Page 1

Page 2

©2004-2005 Dynojet Research, Inc. All Rights Reserved.

Eddy Current Brake Installation and User Guide For Model 224 Above Ground

Automotive Dynamometers.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, and the software described in it, is furnished

under license and may only be used or copied in accordance with the terms of such

license. This manual is furnished for informational use only, is subject to change without

notice, and should not be construed as a commitment by Dynojet. Dynojet assumes no

responsibility or liability for any error or inaccuracies that may appear in this manual.

Except as permitted by such license, no part of this manu al ma y be repr oduced, sto red in

a retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89031, USA.

Printed in USA.

Part Number: 98215100 Version 3 (03/05)

RECORD

Dynamometer Number: ____________________________________________________

Eddy Current Brake

(Retarder) Number:________________________________________ ____ ___ __________

#

Page 3

T

ABLE OF

C

ONTENTS

Chapter 1 Eddy Current Brake Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Power Requirements and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Installing the Wall Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Testing for Correct Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Replacing the Power Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Hard Wiring to the Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Eddy Current Brake Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Before Installing the Eddy Current Brake: Verify Optimal Brake Cooling . . .1-8

Unpacking the Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Removing the Rear Deck Support Brace . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Installing the Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Installing the Spline Shaft and Driveline Assembly . . . . . . . . . . . . . . . . . .1-15

Installing Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Installing the Front and Rear Brake Covers and Theta Controller . . . . . . .1-18

Routing the Brake Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Wiring the Breakout Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

Securing the Brake to the Dyno Room Floor . . . . . . . . . . . . . . . . . . . . . .1-25

Chapter 2 Torque Module Installation

Load Cell Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Installing the Load Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Torque Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Accessing the Dyno Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Installing the Torque Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Routing the Load Cell Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Installing the Side and Top Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Load Cell Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Model 224 Above Ground Eddy Current Brake Installation and User Guide

i

Page 4

TABLE OF CONTENTS

Chapter 3 Basic Dynamometer Operation

Loading the Car . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Connecting The RPM Pickup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

RPM Pickup Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Connecting the Secondary Inductive Pickup . . . . . . . . . . . . . . . . . . . . . . .3-6

Connecting The Primary Inductive Pickup . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Pre-run Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Before Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Engine Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

After Engine Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Making a Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Appendix A Red Head Anchor Installation

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Appendix B Power Requirements—Excluding North America

Power Requirements and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Installing the Wall Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Testing for Correct Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Replacing the Power Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Hard Wiring to the Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Appendix C Installing the Adapter and Bearing—

Early Model Dynamometers

Installing the Adapter and Bearing—Early Model Dynos . . . . . . . . . . . . .C-2

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-i

ii

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 5

E

DDY

C

URRENT

C HAPTER

B

RAKE INSTALLATION

1

This document provides instructions for installing the eddy current brake (retarder)

to the Dynojet model 224 above ground automotive dynamometer (dyno). This

document also provides instructions for installing and calibrating the load cell and

basic dynamometer operation. To ensure safety and accuracy in the procedures,

perform the procedures as they are described.

Document Part Number: 98215100

Version 3

Last Updated: 03-10-05

This chapter is divided into the following categories:

•Introduction, page 1-2

• Power Requirements and Installation, page 1-5

• Eddy Current Brake Installation, page 1-8

Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-1

Page 6

CHAPTER 1

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before installing your eddy current brake, please take a moment to read this guide for

installation instructions and other important information.

This guide is designed to be a reference tool in your everyday work and includes the

following chapters and information:

EDDY CURRENT BRAKE INSTALLATION

This chapter describes the procedures for installing the eddy current brake.

TORQUE MODULE INSTALLATION

This chapter describes the procedures for installing the torque module and load cell

along with load cell calibration.

BASIC DYNO OPERATION

This chapter describes basic dyno operating procedures.

RED HEAD INSTALLATION

This appendix describes the procedures for installing the Red Head anchors.

POWER REQUIREMENTS—EXCLUDING NORTH AMERICA

This appendix describes the power requirements and installation instructions for all

locations excluding North America.

INSTALLING THE ADAPTER AND BEARING—EARLY MODEL DYNOS

This appendix describes the procedures for installing the adapter and bearing needed

for early model dynos.

1-2

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 7

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

The Record # icon reminds you to record your

RECORD

#

dynamometer and/or eddy current brake (retarder)

number on the inside cover of this manual.

EDDY CURRENT BRAKE INSTALLATION

Introduction

Bold

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www .dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, 3D visualizations, and press releases

about our latest product line.

Highlights items you can select on in the software

interface, including buttons and menus.

The arrow indicates a menu choice. For example,

“select File

then select the Open choice on the File menu.”

Open” means “select the File menu,

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-3

Page 8

CHAPTER 1

Introduction

part number description quantity

21217500 Hood, Retarder Top 1

21217501 Hood, Retarder, Side 1

21217502 Hood, Retarder, Right 1

21217503 Hood, Retarder, Left 1

21228102 Blank Pass Through Cover 3

21228105 Double Hole Pass Through Cover 2

21228506 Cable Pass Through Cover 1

21626210 Z-Bracket (cable routing channel) 2

21917100 Foot 2

32355056 Bearing-Flange, 1.75”, 2-Bolt 1

32811195 O-Ring, 7/16 x 11/16”, #-205 1

35430899 Weight, 25 lb. 4

36580804 Screw-Set, 3/8-16 x 1/2”, W/Tlok 2

36708100 Nut, 1/2-13, Nylock-Hex 2

36721100 Nut, 5/8-11 UNC, Hex 1

36801080 Bolt, 1/2-13 x 1.25”, Flange-Hex 4

36923100 Washer, 5/16”, Hardened, Flat, Stl 12

37513200 Anchor, Redhead, 3/8” 2

37518200 Installation Tool, Redhead Anchor 1

37620844 Woodruff Key, 1/2 x 2.75”, 1622-1 1

49950030 Temp Sensor, 30-500C Max 1

61319001 Calibration Arm Assembly 1

62218130 Splined Shaft Assembly 1

62240130 Driveline Assembly, 7C, 224 Retarder 1

66411004 Theta-2 Controller - 240V -20A 1

65412004 PCB, Torque Cell Rev Switch, Loaded 1

66114002

or

66104001

76950505 Torque Cell Assembly, 224 1

76950606 Cable, Input, 224 Torque Rev Sw 1

76950607 Cable, Output, 224 Torque Rev Sw 1

DM150-019-012 Bolt, 3/8-16 x 1”, Hex 10

PARTS LIST

The following table lists all of the parts included in the Eddy Current Brake

(P/N 72912001) Installation kit. Check your kit against the parts listed to make sure

you have received all of the parts. If any part is missing, contact Dynojet Technical

Support.

Torque Module Sub-Assembly

or

Torque Module High Resolution Sub-Assembly

1

1-4

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 9

EDDY CURRENT BRAKE INSTALLATION

Power Requirements and Installation

POWER REQUIREMENTS AND INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following power requirements and instructions are for North America, Japan, and

locations using 60 Hz power. All other locations should refer to the instructions

found in Appendix B.

The eddy current brake requires a dedicated 240VAC single phase power outlet rated

for 30A for proper operation. Failure to follow these instructions could result in

personal injury or damage to the brake. Connecting the brake to the incorrect

voltage will void the brake warranty. Contact Dynojet with any questions.

The eddy current brake requires a dedicated wall receptacle which must be wired for

operation and is included with the brake or may be shipped in advanced in a separate

package. The brake is equipped with a twenty-five foot power cord with a twist lock

plug pre-wired on the end.

