Page 1

Page 2

©2004-2008 Dynojet Research, Inc. All Rights Reserved.

Maintenance Guide For Model 224, Model 224 with 4WD, Model 424x, and Model 248

Automotive Dynamometers.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual is furnished under license and may only be used

or copied in accordance with the terms of such license. This manual is furnished for

informational use only, is subject to change without notice, and should not be construed

as a commitment by Dynojet. Dynojet assumes no responsibility or liability for any error

or inaccuracies that may appear in this manual. Except as permitted by such license, no

part of this manual may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, recording, or otherwise, without the prior

written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89031, USA.

Printed in USA.

Part Number: 98119101 Version 3 (03/2008)

Page 3

T

ABLE OF

C

ONTENTS

Auto Dyno Maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model 224 Dynos with Air Over HyDraulic (AOH) Brake Systems . . . . . . . 3

Things to Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maintaining the Model 224 AOH Drum Brake Shoe Clearance . . . . . . . . . . . 4

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System . 6

Things to Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Verifying the SAAR Brake Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintaining the SAAR Brake Shoe Clearance . . . . . . . . . . . . . . . . . . . . . . . . 8

Changing the SAAR Brake Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4WD Attachment for Model 224 Dynos . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Things to Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Filling the Air Motor Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjusting the Air Motor Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Inspecting the Rail Brake Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Model 424x All-Wheel Drive Dynos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Things to Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Filling the Air Motor Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adjusting the Air Motor Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Verifying the SAAR Brake Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Maintaining the SAAR Brake Shoe Clearance . . . . . . . . . . . . . . . . . . . . . . . 24

Changing the SAAR Brake Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Checking the Air Can Sleeve Retraction . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Model 248 Dynos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Things to Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Checking the 248 Drum Brake Shoe Clearance . . . . . . . . . . . . . . . . . . . . . 28

Maintenance Guide for Automotive Dynamometers

i

Page 4

Page 5

A

UTO

D

YNO

M

AINTENANCE

This document provides instructions for performing maintenance on the model 224

dynamometer (dyno), the model 224 dyno with the four wheel drive (4WD)

attachment, the model 224-2 dyno, the model 424x dyno, and the model 248 dyno. To

ensure safety and accuracy in the procedures, perform the procedures as they are

described.

Document Part Number: 98119101

Version 3

Last Updated: 03-19-08

Maintenance Guide for Automotive Dynamometers

1

Page 6

AUTO DYNO MAINTENANCE

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

You may have a model 224 dyno configured with one drum for testing two-wheel

drive vehicles, or with two drums for testing four-wheel drive vehicles. Model 224

dynos also may use either the Air Over Hydraulic (AOH) brake or the Spring Applied

Air Release brake (SAAR). Model 424x dynos all use the SAAR brake and have two

dyno drums for testing four-wheel drive cars. Or you may have a model 248 dyno.

Make sure to perform all of the maintenance procedures for your dyno configuration.

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89031.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, and press releases about our latest

product line.

2

Maintenance Guide for Automotive Dynamometers

Page 7

AUTO DYNO MAINTENANCE

03

Model 224 Dynos with Air Over HyDraulic (AOH) Brake Systems

MODEL 224 DYNOS WITH AIR OVER HYDRAULIC (AOH) BRAKE SYSTEMS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section covers maintenance items for model 224 dynos with a single drum and

AOH braking.

AD2

Figure 1: Model 224 with Air Over Hydraulic (AOH) Brakes

THINGS TO CHECK

• Check all air fittings for leaks monthly. Correct any leaks found.

• Once per month verify that the drum brake pressure gauge reads 55 to 65psi

(380 - 450kPa). Adjust the regulator if the pressure is out of specification.

• Once per month check the drum brake shoe clearance. Refer to page 4 for more

information.

•Dyno Bearing Grease:

Under steady use, over 25 runs per day, each bearing should receive .65oz (19 ml)

of a recommended grease every 2 months.

Under occasional use, less than 25 runs per day, each bearing should receive

.65oz (19 ml) of a recommended grease every six months.

Recommended Grease:

grease specification description

thickener Lithium 12 Hydroxy Stearate

oil Petroleum

thickness NLGI 2

operating temperature

(Fahrenheit)

operating temperature

(Celsius)

EP additive yes

examples Mobil Mobilith AW-2

-20°F to 200°F, intermittent to 250°F

-29°C to 93°C, intermittent to 121°C

Version 3 Maintenance Guide for Automotive Dynamometers

3

Page 8

AUTO DYNO MAINTENANCE

Model 224 Dynos with Air Over HyDraulic (AOH) Brake Systems

MAINTAINING THE MODEL 224 AOH DRUM BRAKE SHOE CLEARANCE

The 224 AOH drum brake shoe clearance must be checked once per month. If you

have upgraded your 224 dyno to use the Spring Applied Air Release (SAAR) braking

system, refer to “Maintaining the SAAR Brake Shoe Clearance” on page 8.

