power to get

the maximum performance out of vehicles you evaluate. Whether you are new to the

benefits of a chassis dynamometer or an experienced performance leader, the

repeatability and diagnostic tools of WinPEP 7 software and a Dynojet dynamometer

will give you the professional results you are looking for.

This document provides instructions for installing the in ground motorcycle

dynamometer (dyno) along with the kart upgrade. This document will walk you

through operating requirements, installation, accessories, and basic dyno operation.

To ensure safety and accuracy in the procedures, perform the procedures as they are

described.

Document Part Number: 98200018

O

PERATING

R

EQUIREMENTS

1

Versio n 2

Last Updated: 01-12-09

This chapter is divided into the following categories:

•Introduction, page 1-2

• Dynamometer Specifications and Requirements, page 1-5

• Dyno Electronics, page 1-10

• Verify the Pit Dimensions, page 1-11

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

1-1

Page 12

CHAPTER 1

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before installing your dyno, please take a moment to read this guide for installation

instructions, dyno features, and other important information.

This guide is designed to be a reference tool in your everyday work and includes the

following chapters and information:

SPECIFICATIONS AND OPERATING REQUIREMENTS

This chapter describes the requirements and specifications for the dyno.

INSTALLATION

This chapter describes the procedures for installing the dyno.

ACCESSORIES

This chapter lists each dyno accessory alphabetically and describes the procedures for

installing and using the accessory.

CONTROL PANEL INTERFACE OPERATION

This chapter describes the Control Panel Interface (CPI) operating procedures.

BASIC DYNO OPERATION

This chapter describes basic dyno operating procedures.

RED HEAD INSTALLATION

This appendix describes the procedures for installing the Red Head anchors.

POWER REQUIREMENTS

This appendix describes the power requirements and installation instructions for all

locations excluding North America.

EEC FINGER GUARD & DOOR SAFETY SWITCH KIT

This appendix describes the procedures for installing the EEC finger guards and door

safety switch.

THETA CONTROLLER

This appendix describes how to make power adjustments to the theta controller.

DYNO PREPARATION FOR UPGRADE INSTALLATION

This appendix describes how to prepare an existing dyno for installing the iPX

upgrade kit.

1-2

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 13

SPECIFICATIONS AND OPERATING REQUIREMENTS

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

The Record # icon reminds you to record your

RECORD

#

dynamometer and/or eddy current brake (retarder)

number on the inside cover of this manual.

Introduction

Bold Highlights items you can select on in the software

!

interface, including buttons and menus.

The arrow indicates a menu choice. For example,

“select

File !Open” means “select the File menu,

then select the

Open choice on the File menu.”

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, 3D visualizations, and press releases

about our latest product lines.

CONFIRMATION OF COMPLIANCE TESTING AND CERTIFICATION

Dynojet Model 200iP, 200iPX, 250iP, and 250iPX dynamometers have

been tested to NFPA 79:2002 and UL 508(A) standards and pass the

requirements.

Certificate Number: US72080032.01

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

1-3

Page 14

CHAPTER 1

Introduction

YOUR DYNO ROOM

This section is not meant to imply that a dyno room is essential to repeatable results

on a Dynojet dynamometer. However, a dyno room with an engine cooling intake fan,

exhaust extraction, and noise reduction capabilities can add a new dimension to your

shop.

A proper dyno room design will help to ensure repeatable, accurate runs. A good

dyno room should do the following:

• minimize noise

• provide a controlled environment for testing

• provide a view window (safety glass) for customers

• be designed with safety in mind

Intake Air Fan—After building your dyno room, you will need to supply an intake air

fan. The intake air fan supplies air to cool the bike’s engine while supplying fresh

oxygen for you and your bike to breathe. It is a common misconception that you

cannot tune a bike without a large fan simulating exact road conditions; however, a

good cooling fan is the only requirement for consistent diagnostics and tuning. The

installed fan should be 5200 CFM.

Equalizer Box—If the air flow rate coming into the dyno room is greater than the air

flow rate leaving the dyno room, the room will become pressurized. A pressurized

dyno room will make measured power misleading. To compensate, you need an

equalizer box. The equalizer box is a baffled (to reduce noise) vent to the outside of

your dyno room. The size of the equalizer box is dependent on the size of your dyno

room and the size of your fans.

Exhaust Extraction—An exhaust fan is needed to remove exhaust gasses, especially

carbon monoxide, from the dyno room. Carbon monoxide is potentially lethal to

people if not removed from the room and will affect engine power when mixed with

fresh air. Plans for exhaust extraction (P/N 73429201) are available from Dynojet.

Engine exhaust contains poisonous carbon monoxide gas. Breathing it could

cause death. Operate machine in well ventilated area.

Fire Suppression—Always have adequate fire suppression or fire extinguishers in

your dyno room.

Industrial Noise Control, Inc.—Industrial Noise Control, Inc. offers a zinc-coated

steel room custom built to your specifications. This room meets all dyno room

requirements. The dyno room must be clean and dry with a comfortable room air

temperature above 32 degrees Fahrenheit (0 degrees Celsius), and have some system

of exhaust extraction. For more information on a dyno room, refer to your

Pre-Installation Guide For Model 200i, 250i, 200iP, and 250iP Motorcycle

Dynamometers (P/N 98129103).

1-4

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 15

SPECIFICATIONS AND OPERATING REQUIREMENTS

Dynamometer Specifications and Requirements

DYNAMOMETER SPECIFICATIONS AND REQUIREMENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following specifications and requirements will help you set up your dyno area

and verify you have the requirements to operate your dyno safely.

BATTERY REQUIREMENTS

Your 200iPX/250iPX dyno is designed to carry a group 24 deep-cycle discharge series

battery for operating the starter, power carriage, and optional wheel clamp. The

typical dimensions for this series of batteries are 27 cm long by 17 cm wide by 23 cm

tall (10.625-inches by 6.75-inches by 9.125-inches). The mounting is flexible so a

battery that has dimensions close to this will work satisfactorily. The built-in battery

cables are configured for top-post batteries. This battery is not included with your

dyno. You will need to provide this battery. For more information on installing the

battery, refer to “Installing the Battery” on page 2-31.

CHASSIS SPECIFICATIONS

description specifications

Length

with standard carriage allow 304.80 cm (120.00 in.)

with extended carriage allow 355.60 cm (140.00 in.)

iPX drum module 76.20 cm (30.00 in.)

pit covers 137.16 cm (54.00 in.)

Height

from bottom of dyno to top of dyno 45.72-46.67 cm (18.00-18.38 in.)

from top of pit to drum guard 5.40 cm (2.13 in.)

from top of pit to top of tire carriage 50.64 cm (16.00 in.)

Width

dyno with upgrade 271.42 cm (106.86 in.)

pit covers with eddy current brake 310.29 cm (122.16 in.)

Weight

model 200iP drum module/crated dyno 725 kg (1600 pounds)/817 kg (1800 pounds)

model 250iP retarder module/crated dyno 953 kg (2100 pounds)/1,089 kg (2400 pounds)

200iPX/250iPX drum module/crated 136 kg (300 pounds)/363 kg (800 pounds)

Drum

diameter 45.72 cm (18.00 in.)

width 50.80 cm (20.00 in.)

diameter, 200iPX/250iPX upgrade 45.72 cm (18.00 in.)

width, 200iPX/250iPX upgrade 55.88 cm (22.00 in.)

Frame structural steel

Maximum Speed 322 KPH (200 MPH)

Maximum Motorcycle Length (front of front

wheel to center of rear wheel)

standard carriage 213.00 cm (84.00 in.)

extended carriage 256.54 cm (101.00 in.)

Remote Switches remote software control

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

1-5

Page 16

CHAPTER 1

Dynamometer Specifications and Requirements

standard carriage

304.80 cm (120.00 in.)

extended carriage

355.60 cm (140.00 in.)

137.16 cm

(54.00 in.)

45.72 - 46.67 cm

(18.00 - 18.38 in.)

PD104

239.00 cm (91.10 in.)

pit covers

310.29 cm (122.16 in.)

including eddy current

brake cover

271.42 cm

(106.86 in.)

76.20 cm

(30.00 in.)