The dedicated wall receptacle is a twist lock four wire grounded 30A NEMA L14-30

type and must be wired in accordance with local building codes and requirements. If

the facility does not have 120/240 volt single phase power, and it does have 120/208

volt three phase Y power, then it is acceptable to connect the four wire receptacle

with two of the three phase lines, the neutral and the ground. With this arrangement,

there will only be 208 volts between line 1 and line 2 instead of 240 volts. This

acceptable, but performance of the eddy current brake will be reduced. In no case

shall all three phase lines be connected to the receptacle! Installation may

require a licensed electrician and must conform to UL and NEC safety standards.

Note: If you are installing your brake in North American or Japan and the brake is

not equipped with twist lock four wire grounded plug, contact Dynojet before

attempting to connect the brake.

Local and national electrical codes require a grounded receptacle box.

• This circuit should have a dedicated 30A double pole circuit breaker.

• The brake should be the only device connected to this circuit.

INSTALLING THE WALL RECEPTACLE

The wall receptacle is included with your brake and is shipped in a separate box or

may be shipped in advance in a separate package.

The wall receptacle is a single phase 240 volt 30A dedicated circuit with a neutral

connection and a ground. The neutral connection is required to split the 240 volt into

two 120 volt connections internal to the dyno.

The cable carrying the power to this receptacle should be ten gauge or larger. Check

with local building codes for the correct size.

1 Connect one of the 240V legs to the X terminal (gold co lo re d scr e w) .

2 Connect the other 240V leg to the Y terminal (gold colored screw).

3 Connect the neutral conductor to the W or WH terminal (silver screw).

4 Connect the ground conductor to the green grounding screw.

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-5

Page 10

CHAPTER 1

Power Requirements and Installation

TESTING FOR CORRECT VOLTAGES

You must test the receptacle for proper voltages before the eddy current brake is

connected to the outlet.

If the voltage readings do not match the following table, DO NOT connect the

brake. You must have a licensed electrician correct the power connection.

Connecting the brake to the incorrect voltage can result in damage to the brake

and will void the brake warranty. Contact Dynojet with any questions.

Using a voltmeter that is capable of measuring AC voltage, measure between the

points listed below and verify that the correct voltages are present.

probe 1 probe 2 desired voltage measurement

2 4 216V to 260V*

1 4 108V to 130V

1 2 108V to 130V

13 <5V

3box<5V

*If using two of the three phase lines of a 120/208 V 3 phase Y system,

then expect to see 187V to 225V.

3

2

1

Figure 1-1: Dedicated Power Receptacle

1-6

Model 224 Above Ground Eddy Current Brake Installation and User Guide

4

Page 11

REPLACING THE POWER PLUG

Use the following instructions to replace the four wire plug and socket.

The plug and socket configuration must be rated for at least 240VAC 30A and have a

minimum of four conductors.

The power cord that attaches to the brake has four conductors internally and their

colors are brown, blue, black, and green/yellow.

1 Connect 240VAC single phase power between the brown and the blue wire

connection points.

2 Connect the green/yellow wire to the ground connection point.

3 Wrap the black wire with the white tape to denote that it is a neutral connection

and connect it to the neutral connection point.

4 Refer to the previous table for testing and probe the new connections as follows:

• blue wire as location #2

• brown wire as location #4

• black wire as location #1

• green/yellow wire as location #3.

EDDY CURRENT BRAKE INSTALLATION

Power Requirements and Installation

HARD WIRING TO THE BUILDING

Use the following instructions to wire the dyno directly to the building.

The brake must connect to a two pole disconnect switch to allow the removal of all

power to the dyno for servicing. This box may contain fusing, circuit breakers, or the

circuit protection may be upstream in the building power system. The circuit must be

protected to 30A with slow blow fuses or time delayed circuit breakers.

The power cord that attaches to the dyno has four conductors internally and their

colors are brown, blue, black, and green/yellow.

1 Remove the brake power plug and connect 240VAC single phase between the

brown and the blue wires through the disconnect switch.

2 Connect the green/yellow wire to the ground connection.

3 Wrap the black wire with white tape to denote that it is a neutral connection and

connect it to the neutral connection.

4 Refer to the previous table for testing and probe the new connections as follows:

• blue wire as location #2

• brown wire as location #4

• black wire as location #1

• green/yellow wire as location #3

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-7

Page 12

CHAPTER 1

Eddy Current Brake Installation

EDDY CURRENT BRAKE INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section will walk you through removing the eddy current brake from the crate,

installing the eddy current brake on model 224 automotive dynos, installing the Theta

Controller , and routing cables.

You will need to provide equipment capable of lifting the eddy current brake off the

crate and into position in your dyno room. Y ou will also need a pair of straps. Dynojet

recommends using single loop style straps.

To prevent possible injury, turn off the dyno electronics and unplug the dyno.

BEFORE INSTALLING THE EDDY CURRENT BRAKE: VERIFY OPTIMAL BRAKE COOLING

Placing the eddy current brake on the left or right side of the dyno will determine the

direction that it turns.

For optimal eddy current brake cooling, the brake should turn in the direction of the

arrows on the rotors.

When running mostly rear wheel drive cars, orient the dyno and brake so the brake is

turning in the direction of the arrows when a rear wheel drive car is on the dyno (as

shown in Figure 1-2).

Note: The dyno will function correctly for front wheel drive cars, but cooling of

the rotors will not be optimal.

The rear wheel drive example below shows the brake turning in the direction of the

arrows on the rotors. In this example, the load cell is in compression.

direction of

rotation

arrow on rotor

1-8

Model 224 Above Ground Eddy Current Brake Installation and User Guide

load cell

Figure 1-2: Optimal Brake Cooling

Page 13

UNPACKING THE EDDY CURRENT BRAKE

uprights and cross

members

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake Installation

1 Remove the top and sides of the crate.

2 Remove any hardware and parts boxes and set aside.

3 Remove the uprights and cross members off the crate.

crate top

Figure 1-3: Remove the Crate Top

remove boxes

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-9

Page 14

CHAPTER 1

Eddy Current Brake Installation

4 Remove the six screws securing the top cover to the brake. Set the screws and the

cover aside.

5 Remove the ten screws securing the side cover to the brake. Set the screws and

the cover aside.

side cover

top cover

Figure 1-4: Remove the Top and Side Covers

1-10

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 15

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake Installation

6 Remove the five screws securing the front and rear covers. Set the screws, bolts,

and covers aside.

brake number

RECORD

Be sure you record the dynamometer and/or eddy current brake number on

the inside cover of this manual.

#

front and rear covers

screw

Figure 1-5: Remove the Left and Right Covers

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-11

Page 16

CHAPTER 1

Eddy Current Brake Installation

7 Remove the four lag bolts securing the brake to the crate.

8 Place the nylon loop strap around the shaft on either side of the brake.

Dynojet recommends using single loop style straps.

9 Using a forklift, lift the eddy current brake from the crate and place the brake near

the dyno.

shaft

bolt

shaft

Figure 1-6: Remove the Brake

1-12

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 17

REMOVING THE REAR DECK SUPPORT BRACE

1 Remove the two bolts and washers securing the brace to the rear deck support

and set aside. These will be used later when installing the eddy current brake.

2 Remove the two bolts and washers securing the brace to the dyno and remove the

brace. The brace will not be used.

brace

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake Installation

rear deck support

Figure 1-7: Remove the Brace

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-13

Page 18

CHAPTER 1

Eddy Current Brake Installation

INSTALLING THE BEARING

The eddy current brake can be installed on either side of your dyno, the installation

instructions are the same.

1 Install the bearing using two 1/2-13 x 1.25-inch flanged bolts. Leave the bolts

loose.