1 Remove the air from the system.

1a Shut off or disconnect the air supply to the dyno, and follow lock out

procedure.

1b Press the red button on the pendant to activate the drum brakes; the button

will be lit.

1c Using the red button on the pendant, cycle the drum brakes on and off

several times until all of the air is released from the system.

2 Remove the covers as necessary to provide safe working access to the dyno.

3 Measure the gap between the brake shoe and the drum surface. This gap should

be .125 inch - .375 inch (3mm - 10mm).

4 If the brake shoe clearance is out of specification, perform the following steps:

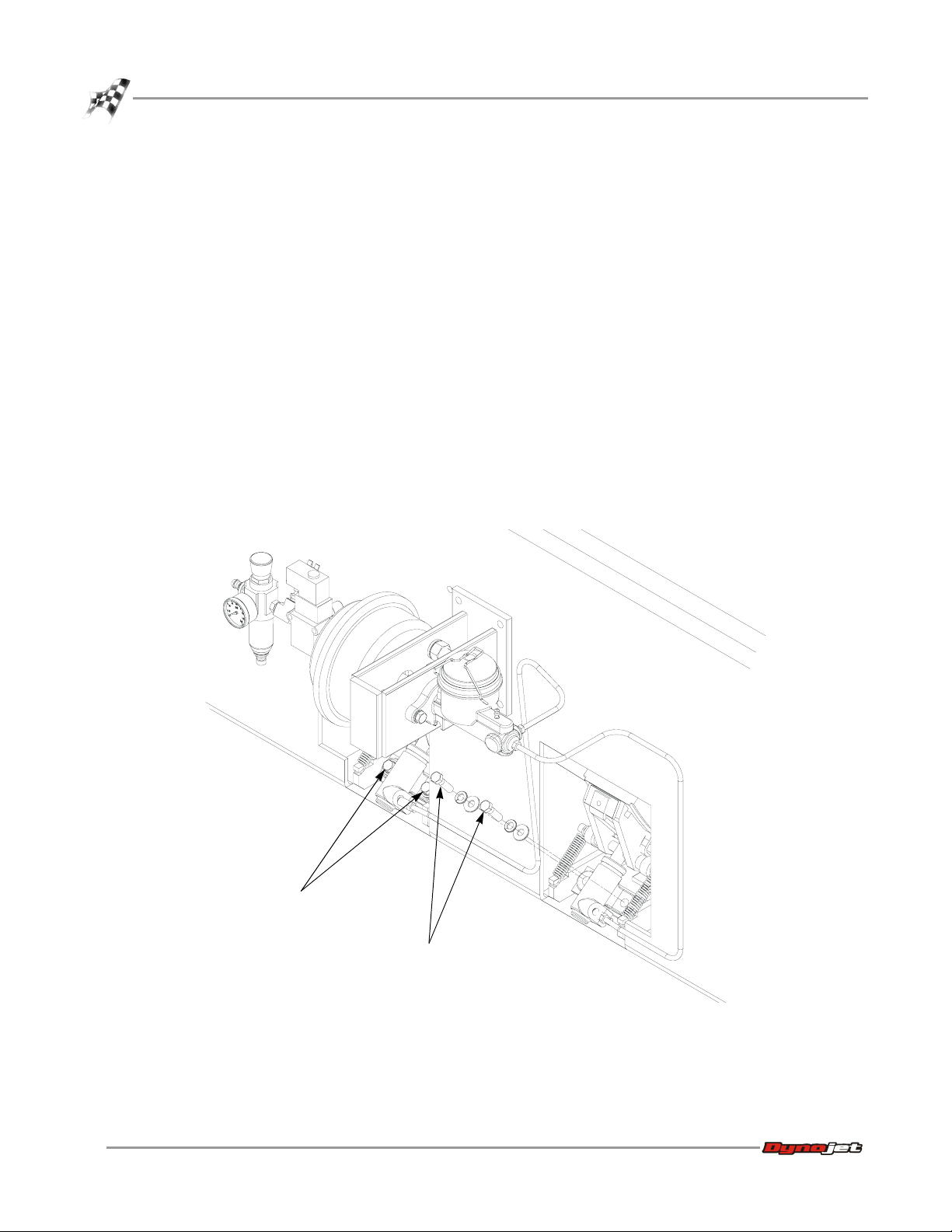

4a Remove the two 3/8-inch bolts and washers that secure the brake slave

cylinder to the dyno frame.