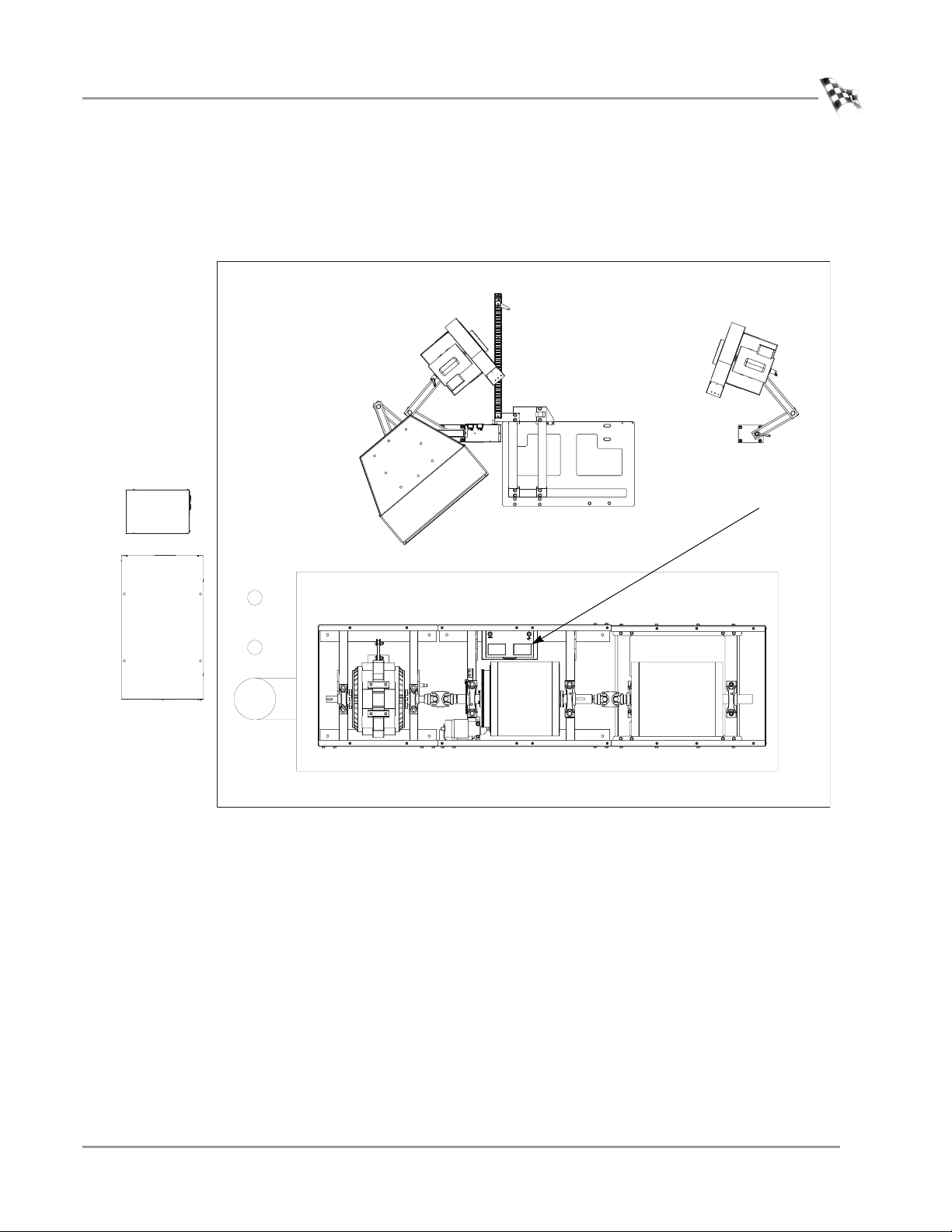

Figure 1-1: Model 250iPX Dyno Dimensions

1-6

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 17

SPECIFICATIONS AND OPERATING REQUIREMENTS

Dynamometer Specifications and Requirements

Control Panel

Interface

houses all electronics

(not shown)

PD105

Eddy Current

Brake

Monitor Support

and Tray

Control Panel

Wheel Clamp

Option

Power Carriage

Tri k e A d ap t er

Assembly

High Pressure

Blower

Air Brake Option

(not shown)

Model 250iP

Dyno Module

iPX Drum

Module

Figure 1-2: Model 250iPX Dyno with Accessories

Air Pump Option

(not shown)

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

1-7

Page 18

CHAPTER 1

Dynamometer Specifications and Requirements

COMPRESSED AIR REQUIREMENTS

The following requirements are needed when the optional air brake is included.

• regulator set to 65 psi max (450 kilopascal)

•air dryer

• shut off valve

• gauge on the regulator

• 1/4-inch NPT pipe thread connector (to attach air to the dyno)

COMPUTER SPECIFICATIONS

You will need to provide a computer system to run the WinPEP software. WinPEP 7

includes complete documentation in online Help. From the WinPEP 7 menu bar,

choose Help

name and password). Refer to the section on Computer Specifications in the WinPEP

documentation, P/N 98118103, for the specific computer system requirements.

!

WinPEP 7 Help or visit www.winpep.com (accessible with a valid user

DRILL AND DRILL BIT REQUIREMENTS

description specifications

Te mp e r at u r e

Humidity 0 to 95% non condensing

You will need to provide a drill and drill bit capable of drilling holes in concrete. Refer

to Appendix A for more information on installing Red Head Anchors.

• drill bit size: 1/2-inch

• minimum hole depth: 1 5/8-inch (41.2 mm)

ELECTRICAL REQUIREMENTS

The Model 200iPX/250iPX dynamometers require a 240V - 30a single-phase electrical

circuit for reliable and precise operation. No other loads should be plugged into these

circuits and these circuits should be independent of the lighting in the dyno room.

Before you plug in your dyno, you or your electrician must refer to Appendix B for

detailed information.

ENVIRONMENTAL REQUIREMENTS

operating min./max 10°C/50°C (50°F/122°F)

storage min./max 0°C/60°C (32°F/140°F)

FORKLIFT REQUIREMENTS

You will need to provide equipment capable of lifting a minimum of 1,089 kg.

(2400 lb.) to lift the dyno off the crate and into position in your dyno room. You will

also need a pair of straps capable of supporting 1,089 kg. (2400 lb.) to attach to the

dyno. Dynojet recommends using single loop style straps.

1-8

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 19

GROUND HOOK REQUIREMENTS

You may wish to install additional ground hooks (included with your dyno) for

securing the motorcycle. The tie-down loops on the pit covers should work for most

motorcycles. If you are running motorcycles that require a different tie-down location,

mount the ground hooks accordingly.

Note: Tie-down straps MUST pull the motorcycle forward.

Using the ground hooks as a pattern, use the hardware included with the ground

hook kit to install the Red Head anchors according to the instructions in Appendix A.

SPECIFICATIONS AND OPERATING REQUIREMENTS

Dynamometer Specifications and Requirements

PHONE AND INTERNET ACCESS

Dynojet recommends you have a phone close to the dyno to call for assistance in an

emergency. You may also wish to contact Dynojet to troubleshoot your dyno.

Internet access on your computer is desirable for contacting Dynojet and

downloading new information and updates.

TIE-DOWN STRAPS

Dynojet recommends using motorcycle tie-down straps for securing the bike on the

dyno. You will need to provide the tie-down straps.

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

1-9

Page 20

CHAPTER 1

Dyno Electronics

DYNO ELECTRONICS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The standard dyno electronics package is comprised of four interconnected modules:

Atmospheric Sensing Module, RPM Module, Dynamometer Input/Output Module, and

the CPU Module. For more information refer to your WinPEP 7 User Guide

(P/N 98128104).

9-pin hand

system expansion

connector

held pendant

25-pin socket

RPM inductive

pickup socket

atmospheric

sensing module

RPM module

input/output module

CPU module

power

9-pin RS-232 socket

3-pin power plug

Figure 1-3: The Dyno Electronics

1-10

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 21

SPECIFICATIONS AND OPERATING REQUIREMENTS

VERIFY THE PIT DIMENSIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before placing the dyno in the pit, take a moment to verify that the dimensions of the

pit are correct.

Refer to the pit dimensions (P/N 98229104) you received from your salesman for

more detailed specifications.

• pit depth: 45.00 cm (18.00 in.)

• pit length: 294.64 cm (116.00 in.)

• pit width: 121.00 cm (48.00 in.)

121.00 cm

(48.00 in.)

Verify the Pit Dimensions

294.64 cm

(116.00 in.)

PD106

Figure 1-4: Verify the Pit Dimensions

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

1-11

Page 22

Page 23

C HAPTER

2

I

NSTALLATION

This chapter will walk you through unpacking and installing the dynamometer. To

ensure safety and accuracy in the procedures, perform the procedures as they are

described.

This chapter is divided into the following categories:

• Dyno Drum Module Installation, page 2-2

• Eddy Current Brake Installation, page 2-9

• iPX Drum Module Installation, page 2-12

• Secure the Drum and Brake Module to the Pit Floor, page 2-17

• Pickup Card, page 2-18

• Left Side Blower Mount and Monitor Arm Installation, page 2-19

• Trike Carriage Adapter Installation, page 2-24

• Routing Cables, page 2-29

• Carriage Assembly and Power Carriage Installation, page 2-45

• Final Adjustments and Tests, page 2-48

• Pit Cover Installation, page 2-50

• Junction Box Cover, Cable Cover, and End Cap, page 2-58

• Zip Tube, page 2-59

• Ground Hook Installation, page 2-60

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-1

Page 24

CHAPTER 2

Dyno Drum Module Installation

DYNO DRUM MODULE INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When you receive your dyno, examine the exterior of the shipping container for any

visible damage. If damage is detected at this stage, contact the shipper or Dynojet

before proceeding with unpacking.

Use the following steps to unload your dyno. You will need to provide equipment

capable of lifting a minimum of 1,089 kg. (2400 lb.) to move the crated dyno into

position in your dyno room. Refer to “Dynamometer Specifications and

Requirements” on page 1-4 for more information.

Note: If this is an iX upgrade to an existing 200iP/250iP dyno, remove the drum

covers and skip to “Installing the iPX Drum Module” on page 2-14.

UNPACKING THE DYNO

1 Move the crated dyno to a clear area near your dyno room.

2 Using a pry bar, or a large flat screwdriver, and a hammer, carefully remove the

top and sides of the crate.

Note: At this point, you will want to inspect the exterior of the dyno for any

indications of damage. Report any damage immediately.

3 Remove the tire carriage and support arm and set aside. The tire carriage and

support arm are fastened to the bottom of the crate.