Note: If you are retrofitting an earl y model dyno which does not have the bearing

mounting holes, refer to the instructions in Appendix C.

bearing mounting

holes

bearing

Figure 1-8: Install the Bearing

1-14

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 19

EDDY CURRENT BRAKE INSTALLATION

INSTALLING THE SPLINE SHAFT AND DRIVELINE ASSEMBLY

1 Insert the spline shaft through the bearing and into the spline hub of drum.

Note: Make sure the short spline end faces out.

2 Push the spline shaft as far as it will go.

3 Torque the bearing mounting bolts to 57 foot-pounds.

4 Torque the two set screws on the bearing to 25 foot-pounds.

Eddy Current Brake Installation

bearing mounting

bolts

spline shaft

bearing set screws

Figure 1-9: Install Spline Shaft

5 Remove the four bolts securing the u-joint to the keyed driveline yoke. Set these

bolts aside; they will be used to secure the eddy current brake to the driveline

assembly.

6 Separate the keyed yoke from the driveline assembly. You may need to use a

screwdriver or pry bar to separate the u-joint from the yoke.

7 Place the driveline assembly on the spline shaft.

remove four bolts,

two on either side

driveline assembly

Figure 1-10: Install Driveline Assembly

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-15

Page 20

CHAPTER 1

Eddy Current Brake Installation

INSTALLING EDDY CURRENT BRAKE

1 Place the keyed yoke onto the eddy current brake shaft.

2 Line up the eddy current brake yoke with the driveline assembly.

3 Slide the brake frame towards the dyno frame until they touch. Make sure the

brake yoke is aligned with the driveline.

4 Secure the yoke to the driveline assembly using the four bolts removed earlier.

Torque the bolts to 70 foot-pounds.

Figure 1-11: Install the Brake Assembly

1-16

Model 224 Above Ground Eddy Current Brake Installation and User Guide

driveline assembly

yoke

Page 21

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake Installation

5 Secure the brake frame to the dyno using eight 3/8 x 1-inch bolts and

eight 5/16-inch hardened flat washers. Not all of the bolts and washers are visible

from this view.

6 Torque the brake yoke set screws to 25 foot-pounds.

bolts and washers

(not all visible)

Figure 1-12: Secure the Brake Frame to the Dyno

bolts and washers

(not all visible)

Figure 1-13: Eddy Current Brake on Right Side of Dyno

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-17

Page 22

CHAPTER 1

Eddy Current Brake Installation

INSTALLING THE FRONT AND REAR BRAKE COVERS AND THETA CONTROLLER

1 Install the front and rear covers to the frame using four 1/4-20 x 3/4-inch button

head flange screws and eight nuts for each cover.

2 Secure the deck support to the cover using the hardware removed earlier.

deck support

front and rear

covers

1/4-20 x 3/4-inch screws

Figure 1-14: Install the Front and Rear Covers

1-18

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 23

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake Installation

3 Install the Theta Controller using four 8-32 x 3/8-inch screws.

theta controller

Figure 1-15: Install the Theta Controller

4 Install the two cable routing channels using three screws each.

cable routing

channels

Figure 1-16: Install Cable Routing Channels

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-19

Page 24

CHAPTER 1

Eddy Current Brake Installation

cable routing channels

(not visible)

Figure 1-17: Eddy Current Brake on Right Side of Dyno

1-20

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 25

ROUTING THE BRAKE CABLES

Refer to Figure 1-18 on page 1-22 for cable routing location information.

1 Before routing the cables, remove the two cable pass through covers (just above

the Theta Controller) and the cable pass through cover on the bottom of the side

panel. Remove the two screws securing each cable pass through cover. Set the

screws and covers aside.

2 Route the temperature sensor cable from the eddy current brake through the

panel opening closest to the dyno and over to the Breakout board.

For more information on wiring the Breakout board refer to page 1-23.

3 Route the speed pick-up cable from the Breakout board through the panel

opening closest to the dyno and over to the pick-up card.

4 Route the 25-pin cable from the Breakout board through the panel opening

closest to the dyno, along the inside of the panel using a cable routing channel

(not used by the input power cable), out through the bottom panel opening, and

to the dyno electronics.

5 Route the brake power cable from the eddy current brake through the panel

opening furthest from the dyno and over to the Theta Controller (underneath).

6 Route the input power cable from the Theta Controller through the panel

opening furthest from the dyno, along the inside of the panel using the cable

routing channel (not used by the 25-pin cable), out through the bottom panel

opening, and to your power source.

7 Route the control cable from the Theta Controller to the Breakout board.

8 Slide the brake power cable and the input power cable into a double cable pass

through. Secure the cable pass through to the panel using the two screws

removed earlier.

9 Slide the temperature sensor, speed pick-up, and 25-pin cables into a single cable

pass through. Secure the cable pass through to the panel using the two screws

removed earlier.

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake Installation

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-21

Page 26

CHAPTER 1

Eddy Current Brake Installation

10 Do not install the cable pass through cover on the bottom of the side panel until

you have routed the load cell cable. Refer to page 2-3.

25-pin cable

input power

cable

temperature

sensor cable

double cable

speed pick-up

cable

theta controller

Figure 1-18: Routing the Cables

pass through

input power

cable

single cable

pass through

breakout board

control cable

brake power cable

1-22

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 27

WIRING THE BREAKOUT BOARD

Refer to Figure 1-19 on page 1-24 for Breakout board location information.

1 Attach the temperature sensor cable to the Breakout board. The temperature

sensor cable has five wires which connect to the wiring block labeled TEMP. This

cable was routed to the Breakout board on page 1-21.

• Green wire connects to G1 • White wire connects to W1

• Black wire connects to B1 • Red wire connects to R1

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake Installation

• Ground (shield) wire connects to S1

2 Attach the control cable to the Breakout board. The control cable has five wires

which connect to the wiring block labeled LOAD CONTROL. This cable was

routed to the Breakout board on page 1-21.

• Black wire connects to V- • Red wire connects to V+

• White wire connects to O+ • Green wire connects to O-

• Ground (shield) wire connects to SH

3 Attach the speed pick-up cable to the Breakout board. The control cable has four

wires which connect to the wiring block labeled DRUM 1. This cable was routed

to the Breakout board on page 1-21.

• Re d wire connects to R1 • Black wire connects to B1

• White wire connects to W1 • Ground (shield) wire connects to S1

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-23

Page 28

CHAPTER 1

Eddy Current Brake Installation

4 Verify jumpers J1 and J2 are set for the eddy current brake as shown in

Figure 1-19.

The air brake will be activated when the dyno electronics power is turned off or

when the red button on the pendant is lit. The eddy current brake is used for load

control.

temp

jumpers

J1 and J2

load control

Figure 1-19: Wire the Breakout Board

speed pick-up

1-24

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 29

SECURING THE BRAKE TO THE DYNO ROOM FLOOR

1 Install the foot to the left and right panels using one 1/2-13 x 1.25-inch flange bolt

and one 1/2-13-inch nylock nut (not visible).

2 Install the Red Head Anchors. Refer to Appendix A for Red Head Anchor

installation instructions.

foot

EDDY CURRENT BRAKE INSTALLATION

Eddy Current Brake Installation

foot

install red head anchor

bolt

(nut not visible)

Figure 1-20: Secure the Brake to the Dyno Room Floor

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

1-25

Page 30

Page 31

T

ORQUE

M

C HAPTER

2

ODULE INSTALLATION

The Torque Module, when added to Dynojet's market leading i nertia dynamometer,

results in a complete vehicle performance test.