AD204

4

Maintenance Guide for Automotive Dynamometers

remove bolts

and washers

Figure 2: 224 Dyno AOH Brake—Remove the Bolts from Brake Slave Cylinder

remove bolts

and washers

Page 9

AUTO DYNO MAINTENANCE

Model 224 Dynos with Air Over HyDraulic (AOH) Brake Systems

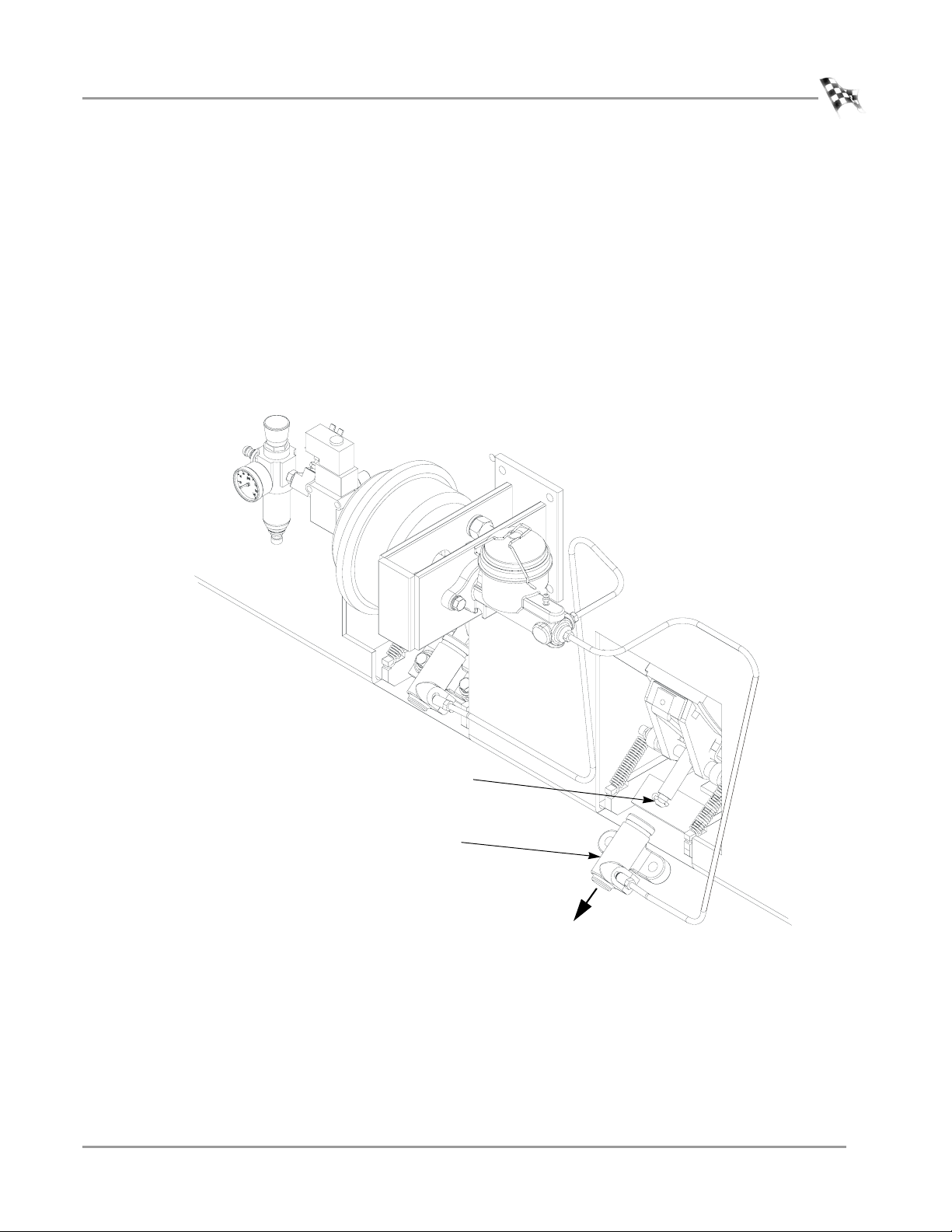

4b Pull the slave cylinder away from the dyno being careful not to kink the

brake line.

4c Screw the brake piston rod in to increase brake shoe clearance or out to

decrease brake shoe clearance. Refer to Figure 3.

4d Attach the slave cylinder using the bolts and washers removed earlier.

4e Recheck the brake shoe clearance. No part of the brake shoe should touch

the drum.

Note: If you cannot adjust the brakes to specification, you will need new brake

shoes. Contact Dynojet.

5 Turn on or reconnect the air supply and verify the drum brakes operate before

replacing the covers and using the dyno.

AD205

screw brake piston rod

in or out to adjust brake

clearance

carefully pull slave

cylinder away to expose

the brake piston rod

Figure 3: 224 Dyno AOH Brake—Pull the Cylinder Away

Version 3 Maintenance Guide for Automotive Dynamometers

5

Page 10

AUTO DYNO MAINTENANCE

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

MODEL 224 DYNOS WITH SPRING APPLIED AIR RELEASE (SAAR) BRAKE SYSTEM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section covers maintenance items for model 224 dynos with the SAAR brake.

THINGS TO CHECK

• Check all air fittings for leaks monthly. Correct any leaks found.