4 Remove the following parts, hardware boxes, the control panel interface, and

accessories from the crate and set aside.

tire carriage

support arm

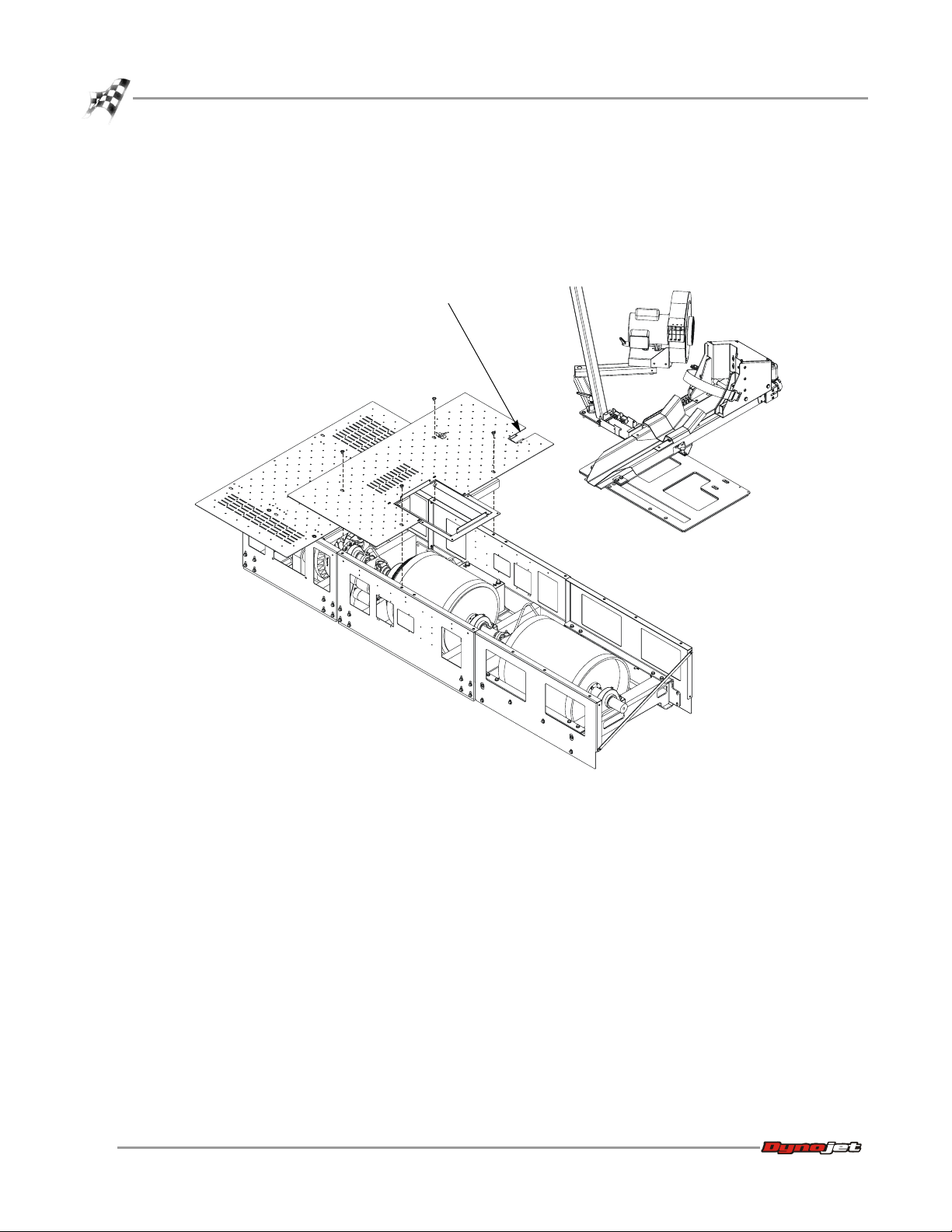

Figure 2-1: Uncrate the Dyno

2-2

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 25

INSTALLATION

Dyno Drum Module Installation

5 Verify the contents of the hardware boxes and set aside.

part description part description

nut, 4-40, hex (4)

P/N 134260301

plug, turnlok, 30A,

125/250V

P/N 43816430

screw, 4-40 x 3/8", flat-head

(4)

P/N 136206141

cover, fan connector holes

P/N 21221500

pit cover plate, left

P/N 21226105

cable junction box base

P/N 21228000

cable routing cover

P/N 21228517

receptacle, turnlok, 30A,

125/250V

P/N 43826430

control pod spindle

assembly

P/N 61329000

monitor arm (2)

P/N 61329100

monitor tray

P/N 61329101

monitor support

P/N 61329500

cable channel end cap

P/N 21228519

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

blower mount (2)

P/N 61329601

included on P/N 76722005

2-3

Page 26

CHAPTER 2

Dyno Drum Module Installation

part description part description

cable hole cover track

mount

P/N 21228520

generic i dyno, pit

P/N 62919003

cable junction box cover

P/N 21228521

drum guard, side (2)

P/N 21229111

drum guard mounting

bracket

P/N 21624103

cable track mounting

bracket

P/N 21626217

cable track adapter bracket

P/N 21626218

retarder module, pit

P/N 62919004

tire stop

P/N 63310902

not included if you ordered

the optional wheel clamp

control panel button subassembly

P/N 66117001

wheel clamp

P/N 71329000

optional accessory

power distribution stand

alone

P/N 76129010

cable cover, pit to junction

box

P/N 21626902

screw, 4-40 x 1/2", BH,

Allen(6)

P/N 36520834

2-4

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

dyno electronics assembly

P/N 76199001P

blower assembly

P/N 76722005

optional accessory

Page 27

INSTALLATION

Dyno Drum Module Installation

part description part description

screw, 8-32 x 3/8", pan-head,

phil (34)

P/N 36540643

iPX upgrade kit

P/N 77000004

shipped in a separate crate,

refer to page 2-12

screw, 1/4-20 x 5/8", panhead, torx (12)

P/N 36561045

bolt, 3/8-16 x 1/2", buttonhead, flange, allen (16)

P/N 36580434

washer, 3/8", splitlock,

steel (12)

P/N 36932100

anchor, redhead, 3/8" (12)

P/N 37513200

installation tool, redhead

anchor

P/N 37518200

standard carriage

P/N 78100004

or

extended carriage

P/N 78100005

ground hook kit (2)

P/N 79190001

see list of parts below

power carriage

P/N 82943001

included on P/N 78100004

or 78100005

banner, dynojet (2)

P/N D706

inductive secondary

pickup (2)

P/N DE100-109S

woodruff key, 3/8 x 1-3/8"

P/N 37620622

cable harness wrap kit

P/N 43400000

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

inductive primary pickup

clip

P/N DE100-110L

washer, 5/16", flat (18)

P/N DM150-002-007

2-5

Page 28

CHAPTER 2

Dyno Drum Module Installation

part description part description

cable clamp, 5/8" (7)

P/N 43428232

bolt, 3/8-16 x 1", hex (12)

P/N DM150-019-012

cable track

P/N 43432150

cable track mounting

bracket

P/N 43432151

nut, crush, 1/4-20 (8)

P/N DM150-020-005

The following parts are included in the Retarder Module, Pit P/N 62919004:

pit cover, plate, retarder

P/N 21226106

retarder driveline assembly

P/N 62240070

theta-2 controller-240V

P/N 66411003

temperature probe

assembly

P/N 76955001

The following parts are included in each Ground Hook Kit P/N 79190001:

ground hook/D-ring

P/N 10111

2-6

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

D-ring bracket, surface

mount

P/N 10112

washer, 3/8", splitlock,

steel (2)

P/N 36932100

anchor, redhead, 3/8" (2)

P/N 37513200

washer, 5/16", flat (2)

P/N DM150-002-007

bolt, 3/8-16 x 1", hex (2)

P/N DM150-019-012

Page 29

REMOVING THE DYNO FROM THE CRATE

This section will walk you through removing the dyno from the crate and installing

the dyno in your pit.

You will need to provide equipment capable of lifting a minimum of 1,089 kg.

(2400 lb.) to lift the dyno (drum module) off the crate and into position in your dyno

room. You will also need a pair of straps capable of supporting 1,089 kg. (2400 lb.) to

attach to the dyno. Dynojet recommends using a single loop style strap.

INSTALLATION

Dyno Drum Module Installation

dyno number

stamped on frame

(not visible)

RECORD

Be sure you record the dynamometer number on the inside cover of this

manual.

1 Remove the four lag bolts and washers securing the drum module to the crate

base using a 9/16-inch socket, open or box end wrench.

2 Wrap the single loop straps around the drum module shaft.

3 Lift the drum module off the crate and move into position in your pit.

#

Figure 2-2: Remove the Dyno From the Crate Base

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-7

Page 30

CHAPTER 2

Dyno Drum Module Installation

PLACING THE DYNO IN THE PIT

Place the drum module in the pit as shown in Figure 2-3.

Note: Figure 2-3 shows drum placement for an eddy current brake.

PD107

15.24 cm

(6.00 in.)

105.41 cm

(41.50 in.)

Figure 2-3: Drum Module Placement in Pit

2-8

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 31

Eddy Current Brake Installation

EDDY CURRENT BRAKE INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section will walk you through removing the eddy current brake (or retarder)

from the crate and attaching the brake to your dyno. To route and wire the

temperature sensor cable and the theta controller to the Breakout board refer to

“Routing the Eddy Current Brake, Battery, and Dyno Power Cables” on page 2-39 and

“Wiring the Breakout Board” on page 2-43.

You will need to provide equipment capable of lifting the eddy current brake off the

crate and into position in your dyno room. You will also need a pair of straps. Dynojet

recommends using continuous nylon loop style straps.

To prevent possible injury, unplug all power cords and disconnect the battery.

You will need the following parts:

• 62919004 Eddy Current Brake

• 37620622 Woodruff Key, 3/8 x 1-3/8"

• 62240070 Driveline Assembly

INSTALLATION

UNPACKING THE EDDY CURRENT BRAKE

1 Remove the four bolts securing the brake to the crate.

2 Remove the retarder connector plates, if present.

3 Place the ends of a nylon loop strap through the lifting eyes on either side of the

brake and hook onto the shaft.