This chapter provides instructions for installing and using the Torque Module with

WinPEP 7. To ensure safety and accuracy in the procedures, perform the procedures

as they are described.

This chapter is divided into the following categories:

• Load Cell Installation, page 2-2

• Torque Module Installation, page 2-4

• Load Cell Calibration, page 2-10

Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-1

Page 32

CHAPTER 2

Load Cell Installation

LOAD CELL INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes how to install the load cell.

PARTS LIST

The following table lists all of the parts included in the Torque Module Installation kit

(P/N 73920007). Check your kit against the parts listed to make sure you have

received all of the parts. If any part is missing, contact Dynojet Technical Support.

part number description quantity

35430899 Weight, 25 lb 4

61319001 Calibration Arm Assembly 1

66114002

or

66104001

76950505 Torque Cell Assembly, 224 1

76950606 Cable, Input, 224 Torque Rev Sw 1

76950607 Cable, Output, 224 Torque Rev Sw 1

Torque Module Sub-Assembly

or

Torque Module High Resolution Sub-Assembly

1

INSTALLING THE LOAD CELL

1 Verify the main dyno power is disconnected.

2 Remove the two bolts and nuts securing the existing bar on the eddy current

brake and remove the bar. Set the bolts and nuts aside.

3 Verify the eyelets on the load cell are spaced the same as the bar removed earlier.

Adjust the load cell spacing by loosening the lock nut and turning the eyelet.

bar

distance must be

the same

Figure 2-1: Verify Load Cell Spacing

eyelet

lock nut

2-2

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 33

TORQUE MODULE INSTALLATION

Load Cell Installation

4 Secure the load cell to the mounting bracket using the two bolts and nuts

removed earlier.

5 Route the load cell cable out through the bottom panel opening. Make sure the

load cell cable is clear of any power cable or hot or rotating objects.

6 Slide the input power cable (routed on page 1-22) into one side of the double

cable pass through removed earlier.

7 Slide the 25-pin cable and load cell cable through the other side of the double

cable pass through cover.

8 Secure the cable pass through cover to the panel using the two screws removed

earlier.

load cell cable

dyno

load cell and 25-

pin cable on left,

input power cable

on right

route cables through

cable pass through

Figure 2-2: Install the Load Cell

install the load cell

(the brake is not

shown for clarity)

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-3

Page 34

CHAPTER 2

Torque Module Installation

TORQUE MODULE INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes how to access the dyno electronics, install the Torque Module,

route the load cell cable, and install the side and top brake covers.

ACCESSING THE DYNO ELECTRONICS

You will need to access your dyno electronics in order to add the torque module. Use

the following steps to access the dyno electronics.

1 Remove the eight screws securing the cover and lift the cover off.

2 Add the torque module to the top of the dyno electronics. Refer to “Installing the

Torque Module” on page 2-5.

3 Leave the dyno electronics enclosure out. You will need to route the load cell

cable to the Torque Module later.

dyno electronics

Figure 2-3: Inside the Electronics Enclosure

2-4

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 35

INSTALLING THE TORQUE MODULE

1 Verify the main dyno power is disconnected.

2 Turn off the main power switch on the CPU Module on the dyno electronics and

unplug the power cord.

3 Remove the dust cover from the existing top module.

TORQUE MODULE INSTALLATION

Torque Module Installation

dust cover

power cord

input

power switch

Figure 2-4: Remove Dust Cover

4 Loosen the top right screw on the back of the existing top module.

5 Plug the Torque Module into the existing top module. Place the dust cover,

removed in step 3, on the Torque Module.

6 Secure the grounding strap on the back of the Torque Module to the existing top

module.

grounding strap

Figure 2-5: Secure Grounding Strap

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-5

Page 36

CHAPTER 2

Torque Module Installation

7 Secure the Torque Module to the dyno electronics with the plastic tie straps (one

on each side).

Note: Do not attach the load cell cable at this time.

torque module

tie strap

green LED light

load cell cable and port

do not attach at this time

Figure 2-6: Attach Torque Module

2-6

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 37

ROUTING THE LOAD CELL CABLE

1 Route the load cell cable from the cable pass through on the eddy current brake

to the dyno electronics.

Make sure the load cell cable is clear of any power cables or hot or rotating

objects.

2 Route the load cell cable through the cable clamp on the back of the dyno

electronics enclosure.

2a Loosen the two screws and lift the clamp up to slide the load cell cable

through.

2b Secure the clamp with the two screws.

3 Attach the 9-pin connector on the load cell cable to the front of the Torque

Module and tighten down the screws.