• Once per month verify the drum brake pressure gauge reads 100psi (690kPa).

Adjust the regulator if the pressure is out of specification. Refer to “Verifying the

SAAR Brake Pressure” on page 7 for more information.

• Check the drum brake shoe clearance. Refer to “Maintaining the SAAR Brake Shoe

Clearance” on page 8 for more information.

•Dyno Bearing Grease:

Under steady use, over 25 runs per day, each bearing should receive .65oz (19 ml)

of a recommended grease every 2 months.

Under occasional use, less than 25 runs per day, each bearing should receive

.65oz (19 ml) of a recommended grease every six months.

Recommended Grease:

grease specification description

thickener Lithium 12 Hydroxy Stearate

oil Petroleum

thickness NLGI 2

operating temperature

(Fahrenheit)

operating temperature

(Celsius)

EP additive yes

examples Mobil Mobilith AW-2

-20°F to 200°F, intermittent to 250°F

-29°C to 93°C, intermittent to 121°C

6

Maintenance Guide for Automotive Dynamometers

Page 11

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

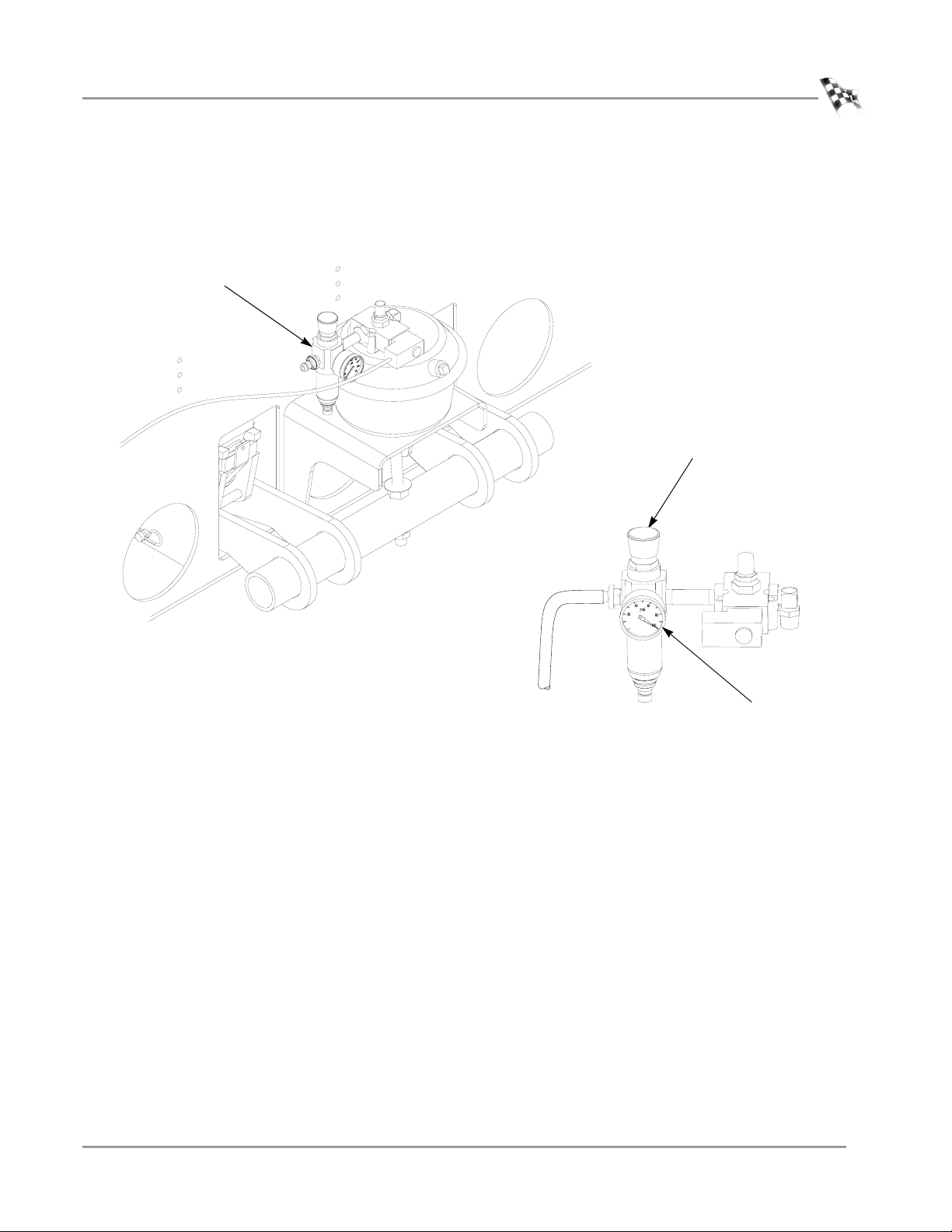

VERIFYING THE SAAR BRAKE PRESSURE

1 Verify the SAAR brake pressure gauge reads 100psi (690kPa).

2 Using the knob, adjust the regulator until the correct pressure is achieved.

brake pressure

regulator

AUTO DYNO MAINTENANCE

AB096

use knob to adjust

regulator until correct

pressure is achieved

0

brake pressure gauge

should read 100psi

(690kPA)