4 Using a forklift, lift the eddy current brake from the crate and place the brake in

the pit near the drum module making sure not to hit the driveline assembly.

5 Record the eddy current brake number on the inside cover of this manual.

RECORD

Be sure you record the eddy current brake number on the inside cover of this

manual.

#

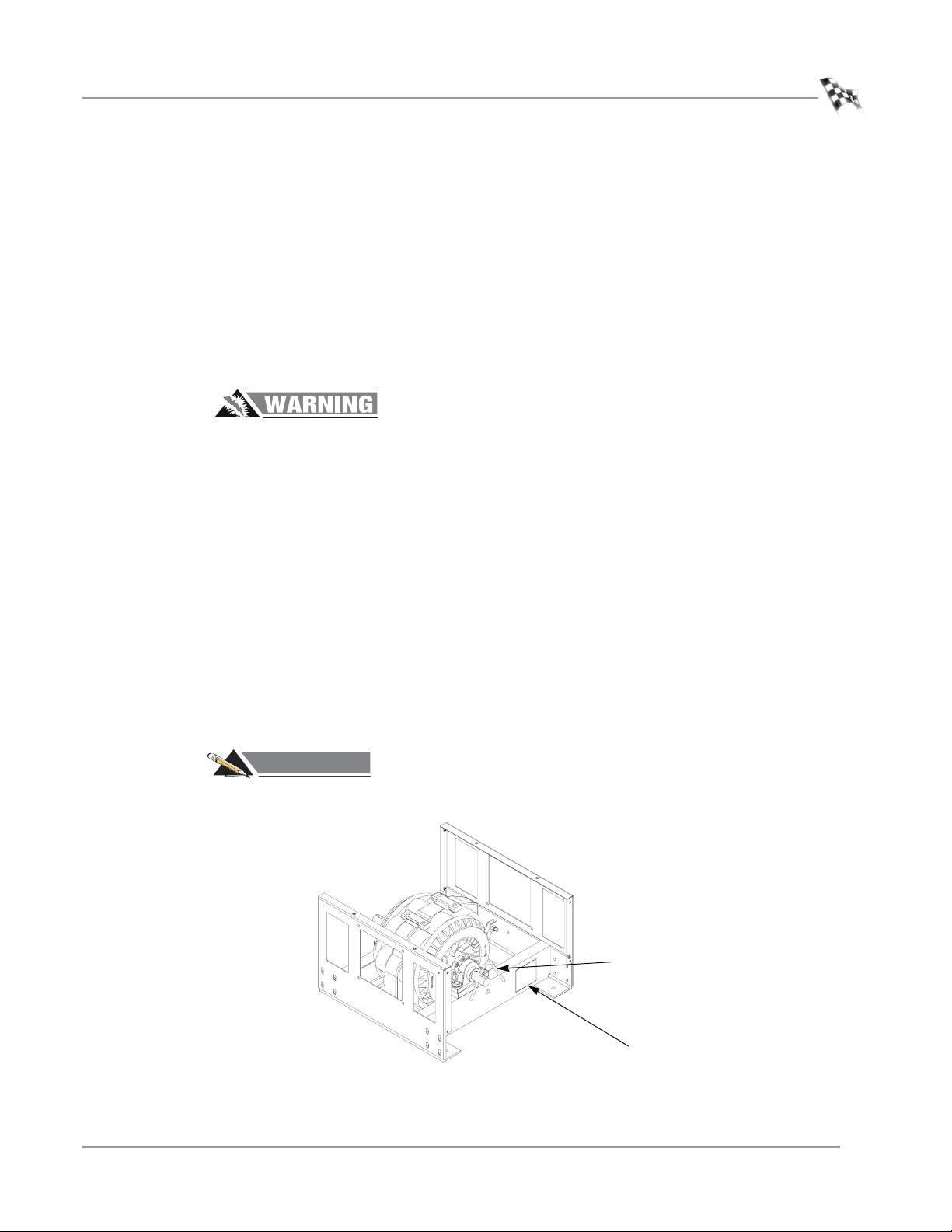

lifting eye

eddy current brake number

Figure 2-4: Record the Eddy Current Brake Number

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-9

Page 32

CHAPTER 2

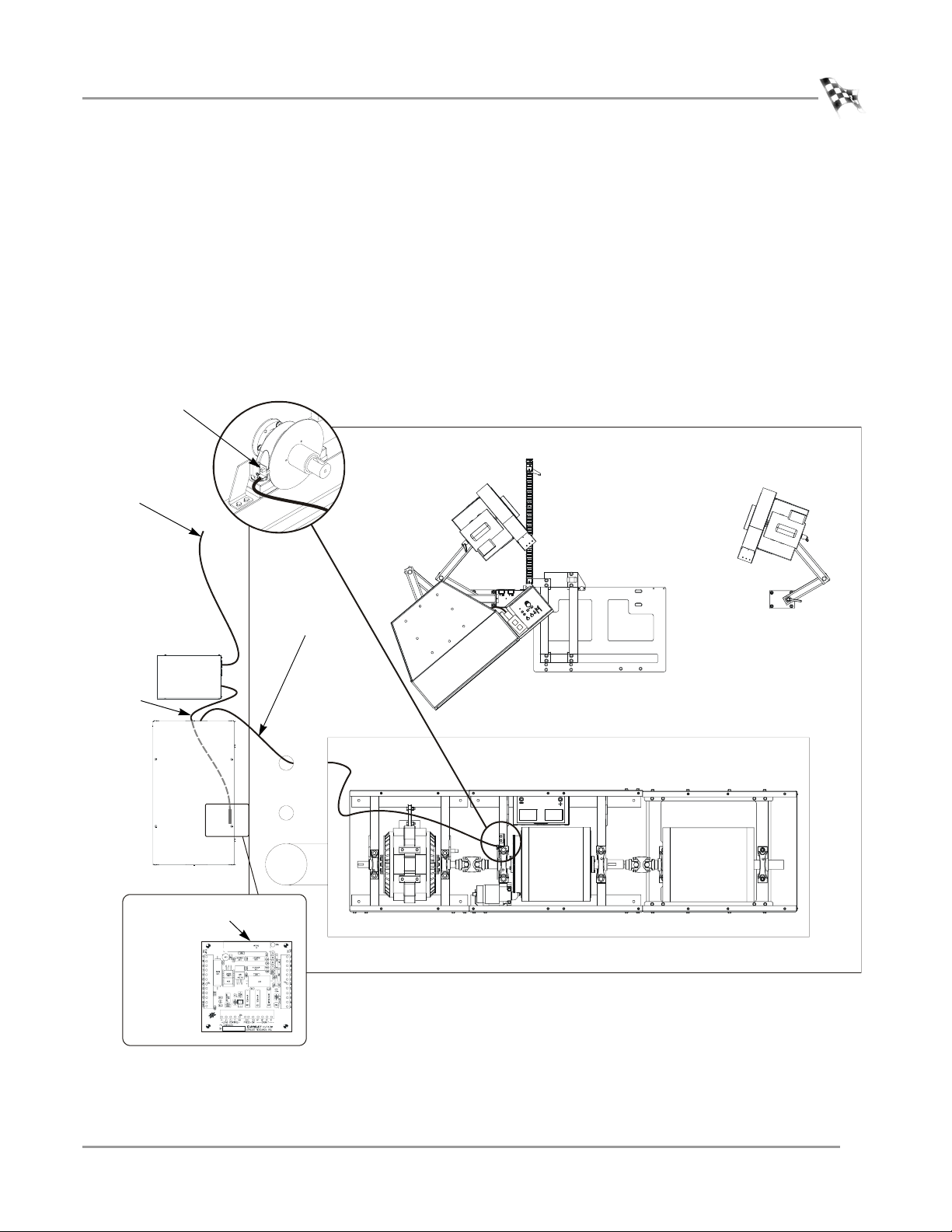

Eddy Current Brake Installation

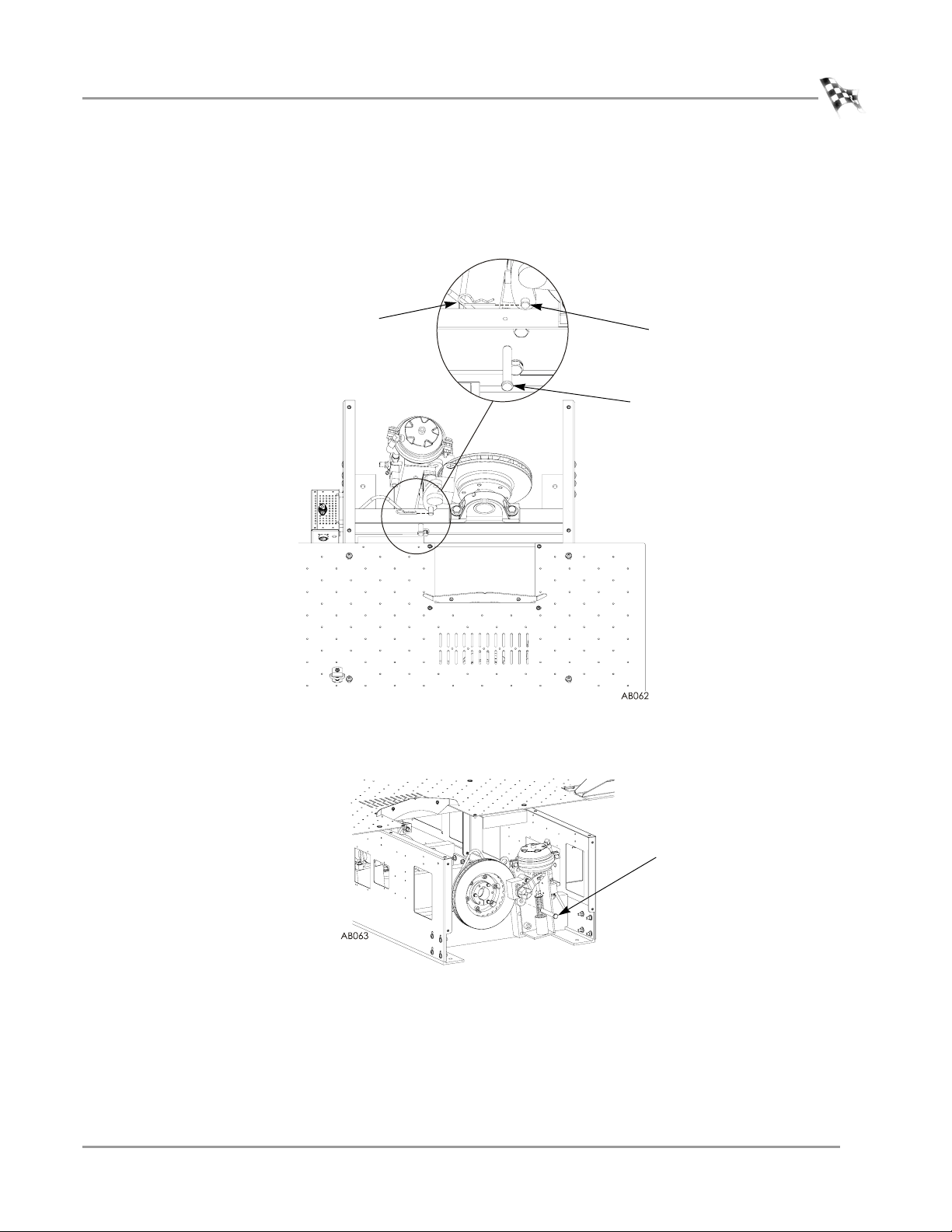

INSTALLING THE EDDY CURRENT BRAKE

1 Insert the key into the keyway on the drum module shaft.

2 Use a c-clamp to press the key in.

key

key way on dyno shaft

PD108

Figure 2-5: Install the Key

2-10

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 33

INSTALLATION

Eddy Current Brake Installation

3 Remove the eight bolts, washers, and six nuts from the dyno frame where the

connector plates will attach (where the connector plate attaches to the starter

brace, there are only two nuts).

4 Remove the starter brace and set aside.