4 Attach the power cord to the dyno electronics and turn the power switch on.

cable clamp

TORQUE MODULE INSTALLATION

Torque Module Installation

torque module

load cell cable

Figure 2-7: Route the Load Cell Cable to the Torque Module

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-7

Page 38

CHAPTER 2

Torque Module Installation

5 The green LED light on the Torque Module should now be on.

6 Replace the dyno electronics cover.

torque module

tie strap

green LED light

load cell cable and port

do not attach at this time

Figure 2-8: Attach Torque Module and Load Cell Cable

2-8

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 39

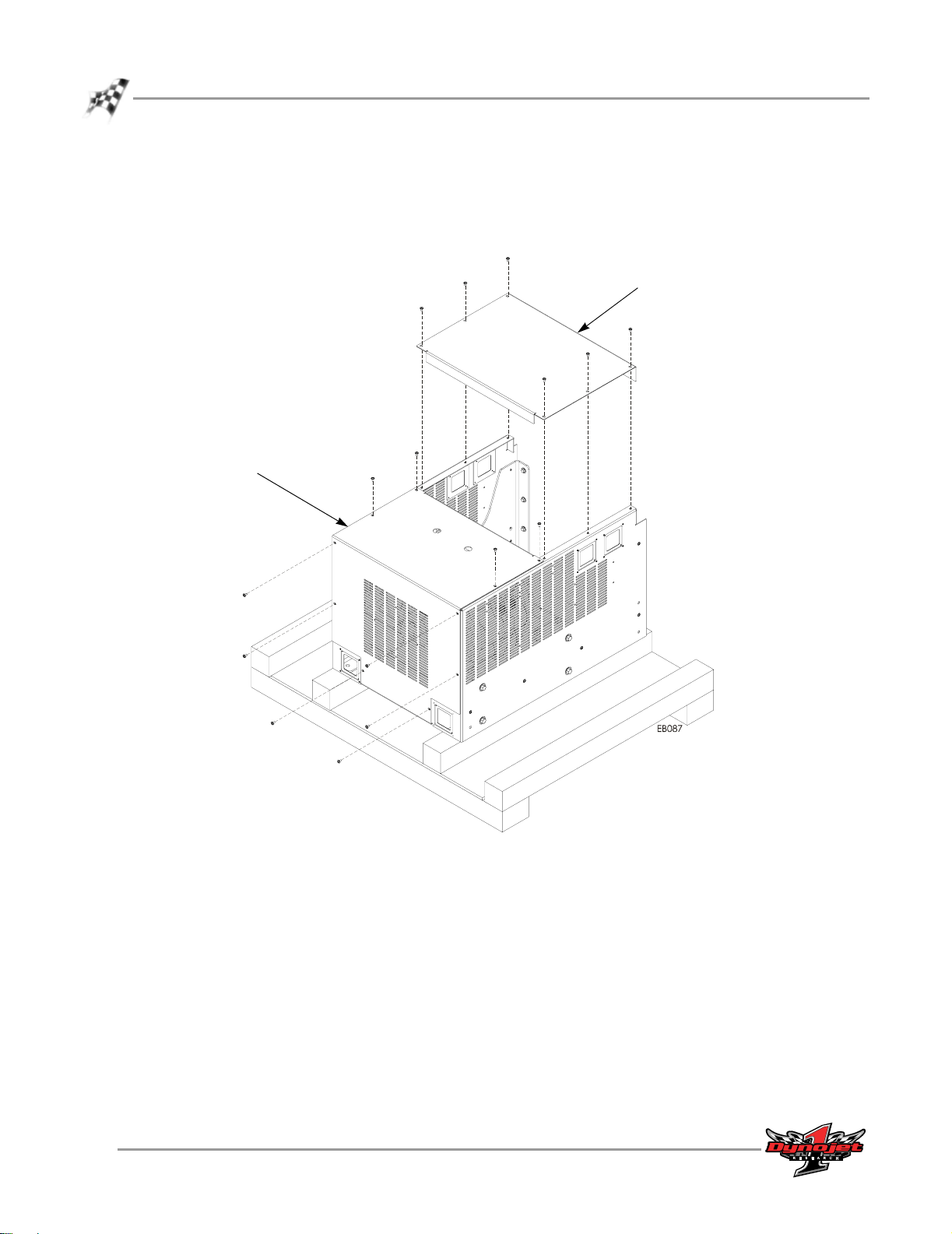

INSTALLING THE SIDE AND TOP COVERS

1 Install the brake side cover using ten 1/4-20 x 3/4-inch button head flange screws.

side cover

TORQUE MODULE INSTALLATION

Torque Module Installation

Figure 2-9: Install the Side Cover

2 Install the brake top cover using six 1/4-20 x 3/4-inch button head flange screws.

top cover

Figure 2-10: Install the Top Cover

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-9

Page 40

CHAPTER 2

Load Cell Calibration

LOAD CELL CALIBRATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section provides instructions for using the Torque Module with WinPEP 7. The

Torque Module must be calibrated prior to use. Follow the directio ns on the scr een

exactly. Failure to perform the directions accurately will result in improper torque

values.

1 Verify you are in the MakeRun screen.

2 Verify you are connected to the dyno electronics.

Note: For more information on connecting to the dyno electronics, refer to the

WinPEP 7 User Guide (on your WinPEP CD or at

www.dynojet.com/manuals.shtml) or the WinPEP 7 Online Help.

3Select Tools

Note: Before proceeding, be sure the eddy current brake is free and clear of any

obstructions. There should not be anything resting on the eddy current brake or

the dynamometer drum during this procedure.

4Click Next to perform the Zero Calibration.

The Calibration window will appear. The hardware is now zeroing out the torque

cell. If the unit does not calibrate, recheck the setup and retry.

MakeRun Options Torque Cell Calibration.

Figure 2-11: Zero Calibration Window

2-10

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 41

TORQUE MODULE INSTALLATION

Load Cell Calibration

Once the Zero Calibration is complete, the Calibration Mass window will appear.

5 Enter the Torque Module calibration value. Refer to Figure 2-13.

Note: You must perform this step the first time you calibrate the load cell.

Or

If you are only performing a Zero Calibration, click Finish.

bolt pattern closest to

the end of the

calibration arm

Figure 2-12: Calibration Mass Window

Enter the calibration number stamped near the bolt pattern at the end of the

calibration arm. If you do not have enough room to use the bolt pattern closest to

the end of the calibration arm, use the number stamped near the bolt pattern in

the center of the arm.

Note: Dynojet recommends you secure the calibration arm using the bolt pattern

closest to the end of the arm unless space constraints in your dyno room do not

allow you to.

bolt pattern near the

center of the

calibration arm

Figure 2-13: Calibration Arm Number

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-11

Page 42

CHAPTER 2

Load Cell Calibration

6Click Next to continue.

7 Install the calibration arm and weights. Refer to step 8 and

The Span Calibration window will appear.

Figure 2-15 on page 2-13.

Figure 2-14: Span Calibration Window

2-12

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 43

TORQUE MODULE INSTALLATION

Load Cell Calibration

8 Install the calibration arm and weights using the bolts at the end of the calibration

arm.

Note: If you do not have enough room to use the bolt pattern closest to the end

of the calibration arm, use the bolt pattern in the center of the arm. Refer to

Figure 2-16 on page 2-14.

8a Secure the calibration arm to the eddy current brake by tightening the bolt

using the handle.

8b Gently place the weights on the calibration arm.

Note: Verify the calibration arm is not contacting the cover.

The calibration weights are very heavy. The weights must be set on the arm

gently or you will damage the load cell.

secure arm to brake by

tightening handle

weight support

pin

weights

Figure 2-15: Install Calibration Arm and Weights Using the Bolt Pattern Closest to the End

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-13

Page 44

CHAPTER 2

Load Cell Calibration

If you do not have enough room to use the bolt pattern closest to the end of the

calibration arm, use the bolt pattern in the center of the arm as shown in

Figure 2-16.

secure arm to brake by

tightening handle

weight support

pin

weights

Figure 2-16: Install Calibration Arm and Weights Using the Bolt Pattern in the Center

2-14

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 45

TORQUE MODULE INSTALLATION

Load Cell Calibration

While installing the calibration weights, you should notice the Torque Gauge on the

DynoTrac Window moving from 0 to about 500 foot-pounds.

Note: The Torque Gauge may or may not be in this range.

• If the torque cell has been previously calibrated incorrectly or has not been

calibrated for a while, the gauge may show values out of this range until

calibration is complete.

• If you use the bolt pattern in the center of the calibration arm, the gauge will

show values around 250-260 foot-pounds.

Note: Let the torque gauge needle stabilize before clicking Next.

9From the Span Calibration window (Figure 2-14), click Next to continue.

At this point, the value on the gauge should match the value on the calibration

arm.

10 Remove the calibration arm and weights and click Finish.

Figure 2-17: Calibration Is Complete Window

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-15

Page 46

Page 47

B

ASIC

D

YNAMOMETER

C HAPTER

O

PERATION

3

The Dynojet dynamometer (dyno) gives state of the art technology, durability, and

accuracy that you need. Dynojet’s advanced engineering delivers the precise

horsepower measurements a technician needs to make quick and accurate

evaluations of engine performance and drive train problems.

This chapter will walk you through loading and preparing your dynamometer and

includes instructions for basic dyno operation. For more detailed instructions, refer

to the WinPEP 7 User Guide. This manual can be found on your WinPEP CD or at

www.dynojet.com/manuals.shtml.

This chapter is divided into the following categories:

•Loading the Car, page 3-2

• Connecting the RPM Pickup, page 3-5

•Pre-Run Inspection, page 3-8

• Making a Test Run, page 3-10

Model 224 Above Ground Eddy Current Brake Installation and User Guide

3-1

Page 48

CHAPTER 3

Loading the Car

LOADING THE CAR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use the following steps to load a car on the dyno.

Note: For more information about lift operation , refer to the instructions

included with the lift.

1 Verify the dyno electronics power is on and connected to your computer.

2 Make sure you are in the MakeRun screen.

3 Set the dyno brake on by pressing the red button on the hand held pendant.

4 For four or all wheel drive vehicles, measure the wheel base on the vehicle and

adjust the 224-4WD dyno to the dimension before driving the vehicle on the

dyno.

5 Drive the vehicle onto the dyno and align the vehicle straight with the dyno.

6 Stop the vehicle when the drive axle(s) is centered on the drum(s).

rear or front wheel

drive vehicles

center drive axle on dyno drum

four or all wheel

drive vehicles

adjust wheel base of

224-4wd dyno

center drive axle on both dyno drums

Figure 3-1: Center the Drive Axle(s) on the Drum(s)

3-2

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 49

BASIC DYNAMOMETER OPERATION

Loading the Car

7 When the vehicle is positioned properly on the dyno, shut the engine off.

• If the vehicle has an automatic transmission, place it in park.