Figure 4: 224 Dyno—Verify the SAAR Brake Pressure and Adjust Using the Regulator

AB095

Version 3 Maintenance Guide for Automotive Dynamometers

7

Page 12

AUTO DYNO MAINTENANCE

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

MAINTAINING THE SAAR BRAKE SHOE CLEARANCE

1 Verify the area is clear and the dyno can be operated safely.

2 Power up the dyno electronics.

3 Using the pendant, turn the brake to the off position. This will release the SAAR

brake by moving the brake shoe away from the drum.

Keep hands and fingers clear when operating dyno.

4 Measure the gap between the brake shoe and the drum surface. This gap should

be between .125 inch - .375 inch (3mm - 10mm).

Note: For clarity, the dyno frame is shown transparently to reveal the drum.

Note: The mounting bracket shown is used with the SAAR upgrade. Factory

installed SAAR brakes use a slightly different bracket.

brake shoe

drum

measure gap

AB094

Figure 5: 224 SAAR Brake—Measure the Gap Between the Brake Shoe and Drum

8

Maintenance Guide for Automotive Dynamometers

Page 13

AUTO DYNO MAINTENANCE

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

5 If the brake shoe clearance is out of specification, loosen the upper nut on the air

can rod.

6 Adjust the lower nut until the brake shoes are .25 inch (6mm) away from the dyno

drum.

7 Tighten the upper nut on the air can rod down onto the brake actuating tube to

sandwich the tube between the two nuts.

8 Torque the lower nut to 110 foot-pounds.

If you cannot adjust the brakes to specification, you will need new brake shoes.

Contact Dynojet.

air can rod

upper nut

brake actuating tube

BR032

lower nut

Figure 6: 224 SAAR Brake—Adjust the Brake Shoe Clearance

Version 3 Maintenance Guide for Automotive Dynamometers

9

Page 14

AUTO DYNO MAINTENANCE

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

CHANGING THE SAAR BRAKE SHOES

1 Apply air to the brake system.

Air pressure to the brake system must be maintained while changing the SAAR

brake shoes.

2 Release the brakes.

2a Turn on the dyno electronics.

2b Verify the brake button on the pendant is not lit.

3 Remove the nut from the bottom air can rod and set aside.

Figure 7: 224 SAAR Brake—Remove the Nut from the Bottom Air Can Rod

10

Maintenance Guide for Automotive Dynamometers

air can rod

nut

Page 15

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

4 Slowly lower the pressure using the regulator.

The air can rod will retract from the tube.

Note: Verify the rod does not bind on the tube.

AUTO DYNO MAINTENANCE

regulator

air can rod

Figure 8: 224 SAAR Brake—Retract the Air Can Rod from the Tube

Version 3 Maintenance Guide for Automotive Dynamometers

tube

11

Page 16

AUTO DYNO MAINTENANCE

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

5 Slide the tube out and set aside.

tube

Figure 9: 224 SAAR Brake—Slide the Tube Out

6 Using the access holes in the dyno frame, remove the cotter key from each brake.

7 Remove the pin from each brake.

Note: For clarity, the drum is not shown.

pin

top view

drum not shown

for clarity

cotter key

Figure 10: 224 SAAR Brake—Remove the Cotter Key and Pin

12

Maintenance Guide for Automotive Dynamometers

Page 17

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

8 Remove each brake arm assembly.

AUTO DYNO MAINTENANCE

brake arm assembly

brake shoe

cotter key

Figure 11: 224 SAAR Brake—Remove the Brake Arm Assembly

9 Remove the cotter key from the brake arm assembly.

10 Remove the pin.

11 Remove the retainer and shoe.

12 Install the new brake shoe and replace the retainer.

Note: Verify the brake shoe is secure.

13 Replace the pin and cotter key.

retainer

pin

Figure 12: 224 SAAR Brake—Replace the Brake Shoe

cotter key

pin

brake shoe

retainer

Version 3 Maintenance Guide for Automotive Dynamometers

13

Page 18

AUTO DYNO MAINTENANCE

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

14 Replace each brake arm assembly using the pin and cotter key removed earlier.

Refer to Figure 10.

15 Slide the tube in.

16 Slowly raise the pressure using the regulator.

The air can rod will go through the tube.

Note: Verify the rod does not bind on the tube.

regulator

Figure 13: 224 SAAR Brake—Replace the Air Can Rod Through the Tube

14

Maintenance Guide for Automotive Dynamometers

air can rod

tube

Page 19

AUTO DYNO MAINTENANCE

Model 224 Dynos with Spring Applied Air Release (SAAR) Brake System

17 Replace the nut, removed earlier, on the bottom air can rod.

18 Adjust the brake shoe clearance as necessary. Refer to “Maintaining the SAAR

Brake Shoe Clearance” on page 8 for more information.