5 Keeping the panels parallel, slide the eddy current brake towards the dyno. Slide

the driveline assembly over the key on the dyno shaft. You will need to support

the driveline assembly as you slide it onto the dyno shaft.

6 Continue sliding the eddy current brake towards the dyno until the uprights on

the brake and dyno are flush.

7 Loosely secure the connector plates to the dyno frame using the eight bolts,

washers, and six nuts removed earlier.

Note: Do not tighten the bolts.

8 Replace the existing set screws on the driveline assembly with the thread-lock set

screws provided.

9 Tighten the driveline assembly set screws.

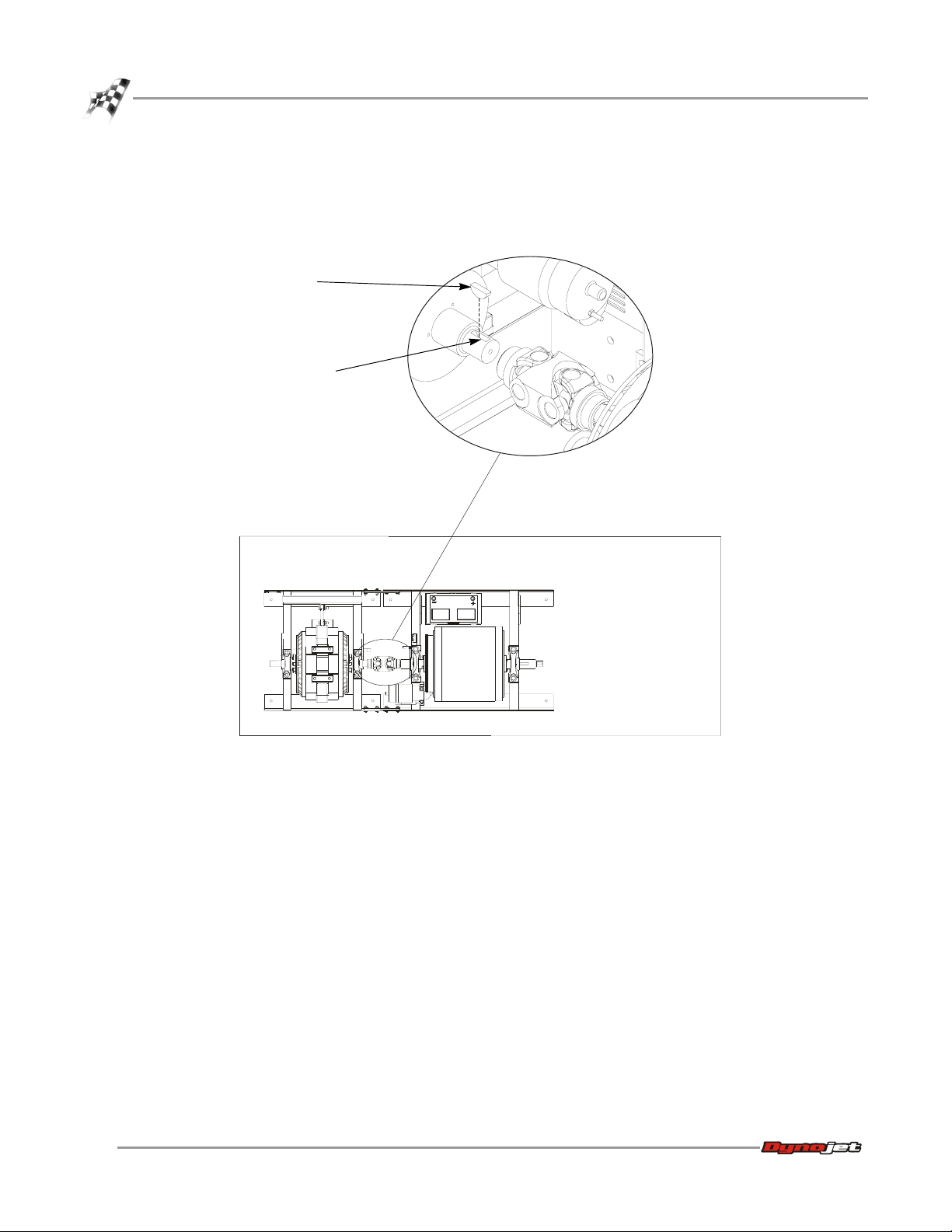

brake shaft

set screw

Figure 2-6: Tighten the Set Screws

dyno shaft

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-11

Page 34

CHAPTER 2

iPX Drum Module Installation

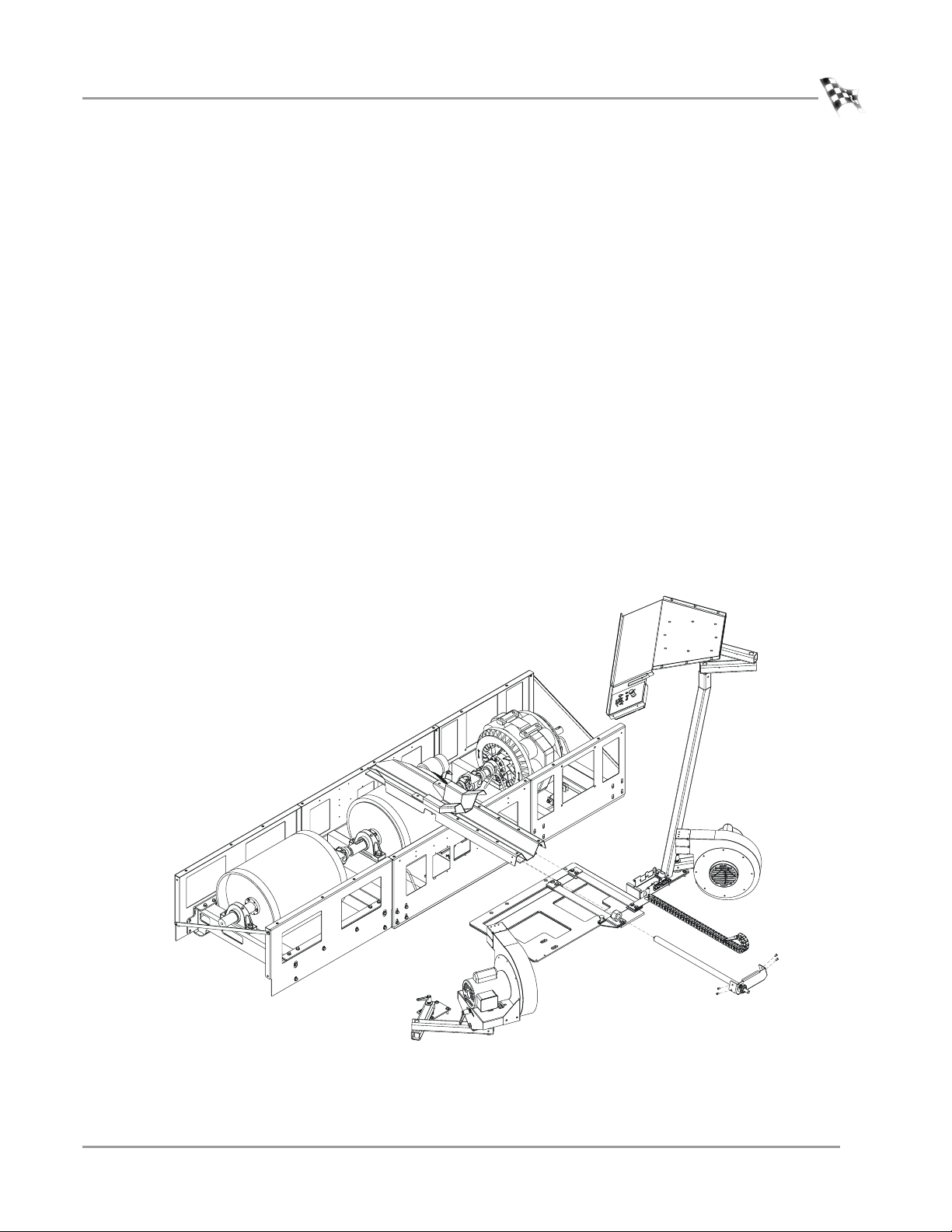

IPX DRUM MODULE INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When you receive your iPX upgrade kit, examine the exterior of the shipping

container for any visible damage. If damage is detected at this stage, contact the

shipper or Dynojet before proceeding with unpacking.