• If the vehicle has a manual transmission, place it in gear.

8 Set the vehicle’s emergency brake.

9 Secure the non-drive wheels using the provided tire chocks. Do not use tire

chocks for four wheel drive vehicles.

10 Attach the tie-down straps.

Rear Wheel Drive

• Attach two tie-down straps from secure anchor points to the rear of the

vehicle. Attach additional tie-down straps from the rear of the vehicle as shown

in Figure 3-2.

• Attach two tie-down straps from secure anchor points to the front of the

vehicle.

Front Wheel Drive

• Attach two tie-down straps from secure anchor points to the rear of the

vehicle.

• Attach two tie-down straps from secure anchor points to the front of the

vehicle. Attach additional tie-down straps across the front of the vehicle to

form a crisscross.

Four Wheel (All Wheel) Drive

• Attach two tie-down straps from secure anchor points to the rear of the

vehicle. If the vehicle is equipped with a rear steering system, attach additional

tie-down straps across the rear of the vehicle to form a crisscross.

• Attach two tie-down straps from secure anchor points to the front of the

vehicle. Attach additional tie-down straps across the front of the vehicle to

form a crisscross.

rear wheel drive

Figure 3-2: Attach Tie-down Straps

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

front wheel drive

four wheel drive

3-3

Page 50

CHAPTER 3

Loading the Car

11 Tighten the tie-down straps evenly making sure that the drive wheels remain

centered on the drum.

The tie-down straps should always be connected to the vehicle’s solid axle or

the suspension control arms. Factory tie-down hooks connected to the

vehicle’s frame may be used on the end opposite the drive wheels (for

example: the front end of a rear driven vehicle).

12 Release the brake on the vehicle and the dyno.

13 Start the vehicle and put the transmission into first gear or drive.

14 Press the accelerator pedal so the drums begin turning slowly. While the drums

are slowly turning, get a feel for the stability of the vehicle. Stop the drum with the

dyno brakes.

15 Check all the straps and ensure the vehicle is tracking straight on the dyno.

3-4

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 51

BASIC DYNAMOMETER OPERATION

CONNECTING THE RPM PICKUP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Your Dynojet dynamometer includes a primary wire inductive pickup and two

secondary wire inductive pickups. These small “clothespin like” inductive pickups are

used to sense RPM. An RPM pickup is required if you want to view torque graphs.

Generally you will use one secondary wire inductive pickup on a spark plug wire.

Vehicles with wasted spark ignition systems may require two secondary inductive

pickups. On a wasted spark ignition, typically one coil will be connected to two spark

plug wires. Attach one secondary pickup to each of these wires. If the pickups are

connected to two plug wires that do not fire at the same time, an erratic RPM readout

may occur. The primary wire ind uctive pickup senses RPM pulses from the coil.

Although this pickup location generally works better, it is harder to find the correct

location to connect the RPM pickup.

Note: If a pickup is not being used, disconnect it from the dyno electronics to

prevent any stray pick up of signals.

The optional Optical Sensor is useful on diesel powered vehicles, MSD ignitions, and

other high RFI ignition systems. For more detailed information on the Optical Sensor,

refer to the Optical RPM Sensor Installation Guide (P/N 98295109).

Connecting The RPM Pickup

Inductive pickups are very fragile. The ferrite core can easily be damaged and

is not covered under warranty. Dr opp ing, snapping, vibration, and heat can all

damage the ferrite core.

The dyno electronics RPM module contains the electronics that sense the RPM pulses.

An auto-gain circuit looks at only the peak voltage of the vehicle’s spark, ignoring the

lower voltages to help reduce electronic noise problems. Wasted spark ignition

systems will produce a lower voltage level on the exhaust stroke than the

compression stroke. By definition of the auto-gain circuit, lower voltage spark levels

will be ignored, missing every other spark the vehicle would produce.

RPM PICKUP DESCRIPTIONS

RPM pickup description

Secondaries (Non- wasted spark system) Use one secondary pickup. Unplug the other pickup from the RPM

module and set the degrees between plug fires to 720° in WinPEP.

Secondaries (Wasted spark ignition

system)

Primary pickup Attach the primary wire pickup to the primary side of the coil. Set

Optional Optical RPM Sensor Attach the sensor wire to the RPM module, also be sure to plug in

Use two secondary pickups. Attach one pickup on each spark plug

wire on the same coil and set the degrees between plug fires to

360° in WinPEP.

the degrees between plug fires by taking 720/number of cylinders.

For example, the number of degrees between plug fires on a V-8

engine with a single coil is 720/8=90 degrees.

the small power lead into the CPU module. The other end of the

wire attaches to the Optical Sensor. Set the degrees between plug

fires to 360° in WinPEP. Refer to the Optical RPM Sensor

Installation Guide (P/N 98295109).

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

3-5

Page 52

CHAPTER 3

Connecting The RPM Pickup

CONNECTING THE SECONDARY INDUCTIVE PICKUP

The secondary inductive pickup cannot be in contact with, or it’s connecting wire be

crossing, other engine electrical wires or stray RF interference may result.

1 Clip the secondary inductive pickup around one spark plug wire.

2 Route the inductive pickup cable clear of devices that produce electronic noise

(spark plug wires, coil wire, coil etc.).

Note: Inductive pickup placement is important. Position the inductive pickup so

that it is not making contact with any other spark plug wires. Separate the spark

plug wire from the spark plug wire bundle for proper operation.

Note: You must ground the vehicle to the dyno for the electronics to function

properly.

connect secondary

inductive pickup on a

single spark plug wire

automobile

distributor

Figure 3-3: Secondary Inductive Pickup

Figure 3-4: Separate Spark Plug Wire

3-6

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 53

CONNECTING THE PRIMARY INDUCTIVE PICKUP

The primary inductive pickup cannot be in contact with, or it’s connecting wire be

crossing, other engine electrical wires or stray RF interference may result.

1 Clip the primary inductive pickup around the primary side of the coil.

2 Route the primary wire cable clear of devices that produce electronic noise.

Note: You must ground the vehicle to the dyno for the electronics to function

properly.

BASIC DYNAMOMETER OPERATION

Connecting The RPM Pickup

coil

Figure 3-5: Primary Inductive Pickup

connect primary

inductive pickup on the

negative side of the coil

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

3-7

Page 54

CHAPTER 3

Pre-run Inspection

PRE-RUN INSPECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perform a vehicle inspection before making a run.

• Check the radiator coolant and oil levels.

•Check the fuel source.

• Rotate the drum(s) and check for rocks caught in the tire tread that could fly out.

• Check the tire pressure and tire speed rating. Improperly inflated tires or

exceeding the maximum speed rating can result in premature wear or severe tire

damage. Make sure the tire has no major deficiencies (cracks in sidewalls, tread life,

etc.).

• Visually inspect the vehicle. Make sure it is in safe running order.

• Make sure ear protection and safety glasses are used when the dyno is being

operated.

• Check the tie-down straps to make sure that they are tight and secured.

• Check the drive tires to be sure that they are aligned correctly on the

dynamometer’s drums.

• Keep all rotating components clear at all times.

• Only the operator should be near the dyno or the vehicle during the test.

• Never allow any person(s) to stand behind the dyno or vehicle when it is being

operated.

• Perform any other safety inspections appropriate to running your vehicle on the

dyno.