19 Press the red button on the pendant to activate the drum brakes; the button will

be lit.

air can rod

Figure 14: 224 SAAR Brake—Replace the Nut on the Bottom Air Can Rod

Version 3 Maintenance Guide for Automotive Dynamometers

nut

15

Page 20

AUTO DYNO MAINTENANCE

4WD Attachment for Model 224 Dynos

4WD ATTACHMENT FOR MODEL 224 DYNOS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section covers maintenance items for model 224 dynos with the 4WD

attachment.

THINGS TO CHECK

• Check customer supplied air filter/dryer daily, empty and clean as necessary.

• Inspect the 4WD dyno movement rails for debris once per month. Clear any debris

from the rails.

• Check all air fittings for leaks monthly. Correct any leaks found.

• Once per month maintain the brake pressure and brake shoe clearance. For AOH

brakes refer to page 3. If you have upgraded to the SAAR brake, see page 6.

• Adjust the lubrication provided by the air motor lubricator. Refer to “Adjusting the

Air Motor Lubricator” on page 18 for more information.

• Check the air motor lubricator once per month and fill as necessary. Refer to

“Filling the Air Motor Lubricator” on page 17 for more information.

•Dyno Bearing Grease:

Under steady use, over 25 runs per day, each bearing should receive .65oz (19 ml)

of a recommended grease every 2 months.

Under occasional use, less than 25 runs per day, each bearing should receive

.65oz (19 ml) of a recommended grease every six months.

Recommended Grease:

grease specification description

thickener Lithium 12 Hydroxy Stearate

oil Petroleum

thickness NLGI 2

operating temperature

(Fahrenheit)

operating temperature

(Celsius)

EP additive yes

examples Mobil Mobilith AW-2

-20°F to 200°F, intermittent to 250°F

-29°C to 93°C, intermittent to 121°C

16

Maintenance Guide for Automotive Dynamometers

Page 21

FILLING THE AIR MOTOR LUBRICATOR

3

Check the air motor lubricator once per month and fill as necessary.

1 Disconnect the air before removing the lubricator bowl.

2 Shut off or disconnect the air supply to the dyno, and follow lock out procedure.

3 Press and hold the dyno in or out movement switch until you cannot hear any air

going through the movement motor.

4 Before running the Gast Air Motor, remove the lubricator bowl and fill the bowl

with oil.

Note: Use a non-detergent SAE #10 automotive engine oil (Gast Part #AD220).

AUTO DYNO MAINTENANCE

4WD Attachment for Model 224 Dynos

remove bowl and

fill to line with oil

BR04

Figure 15: 224 4WD Attachment—Check Air Motor Lubricator

Version 3 Maintenance Guide for Automotive Dynamometers

17

Page 22

AUTO DYNO MAINTENANCE

4WD Attachment for Model 224 Dynos

ADJUSTING THE AIR MOTOR LUBRICATOR

Use the following steps to adjust the amount of oil provided by the air motor

lubricator.

1 Turn the top knob on the air motor lubricator clockwise until it shuts off the flow

of oil.

2 Back off the knob one turn counter-clockwise to start the flow of oil.

3 Adjust the knob as needed between one turn and fully on (turning counter-

clockwise) as needed for the particular environment in your dyno room.

turn knob

clockwise to shut

off oil, back off one

turn counter-

clockwise to start

the flow of oil

AD206

Figure 16: 224 4WD Attachment—Adjust the Air Motor Lubricator

18

Maintenance Guide for Automotive Dynamometers

Page 23

INSPECTING THE RAIL BRAKE CLEARANCE

Inspect the rail brake clearance once per month.

1 Shut off or disconnect the air supply to dyno, and follow your company’s lock out

procedure.

2 Press the red button on the pendant to activate the drum brakes; the button will

be lit.

3 Press and hold the dyno movement switch in either the in or out position until

you cannot hear any air going through the movement motor.

4 Using the red button on the pendant, cycle the drum brakes on and off several

times until no air is heard.

5 Remove the covers as necessary to provide safe working access to the dyno.

6 Using a ruler, measure the free play movement of each rail brake. The free play

should not exceed 3/16 inch (5mm).

7 If the rail brake free play is out of specification, adjust by loosening the jam nut

and turning the adjusting bolt until free play is within specification. Tighten the

jam nut while holding the adjusting bolt.

AUTO DYNO MAINTENANCE

4WD Attachment for Model 224 Dynos

Figure 17: 224 4WD Attachment—Inspect the Rail Brake Clearance

Version 3 Maintenance Guide for Automotive Dynamometers

19

Page 24

AUTO DYNO MAINTENANCE

Model 424x All-Wheel Drive Dynos

MODEL 424X ALL-WHEEL DRIVE DYNOS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section covers maintenance items for model 424x dynos.