Use the following steps to unload the iPX drum module and related items. You will

need to provide equipment capable of lifting a minimum of 363 kg. (800 lb.) to move

the crated drum into position in your dyno room.

REMOVING THE ITEMS FROM CRATE

1 Move the crate to a clear area near your dyno room.

2 Using a pry bar, or a large flat screwdriver, and a hammer, carefully remove the

top and sides of the crate.

3 Remove the following parts from the crate and set aside.

part description part description

drum guard mounting

bracket

P/N 21200025

pit cover, middle

P/N 61100005

drum safety cover

P/N 21200038

cable track mounting

bracket (to trike carriage

adapter)

P/N 21200069

drum guard (2)

P/N 21229106

screw, 1/4-20 x 5/8",

pan-head, torx (12)

P/N 36561045

pit cover, right

P/N 61100006

retarder driveline assembly

P/N 62240070

drum module, pit

P/N 63200002

trike carriage adapter

assembly

P/N 71300002

2-12

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 35

INSTALLATION

iPX Drum Module Installation

part description part description

bolt, 3/8-16 x 1/2", buttonhead, flange, allen (6)

P/N 36580434

ground hook kit (4)

P/N 79190001

see list of parts below

woodruff key, 3/8 x 1-3/8"

P/N 37620622

The following parts are included in each Ground Hook Kit P/N 79190001:

ground hook/D-ring

P/N 10111

D-ring bracket, surface

mount

P/N 10112

washer, 3/8", splitlock,

steel (2)

P/N 36932100

nut, crush, 1/4-20 (4)

P/N DM150-020-005

anchor, redhead, 3/8" (2)

P/N 37513200

washer, 5/16", flat (2)

P/N DM150-002-007

bolt, 3/8-16 x 1", hex (2)

P/N DM150-019-012

4 Remove the crate braces that support the top portion of the crate.

5 Remove the four lag bolts and washers securing the drum to the crate base using

a 9/16-inch socket, open or box end wrench.

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-13

Page 36

CHAPTER 2

iPX Drum Module Installation

INSTALLING THE IPX DRUM MODULE

You will need the following parts:

• 37620622 Woodruff Key (2)

• 62240070 Driveline Assembly

• 63200002 iPX Drum Module

1 Place the nylon loop strap around the shaft on either side of the drum module.

2 Remove the two existing screws from each side of the dyno frame where the

connector plates will attach.

3 Insert the woodruff key into the keyway on the drum module shaft.

4 Insert the woodruff key into the keyway on the dyno shaft.

5 Using a forklift, lift the drum module from the crate and place the drum module

in the pit with the stepped end of the shaft towards the dyno. Make sure the

panels on the drum module and the dyno are parallel.

6 Slide the driveline over the key on the drum module shaft.

7 Keeping the panels parallel, slide the drum module towards the dyno. Slide the

driveline over the key on the dyno shaft. You will need to support the driveline as

you slide it onto the dyno shaft.

8 Continue sliding the drum module towards the dyno until the side panels on the

drum module and the dyno are flush.

PD109

existing screws

woodruff key

existing screws

woodruff key

iPX drum module

driveline

Figure 2-7: Install the Driveline and the iPX Drum Module

2-14

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 37

INSTALLATION

iPX Drum Module Installation

9 Secure the connector plate on either side of the iPX drum module to the dyno

drum module using the bolts removed earlier.

10 Loosen the four bolts on either side of the iPX drum module as shown in

Figure 2-8.

11 Align the iPX drum module panels until they are flush with the top of the pit floor

and the dyno drum module panels.

12 Once you have verified the panels are flush and parallel, tighten all the screws.

13 Tighten the driveline set screws.

Note: Dynojet recommends using red loctite on the set screws.

14 Install upright bar removed earlier to the side of the iPX drum module using the

two 1/4-20 screws removed earlier.

dyno drum

module panel

PD110

secure connector plate

iPX drum module

panel

upright bar

loosen these bolts on both

sides of iPX drum module

Figure 2-8: Install the Drum Module to the Dyno

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-15

Page 38

CHAPTER 2

iPX Drum Module Installation

LINING UP AND SECURING THE MODULE UPRIGHTS

1 Verify the uprights on the drum and eddy current brake modules are flush with

the top of the pit floor before you tighten the connector plates.

1a Loosen all upright bolts.

1b Place two straight edges across the drum module uprights.

1c With the upright tight against the straight edges and flush with the pit floor,

tighten the connector plate bolts and nuts on the drum module.

Note: You can use c-clamps to attach the upright to the straight edges to make

this quicker. Tighten the c-clamps until the uprights are flush with the pit floor.

1d Tighten the upright bolts and nuts on the drum module.

1e Repeat this for the eddy current brake module uprights.

2 Secure the starter brace to the starter using the washer and nut removed earlier.

3 Remove the straight edges.

eddy current brake

module upright

drum module

upright

loosen bolts

securing

uprights

connector

plate bolts

2-16

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Figure 2-9: Secure the Uprights

PD144

Page 39

Secure the Drum and Brake Module to the Pit Floor

SECURE THE DRUM AND BRAKE MODULE TO THE PIT FLOOR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynojet recommends you secure your drum and brake modules to the pit floor in

your dyno room using concrete anchors. You will want to drill the holes and secure

the dyno before placing the covers on your dyno.

Note: You may wish to drill the holes for the left and right blower mounts along

with the trike adapter mounting plate this time. Refer to page 2-19 for the left

blower mount instructions, page 2-24 for the trike adapter mounting plate

instructions, and page 2-25 for the right blower mount instructions.

You will need the following parts:

• 37513200 Anchor, Redhead, 3/8" (8)

• DM150-002-007 Washer, 5/16", Flat (8)

• DM150-019-012 Bolt, 3/8-16 x 1", Hex (8)

1 Mark and drill each hole needed to secure the drum and brake modules to the pit

floor.

2 Install the Red Head anchors. Refer to Appendix A for installation instructions.

INSTALLATION

PD143

drill holes

drill holes

Figure 2-10: Secure the Drum and Brake Module to the Pit Floor

drill holes

drill holes

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-17

Page 40

CHAPTER 2

Pickup Card

PICKUP CARD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The pickup card is an electronic circuit board that accurately senses each drum

revolution.

1 Locate the pickup card bracket on the starter side of the dyno just ahead of the

drum.

2 Install the pickup card to the bracket using two No. 8 screws. Do not tighten, the

card must be aligned first.

Note: If your dyno is equipped with an air brake, you will need to attach

compressed air and power to your dyno before you can turn the drum.

3 Align the optical pickup card with the tab on the dyno drum axle. Be sure the tab

passes freely through the optical pickup. You may need to loosen the bracket to

help with alignment.

4 Once aligned, tighten the screws to secure the pickup card in place.

5 Refer to page page 2-41 for instructions on routing and connecting the pickup

card cable.

PD111

pickup card

bracket

The optical pickup is very delicate. Be careful not to damage the optical pickup

during alignment.

tab on dyno

optical pickup

pickup card

top view of pickup card, optical

pickup, and tab on dyno

tab on dyno

pickup card

Figure 2-11: Install the Pickup Card

2-18

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 41

Left Side Blower and Monitor Arm Installation

LEFT SIDE BLOWER AND MONITOR ARM INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use the following instructions to install the left side blower mount, monitor support,

and junction box along with the left blower assembly and monitor tray. The right

blower mount and assembly will be installed later.

You will need the following parts:

• 21221500 Blank Plate, Junction Box

• 21228000 Junction Box Base

• 26215520 Washer, 1/8", Poly, for Monitor Support (3)

• 35521420 Cap Plug, for Monitor Support (4)

• 61329100 Monitor Arm (2)

• 61329101 Monitor Tray

• 61329500 Monitor Support

The following parts are included in the Blower Assembly, P/N 76722005:

• 21600015 Lower Blower Arm

• 26215220 Washer, 3/8", Metal

• 26215520 Washer, 1/8", Poly (2)

• 26215521 Washer, 1/4", Poly (2)

• 35521420 Cap Plug (4)

• 35712991 Clamp Lever

• 37513200 Anchor, Redhead, 3/8" (4)

• 61328101 Blower Assembly

• 61329601 Blower Mount

• 63413001 Upper Blower Arm

• DM150-002-007 Washer, 5/16", Flat (4)

• DM150-019-012 Bolt, 3/8-16 x 1", Hex (4)

INSTALLATION

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-19

Page 42

CHAPTER 2

Left Side Blower and Monitor Arm Installation

INSTALLING THE LEFT BLOWER MOUNT

If this is an iX upgrade to an existing 200iP/250iP dyno, skip these instructions and

refer to Appendix E for upgrade instructions.