Never allow any person(s) to stand behind the dyno or vehicle when it is being

operated. Only the operator should be near the dyno or the vehicle during the

test.

BEFORE STARTING THE ENGINE

Connect an exhaust hose or hoses (if dual exhaust) on the vehicle, make sure the

hose fits over the tail pipe, is not plugged or kinked and the hose is vented correctly

out of the dyno room.

Engine exhaust contains poisonous carbon monoxide gas. Breathing it could

cause death. Operate machine in well ventilated area.

3-8

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 55

ENGINE WARM UP

Warm the vehicle’s engine and drivetrain before beginning testing. Consistent engine

temperatures will assure your runs are repeatable.

AFTER ENGINE WARM UP

Always leave the vehicle in park (automatic transmission) or in first gear (manual

transmission), with the engine off, and make sure the emergency brake and the dyno

brake are on when you get out of the vehicle.

• Fix any fuel, oil, or coolant leaks that may have shown up after engine warm up and

check the carburetor for leaks.

• Any loud or unusual engine noises or excessive exhaust smoke should be resolved

before continuing.

BASIC DYNAMOMETER OPERATION

Pre-run Inspection

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

3-9

Page 56

CHAPTER 3

Making a Test Run

MAKING A TEST RUN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dyno runs provide safe, reliable road testing right in the shop. The dyno allows you to

measure, record, and diagnose performance problems quickly. The dyno combined

with WinPEP 7 produces consistent, easily interpretable power graphs. Use the

following instructions to ensure repeatable and accurate measurements.

1 Verify the vehicle is secured properly.

2 Place the vehicle in a low gear and release the dyno brake using the hand held

pendant.

3 Slowly accelerate the vehicle to 20 m.p.h.

4 Test the tachometer operation.

4a Rev the engine. The gauges on the computer screen should be moving. If

the tachometer is moving but not registering the correct RPM values, the

number of degrees of revolution of the crank shaft (the plug fires number) is

incorrect.

4b Stop the vehicle, return to the MakeRun Configuration dialog box, and enter

the correct value for the plug firing order.

5 Press the red brake button to apply 100% braking and slow down the vehicle.

Using the vehicle’s own brakes to slow or stop the drum at speeds over 30

m.p.h. can severely over heat the brake parts. Dynojet dynamometers with the

mechanical brake, air brake, or eddy current brake accessory can be used to

slow the vehicle and drum to a full stop at any speed. The vehicle’s brakes

should be used in an emergency stop situation only.

6 Shut the engine off and put the vehicle in gear (manual transmission) or park

(automatic transmission).

7 Set the vehicle’s parking brake and leave the dyno brake on.

8 Perform a final inspection.

• Verify the drive tire’s alignment on the dyno drums.

• Make any adjustments to the tie-down straps as needed.

• Perform any other safety checks that you deem appropriate to your particular

situation.

You are now ready to make a high speed run on the dyno. Refer to your WinPEP 7

User Guide for more detailed instructions.

3-10

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 57

R

ED

H

EAD

A PPENDIX

A

A

NCHOR INSTALLATION

This appendix contains instructions for installing the Red Head Multi-Set™II Anchors.

The anchors will be used to secure the dyno to concrete. To ensure safety and

accuracy in the procedures, perform the procedures as they are described. Be sure to

read and understand the warnings included in this appendix.

WARNINGS

Always wear safety glasses and other necessary protective devices or apparel

when installing or working with anchors.

ITW Ramset/Red Head Multi-Set II Anchors are designed to operate properly

only when installed with ITW Ramset/Red Head brand Setting Tools.

The use of a 24 to 40 ounce hammer is recommended for expanding Multi-Set II

anchors.

The use of carbide drill bits manufactured with ANSI B94. 12-77 drill bit diameter

requirements is recommended for installation of this anchor.

Not recommended for use in lightweight masonry material such as block or brick.

Use of core drills is not recommended to drill holes for use with this anchor.

Not recommended for use in new concrete which has not had sufficient time to cure.

Anchor spacing and edge distance requirements (anchor installation locations) are

the responsibility of the engineer of record.

CONTACT INFORMATION FOR ITW RAMSET/RED HEAD

Contact ITW Ramset/Red Head at 1-630-350-0370, or 1300 North Michael Drive,

Wood Dale, IL 60191.

Model 224 Above Ground Eddy Current Brake Installation and User Guide

A-1

Page 58

APPENDIXA

Installation

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use the table below to determine the catalog number, drill bit size, minimum hole

depth, and setting tool catalog number.

setting tool

catalog number drill bit size minimum hole depth

Carbon Steel

RM-38/RL-38 (9.5 mm)

Use the following instructions to install the Red Head anchors.

1 Drill the hole in the concrete the same outside diameter as the anchor being used

to any depth exceeding minimum embedment.

1/2-inch 1 5/8-inch (41.2 mm) RT-138

catalog number

Figure A-1: Red Head Anchor—Drill the Hole

2 Insert the anchor.

anchor

Figure A-2: Red Head Anchor—Insert the Anchor

A-2

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 59

RED HEAD ANCHOR INSTALLATION

Installation

3 Using a hammer, drive the anchor flush with the surface of the concrete, or below

the surface if the hole depth exceeds minimum embedment.

Figure A-3: Red Head Anchor—Drive the Anchor Flush

4 Using a hammer, expand the anchor with the setting tool. The anchor is properly

expanded when the shoulder of the setting tool is flush with the top of the

anchor.

Note: Use only Ramset/Red Head setting tools to insure proper installtion.

setting tool

Figure A-4: Red Head Anchor—Expand the Anchor

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

A-3

Page 60

Page 61

A PPENDIX

P

OWER

This appendix contains the power requirements and inst ruc tio ns fo r all lo cations

excluding North America brake installations. Refer to page 1-5 for power

requirements and instructions for North America and Japan. To ensure safety and

accuracy in the procedures, perform the procedures as they are described.

R

EQUIREMENTS

—E

N

ORTH

XCLUDING

A

MERICA

B

Model 224 Above Ground Eddy Current Brake Installation and User Guide

B-1

Page 62

APPENDIXB

Power Requirements and Installation

POWER REQUIREMENTS AND INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The eddy current brake (excluding North America and Japan) requires a dedicated

wall receptacle which must be wired for operation and is included with the brake or

may be shipped in advanced in a separate package.

The eddy current brake requires a dedicated 240V AC single phase power outlet rated

for 30A for proper operation. Failure to follow these instructions could result in

personal injury or damage to the brake. Connecting the brake to the incorrect

voltage will void the brake warranty. Contact Dynojet with any questions.

The dedicated wall receptacle is a three-pin IEC grounded 30A type and must be

wired in accordance with local building codes and requirements. Installation may

require a licensed electrician to conform to applicable safety standards.

If you are installing your brake in a location other than North America or Japan

and the brake is not equipped with a three pin IEC grounded plug, contact

Dynojet before attempting to connect the brake.

Local and national electrical codes will require that the box containing the receptacle

is grounded.

• This circuit should have a dedicated 30A double pole circuit breaker.

• The brake should be the only device connected to this circuit.

B-2

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 63

POWER REQUIREMENTS—EXCLUDING NORTH AMERICA

INSTALLING THE WALL RECEPTACLE

The wall receptacle is a single 240 volt 30A dedicated circuit with a ground.

The cable carrying the power to this receptacle should be 4.0 mm

larger. Check with local building codes for th e correct size.