THINGS TO CHECK

• Check all air fittings for leaks monthly. Correct any leaks found.

• Check the air motor lubricator once per month and fill as necessary. Refer to

“Filling the Air Motor Lubricator” on page 21 for more information.

• Once per month verify that the SAAR brake pressure gauge reads 100psi

(690kPa). Adjust the regulator if the pressure is out of specification. Refer to

“Verifying the SAAR Brake Pressure” on page 23 for more information.

• Check the drum brake clearance. Refer to “Maintaining the SAAR Brake Shoe

Clearance” on page 24 for more information.

• Check the air can sleeve retraction. Refer to “Checking the Air Can Sleeve

Retraction” on page 26 for more information.

• Check customer supplied air filter/dryer daily, empty and clean as necessary.

• Inspect the 4WD dyno movement rails for debris once per month. Clear any debris

from the rails.

•Dyno Bearing Grease:

Under steady use, over 25 runs per day, each bearing should receive .65oz (19 ml)

of a recommended grease every 2 months.

Under occasional use, less than 25 runs per day, each bearing should receive

.65oz (19 ml) of a recommended grease every six months.

Recommended Grease:

grease specification description

thickener Lithium 12 Hydroxy Stearate

oil Petroleum

thickness NLGI 2

operating temperature

(Fahrenheit)

operating temperature

(Celsius)

EP additive yes

20

Maintenance Guide for Automotive Dynamometers

examples Mobil Mobilith AW-2

-20°F to 200°F, intermittent to 250°F

-29°C to 93°C, intermittent to 121°C

Page 25

FILLING THE AIR MOTOR LUBRICATOR

Check the air motor lubricator once per month and fill as necessary.

1 Disconnect the air before removing the lubricator bowl.

2 Shut off or disconnect the air supply to the dyno, and follow lock out procedure.

3 Press and hold the dyno in or out movement switch until you cannot hear any air

going through the movement motor.

4 Before running the Gast Air Motor, remove the lubricator bowl and fill the bowl

with oil.

Note: Use a non-detergent SAE #10 automotive engine oil (Gast Part #AD220).

remove bowl and

fill to line with oil

AUTO DYNO MAINTENANCE

Model 424x All-Wheel Drive Dynos

AD0195

Figure 18: 424x Dyno—Filling the Air Motor Lubricator

Version 3 Maintenance Guide for Automotive Dynamometers

21

Page 26

AUTO DYNO MAINTENANCE

Model 424x All-Wheel Drive Dynos

ADJUSTING THE AIR MOTOR LUBRICATOR

Use the following steps to adjust the amount of oil provided by the air motor

lubricator.

1 Turn the top knob on the air motor lubricator clockwise until it shuts off the flow

of oil.

2 Back off the knob one turn counter-clockwise to start the flow of oil.

3 Adjust the knob as needed between one turn and fully on (turning counter-

clockwise) as needed for the particular environment in your dyno room.

turn knob to adjust

amount of oil delivered

Figure 19: 424x Dyno—Adjusting the Air Motor Lubricator

22

Maintenance Guide for Automotive Dynamometers

AD0195

Page 27

VERIFYING THE SAAR BRAKE PRESSURE

1 Verify the SAAR brake pressure gauge reads 100psi (690kPa).

2 Using the knob, adjust the regulator until the correct pressure is achieved.

brake pressure

regulator

AUTO DYNO MAINTENANCE

Model 424x All-Wheel Drive Dynos

AB096

use knob to adjust

regulator until correct

pressure is achieved

0

brake pressure gauge

should read 100psi

Figure 20: 424x Dyno—Check the SAAR Brake Pressure and Adjust the Regulator

AB095

(690kPA)

Version 3 Maintenance Guide for Automotive Dynamometers

23

Page 28

AUTO DYNO MAINTENANCE

Model 424x All-Wheel Drive Dynos

MAINTAINING THE SAAR BRAKE SHOE CLEARANCE

1 Verify the area is clear and the dyno can be operated safely.

2 Power up the dyno electronics.

3 Using the pendant, turn the brake to the off position. This will release the SAAR

brake by moving the brake shoe away from the drum.

Keep hands and fingers clear when operating dyno.

4 Measure the gap between the brake shoe and the drum surface. This gap should

be between .125 inch - .375 inch (3mm - 10mm).

Note: For clarity, the dyno frame is shown transparently to reveal the drum.

Note: The mounting bracket shown is used with the SAAR upgrade. Factory

installed SAAR brakes use a slightly different bracket.

brake shoe

drum

measure gap

AB094

Figure 21: 424x SAAR Brake—Measure the Gap Between the Brake Shoe and Drum

24

Maintenance Guide for Automotive Dynamometers

Page 29

AUTO DYNO MAINTENANCE

Model 424x All-Wheel Drive Dynos

5 If the brake shoe clearance is out of specification, loosen the upper nut on the air

can rod.