1 Mark the left blower mount placement as shown in Figure 2-12.

2 Using the blower mount as a template, mark and drill the four holes needed to

secure the blower mount to the floor.

3 Install the Red Head anchors. Refer to Appendix A for installation instructions.

111.76 cm

(44.00 in.)

184.05 cm

(72.46 in.)

PD152

Figure 2-12: Install the Left Blower Mount

2-20

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 43

Left Side Blower and Monitor Arm Installation

INSTALLING THE MONITOR SUPPORT AND THE JUNCTION BOX

1 Place the blower mount where you installed the Red Head anchors on page 2-20.

2 Secure the blower mount, monitor support arm, and junction box to the pit floor

using four 3/8 x 1-inch bolts and four washers.

Note: The left blower mount is secured under the support arm.

3 Verify the blank plate is secured to the junction box as shown in Figure 2-13.

4 Verify the fan connectors are secured to the junction box in the location shown in

Figure 2-13.

INSTALLATION

PD113

support arm

blower mount

(under support arm)

blank plate

fan connectors

junction box

Figure 2-13: Install the Monitor Support Arm and Junction Box

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-21

Page 44

CHAPTER 2

Left Side Blower and Monitor Arm Installation

INSTALLING THE LEFT BLOWER ASSEMBLY

1 Insert a plastic cap in both ends of each arm.

2 Place one 1/4-inch thick poly washer around the pin on the blower mount.

3 Place the lower blower arm over the blower mount pin.

4 Place a 3/8-inch thick metal washer on top of the lower blower arm.

5 Secure the lower blower arm using the clamp lever.

6 Place a 1/8-inch thick poly washer around the pin on the upper blower arm.

7 Insert the pin on the upper arm into the lower arm.

8 Place a 1/8-inch thick poly washer around the pin on the blower assembly.

9 Insert the pin on the blower assembly into the upper arm.

Note: The right blower assembly will be installed later.

blower

assembly

PD114

poly washer

lower blower arm

clamp lever

(not visible)

metal washer

(not visible)

poly washer

Figure 2-14: Install the Left Blower Assembly

poly washer

upper blower arm

2-22

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 45

INSTALLING THE MONITOR ARMS AND MONITOR TRAY

1 Insert a plastic cap in both ends of each arm.

2 Place a poly washer around the pin of the first arm and insert the pin into the

support arm.

3 Place a poly washer around the pin of the second arm and insert the pin into the

first arm.

4 Place a poly washer around the pin of the tray and insert the pin into the second

arm.

Note: The monitor tray is an optional accessory. If you did not order a monitor

tray, skip this step.

5 Check for clearance between the monitor arm and motorcycle, walls, ceiling, etc.

Note: Dynojet does not recommend placing the computer CPU on the

monitor/keyboard tray since vibration can cause damage to the computer.

tray

INSTALLATION

Left Side Blower and Monitor Arm Installation

arms

monitor

support

PD115

Figure 2-15: Install the Monitor Arms and Monitor Tray

washers

washer

left blower

assembly

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-23

Page 46

CHAPTER 2

Trike Carriage Adapter Installation

TRIKE CARRIAGE ADAPTER INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use the following instructions to install the trike carriage adapter plate, right blower

assembly, and the cable track.

The installation instructions are the same for both the standard and the extended

carriage; verify you use the correct dimensions for the type of carriage you are

installing.

INSTALLING THE TRIKE CARRIAGE ADAPTER PLATE

You will need the following parts:

• 15331100 Chain Lube

• 37513200 Anchor, Redhead, 3/8" (8)

• 71300002 Trike Carriage Adapter Assembly

• DM150-002-007 Washer, 5/16", Flat (8)

• DM150-019-012 Bolt, 3/8-16 x 1", Hex (8)

1 Mark the trike carriage adapter plate placement as shown in Figure 2-16.

2 Using the trike carriage adapter plate as a template, mark and drill eight 1/2-inch

holes needed to secure the adapter plate to the floor.

3 Install the Red Head anchors. Refer to Appendix A for installation instructions.

4 Secure the adapter plate to the floor using eight 3/8-16 x 1-inch bolts and eight

5/16-inch flat washers.

5 Lube the tracks with the included lube or use grease.

PD116

mark and trill for

redhead anchors

0.635 cm

(0.25 in.)

Figure 2-16: Install the Trike Carriage Adapter Plate

standard carriage

72.39 cm (28.50 in.)

extended carriage

97.79 cm (38.50 in.)

2-24

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 47

Trike Carriage Adapter Installation

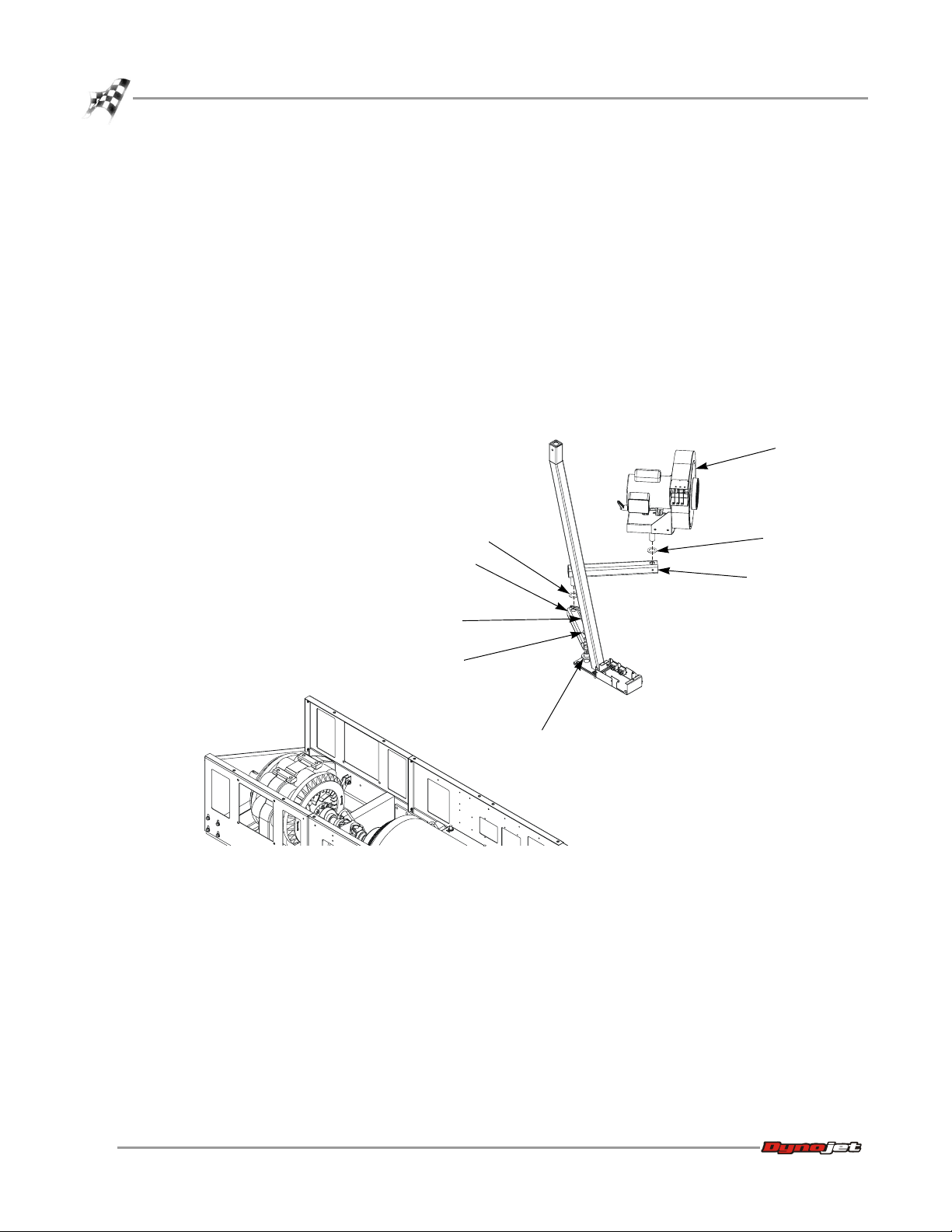

INSTALLING THE RIGHT BLOWER MOUNT AND BLOWER ASSEMBLY

You will need the following parts:

• 21600015 Lower Blower Arm

• 26215220 Washer, 3/8", Metal

• 26215520 Washer, 1/8", Poly (2)

• 26215521 Washer, 1/4", Poly (2)

• 35521420 Cap Plug (4)

• 35712991 Clamp Lever

• 37513200 Anchor, Redhead, 3/8" (4)

• 61328101 Blower Assembly

• 61329601 Blower Mount

• 63413001 Upper Blower Arm

• DM150-002-007 Washer, 5/16", Flat (4)

• DM150-019-012 Bolt, 3/8-16 x 1", Hex (4)

1 Using Figure 2-17 as a guide, place the blower mount in a location that works best

for your dyno application.

2 Using the blower mount as a template, mark and drill the four holes needed to

secure the blower mount to the floor.

3 Install the Red Head anchors. Refer to Appendix A for installation instructions.

4 Secure the blower mount to the floor using four 3/8-16 x 1-inch hex bolts and

four 5/16-inch flat washers.

INSTALLATION

63.50 cm

(25.00 in.)