1 Connect one of the 240V legs to the N terminal (white).

2 Connect the other 240V leg to the L terminal (no color).

3 Connect the ground conductor to the green terminal.

Power Requirements and Installation

2

(ten gauge) or

L terminal

N terminal

(white)

Figure B-1: Wiring the Wall Receptacle

ground terminal

(green)

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

B-3

Page 64

APPENDIXB

Power Requirements and Installation

TESTING FOR CORRECT VOLTAGES

You must test the receptacle for proper voltages before the dyno is connected to the

outlet.

Using a voltmeter that is capable of measuring AC voltage, measure between the

points listed below and verify that the correct voltages are present.

probe 1 probe 2 desired voltage measurement

1 3 220V to 250V

2box<5V

3

1

2

Figure B-2: Testing the Wall Receptacle

B-4

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 65

POWER REQUIREMENTS—EXCLUDING NORTH AMERICA

REPLACING THE POWER PLUG

Use the following instructions to replace the plug and socket.

The plug and socket configuration must be rated for at least 240VAC 30A and have a

minimum of three conductors.

The power cord that attaches to the dyno has four conductors internally and their

colors are brown, blue, black, and green/yellow.

1 Connect 240VAC single phase power between the brown and the blue wire

connection points.

2 Connect the green/yellow wire to the ground connection point.

3 Cut off the black wire.

4 Refer to the previous table for testing and probe the new connections as follows:

• blue wire as location #1

• brown wire as location #3

• green/yellow wire as location #2

HARD WIRING TO THE BUILDING

Power Requirements and Installation

Use the following instructions to wire the brake directly to the building.

The brake must connect to a two pole disconnect switch to allow the removal of all

power to the brake for servicing. This box may contain fusing, circuit breakers, or the

circuit protection may be upstream in the building power system. The circuit must be

protected to 30A with slow blow fuses or time delayed circuit breakers.

The power cord that attaches to the brake has four conductors internally and their

colors are brown, blue, black, and green/yellow.

1 Remove the brake power plug and connect 240VAC single phase between the

brown and the blue wires through the disconnect switch.

2 Connect the green/yellow wire to the ground connection.

3 Cut off the black wire.

4 Refer to the previous table for testing and probe the new connections as follows:

• blue wire as location #1

• brown wire as location #3

• green/yellow wire as location #2

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

B-5

Page 66

Page 67

I

NSTALLING THE

E

ARLY

This appendix contains instructions for installing the adapter and bearing on early

model dynamometers (dynos); this includes dynos with serial numbers between

2240088 and 2240120. To ensure safety and accuracy in the procedures, perform the

procedures as they are described.

A

DAPTER AND

M

ODEL

D

A PPENDIX

C

B

EARING

YNAMOMETERS

—

Model 224 Above Ground Eddy Current Brake Installation and User Guide

C-1

Page 68

APPENDIXC

Installing the Adapter and Bearing—Early Model Dynos

INSTALLING THE ADAPTER AND BEARING—EARLY MODEL DYNOS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynos missing the bearing mounting holes, shown in Figure 1-8 on page 1-14, will

need to use the adapter (P/N 79110001) to install the bearing. This includes dynos

with serial numbers between 2240088 and 2240120.

1 Orient the bearing to the adapter as shown in Figure C-1. The arrow on the

adapter plate must point up.

2 Secure the bearing to the adapter plate using two 1/2-13 x 1.25-inch flange bolts

and two 1/2-13-inch nuts. Leave the bolts loose.

Note: The bolts are included with the eddy current brake while the nuts are

included with the adapter kit.

bearing

adapter plate

arrow

Figure C-1: Early Model Dynos—Install Bearing to Adapter

3 Secure the adapter plate to the dyno using six 1/2-13 x 3/4-inch bolts.

bolt

adapter plate

Figure C-2: Early Model Dynos—Install Adapter Plate

C-2

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Page 69

INSTALLING THE ADAPTER AND BEARING— EARLY MODEL DYNAMOMETERS

Installing the Adapter and Bearing—Early Model Dynos

4 Using the template included in this appendix, drill four additional holes into the

dyno frame as shown.

Note: If you needed to use the adapter plate, you will need to drill brake

mounting holes in the dyno frame.

4a Line the template up with the existing hole on the dyno.

4b Drill two 3/8-16-inch UNC holes on each side of the dyno.

template

drill holes

existing hole

template

drill holes

existing hole

Figure C-3: Early Model Dynos—Using the Template

Version 3 Model 224 Above Ground Eddy Current Brake Installation and User Guide

C-3

Page 70

Page 71

Template Placement—

Early Model Dynos

ADD 3/8-16 UNC HOLES

EXISTING HOLES

ADD 3/8-16 UNC HOLES

5 3/4"

5 3/4"

EXISTING HOLES

Template—Early Model Dynos

1 5/8"

DYNO FRAME END

Template—Early Model Dynos

EXISTING HOLE

UP

ø 5/16"

5 3/4" 5 3/4"

Page 72

I

NDEX

25-pin cable

routing 1-21

A

accessing dyno electronics 2-4

adapter plate C-2

B

bearing 1-14

retrofit C-2

brace 1-13

brake power cable 1-21

breakout board

control cable 1-23

jumpers 1-24

speed pick-up cable 1-23

temperature sensor cable 1-23

wiring 1-23

C

cable clamp 2-7

cable pass through 1-21

cable routing channels 1-19

calibration arm 2-11

number 2-11

weights 2-13

control cable

routing 1-21

wiring 1-23

conventions 1-3

covers

front and rear 1-11, 1-18

side 1-10

top 1-10

D

deck support 1-18

document part number 1-1

dyno electronics

accessing 2-4

cable clamp 2-7

E

eddy current brake

installation 1-8–1-25

optimal cooling 1-8

parts list 1-4

right side install 1-20

securing to floor 1-25

unpacking 1-9

wiring breakout board 1-23

F

front and rear covers

installing 1-18

removing 1-11

I

input power cable 1-21

installation requirements

power 1-5, B-2

K

keyed yoke 1-15, 1-16

L

load cell

installation 2-2–2-3

routing the cable 2-7

loading the car 3-2–3-4

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Index-i

Page 73

INDEX

M

making a test run 3-10

O

optimal brake cooling 1-8

P

parts list 2-2

power 1-5, B-2

hard wiring 1-7, B-5

installation 1-5, B-2

installing receptacle 1-5, B-3

replacing power plug 1-7, B-5

requirements 1-5, B-2

testing voltages 1-6, B-4

power requirements 1-5, B-2

pre-run inspection 3-8–3-9

R

rear deck support 1-13

brace 1-13

red head anchor

contact information A-1

installation A-2

placement 1-25

setting tool A-3

warnings A-1

routing cables

25-pin 1-21

brake power 1-21

control cable 1-21

input power cable 1-21

load cell 2-7

speed pick-up 1-21

temperature sensor 1-21

T

technical support 1-3

temperature sensor cable

routing 1-21

wiring 1-23

template C-3

testing voltages 1-6, B-4

theta controller 1-19

top cover

installing 2-9

removing 1-10

torque cell calibration 2-10–2-15

calibration arm 2-11

calibration number 2-11

calibration weights 2-13

torque gauge 2-15

torque module

installation 2-5–2-8

U

u-joint 1-15

W

WinPEP 7 2-10

wiring breakout board

control cable 1-23

jumpers 1-24

speed pick-up cable 1-23

temperature sensor cable 1-23

Z

zero calibration 2-10

S

setting tool A-3

side cover

installing 2-9

removing 1-10

speed pick-up cable

routing 1-21

wiring 1-23

spline hub 1-15

spline shaft 1-15

Index-ii

Model 224 Above Ground Eddy Current Brake Installation and User Guide

Loading...

Loading...