6 Adjust the lower nut until the brake shoes are .25 inch (6mm) away from the dyno

drum.

7 Tighten the upper nut on the air can rod down onto the brake actuating tube to

sandwich the tube between the two nuts.

8 Torque the lower nut to 110 foot-pounds.

If you cannot adjust the brakes to specification, you will need new brake shoes.

Contact Dynojet.

air can rod

upper nut

brake actuating tube

BR032

lower nut

Figure 22: 424x SAAR Brake—Adjust the Brake Shoe Clearance

CHANGING THE SAAR BRAKE SHOES

Refer to “Changing the SAAR Brake Shoes” on page 10 for detailed instructions.

Version 3 Maintenance Guide for Automotive Dynamometers

25

Page 30

AUTO DYNO MAINTENANCE

Model 424x All-Wheel Drive Dynos

CHECKING THE AIR CAN SLEEVE RETRACTION

The SAAR brake’s air can sleeve must be positioned correctly for safe operation.

If the air can sleeve is not in the correct location, use a wrench and loosen the nut as

far as you can. The sleeve will drop down as shown in Figure 23. Check all four air

cans.

Note: Verify that the brakes are operating properly before replacing the covers

and using the dyno.

sleeve

nut

correct placement of

nut and sleeve

incorrect placement of

nut and sleeve

sleeve

nut

26

Maintenance Guide for Automotive Dynamometers

AD0194

Figure 23: 424x Dyno—Air Can Sleeve

Page 31

AUTO DYNO MAINTENANCE

MODEL 248 DYNOS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section covers maintenance items for model 248 dynos.

THINGS TO CHECK

• Check all air fittings for leaks monthly. Correct any leaks found.

• Once per month verify the drum brake pressure gauge is reading 55 to 65psi

(450kPa). Adjust the regulator if the pressure is out of specification.

• Maintain the brake shoe clearance. Refer to “Checking the 248 Drum Brake Shoe

Clearance” on page 28 for more information.

•Dyno Bearing Grease:

Under steady use, over 25 runs per day, each bearing should receive 1.5oz

(44.36 ml) of a recommended grease every 2 months.

Under occasional use, less than 25 runs per day, each bearing should receive

1.5oz (44.36 ml) of a recommended grease every six months.

Recommended Grease:

Model 248 Dynos

grease specification description

thickener Lithium Complex

oil Petroleum

thickness NLGI 2

operating temperature

(Fahrenheit)

operating temperature

(Celsius)

examples Mobil Mobilith AW-2

-20°F to 200°F, intermittent to 250°F

-29°C to 93°C, intermittent to 121°C

Version 3 Maintenance Guide for Automotive Dynamometers

27

Page 32

AUTO DYNO MAINTENANCE

Model 248 Dynos

CHECKING THE 248 DRUM BRAKE SHOE CLEARANCE

The 248 drum brake shoe clearance needs to be checked once per month. Use the

following steps.

1 Remove the air from the system.

1a Shut off or disconnect the air supply to the dyno, and follow lock out

procedure.

1b Press the red button on the pendant to activate the drum brakes; the button

will be lit.

1c Press and hold the dyno in or out movement switch until you cannot hear

any air going through the movement motor.

Note: If there is no 4WD dyno, skip this step.

1d Using the red button on the pendant, cycle the drum brakes on and off

several times until no air is heard.

2 Remove the covers as necessary to provide safe working access to the dyno.

3 Measure the gap between the brake shoe and the drum surface. This gap should

be .125 inch - .50 inch (3mm - 13mm).

28

Maintenance Guide for Automotive Dynamometers

Page 33

AUTO DYNO MAINTENANCE

Model 248 Dynos

4 If the brake shoe clearance is out of specification perform the following steps:

4a Remove the cotter key from the clevis pin and remove clevis pin.

4b Remove the two 5/8-inch nuts and washers securing the air can to the brake

bracket.

4c Loosen the jam nut.

4d Pull the air can up so that the clevis can be turned. Screwing the clevis down

the air can rod will decrease brake shoe clearance.

4e With the clevis adjusted, secure the jam nut.

4f Place the air can on brake bracket and secure with nuts and washers

removed earlier.

4g Secure clevis with pin and cotter key.

4h Adjust the brake shoe support so that the brake shoe clearance is even over

the length of the shoe.

• Loosen the jam nut and turn the brake shoe support.

• With the brake shoe support adjusted, tighten the jam nut.

If you cannot adjust the brakes to specification, you will need new brake shoes.

Contact Dynojet.

5 Turn on or reconnect the air supply and check that the drum brakes operate

before replacing the covers and using the dyno.

Figure 24: 248 Dyno—Remove Cotter Key

Version 3 Maintenance Guide for Automotive Dynamometers

29

Page 34

Page 35

Loading...

Loading...