111.76 cm

(44.00 in.)

PD145

Figure 2-17: Install the Right Blower Mount

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-25

Page 48

CHAPTER 2

Trike Carriage Adapter Installation

5 Insert a plastic cap in both ends of each arm.

6 Place two 1/4-inch thick poly washers around the pin on the blower mount.

7 Place the lower blower arm over the blower mount pin.

8 Place a 3/8-inch thick metal washer on top of the lower blower arm.

9 Secure the lower blower arm using the clamp lever.

10 Place a 1/8-inch thick poly washer around the pin on the upper blower arm.

11 Insert the pin on the upper arm into the lower arm.

12 Place a 1/8-inch thick poly washer around the pin on the blower assembly.

13 Insert the pin on the blower assembly into the upper arm.

The blowers can run at any time once the cord is plugged into a power source.

right blower

assembly

PD146

clamp lever

aluminum washer

Figure 2-18: Install the Right Blower Assembly

upper blower

arm

lower blower

arm

1/4-inch thick

poly washer

2-26

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 49

INSTALLING THE CABLE TRACK

You will need the following parts:

• 134260301 Nut, 4-40, Hex (4)

• 136206141 Screw, 4-40 x 3/8", Flat-Head (4)

• 21200069 Cable Track Mounting Bracket, to Trike Adapter Assembly

• 21626217 Cable Track Mounting Bracket

• 43432150 Cable Track

1 Remove the two 5/16-inch bolts and washers securing the carriage clamp as

shown in Figure 2-19.

2 Secure the cable track mounting bracket to the carriage clamp using the

two 5/16-inch bolts and washers removed earlier.

INSTALLATION

Trike Carriage Adapter Installation

mounting bracket

carriage clamp

PD117

Figure 2-19: Install the Cable Track Mounting Bracket

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-27

Page 50

CHAPTER 2

Trike Carriage Adapter Installation

3 Secure the cable track to the mounting bracket on the trike adapter assembly

using two 4-40 x 3/8-inch screws and two 4-40 nuts.

4 Secure the cable track mounting bracket to the cable track using two

4-40 x 3/8-inch screws and two 4-40 nuts.

PD118

Figure 2-20: Install the Cable Track and Mounting Bracket

2-28

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 51

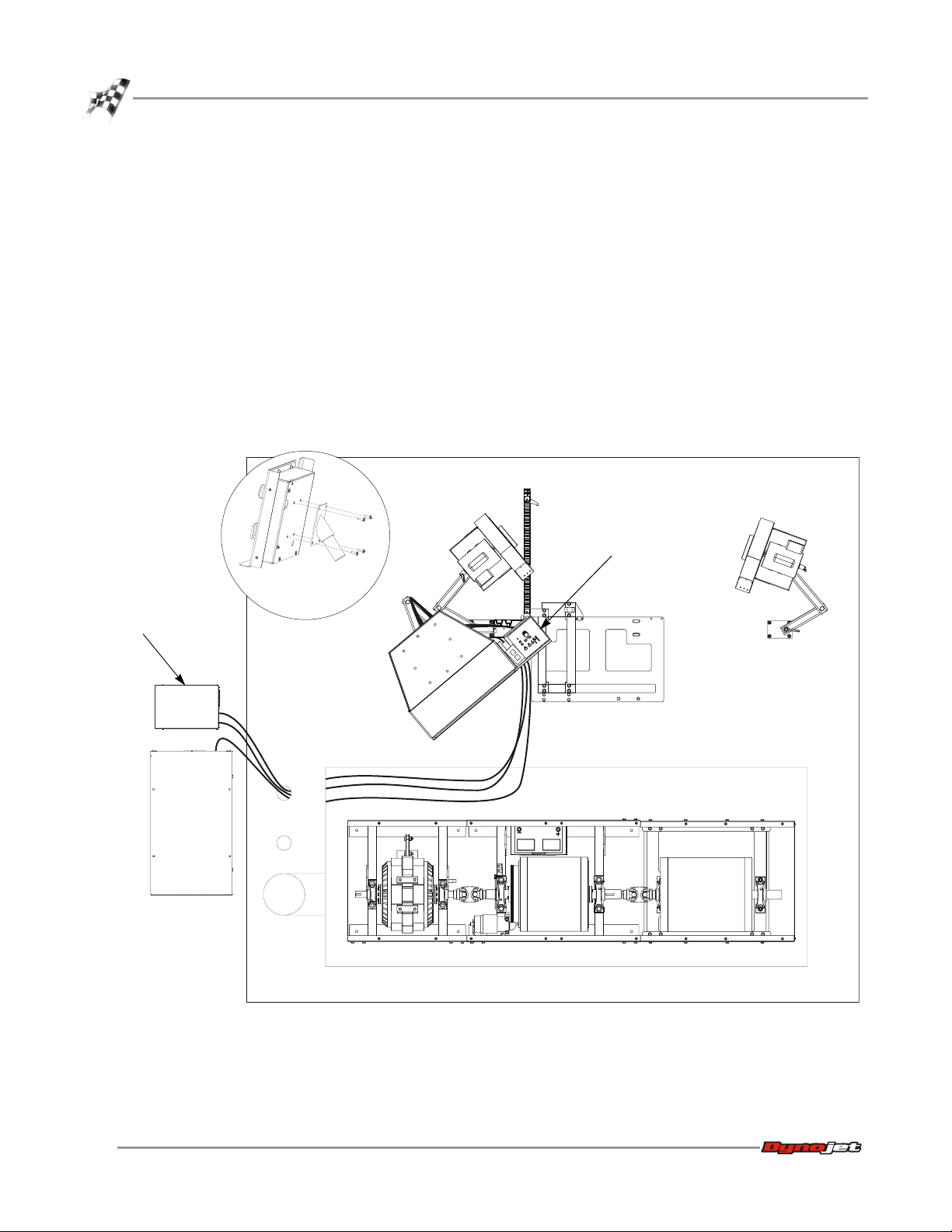

ROUTING CABLES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The CPI and dyno electronics must be placed near the conduits in the pit. Be sure to

keep the power and communications cables in different pit conduits. For the

following instructions, we will designate the pit conduits as shown in Figure 2-21.

junction box

cable track

INSTALLATION

Routing Cables

route communications

cables in designated

conduit

dyno

electronics

control panel

interface

(CPI)

route power cables

in designated conduit

monitor support

and tray

control panel

Figure 2-21: Pit Dyno Room Layout

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-29

Page 52

CHAPTER 2

Routing Cables

BATTERY REQUIREMENTS

The model 200iPX/250iPX dyno is designed to carry a group 24 deep cycle discharge

series battery for operating the starter, optional power carriage, and optional wheel

clamp. The typical dimensions for this series of batteries are 10 5/8-inches long by 6

3/4-inches wide by 9 1/8-inches tall. The mounting is flexible so a battery that has

dimensions close to this will work satisfactorily. The built in battery cables are

configured for top post batteries. This battery is not included with your dyno. You will

need to provide this battery.

The battery provides the necessary energy to run the starter, optional power carriage,

and optional wheel clamp. The CPI has a built in battery charging circuit to keep the

battery charged. Each time the starter, power carriage, or wheel clamp is used, this

built in charging circuit will recharge the battery. The charging rate is sufficient to

keep up with loading a bike, operating the wheel clamp, and adjusting the power

carriage every five minutes. Recharging from use of the built in dyno starter will take

longer. Do not add any external battery chargers to the car battery.

Note: If you do not install the battery make sure the positive battery cable is

insulated from the chassis as the charging circuit is always providing charging

current whenever the dyno main power breaker is turned on.

The battery charging circuit is active anytime the main power on the dyno is turned

on. If the main breaker is turned off then the battery will not be charged. Frequent

use of the starter will quickly deplete the battery and it may need several hours of the

internal charging to bring the battery back to a full charge.

For more information on installing the battery, refer to page 2-31.

Note: If you do not wish to use the wheel clamp and the power carriage or

operate the built-in starter then it is not necessary to install the battery.

USING A BATTERY CHARGER

In order to utilize the starter on dynos that do not have the Control Panel, you will

need to provide an on board battery charger. A small trickle charger or battery minder

is sufficient in the charging range of 1A. Verify the battery charger does not overcharge

the battery when left attached.

Note: Dynojet recommends using a ring connector style charger.

• Using the bolts from the battery terminals, secure the ring connectors from the

charger to the battery terminals.

• Secure the charger in a safe location in the dyno.

• Route the power cable out of the dyno. Make sure the cable cannot be

damaged.

These small chargers should be available from your normal distribution supply chain

or other sources such as NAPA, JC Whitney, or Northern Tools.

There is danger of explosion if the battery is incorrectly replaced. Wear

protective clothing, eye, and face protection when charging or handling

batteries. Refer to Warnings for more information.

2-30

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

Page 53

INSTALLING THE BATTERY

1 Secure the battery to the tray with the battery hold-down.

2 Refer to page 2-39 for instructions on routing and connecting the battery cable.

INSTALLATION

Routing Cables

battery

PD120

Figure 2-22: Install the Battery

Version 2 In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-31

Page 54

CHAPTER 2

Routing Cables

ACCESSING THE CPI

The CPI comes wired and ready to install. Should you need to re-route the cables so

they come out a different side of the box, use the following instructions to access the

CPI box.

1 Turn off the power to the dyno. Refer to “Main Dyno Power” on page 3-2 for more

information.

2 Remove the eight button-head screws securing the cover and set aside.

3 Remove the cover and set aside.

4 Open the front panel to access the breakers and Breakout board.

cover

front panel access

PD027

Figure 2-23: Access the CPI

2-32